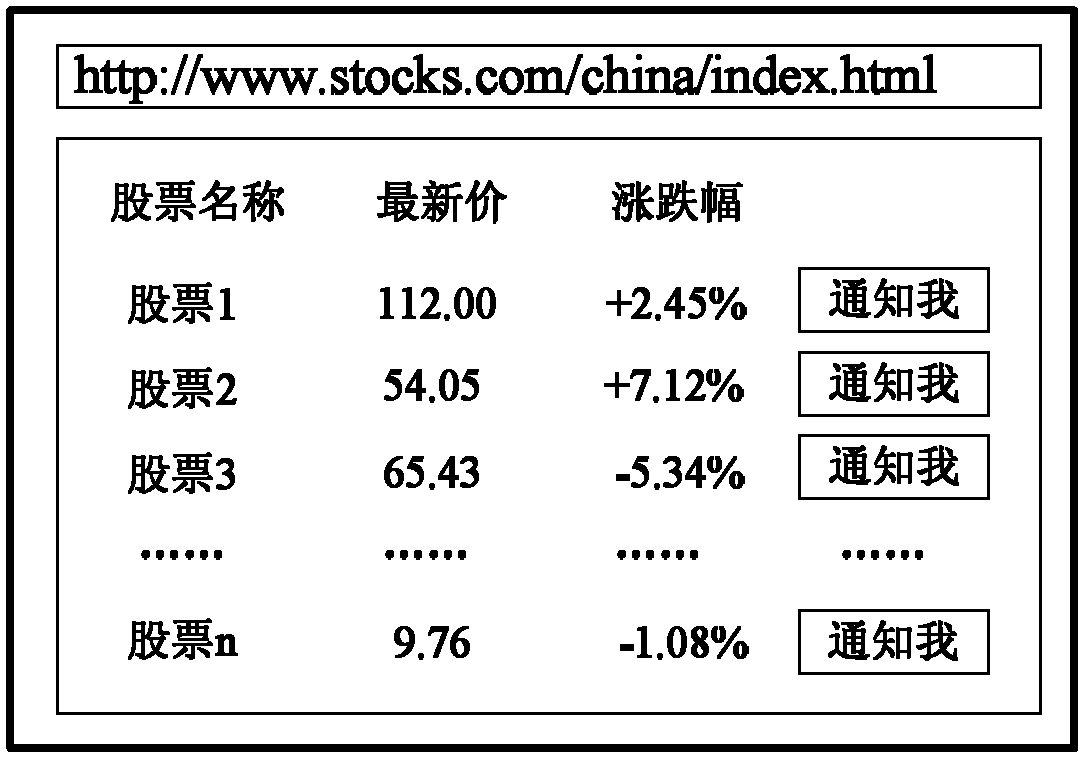

Patents

Literature

319results about How to "Add flexibly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

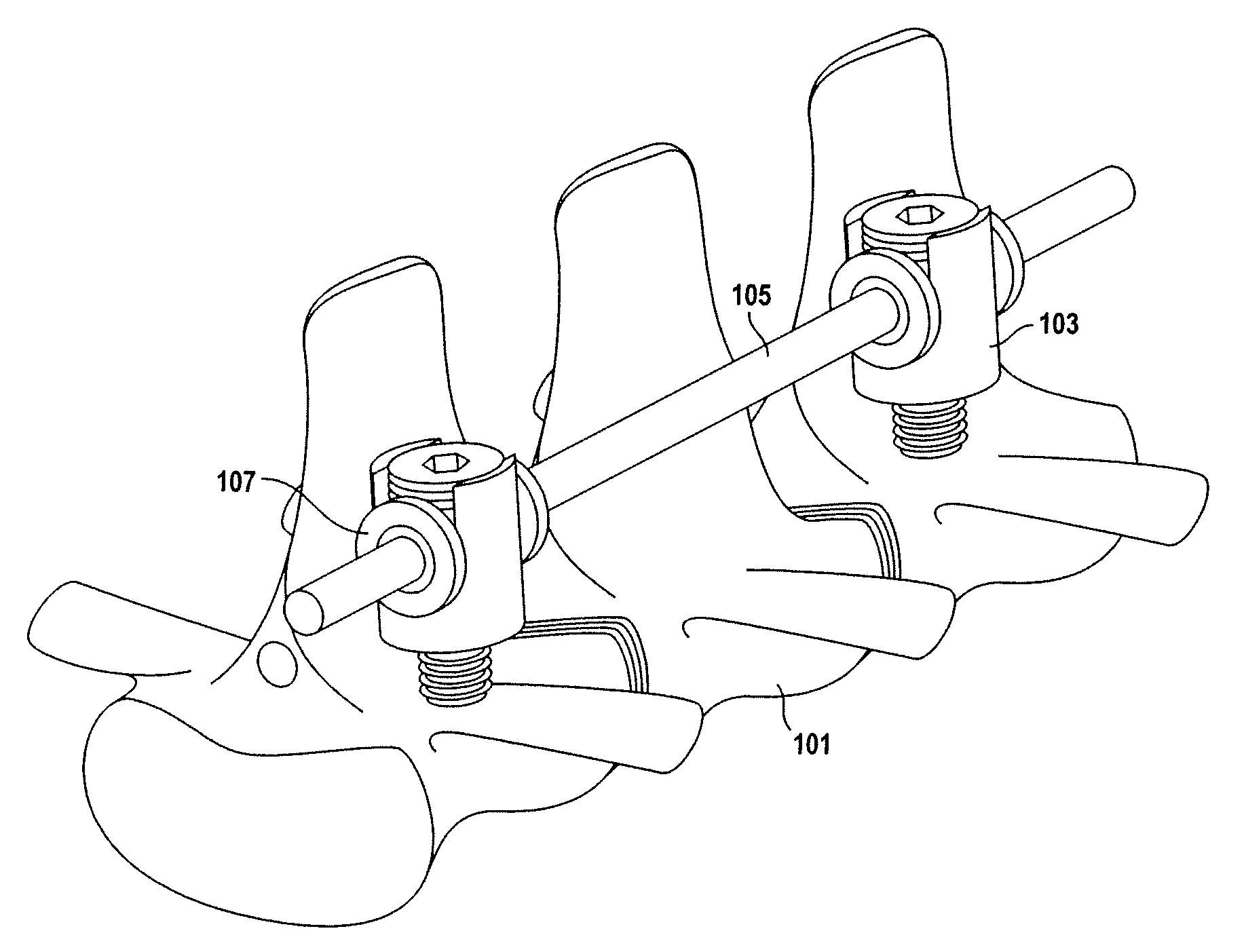

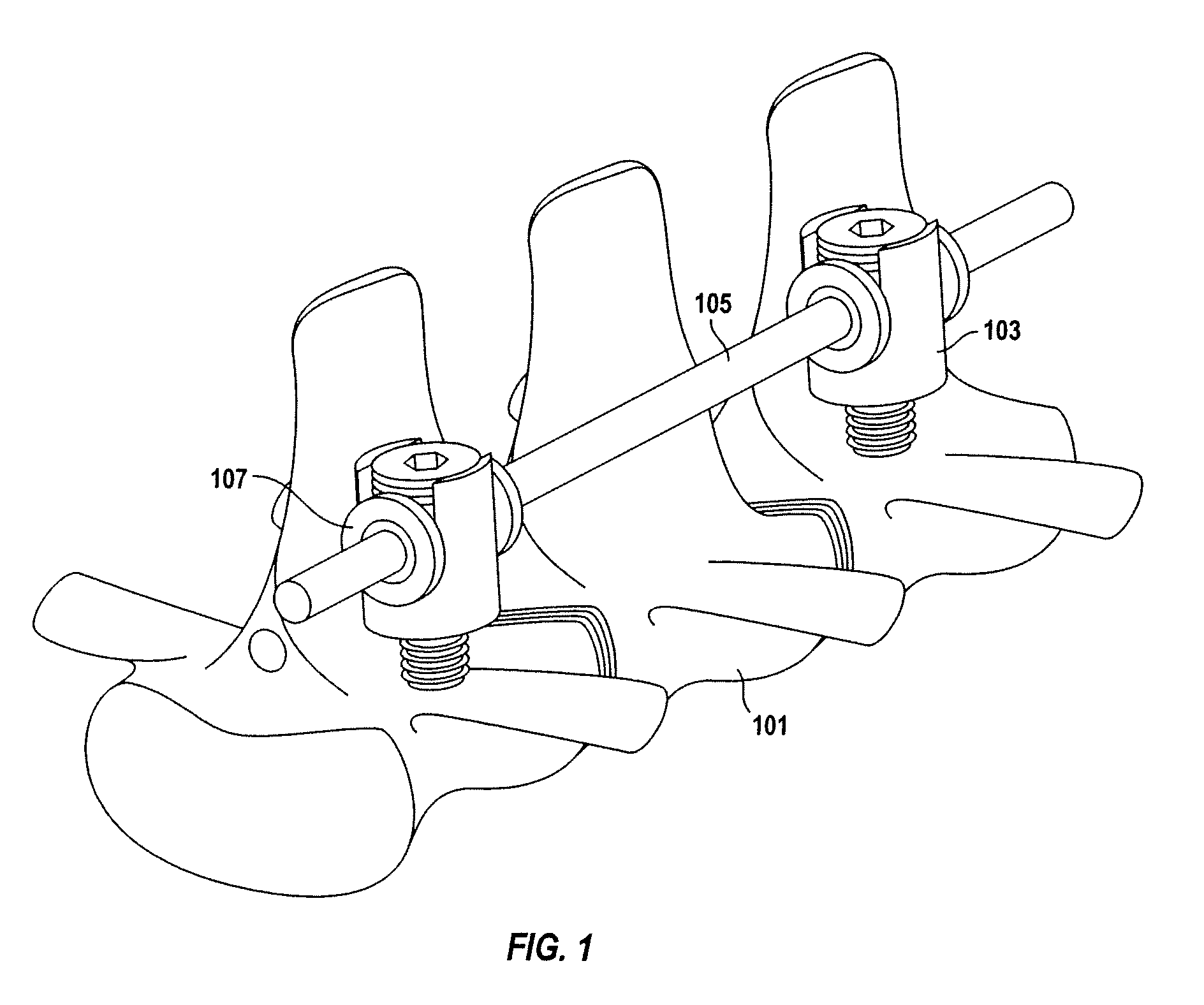

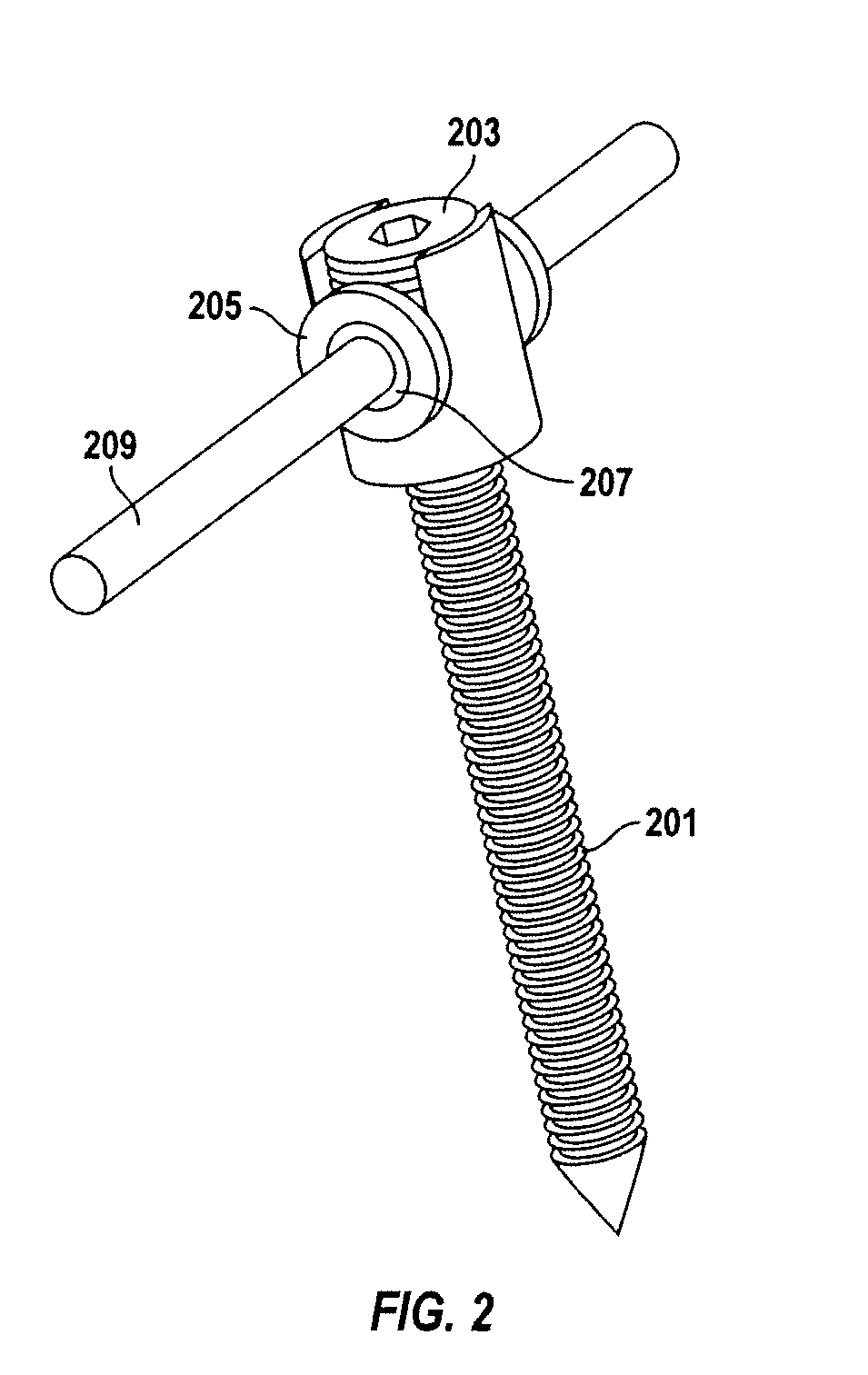

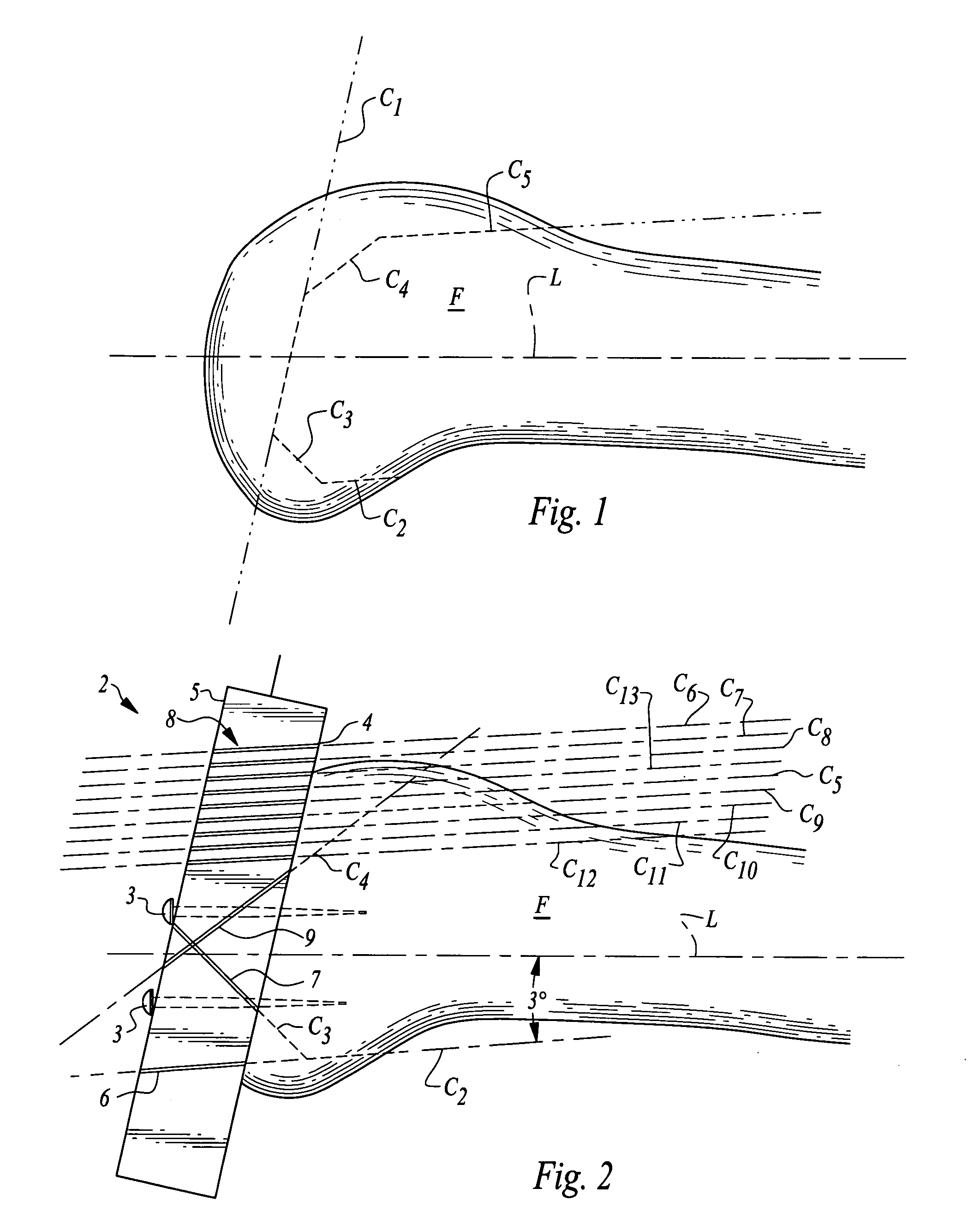

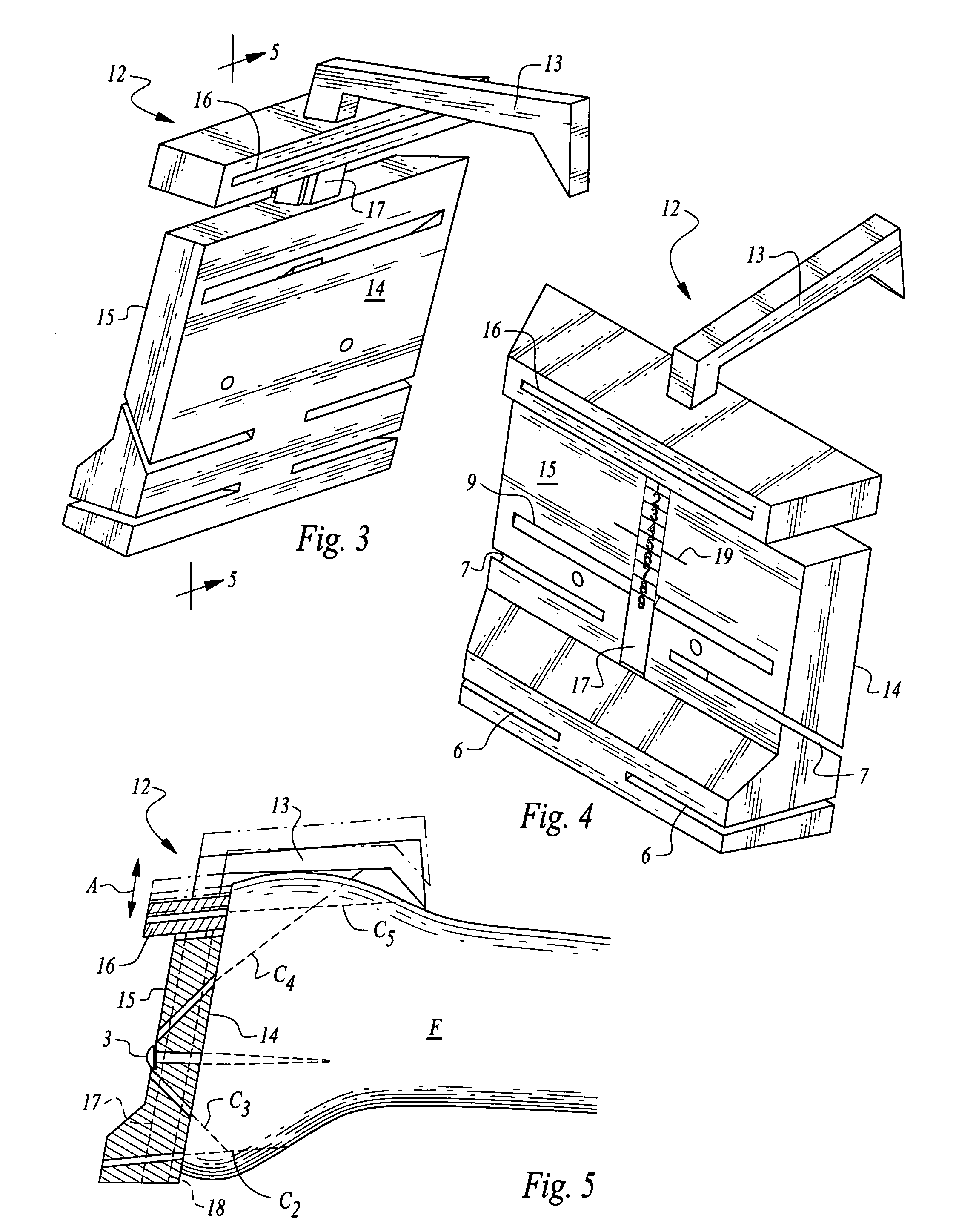

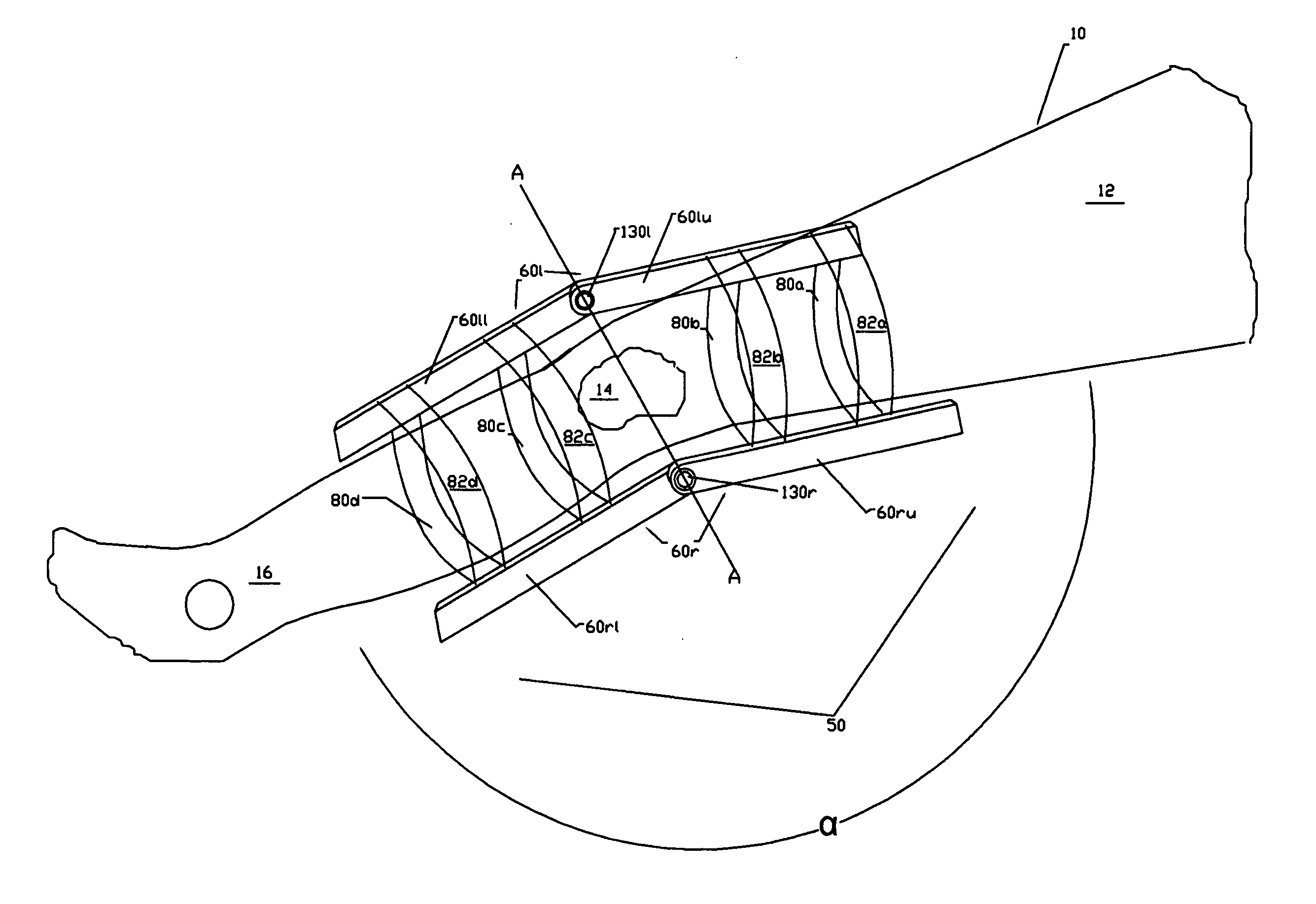

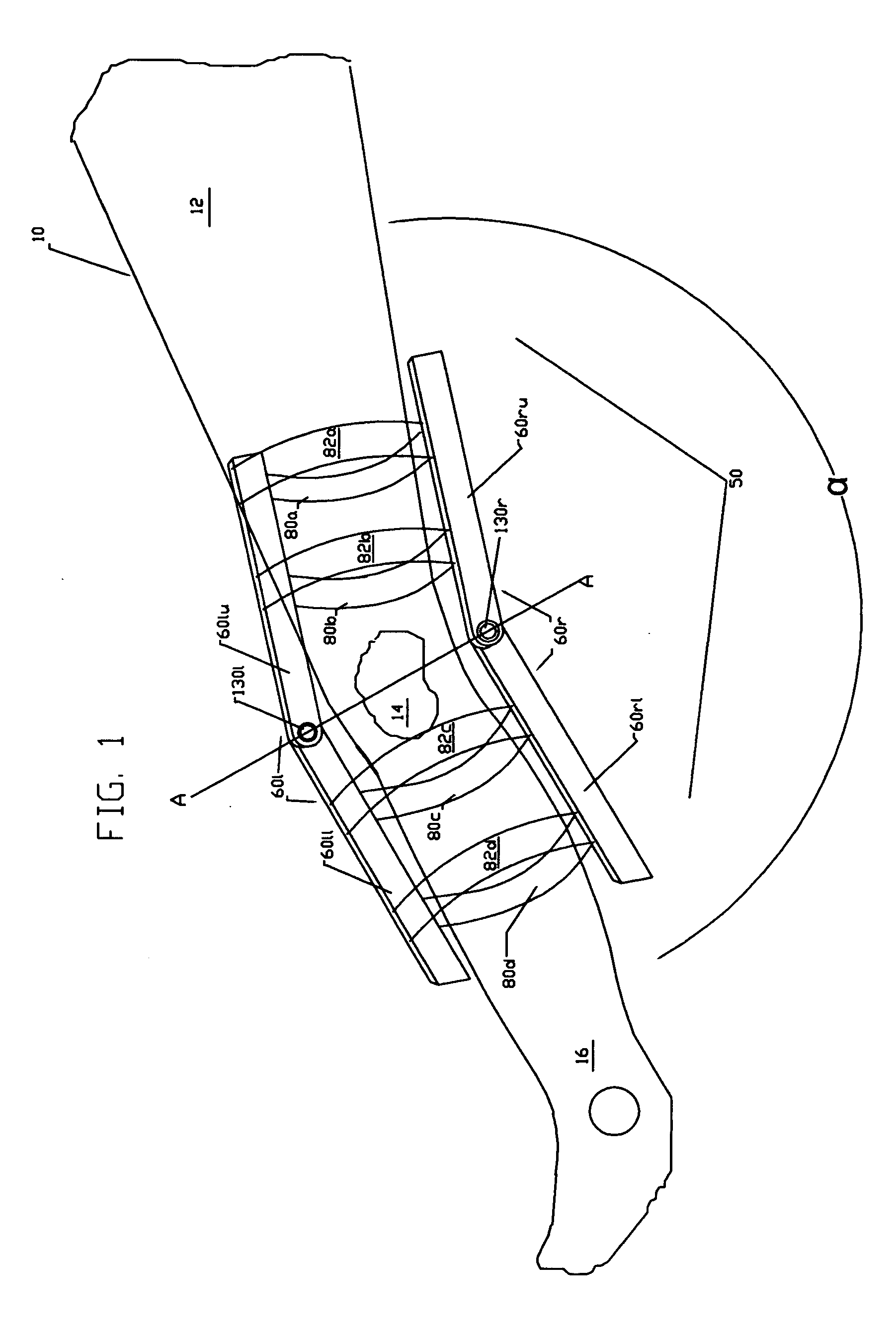

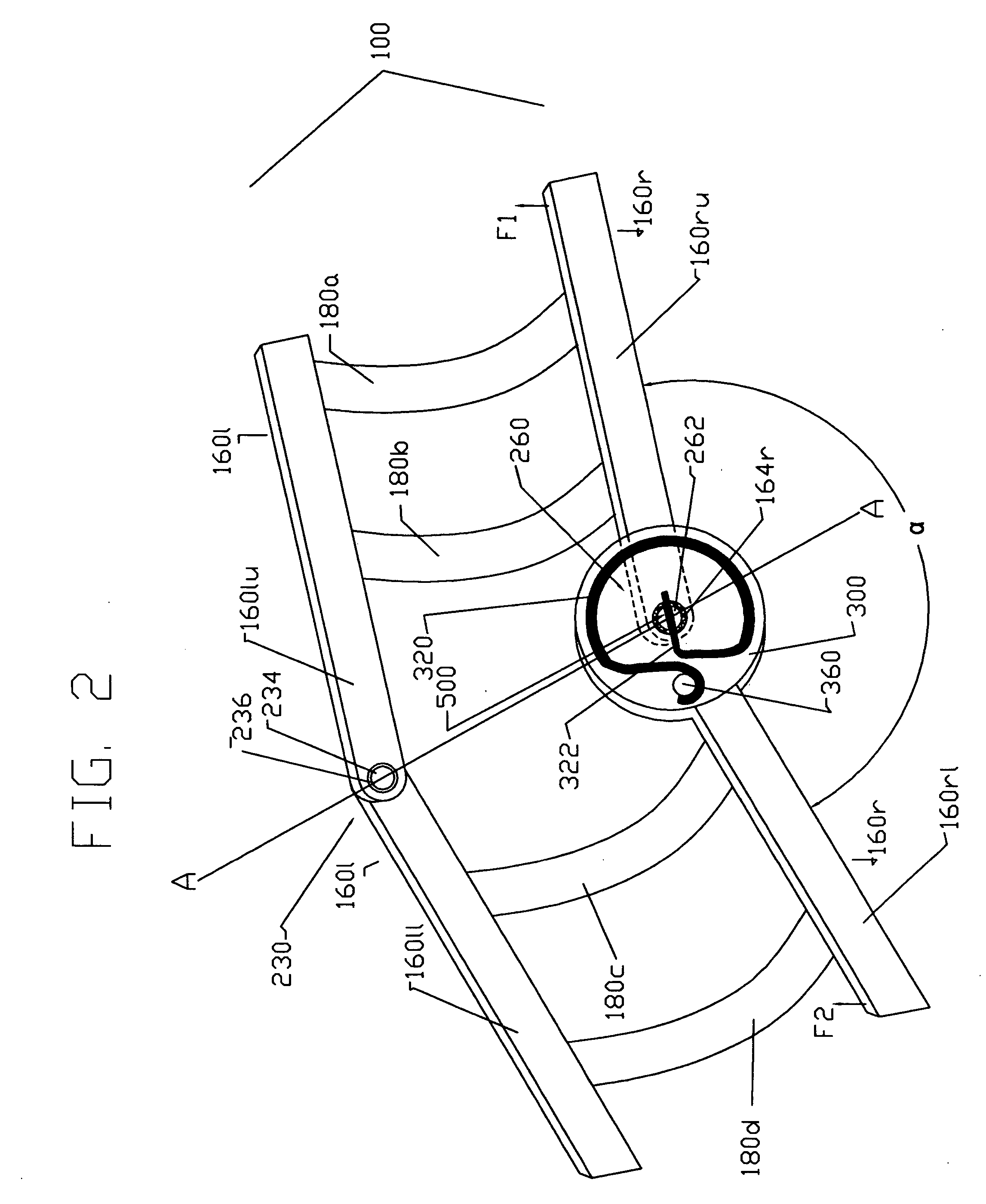

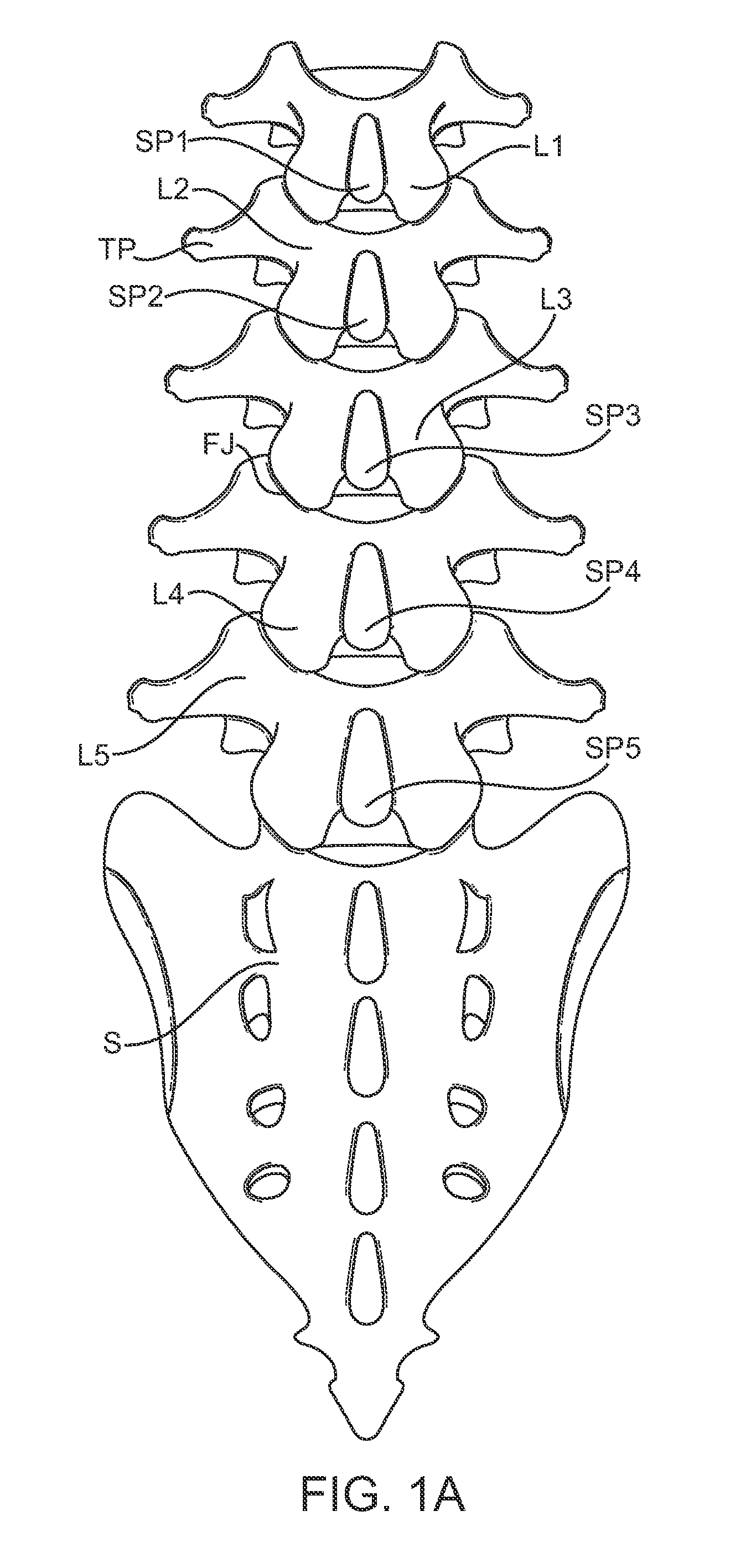

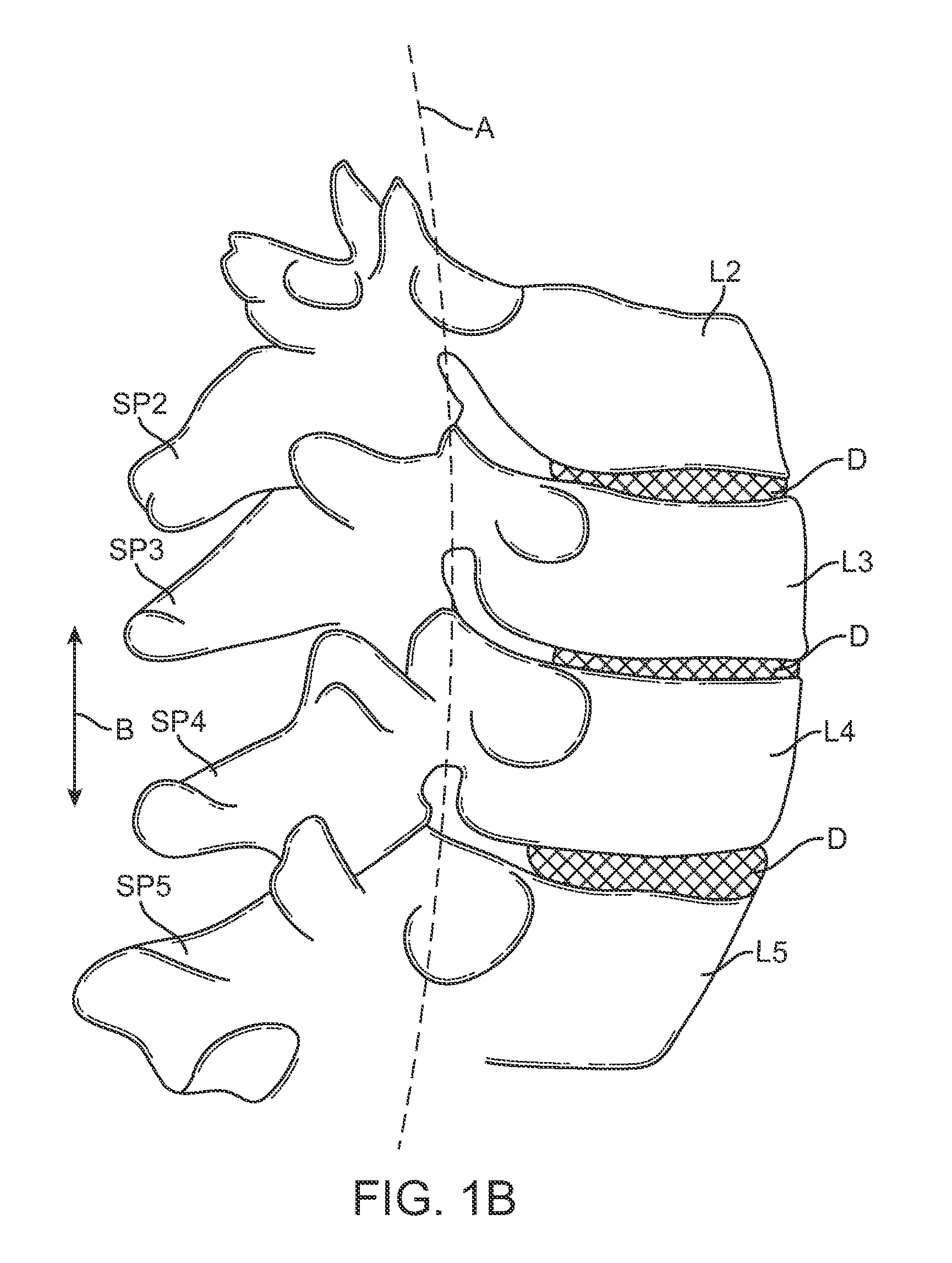

Dynamic spinal deformity correction

InactiveUS20080195153A1Add flexiblyInternal osteosythesisJoint implantsSpinal columnSpinal deformity correction

A system for treating spinal deformities. A plurality of retaining clamps are fixed to a plurality of vertebrae and at least one elastic or super elastic rod is caused to pass through openings in the plurality of retaining clamps, the at least one elastic or super elastic rod being slidable within each of the plurality of retaining clamps along the axis of the spine to enable the spine to retain full flexion and extension in both its coronal and saggital planes.

