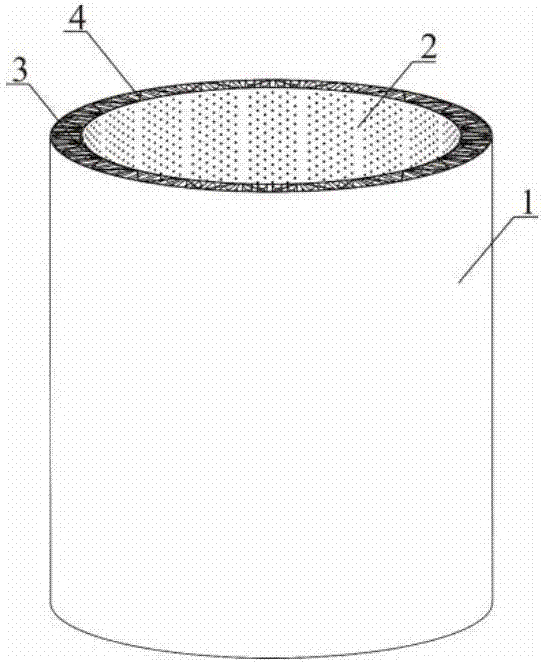

Honeycomb-corrugated composite lattice sandwich cylindrical shell and preparation method thereof

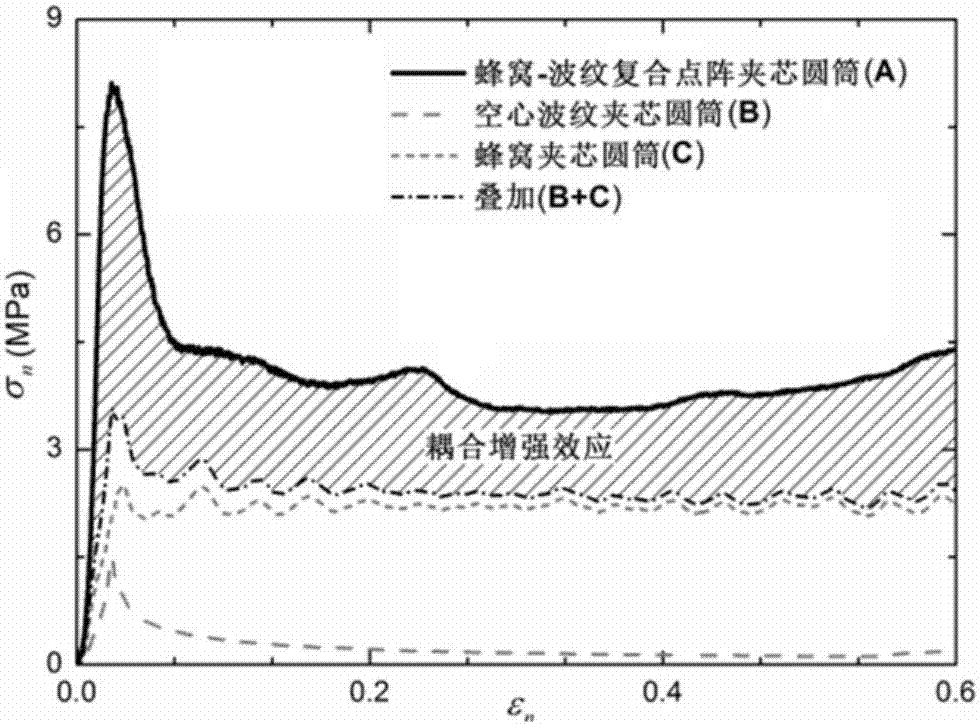

A technology of composite lattice and cylindrical shell, applied in the field of honeycomb-corrugated composite lattice sandwich cylindrical shell and its preparation, can solve the problems of weak energy absorption capacity, elastic-plastic buckling instability, limited application range, etc. Sound frequency range, the effect of good sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

