Mounting method for sill anchor combined support frame for steel structure shear wall and outer frame column base of super high-rise building

A foundation anchor bolt and installation method technology, applied in building construction, building material processing, construction, etc., to achieve the effects of convenient adjustment and fixation, easy anchor bolt perforation frame, easy adjustment and correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

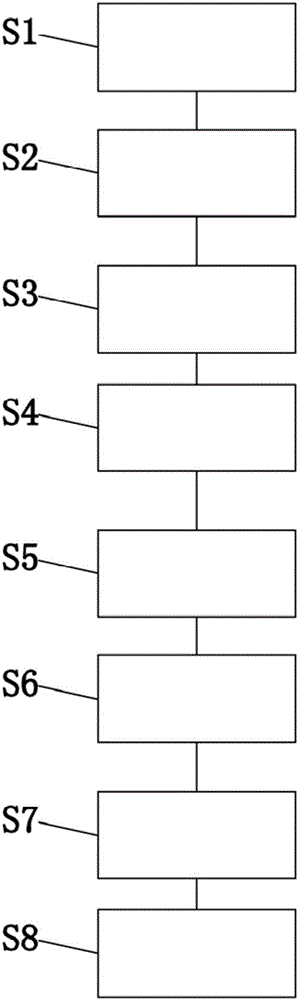

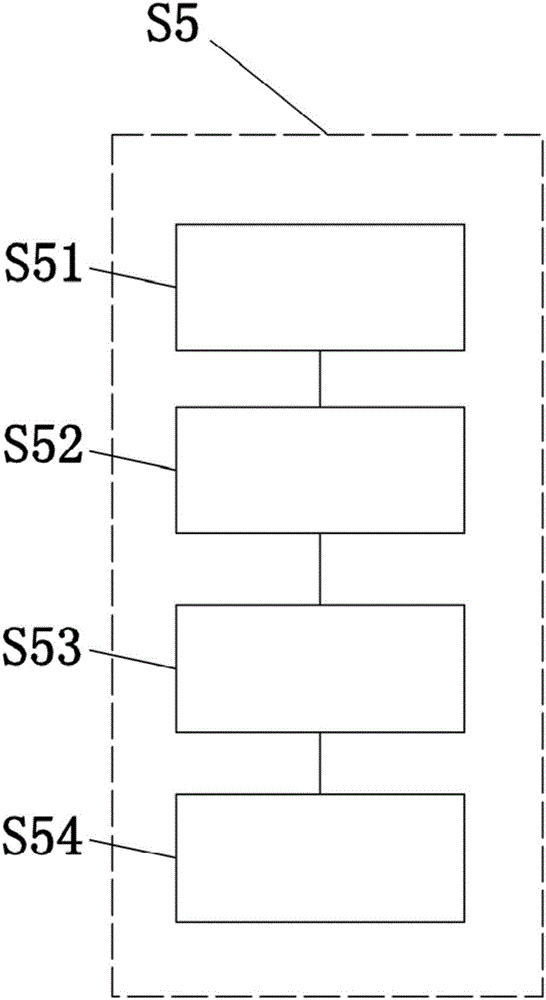

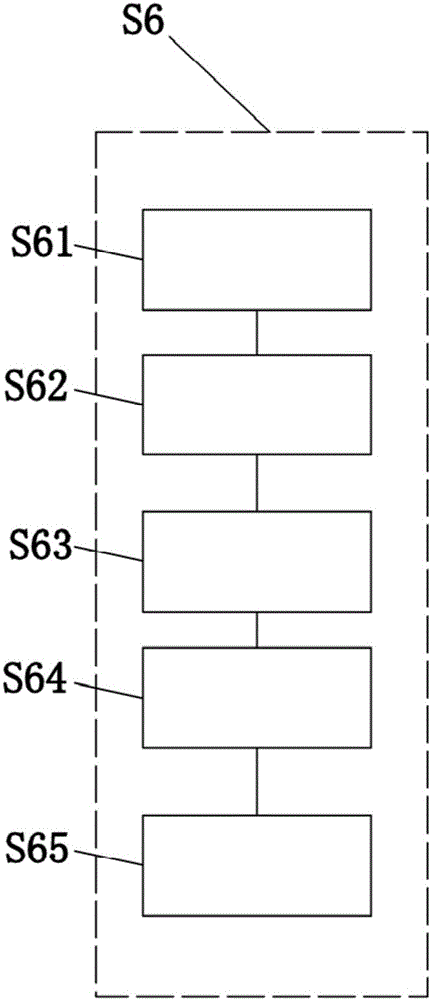

[0062] Such as Figures 1 to 10 Shown, a kind of installation method that is used for the foundation anchor combination supporting frame of steel structure shear wall of super high-rise building and outer frame column foot, described installation method comprises the following steps:

[0063] S1. After the construction of the foundation cushion of the civil engineering is completed, the position of the anchor bolt combination support frame is set out;

[0064] S2. After the steel bars at the lower part of the foundation are tied, install the transition frame with vertical support legs in the anchor bolt combination support frame in place, that is, the vertical support legs of the transition frame pass through the steel bars at the lower part of the foundation, and after positioning, connect with the foundation Rebar connection and fixatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com