Owner:REDUCTION TECH

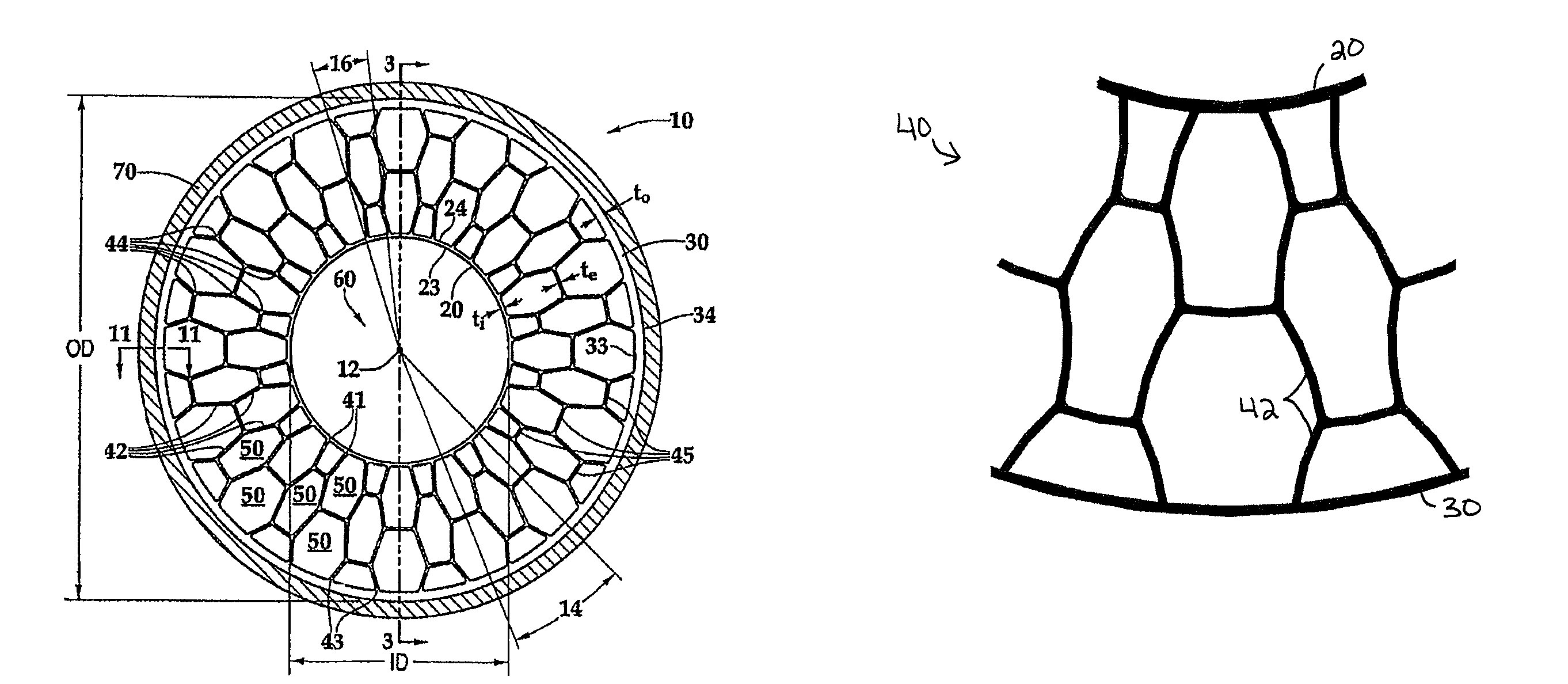

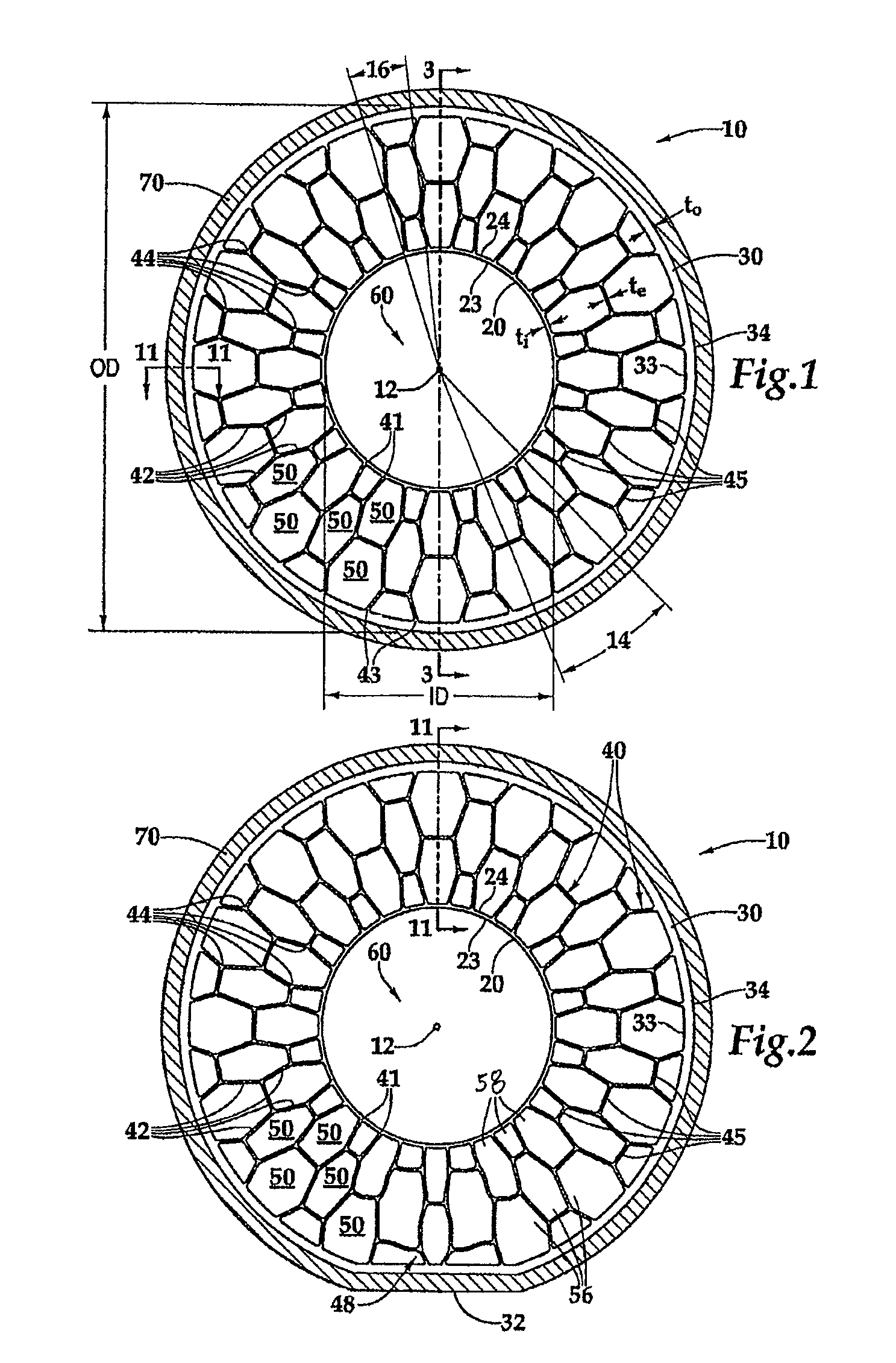

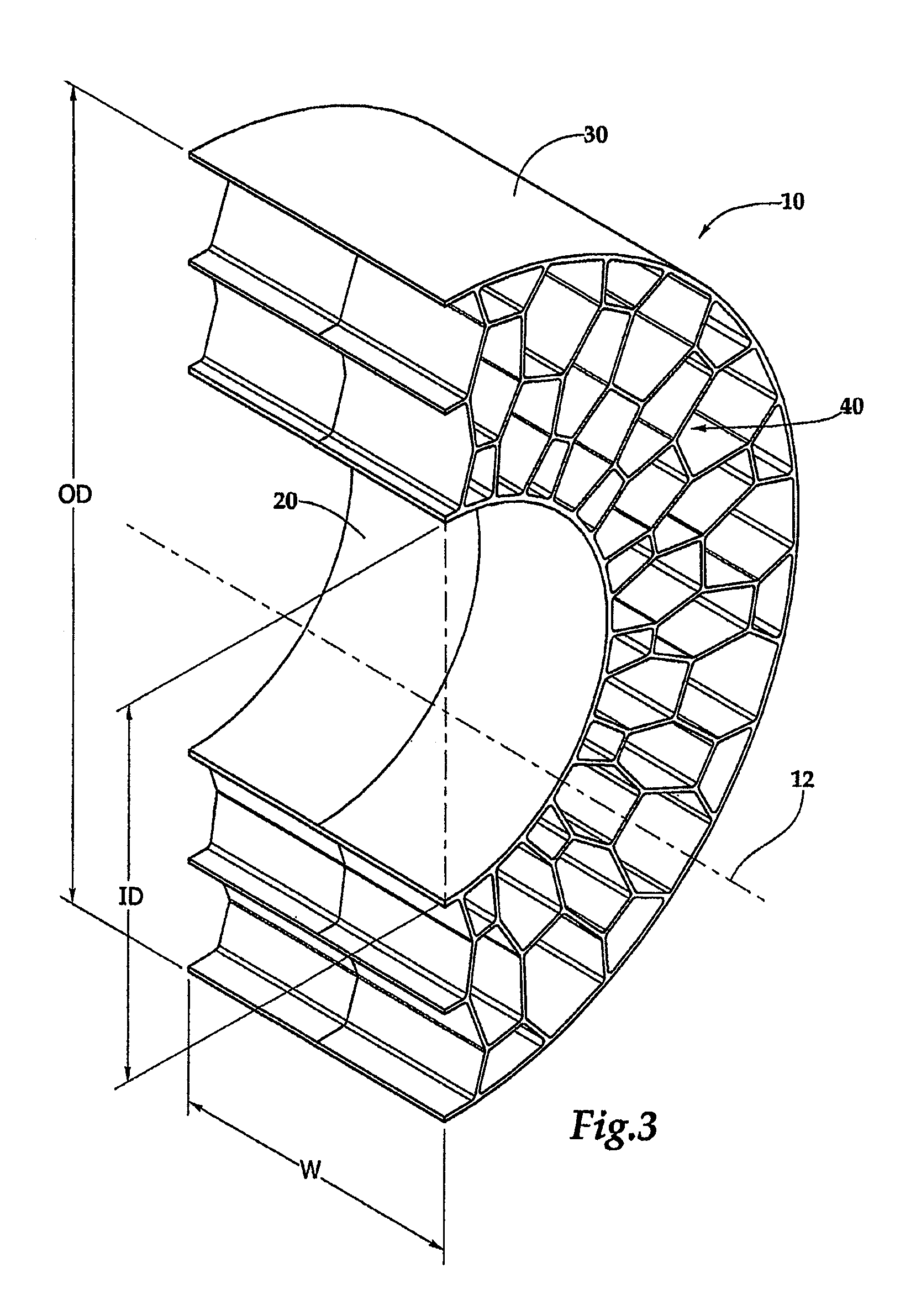

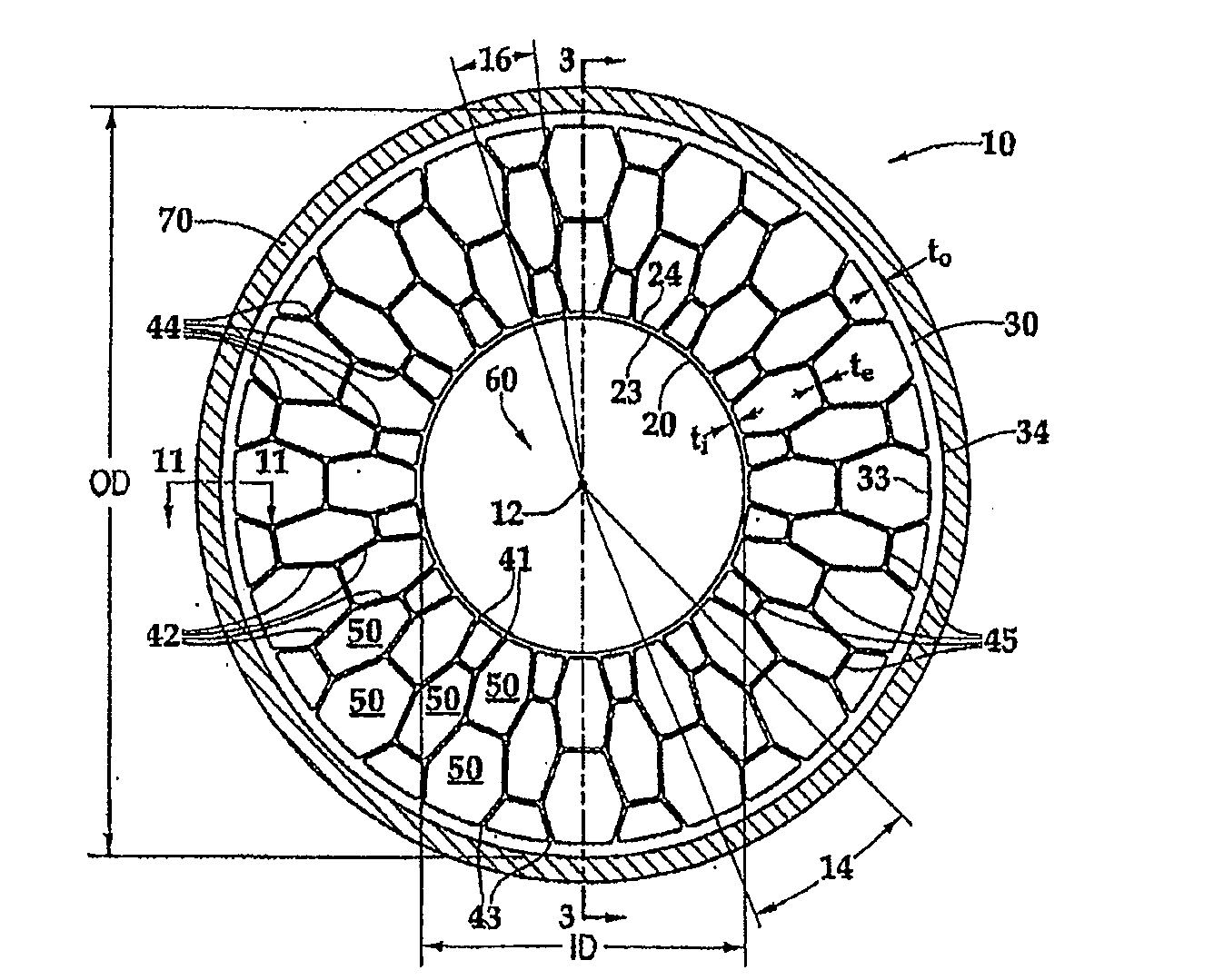

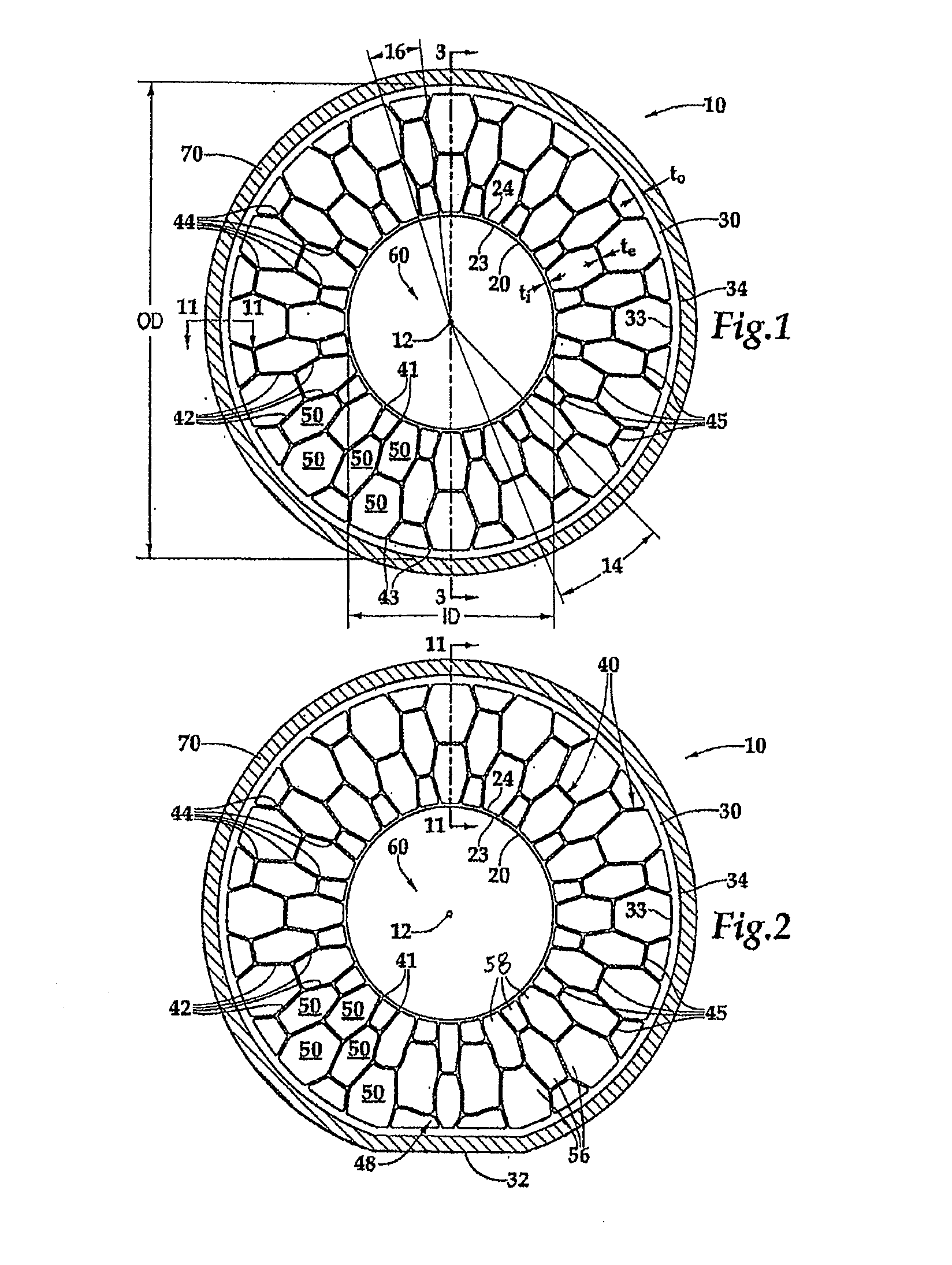

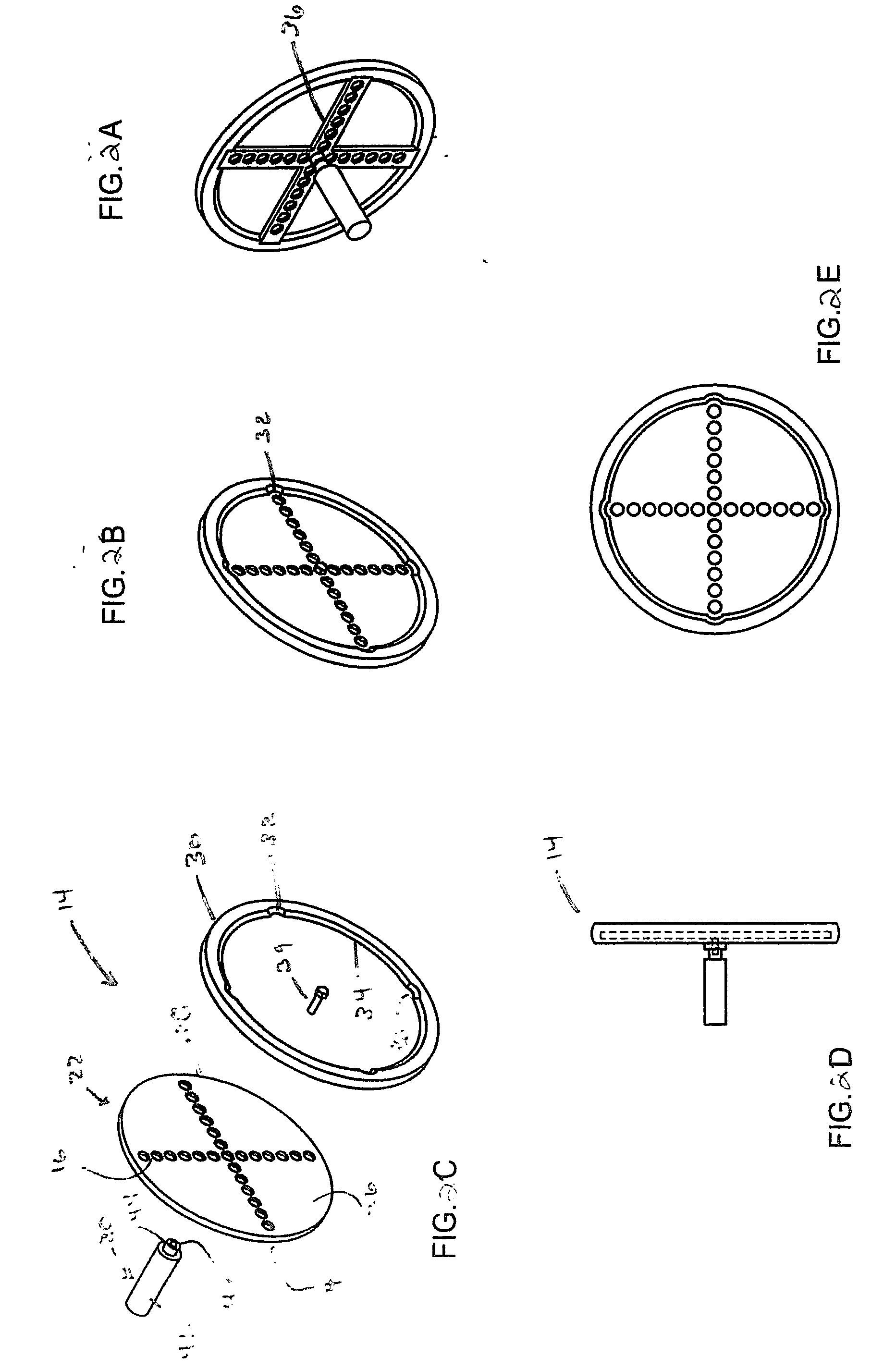

Tension-based non-pneumatic tire

A non-pneumatic tire for supporting a load by working in tension comprising a generally annular inner ring, a generally annular outer ring, and an interconnected web having a plurality of web elements and comprising a plurality of generally polygonal openings. Web elements are sized, curved, oriented, and comprised of varying thicknesses of material which facilitates buckling when subjected to a compressive load. By buckling, those elements in a deformed portion of the tire between a wheel and a footprint region where the tire contacts a surface can assume a significantly reduced portion of the load, if any. This causes web elements in other portions of the interconnected web to operate in tension to support the load.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

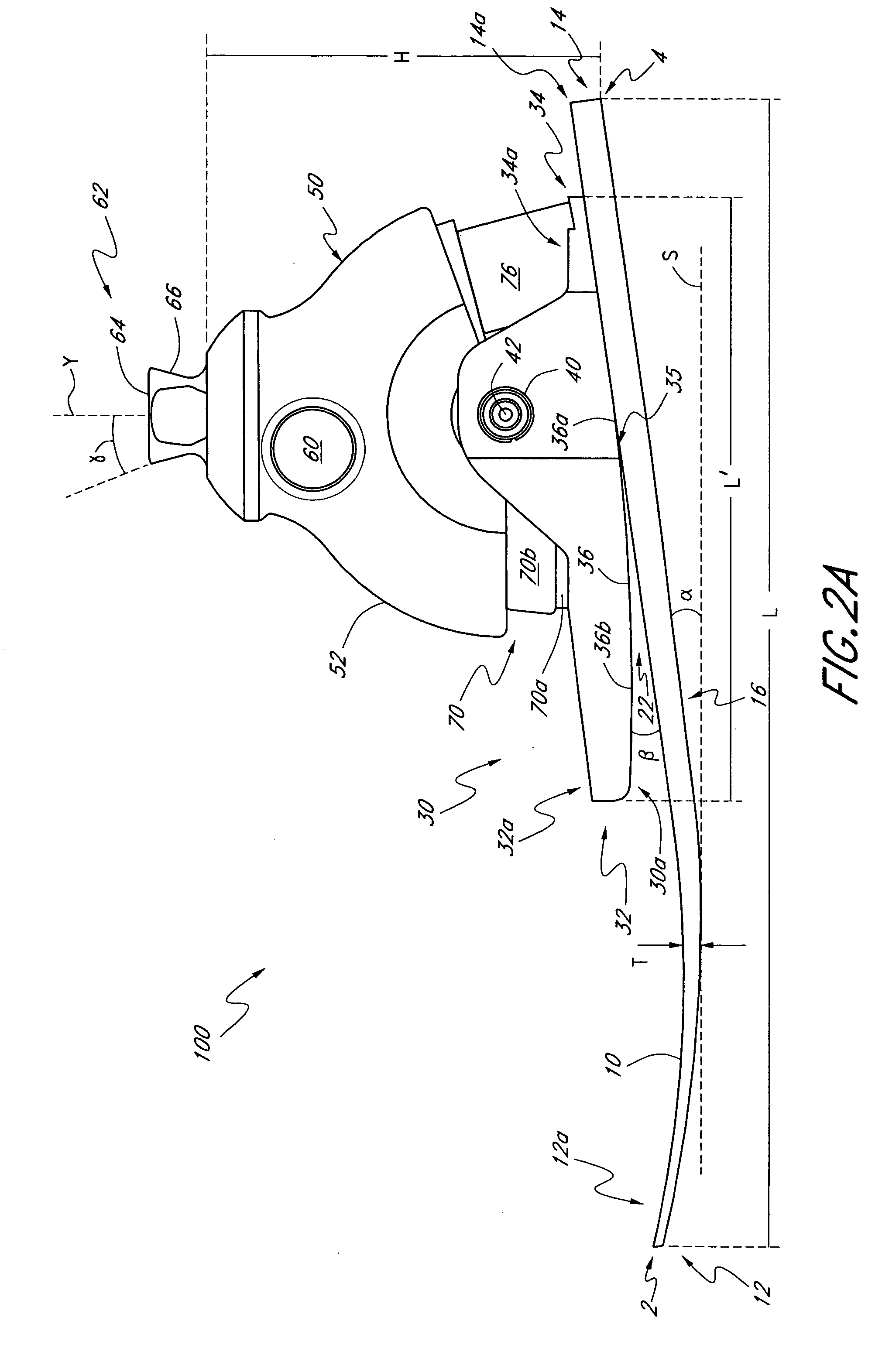

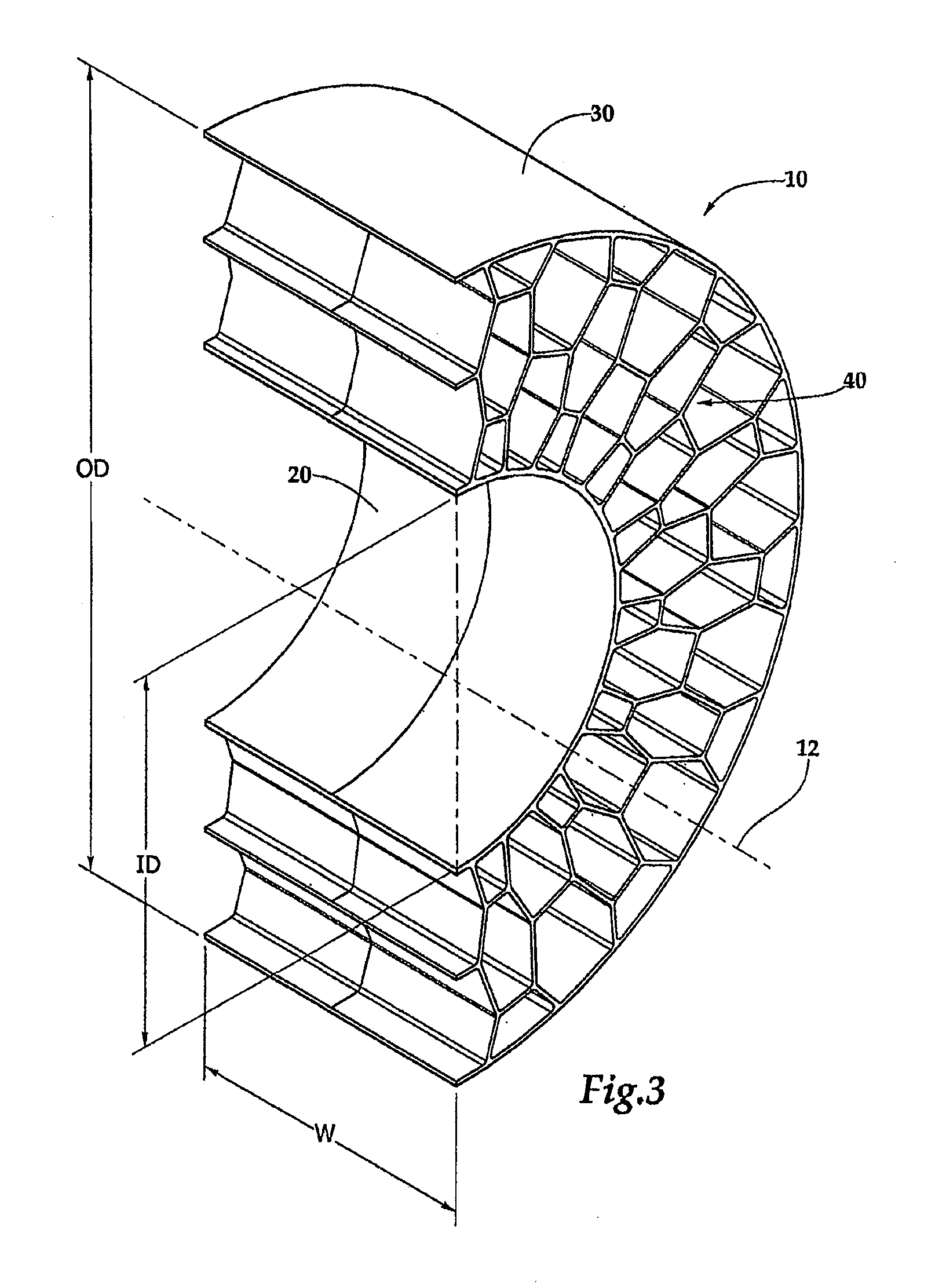

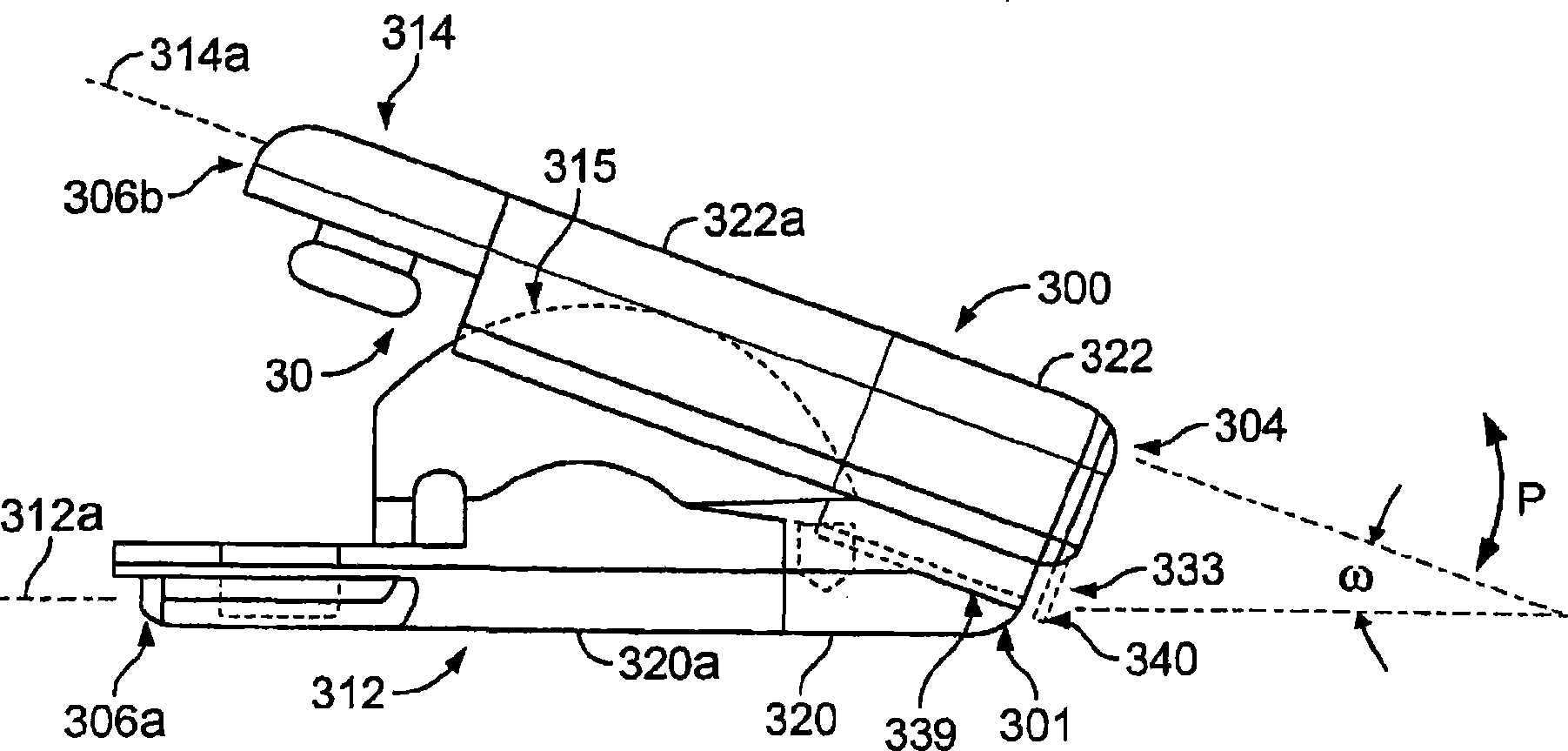

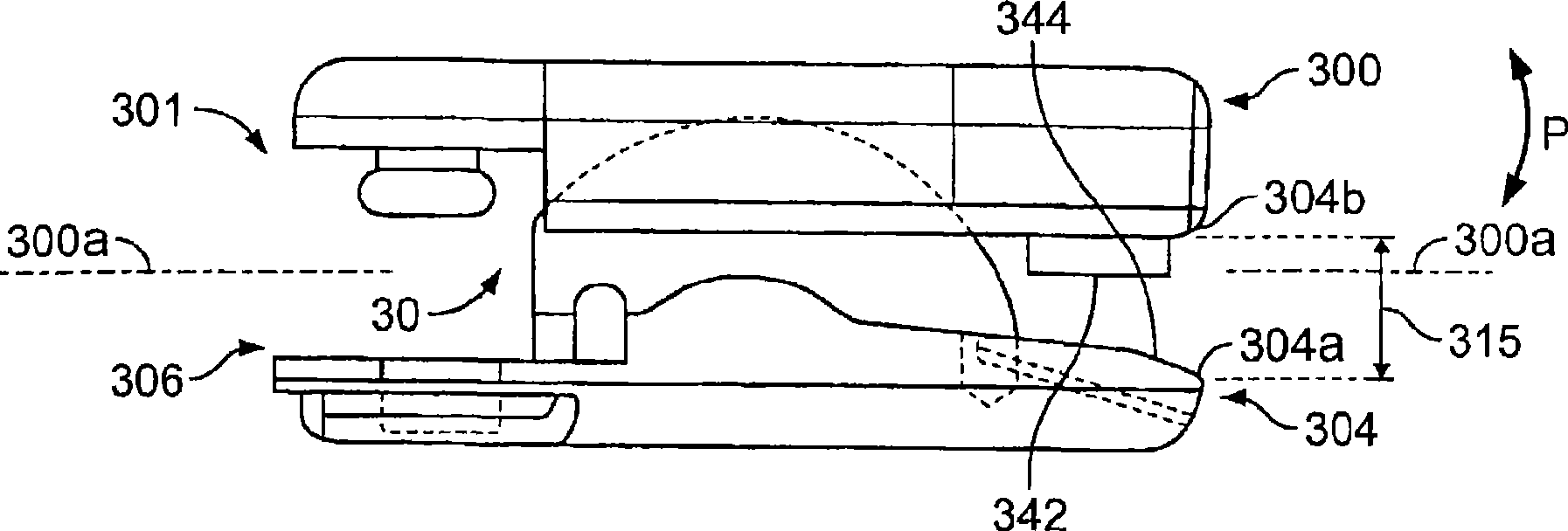

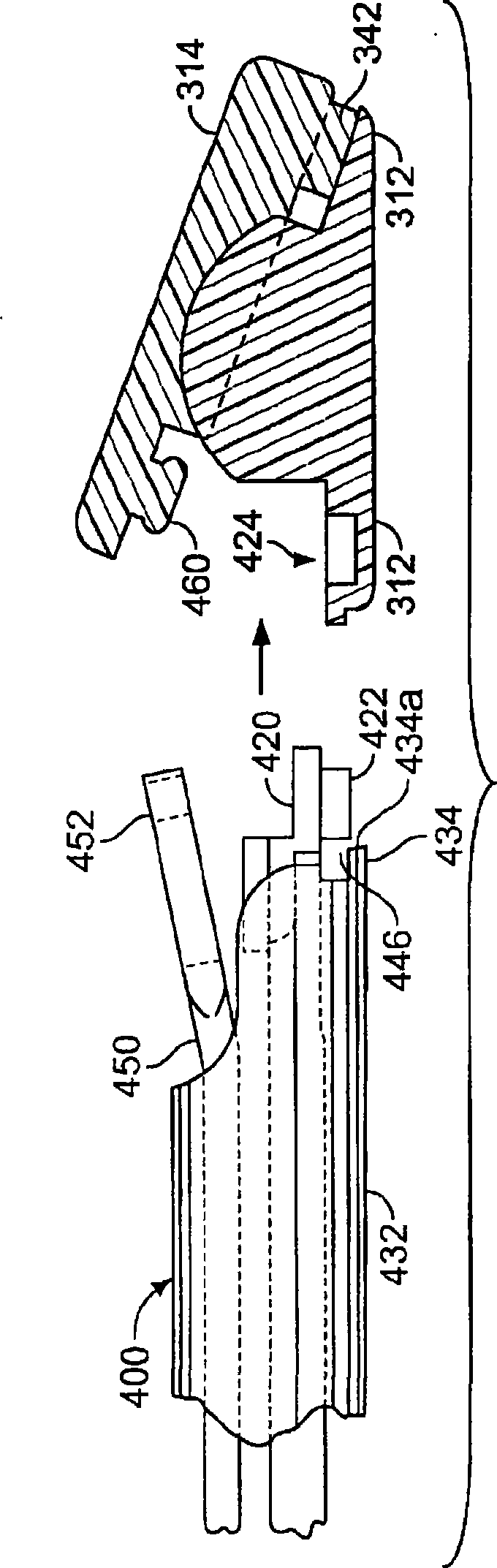

Prosthetic foot with rocker member

InactiveUS20050137717A1Easy introduction intoEasy to removeArtificial legsPhysical medicine and rehabilitationCantilever

A prosthetic foot comprises a foot member, a rocker member connected in cantilever fashion to the foot member, and an ankle module movably connected to the rocker member about an axis, wherein an anterior section of the rocker member is configured to roll-up onto the foot member an amount corresponding to the load applied on the foot, and wherein the foot member is configured to facilitate the initial roll-up of the rocker member.

