Patents

Literature

56 results about "Buckling instability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Buckling instability is a treacherous phenomenon in structural engineering, where a small increase in the load can lead to a sudden catastrophic failure.

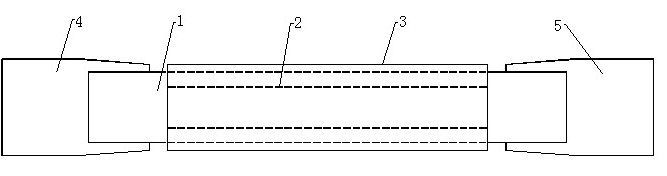

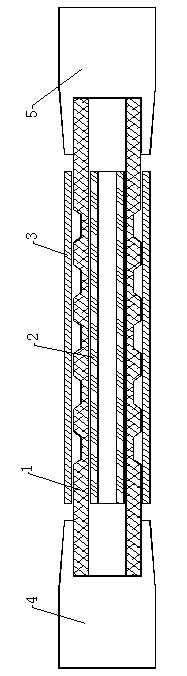

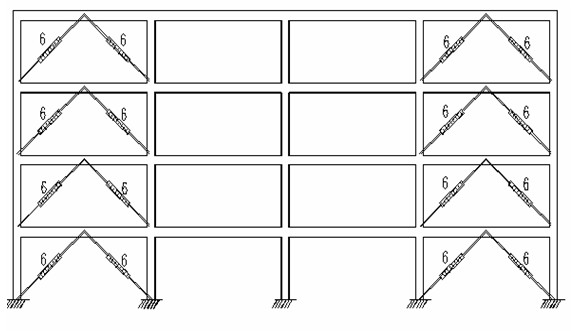

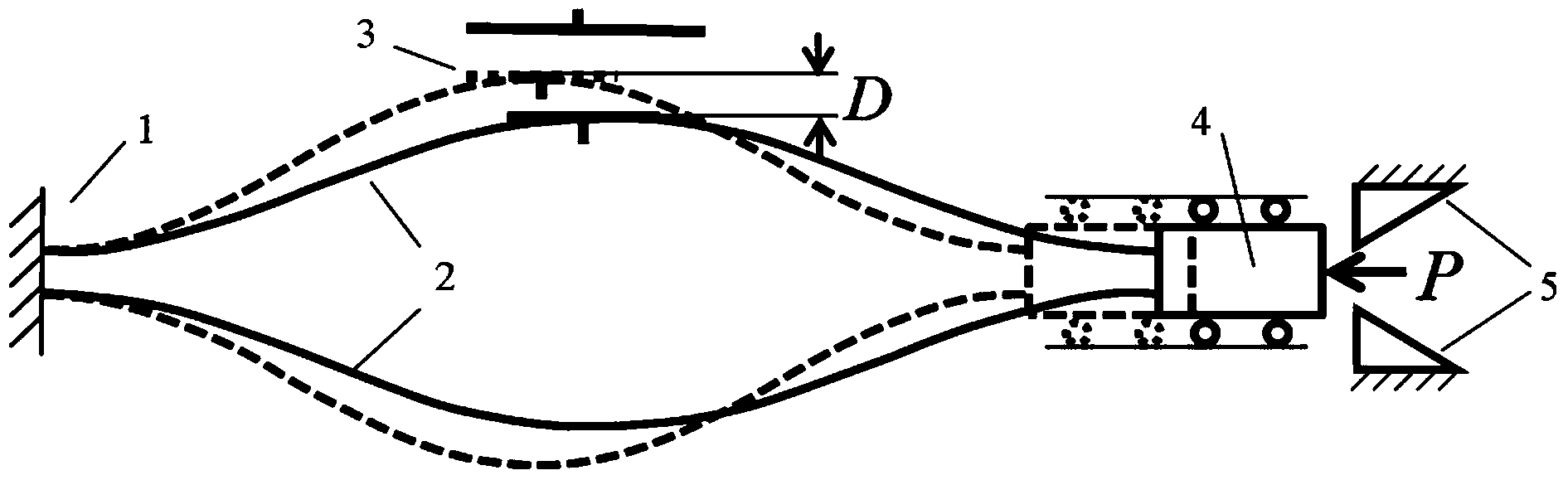

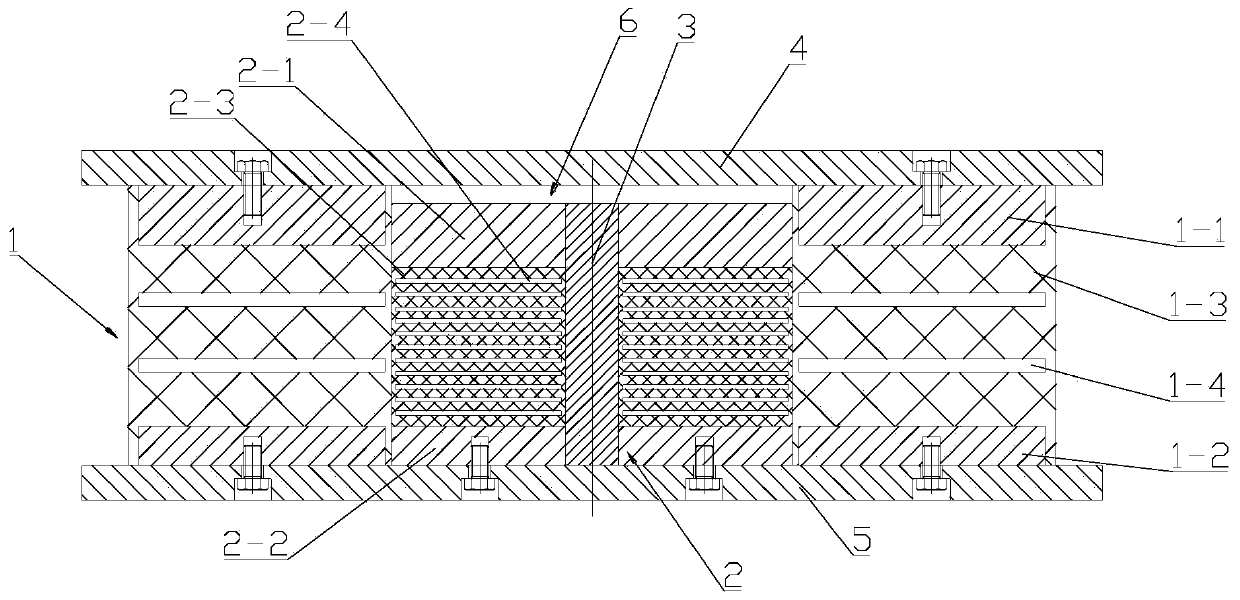

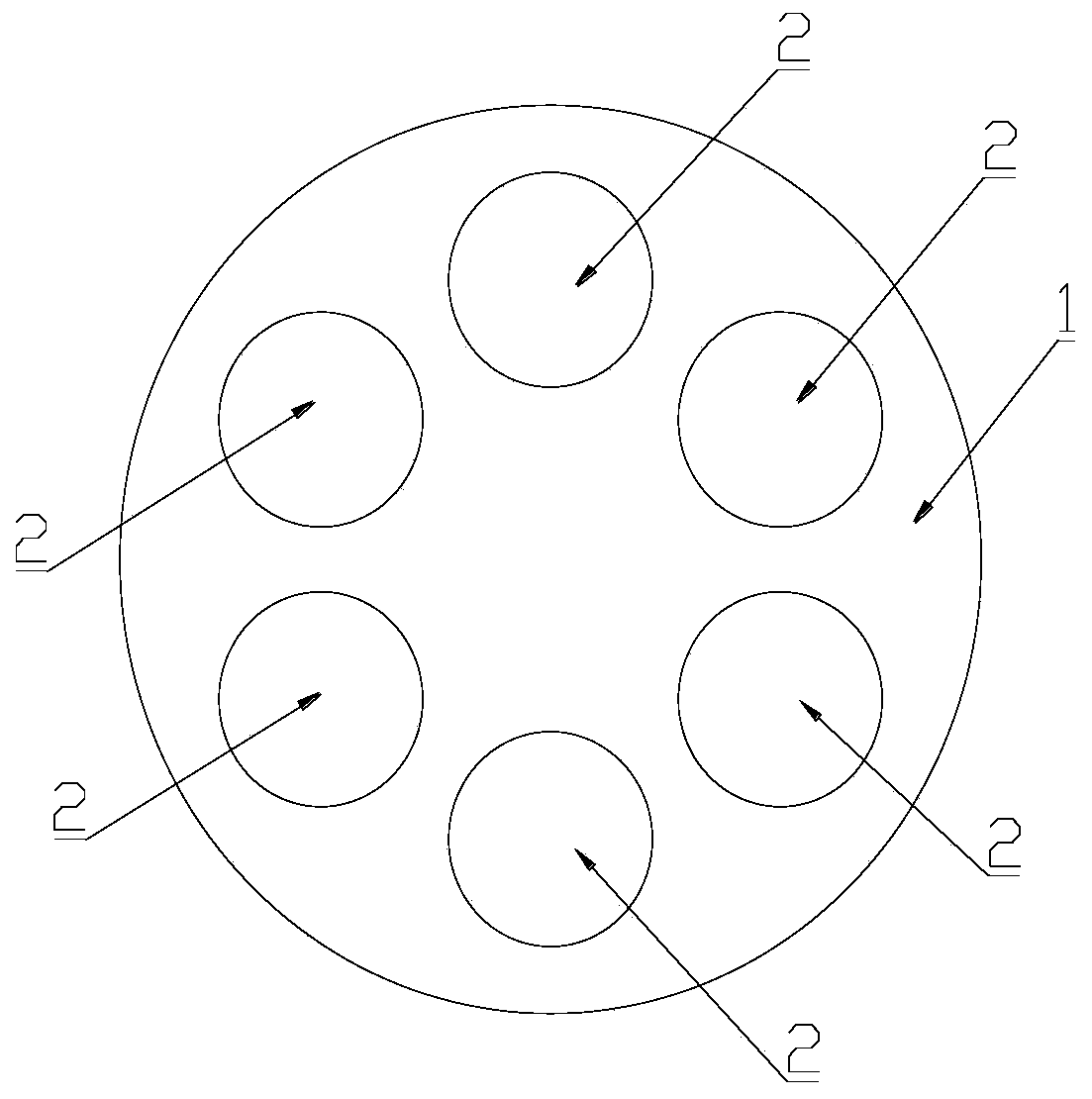

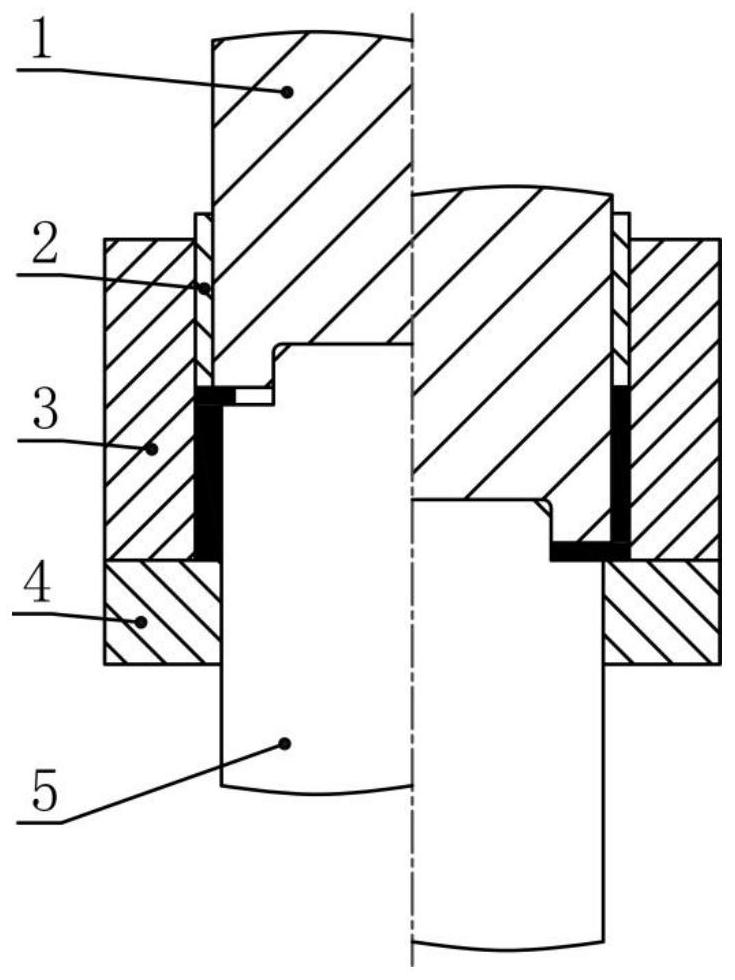

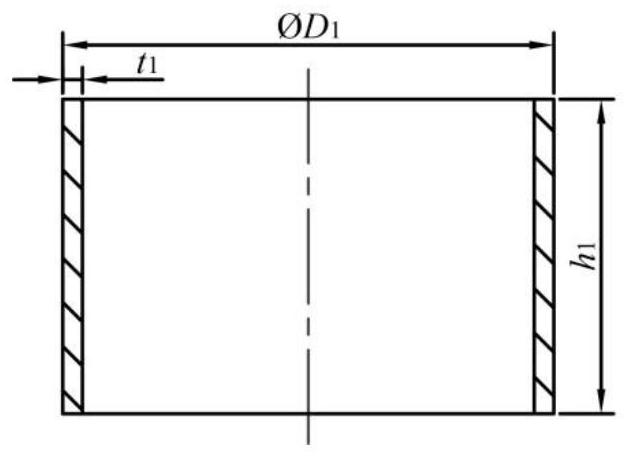

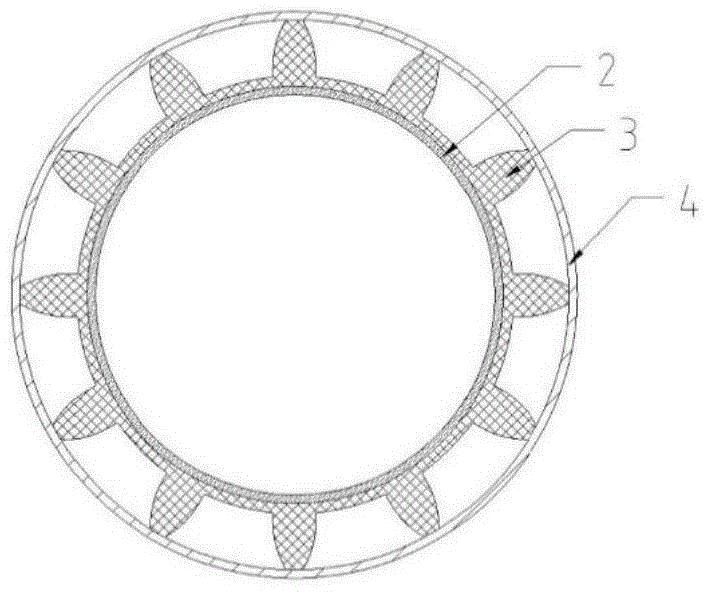

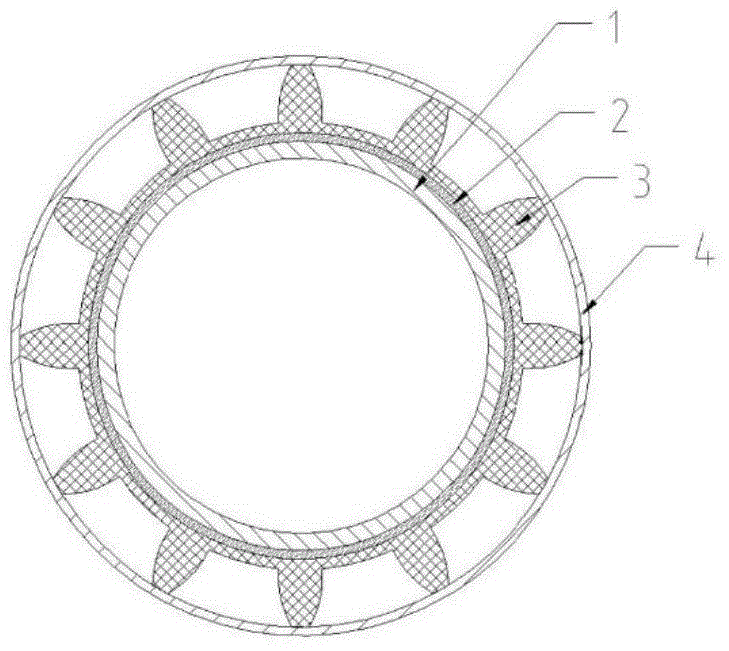

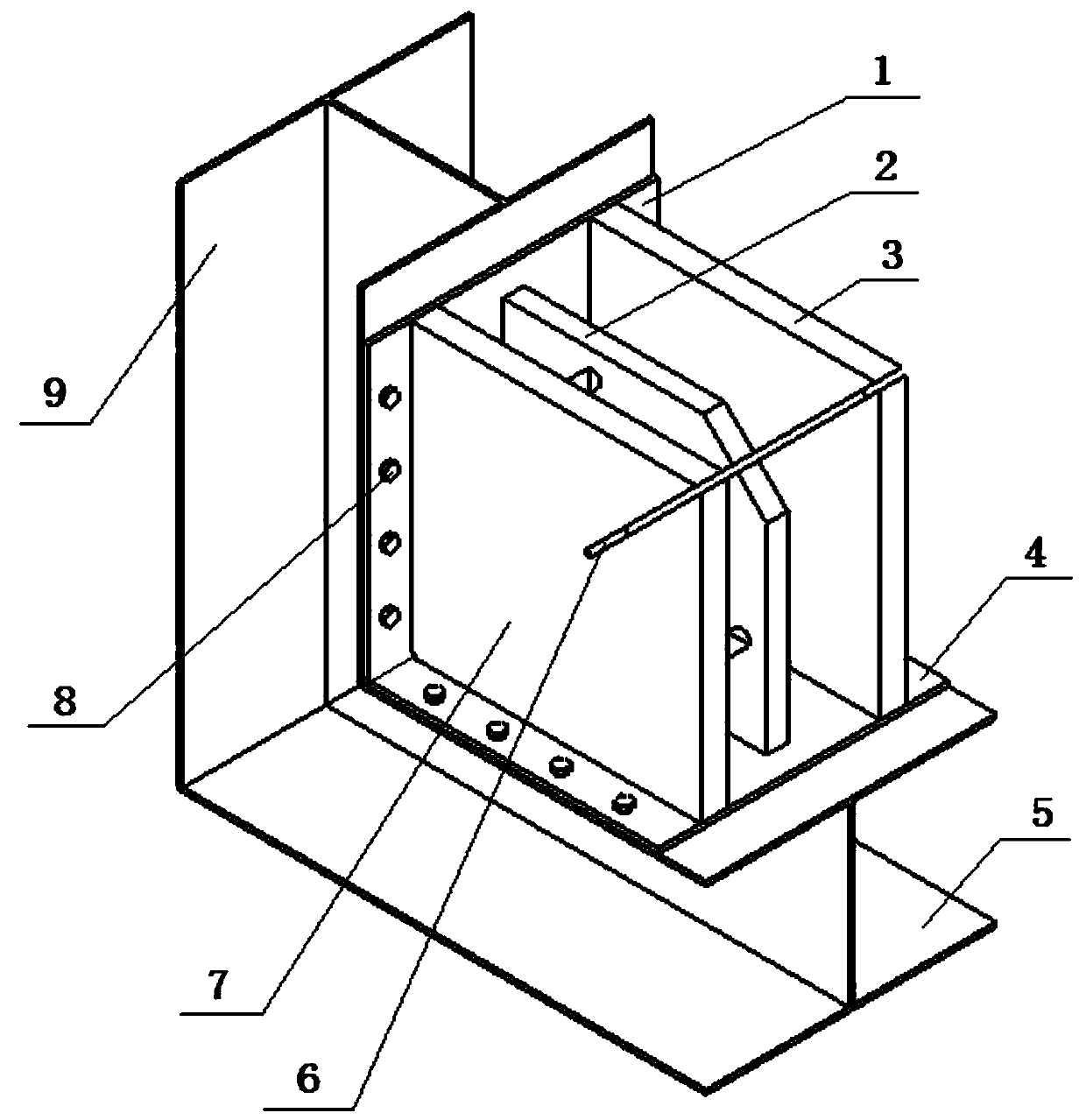

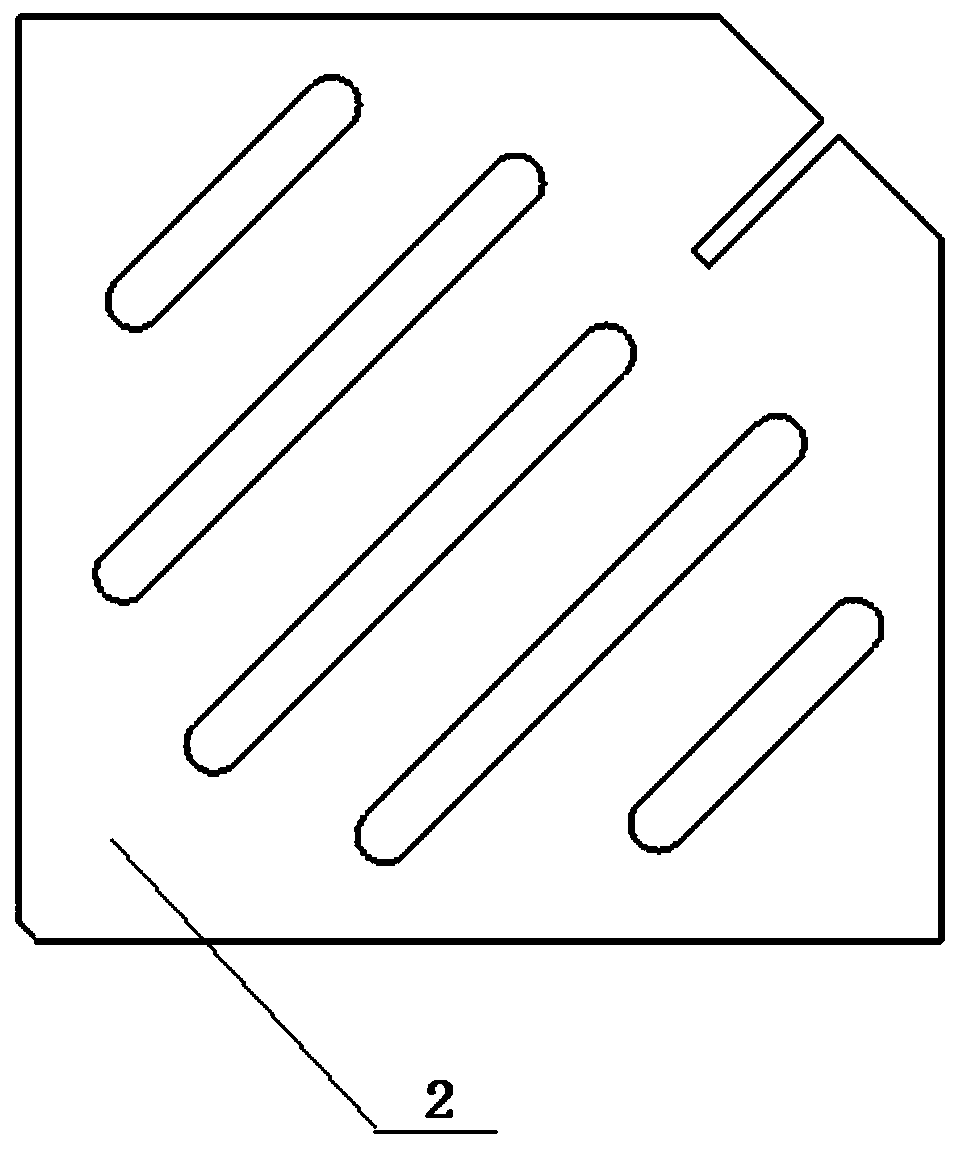

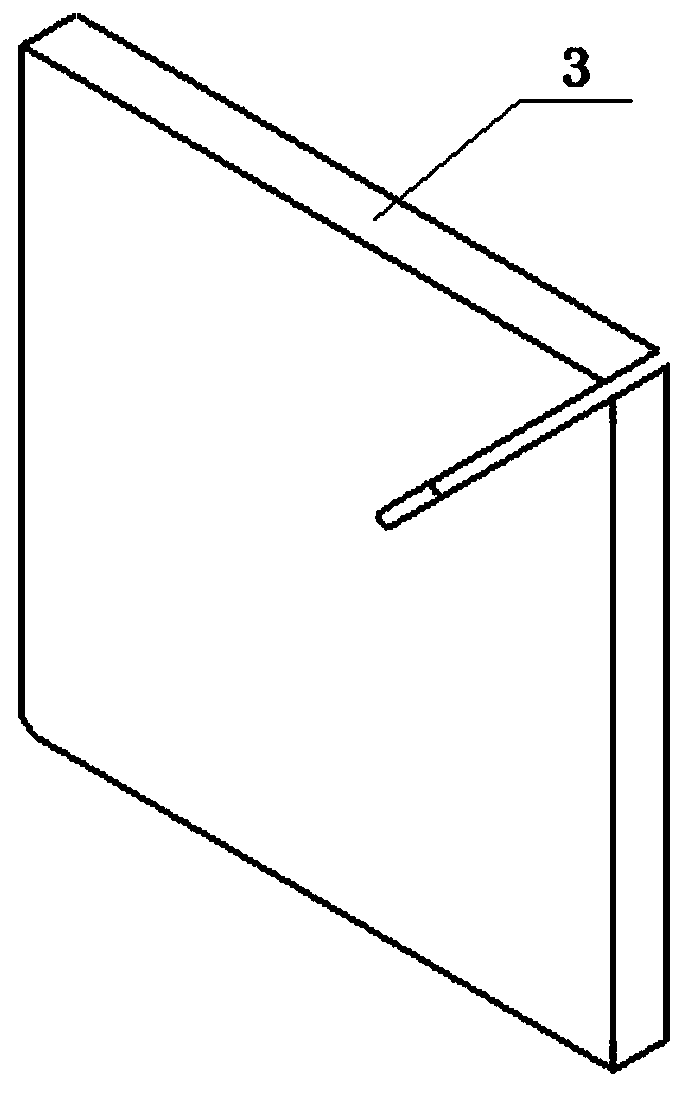

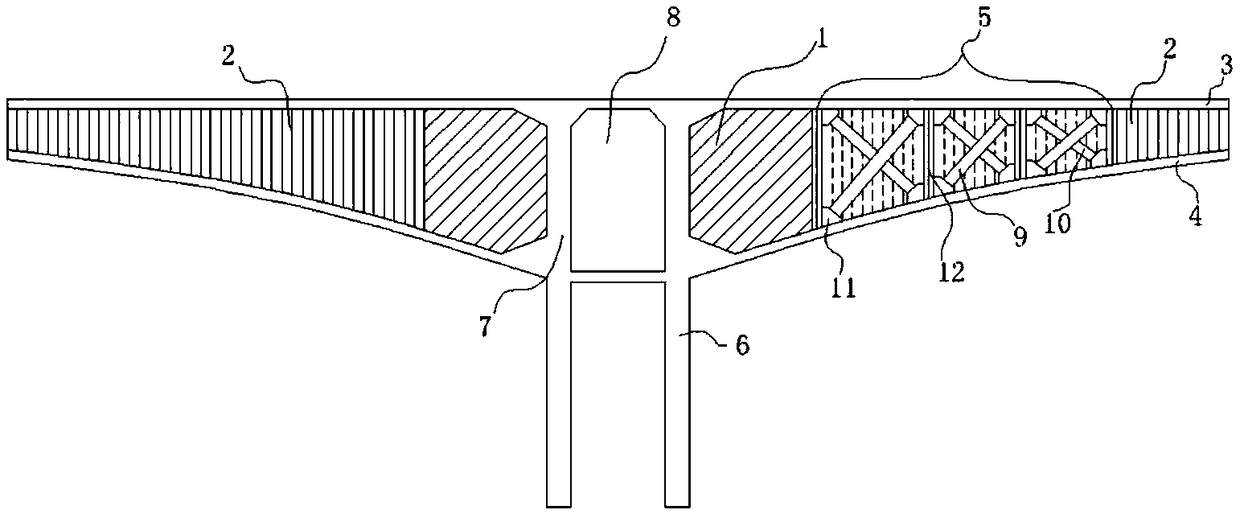

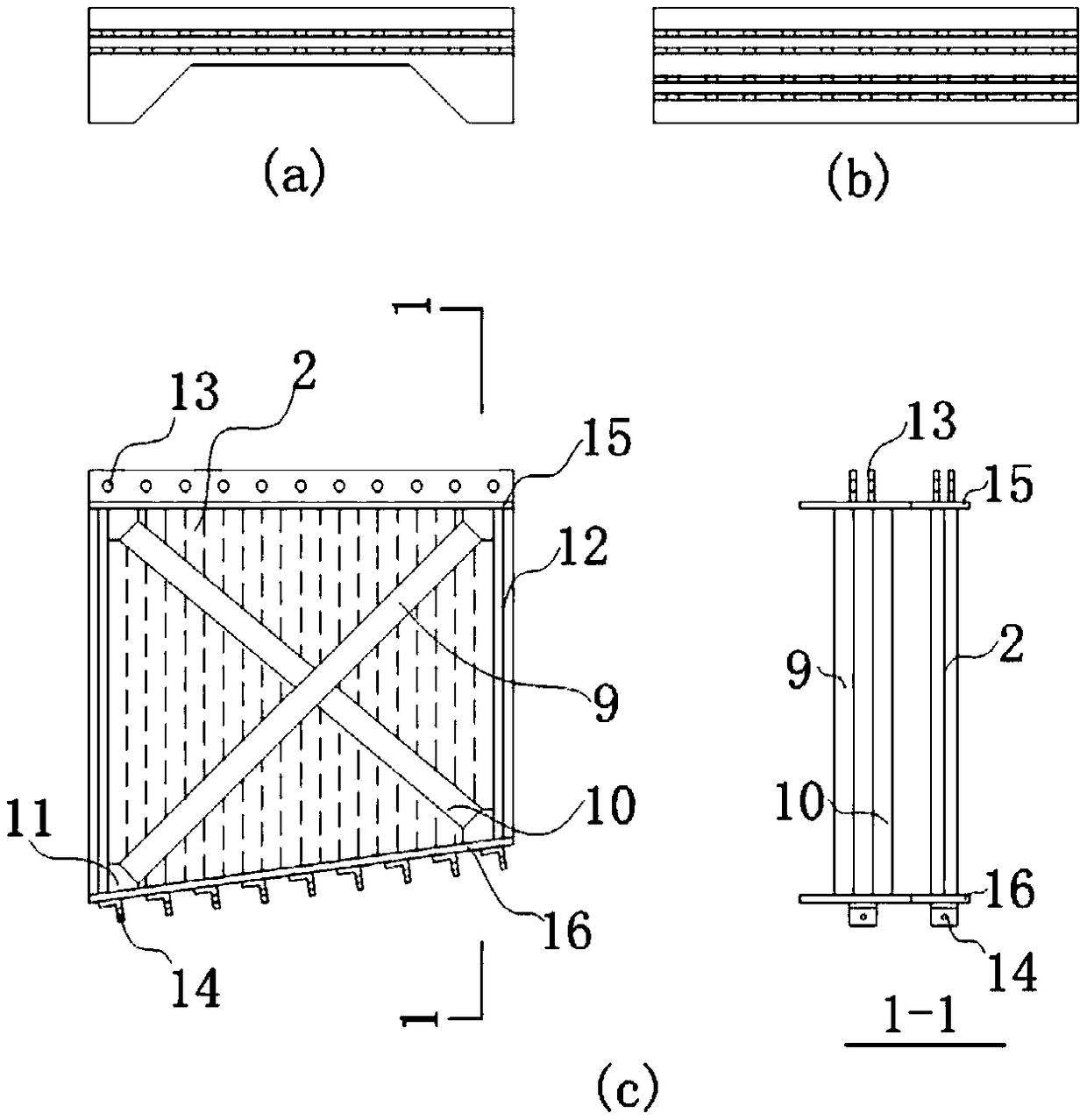

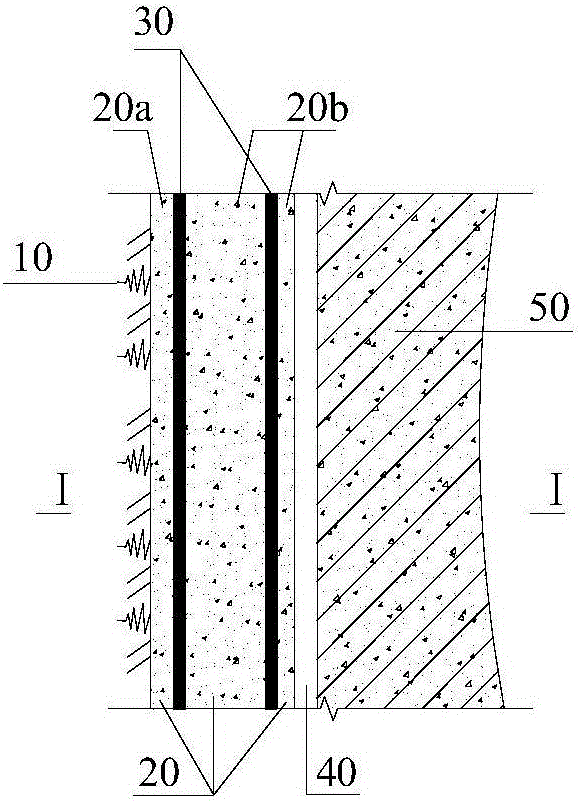

Buckling restrained energy-consumption supporting device of building frame structure

InactiveCN102505772AIncrease stiffnessImprove deformation abilityShock proofingBuckling instabilityHigh energy

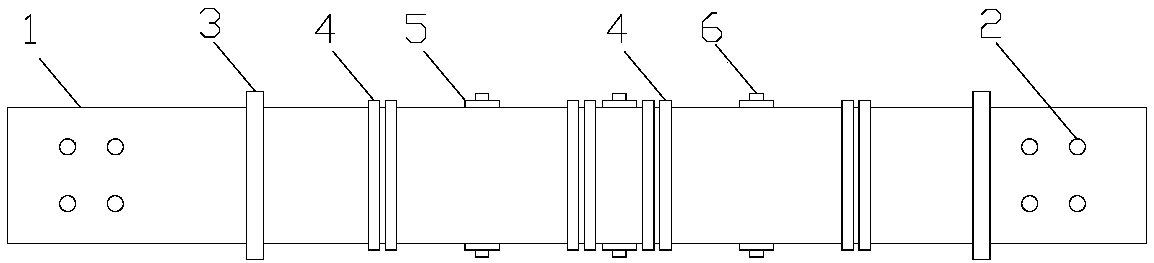

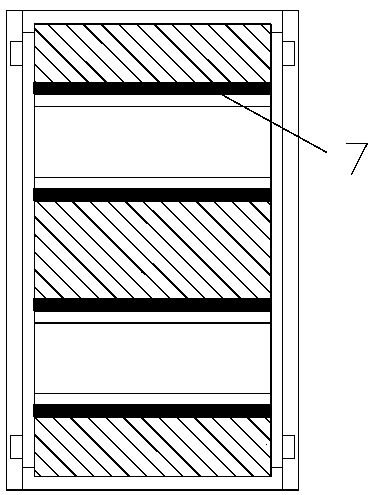

The invention relates to a buckling restrained energy-consumption supporting device of a building frame structure, which consists of an energy-consumption steel tube (1), an inner restraining steel tube (2), an outer restraining steel tube (3) and connecting steel plates (4 and 5). Corrugations are formed on the outer side of the wall of the energy-consumption steel tube (1) at certain intervals, two ends of the energy-consumption steel tube (1) are respectively connected onto the connecting steel plates (4 and 5), and the inner restraining steel tube (2) and the outer restraining steel tube (3) are placed on the inner side and the outer side of the energy-consumption steel tube (1). The buckling restrained energy-consumption supporting device of the building frame structure has the advantages of high rigidity and deformation ability, easiness in control of buckling, avoidance of buckling instability and high energy consumption ability, and is accurate in stress, simple in structure, convenient in manufacture, easy in installation and maintenance and fine in durability. The buckling restrained energy-consumption supporting device can be used for buildings with multilayered and high-rise concrete structures and buildings with steel structures, and resolves the problem of insecurity of the structures of the buildings in violent earthquake.

Owner:卢锐

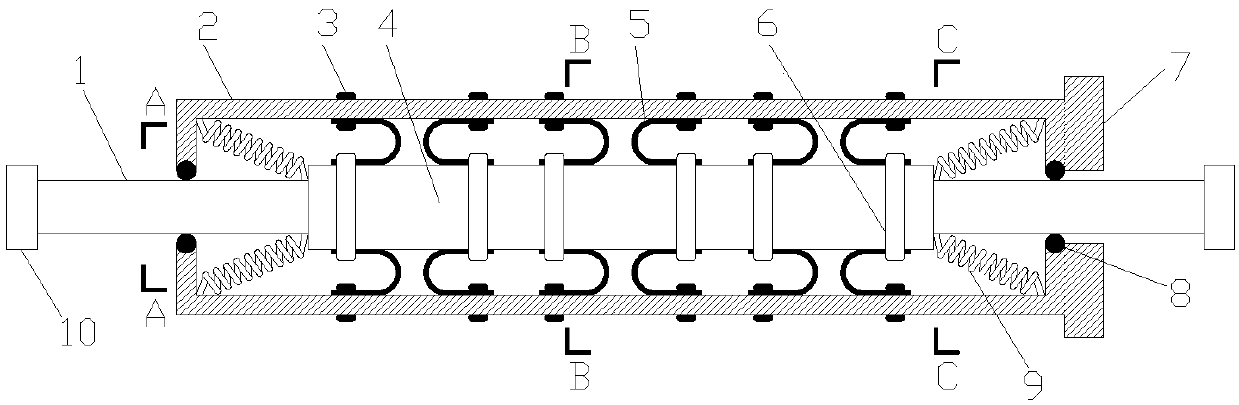

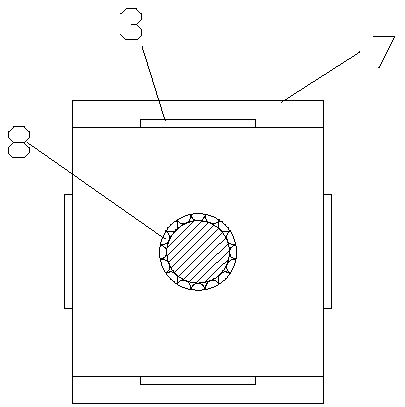

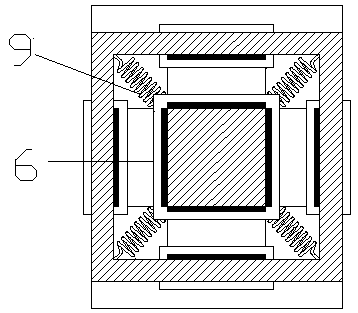

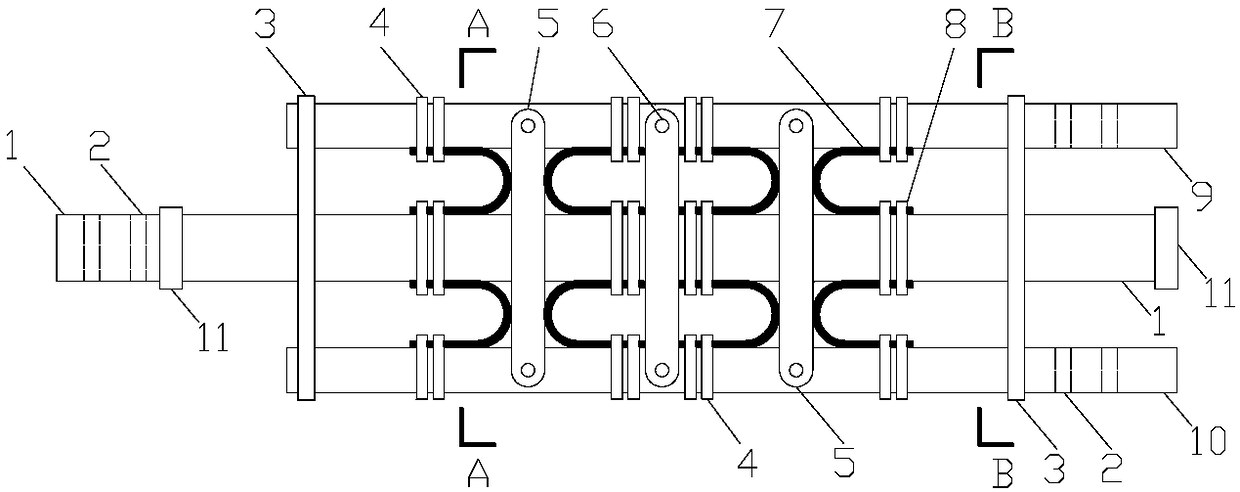

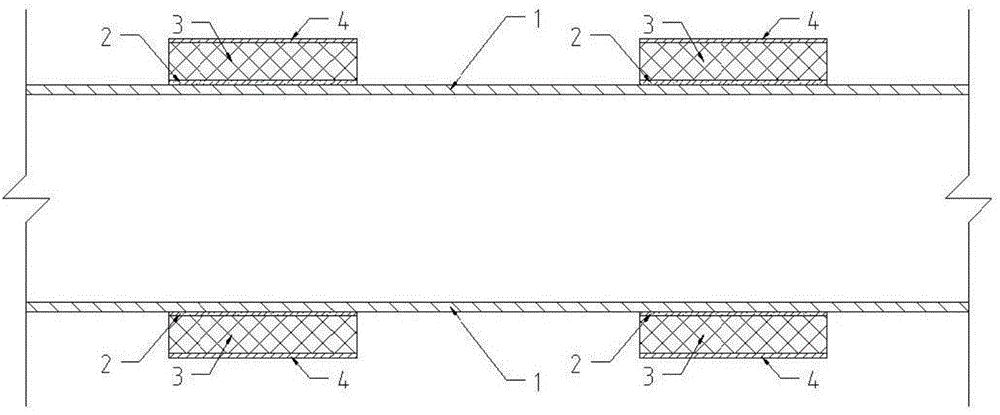

Limit sleeve U-shaped soft steel damper

InactiveCN108179910APrevent bucklingSimple structureProtective buildings/sheltersShock proofingStress concentrationBuckling instability

