Polyurethane foam

A polyurethane foam and foam technology, applied in the field of polyurethane foam, can solve problems such as voids and unpractical sealing materials, and achieve the effect of small compressive residual strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

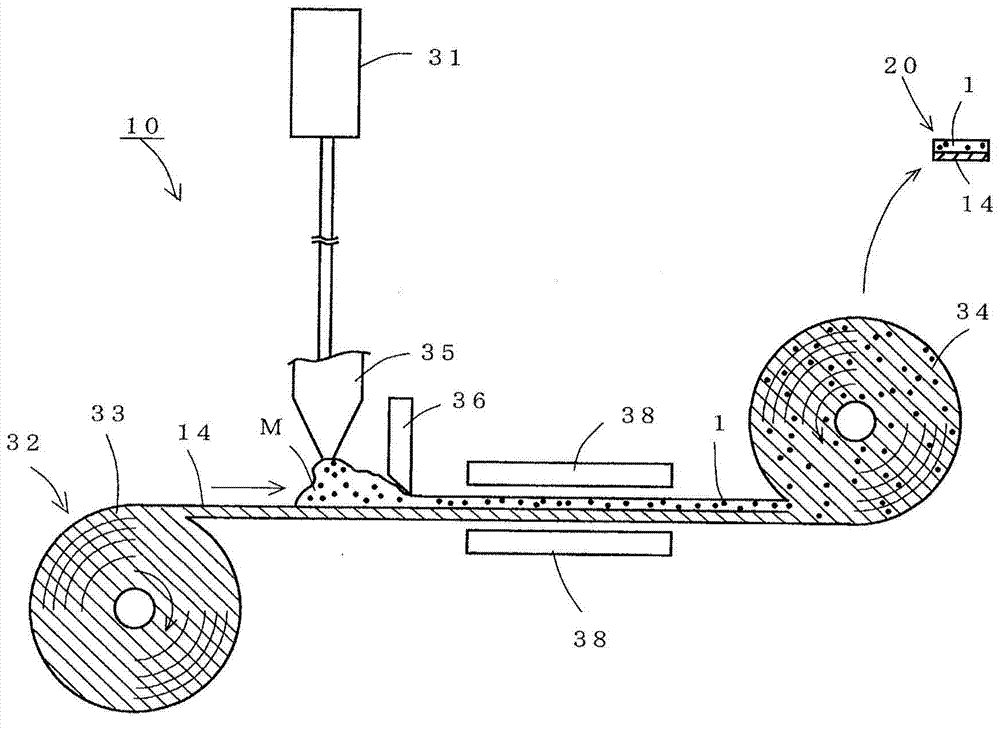

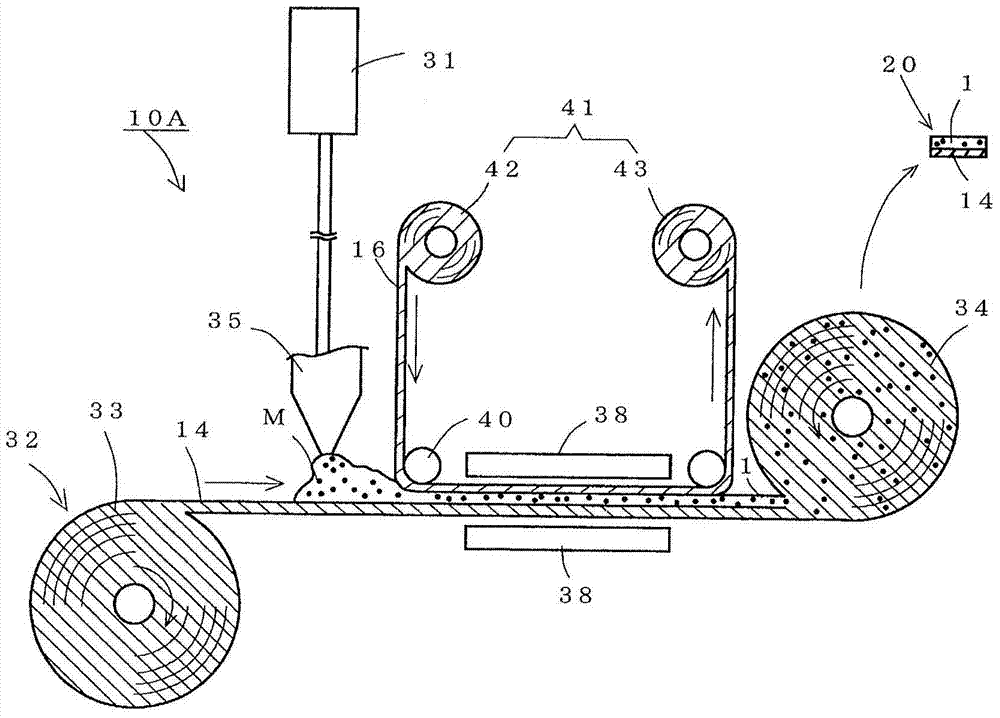

[0080] use figure 2 The production apparatus 10 shown in , produced the polyurethane foam 1 of Examples 1-15 from the polyurethane raw material M having the formulation shown in Tables 1 and 2. In this case, a PET film having a thickness of 25 to 125 μm is used as the base material 14 , and the polyurethane raw material is heated to 120 to 200° C. by heating means 38 . Nitrogen as a gas for foam formation was supplied into the mixing section 31 at a flow rate of 0.1 NL / min and mixed with the polyurethane raw material so as to achieve the mixing ratios (volume %) in Tables 1 and 2. The feeding speed of the substrate 14 in the roller mechanism 32 was 5 m / min.

[0081] For comparison, polyurethane foams of Comparative Examples 1 to 10 were obtained from polyurethane raw materials having the formulations shown in Table 3. In Comparative Examples 1 to 7, the polyurethane foam was produced by the same production method as in Examples 1 to 14, but the formulation of the polyuretha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com