Owner:GRAMTEC INNOVATION +1

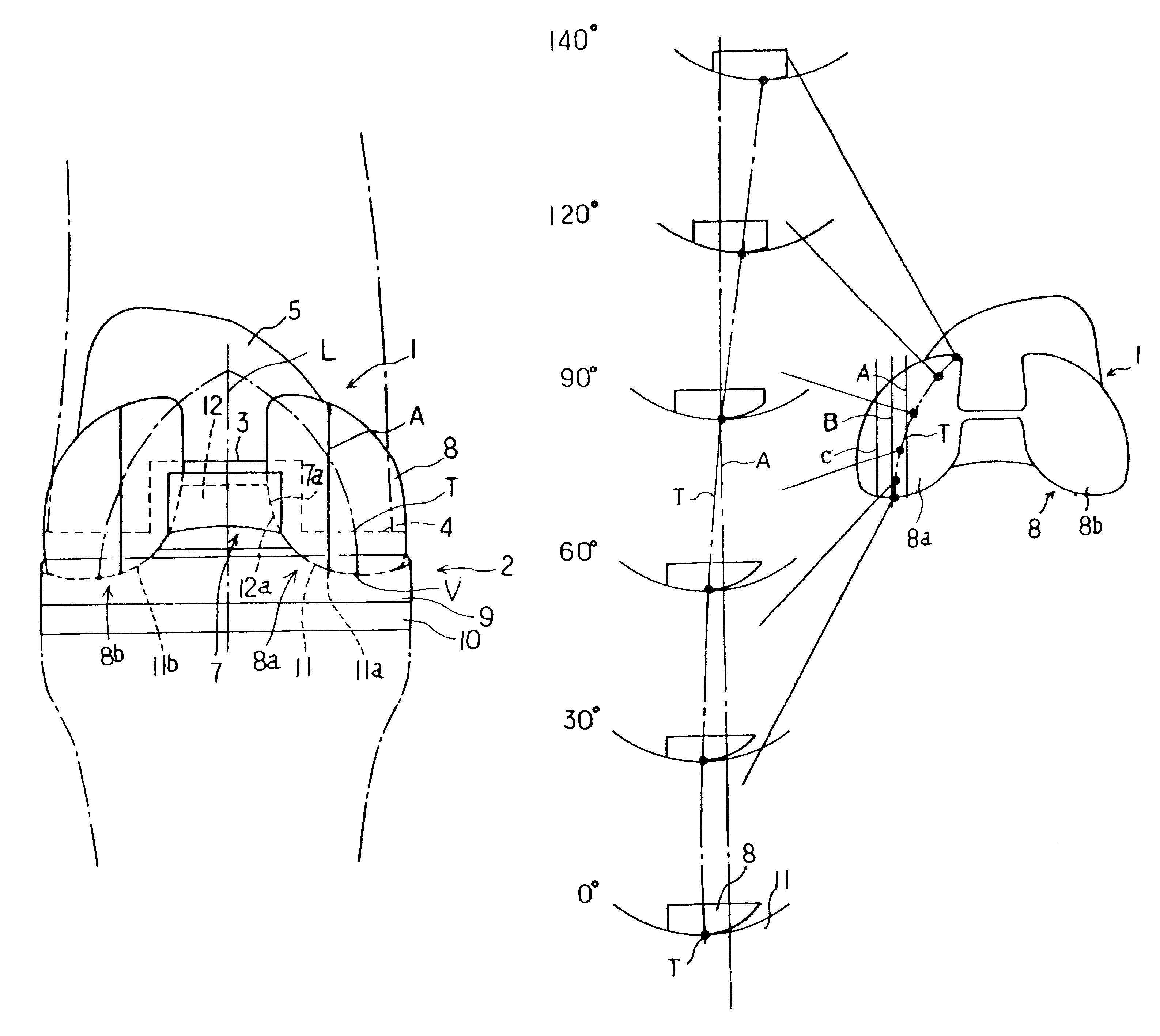

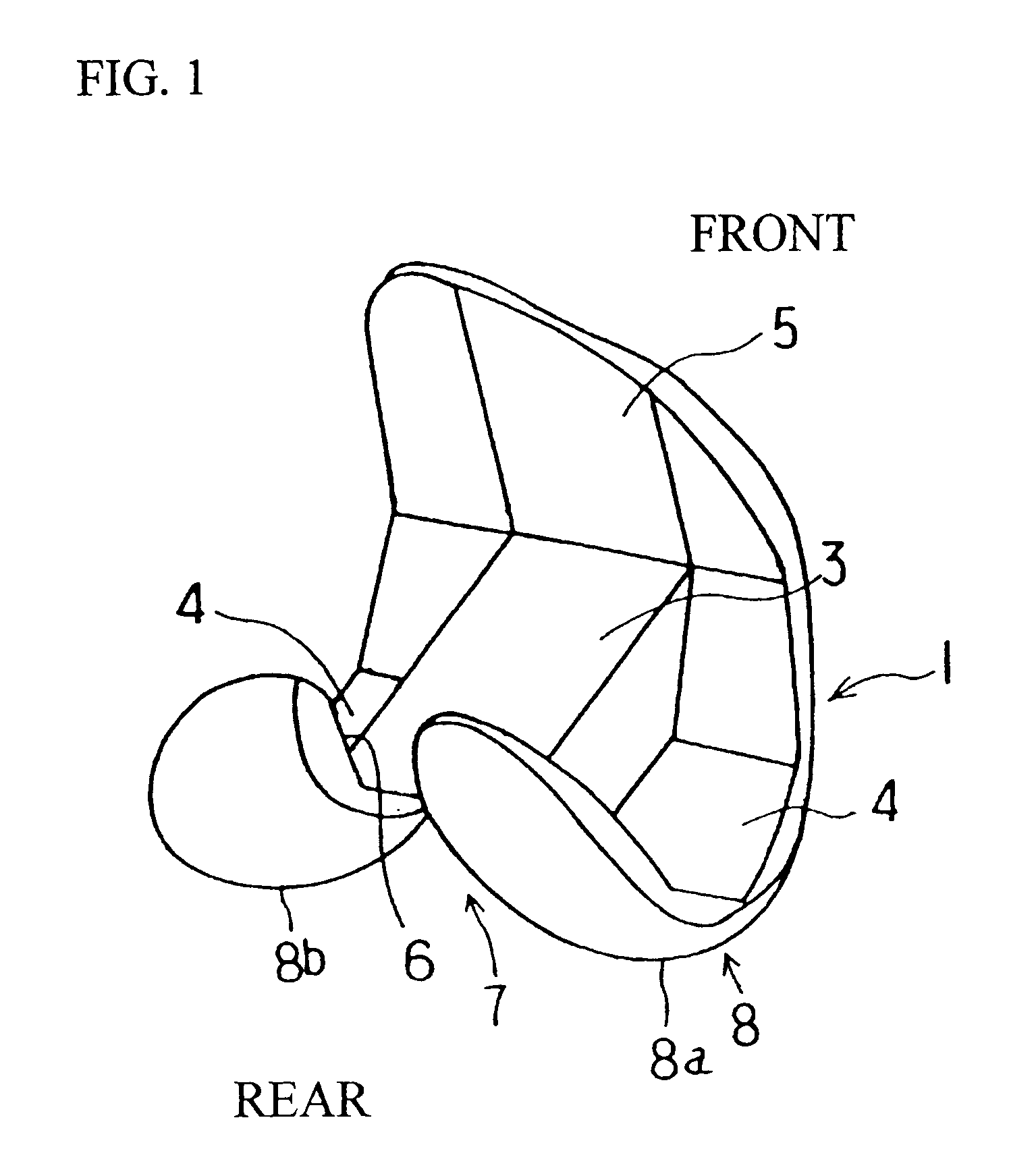

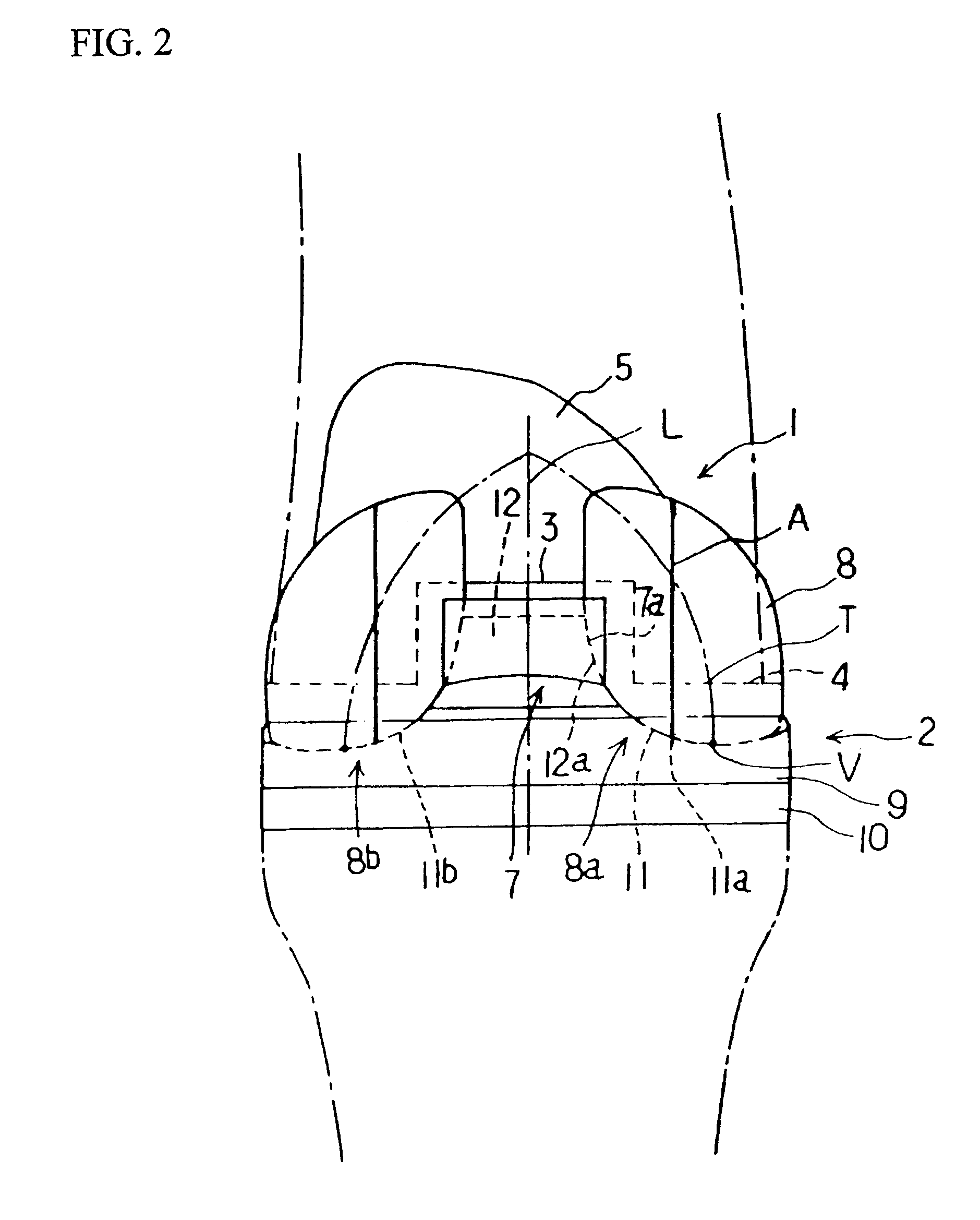

Artificial knee joint

An artificial knee joint comprising: a femoral component comprising a femoral condylar portion made of a medial condylar section and a lateral condylar section which extend in an anteroposterior direction of the knee joint and have convex exterior surfaces, and a tibial component comprising a tibial condylar portion made of a medial condylar section and a lateral condylar section which extend in an anteroposterior direction of the knee joint and have concave interior surfaces so as to slidably receive the medial and lateral condylar sections of the fermoral condylar portion therein; and a space between the respective medial and lateral condylar sections of the femoral condylar portion and of the tibial condylar portion being formed so as to be gradually narrower toward the rear side of the knee joint, thus forming a "rear-in" configuration.

Owner:TSUNENORI TAKEI +2

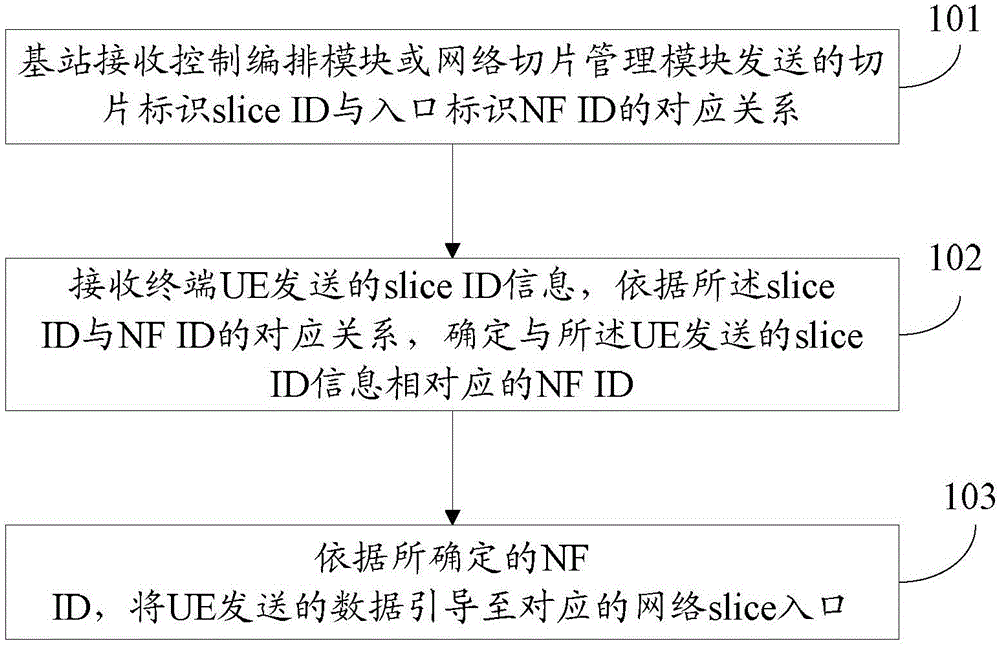

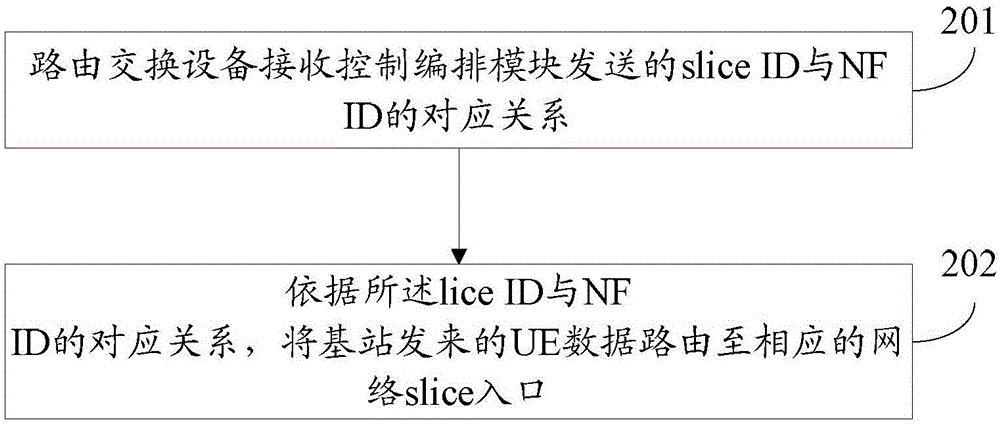

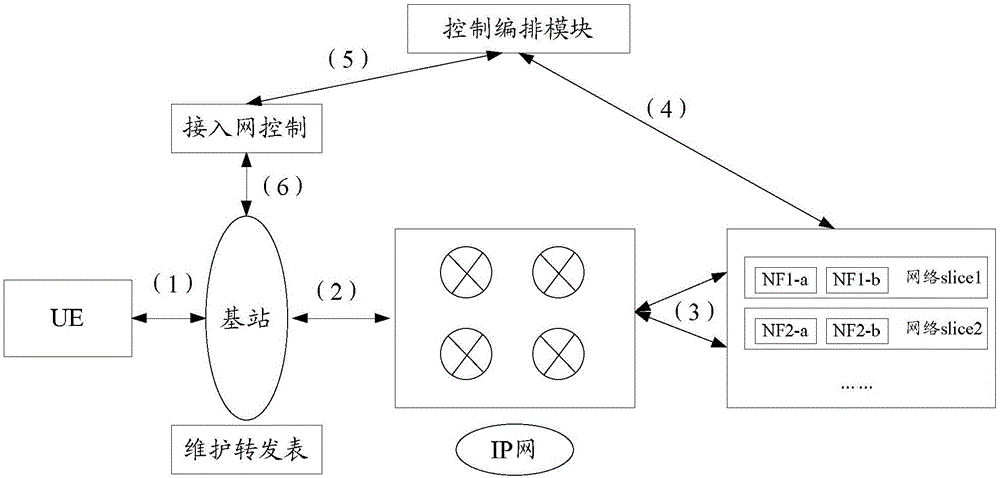

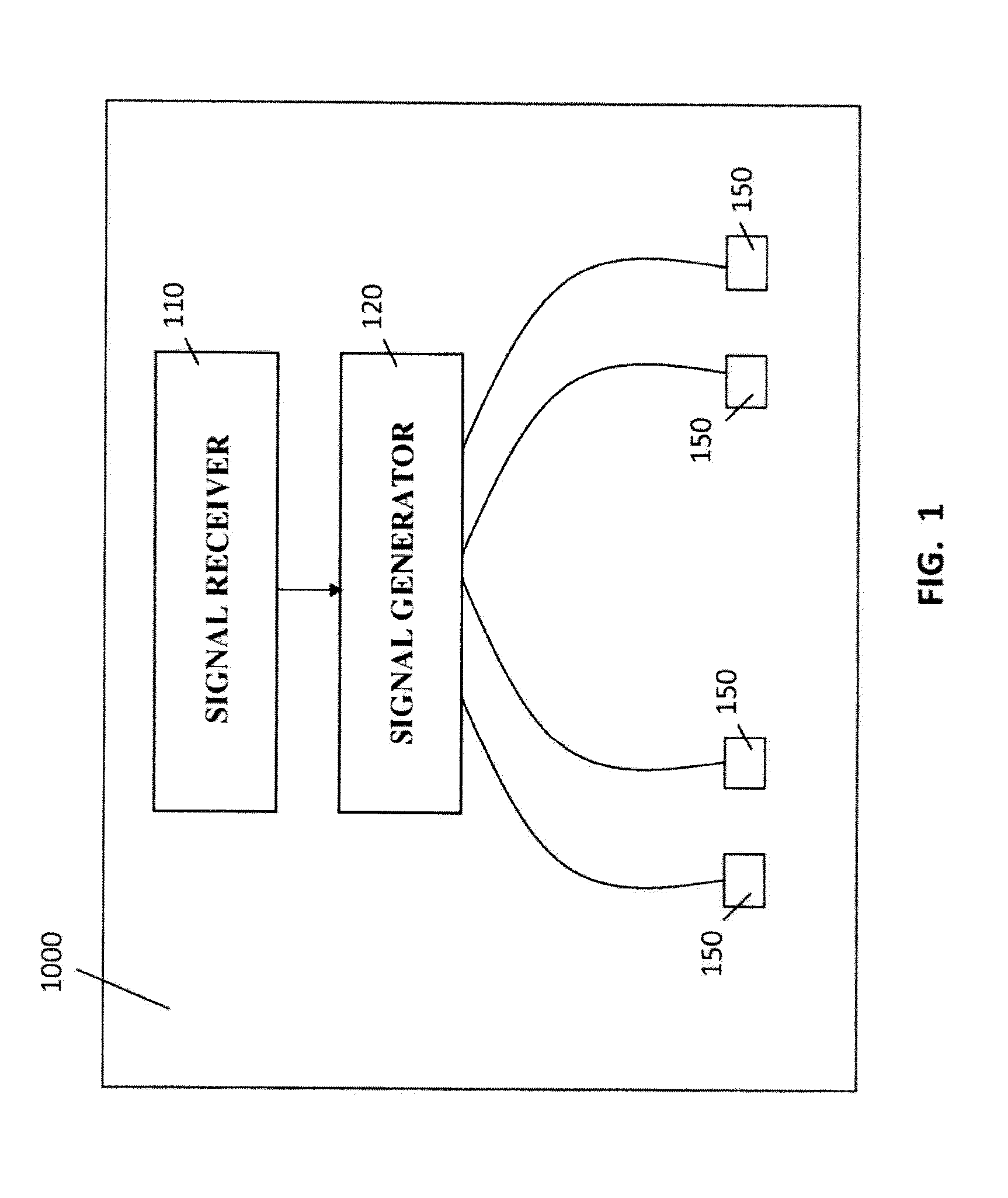

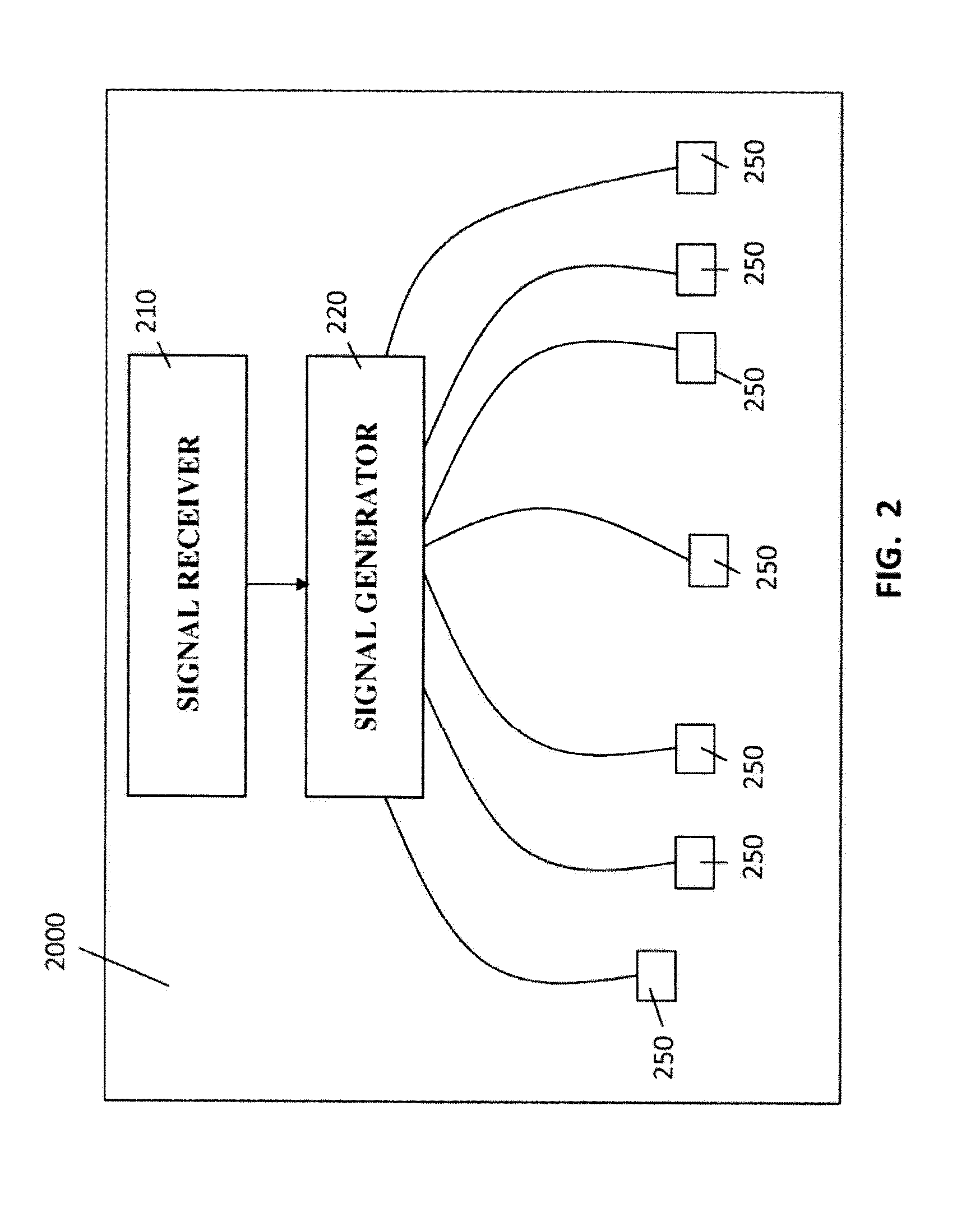

Network slice management and selection method and system, base station and route switching equipment

The invention discloses a network slice management and selection method and system, a base station and route switching equipment. The network slice management and selection method comprises the steps of receiving a corresponding relation, which is sent by a control arrangement module, between slice IDs and NF IDs, or querying a corresponding NF ID according to a slice ID; receiving slice ID information sent by UE (User Equipment), and determining an NF ID corresponding to the slice ID information sent by the UE according to the corresponding relation between the slice IDs and the NF IDs; guiding data sent by the UE to a corresponding slice entry according to the determined NF ID; and performing network slice addition, update and deletion through the control arrangement module.

Owner:CHINA MOBILE COMM GRP CO LTD

Tension-based non-pneumatic tire

ActiveUS20110079335A1Facilitate bucklingAdd benefitNon-inflatable tyresTyre tread bands/patternsEngineeringMechanical engineering

A non-pneumatic tire for supporting a load by working in tension comprising a generally annular inner ring, a generally annular outer ring, and an interconnected web having a plurality of web elements and comprising a plurality of generally polygonal openings. Web elements are sized, curved, oriented, and comprised of varying thicknesses of material which facilitates buckling when subjected to a compressive load. By buckling, those elements in a deformed portion of the tire between a wheel and a footprint region where the tire contacts a surface can assume a significantly reduced portion of the load, if any. This causes web elements in other portions of the interconnected web to operate in tension to support the load.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

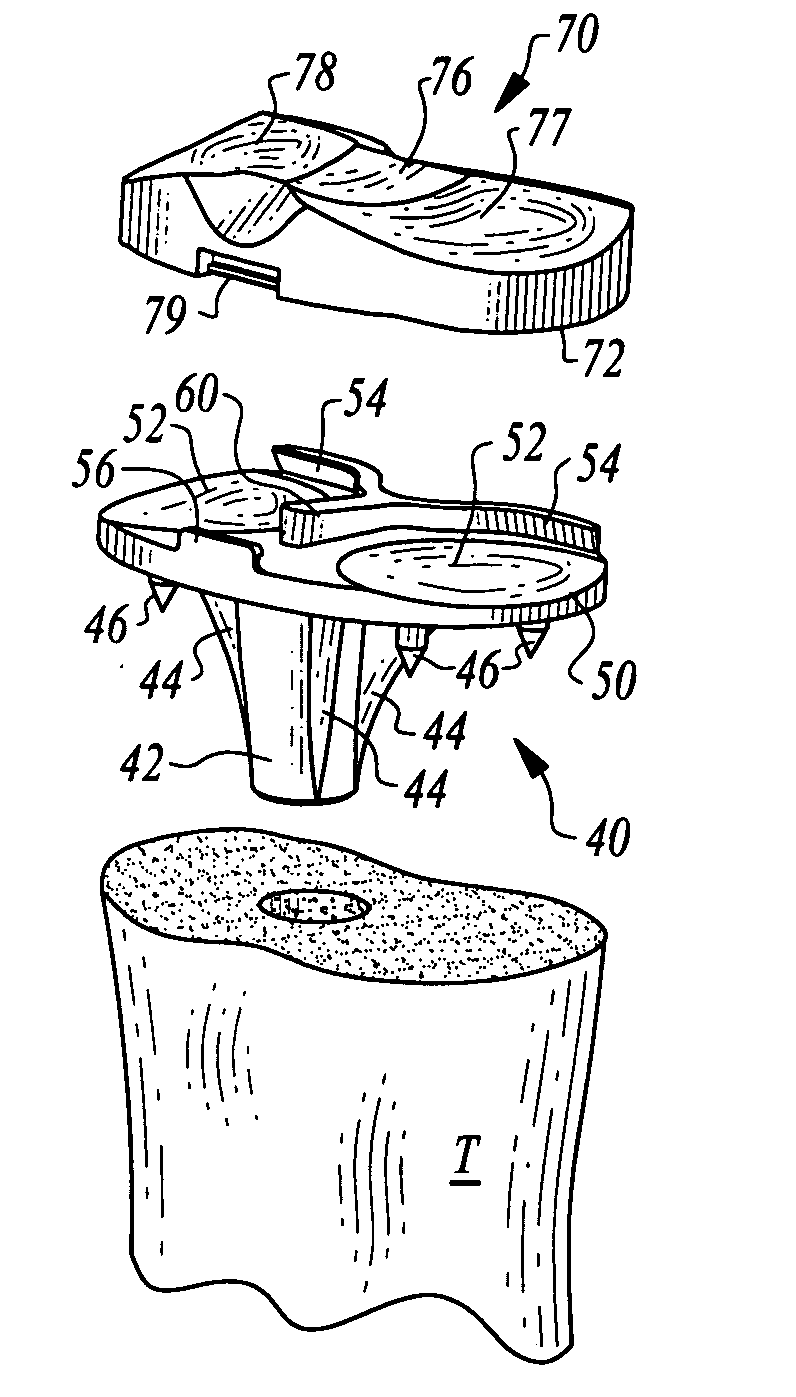

Femoral component of an artificial knee joint

InactiveUS20090265011A1Add flexiblySimplify different cutJoint implantsKnee jointsFemoral prosthesisArtificial knee

A femoral component of an artificial knee joint is configured with multiple different facets which are similar in size and shape for many different sizes, to simplify an associated method for forming a distal end of the femur to receive the femoral component. Jig embodiments are provided to form surfaces on a distal end of a femur to correspond with facets of the femoral component, with the same jig usable for femoral components of differing size. The femoral component includes medial and lateral condylar legs with a posterior facet of the femoral component exhibiting a negative angle relative to a central axis of the femur, to maximize contact and increase flexion of the artificial knee joint.

Owner:MANDELL STEVEN L

Method for preparing powder metallurgy complex shape part by using 3D printing mold

The invention provides a method for preparing a powder metallurgy complex shape part by using a 3D printing mold. A 3D printing technology and a gel-casting forming technology are combined, namely a 3D printer is used for printing a thin-wall hollow part minus mold in a complex shape, the gel-casting technology is used for preparing metal slurry, after a catalyst and an initiator are added, the metal slurry is injected into the part minus mold, the metal slurry is solidified and dried, then organic solvent is used for dissolving a plastic mold or the plastic mold is subjected to thermal decomposition to be removed, so that a formed part blank body is obtained, and after the part blank body is dried, degummed and sintered, the needed powder metallurgy part is obtained. The method is capable of being used for preparing powder metallurgy parts of any complex shape, even and small in part tissue, stable and reliable in technology, high in operability, short in consumed time, high in efficiency, low in cost and beneficial to industrial production for preparation of the powder metallurgy parts through the 3D printing technology.