The invention discloses a limit sleeve U-shaped soft steel energy dissipation damper. A protective shell is added in the limit sleeve U-shaped soft steel energy dissipation damper to prevent a U-shaped soft steel damper from buckling instability out of the surface; a fixing piece for fixing U-shaped soft steel plate is added in the limit sleeve U-shaped soft steel energy dissipation damper, the cross section is designed as a special arc shape, the arc fixing piece can prevent a serious stress concentration phenomenon generated in the position of fixing the U-shaped soft steel plate; a main body of the U-shaped soft steel damper is composed of the U-shaped soft steel plate, springs, sliding guide rods, rectangular guide rods and the protective shell; and two ends of the sliding guide rods are provided with ultimate displacement protection plates to avoid oversize deformation to suddenly break a damper. The limit sleeve U-shaped soft steel energy dissipation damper is simple in structure, low in price and easy to produce in batches, and can be applied to energy dissipation vibration reduction systems with various structures.

Owner:ANHUI UNIV OF SCI & TECH

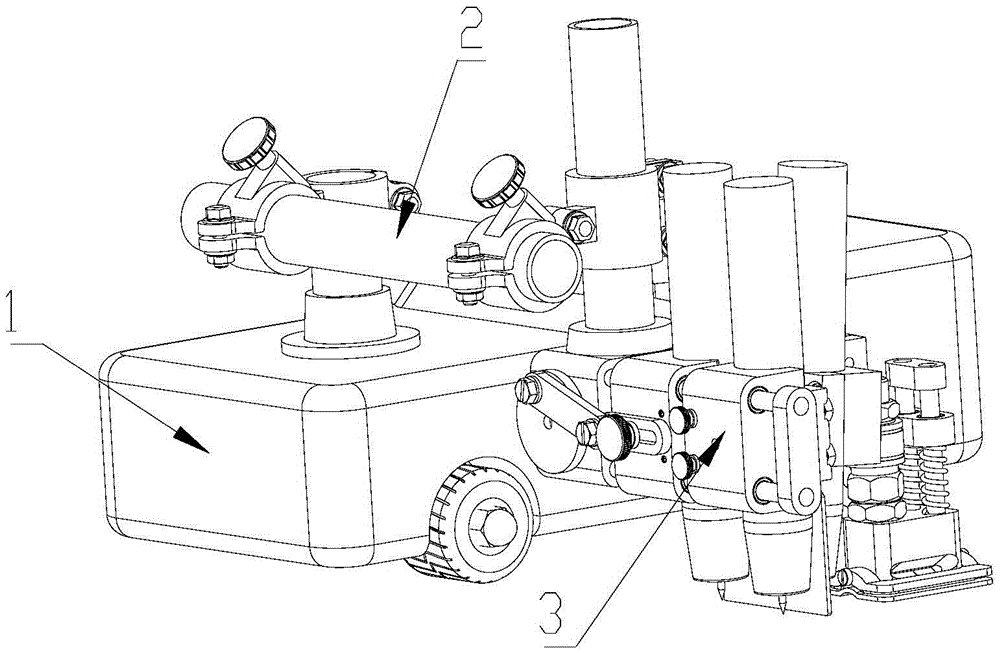

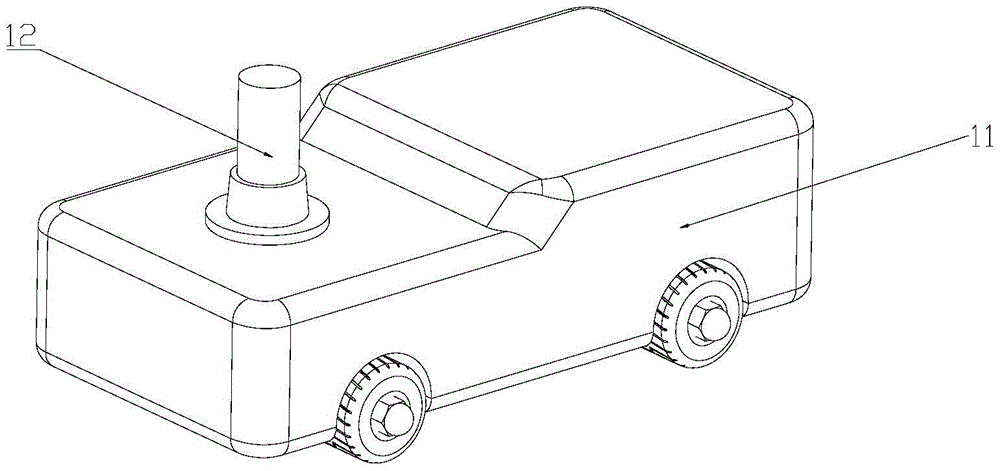

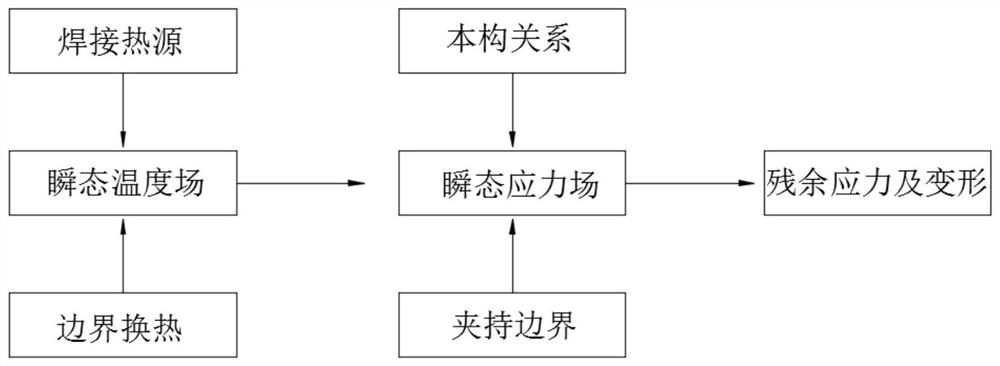

Thin plate weld with trailing deformation control device and method with dynamic hot stretching and chilling combined

ActiveCN105643122AControlled bucklingControl bending deformationWelding/soldering/cutting articlesMetal working apparatusBuckling instabilityWelding residual stress

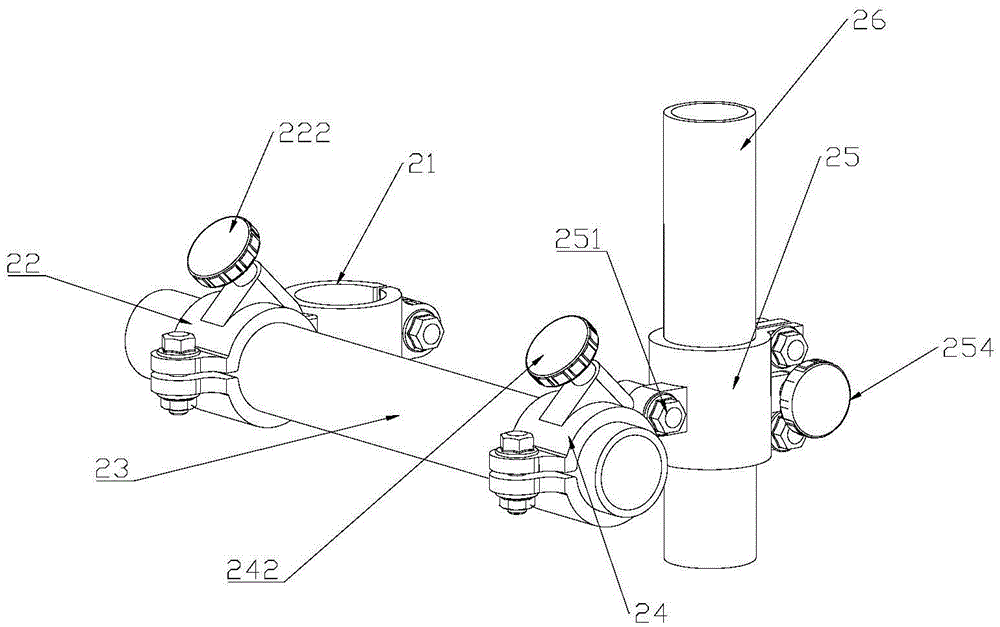

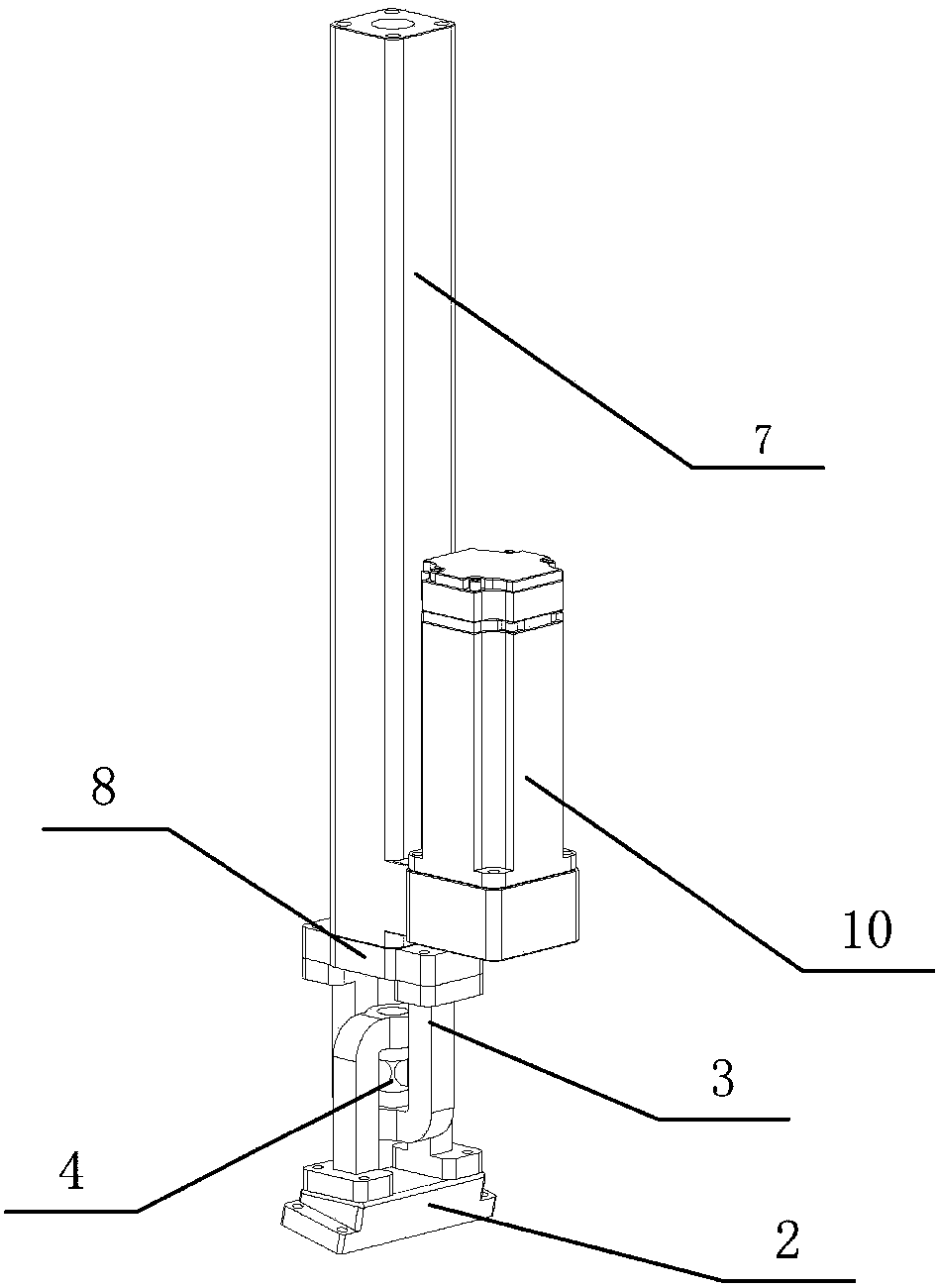

The invention relates to a thin plate weld with trailing deformation control device and method with dynamic hot stretching and chilling combined. The thin plate weld with trailing deformation control device comprises a walking module, a connecting device and a weld with trailing deformation control module. The weld with trailing deformation control module is borne on the walking module through the connecting device. The weld with trailing deformation control module comprises a dynamic hot stretching module, welding gun modules and a trailing intensive cooling module. Parallel transverse swing heating of dual TIG arcs can be achieved through the dynamic hot stretching module. The thin plate weld with trailing deformation control method comprises the steps that the TIG arcs are used for carrying out dynamic hot stretching on the two sides of a welding seam before welding, the welding seam is welded, and then a chilling medium is used for carrying out chilling on the welding seam. According to the thin plate weld with trailing deformation control device and method, the overall structure is compact, and the size is small; and on the basis of guaranteeing the quality of the welding seam, the welding residual stress level can be lowered, and compressional buckling instability and bending deformation can be controlled well.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