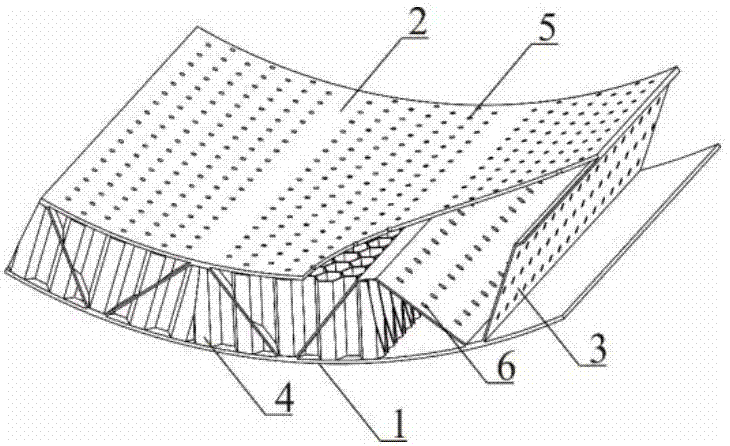

[0041]The invention also discloses a method for preparing a honeycomb-corrugated composite lattice sandwich cylindrical shell, the specific steps are as follows:

[0042] S1. Cut the aluminum honeycomb into a rectangular structure by wire cutting;

[0043] S2. Laser drilling technology is used to drill micro-perforations on the flat metal plate, and the metal plate is made into a micro-perforated metal corrugated plate by molding or bending technology;

[0044] S3. After cleaning the micro-perforated metal corrugated plate prepared in step S2 to remove oil and rust, solidify it on the ring-shaped corrugated mold, connect it into one, and demould to obtain the micro-perforated ring-shaped corrugated core;

[0045] S4. Cut the flattened metal sheet, remove oil and rust through surface treatment, use a metal cylinder with a diameter of 114-133mm as a mold, cover the metal sheet on it and connect it into one, and demould to make an outer circle A barrel and an inner cylinder, bef...

Embodiment 1

[0049] 1) Cut the cleaned hexagonal aluminum honeycomb into rectangular structures.

[0050] 2) Using laser drilling technology to drill micro-perforations on the flattened 0.2mm thick 1060 aluminum plate, the diameter of the micro-perforations is 0.5mm. The metal sheet is then made into a micro-perforated metal corrugated sheet by molding technology;

[0051] 3) After cleaning the micro-perforated metal corrugated plate with a metal cleaning agent in an ultrasonic cleaning machine to remove oil and rust, solidify it on the ring corrugated mold, and evenly coat a layer of adhesive on the corrugated joint, and place it at 40-60 °C Curing in an oven, demoulding to obtain an annular metal corrugated core structure.

[0052] The adhesive used is Loctite E-120HP epoxy glue.

[0053] 4) Cut the flattened 0.5mm thick 1060 aluminum plate into a rectangular structure, and add metal cleaning agent in an ultrasonic cleaning machine to clean and remove oil and rust. Laser drilling tech...

Embodiment 2

[0061] 1) Cut the cleaned hexagonal aluminum honeycomb into rectangular structures.

[0062] 2) Using laser drilling technology to drill micro-perforations on the flattened 0.2mm thick 304 stainless steel plate, the diameter of the micro-perforations is 0.5mm. The metal sheet is then made into a micro-perforated metal corrugated sheet by molding technology;

[0063] 3) After cleaning the micro-perforated metal corrugated plate with a metal cleaning agent in an ultrasonic cleaning machine to remove oil and rust, solidify it on the ring corrugated mold, and place a layer of high-silica glass fiber tape between the ring corrugated and the mold to Prevent the corrugated core from welding with the mold. Apply NiCr25P10 brazing paste evenly on the corrugated joint, dry it in an oven at 40-50°C, then put the above structure into a high-temperature brazing furnace for welding, and slowly cool to room temperature after welding, then disassemble the mold and demould An annular metal c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com