Owner:UNIV OF SCI & TECH BEIJING

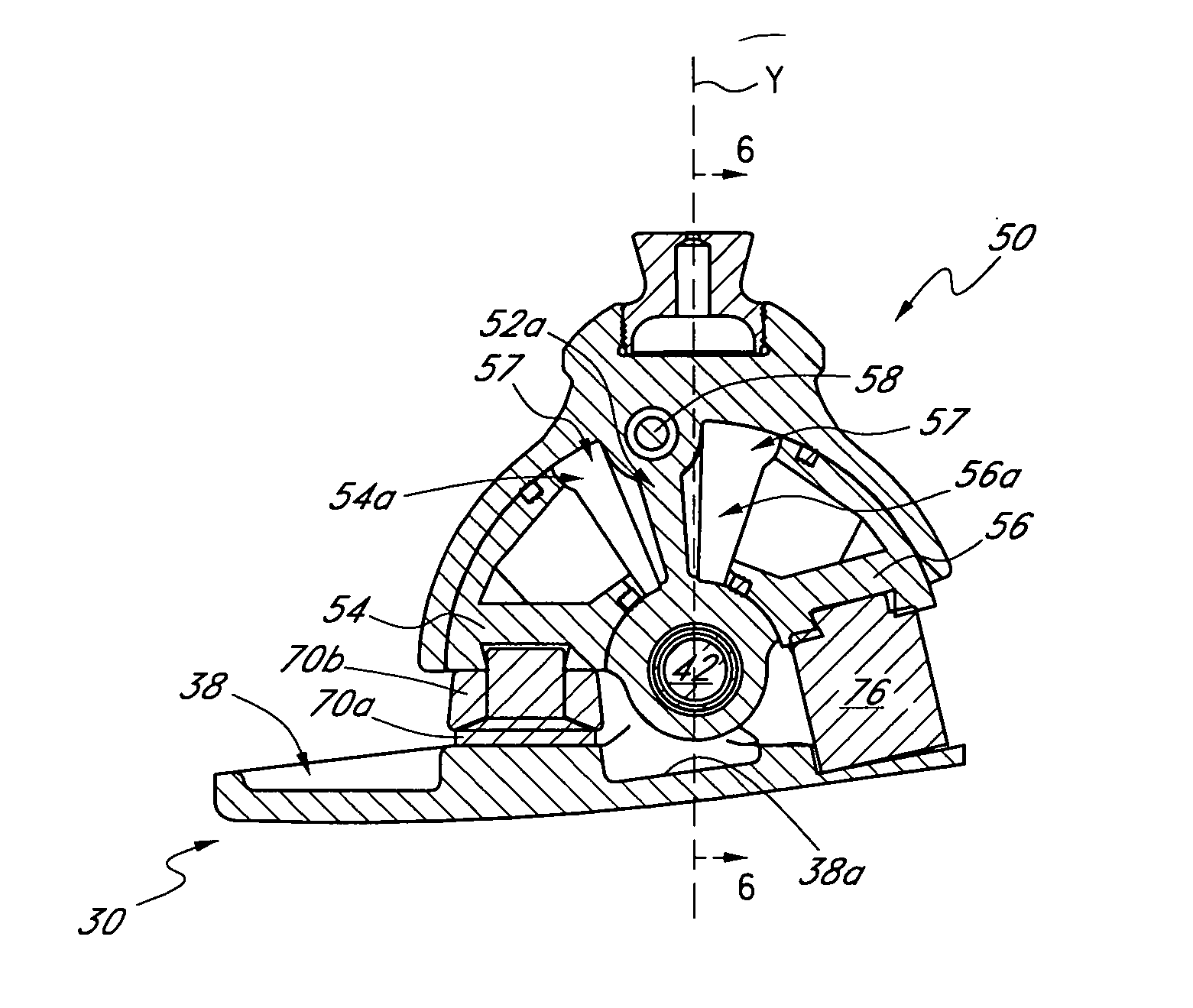

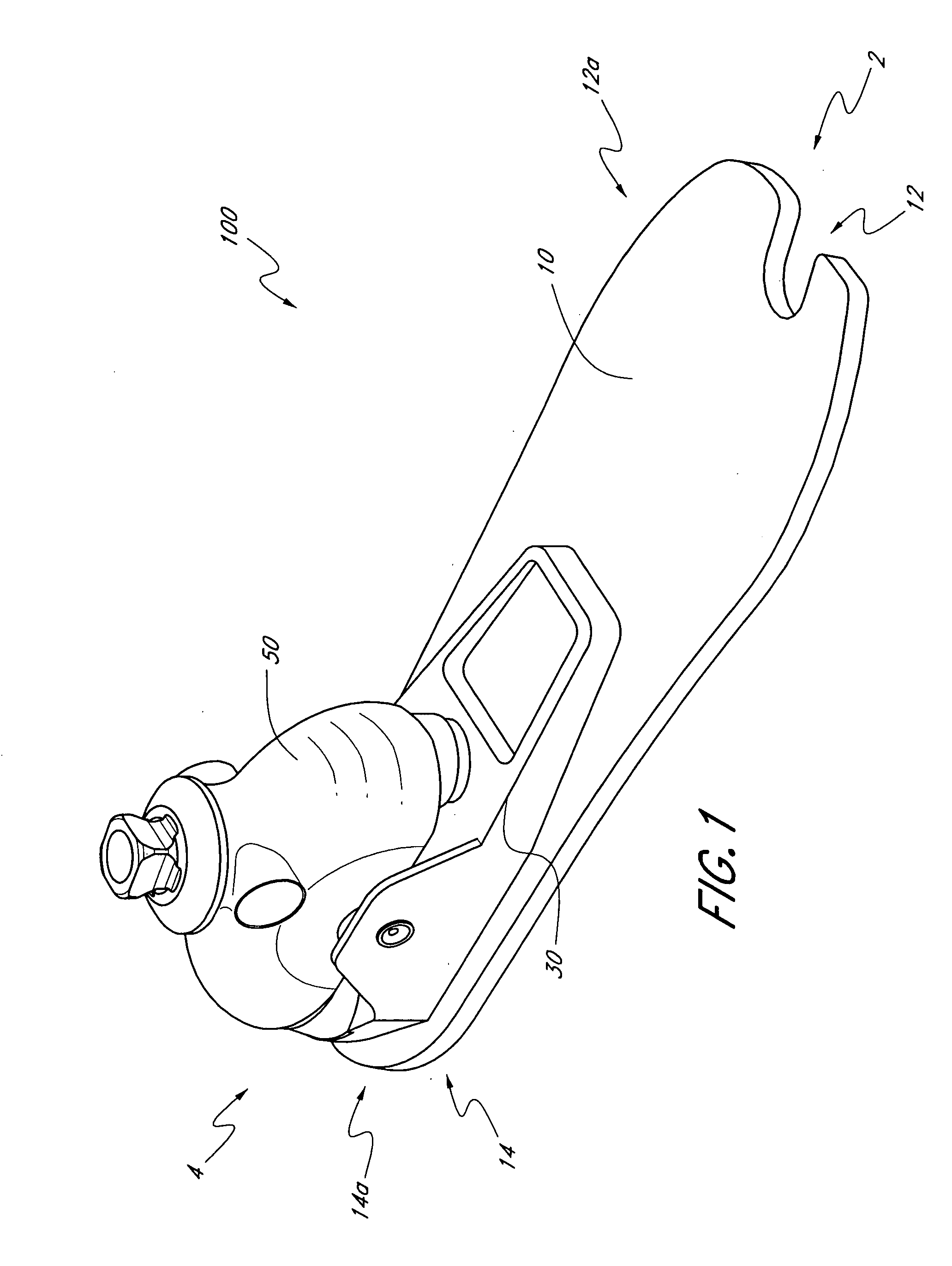

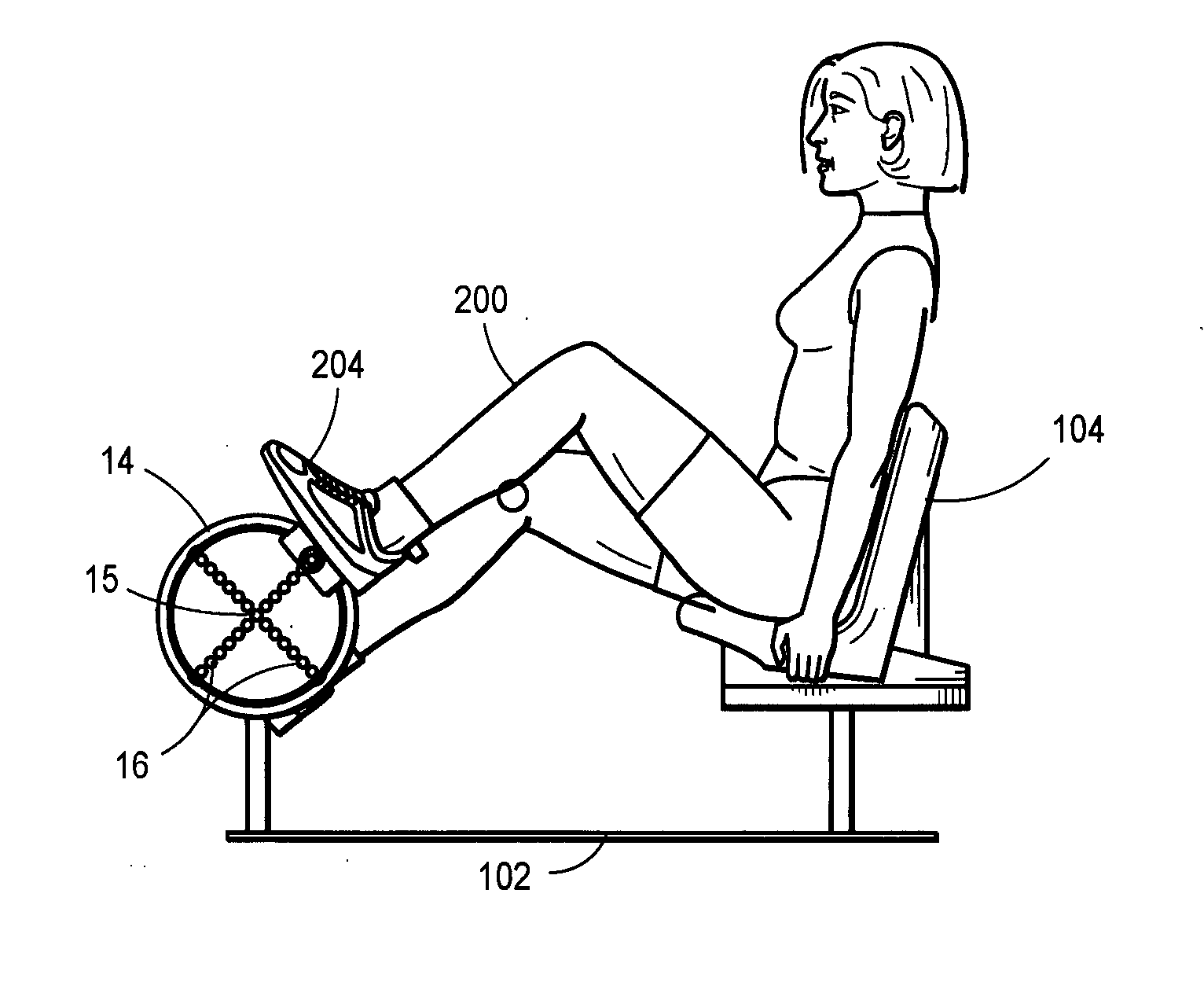

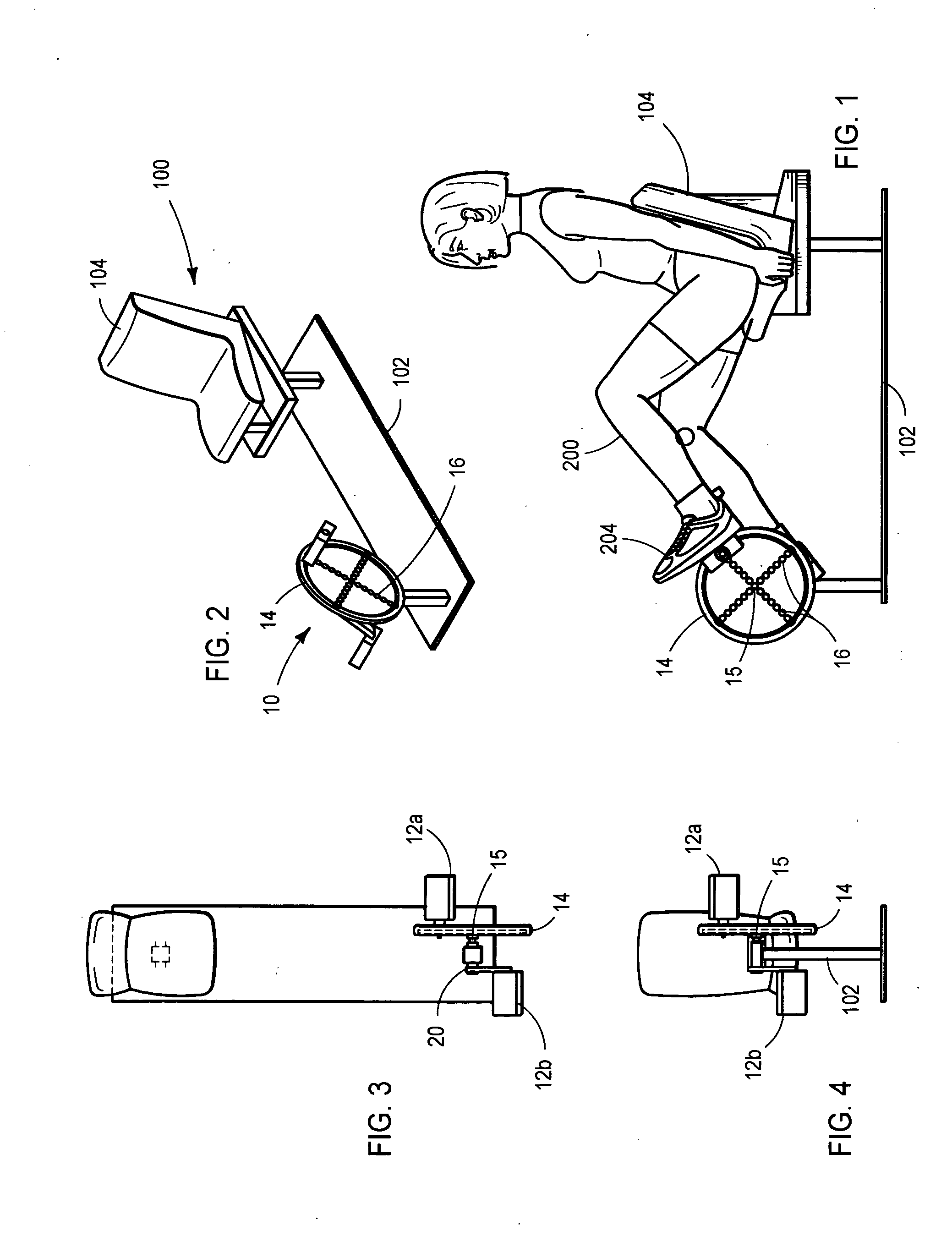

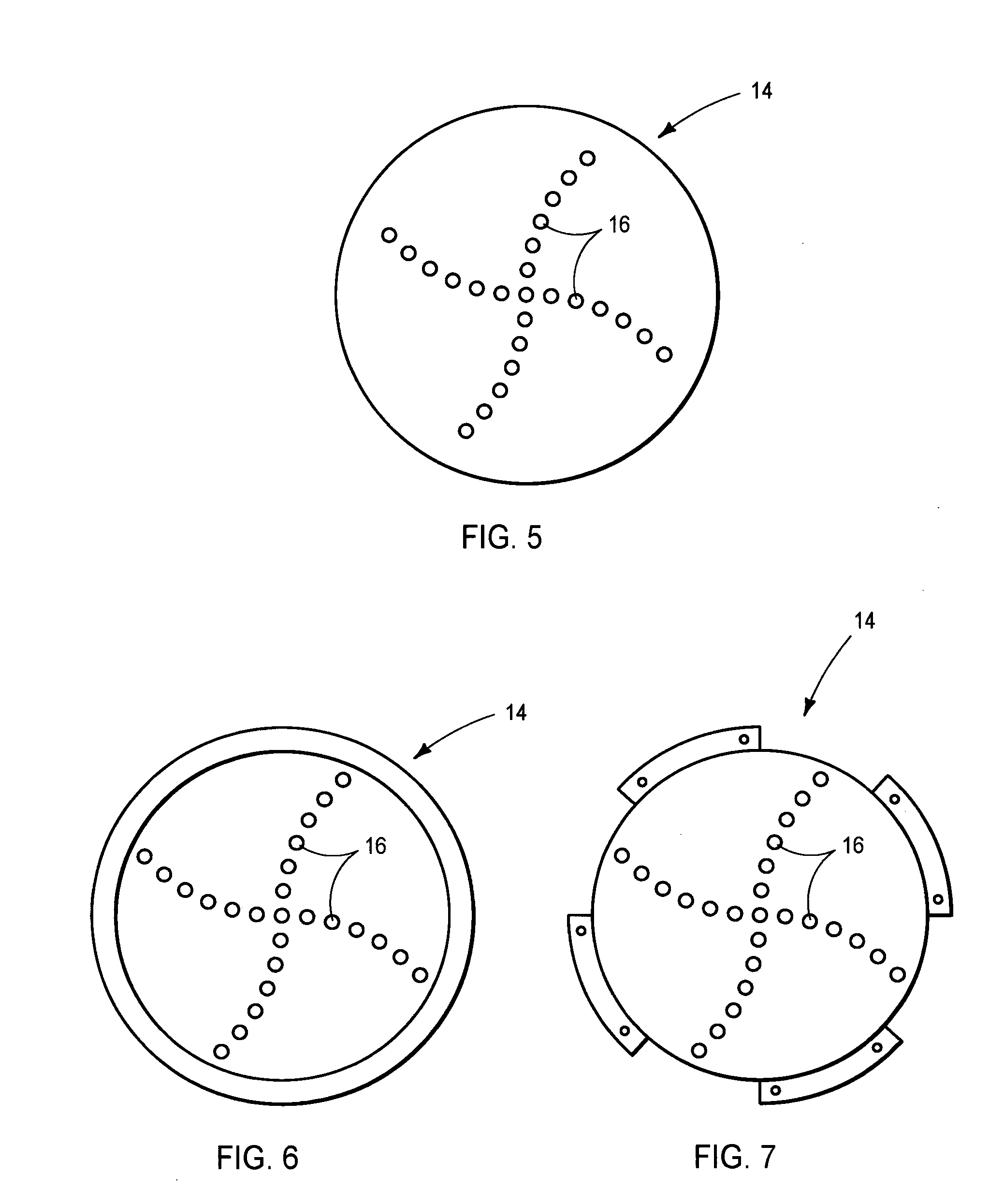

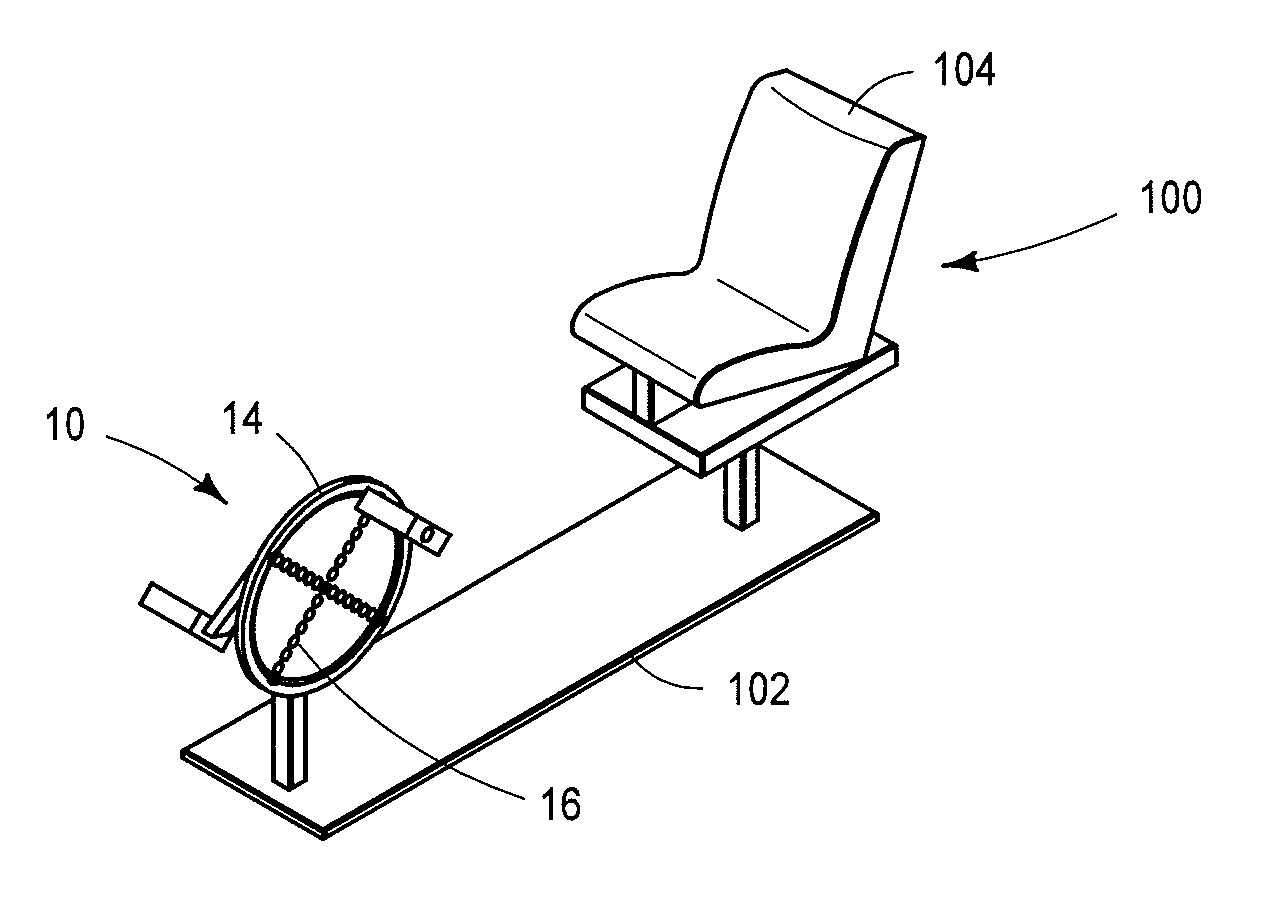

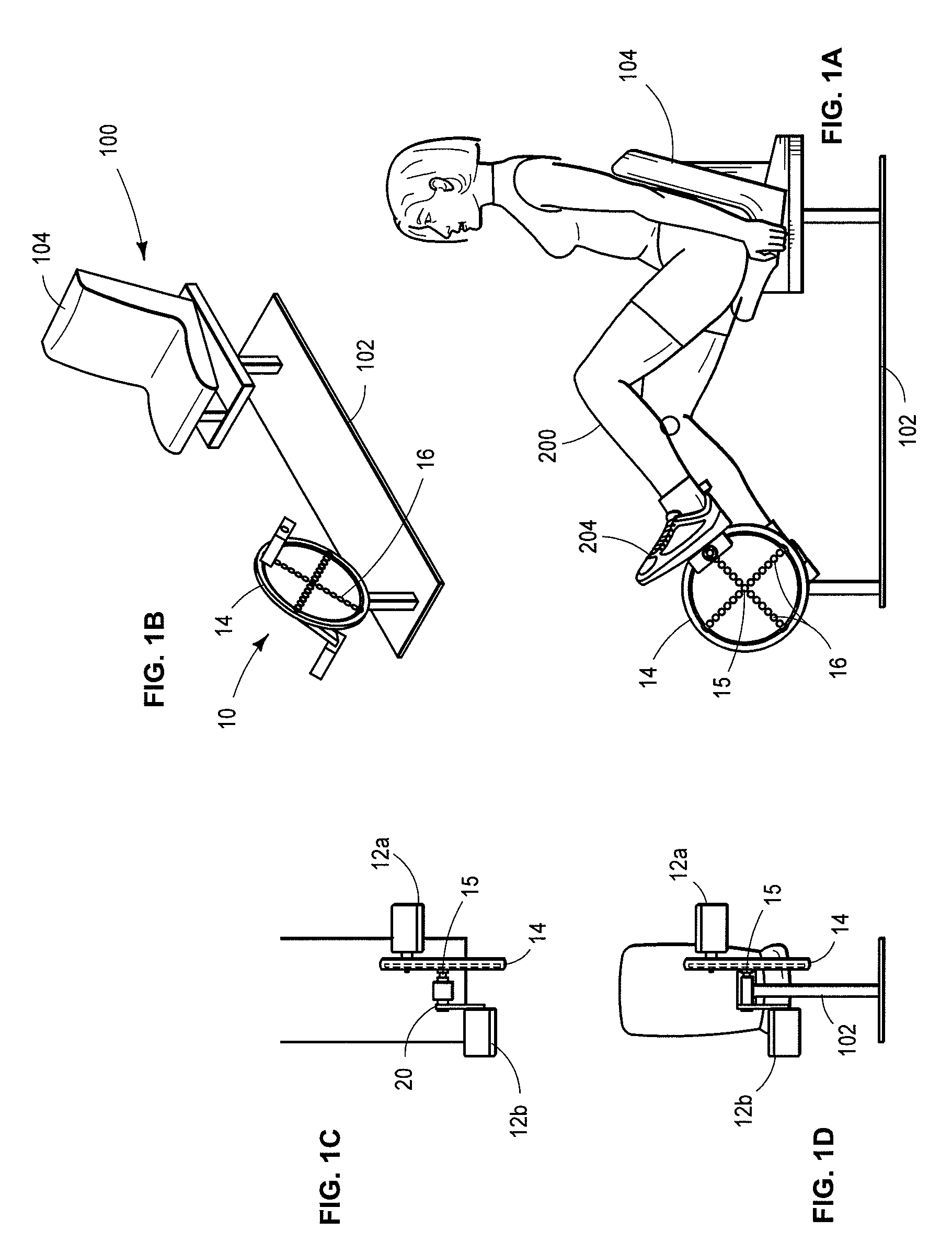

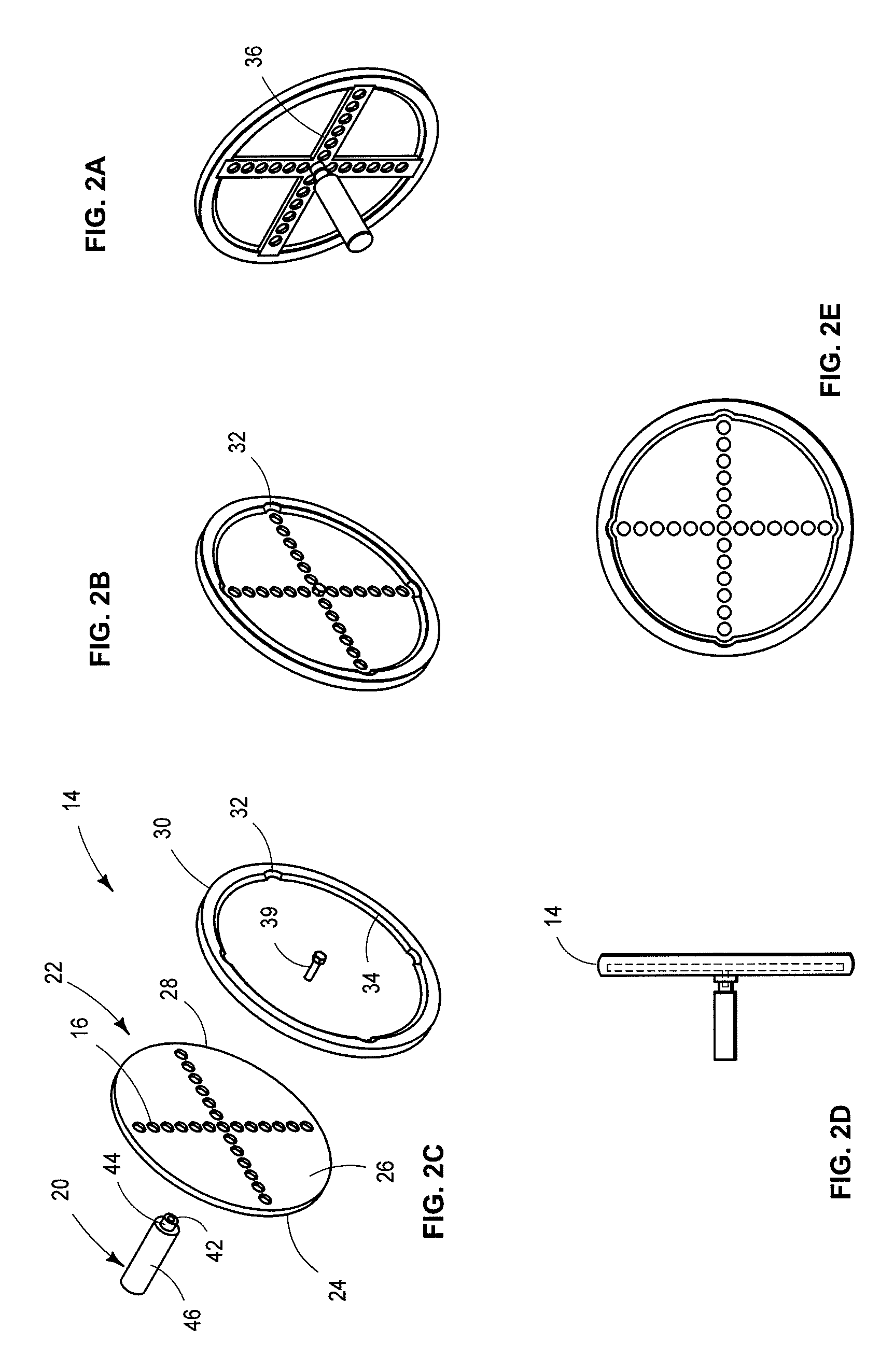

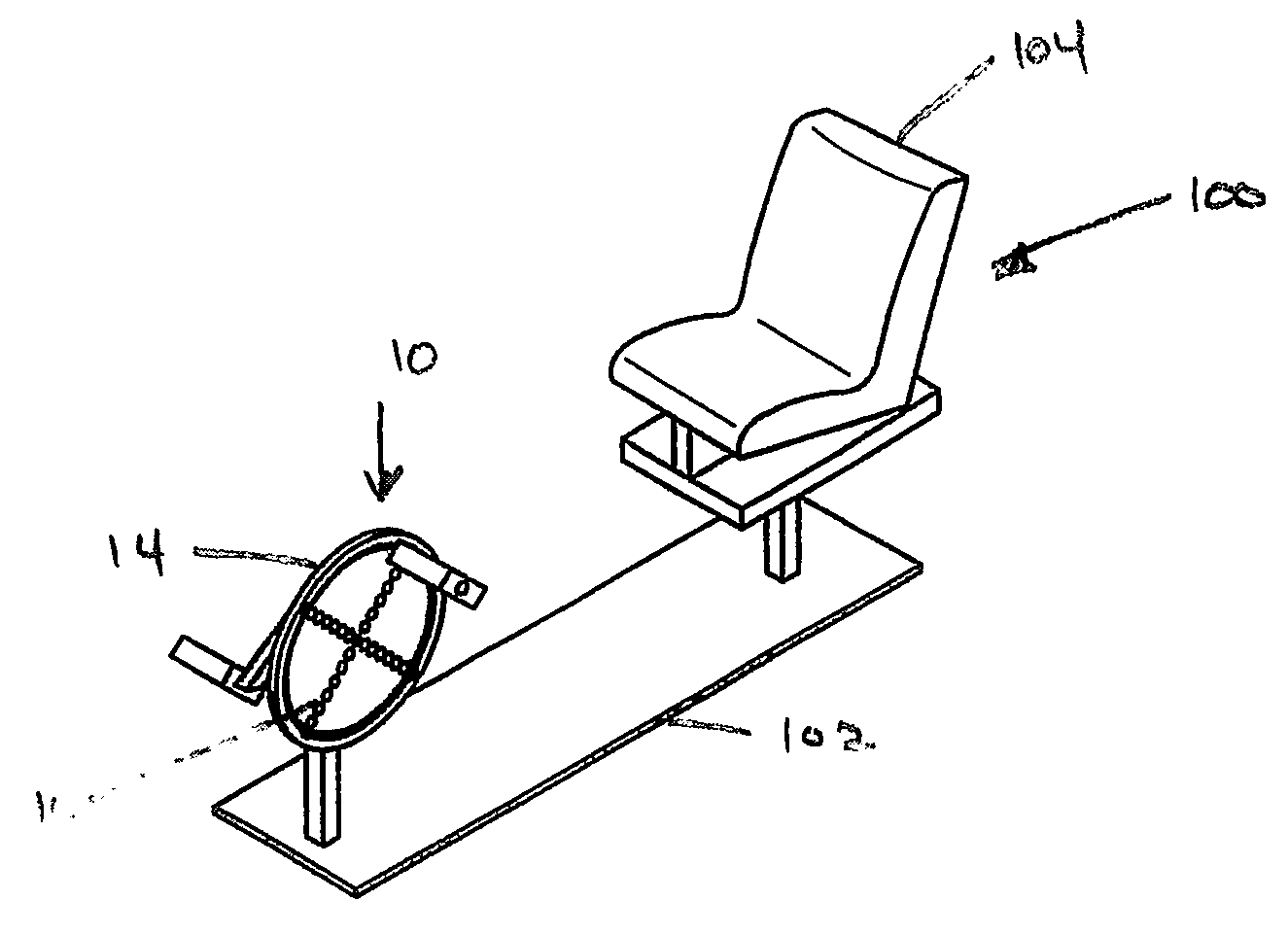

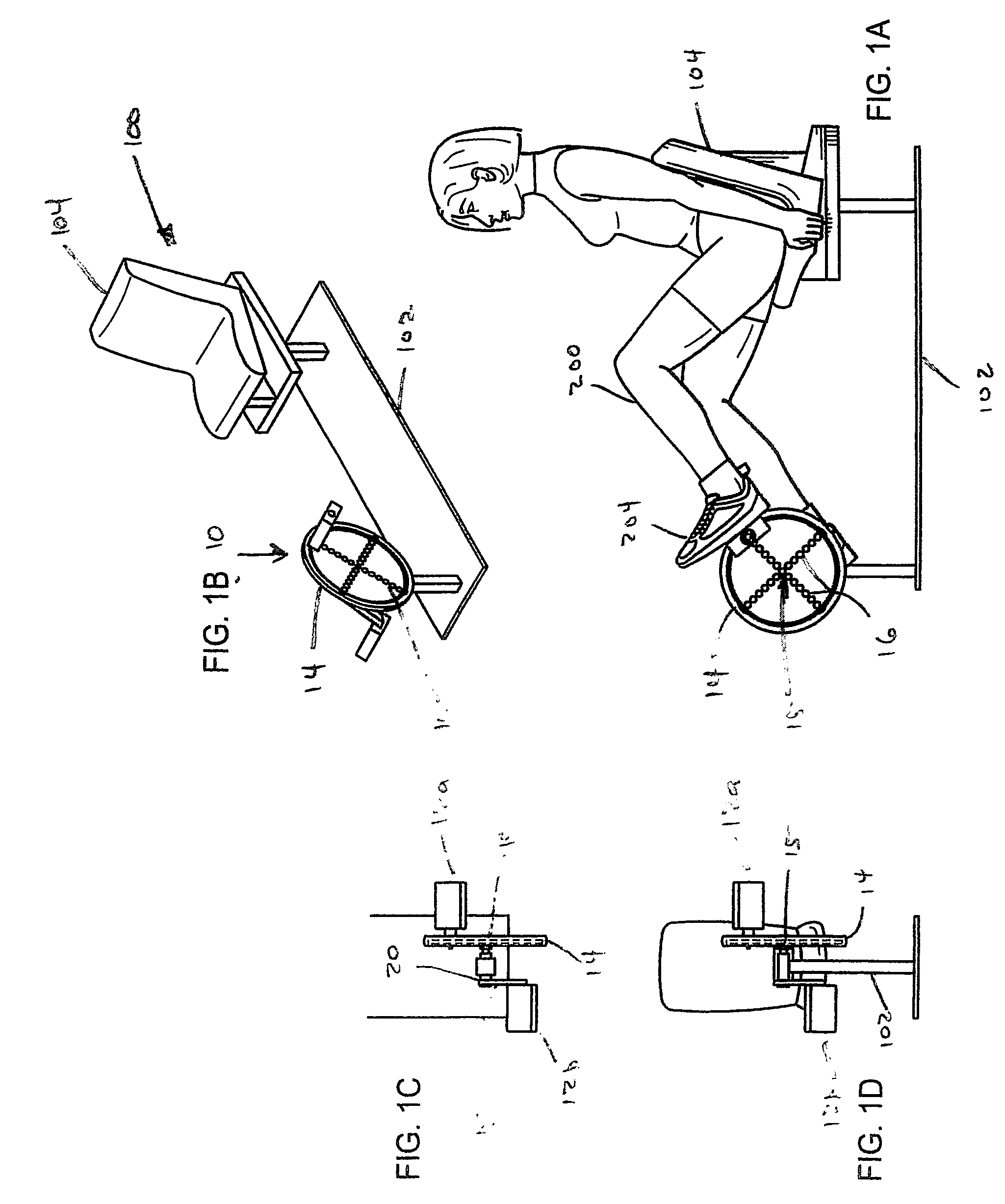

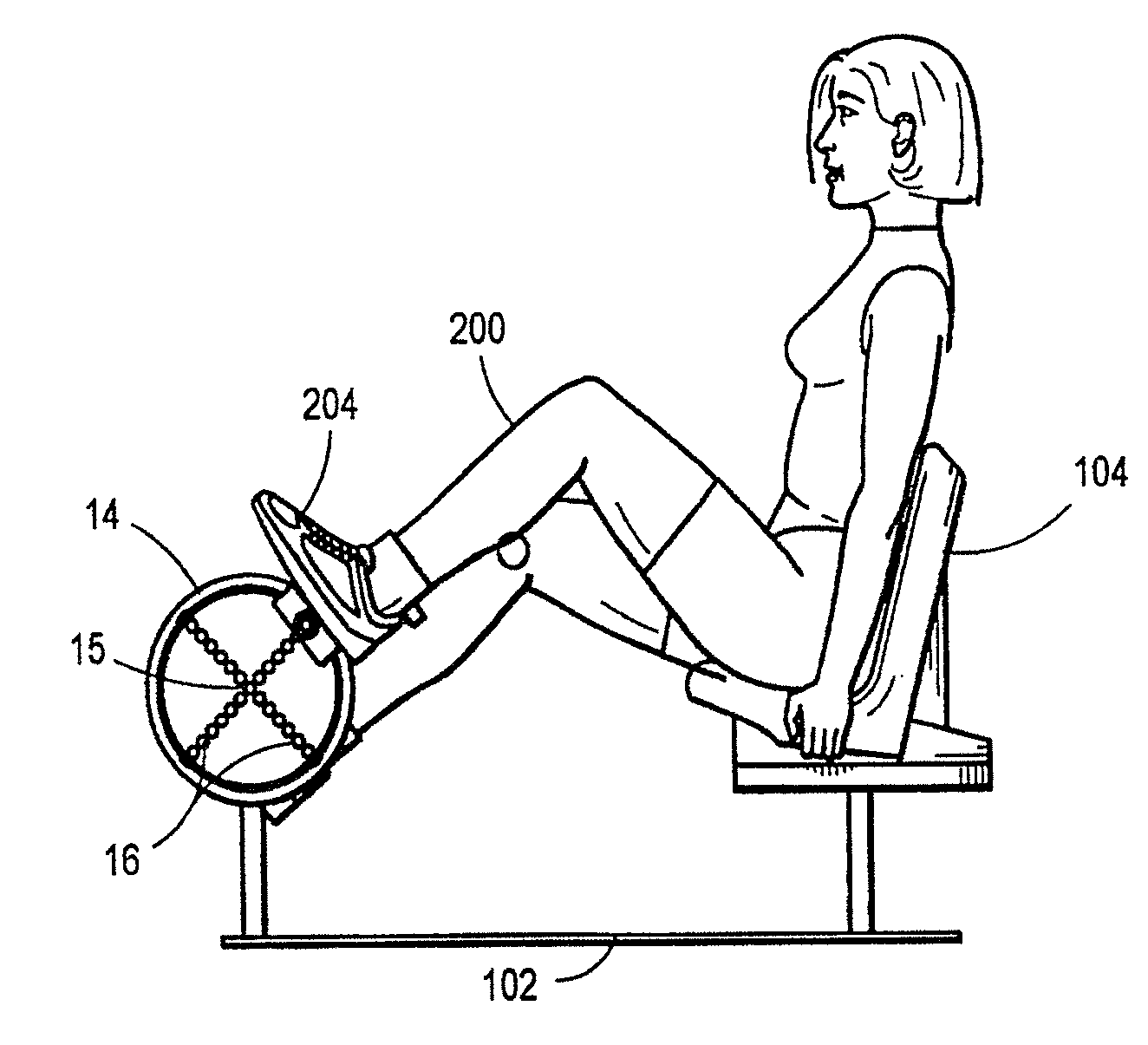

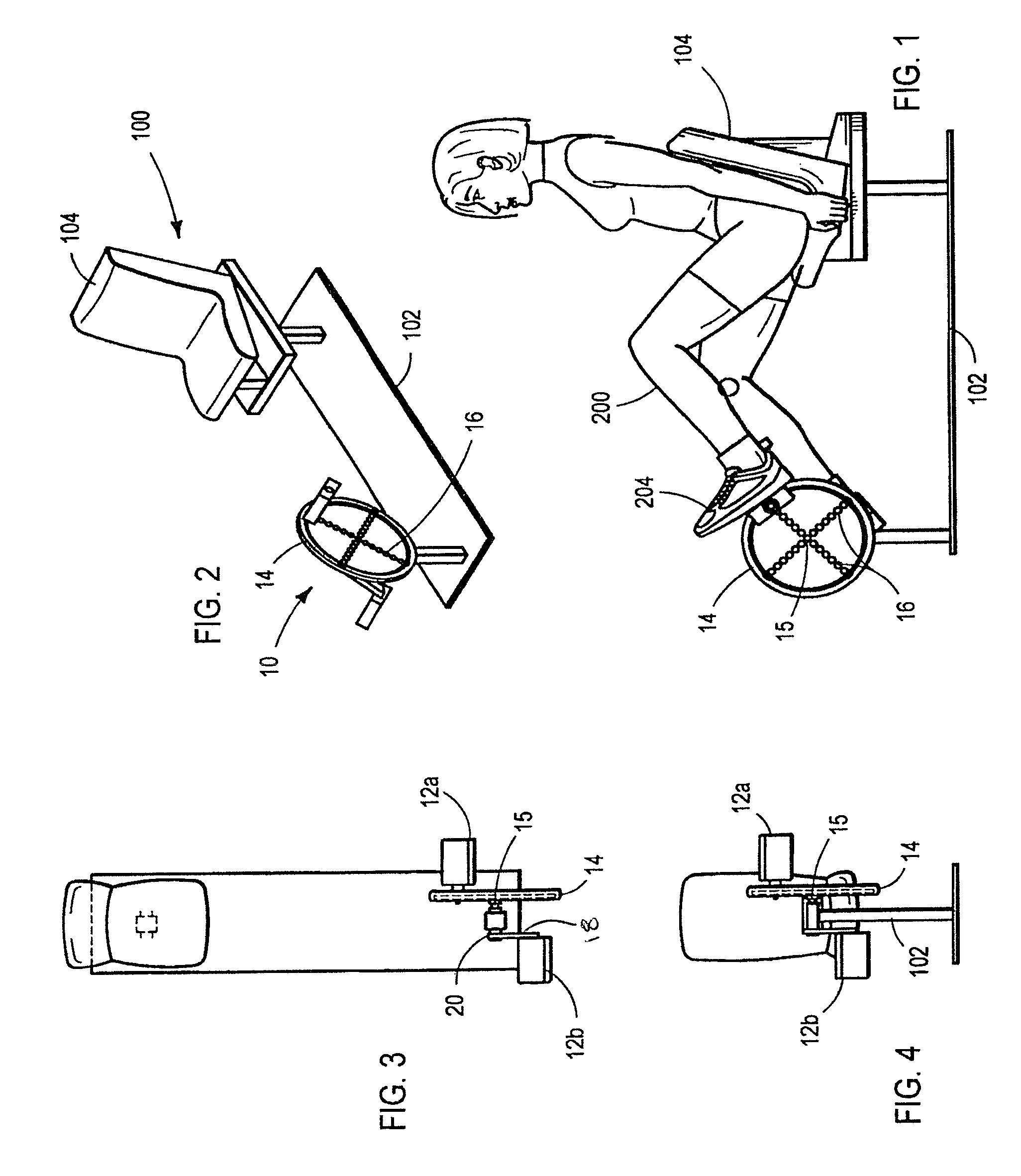

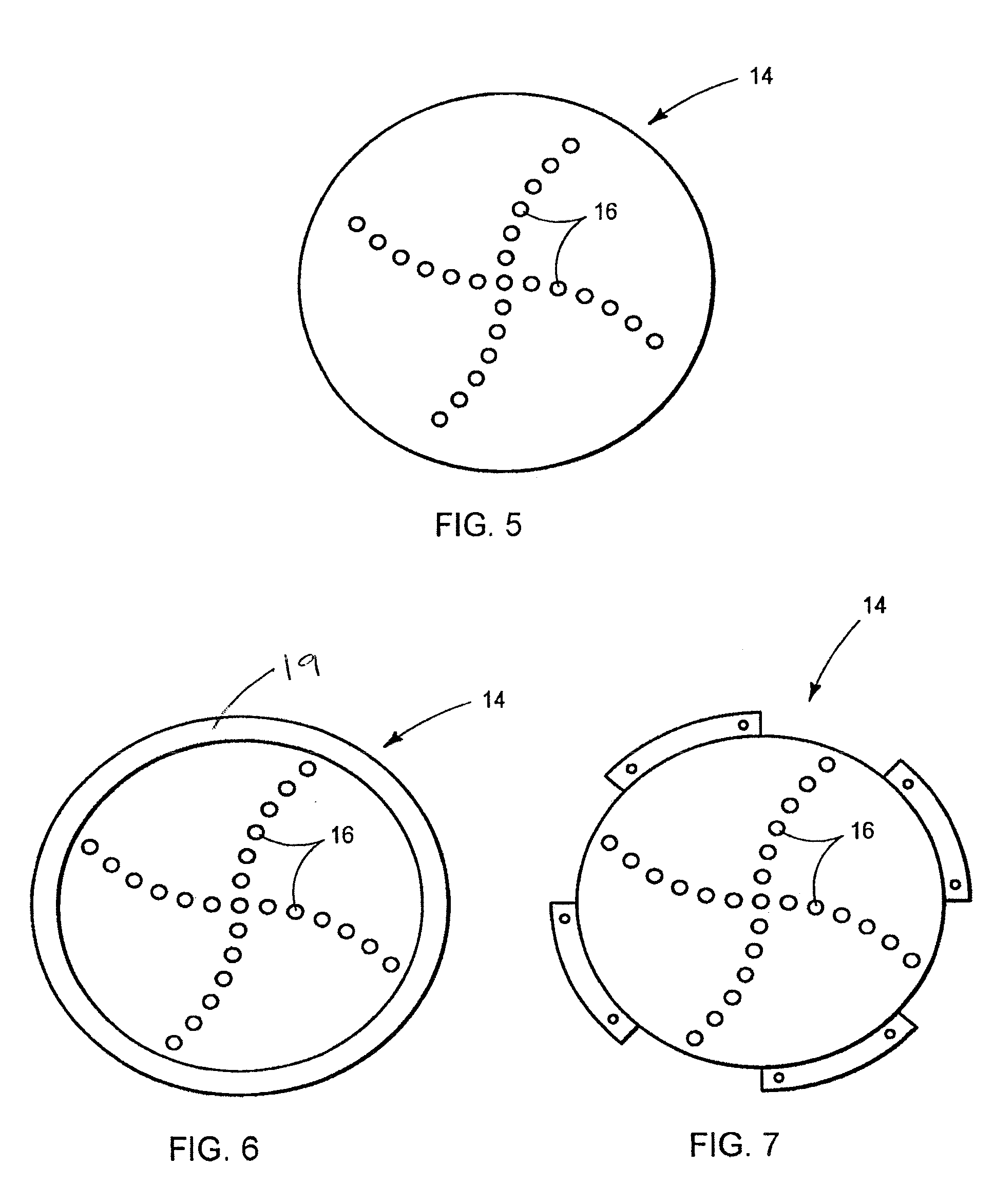

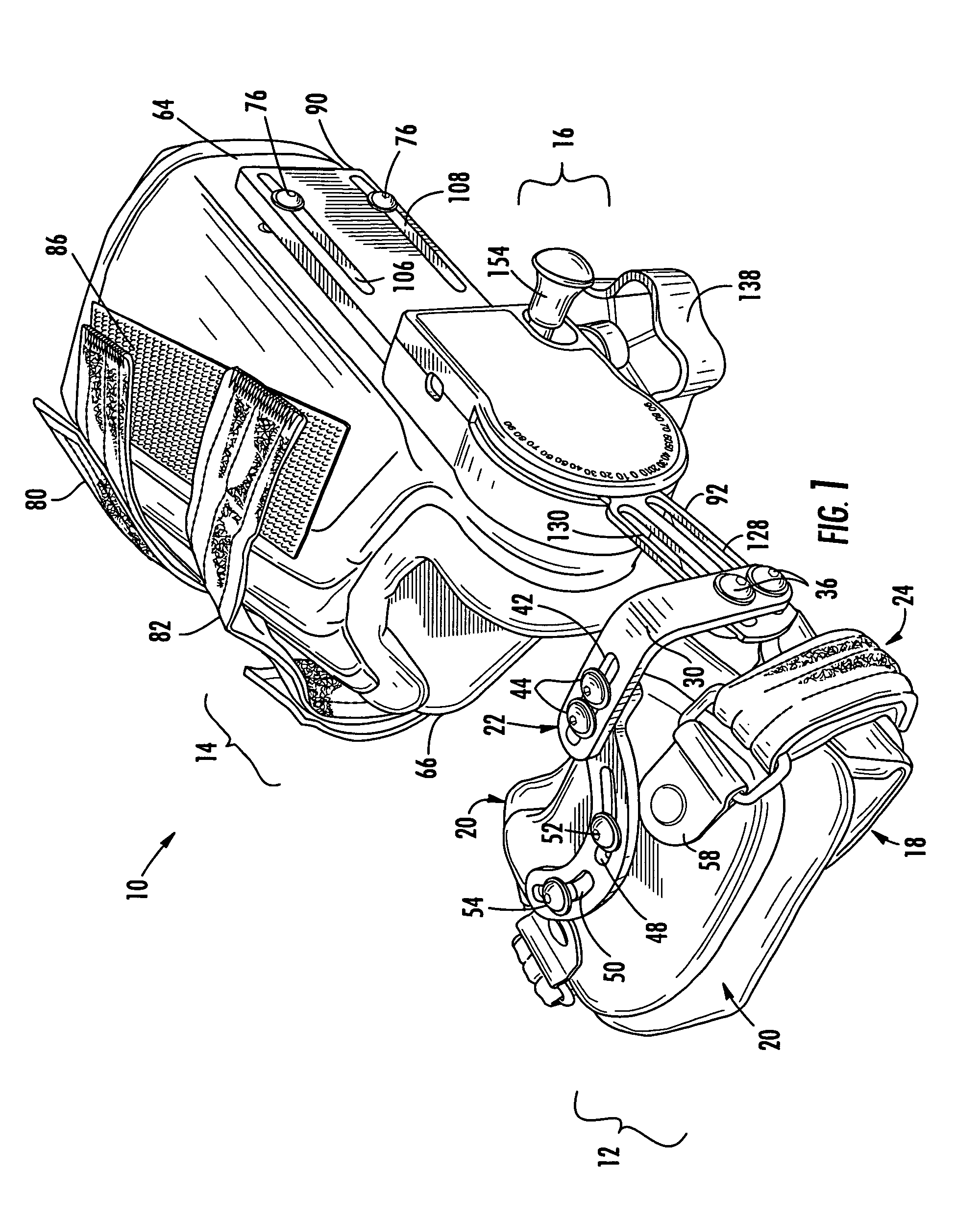

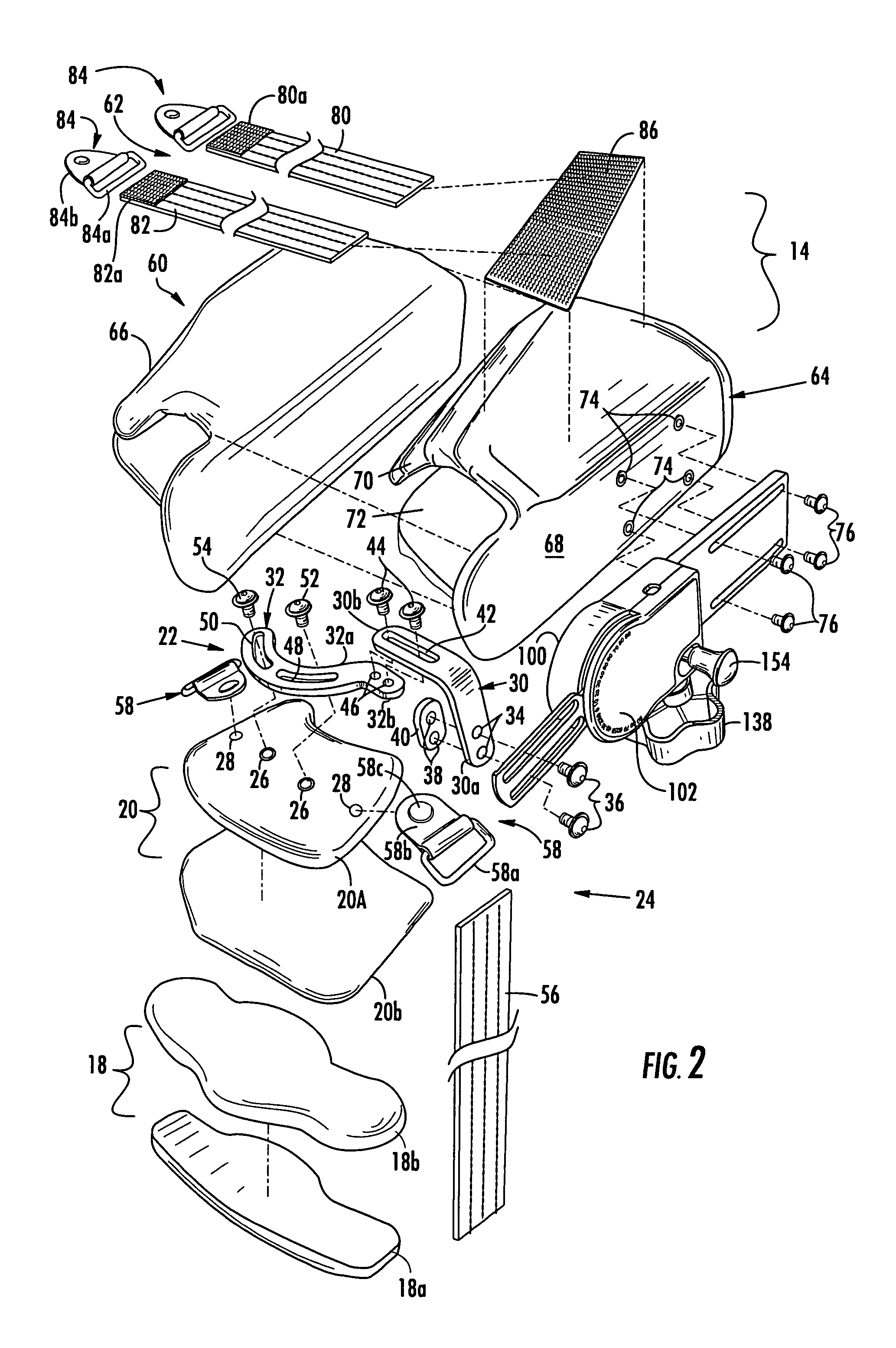

Rotary rehabilitation apparatus and method

ActiveUS20050085353A1High strengthIncrease flexibilityMechanical apparatusVehicle cranksRange of motionEngineering

A rotary rehabilitation apparatus is presented for rehabilitation of a person's extremity, including the joints and assorted muscles, tendons, ligaments, that can be tailored to the person's needs based upon their physical size, type of injury, and plan for recovery. The apparatus facilitates the adjustment of the range of motion of the user's extremity in a cycling action by offsetting a moveable lever from a fixed lever at a plurality of angles. As the user's extremity moves in a circular path, the extremity engages in extension and flexion to cause movements in the articulations formed at the user's joints.

Owner:ROM TECH INC

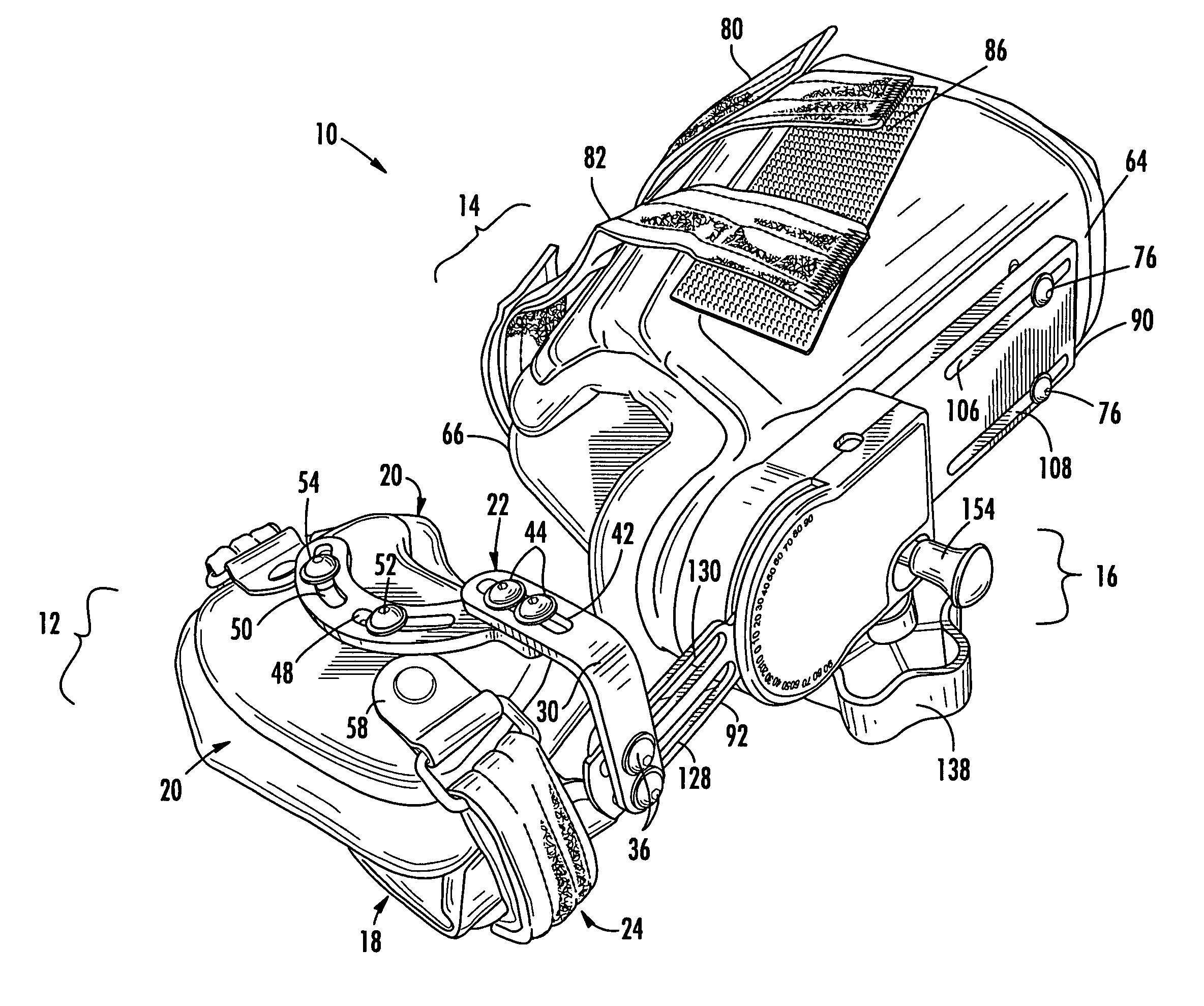

Active assist for the ankle, knee and other human joints

InactiveUS20060142680A1Reduce the risk of injuryLower requirementNon-surgical orthopedic devicesSports activityKnee Joint

A human joint assist device that applies a torque at the joint to assist physiological exertion forces, that is the load carrying task of the joint and surrounding muscles, tendons, and ligaments. The application of this device reduces the physiological exertion force requirement, and may be adjusted with respect to assist level, to suit the issue associated with joint motion and is useful for joint rehabilitation and sports activities. Among other things, this results in a reduction of physiological exertion force in a fashion that makes it easier to extend the levers (long bones) associated with extension against a given resistance. For example, standing from a squatted position with the assist of this device reduces the stress on physiological members associated with joint articulation.

Owner:IAROCCI MICHAEL ANTHONY

Rotary rehabilitation apparatus and method

ActiveUS7226394B2Safer, more immediate rehabilitationRelieve painMechanical apparatusVehicle cranksRange of motionEngineering

A rotary rehabilitation apparatus for rehabilitation of a person's extremity, including the joints and assorted muscles, tendons, ligaments, that can be tailored to the person's needs based upon their physical size, type of injury, and plan for recovery. The apparatus facilitates the adjustment of the range of motion of the user's extremity in a cycling action by offsetting a moveable lever from a fixed lever at a plurality of angles. As the user's extremity moves in a circular path, the extremity engages in extension and flexion to cause movements in the articulations formed at the user's joints.

Owner:ROM TECH INC

Rotary rehabilitation apparatus and method

