PVC (polyvinyl chloride) composite board

A composite plate and substrate technology, applied in the field of building materials, can solve the problems of waste of resources, poor adhesion, low weather resistance, etc., and achieve the effect of improving service life, significant effect, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with specific embodiments.

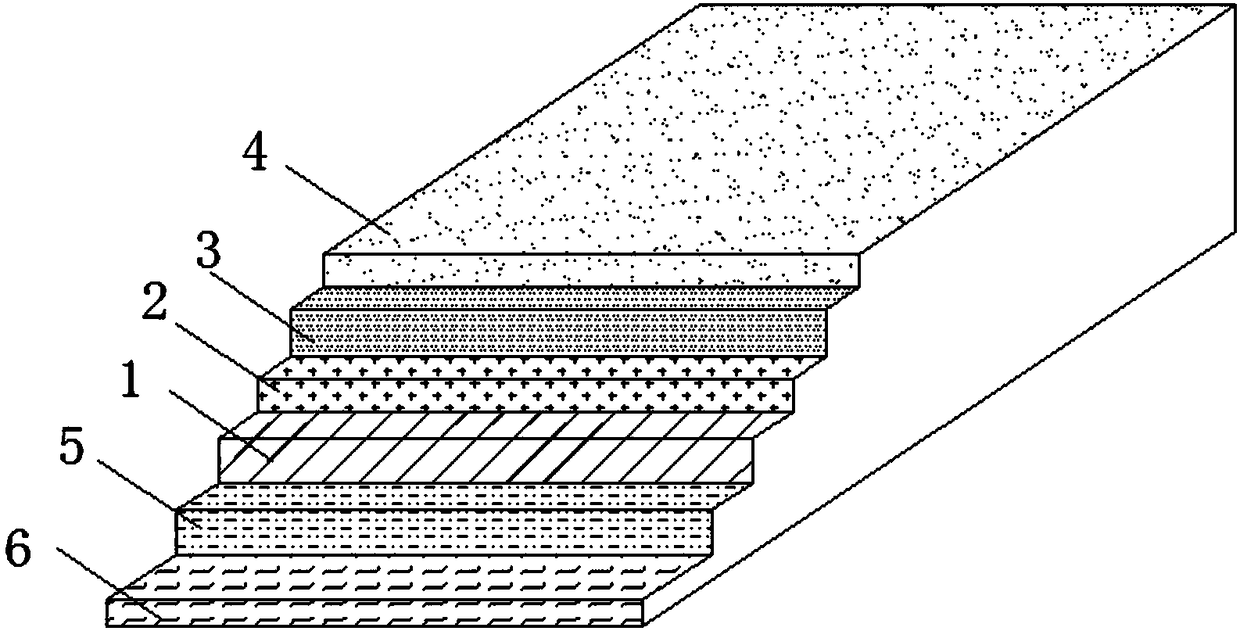

[0020] Such as Figure 1-3 , Example 1

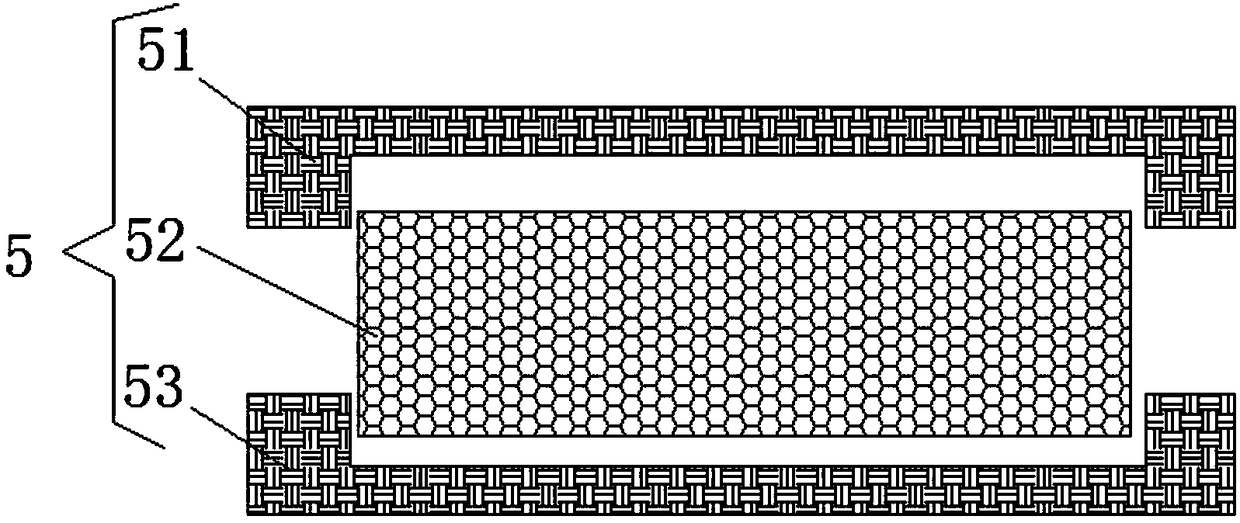

[0021] A PVC composite board, comprising a substrate 1, the upper end of the substrate 1 is laminated with a noise-proof and moisture-proof layer 2, and the top of the noise-proof and moisture-proof layer 2 is pasted with