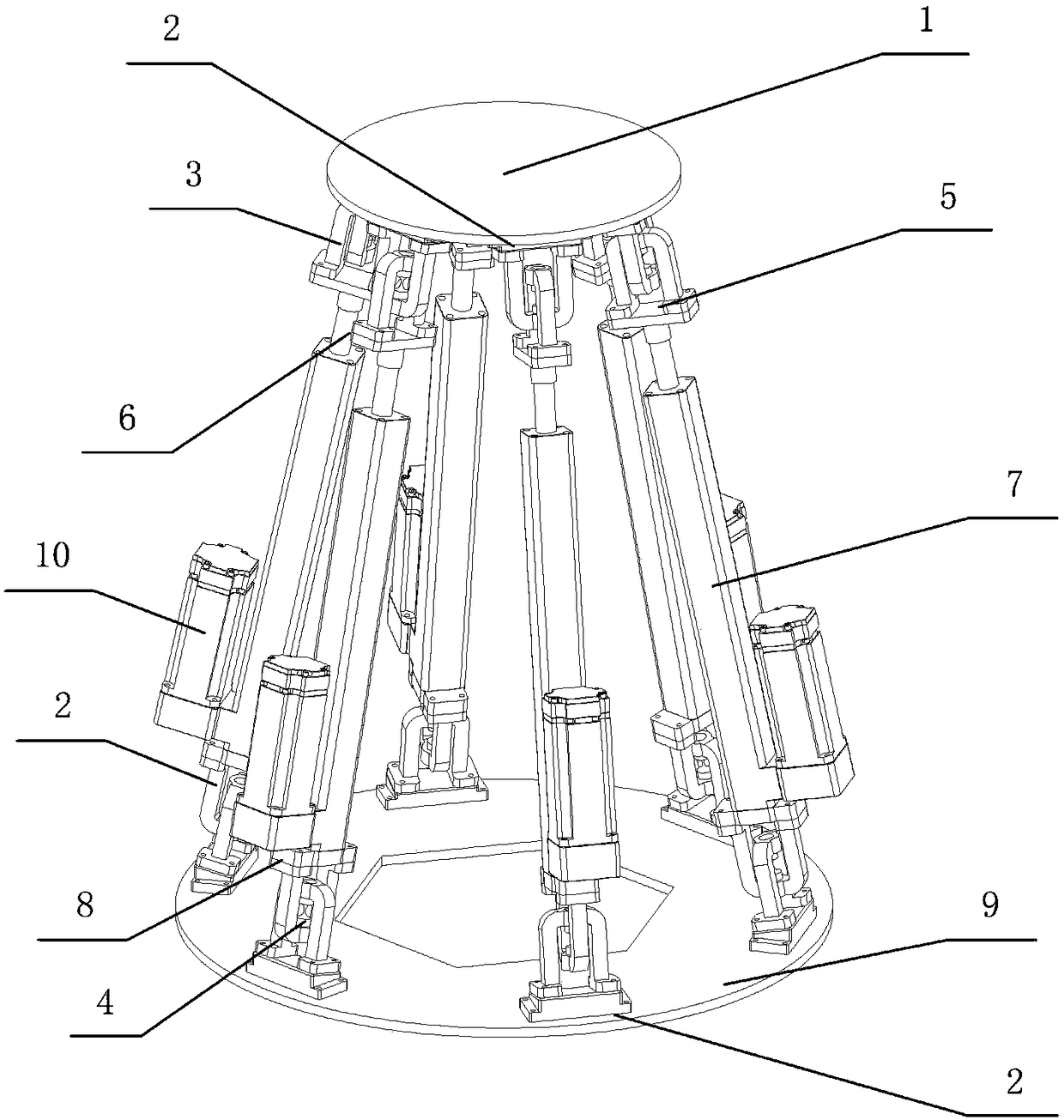

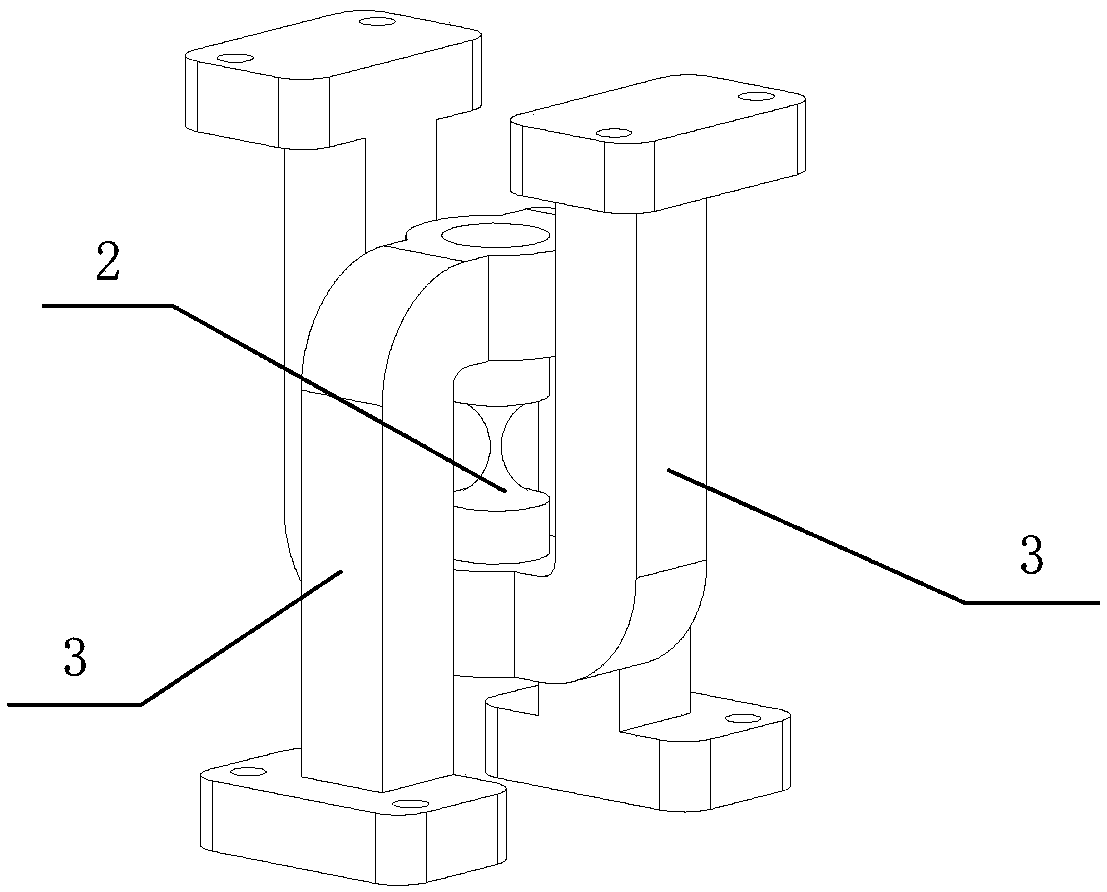

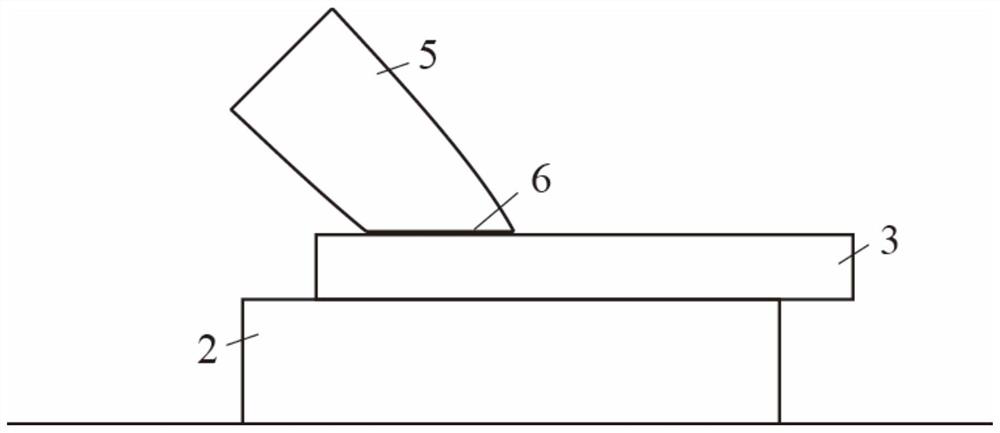

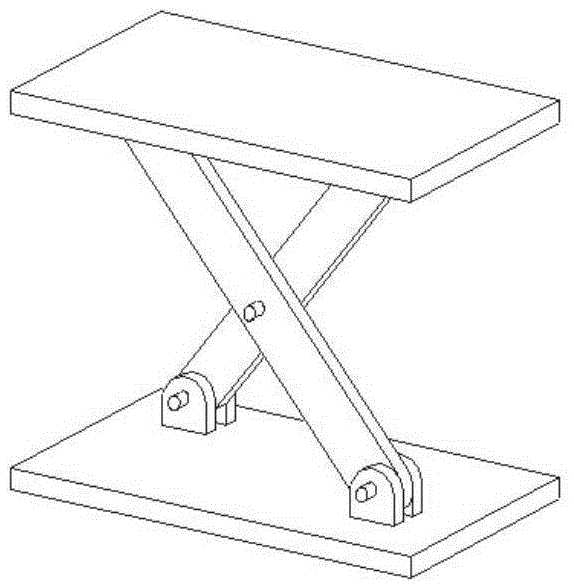

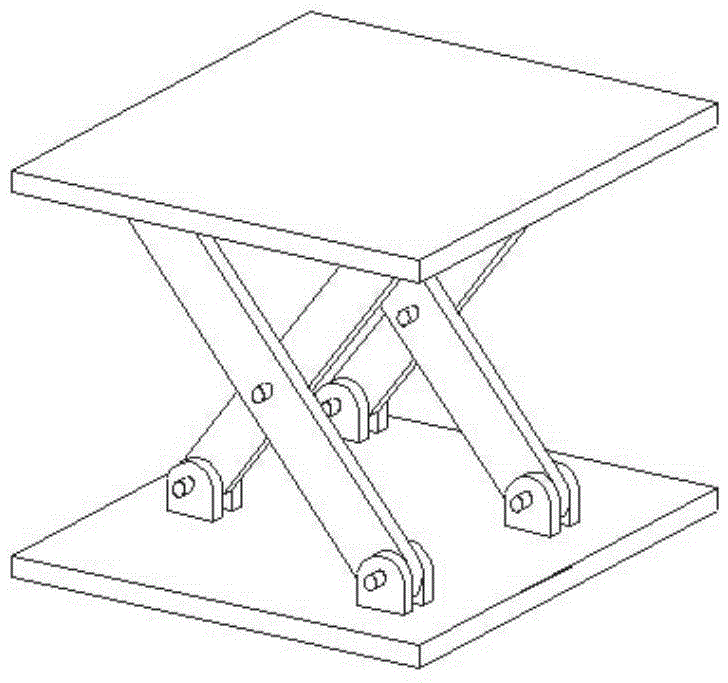

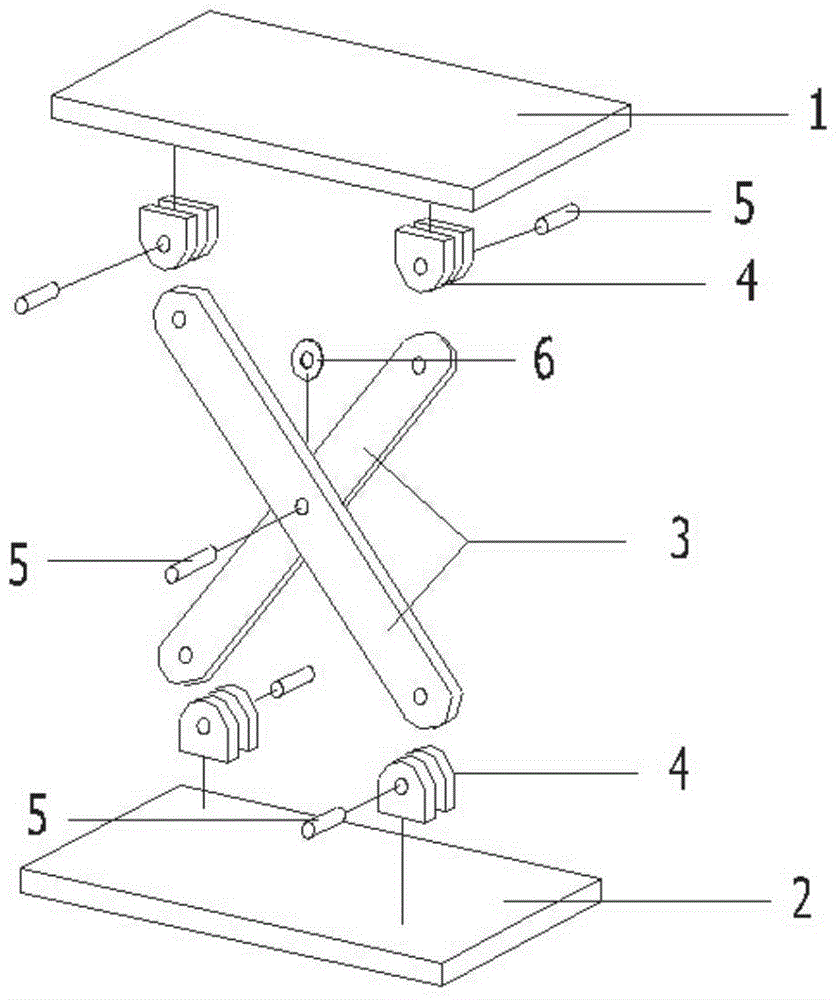

Heavy-load six-degree-of-freedom compliant parallel robot system

ActiveCN108481306ANo buckling instabilityProgramme-controlled manipulatorCompliant mechanismRobotic systems

The invention belongs to the technical field of manipulators, and discloses a heavy-load six-degree-of-freedom compliant parallel robot system. Six small electric cylinders are adopted to drive to realize six-degree-of-freedom movement of a moving platform of three-degree-of-freedom of translational movement and three-degree-of-freedom of rotary movement, and upper and lower platforms and the electric cylinders are connected by bevel fixing blocks and force steering parts. Compliant spherical hinges are core parts of the force steering parts, and the single force steering part is composed of one compliant ball hinge and two U-shaped parts. The gravity of compliant hinges borne from other parts and the pressure exerted by the moving platform load on the compliant hinges are turned into tensile force on the compliant hinges through the force steering parts, and the advantages of a conventional six-degree-of-freedom platform are combined with the advantages of a compliant mechanism. Afterthe improvement of the force steering parts of the compliant hinge design, the positioning accuracy of the mechanism can reach a micron level, and the bearable load is much more than a few grams, sothat the compliant ball hinges do not generate buckling instability due to excessive load and can realize micro size motion.

Owner:XIDIAN UNIV

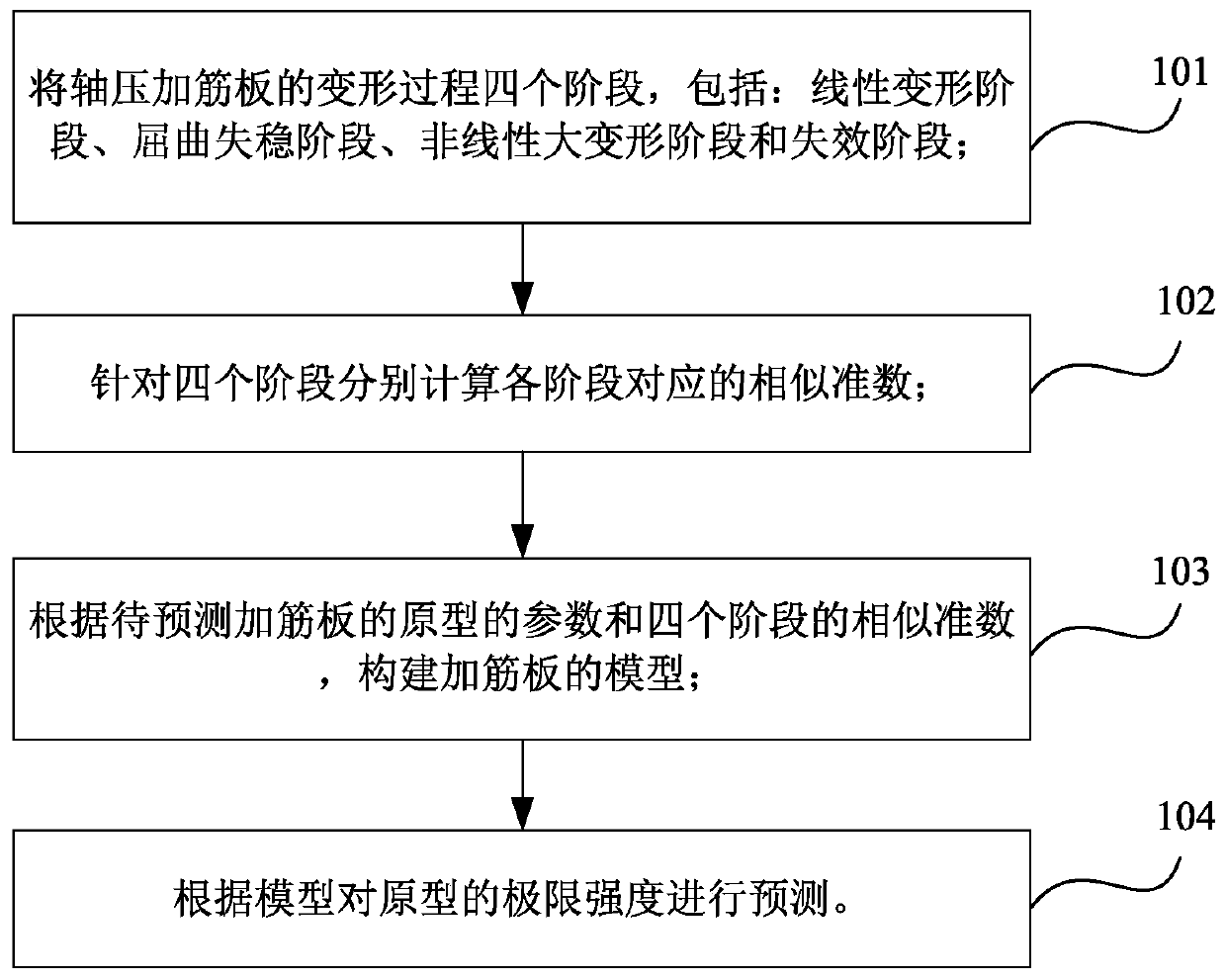

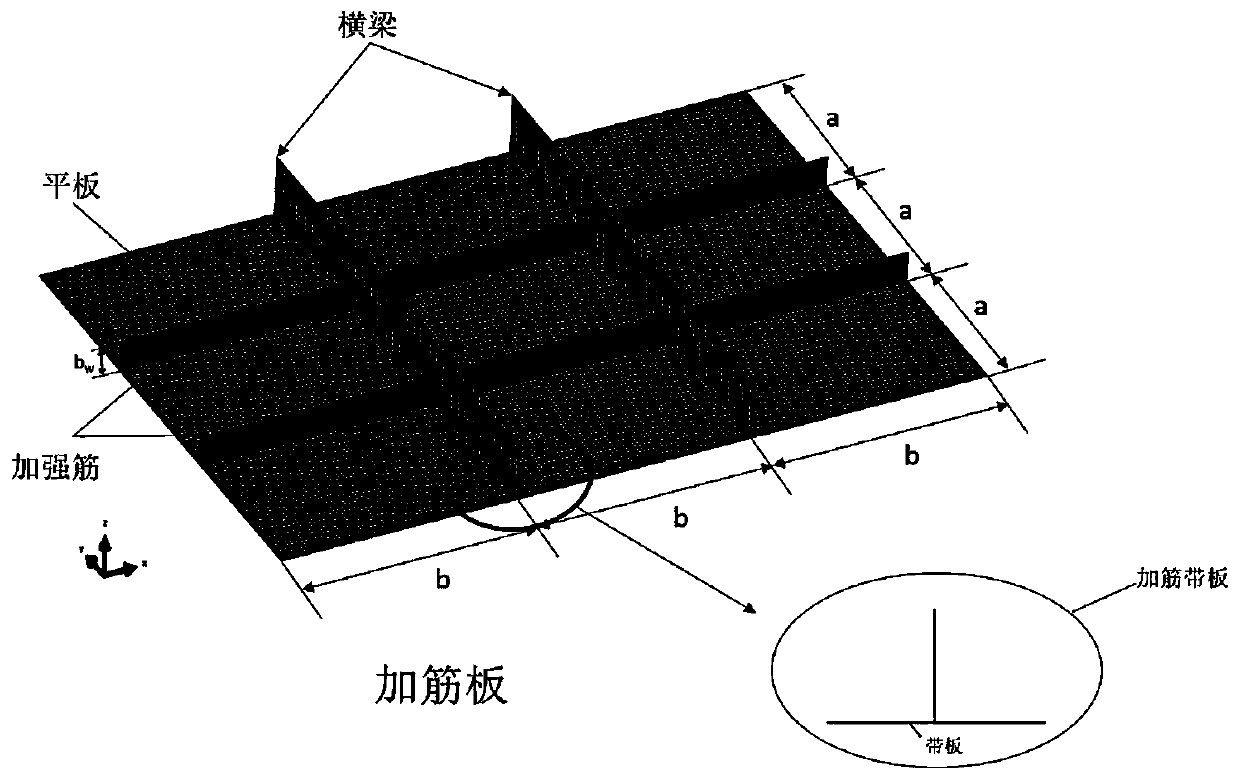

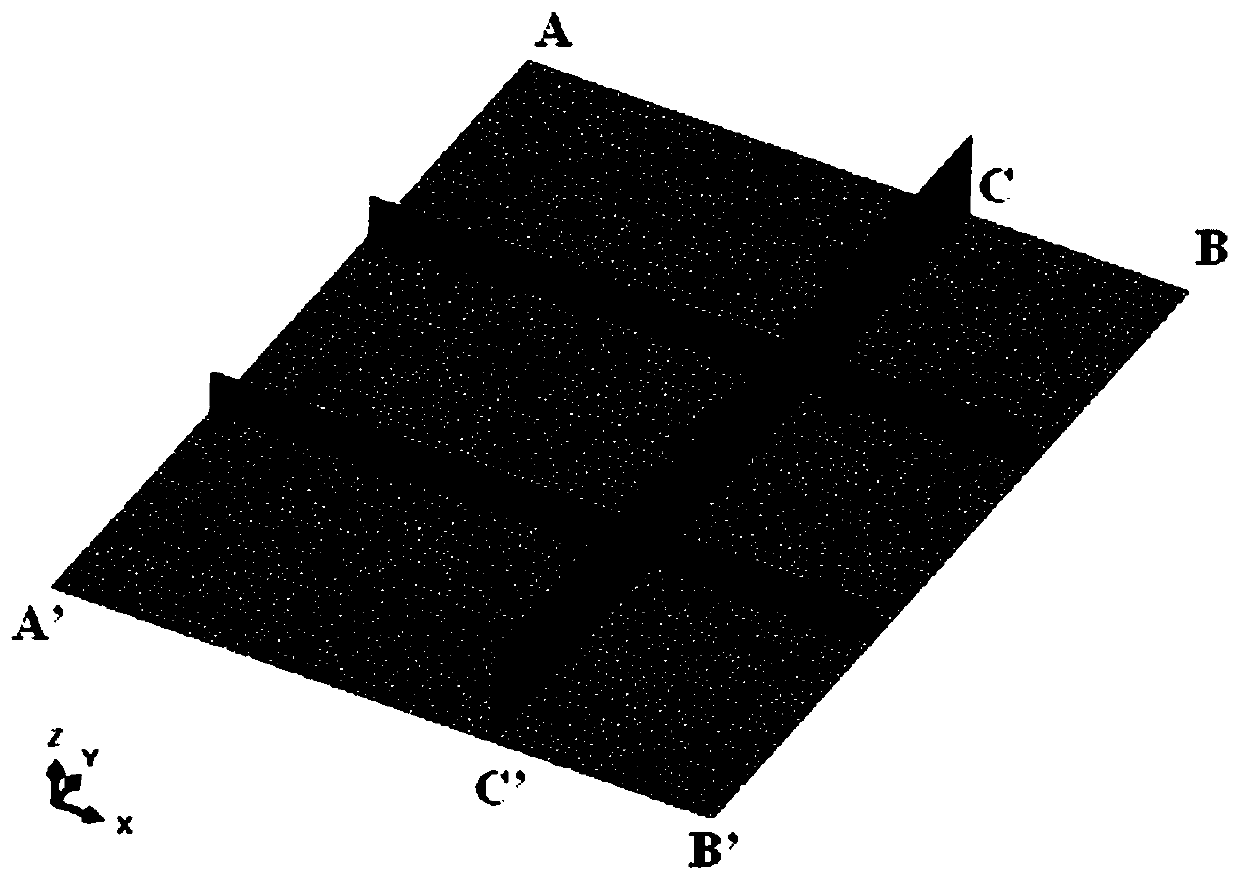

Axial pressure stiffened plate ultimate strength prediction method

InactiveCN110852012AGuaranteed similarityAvoid errorsGeometric CADDesign optimisation/simulationBuckling instabilityAxial pressure

The invention relates to the technical field of hull beam ultimate bearing capacity prediction, in particular to an axial pressure stiffened plate ultimate strength prediction method, which comprisesfour stages including a linear deformation stage, a buckling instability stage, a nonlinear large deformation stage and a failure stage in the deformation process of an axial pressure stiffened plate,for the four stages, respectively calculating a similarity criterion corresponding to each stage; constructing a model of the stiffened plate according to the parameters of the prototype of the stiffened plate to be predicted and the similarity criterion of the four stages; and predicting the ultimate strength of the prototype according to the model. According to the method, the stiffened plate can be predicted according to the whole deformation process of the stiffened plate under the axial compression condition, so that the similarity prediction precision is improved.