ActiveUS20050085346A1High strengthIncrease flexibilityMechanical apparatusVehicle cranksRange of motionSacroiliac joint

A rotary rehabilitation apparatus for rehabilitation of a person's extremity, including the joints and assorted muscles, tendons, ligaments, that can be tailored to the person's needs based upon their physical size, type of injury, and plan for recovery. The apparatus facilitates the adjustment of the range of motion of the user's extremity in a cycling action by offsetting a moveable lever from a fixed lever at a plurality of angles. As the user's extremity moves in a circular path, the extremity engages in extension and flexion to cause movements in the articulations formed at the user's joints.

Owner:ROM TECH INC

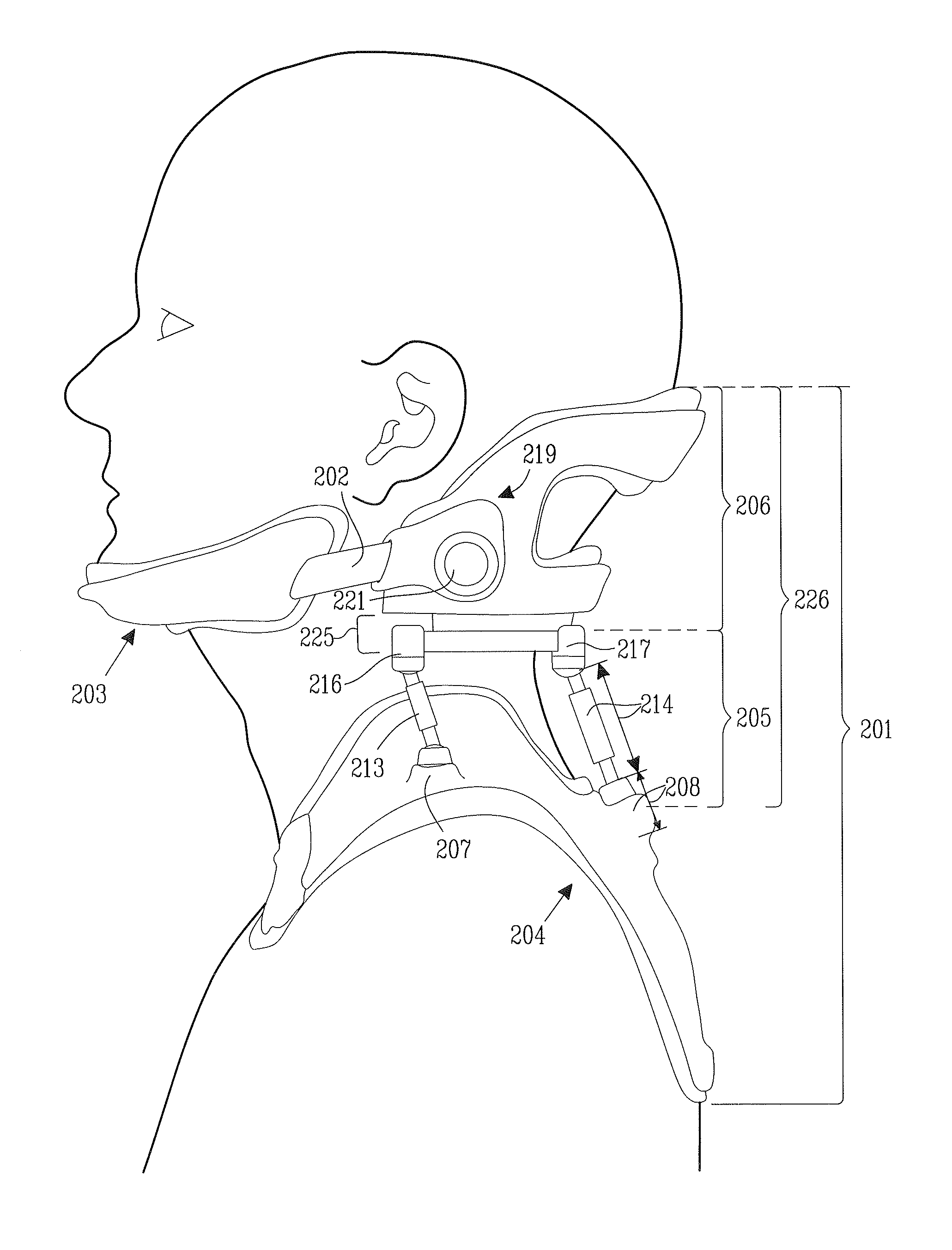

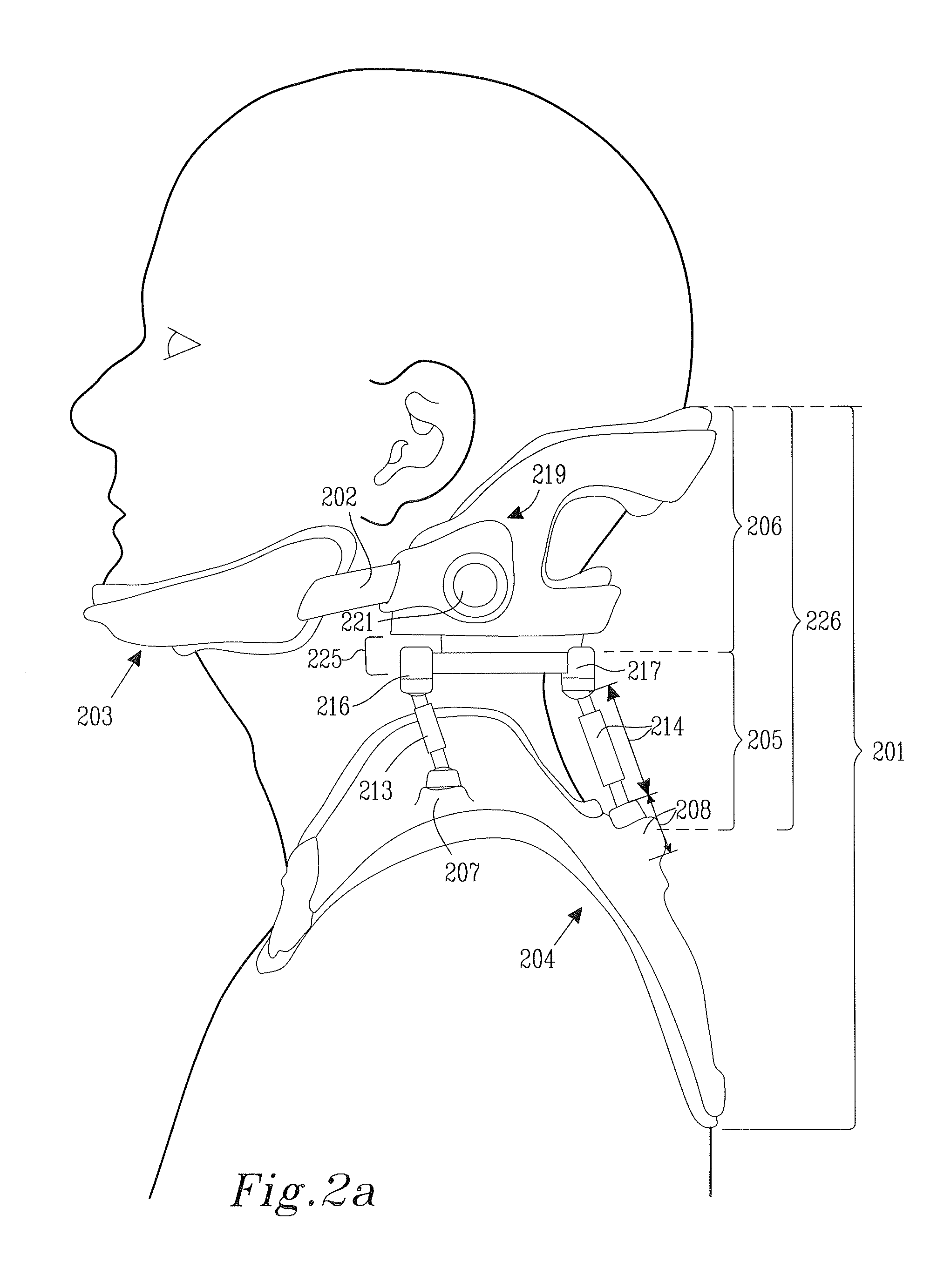

Mobilizing neck support device

InactiveUS20100298748A1Comfortable supportComfortable safetyFractureChinPhysical medicine and rehabilitation

The invention discloses a cervical collar which provides support, safety and stability to the neck of the wearer, and is arranged to prevent cervical flexion, extension and bilateral lateral flexion while allowing cervical rotation. The cervical collar comprises two parts; one back piece including a shoulder and back support piece attached to an adjustable neck piece and a chin support piece. The chin support piece can be lowered, raised and / or removed by the wearer of the collar in order to allow opening of the mouth sufficiently for eating or performing personal hygiene without unwanted extension of the neck.

Owner:CERVRITE

Rotary rehabilitation apparatus and method

ActiveUS7594879B2Safer, more immediate rehabilitationRelieve painMechanical apparatusVehicle cranksRange of motionEngineering

A rotary rehabilitation apparatus is presented for rehabilitation of a person's extremity, including the joints and assorted muscles, tendons, ligaments, that can be tailored to the person's needs based upon their physical size, type of injury, and plan for recovery. The apparatus facilitates the adjustment of the range of motion of the user's extremity in a cycling action by offsetting a moveable lever from a fixed lever at a plurality of angles. As the user's extremity moves in a circular path, the extremity engages in extension and flexion to cause movements in the articulations formed at the user's joints.

Owner:ROM TECH INC

Brace with worm gear

A patient care system for positioning on a limb of a patient for assisting in flexion or extension of a joint. The system has a threaded shaft which engages a toothed gear. The threaded shaft is rotated to rotate the toothed gear for assisting in flexion or extension of the joint.

Owner:DEROYAL INDUSTRIES INC

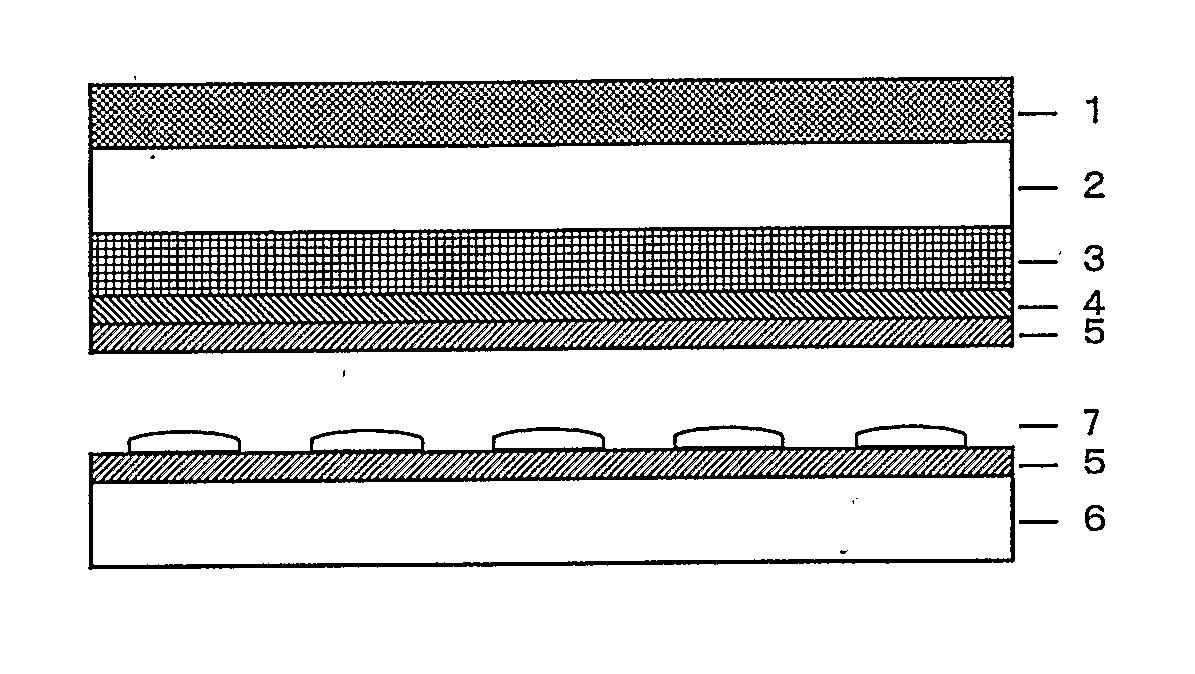

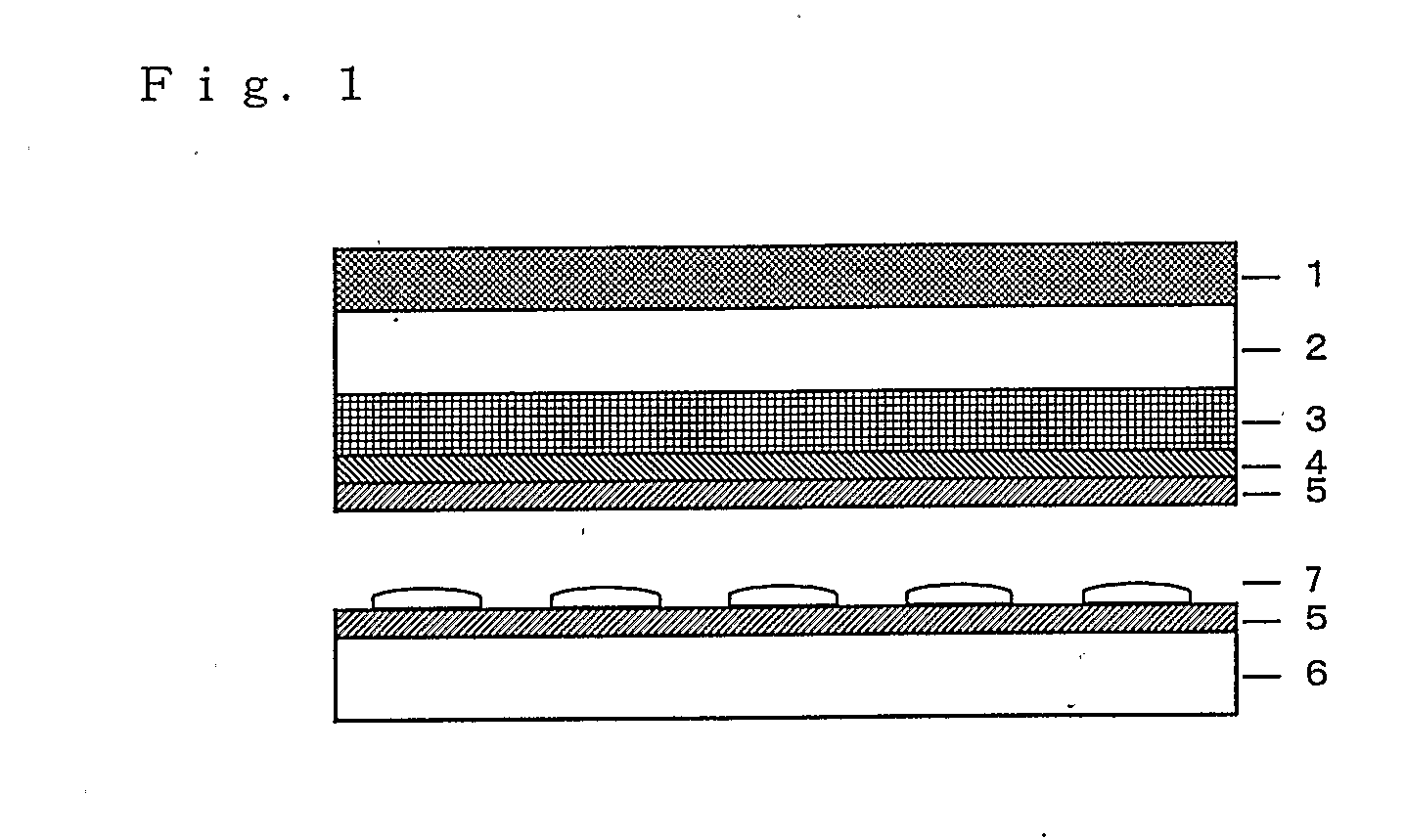

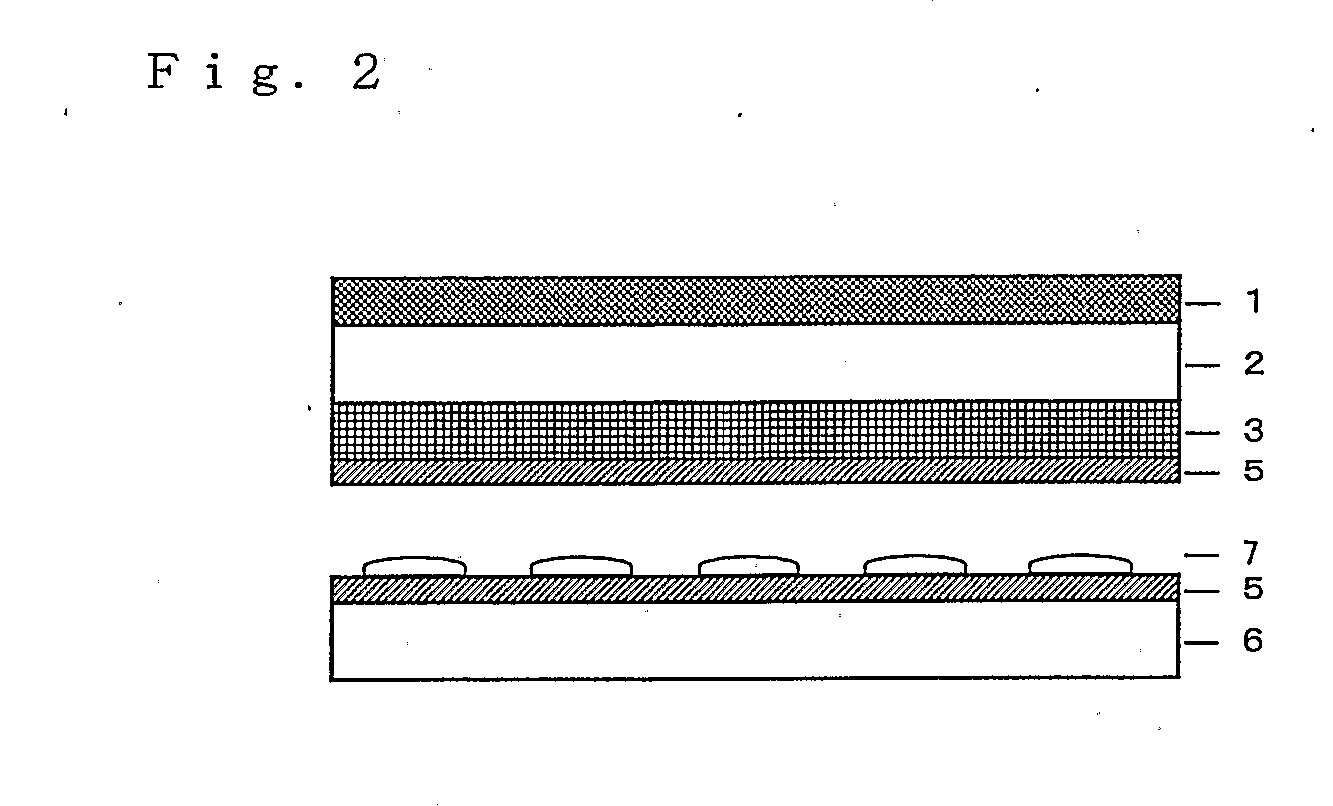

Transparent Conductive Laminated Body and Transparent Touch-Sensitive Panel

InactiveUS20070224412A1Add flexiblyAutomatic/semiautomatic turning machinesConductive layers on insulating-supportsOptoelectronicsPolymer

A transparent conductive laminated body (1) contains a polymer film having a metallic compound layer and a transparent conductive layer laminated sequentially on at least one surface thereof, (2) the metallic compound layer is in contact with the transparent conductive layer, and (3) the metallic compound layer has a thickness of 0.5 nm or more and less than 10.0 nm.