a high-strength layer 3, and the upper surface of the high-strength layer 3 is laid There is a surface treatment layer 4 , a PVC foam board 5 is laminated on the lower surface of the substrate 1 , and a wear-resistant layer 6 is laminated on the lower surface of the PVC foam board 5 .

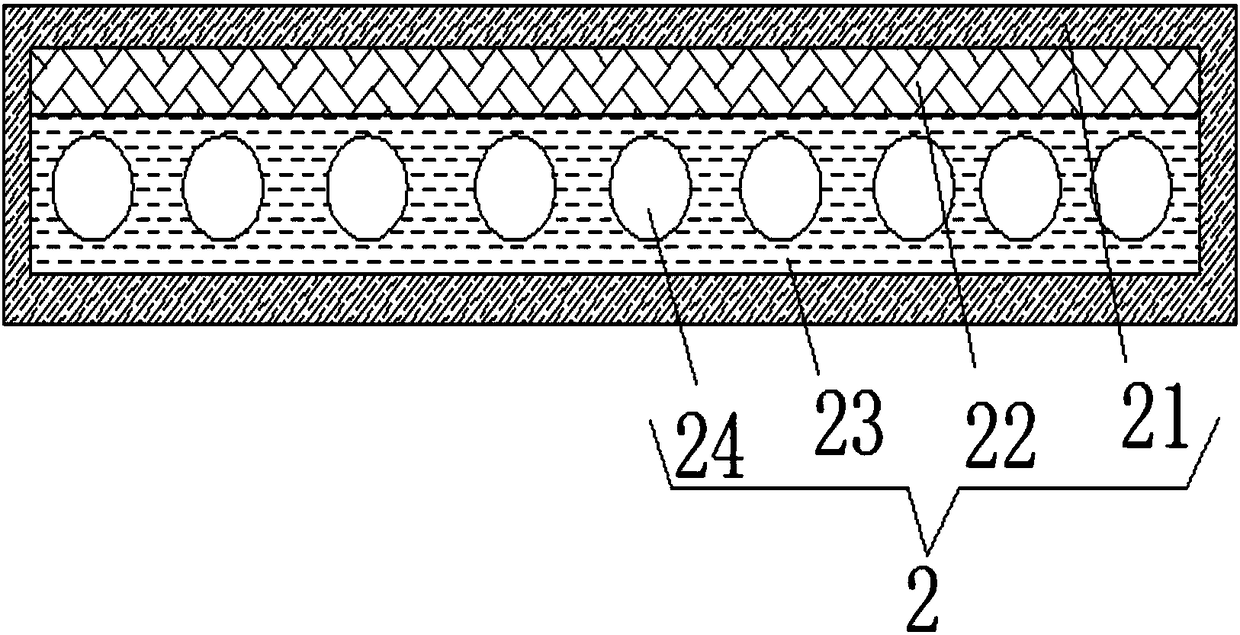

[0022] The noise-proof and moisture-proof layer 2 includes a fiberboard layer 21, a sound-absorbing cotton layer 22, a sound-insulating felt 23 and water-absorbing balls 24. The upper end of the inner cavity of the fiberboard layer 21 is pasted with a sound-absorbing cotton layer 22, and the lower end of the sound-absorbing surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com