Welding simulation method

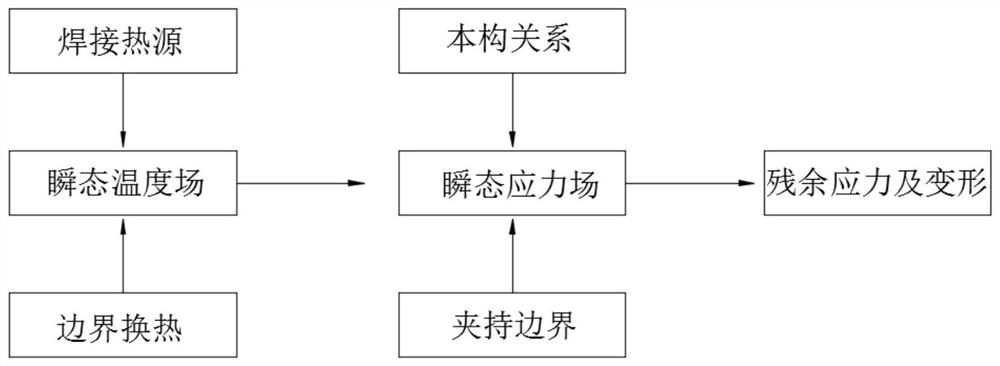

A simulation method and technology of welded joints, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve the problem of unbearable thermal elastic-plastic calculation time, difficult to predict thin plate bending, buckling instability of thick-walled structural mechanical behavior, etc. problem, to achieve the effect of breaking through the problems of efficiency and accuracy, improving the efficiency of solving, and the modular structure is easy to learn and operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The idea of predicting stress and deformation of large-scale welded structures based on the calculation of local joint thermoelastoplasticity and overall structural elasticity; adaptive grid technology based on octree; thermoelastoplastic finite element analysis is performed on each local welded joint model to obtain the same Welding residual plastic strain information corresponding to each local welded joint model; import the welding residual plastic strain information into the pre-established full-process welding process model of structural parts, and calculate the full-process welding mechanical field of structural parts to obtain the full-process welding mechanical field of structural parts Process welding stress and deformation; according to the material parameters, environmental parameters and welding process parameters, the actual welding of the components to be welded is carried out to obtain the actual displacement and actual residual stress; the simulation mod...

Embodiment 2

[0038] In embodiment one, add following operation:

[0039]In step 1, in the stress-deformation simulation of welded structural parts, the error-controlled mathematical method of full-component mapping from local joint plastic strain to overall welded structure load is used, which significantly improves the solution efficiency and accuracy of large-scale structural parts; based on The concept of stress and deformation prediction of large welded structures based on thermoelastoplasticity of local joints and elastic calculation of the overall structure, a mapping error function based on the moment similarity between the joint and the overall structure is proposed, and an error-controlled local plastic strain to global load full component mapping iteration is created method. At the same time, the efficiency of the calculation process and the accuracy of the calculation results are improved.

[0040] The idea of predicting stress and deformation of large-scale welded structures...

Embodiment 3

[0042] In embodiment two, add following operation:

[0043] In step 2, in the numerical simulation of the welding process, it is necessary to deal with physical behaviors such as molten pool flow, heat transfer, and free interface changes, which involve multi-phase and multi-field coupling, and the calculation is extremely time-consuming and inefficient. To this end, it is necessary to develop an efficient numerical calculation method; considering that the grid adaptive method is a key efficiency improvement method in the field of numerical calculation, this project proposes to develop an adaptive grid technology based on octree to speed up the discretization and solution The control equation of the welding process mathematical model greatly reduces the calculation time consumption. In the implementation, the key points include the discretization and solution of the mathematical model on the octree grid, and the high-precision and efficient control of grid self-adaptation.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com