Owner:TEIJIN LTD

Joint arthroplasty devices having articulating members

InactiveCN101534751ADoes not affect imagingNot easy to damageSpinal implantsJoint arthroplastySacroiliac joint

Articulating devices for replacing damaged or degenerated weight bearing joints are provided. The devices may have two or more surfaces that articulate against one another that are coated or fully formed of PEEK or similar materials to provide improved wear capabilities while maintaining sufficient strength to operate in a weight bearing capacity.

Owner:PIONEER SURGICAL TECH INC

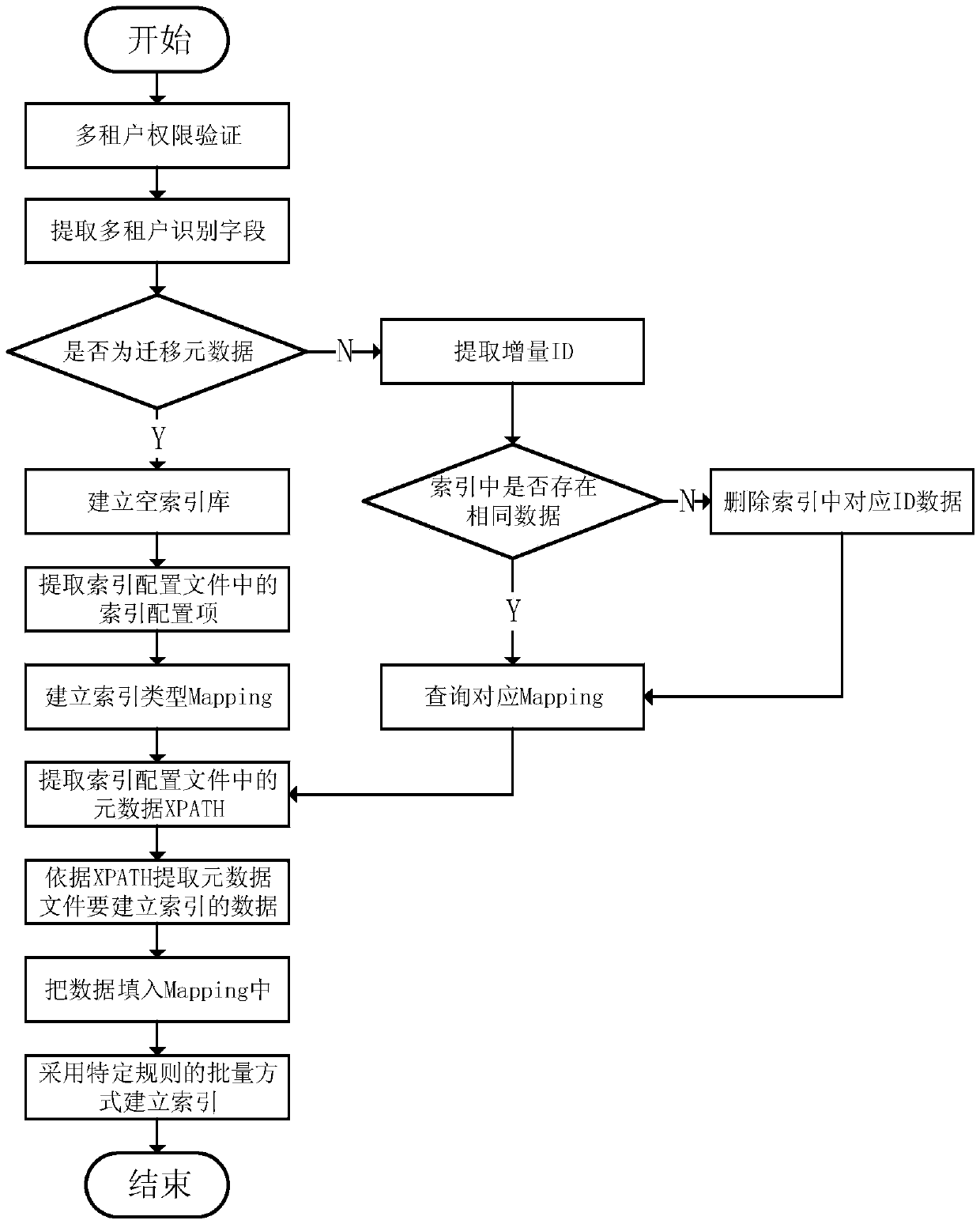

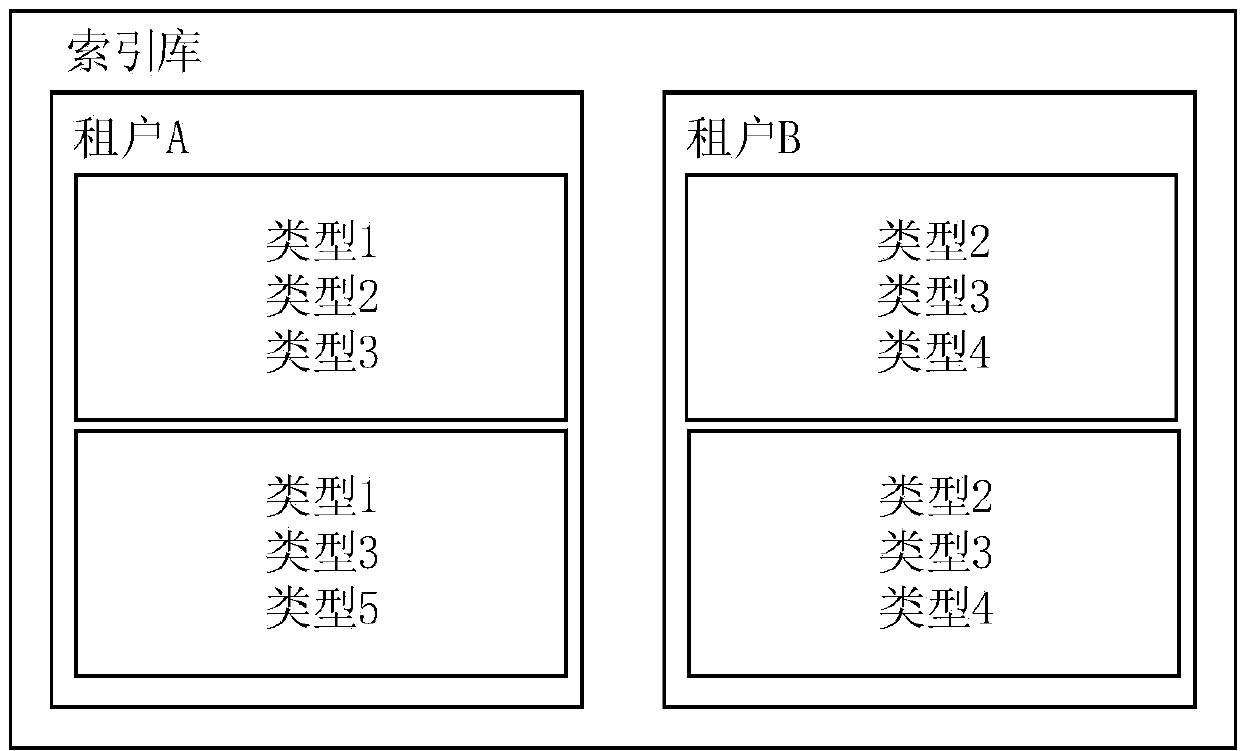

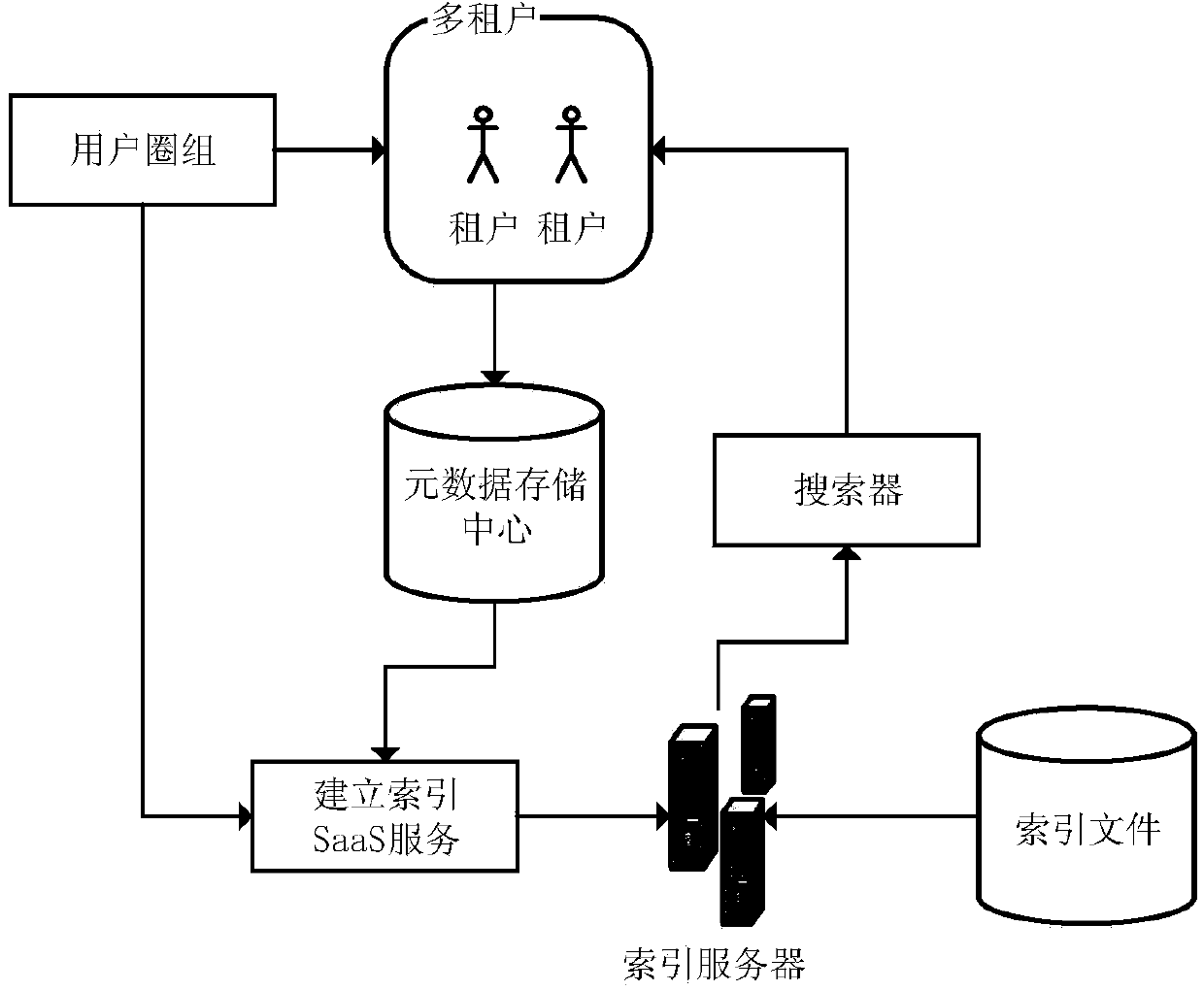

Metadata indexing module and method based on cloud platform

InactiveCN103744960AUp to speedHigh speedSpecial data processing applicationsEngineeringReal-time Search

The invention discloses a metadata indexing model and a metadata indexing method based on a cloud platform. The model comprises a full volume indexing module, for mainly solving the problem of building full volume indexes for legacy data and migration data; an increment indexing module, for adding metadata which has passed audit into an index database in an incremental manner; an index management module, for meeting the basal management requirement of indexing. The method establishes a set of SaaS service for building indexes for the metabata. A tenant stores metadata into a metadata storage center through a migrating or registering process, the manner of building full volume index is adopted for the migration data, an increment index interface is called and built and the manner of incrementing is adopted for the metadata stored through the registering process, and thus data is added into the index database; building the index by a distributed search tool Elasticsearch. According to the metadata indexing model and the metadata indexing method based on the cloud platform, the speed for building index is obviously improved, real-time search can be achieved, and good expandability is provided.

Owner:HOHAI UNIV

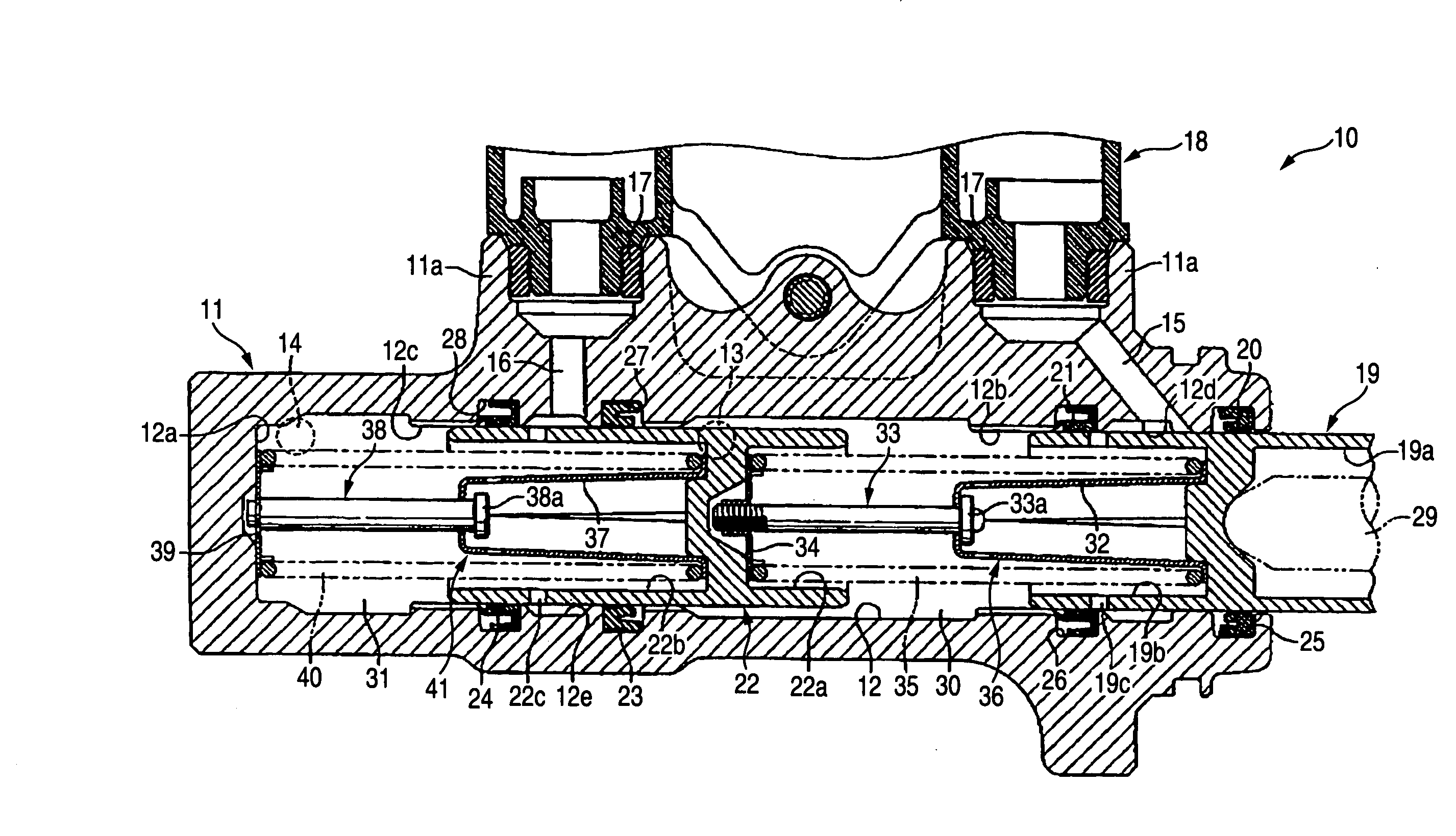

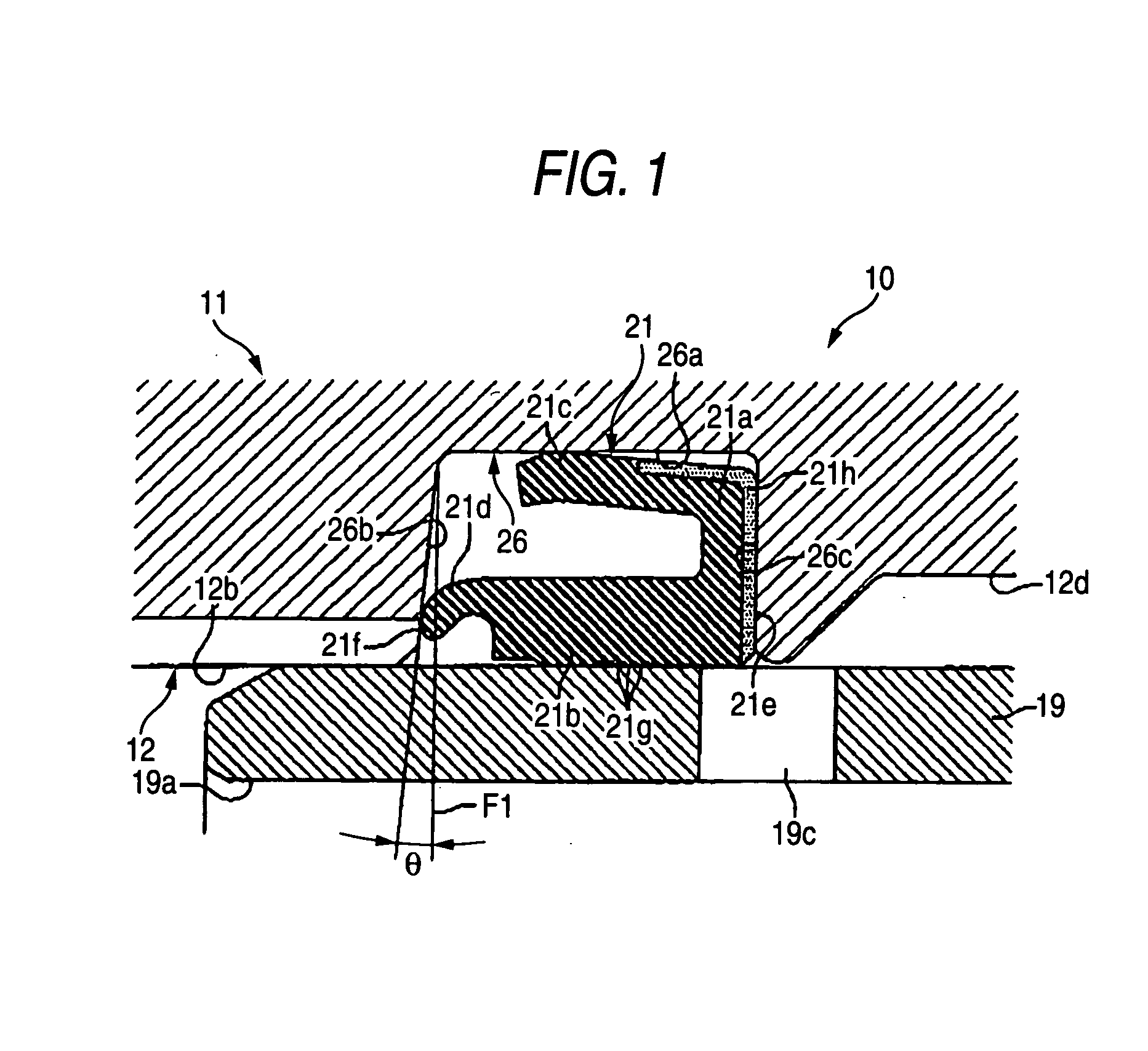

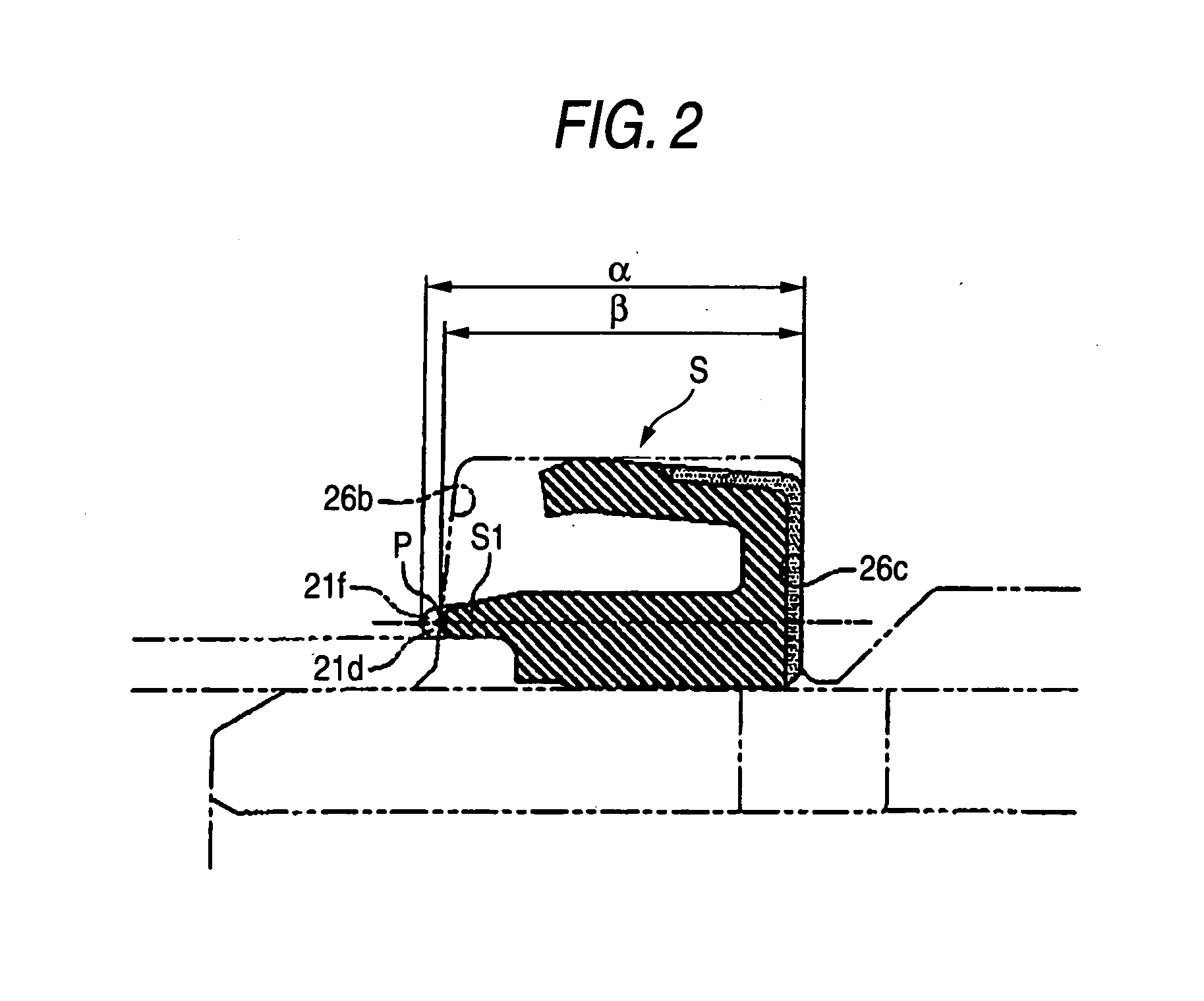

Cylinder device

ActiveUS20090071325A1Secure proper seal performanceSimple structureEngine sealsPiston ringsMechanical engineeringPiston

A cup seal 21 includes a base portion 21a, an inner circumferential lip 21b slidingly contactable with a plunger 19 and an outer circumferential lip 21c contactable with the bottom surface 26a of the seal groove 26. Further, on the cup seal 21, there are provided elastic projections 21d projecting from the outer circumferential side leading end of the inner circumferential lip 21b toward the cylinder hole bottom portion. The length of the cup seal 21 from the base end face 21e to the leading end portions 21f is set longer than axial length of the seal groove 26. When the cup seal 21 is fitted into the seal groove 26, force is imparted on the inner circumferential lip 21b toward the cylinder hole inner circumferential direction to energize the inner circumferential lip 21b toward the piston all the time.

Owner:HITACHI ASTEMO LTD

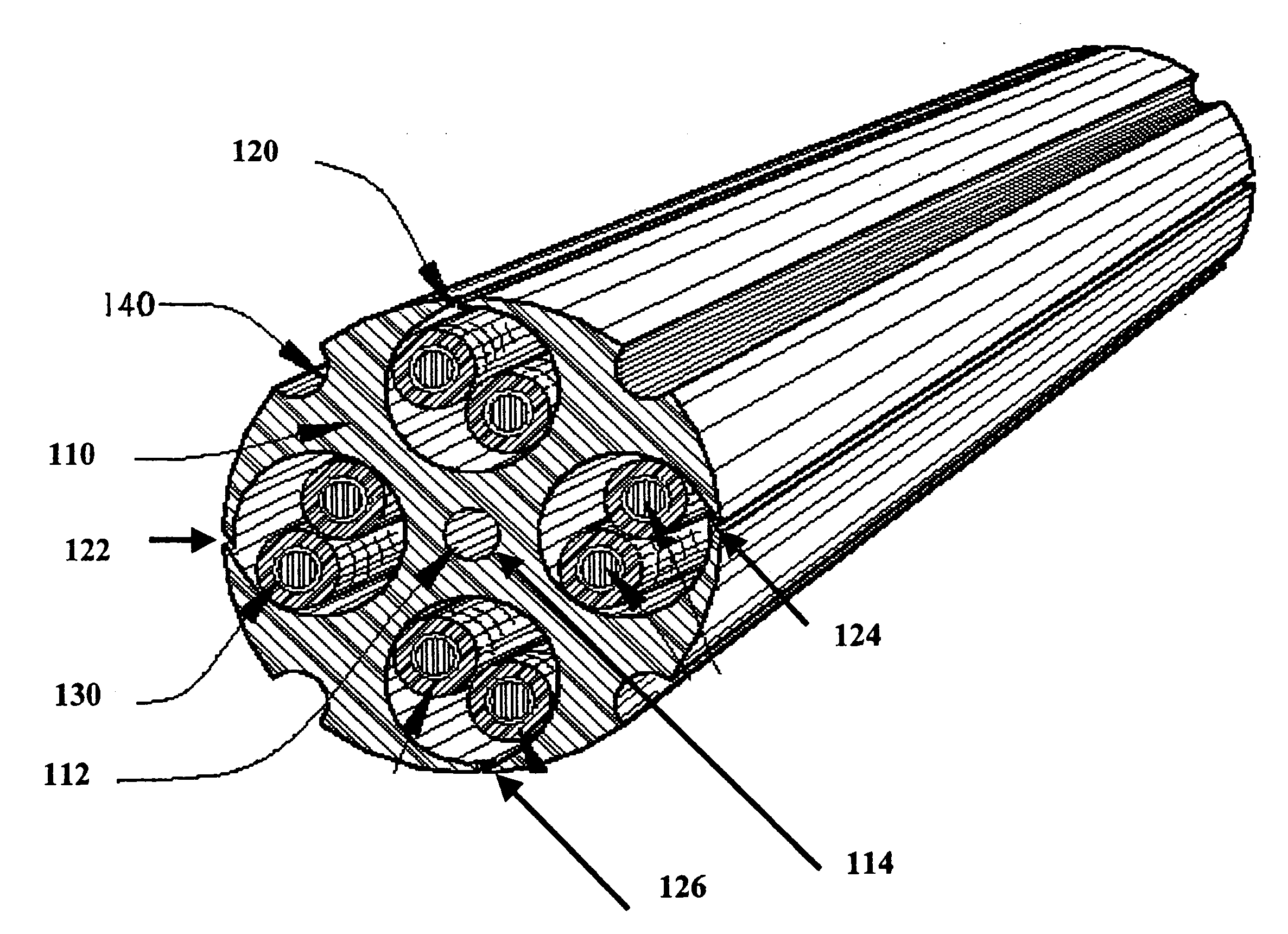

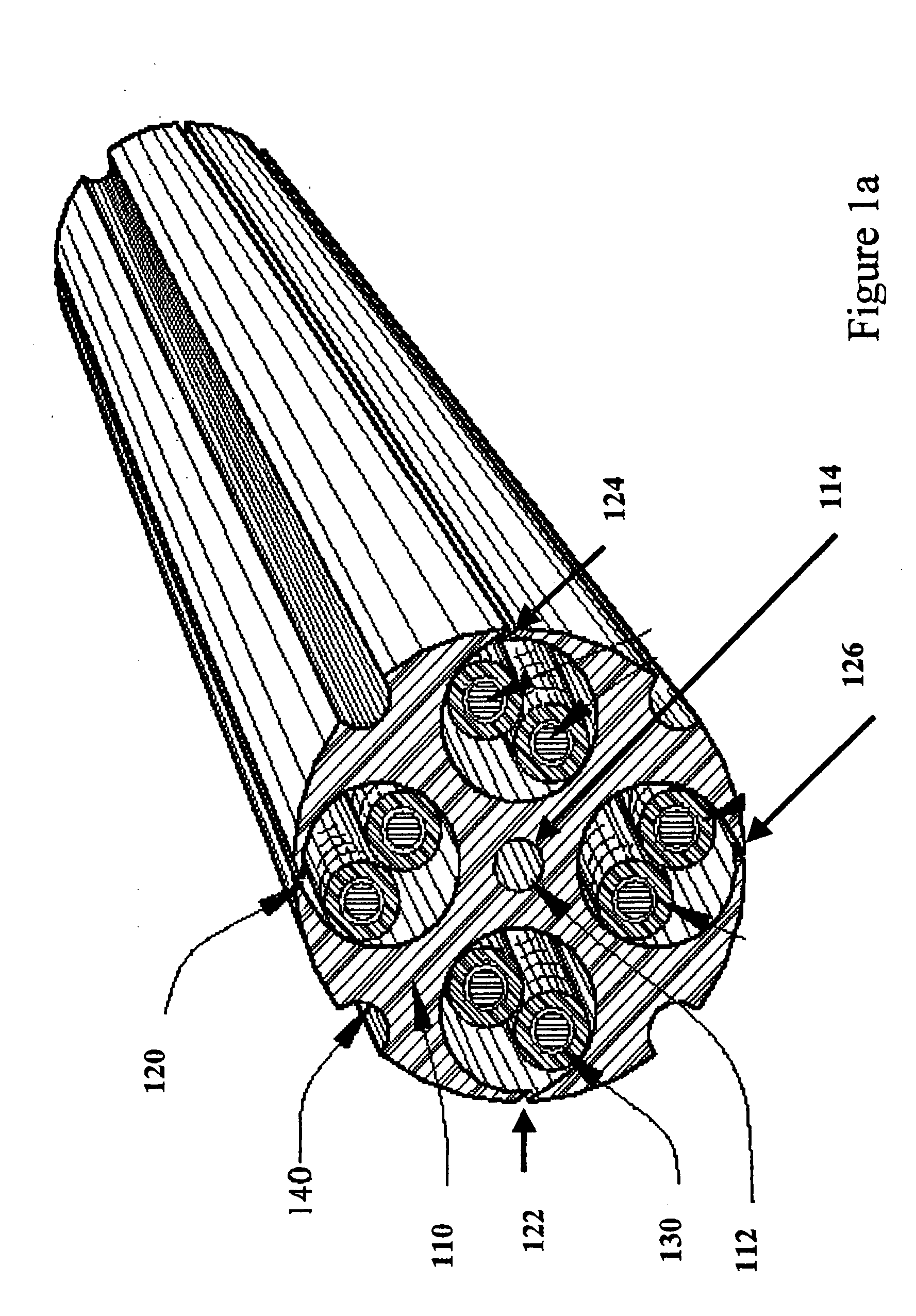

High performance support-separators for communications cables

InactiveUS20060096777A1Improve NEXT controlReduce needInsulated cablesInsulated conductorsElectrical conductorHigh performance communication

The present invention includes a high performance communications cable exhibiting reduced cross-talk between transmission media that includes one or more core support-separators having various shaped profiles which define a clearance to maintain a spacing between transmission media or transmission media pairs. The core may be formed of a conductive or insulative material. A method of producing this cable introduce core support-separators as described above into the cable assembly. The specially shaped core support-separator can be either interior to the cable jacket or be employed singularly without the benefit of a jacket and extends along the longitudinal length of the communications cable. Alternatively, with no jacket for cable completion, a portion of the separator wherein a thin layer of material can act as a type of skin for future mechanical protection is provided. The specially shaped core support-separator has a central region that is either solid or partially solid. The cable may include a plurality of shaped sections that extend outward from the central region along the length of the central region. The specially shaped sections of the core support-separator may be helixed as the core extends along the length of the communications cable. Each of the adjacent specially shaped sections defines a distinct clearance channel that extends along the longitudinal length of the core support-separator. Each of the defined clearance channels allow for disposal therein of conductors and / or optical fibers.