Owner:WUHAN UNIV OF TECH

Buckling micro-force sensor and micro-force measuring method based on twin beams or serial connection twin beams

InactiveCN103471745AMeet force measurement requirementsConducive to systematizationForce measurementStructural/machines measurementCapacitanceBuckling instability

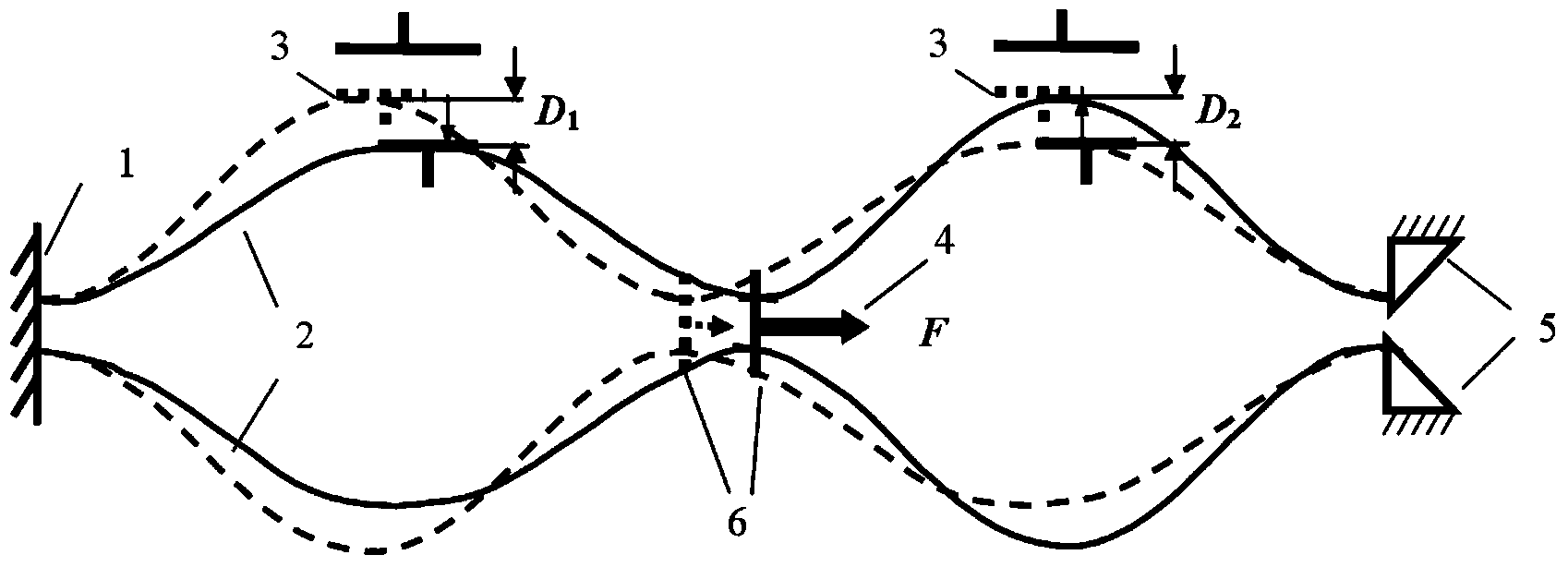

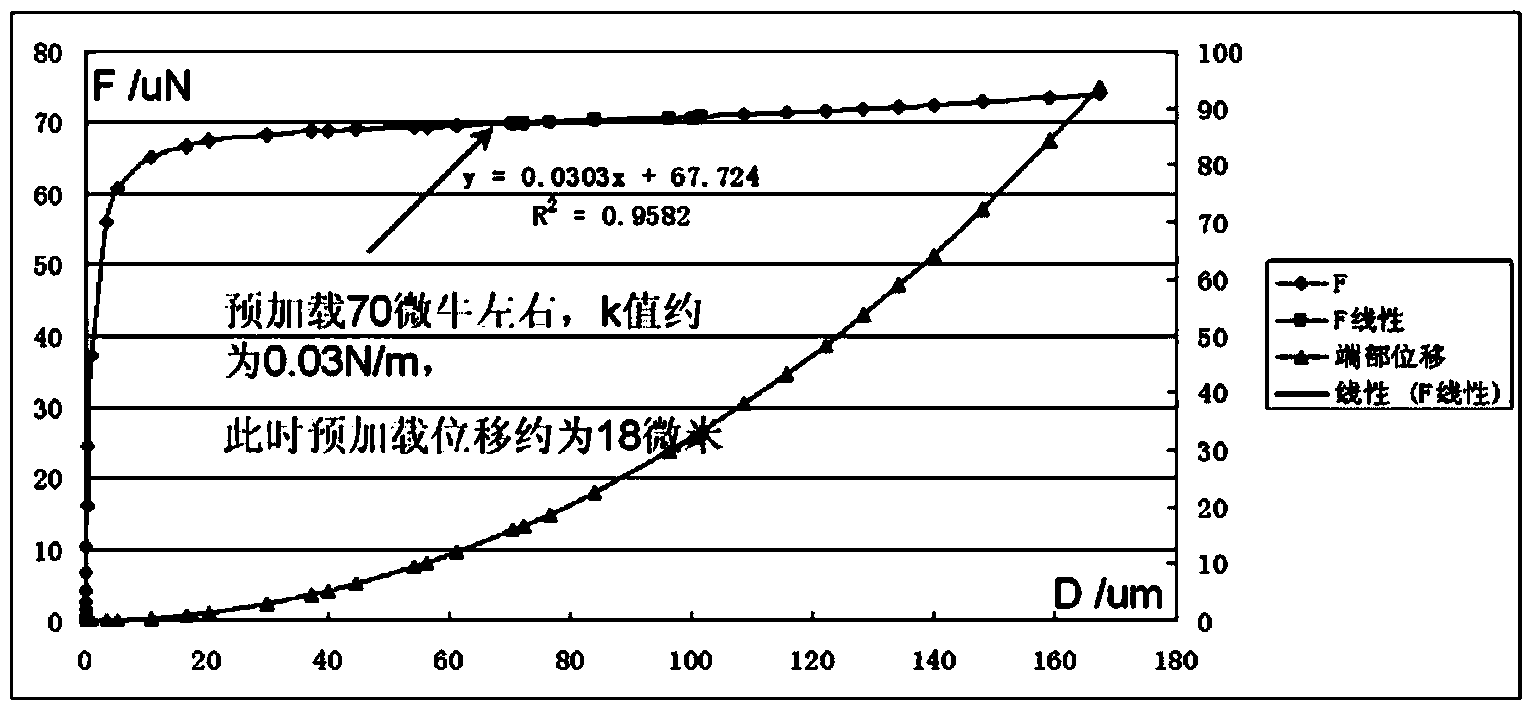

The invention discloses a buckling micro-force sensor and a micro-force measuring method based on twin beams or serial connection twin beams, and belongs to the fields of micro-nanomechanics and precise measurement. A group of symmetrical slim beams or two groups of serial connection slim beams are adopted in the sensor, the slim beams are arranged in a parallel mode, one end of each slim beam is fixed, the deformation of the slim beams is limited through limiting ends, a load is applied through a probe and a capacitor, and the displacement is measured. In the process of using, the twin beams are bent to be instable in the axis in advance, and the buckling mode of the twin beams is kept. By appropriately leading in the transverse displacement of the twin beams, the obvious transverse displacement change of the twin beams can be obtained under the very small axial force within a certain load range, and the value of the measured micro-force is obtained through load calculation based on the buckling instability formula or directly obtained through the changes of the displacement via the early calibration. The buckling micro-force sensor is simple in structure and in sensitivity, sequence sensors in different measuring ranges can be formed, and therefore the micro-force measuring method and the sensor design both of which have a wide range of loads and high sensitivity can be provided for the measurement of the micro-nanomechanics.

Owner:TSINGHUA UNIV

Preparation method of super-sliding block

ActiveCN111717881AImprove yieldThe method is simple and fastPiezoelectric/electrostriction/magnetostriction machinesDecorative surface effectsEtchingBuckling instability

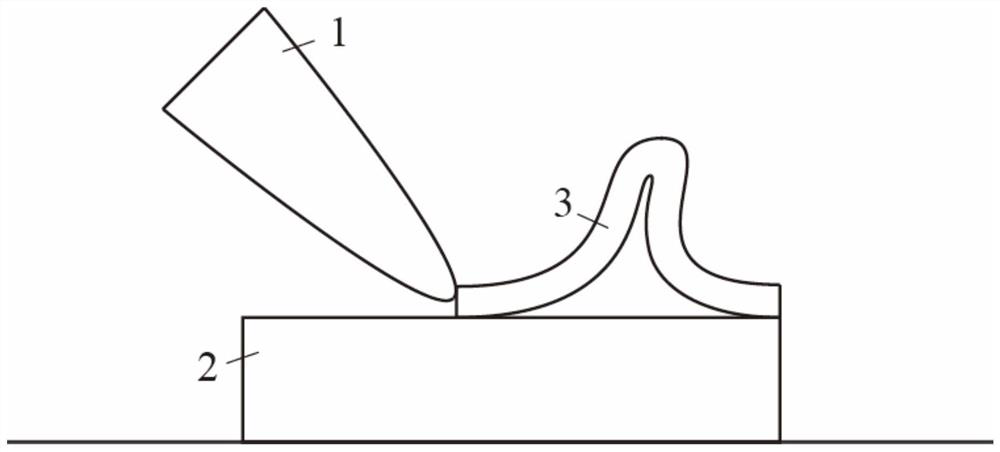

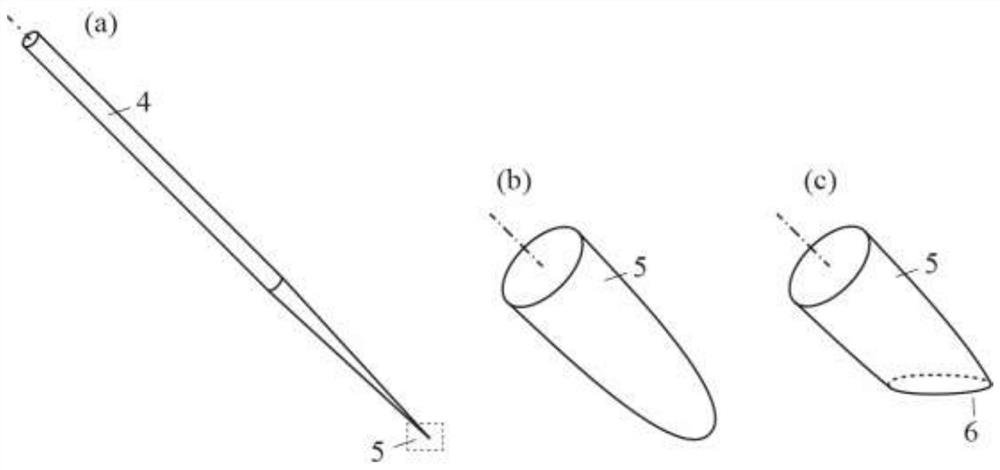

The invention provides a preparation method of a super-sliding block. According to the preparation method, buckling instability and structural damage of the super-sliding block are avoided by improving a loading mode. The method comprises the following steps: etching a platform at the tip of a probe by using a focused ion beam etching method and the like, contacting the platform with a super-slideblock, changing a loading mode into a mode of contacting the super-slide block from the top by using the probe, and applying positive pressure and shearing force so as to push the slide block. The method provided by the invention is simple and convenient, and can avoid the problem that the slide block is damaged due to buckling instability under the pushing of the probe when the super-slide blockis large. Meanwhile, the method provided by the invention can improve the yield of batch production of the ultra-sliding blocks, and has wide applicability.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

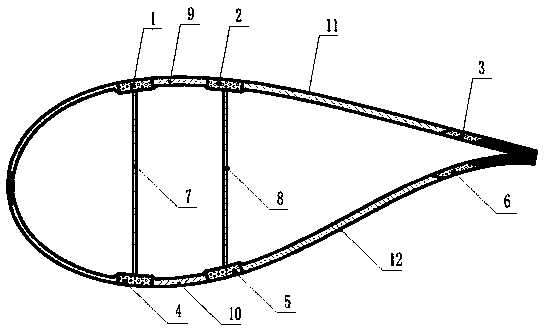

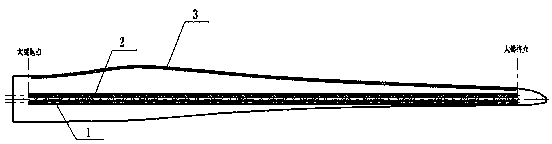

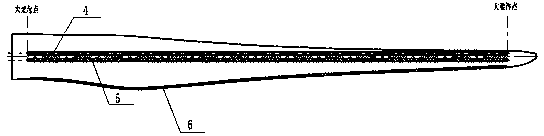

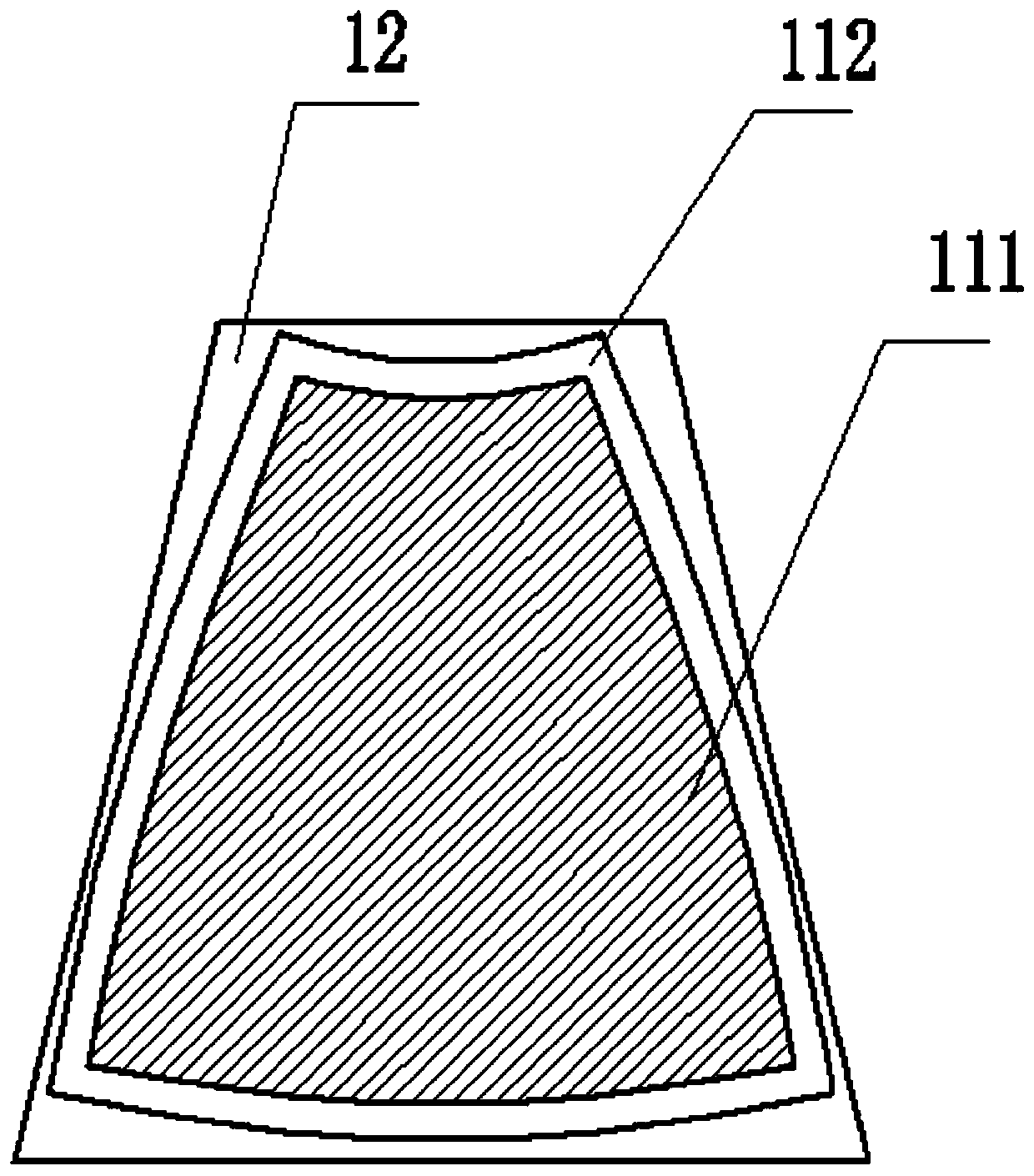

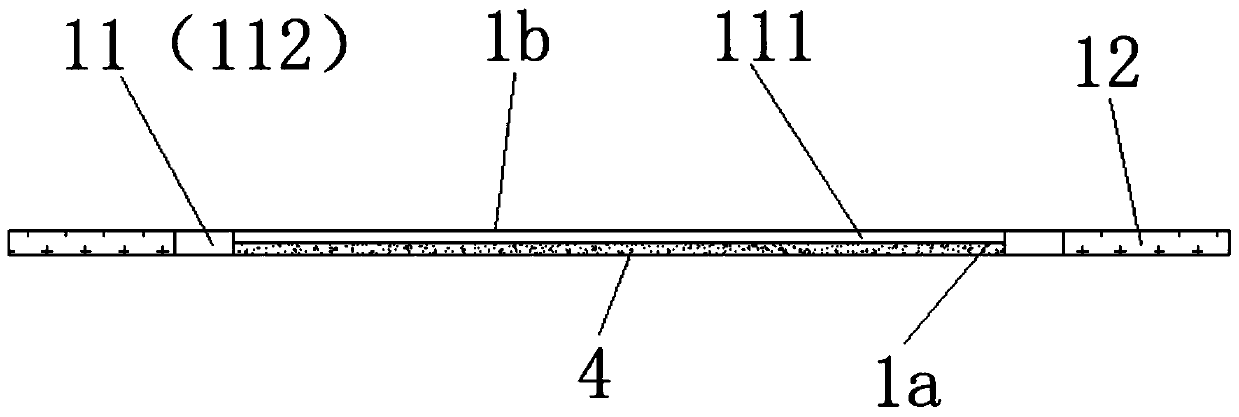

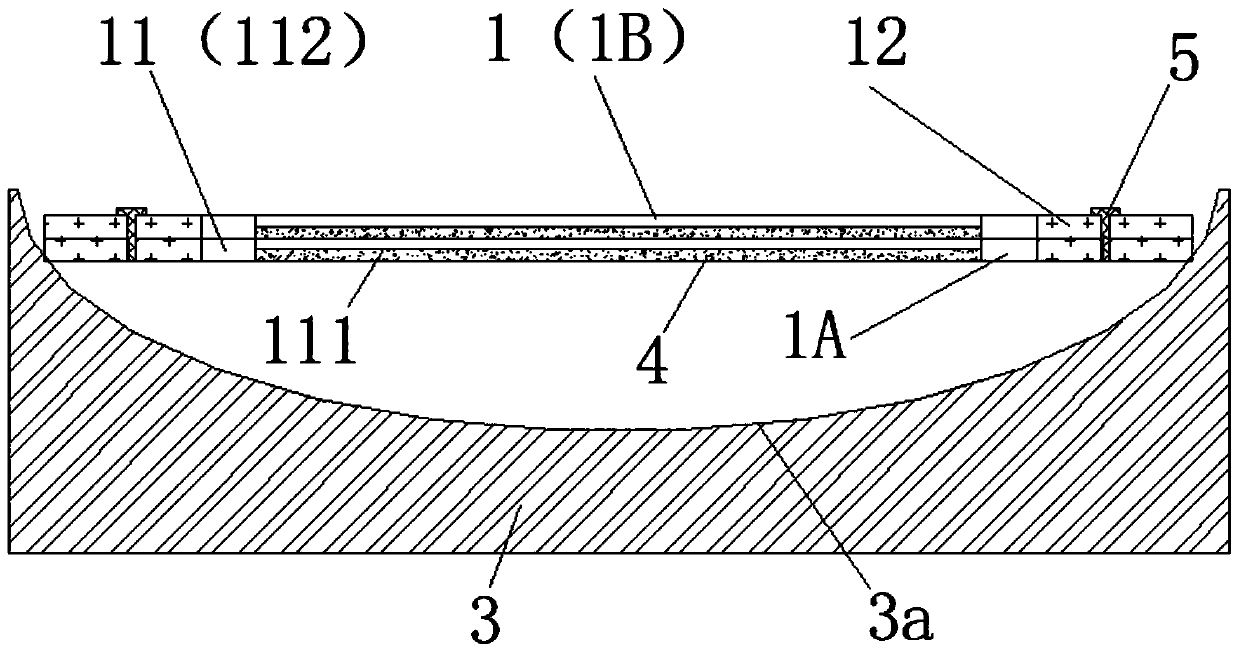

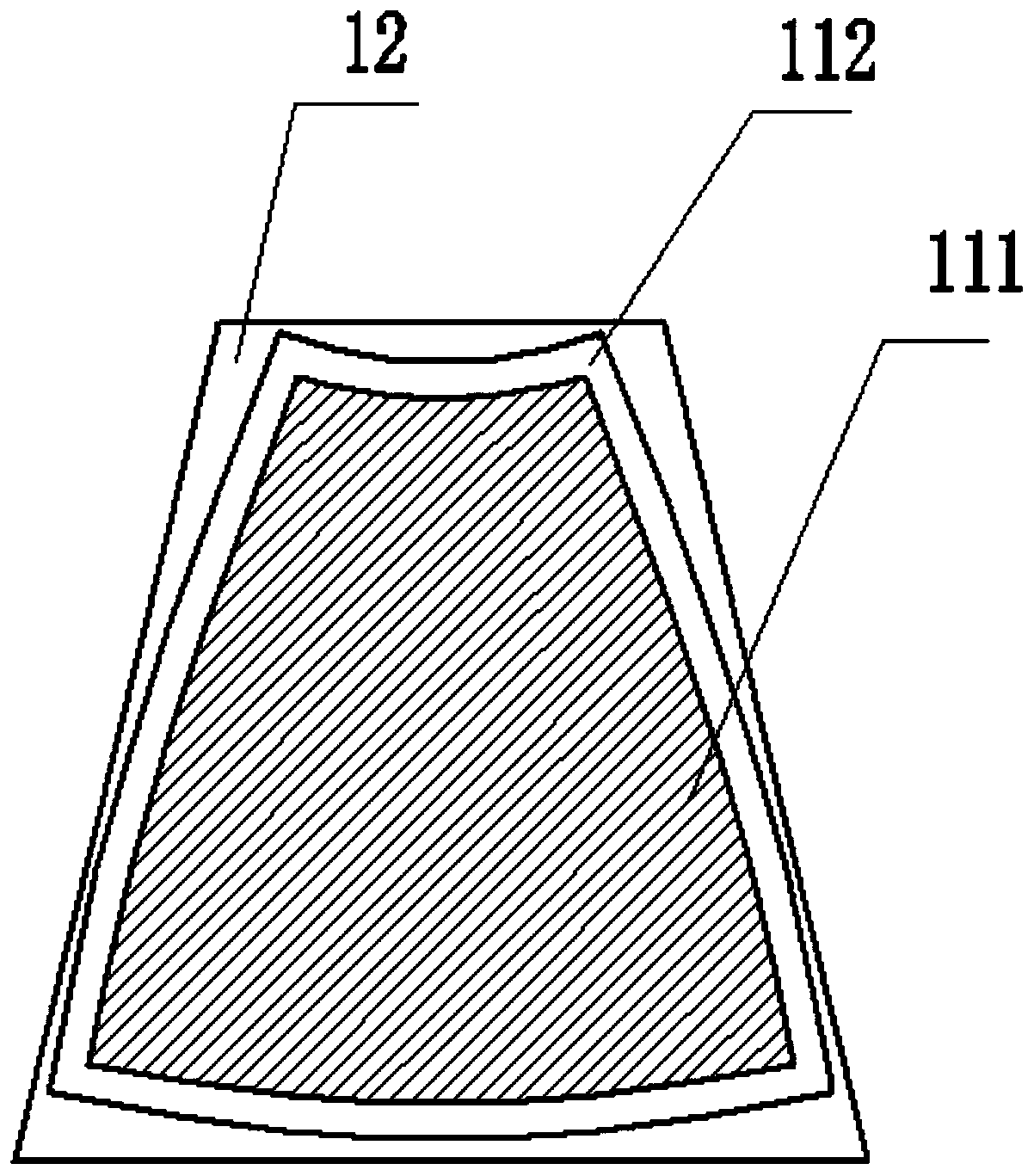

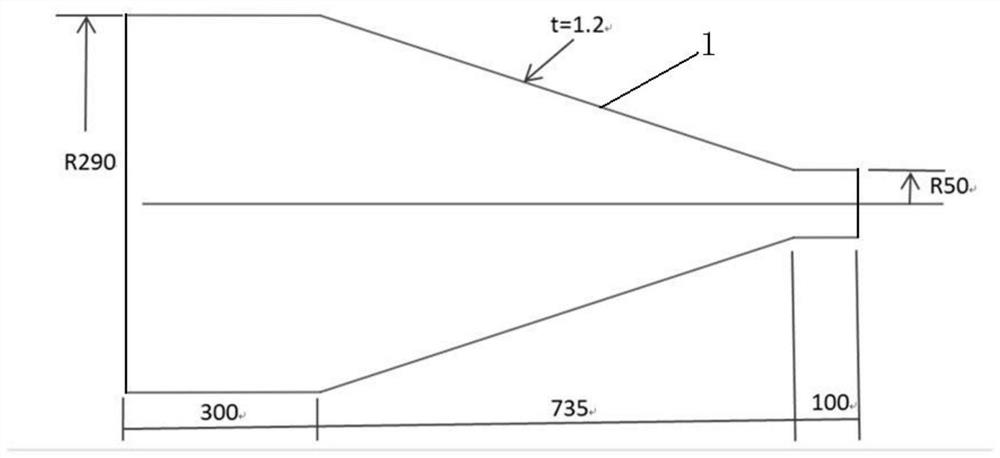

Multi-girder structure large size wind power blade and production method thereof

ActiveCN105508142AImprove the ability to resist buckling instabilityImprove structural rigidityEngine manufactureFinal product manufactureFiberCarbon fibers

