Nested multifunctional vibration isolation rubber support

A vibration isolation rubber and rubber bearing technology, applied in the direction of earthquake resistance, protective buildings/shelters, building types, etc., can solve the problems of failure, material waste, sacrificing the horizontal isolation effect, etc., to achieve uniform deformation and improve the effect. , the effect of not easy buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

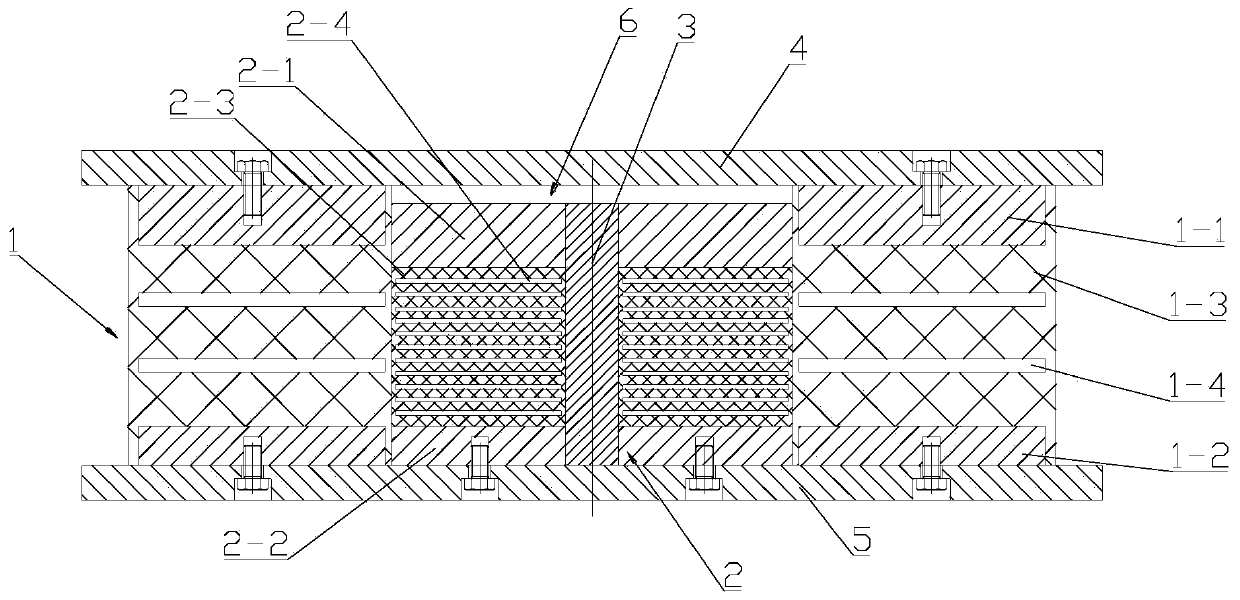

[0038] see figure 1 , the nested multifunctional vibration-isolation rubber bearing of the present invention includes a vertical vibration-isolation assembly 1 and several horizontal vibration-isolation assemblies 2 embedded in the vertical vibration-isolation assembly 1, wherein the horizontal vibration-isolation assembly 2 It is single, the single horizontal vibration isolation assembly 2 is embedded in the axial center position of the vertical vibration isolation assembly 1; the upper end of the vertical vibration isolation assembly 1 is connected with the upper structure through the upper connecting plate, and the lower end is connected with the lower connecting plate Connected with the lower structure, the height of the vertical vibration isolation assembly 1 is greater than the height of the horizontal vibration isolation assembly 2; the lower end of the horizontal vibration isolation assembly 2 is a fixed end, and the upper end is a free end, and the free end and the upp...