Owner:CABLE COMPONENTS GROUP

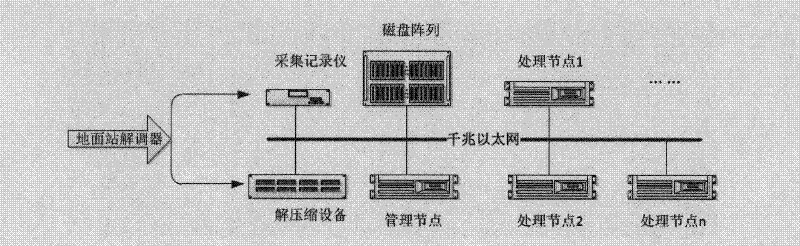

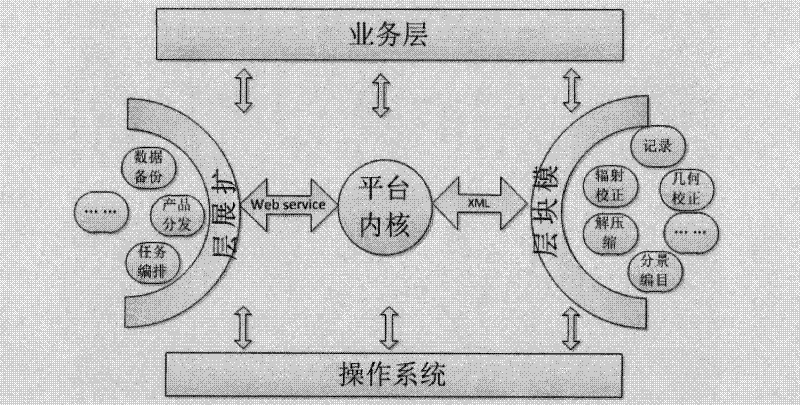

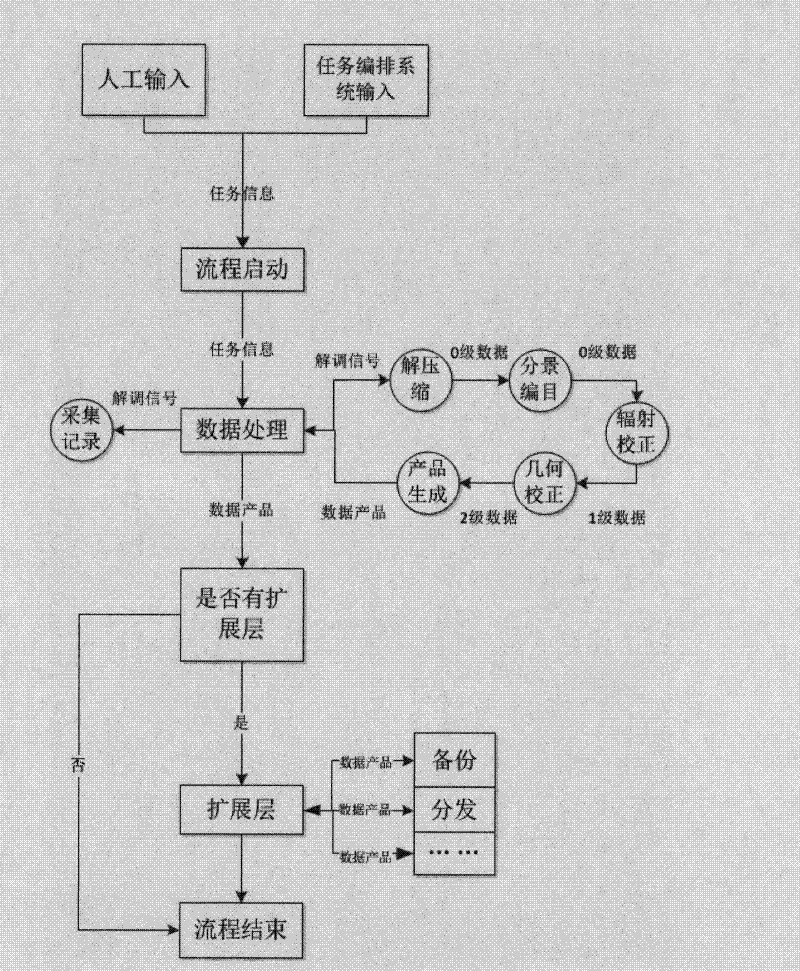

Miniaturized universal platform for preprocessing remote-sensing satellite data

ActiveCN102521687AReduce complexityReduce problem sizeResourcesSpecial data processing applicationsNetwork File SystemExtensible markup

The invention discloses a miniaturized universal platform for preprocessing remote-sensing satellite data. Hardware equipment of the platform comprises a common PC (Personal Computer) server, an NFS (Network File System) storage system and decompression equipment among which communication is carried out by an Ethernet; a basic structure of the platform comprises an inner core layer, a module layer and a service layer; the common PC server comprises a management node and a processing node; the inner core layer and the service layer are deployed on the management node; the module layer is deployed in the NFS storage system; the decompression equipment outputs a signal to a demodulator to carry out data format decompression processing; the module layer comprises various data processing algorithms of remote-sensing satellites and the data processing algorithms operate on the processing node when being called; the service layer analyzes an XML (Extensible Markup Language) file which is input from outside and describes the processing flow of the remote-sensing satellites to be processed, selects the algorithms suitable for data processing of the satellites from the module layer and carries out service logic combination on the algorithms; and the inner core layer calls the corresponding algorithms in the module layer according to the service logic relation, carries out data processing on data output by the decompression equipment and generates needed data products.

Owner:CHINA CENT FOR RESOURCES SATELLITE DATA & APPL

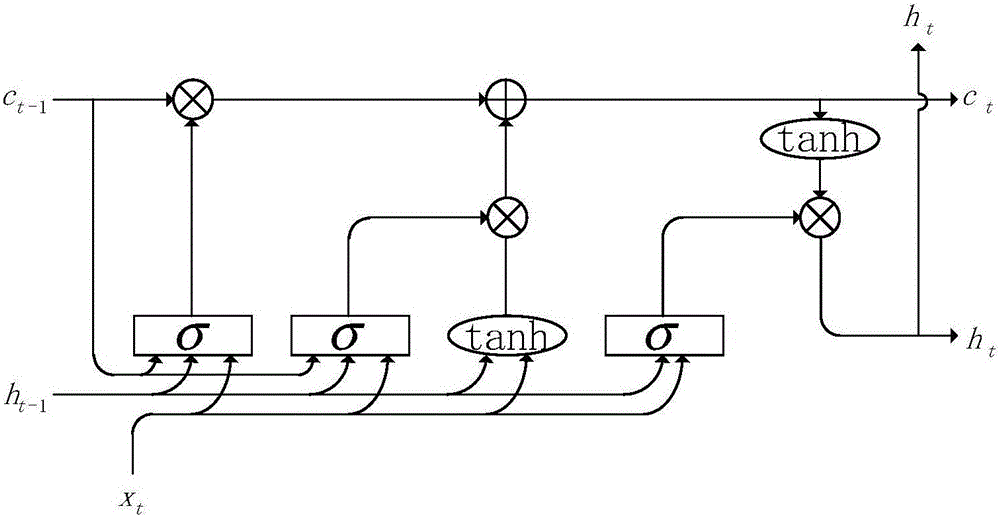

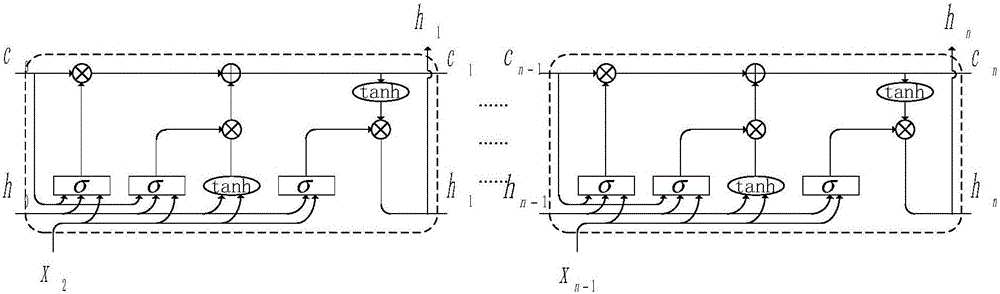

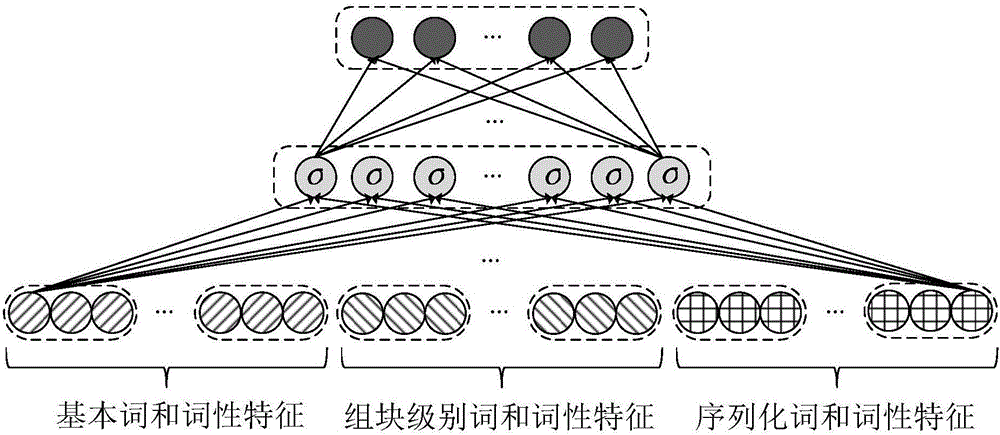

State transition and neural network-based Chinese chunk parsing method

ActiveCN106021227AHigh precisionAdd flexiblyNatural language data processingSpecial data processing applicationsSerializationNetwork model

The invention proposes a state transition and neural network-based Chinese chunk parsing method. The method comprises the steps of converting a chunk parsing task into a serialized tagging task; tagging a sentence by using a state transition-based framework; scoring a transition operation to be carried out in each state by using a forward neural network in the tagging process; and taking a distributed representation characteristic of words and part-of-speech tagging learned by utilizing a two-way long short-term memory neural network model as an additional information characteristic of a tagging model, thereby improving the accuracy of chunk parsing. Compared with other Chinese chunk parsing technologies, the Chinese chunk parsing method has the advantages that characteristics of chunk levels can be more flexibly added by using the state transition-based framework, combination modes among the characteristics can be automatically learned by using the neural network, the useful additional information characteristic is introduced by utilizing the two-way long short-term memory neural network model, and the combination of the state transition-based framework, the neural network and the two-way long short-term memory neural network model effectively improves the accuracy of chunk parsing.

Owner:NANJING UNIV

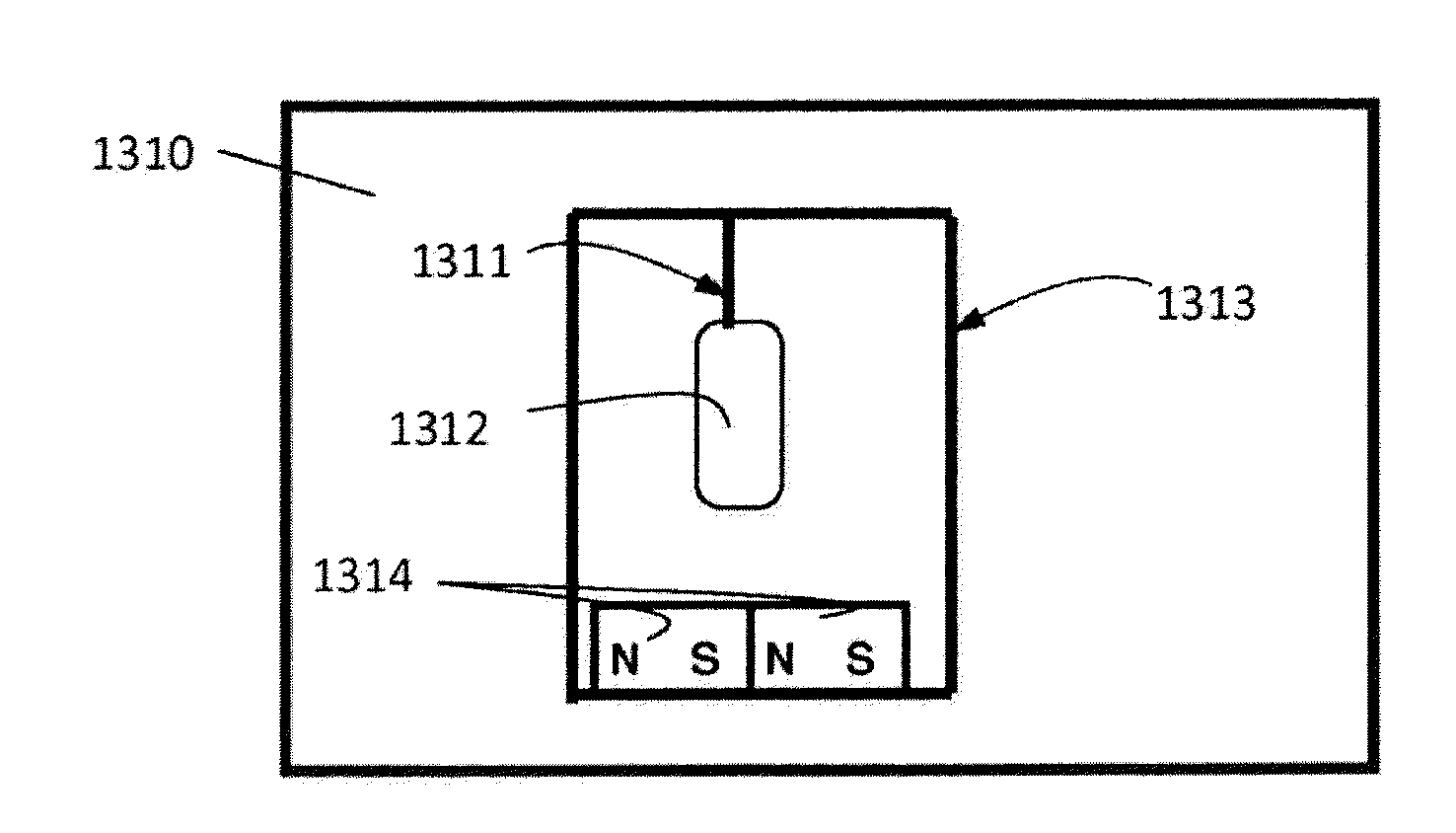

Tactile low frequency transducer

ActiveUS20150156581A1Improve fidelityEnhance the music experienceDynamo-electric machinesFrequency/directions obtaining arrangementsTransducerEngineering

A transducer comprising: a flat strip of metal formed into a closed metal loop with two substantially parallel sides and rounded corners, a solenoid fixed to a surface on a first parallel side, and fixed magnets attached to an opposite parallel side of the trapezoidal shape to bring the fixed magnets into proximity with the solenoid, wherein at least one lateral side of the trapezoidal shape coupling said parallel sides has a continuously varying width, resulting in the transducer being able to resonate with high fidelity over a range of frequencies in response to reception of a signal comprising varying frequencies.

Owner:WOOJER

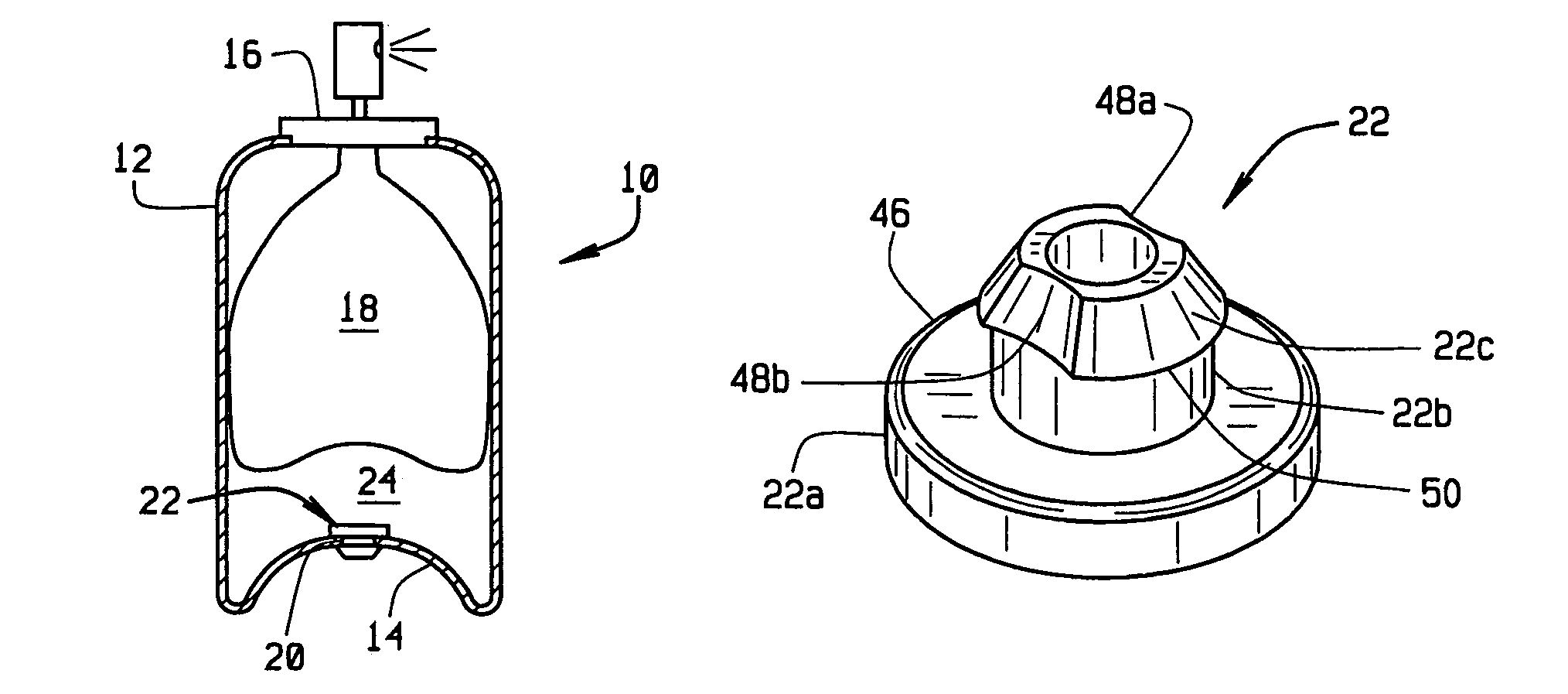

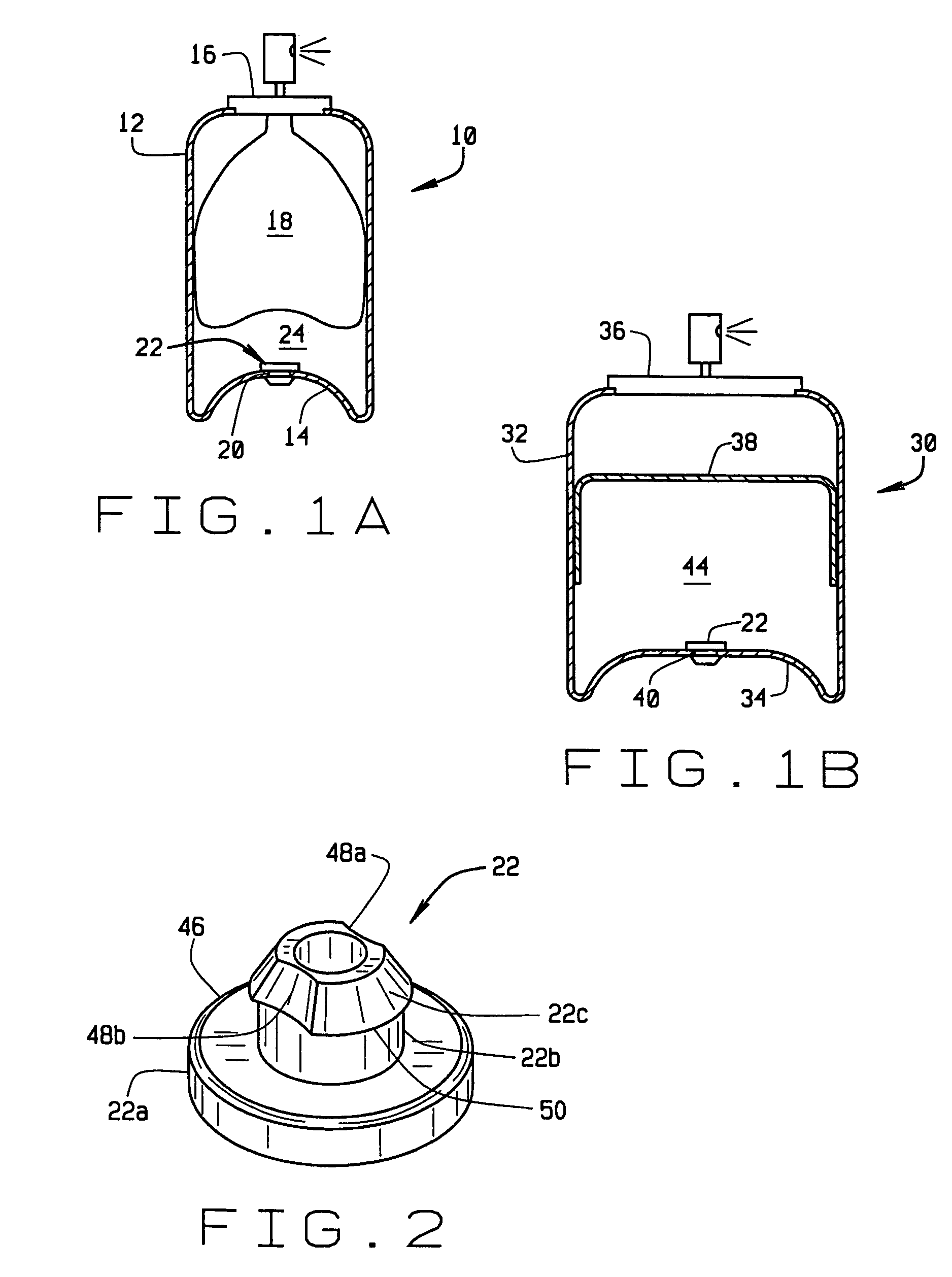

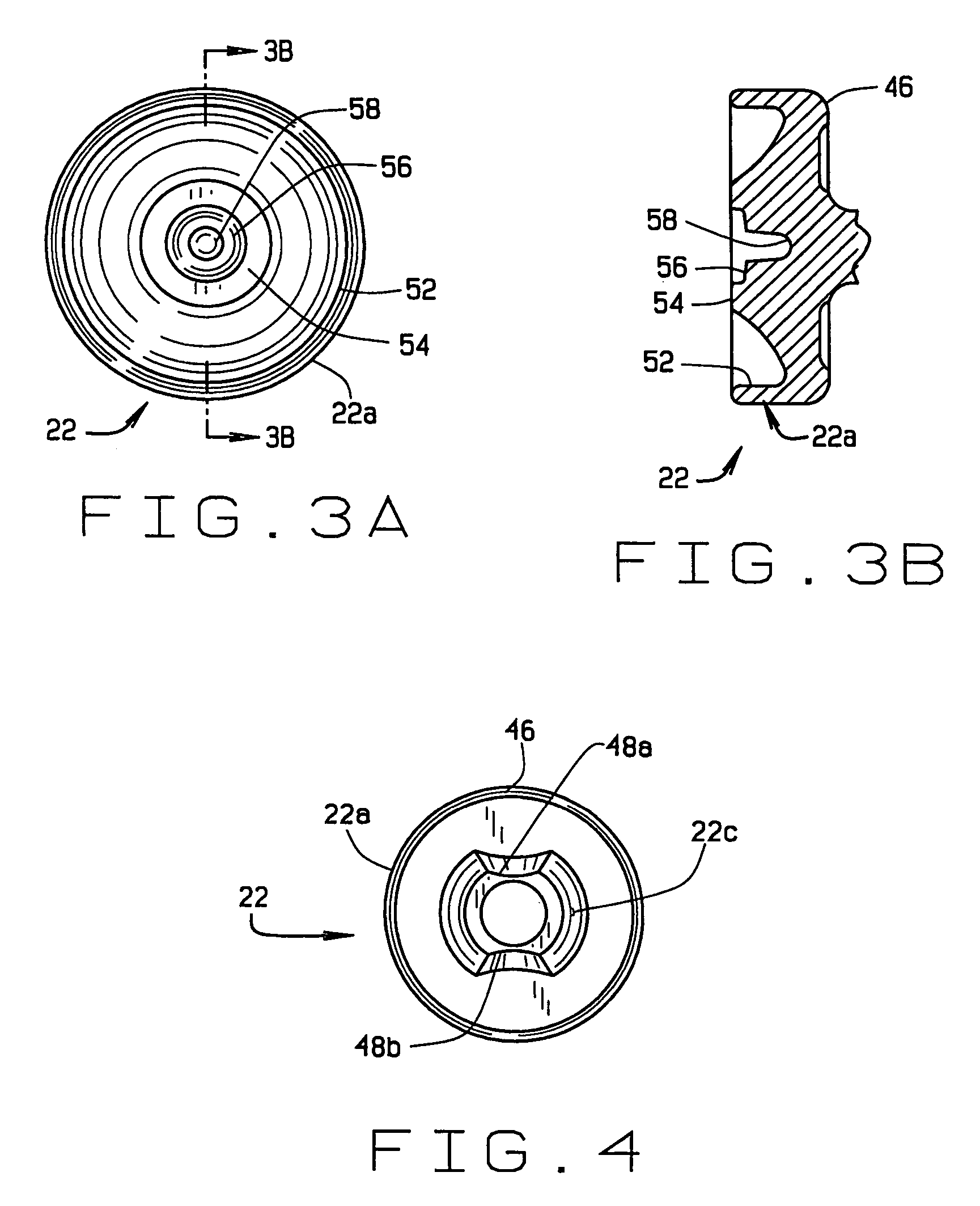

Grommet or fill valve for an aerosol container

ActiveUS7225839B2Add flexiblyEasy to transportSolid materialPackaging under special atmospheric conditionsCross-linkEngineering

The present invention is directed to an improvement for a fill valve (22) for an aerosol container (10, 30) to provide better sealing capability. The fill valve is made using a flashless injection molding process in which both the mold cavity and molding material are heated to elevated temperatures to significantly improve cross-linking which occurs during the molding process. A backside (22a) of the fill valve now has a recessed portion (56) to facilitate ejection of the valve from a mold so leak paths are not created due to the forces applied to the valve during its extraction from the mold. The recessed portion reduces the amount of material required to make the fill valve and makes the fill valve flexible to aid in providing a good seal against leakage of a propellant from the container after filling.

Owner:BALL METALPACK AEROSOL CONTAINER LLC

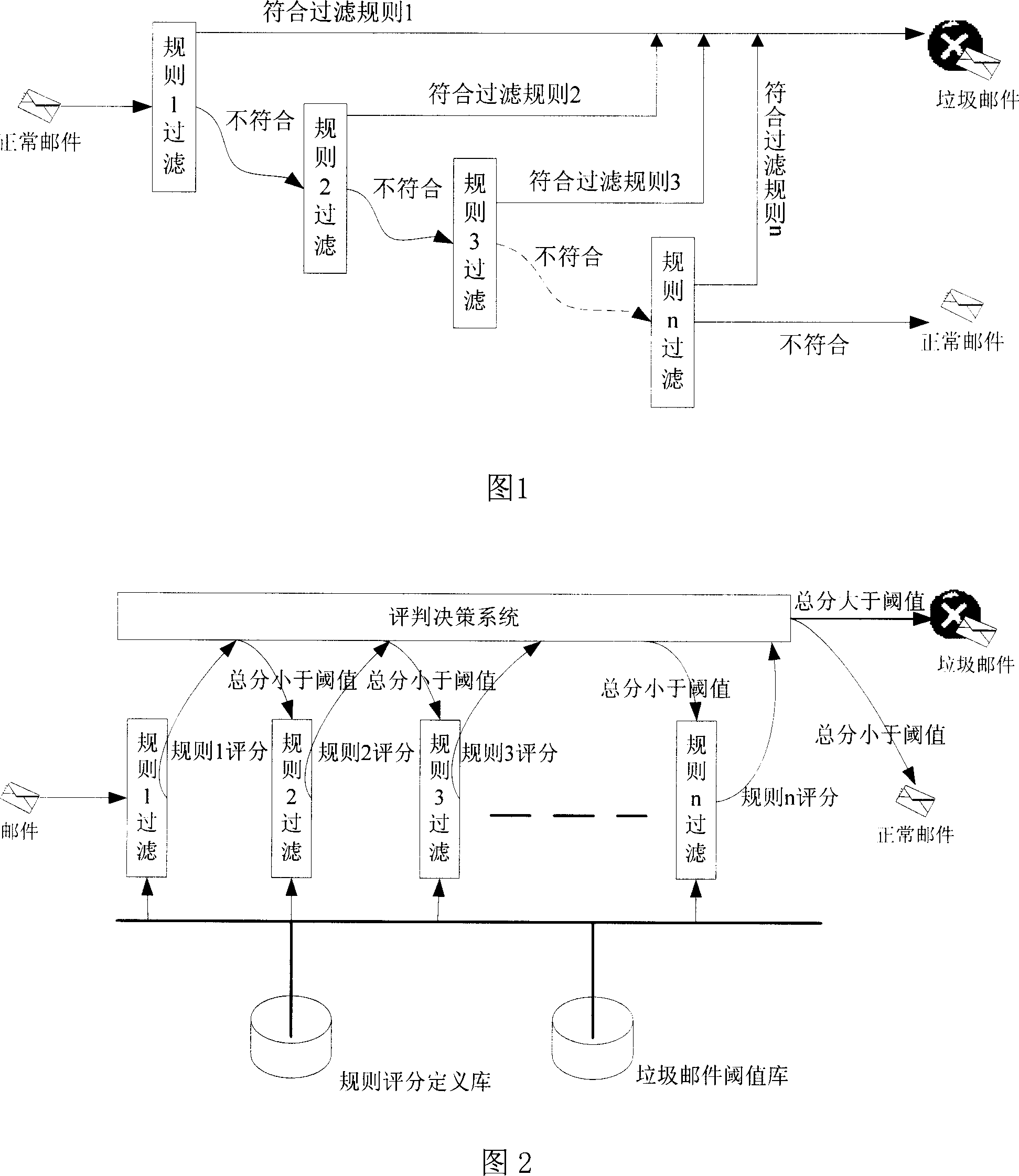

Compound decision based anti-rubbish E-mail error filtering method and system

InactiveCN101136874AAvoid misfilteringStrong operational flexibilityOffice automationData switching networksSingle ruleFiltration

The method includes steps: establishing filtration rules, definition base for rule rating, threshold value base (TVB) for garbage mail (GM), and establishing decision and judgment system (DJS) for GM; mail sent from local client end enters into first filtration rule to carry out matching process so as to obtain a rank score, and then the mail is forwarded to DJS for GM to carry out comparison; DJS for GM adds up the rank scores so as to obtain overall rank score (ORS), which is compared with threshold value (TV) for rating GM setup in TVB; if ORS is higher than TV of GM, then the mail is as GM, and if ORS is lower than TV of GM, then the mail is going to next filtration rule to carry out matching process right along repeatedly till to n pieces of filtration rules are matched completely; and if ORS is still lower than TV of GM, then the mail is a normal. The invention prevents mails from error filtering since the invention changes practice that using single rule judges GM directly.

Owner:SOUTH CHINA UNIV OF TECH +1

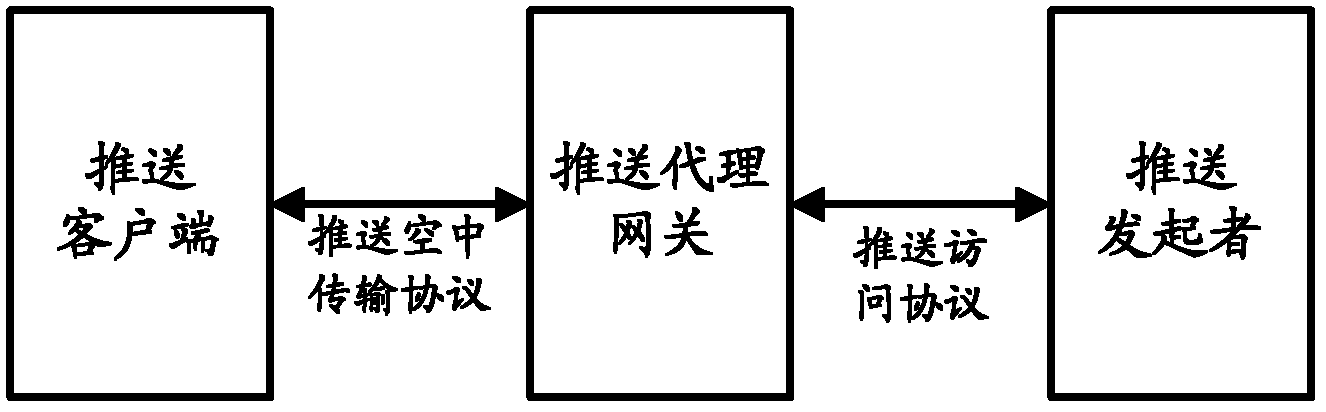

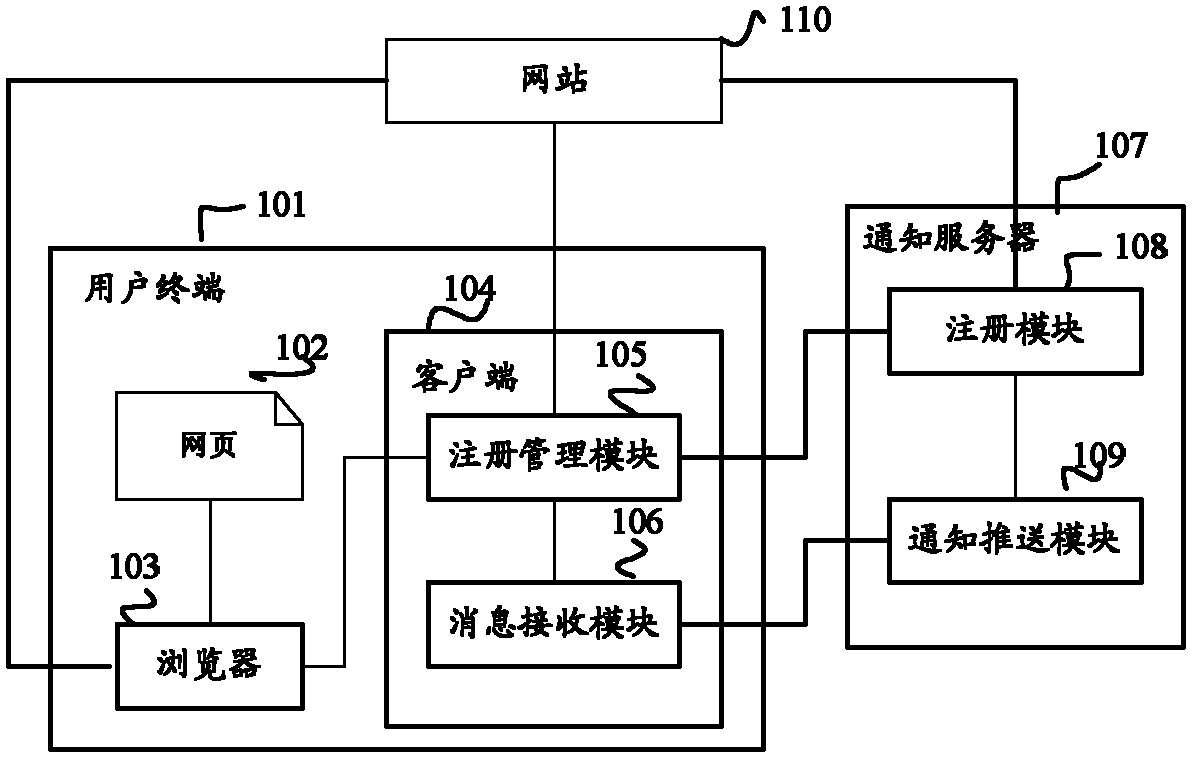

Method, device and system for subscription notification

InactiveCN103001926ASolve the problem of inflexible subscription methodsSolve the problem that needs to provide the clientTransmissionClient-sideWeb page

The invention discloses a method, a device and a system for subscription notification. A user terminal comprises a client and is connected with websites and a notification server through a network. The method includes: by a browser, acquiring and displaying webpages; and by the browser, triggering the client to transmit registration requests to the notification server so as to facilitate the notification server to push notifications of the websites to the user terminal; wherein the registration requests include website identifications.