The invention discloses a multi-girder structure large size wind power blade and a production method thereof. The multi-girder structure large size wind power blade is in a hollow layout structure, and comprises a blade envelope suction edge, a blade envelope pressure edge, main load-carrying construction girders and shearing-resistant web plates, wherein the blade envelope suction edge and the blade envelope pressure edge are combined to form a cavity structure of which the cross section is streamlined; a supporting structure formed by the main load-carrying construction girders and the shearing-resistant web plates is arranged in the cavity structure formed by the blade envelope suction edge and the blade envelope pressure edge; and the blade envelope suction edge and blade envelope pressure edge are in multisection combination structures, and are connected with the side surfaces of the main load-carrying construction girders through a plurality of edge sections respectively to form a blade envelope suction edge and blade envelope pressure edge integrated body. On the premise of ensuring the rigidity and strength of the blade, the resistance to buckling instability of the blade is improved; and by adopting a high-module carbon fiber spread layer, the weight of the blade can be reduced obviously, and loads, particularly a fatigue load, of the blade are reduced.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

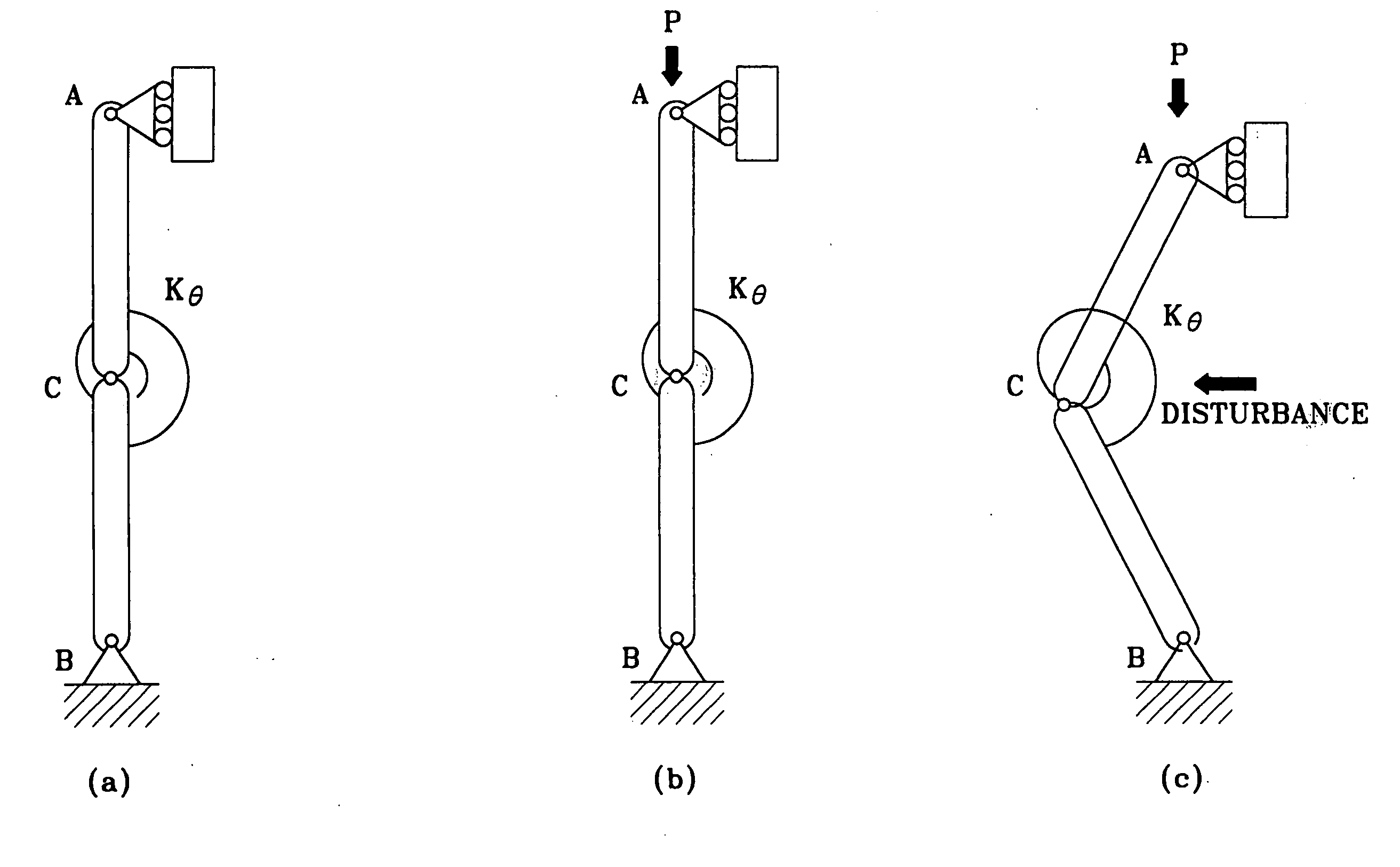

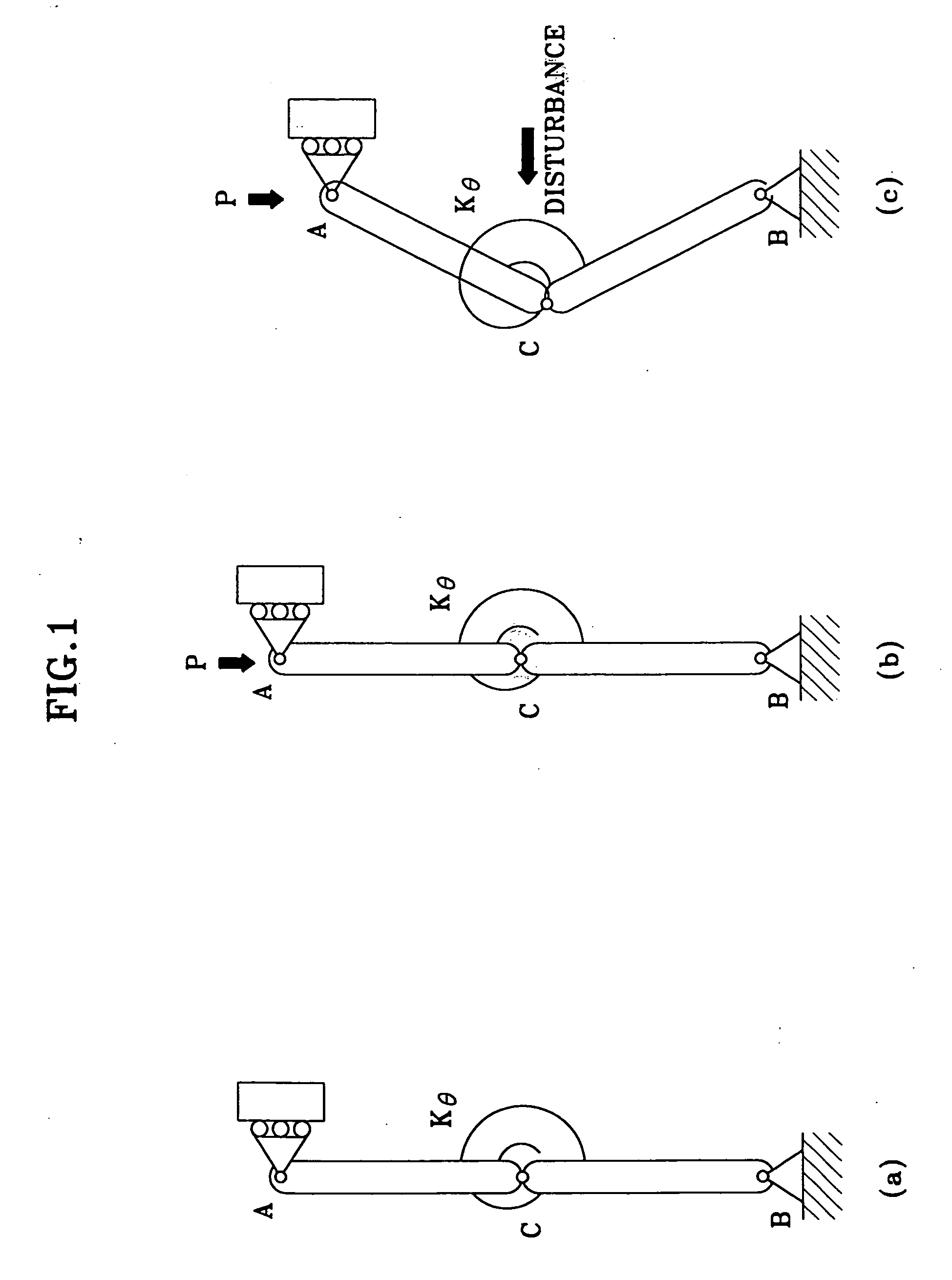

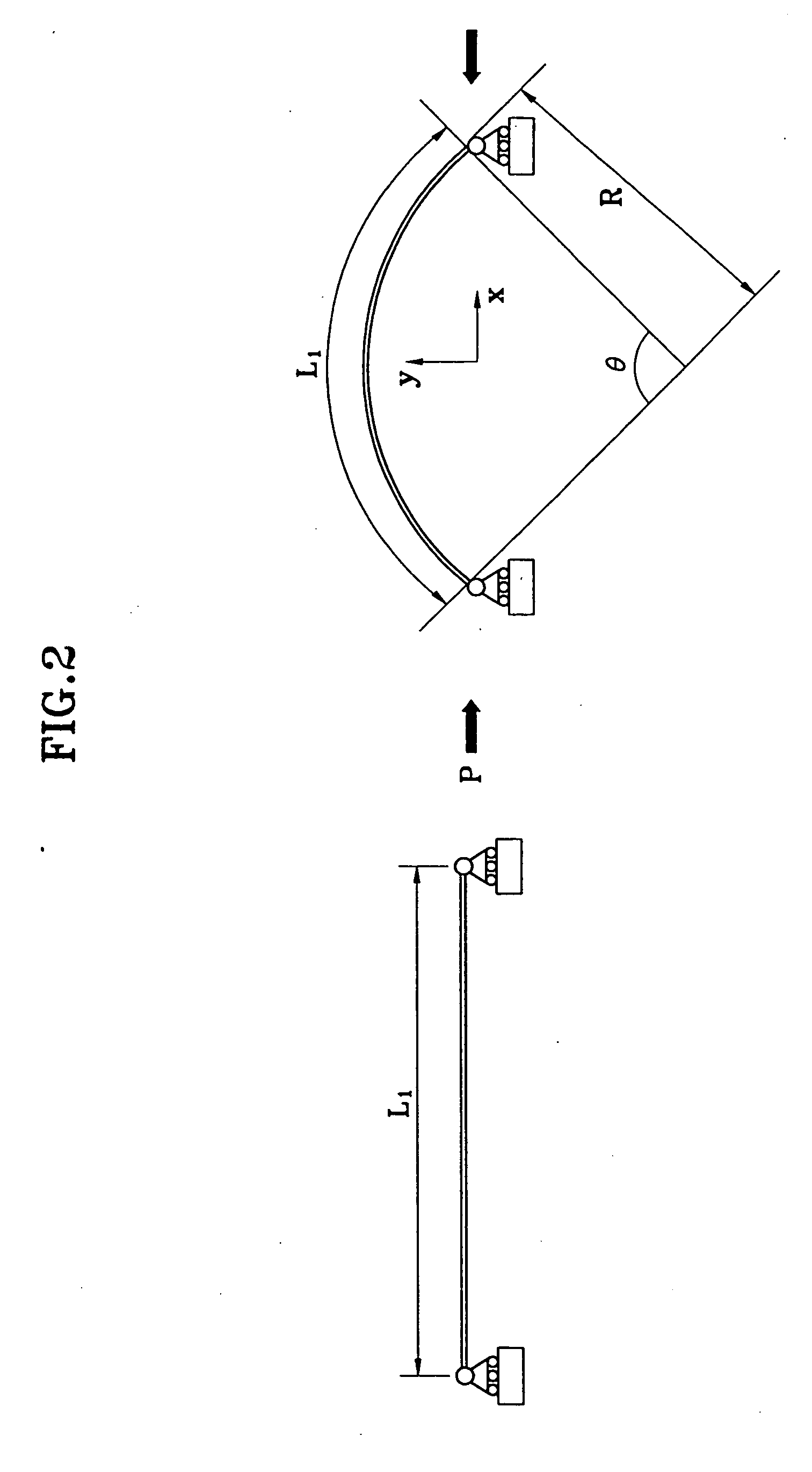

Immediate buckling model, hysteresis model, and cloth simulation method based on the invented models, and computer-readable media storing a program which executes the invented simulation method

InactiveUS20050080604A1Accurate expressionSimulation speedInspecting textilesMaterial strength using tensile/compressive forcesBuckling instabilitySimulation

A method of simulating the movement of cloth and a computer-readable medium storing a program which executes the method of simulating the movement of cloth, wherein cloth deformation by compressive force is simulated by an immediate buckling model when the compressive force is applied to two extremities of a deformation unit which models the cloth, cloth deformation by stretching is simulated by a spring model, and hysteresis phenomenon of cloth is simulated by using spring-slips for modeling. The immediate buckling model is based on a model of the present invention in which a deformation unit is not contracted by compressive force and generates an immediate bending deformation. As for the compressive force and stretching, simulation is implemented by separate models, hysteresis phenomenon of cloth is simulated by use of spring-clips for modeling, whereby cloth characteristics can be well reflected and the buckling instability of cloth caused by compressive force can be solved, thereby increasing the simulation speed.

Owner:FXGEAR

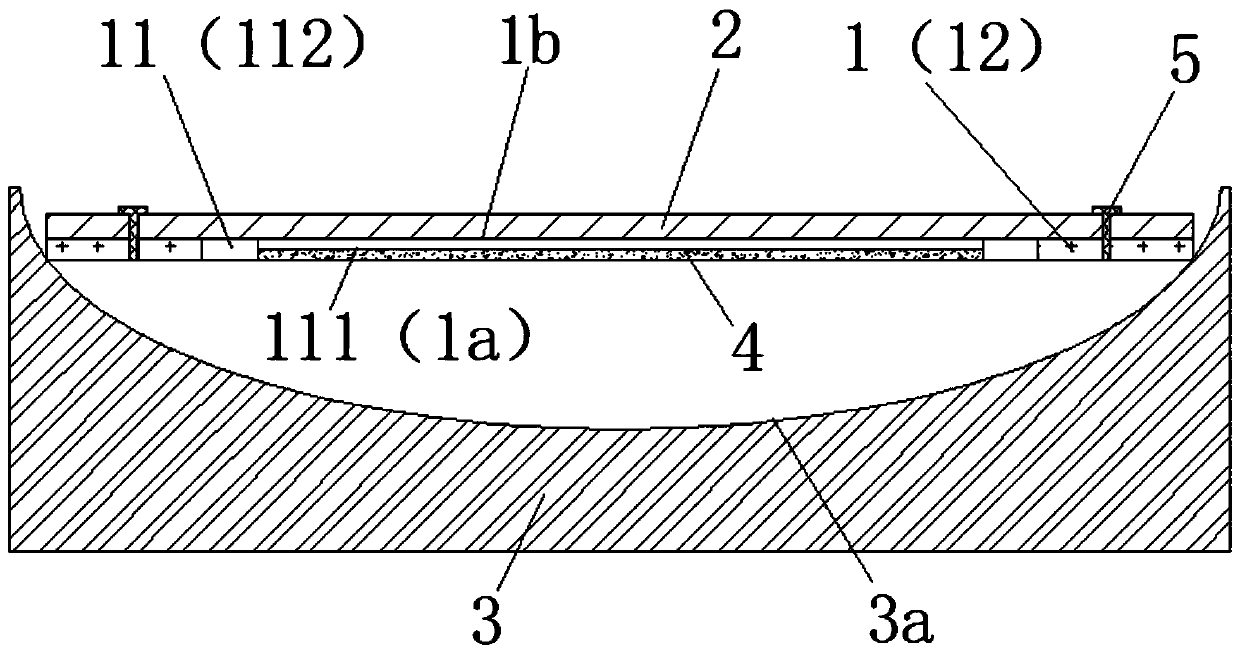

Economical creep aging forming method of large thin-wall component

ActiveCN111195678AInhibition of local buckling instabilitySave materialBuckling instabilityThin walled

The invention discloses an economical creep aging forming method of a large thin-wall component. The economical creep aging forming method comprises the steps that two component plates are firstly cutout; the two component plates are fixed to form a reinforcing plate, and the reinforcing plate is completely covered by ventilated felt and then placed on a mold surface, specifically, the first component plate is close to the mold surface, and the second component plate is away from the mold surface; a vacuum bag is pasted on the edge of a mold to make the vacuum bag and the mold form a closed space; the closed space is vacuumized to make the reinforcing plate approach or keep fit with the mold surface, then the reinforcing plate and the mold are put into a hot-pressing tank to be subjectedto vacuum creep aging forming, and each component plate is separated from the mold after the vacuum creep aging forming is finished; the allowance plate of the first component plate is milled off; andthe process of the vacuum creep aging forming of the reinforcing plate is repeatedly performed on the second component plate to finish a second component. According to the economical creep aging forming method, the precise shape-property integrated forming of the large thin-wall component can be realized, the local buckling instability condition of a component with weak rigidity in the creep aging forming process is effectively inhibited, and meanwhile, the material and the forming time can be saved.