Embodiment 2

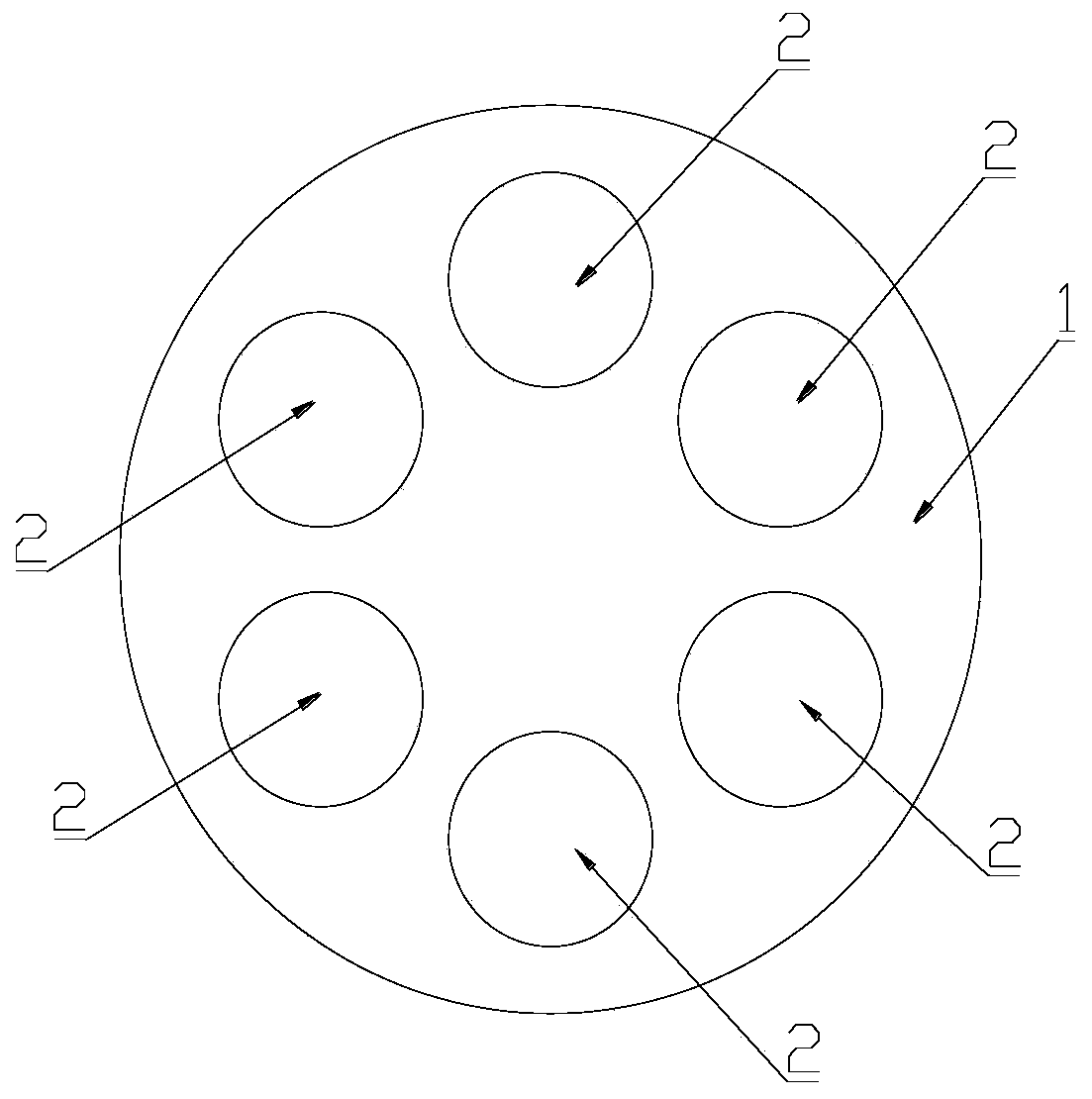

[0054] see figure 2 The difference between this embodiment and Embodiment 1 is that there are multiple horizontal vibration isolation assemblies 2, and the embedding positions of the multiple horizontal vibration isolation assemblies 2 can be located in the vertical vibration isolation assembly 1 according to design requirements. At any position, different horizontal vibration isolation components 2 can be provided in different or the same size and damping material form, and in this embodiment, the multiple horizontal vibration isolation components 2 are along the circumference of the vertical vibration isolation component 1 direction evenly distributed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com