Owner:HUAWEI TECH CO LTD

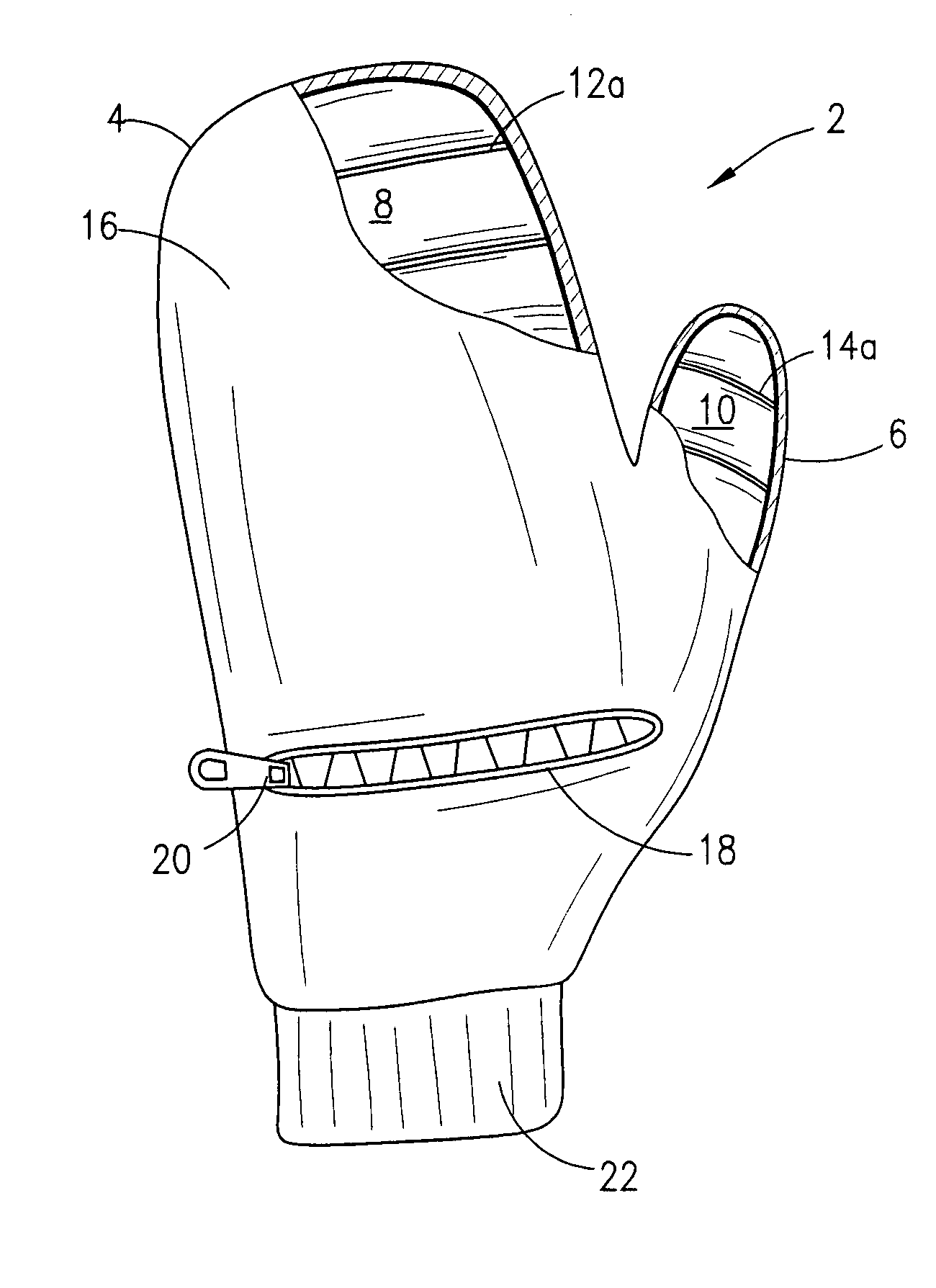

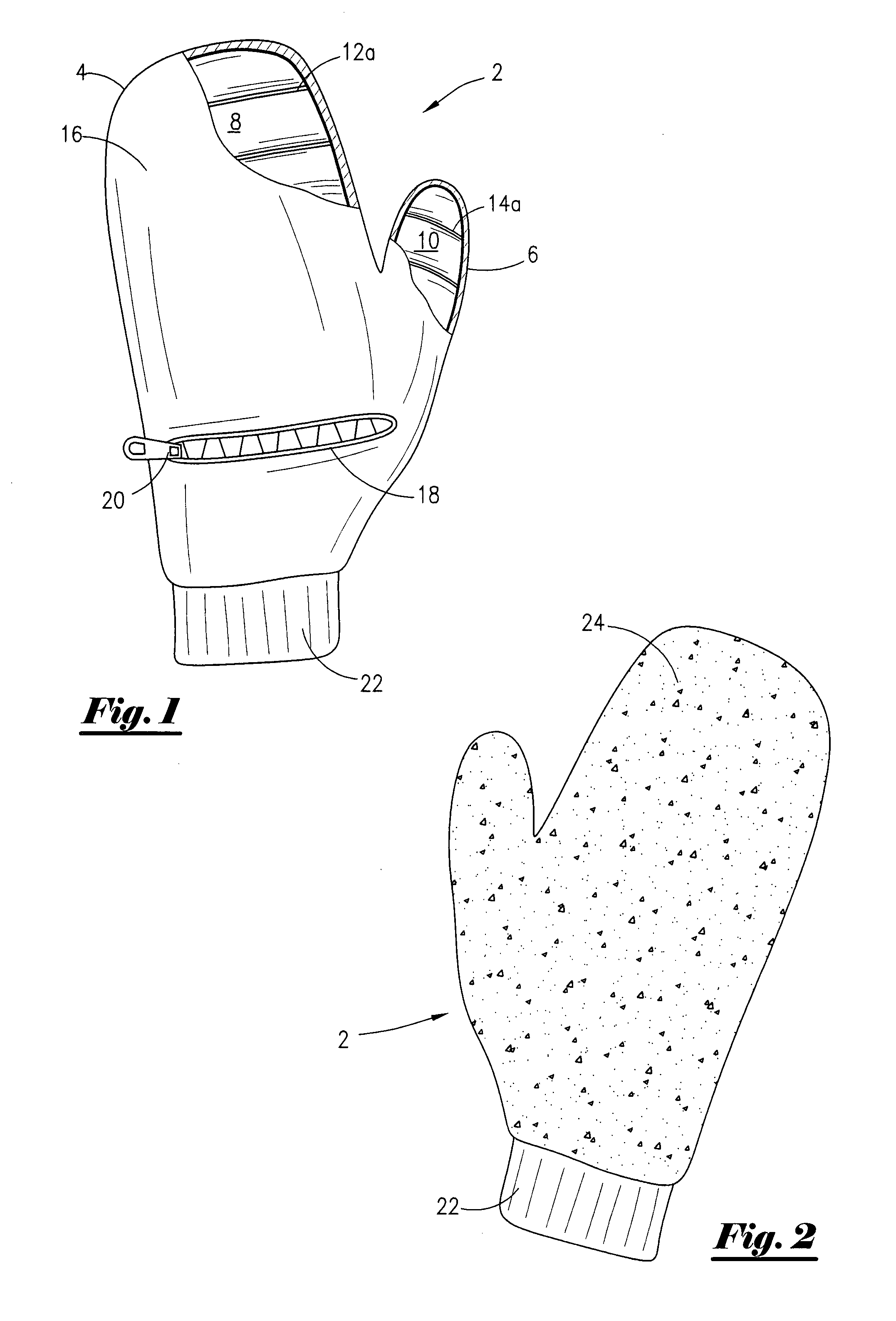

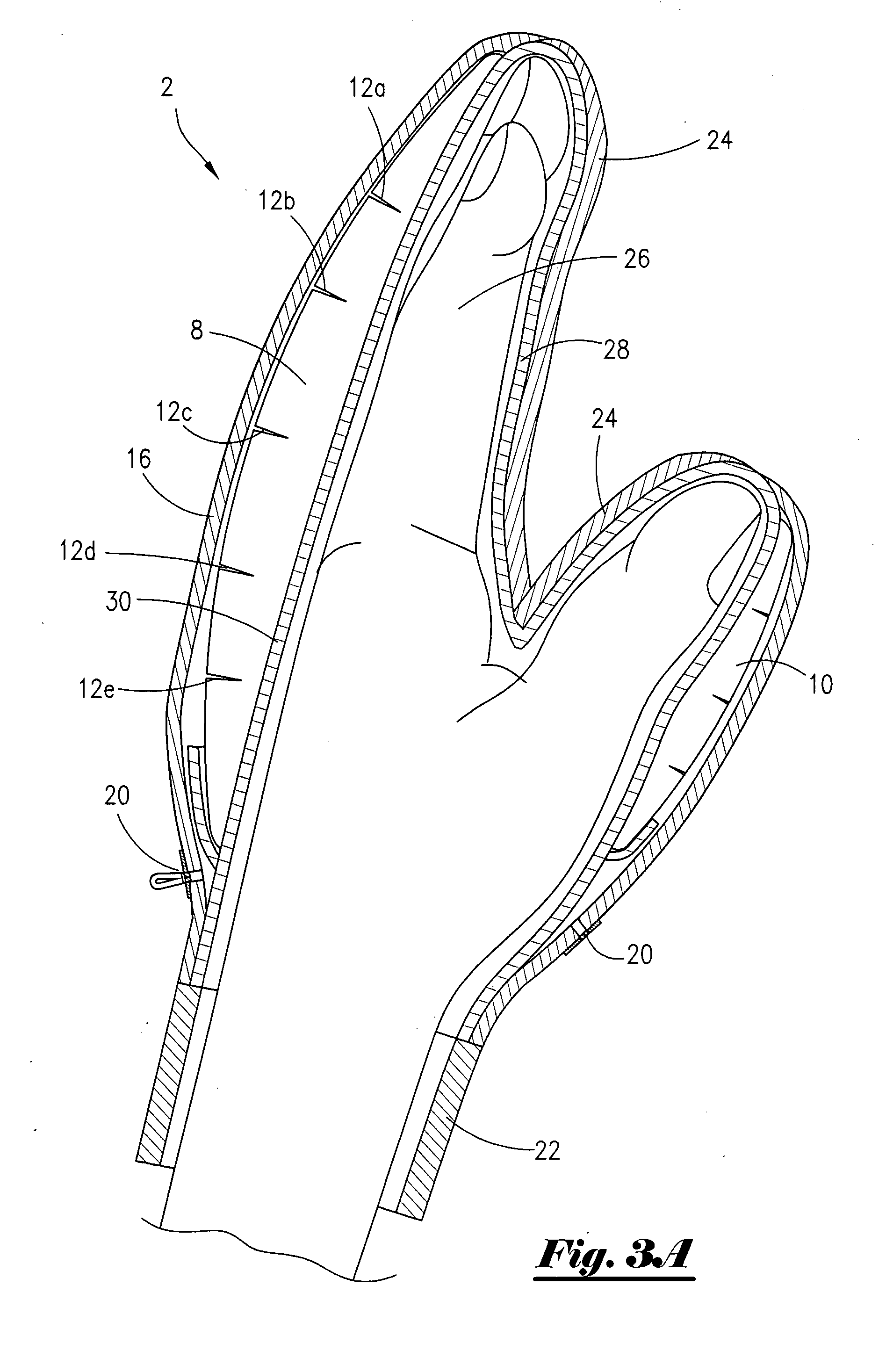

Protective hand device

InactiveUS20080282439A1Easy to manufactureEasy to installGlovesKitchen equipmentEngineeringVolumetric Mass Density

Owner:SARKIES JOSEPH P

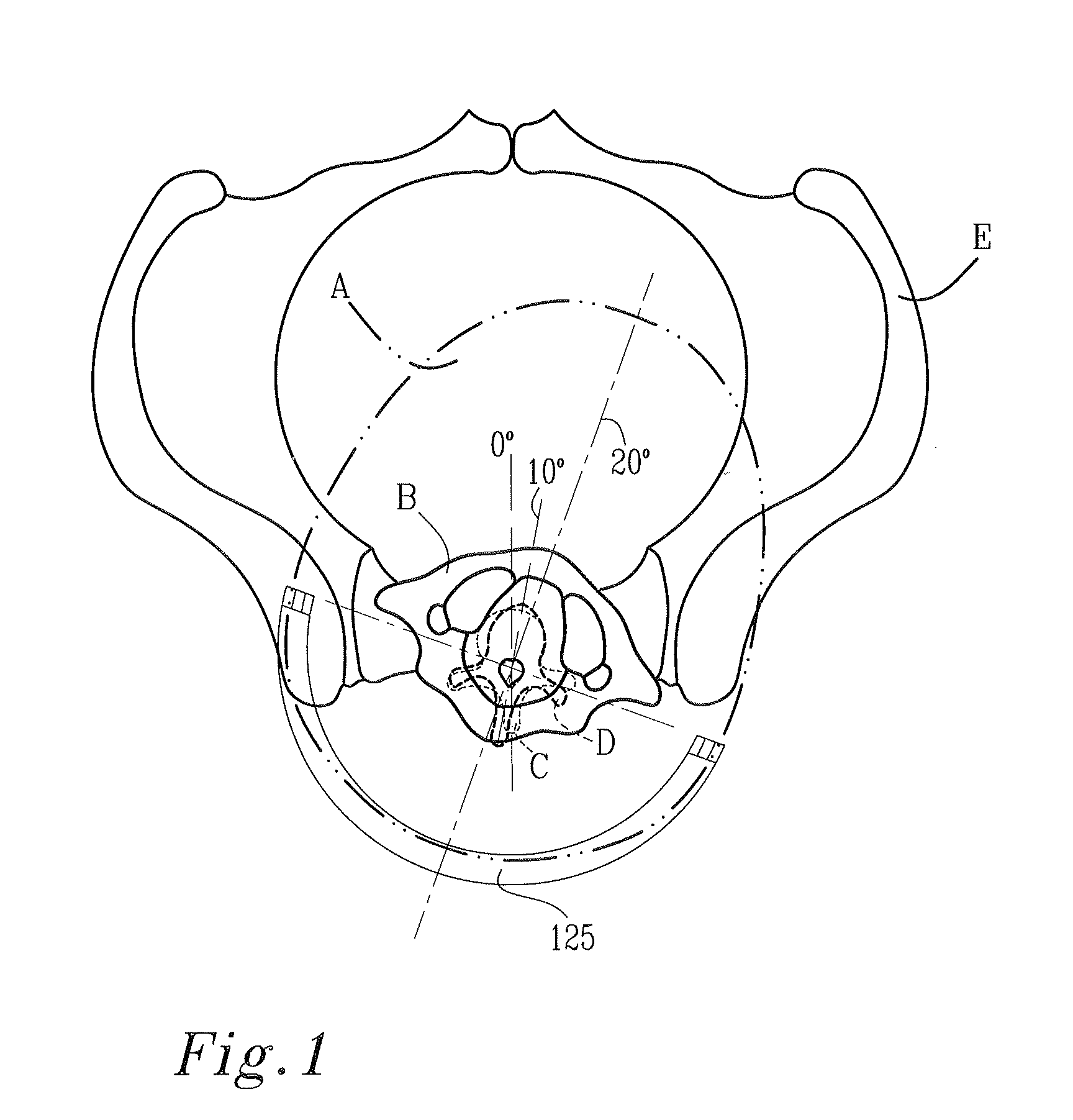

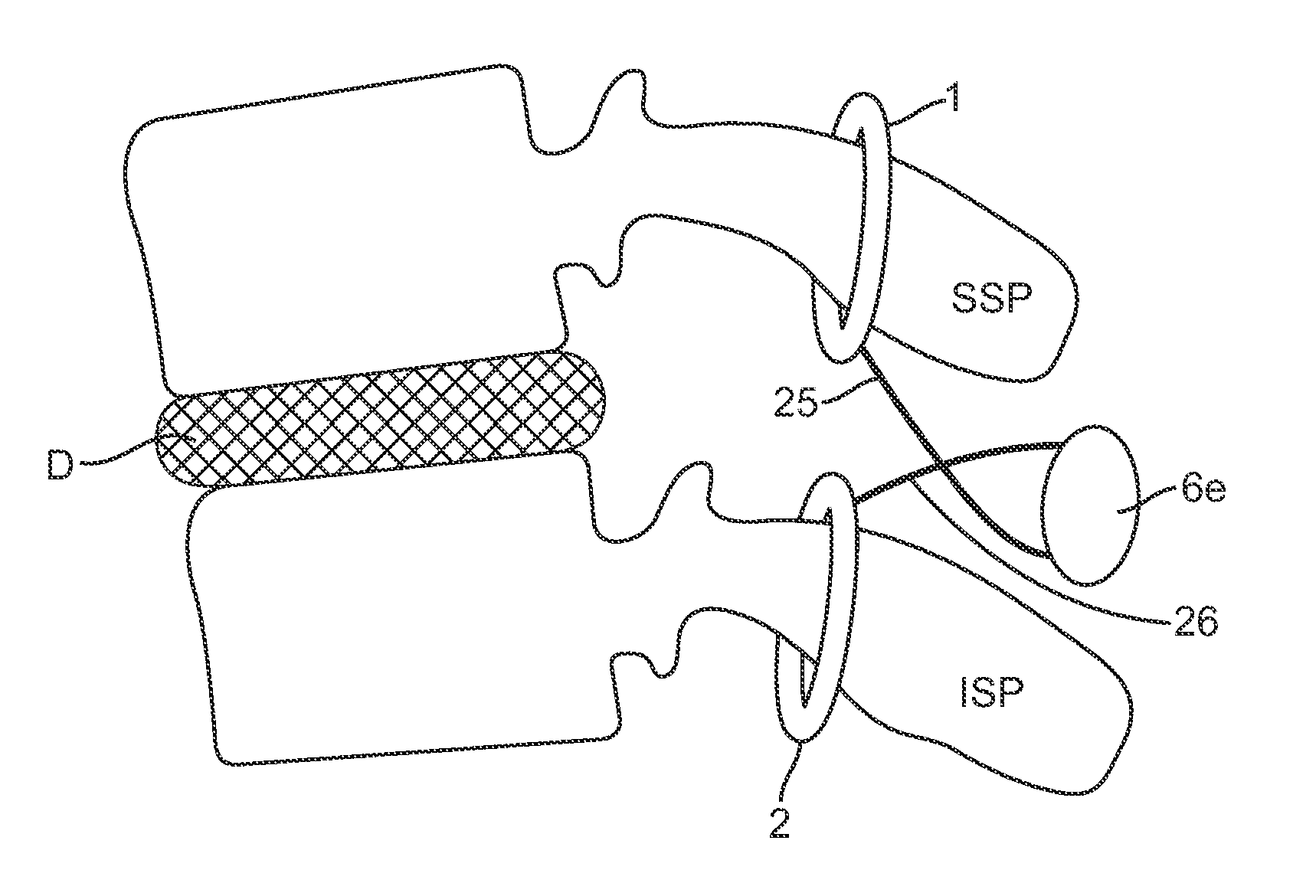

Methods and devices for restricting flexion and extension of a spinal segment

InactiveUS20120109200A1Minimize risk of damageIncrease flexibilityInternal osteosythesisJoint implantsSacrumPhysical therapy

Methods and devices for restricting movement of a spinal segment by providing an adjustable constraining device that includes a tether and a compliance member coupled together. The tether is coupled to a superior spinous process and an inferior spinous process or a sacrum so that the construct of the compliance member and tethers provides a force resistant to flexion and a force resistant to extension of a spinal segment. In some embodiments, the construct of the compliance member and tethers may provide only a force resistant to extension.

Owner:SIMPIRICA SPINE

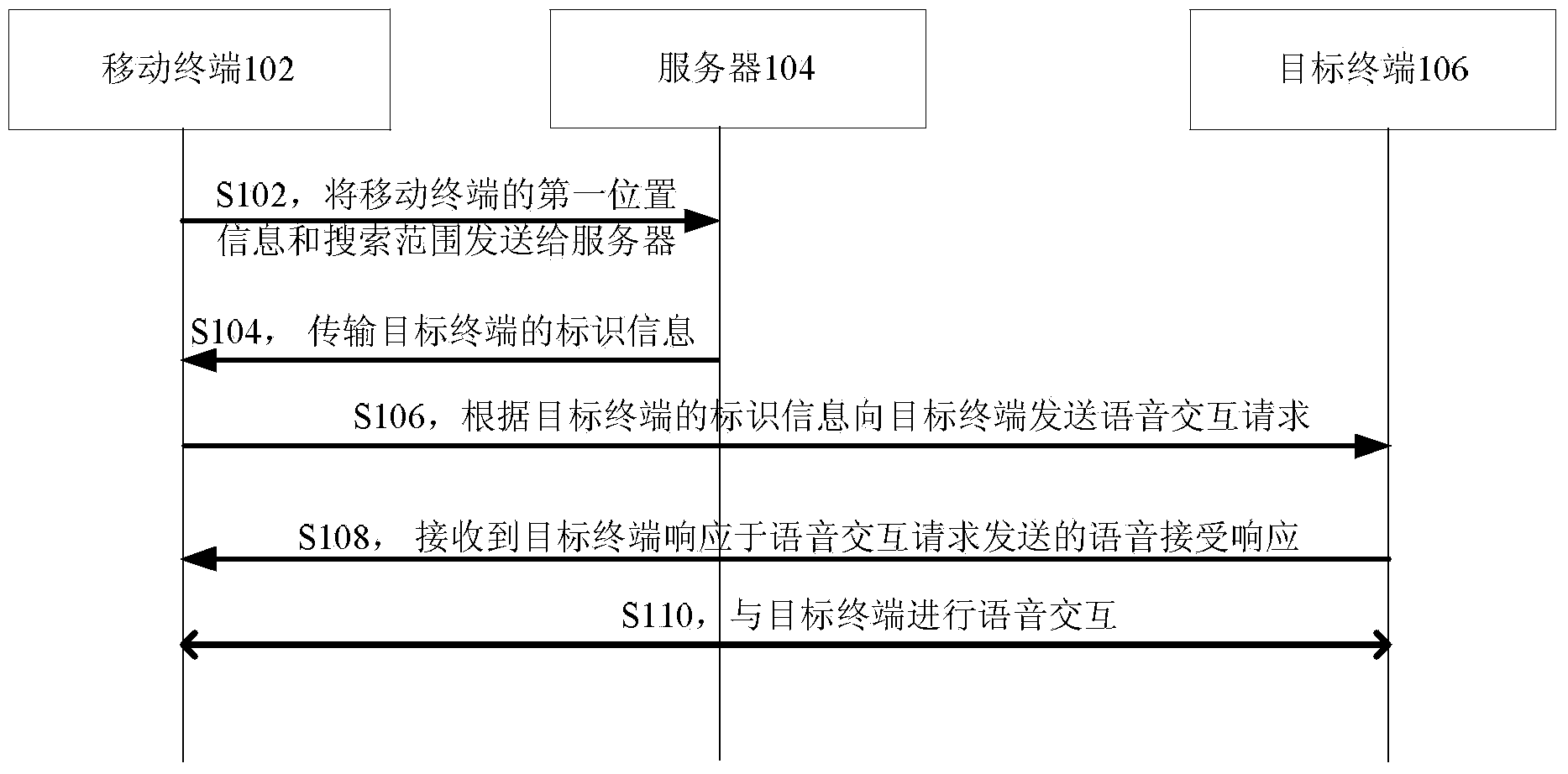

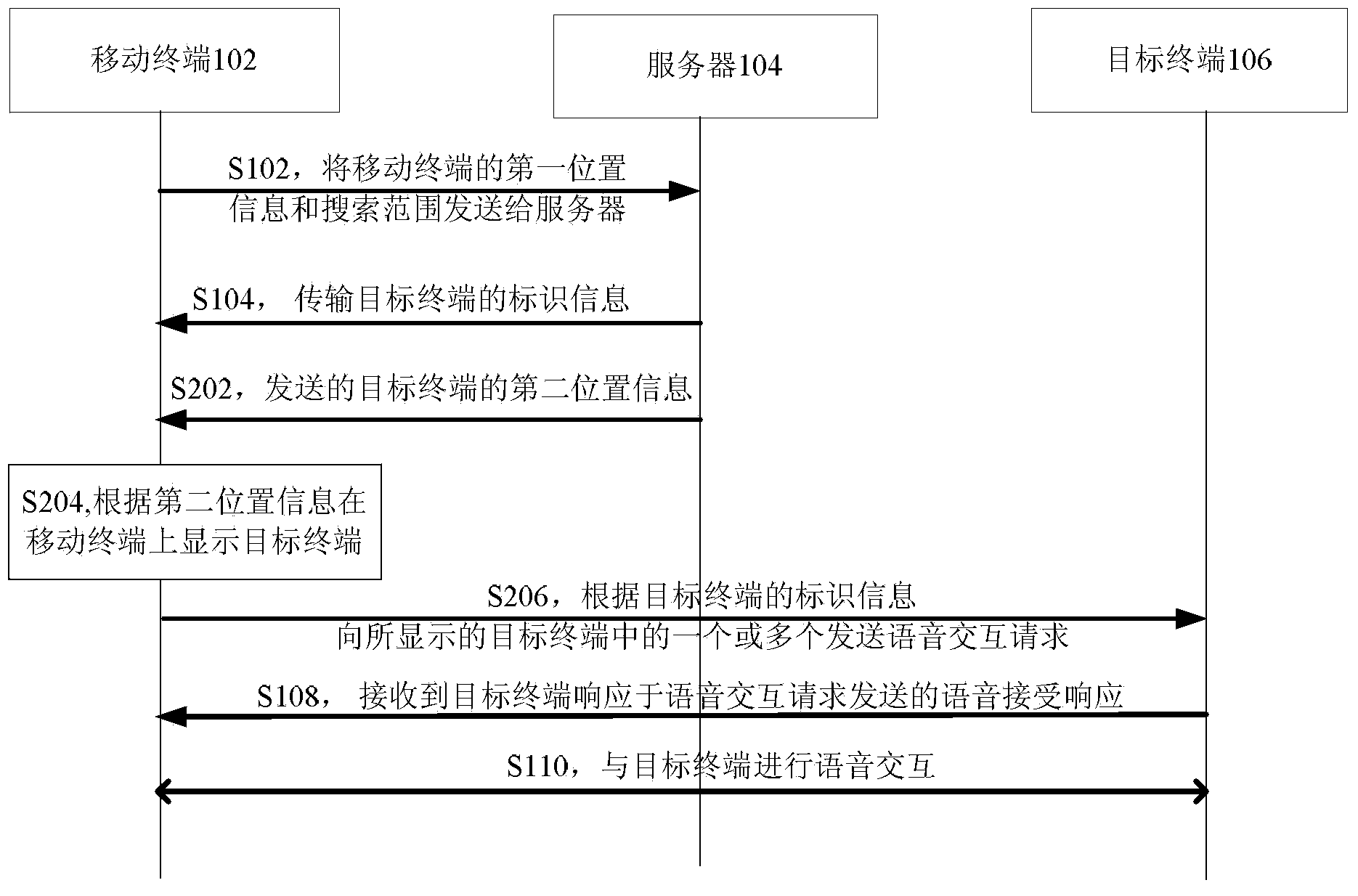

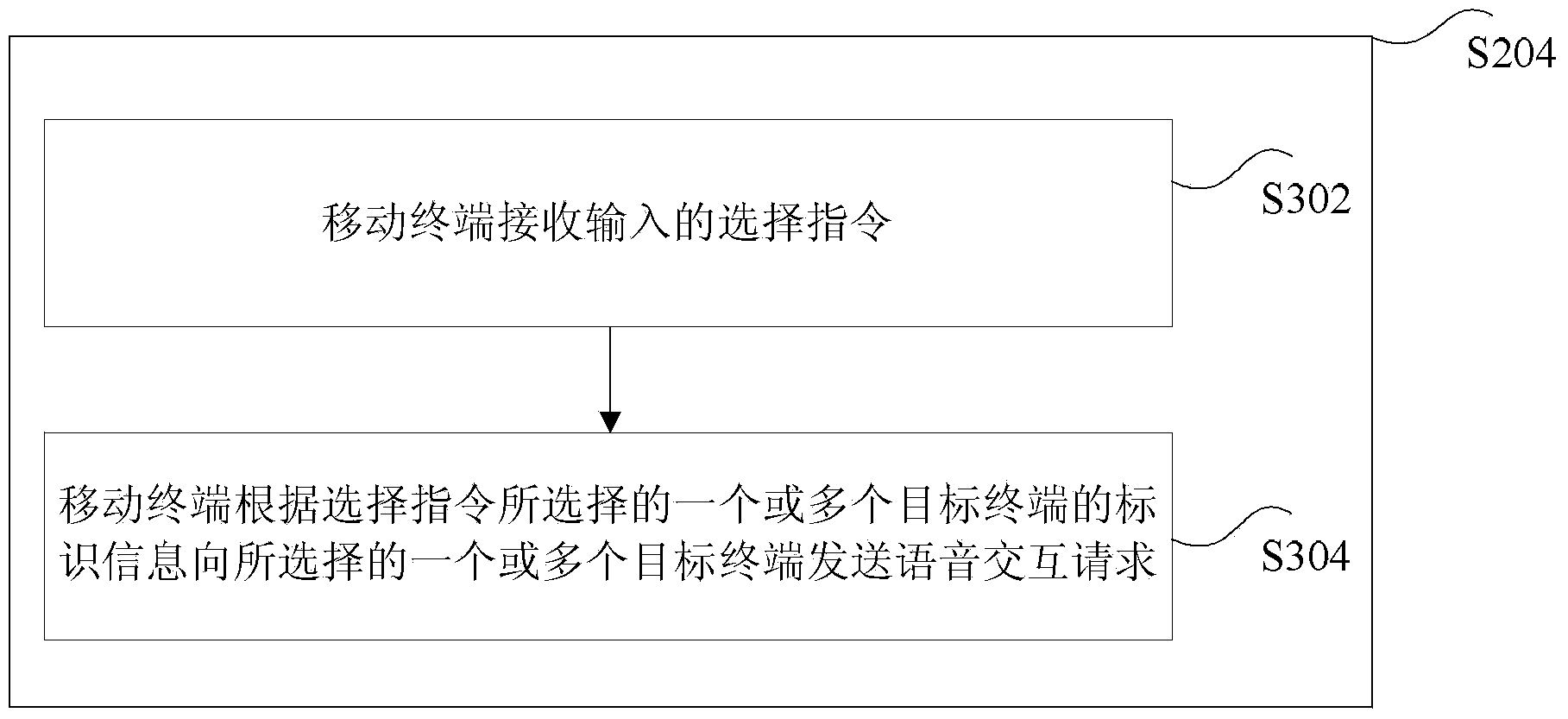

Voice interaction method and device

ActiveCN103874019AAdd flexiblySmart addSubstation equipmentAutomatic exchangesComputer networkInteraction method

The invention discloses a voice interaction method and device. The method comprises the following steps that a mobile terminal sends first position information and a searching range of the mobile terminal to a server, wherein the first position information is used for representing a current position of the mobile terminal; the mobile terminal receives identification information of a target terminal, which is sent by the server; the distance between the current position of the target terminal and the current position of the mobile terminal is in the searching range; the mobile terminal sends a voice interaction request to the target terminal according to the identification information of the target terminal; after the mobile terminal is subjected to voice interaction with the target terminal after receiving a voice receiving response which is sent by the target terminal through being responded to the voice interaction request, the mobile terminal is subjected to the voice interaction with the target terminal. According to the voice interaction method and device, the technical problem that an existing mobile terminal cannot be subjected to the voice interaction with the adjacent mobile terminal is solved, so that the technical effect of carrying out the voice interaction on the mobile terminal based on different position information is realized.

Owner:TENCENT TECH (SHENZHEN) CO LTD +1

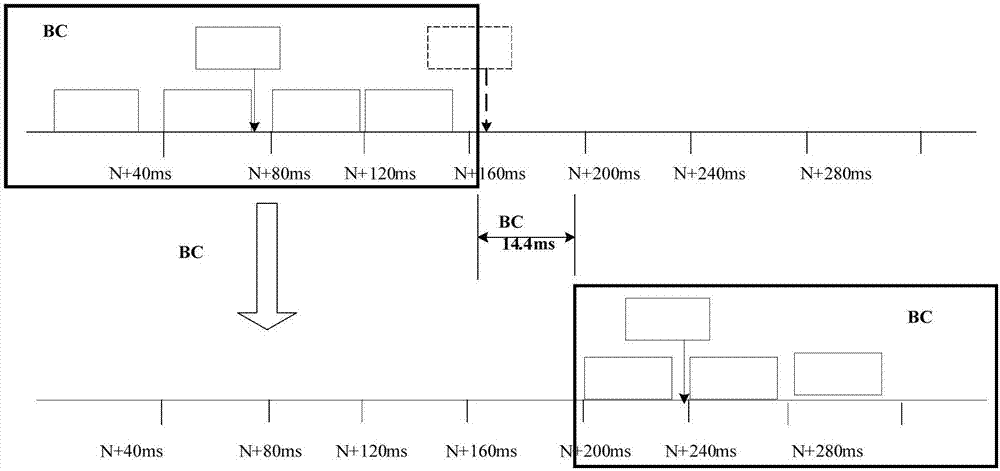

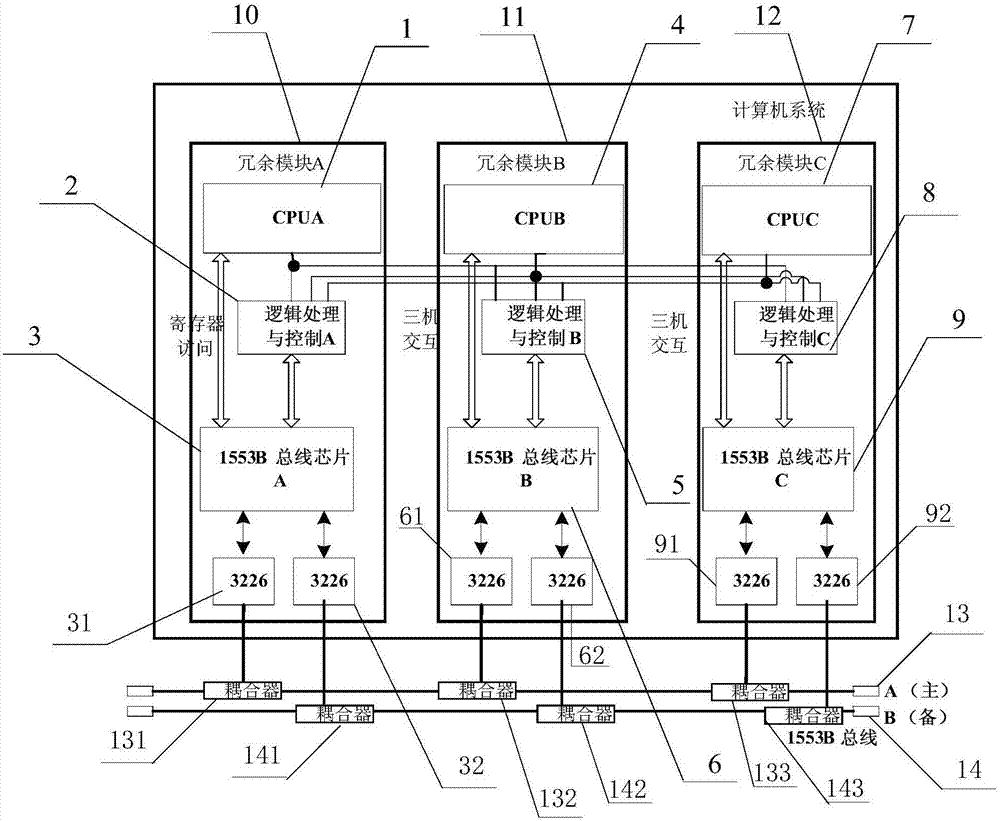

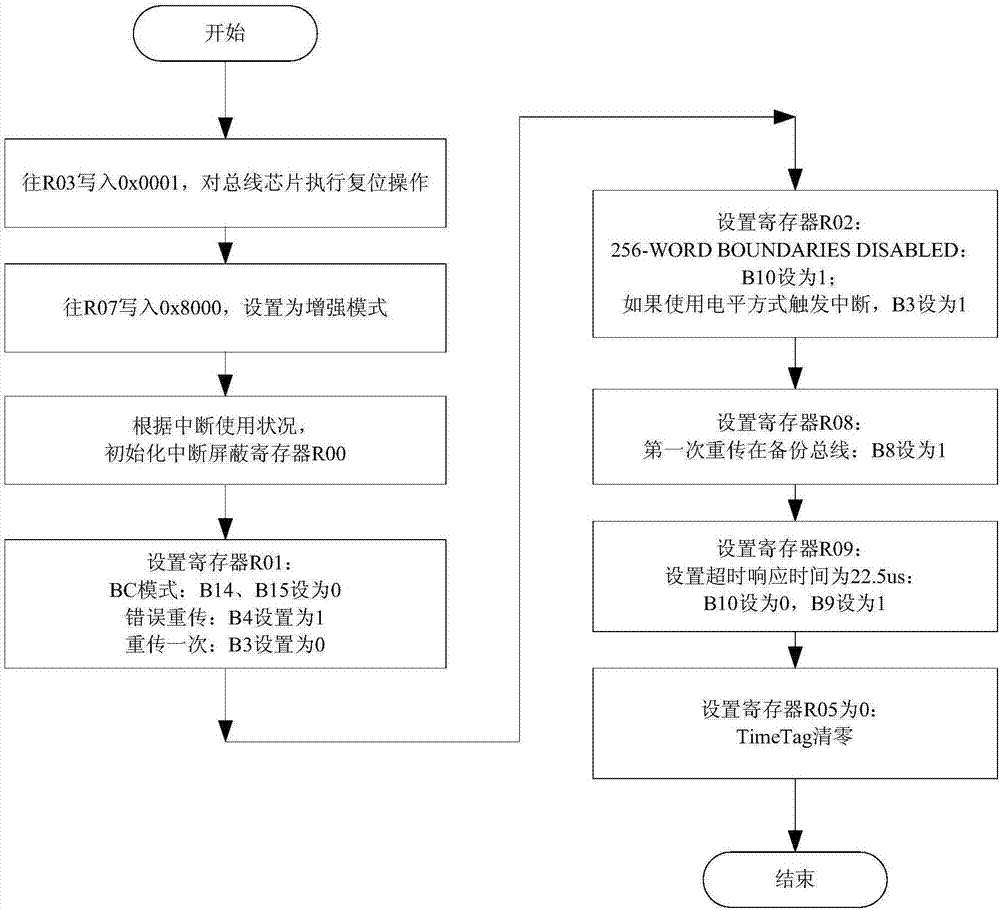

Triple-redundancy 1553B bus dynamic switching method

ActiveCN107347018AImplement fault diagnosisImplement failoverBus networksElectricityDiagnosis methods

The invention provides a triple-redundancy 1553B bus dynamic switching method, which includes the following steps: S1, a triple-modular redundancy bus network computer system architecture is built; S2, a redundancy bus configuration method is designed, a bus A for communication is a main bus by default, a first redundancy module is a on-duty module by default when the computer system is powered on, a first bus chip is configured in a BC mode, and a second bus chip and a third bus chip are configured in an MT mode; S3, a bus fault diagnosis method is designed for triple-modular bus real-time fault identification; and S4, a triple-redundancy bus mode composed of a BC mode and two MT modes is reestablished according to the on-duty module switching principle. A spacecraft computer requiring high real-time performance and reliability can determine a triple-redundancy bus fault by using the serial timing characteristic and the information monitoring function of buses. The method is easy to implement, runs reliably, is not affected by the external environment, is quick, and can be easily used in engineering.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com