Owner:CENT SOUTH UNIV

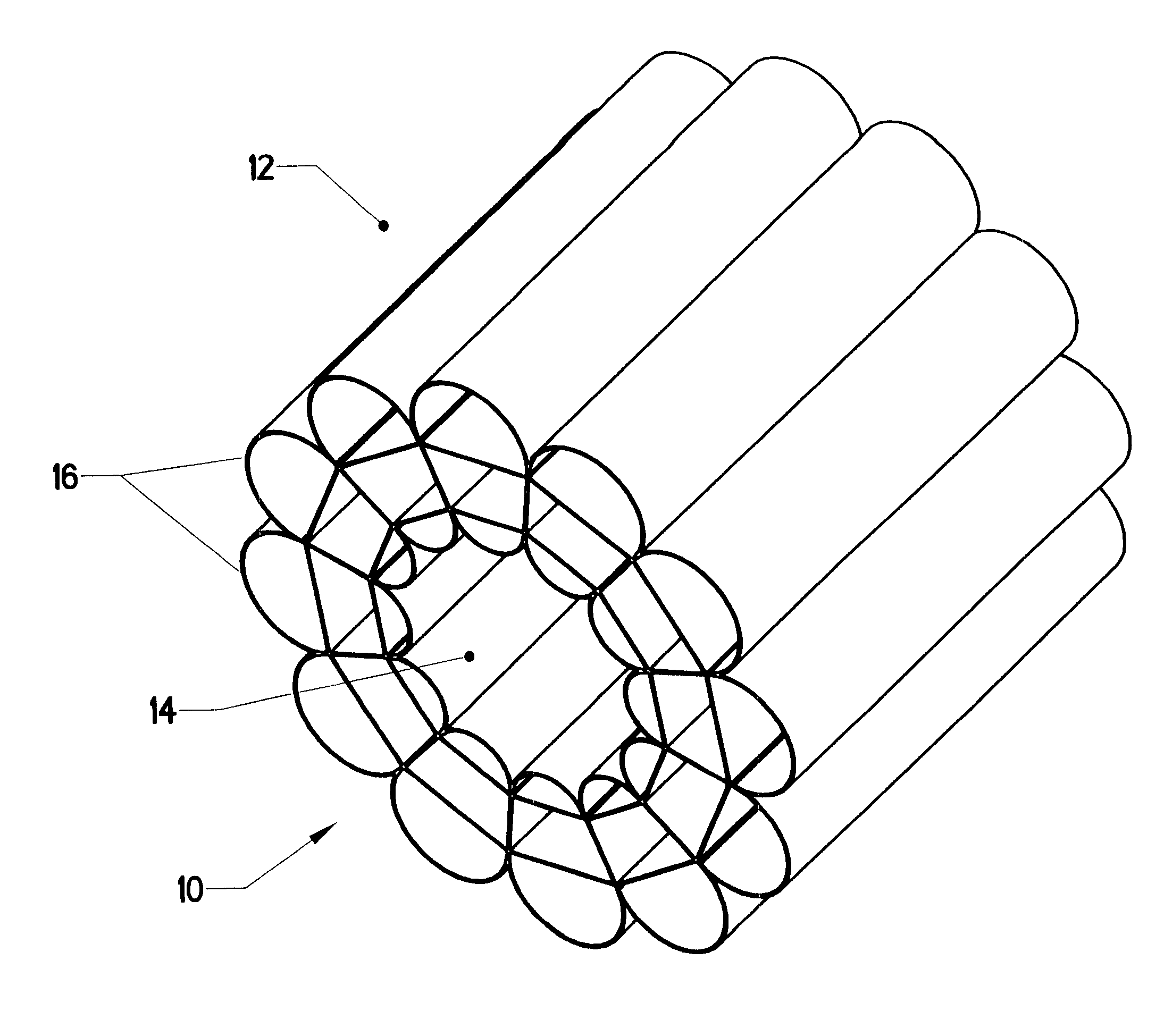

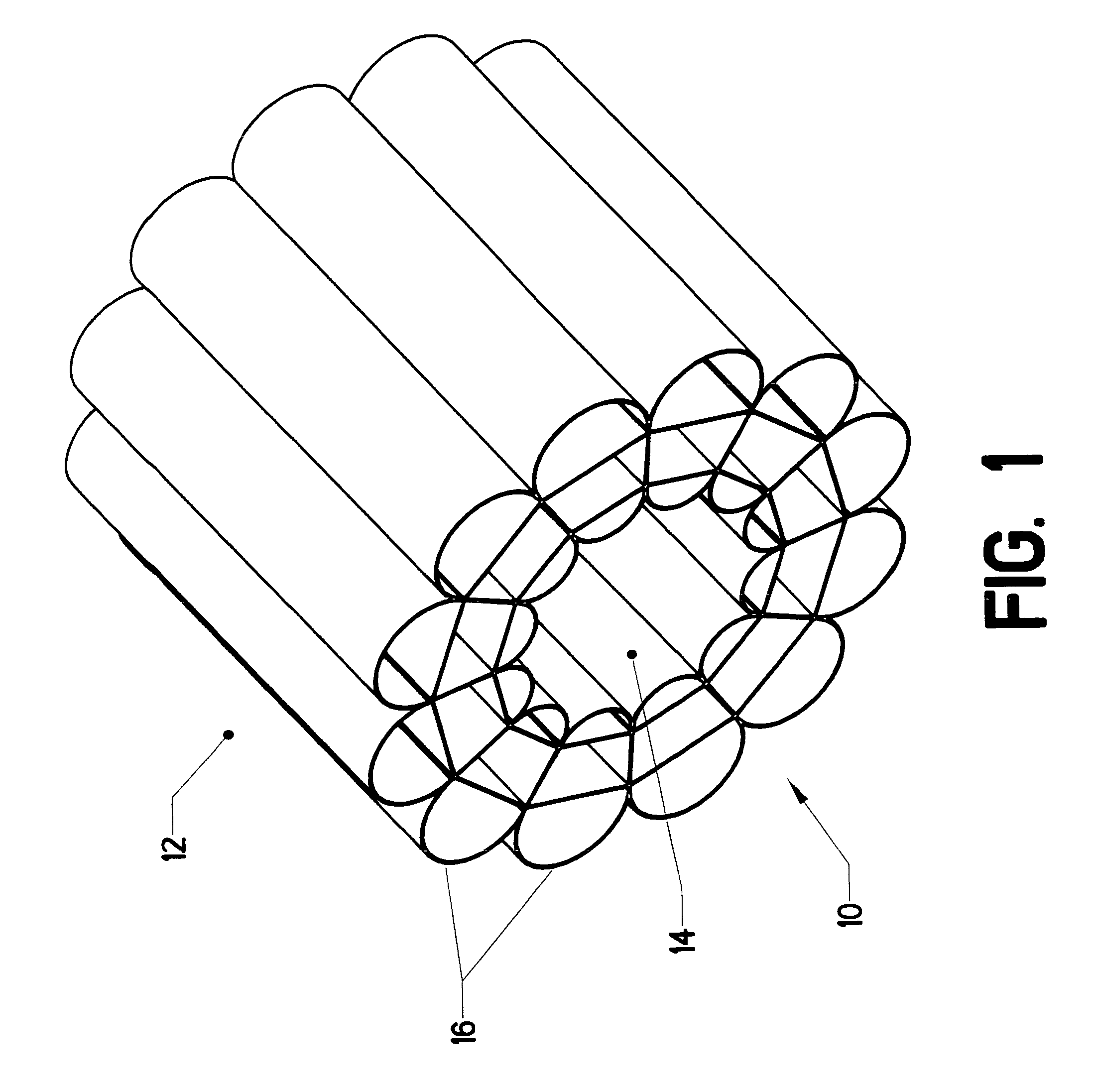

Light-weight vacuum chamber and applications thereof

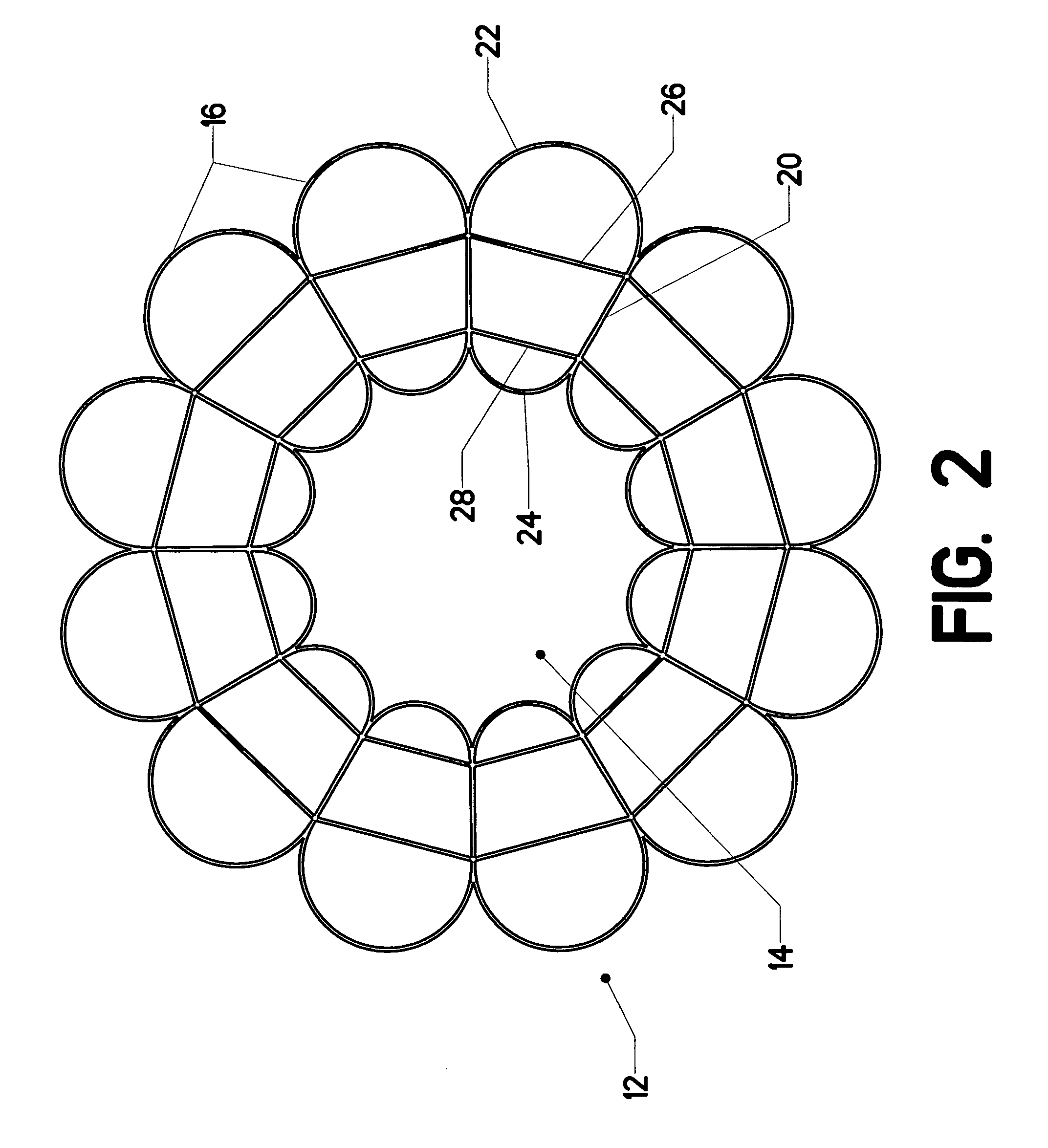

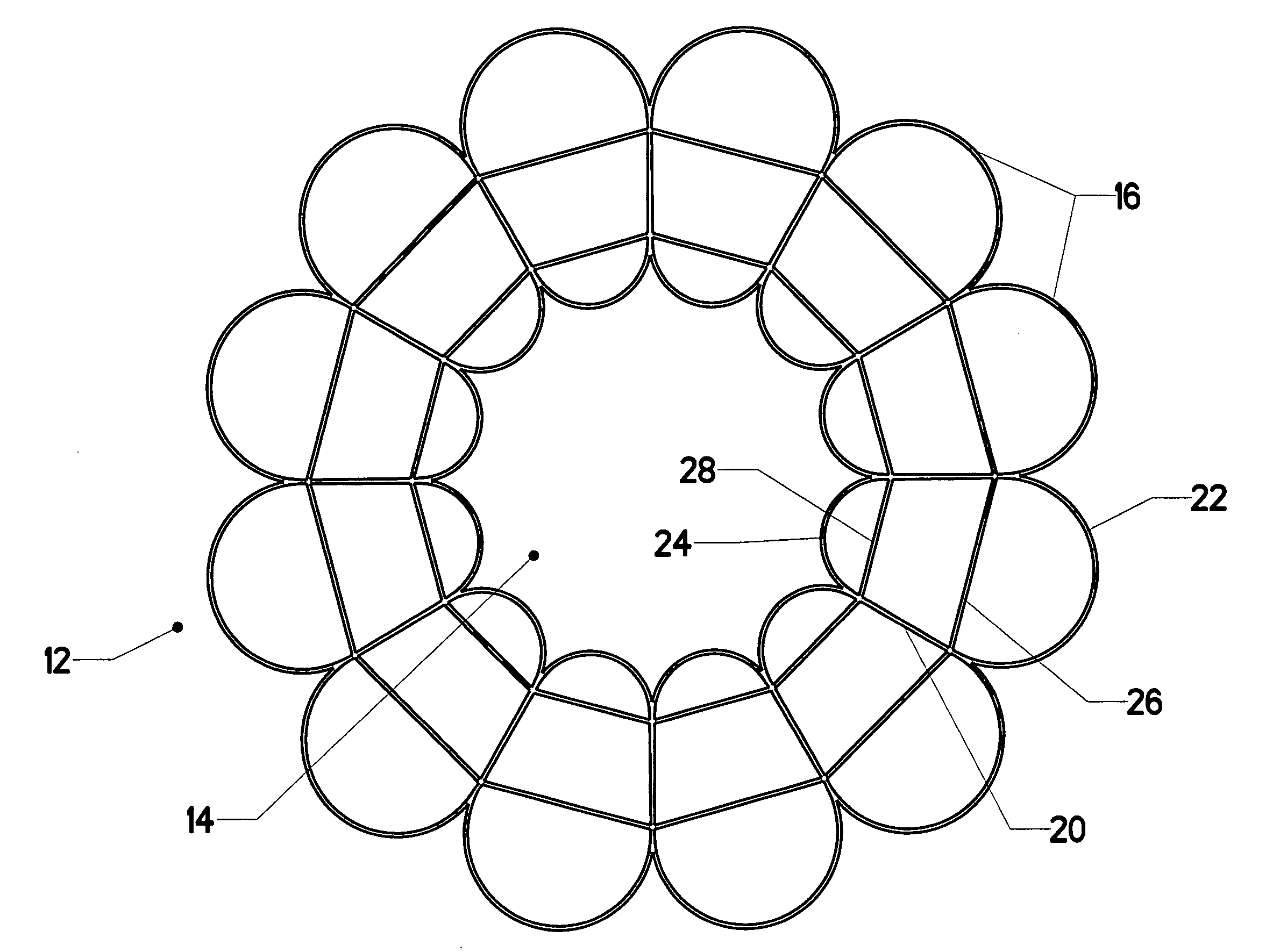

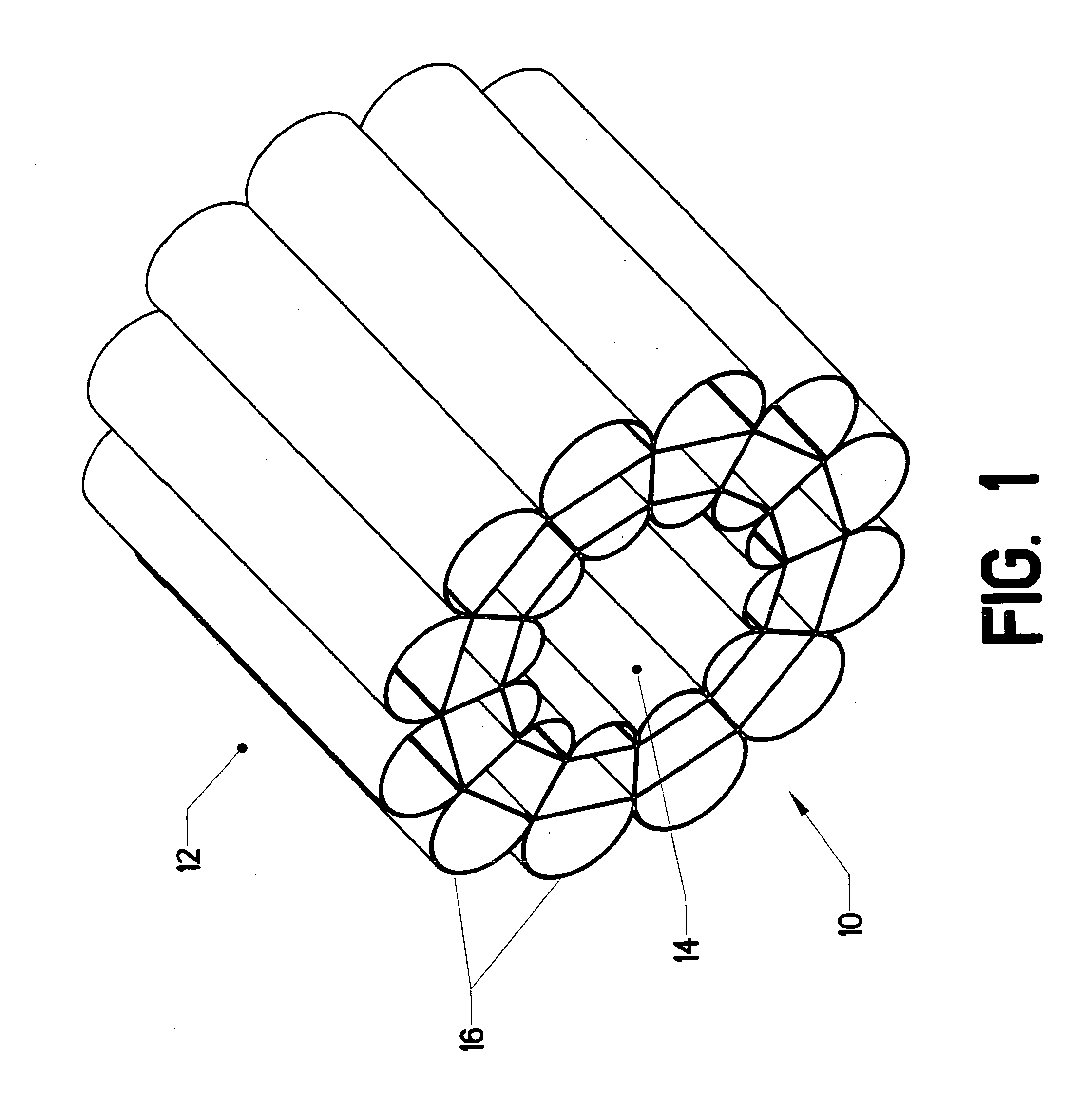

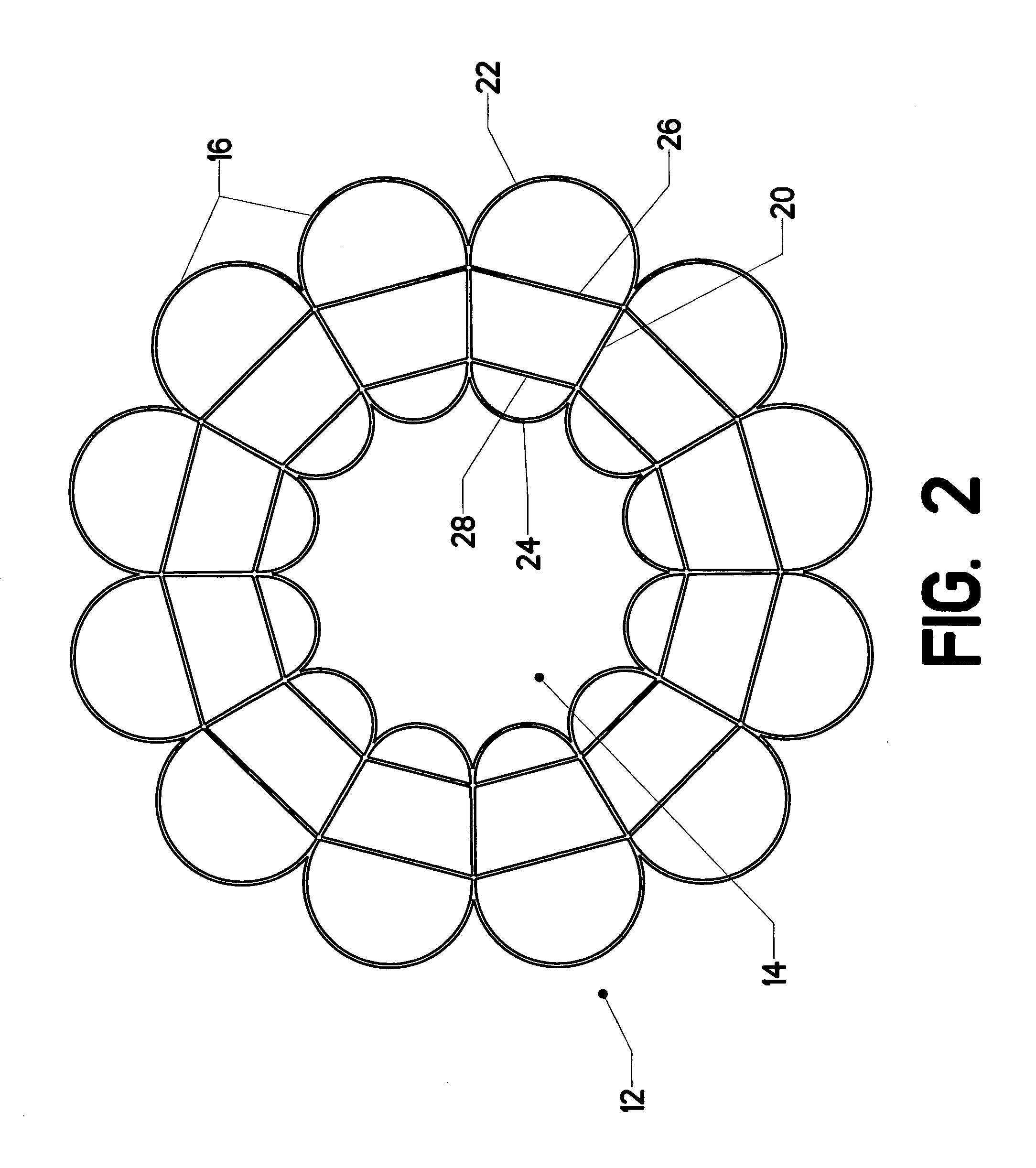

InactiveUS7708161B2Reduce instabilityLight vesselSolar heating energySolar heat devicesBuckling instabilityEngineering

A vacuum chamber with an innovative wall structure. Instead of a conventional homogenous wall structure, the invention uses an array of internally-pressurized, thin-walled cells to contain an enclosed volume. The walls are arranged so that when a vacuum is present in the enclosed volume, the cell walls are placed primarily in tension. In this way the likelihood of buckling instability is substantially reduced. The result is a much lighter vessel compared to a conventional homogenous wall vessel of similar strength.

Owner:FLORIDA STATE UNIV RES FOUND INC

Creep age forming method for large thin-wall component

The invention discloses a creep age forming method for a large thin-wall component. The method comprises the following steps that firstly, an aluminum alloy blank is cut into a component plate containing a component unfolding body; a metal plate is cut into an auxiliary plate with an outer contour consistent with an outer contour of the component plate; the component plate and the auxiliary plateare tightly attached and fixed to form a reinforcing plate; the reinforcing plate is placed on a mold face, and the reinforcing plate is completely coated with ventilated felt; a sealant is pasted onthe edge portion of a mold, and a vacuum bag is pasted on the sealant so as to make the vacuum bag and the mold jointly form a closed space; the closed space is vacuumized to make the reinforcing plate be close to or keep attached to the mold face; the reinforcing plate and the mold are put into an autoclave for vacuum creep age forming, and after completion, the component plate, the auxiliary plate and the mold are separated; and an allowance plate is milled. According to the method, precise shape and property integrated forming of the large thin-wall component can be achieved, and a local buckling instability condition of the component with the weak rigidity in the creep age forming process is effectively restrained.

Owner:CENT SOUTH UNIV

Novel U-shaped soft steel damper

PendingCN108412073APrevent bucklingAvoid sudden destructionProtective buildings/sheltersShock proofingStress concentrationBuckling instability

The invention discloses a novel U-shaped soft steel energy dissipation damper. A rectangular limiting steel plate and an auxiliary limiting piece are additionally arranged in the damper, and the situation that a U-shaped soft steel damper is prone to being subjected to buckling instability outside the face is avoided. The cross sections of fixing pieces for fixing U-shaped soft steel plates are each designed into a specific arc shape, and the form of fixing pieces can prevent the serious stress concentration phenomenon at the positions for fixing the U-shaped soft steel plates. A main body ofthe U-shaped soft steel damper of the structure is formed by connecting the U-shaped soft steel plates with a sliding guide rod, an upper connecting rod and a lower connecting rod; a limiting displacement protective plate is arranged on the sliding guide rod, and sudden damage of over large deformation to the damper is prevented; and the novel U-shaped soft steel energy dissipation damper is suitable for energy dissipation support, energy dissipation joints and energy dissipation connection of a building structure, and the application range of the novel U-shaped soft steel energy dissipation damper is wide.

Owner:ANHUI UNIV OF SCI & TECH

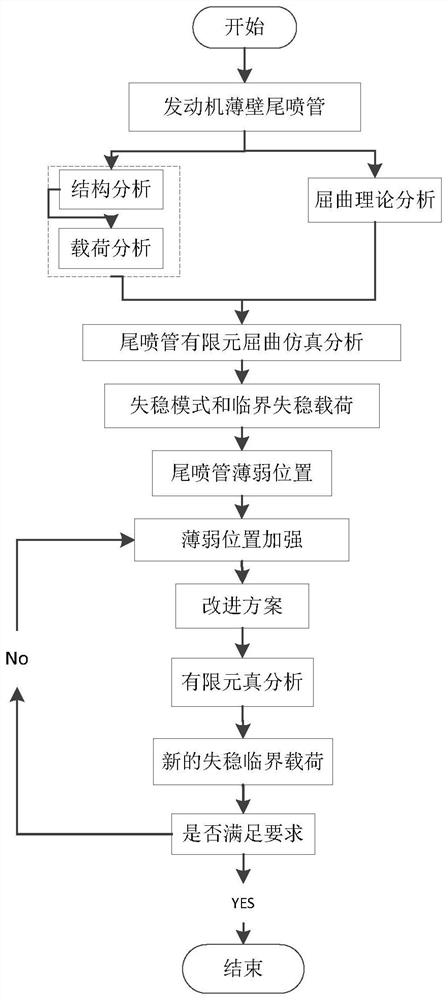

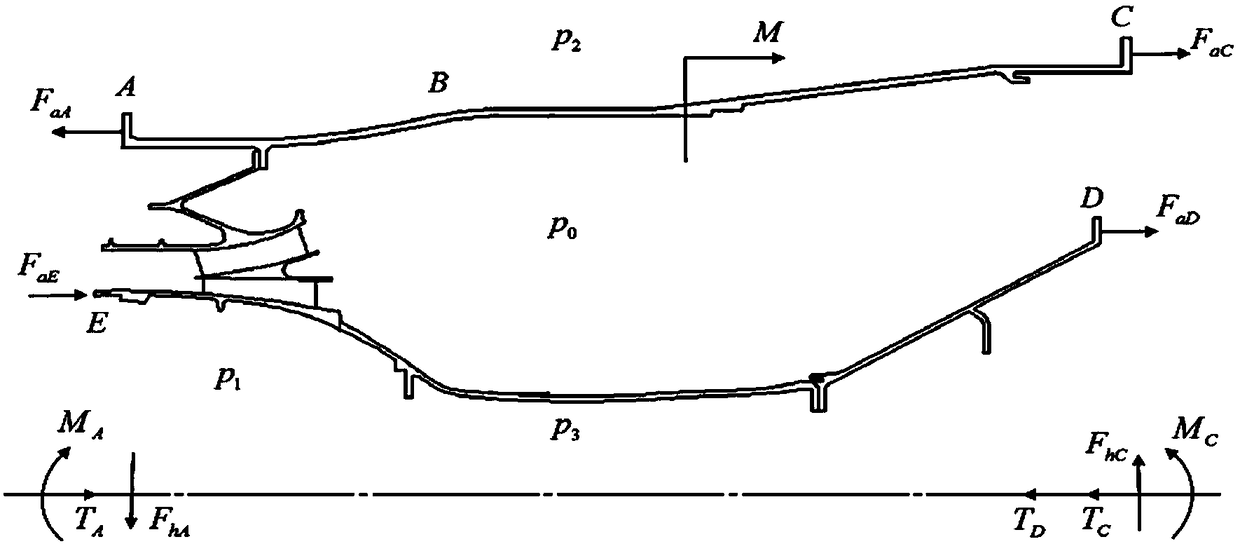

Anti-buckling design method for thin-wall exhaust nozzle of aero-engine

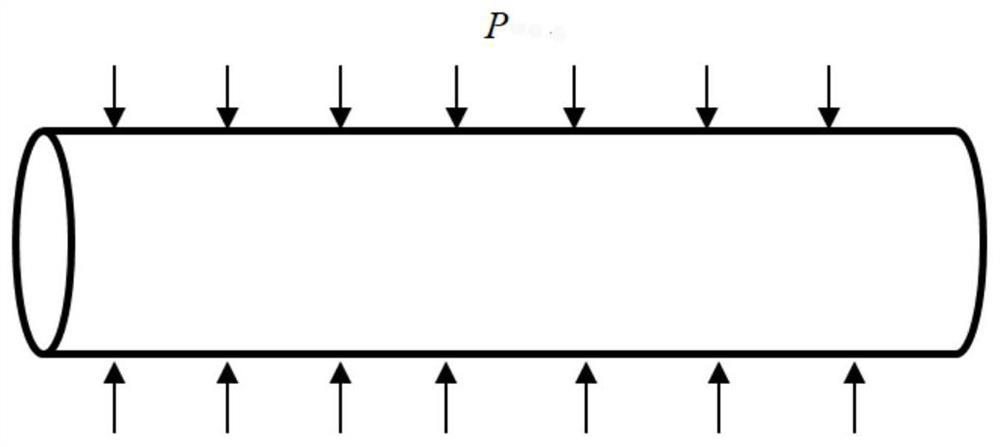

PendingCN114692300AImprove rigidityImprove stabilityGeometric CADDesign optimisation/simulationBuckling instabilityClassical mechanics

The invention belongs to the field of aero-engine structural design, and discloses an aero-engine thin-wall exhaust nozzle buckling resistance design method which comprises the following steps: S1, determining structural parameters and load of a thin-wall exhaust nozzle; s2, finite element buckling simulation analysis is conducted on the thin-wall exhaust nozzle, and a first-order critical instability load coefficient and a buckling instability vibration mode cloud picture are obtained; s3, based on a finite element buckling simulation analysis result, finding a maximum deformation position in the buckling instability vibration type cloud picture, and applying an annular mounting edge; and S4, finite element buckling simulation analysis is conducted on the thin-wall exhaust nozzle with the installation edge applied, a first-order critical instability load coefficient and a buckling instability vibration mode cloud picture are obtained and calculated, whether the first-order critical instability load coefficient meets the requirement or not is judged, if not, the steps S3-S4 are repeated, and if yes, the process is ended. The rigidity and stability of the thin-wall spray pipe can be effectively improved, the structural weight cannot be obviously increased, and meanwhile the overall appearance and pneumatic performance of the spray pipe cannot be affected.

Owner:TAIYUAN UNIV OF TECH

Nested multifunctional vibration isolation rubber support

ActiveCN110984392AAvoid spreadingUniform deformationProtective buildings/sheltersShock proofingVertical vibrationRollover

The invention discloses a nested multifunctional vibration isolation rubber support which comprises a vertical vibration isolation assembly and a horizontal vibration isolation assembly embedded in the vertical vibration isolation assembly. The vertical vibration isolation assembly adopts thick laminated rubber, directly bears the vertical load of an upper structure, and provides the vertical lowrigidity required by isolating environmental vibration; the horizontal vibration isolation assembly adopts thin laminated rubber, can generate horizontal shearing deformation in cooperation with the vertical vibration isolation assembly, and provides horizontal restoring force and damping required by isolating earthquake function; and the horizontal vibration isolation assembly does not directly bear the upper vertical load, provides anti-buckling constraint for the high-flexibility vertical vibration isolation assembly, and avoids rollover or buckling instability of a high-flexibility vibration isolation support. The nested multifunctional vibration isolation rubber support not only can play a role in isolating environmental vibration, but also can play a role in isolating earthquake, andalso has high deformation stability.

Owner:GUANGZHOU UNIVERSITY

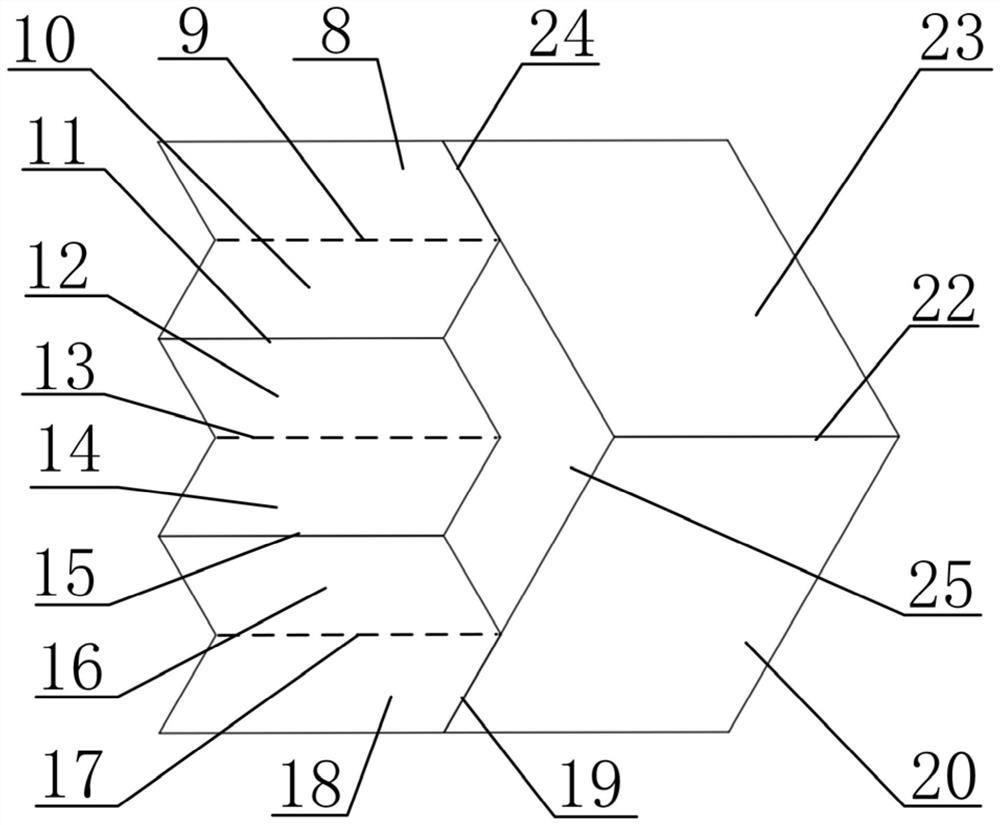

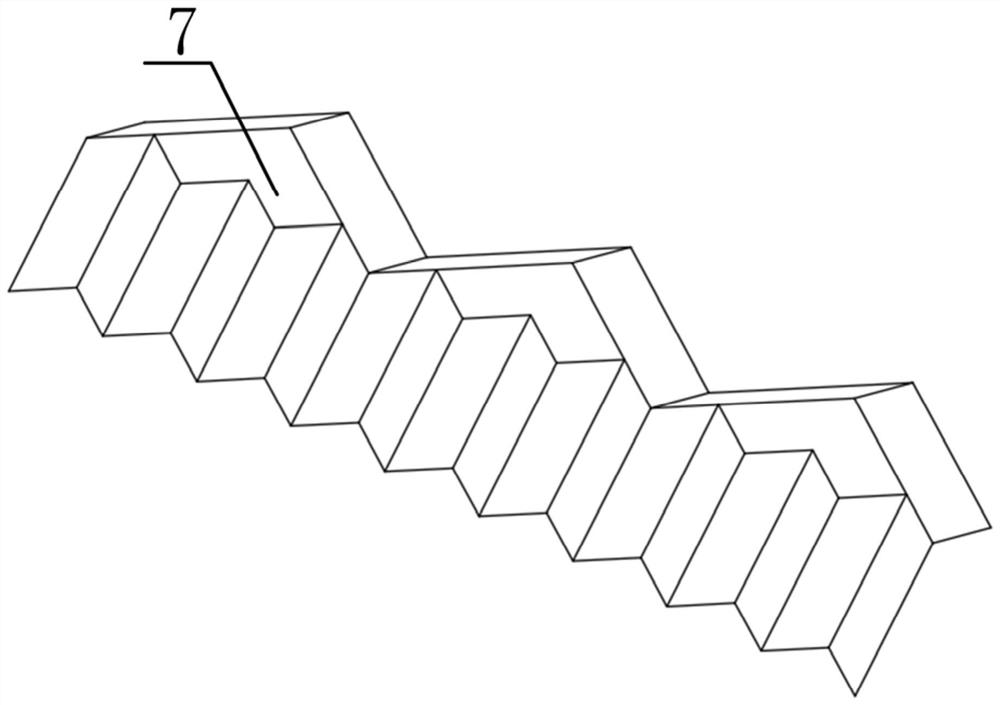

Stacked paper folding structure with variable stiffness characteristic

ActiveCN112208677AWith variable stiffnessIncrease stiffnessPaper/cardboard articlesRailway componentsBuckling instabilityPaperboard

The invention discloses a stacked paper folding structure with variable stiffness characteristics, which comprises a plurality of layers of paper folding tubes stacked up and down, each paper foldingtube comprises two symmetrically arranged paper folding plates, each paper folding plate comprises a plurality of basic units, the basic units are connected in sequence, each basic unit comprises n small planes and two large planes, n is an even number greater than 2, the width ratio of the large plane to the small plane is n / 2, and the large plane and the small plane are parallelograms. Due to the fact that all layers of paper folding pipes of the stacked paper folding structure are different in rigidity, when the stacked paper folding structure is subjected to compression force from top to bottom, the stacked paper folding structure generates a layer-by-layer progressive buckling instability process, firstly, the paper folding pipe with the minimum rigidity is subjected to buckling instability, and then the paper folding pipe with the second small rigidity is triggered to be subjected to buckling instability; therefore, the paper folding pipe with the maximum rigidity is obtained through recursion, and then the variable rigidity characteristic of the stacked paper folding structure is achieved. According to specific requirements, multiple layers of paper folding pipes with different rigidities can be stacked, and multiple variable stiffness characteristics are achieved.

Owner:GUANGZHOU UNIVERSITY

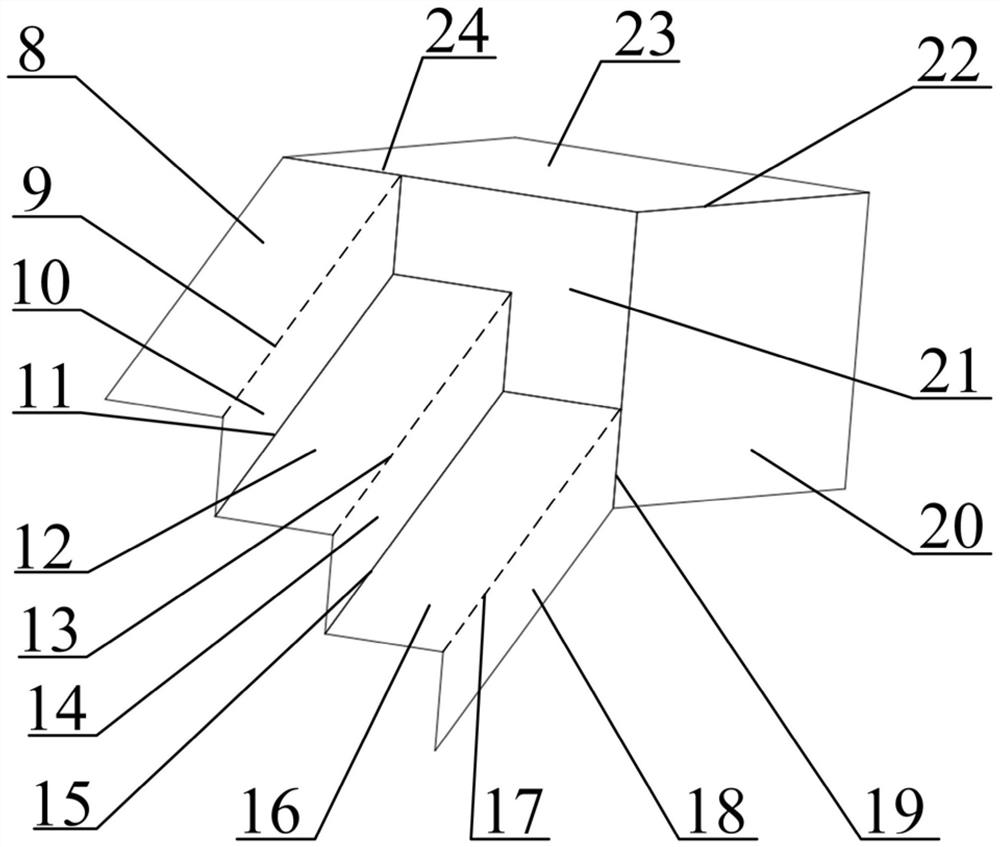

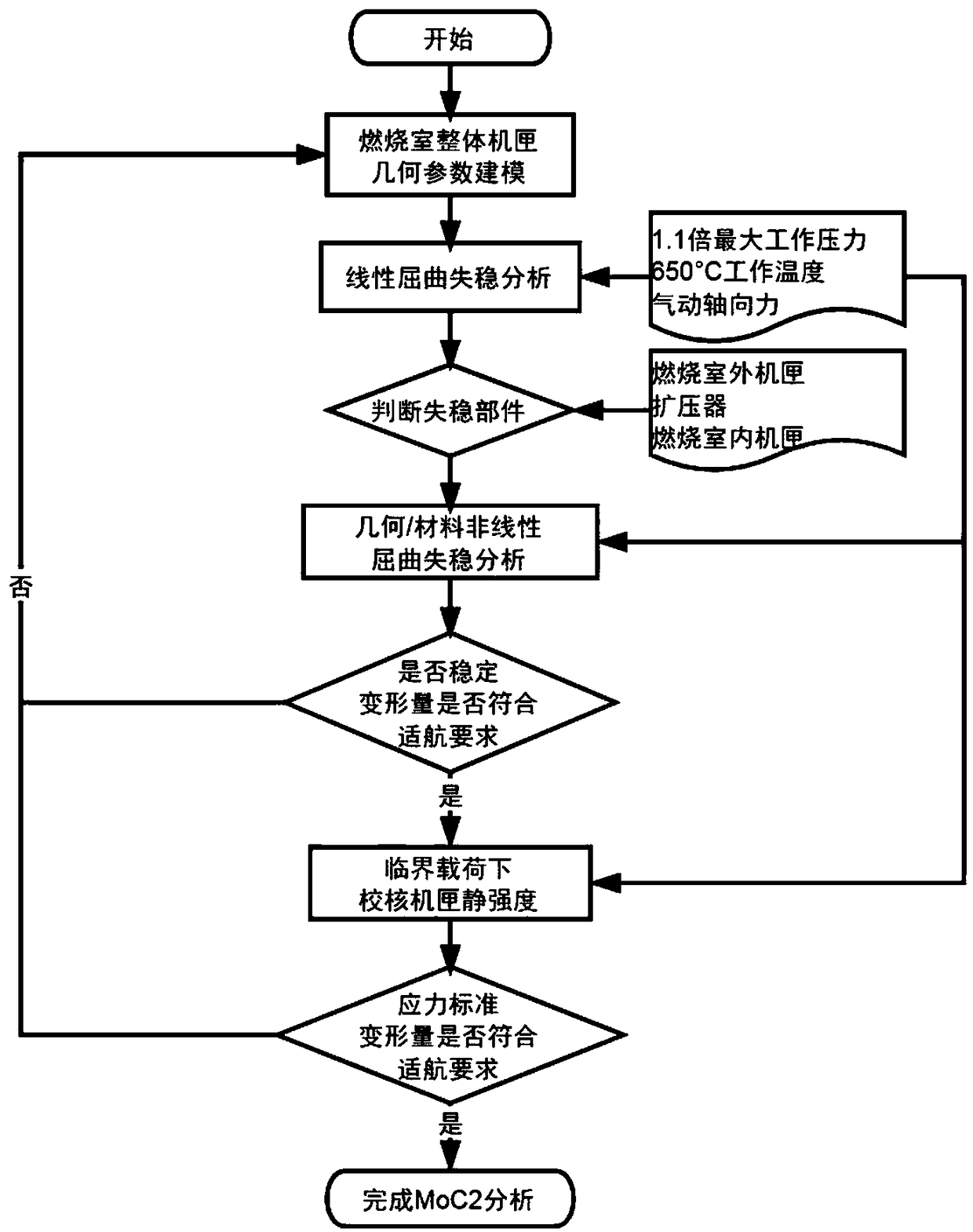

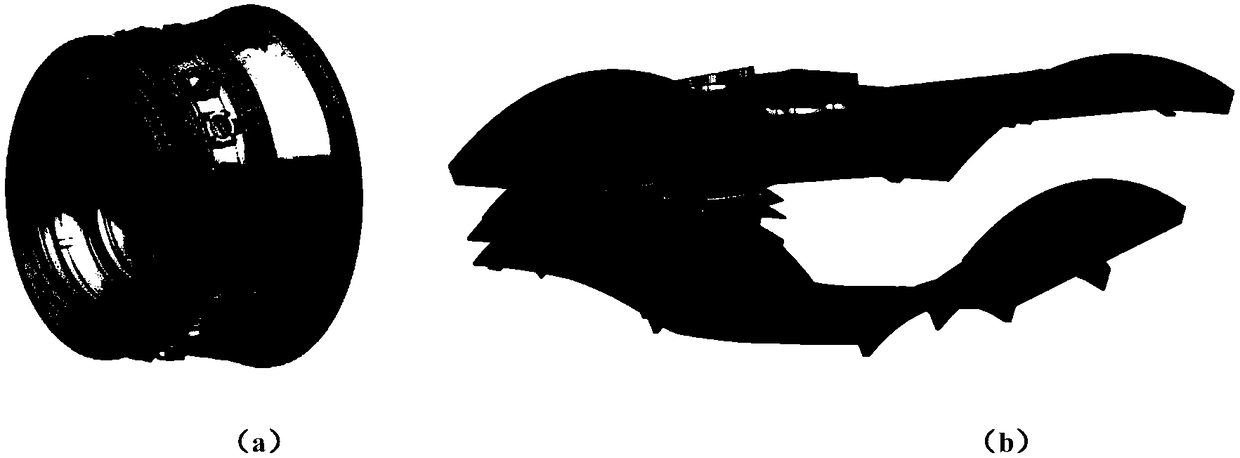

Airworthiness compliance verification method for combustion chamber casing

ActiveCN108897959AGeometric CADDesign optimisation/simulationStatic timing analysisCombustion chamber

The invention discloses an airworthiness compliance verification method for a combustion chamber casing. The method comprises the steps of (1) determining a load boundary condition of the combustion chamber casing according to clauses and requirements of CCAR 33.64, and determining a displacement boundary condition according to a constraint situation under an actual working condition; (2) conducting an eigenvalue buckling analysis on the combustion chamber casing, and obtaining eigenvalues and eigenvalue buckling modes under different orders; (3) selecting a first-order buckling instability portion of the casing as analysis focus, and performing a geometrical and material double nonlinear buckling analysis under a condition (1); (4) calculating a stability safety factor as the condition for determining the stability of the casing; (5) using a nonlinear buckling critical load obtained in (3) through analysis as an internal and external gas pressure difference, loading the boundary condition in (1) for a static strength analysis, and determining the compliance of the combustion chamber casing with the airworthiness clauses. The method simultaneously considers the stability and staticstrength of the combustion chamber casing, proposes a targeted verification analysis method, and indicates the airworthiness compliance of the combustion chamber casing.

Owner:BEIHANG UNIV

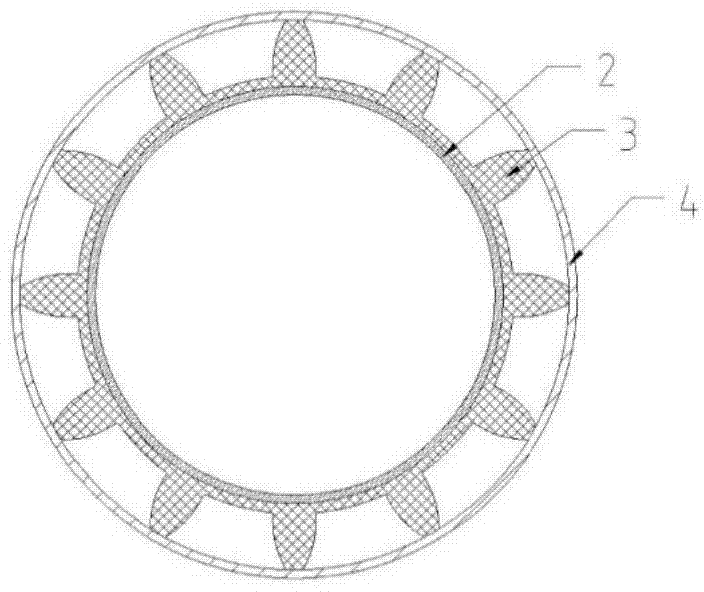

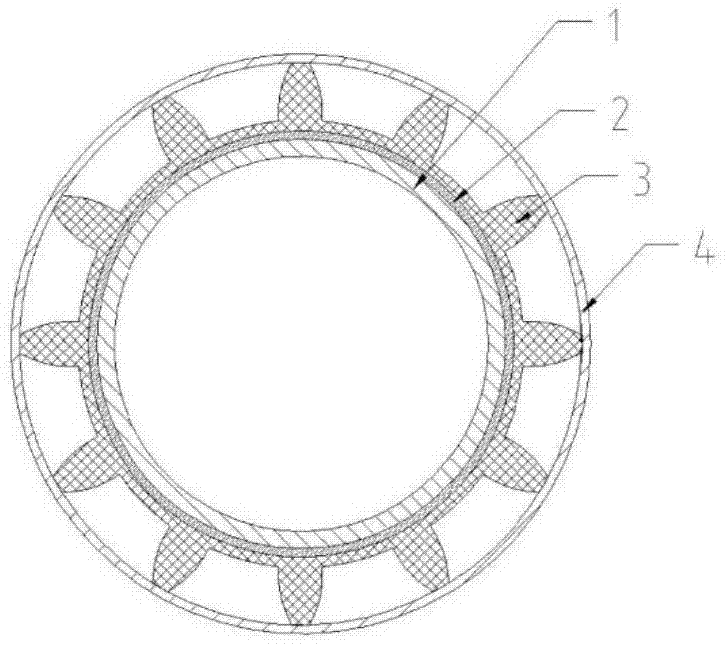

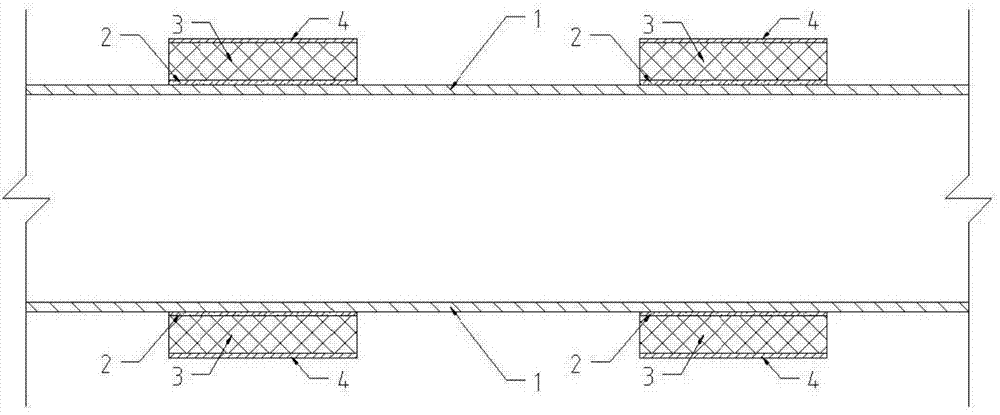

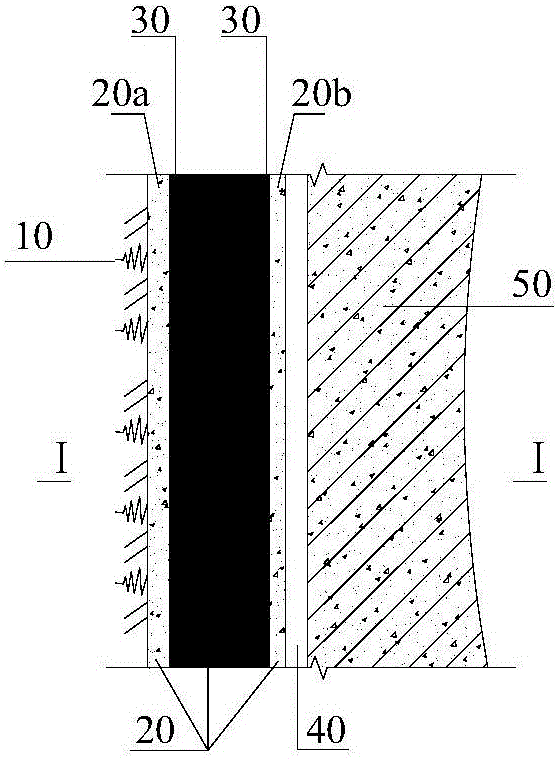

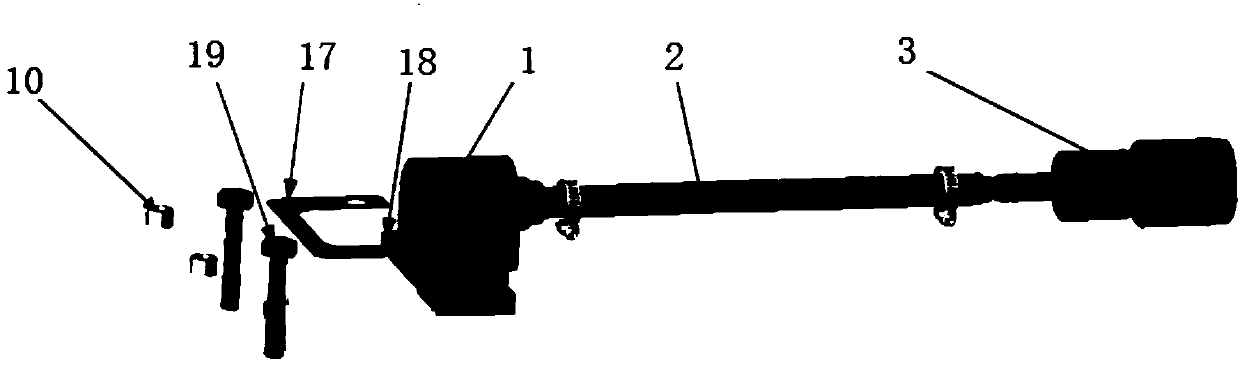

Device for lateral displacement control during integral buckling of submarine pipeline

InactiveCN104500837ARestrained buckling deformationIncrease lateral soil resistancePipe laying and repairOcean bottomEngineering

The invention belongs to the technical field of ocean engineering and relates to a device for lateral displacement control during integral buckling of a submarine pipeline. The device comprises a strain sensor, a power source, a control circuit, an annular rigid structure with peripheral projections, a protecting layer and an actuating mechanism capable of enabling the protecting layer to be stripped off. A support of the strain sensor is a ring matched with the external diameter of the pipeline, strain foils of the strain sensor are distributed circumferentially uniformly along the ring, the internal diameter of the annular rigid structure is larger than the external diameter of the support of the strain sensor, the protecting layer is arranged on the outer portion of the annular rigid structure and used for protecting the annular rigid structure to enable the annular rigid structure not to contact with a seabed, and the control circuit is used for controlling whether or not the actuating mechanism actuates and the protecting layer needs to be stripped off according to strain signal values collected by the strain sensor. The device is capable of solving the problem of overlarge lateral displacement during integral buckling of the submarine pipeline effectively and controlling lateral buckling instability of the pipeline.

Owner:TIANJIN UNIV

Light-weight vacuum chamber and appalications thereof

InactiveUS20080128434A1Avoid heavyReduce instabilitySolar heating energySolar heat devicesBuckling instabilityEngineering

A vacuum chamber with an innovative wall structure. Instead of a conventional homogenous wall structure, the invention uses an array of internally-pressurized, thin-walled cells to contain an enclosed volume. The walls are arranged so that when a vacuum is present in the enclosed volume, the cell walls are placed primarily in tension. In this way the likelihood of buckling instability is substantially reduced. The result is a much lighter vessel compared to a conventional homogenous wall vessel of similar strength.

Owner:FLORIDA STATE UNIV RES FOUND INC

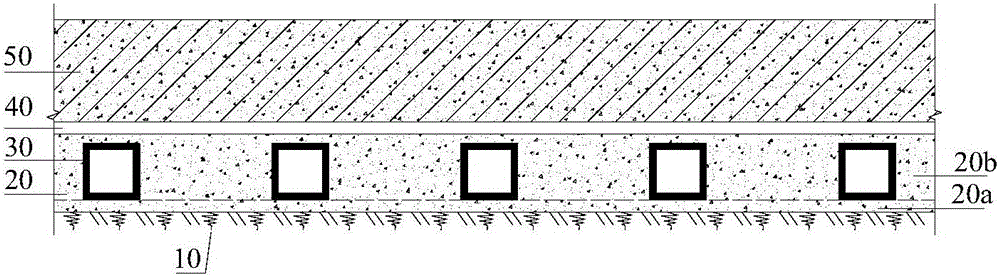

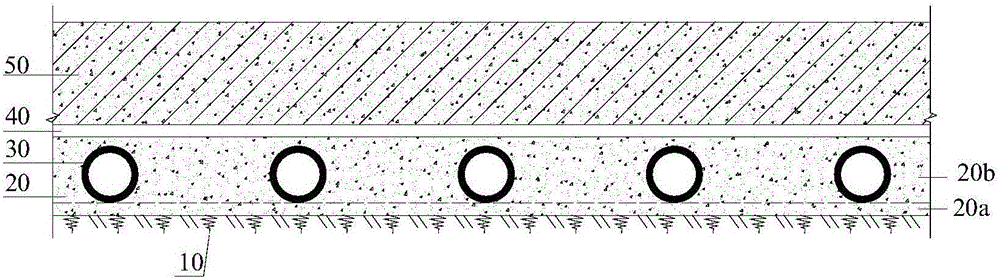

Preliminary tunnel support structure with internal box type steel frames

InactiveCN106050261AEffective gripGive full play to the structural strengthUnderground chambersTunnel liningShotcreteBuckling instability

Provided is a preliminary tunnel support structure with internal box type steel frames. The stress performance of a preliminary support can be effectively improved, the steel frames are protected against buckling instability, and the structural strength of the preliminary support can be given to full play. The preliminary tunnel support structure comprises a sprayed concrete layer covering rock surrounding a cave, and the steel frames buried in the sprayed concrete layer at intervals in the tunnel excavating direction. Each steel frame is the box type steel frame with the rectangular cross section, and each box type steel frame is composed of a pair of flange plates and webs, wherein the flange plates and the webs are perpendicular and welded into a whole; and filling concrete is poured into the portions, except vaults, of the interiors of the box type steel frames.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

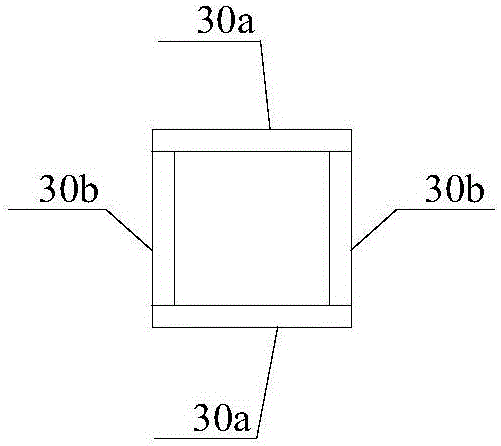

Welding simulation method

PendingCN113806973ADesign optimisation/simulationSpecial data processing applicationsResidual strainBuckling instability

The invention discloses a welding simulation method. The method comprises the following steps: a large welding structure stress deformation prediction thought based on local joint thermoelastoplasticity-overall structure elasticity calculation; an adaptive grid technology based on an octree; a step of performing thermal elastic-plastic finite element analysis on each local welding joint model to obtain welding residual plastic strain information corresponding to each local welding joint model; and a step of importing the welding residual plastic strain information into a pre-established structural part full-process welding process model. The invention aims to provide the welding simulation method, which has the advantages of breaking through the difficulty of considering the efficiency and the precision of welding software, realizing an assembly line type GUI design, meeting a modular structure of various requirements and being easy to learn and operate, solves the problems that an inherent strain method only considers partial components of residual strain and is difficult to predict sheet bending, buckling instability and mechanical behaviors of a thick-wall structure, and improves the solving efficiency by an order of magnitude.

Owner:苏州喻云仿科技有限公司

Forging forming die and method for cylindrical part plate with small fillet characteristic

ActiveCN112139424AImprove mechanical propertiesSolve buckling instability problemsForging/hammering/pressing machinesConstant loadBuckling instability

The invention discloses a forging forming die for a cylindrical part plate with a small fillet characteristic. The forging forming die comprises an inner side male die, an outer side male die, a female die, a female die base plate and a floating mandrel. The invention further provides a forging forming method for the cylindrical part plate with the small fillet characteristic. A pipe blank with the outer diameter equal to that of a cylindrical target part is put on the female die base plate, and the inner side male die and the outer side male die are driven to synchronously move downwards at aconstant speed to upset and extrude the pipe blank to form an inner flange upsetting piece. After moving to the lower limit, the outer side male die is kept still with constant load, the inner side male die continues to descend to shear the inner flange upsetting part, a metal material is forced to continuously flow to a closed cavity defined by the inner side male die, the outer side male die, the female die, the female die base plate and the floating mandrel, and finally the cylindrical part with the small fillet characteristic is upset and extruded. The cylindrical part with the small fillet characteristic is formed in one procedure, the buckling instability problem is solved, the defects of folding, inward sinking and the like are overcome, and the fillet filling plumpness and the mechanical property of the target part are improved.

Owner:XIANGTAN UNIV

Method for controlling lateral displacement of submarine pipeline

InactiveCN104455728ARestrained buckling deformationIncrease lateral soil resistancePipe laying and repairOcean bottomBuckling instability

The invention belongs to the field of ocean engineering technology and particularly relates to a method for controlling lateral displacement of a submarine pipeline. An adopted control device comprises stress sensors, a power source, a control circuit, an annular rigid structure with a protrusion on the periphery, a protective layer, and an actuating mechanism capable of enabling the protective layer to be stripped off. Supports of the stress sensors are circular rings matched with the outer diameter of the pipeline, strain gauges of the stress sensors are distributed in the annular direction of the circular rings, the inner diameter of the annular rigid structure is larger than the outer diameter of the supports of the stress sensors, and the protective layer is arranged outside of the annular rigid structure. The control device is arranged outside the weak position of the submarine pipeline, and the control circuit controls the actuating mechanism to act according to whether strain signals collected by the stress sensors are too large, so that the protective layer is stripped off. By means of the method for controlling the lateral displacement of the submarine pipeline, the problem of too large lateral displacement in the overall buckling process of the submarine pipeline can be effectively solved, and the lateral buckling instability of the pipeline is controlled.

Owner:TIANJIN UNIV

Power transmission tower reinforcing device capable of preventing bending and buckling instability

ActiveCN113833344AAvoid frictional damageIncreased bending stiffnessBuilding repairsTowersTransmission towerBuckling instability

The invention provides a power transmission tower reinforcing device capable of preventing bending and buckling instability, and belongs to the technical field of iron tower reinforcement. The power transmission tower reinforcing device comprises reinforcing channel steel, a reinforcing steel column, two pieces of reinforcing T-shaped steel and a reinforcing outer connecting plate, wherein the reinforcing outer connecting plate is fixedly connected with two free ends of the reinforcing channel steel separately; the reinforcing outer connecting plate and the reinforcing channel steel are enclosed to form a rectangular cavity for accommodating the reinforcing steel column and the two pieces of reinforcing T-shaped steel; the two pieces of reinforcing T-shaped steel and the reinforcing channel steel are enclosed to form a triangular cavity for accommodating power transmission tower angle steel; and the reinforcing steel column and the reinforcing T-shaped steel are separately positioned at the inner side and the outer side of two limbs of the power transmission tower angle steel. According to the power transmission tower reinforcing device capable of preventing bending and buckling instability provided by the invention, the two pieces of reinforcing T-shaped steel and the reinforcing outer connecting plate are arranged at the outer side of the power transmission tower angle steel, and the reinforcing steel column and the reinforcing channel steel are arranged at the inner side of the power transmission tower angle steel, so that the power transmission tower reinforcing device has a prominent bending and buckling preventing effect, has enough stability, is simple in structure, is simple and convenient to mount, and is low in cost.

Owner:HEBEI HUIZHI ELECTRIC POWER ENG DESIGN CO LTD +3

Combined type buckling-restrained joint component

ActiveCN110130486AReduce the impactReduce energy consumptionProtective buildings/sheltersShock proofingJoint componentBuckling instability

The invention discloses a combined type buckling-restrained joint component. The combined type buckling-restrained joint component comprises a damping plate, a first guiding connecting plate, a secondguiding connecting plate, a supporting component connecting plate, a first connecting plate and a second connecting plate; and the plastic deformation of a support-frame structure system is concentrated at the position of a supporting connection joint. According to the principle of buckling energy consumption of metal materials, a supporting joint plate is creatively conceived as the damping plate, a buckling-restrained structure solves the buckling instability problem of the joint plate, the joint plate utilizes own plastic deformation ability to improve the energy consumption capacity of the structure, meanwhile, the combined structure facilitates the disassembly and replacement of the damping plate, the difficulty of construction operation is reduced, and the ability of the structure to quickly restore a use function after the disaster is improved.

Owner:NORTHEAST DIANLI UNIVERSITY

Construction method of long-span composite beam bridge with steel truss and corrugated steel web

ActiveCN109112946AMeet the needs of the designPrevent bucklingBridge structural detailsBridge erection/assemblyBuckling instabilityWave shape

The invention discloses a construction method of long-span composite beam bridge with steel truss and corrugated steel web. The steel truss and corrugated steel web beam segment is arranged outside the fulcrum lining concrete segment in the bridge. The steel truss and corrugated steel web beam segment can effectively share the shear load of beam segment, prevent buckling instability of corrugatedsteel web and structural damage, meet the design requirements of long-span corrugated steel web beam bridge, and solve the problem of large shear of corrugated steel web of long-span corrugated steelweb bridge lining outer beam segment. Accordingly, the inventors also established corresponding construction methods. The invention is applicable to the design and use of beam bridges with spans of 160m and above, and has certain engineering significance and great economic value.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

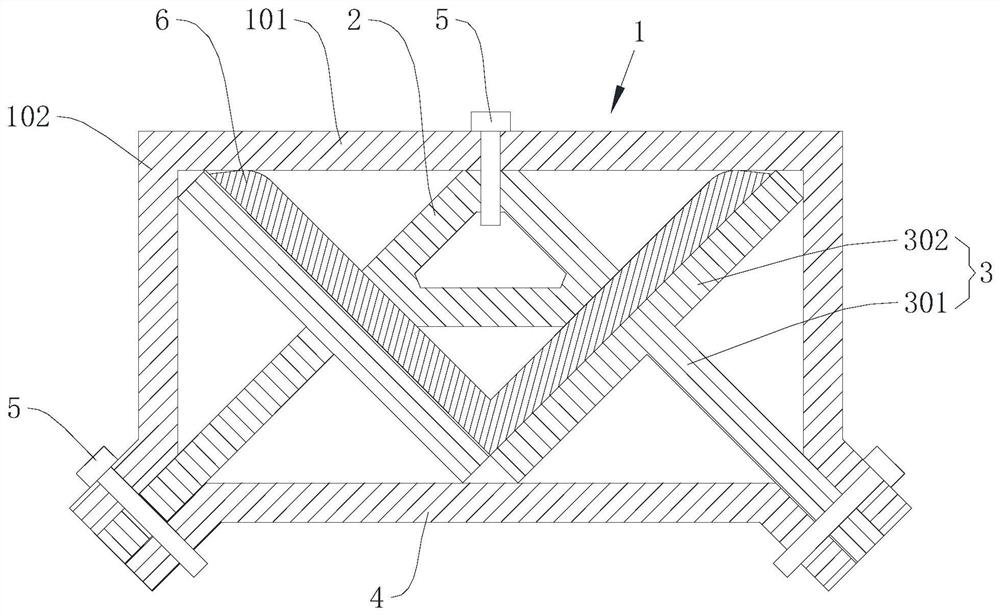

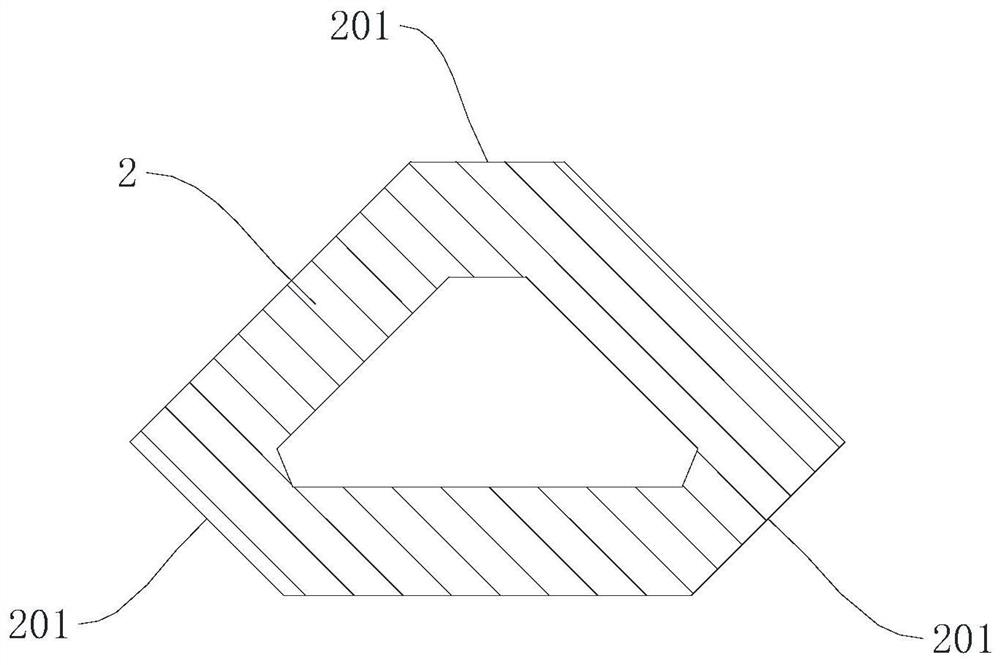

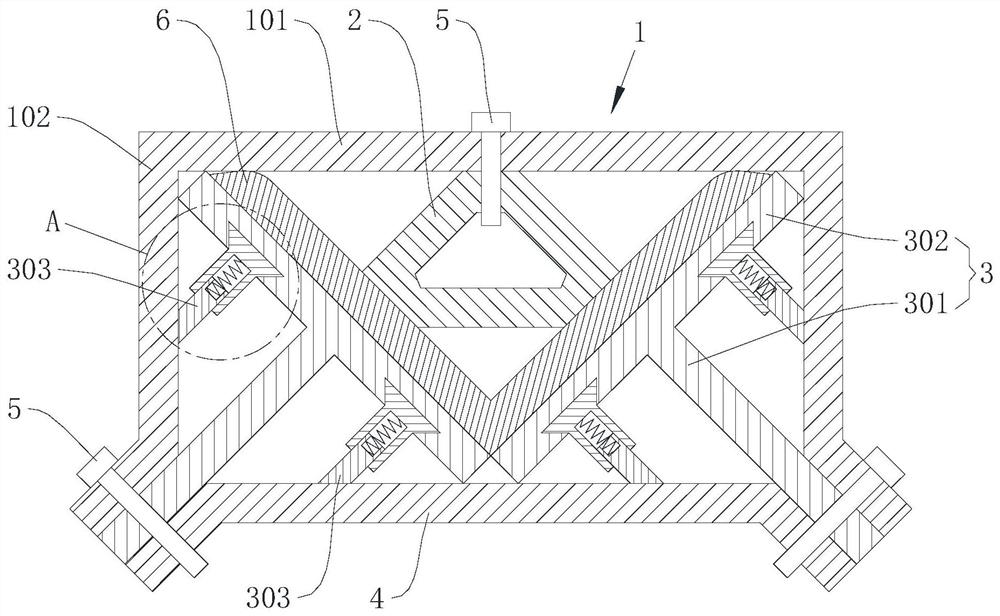

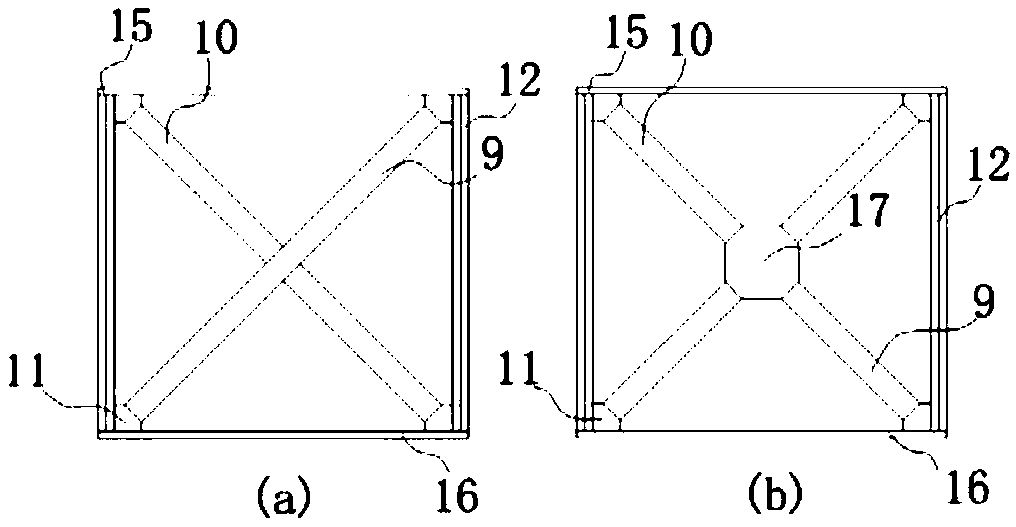

X-brace type energy dissipation device

ActiveCN104453009APrevent bucklingReduce calculation lengthShock proofingBuckling instabilityNuclear engineering

The invention discloses an X-brace type energy dissipation device which comprises core battens, lug plates, dowels, gaskets, an upper ejection plate and a lower ejection plate. Each sliding contact position is provided with antifriction materials. The core battens are arranged in a crossed mode and in pairs. Designers can selection reasonable pair numbers of the core battens according to needs. According to the X-brace type energy dissipation device, axial deformation of the core battens is utilized to dissipate seismic energy, the lug plates mainly play a role of fixing, and the dowels in the centers of the core battens play a role of enabling every two core battens to be connected, when one core batten is pressed, the computation length can be reduced by utilizing connection dowels of the pulled core battens, and then buckling instability can be avoided. The pair numbers of the core battens can be adjusted according to requirements of project designs, and then the energy dissipation device can be used.

Owner:SOUTHEAST UNIV

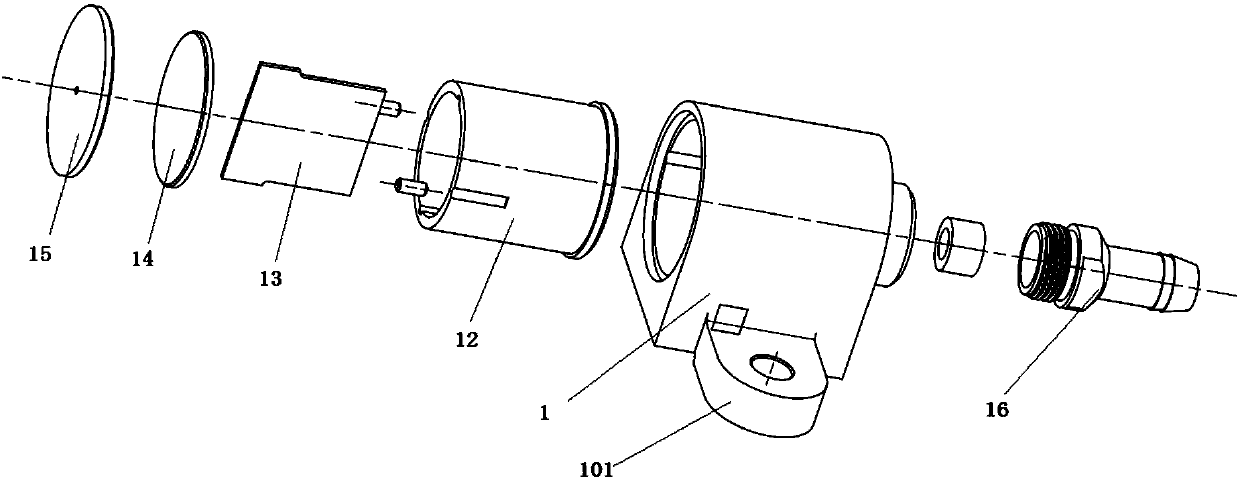

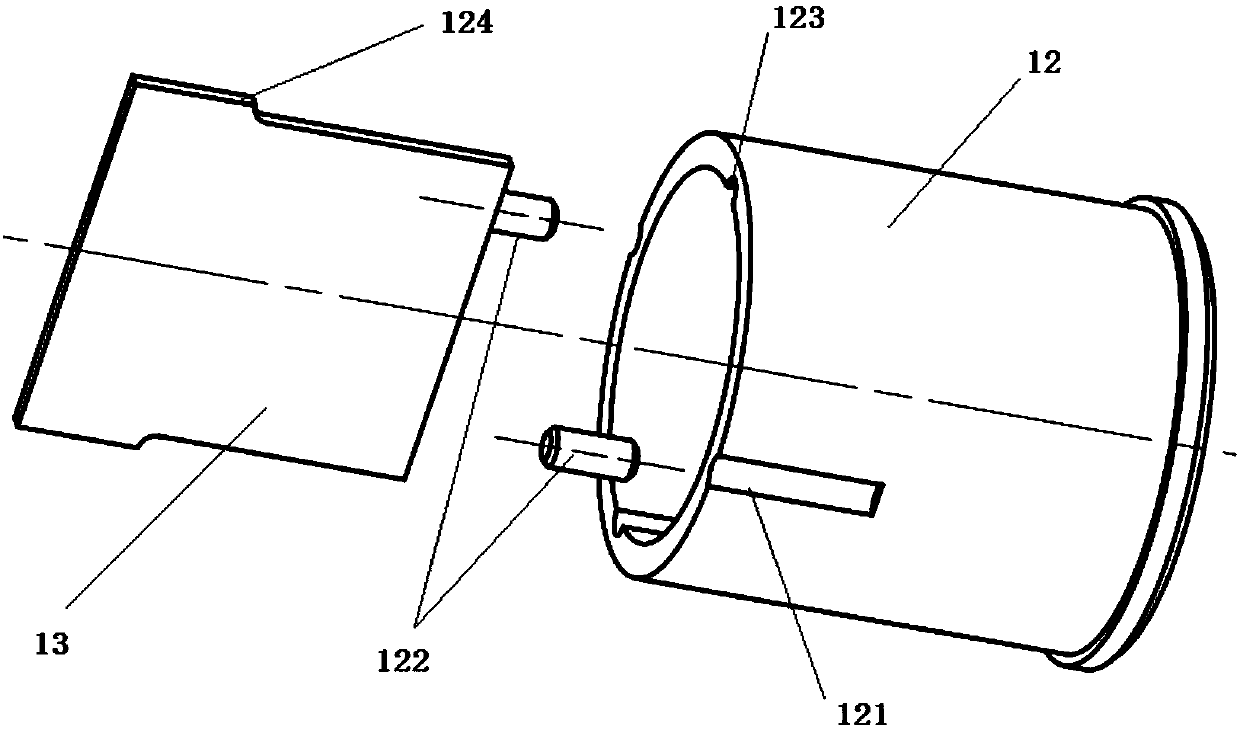

Transverse buckling instability detecting device used for standard D-series high-speed train

PendingCN107907354AEase of mass productionReduce in quantityRailway vehicle testingBuckling instabilityStructural engineering

A transverse buckling instability detecting device used for a standard D-series high-speed train includes a transverse acceleration sensor, a signal cable, a cable connector and a cable sheath tube. The transverse acceleration sensor is in communicational connection with one end of the cable connector through the signal cable. The periphery of the signal cable is provided with the cable sheath tube. The other end of the cable connector is in communicational connection with a BIDS (Buckling Instability Detection System). The invention has beneficial effects that a modularized circuit and structural design idea is adopted; simpleness and reliability are achieved; and batch production is promoted.

Owner:NANJING GAOHUA TECH

Immediate buckling model, hysteresis model, and cloth simulation method based on the invented models, and computer-readable media storing a program which executes the invented simulation method

InactiveUS20070118343A1Accurate expressionSimulation speedInspecting textilesMaterial strength using tensile/compressive forcesBuckling instabilitySimulation

Owner:FXGEAR CO LTD

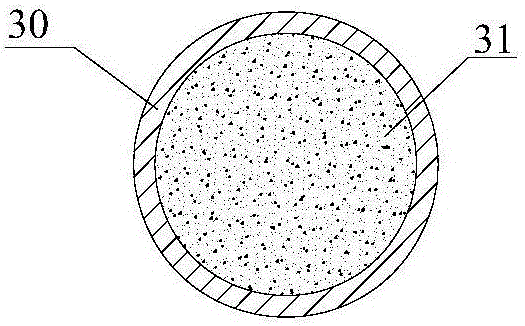

Tunnel primary support structure with built-in steel pipe frame

InactiveCN105888698ASymmetrical section bending stiffnessEffective gripUnderground chambersTunnel liningShotcreteBuckling instability

The invention discloses a tunnel primary support structure with a built-in steel pipe frame, and aims to effectively improve mechanical properties of a primary support, avoid buckling instability of a steel frame and fully achieve the structural strength of the primary support. The tunnel primary support structure comprises a sprayed concrete layer covering cave surrounding rock, and steel frames embedded in the sprayed concrete layer at intervals in the tunnel excavation direction, and is characterized in that the steel frames are steel pipe frames of which the cross sections are circular; the steel pipe frame consists of a left-side wall section, an arch top section and a right-side wall section which are butted with one another, or consists of a left-side wall section, an arch top section, a right-side wall section and an inverted arch section which are butted with one another; the left-side wall section, the right-side wall section and the inverted arch section of the steel pipe frame are filled with concrete.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com