Neutron diffraction measure method for CaO-Al2O3-SiO2 system microcrystalline glass residue stress

A technique of cao-al2o3-sio2, 1.cao-al2o3-sio2, applied in measurement devices, material analysis using wave/particle radiation, preparation of test samples, etc., can solve problems such as low radiation and weak penetrating ability question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: prepare CaO-Al by the aforementioned method 2 o 3 -SiO 2 System glass-ceramic.

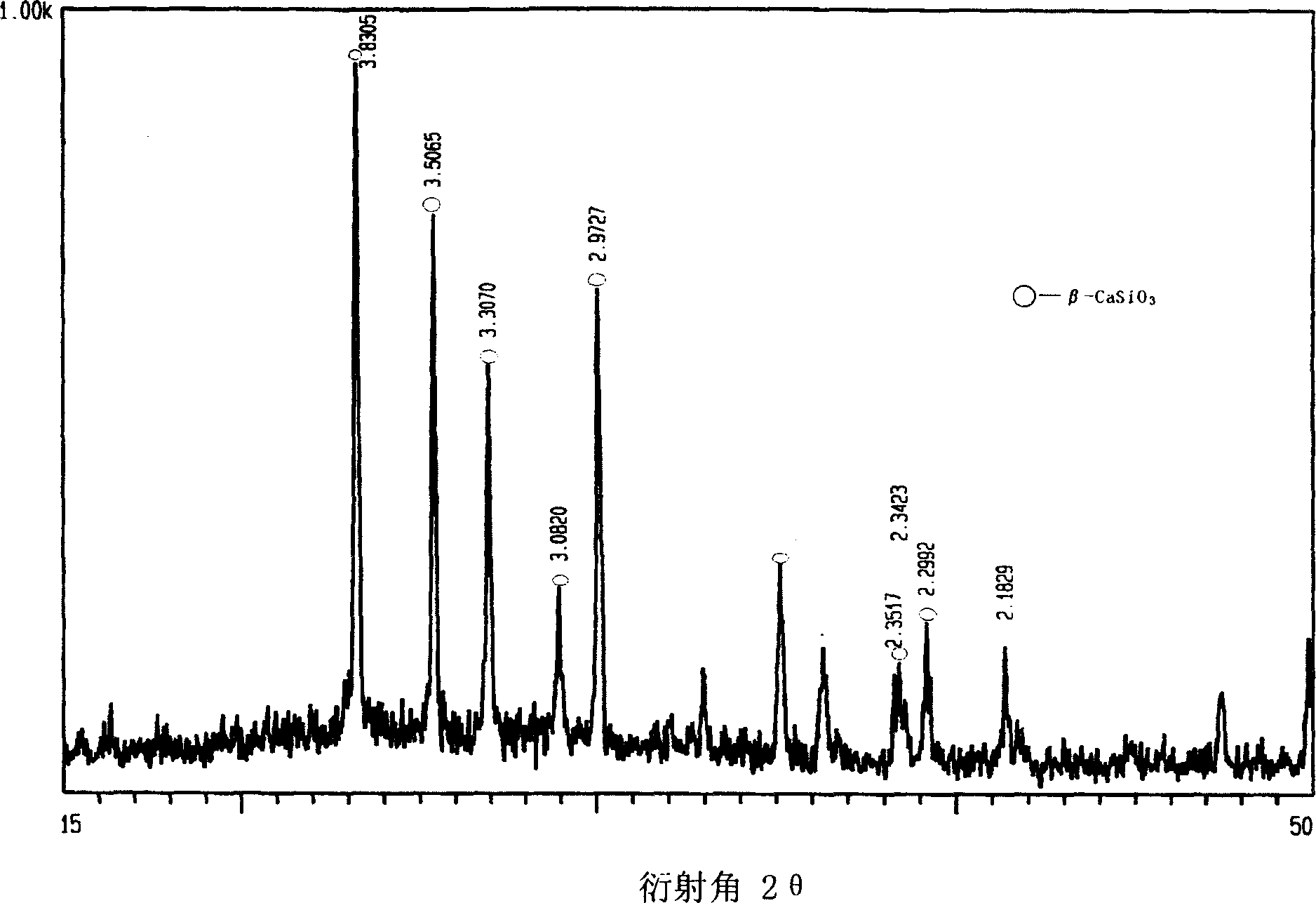

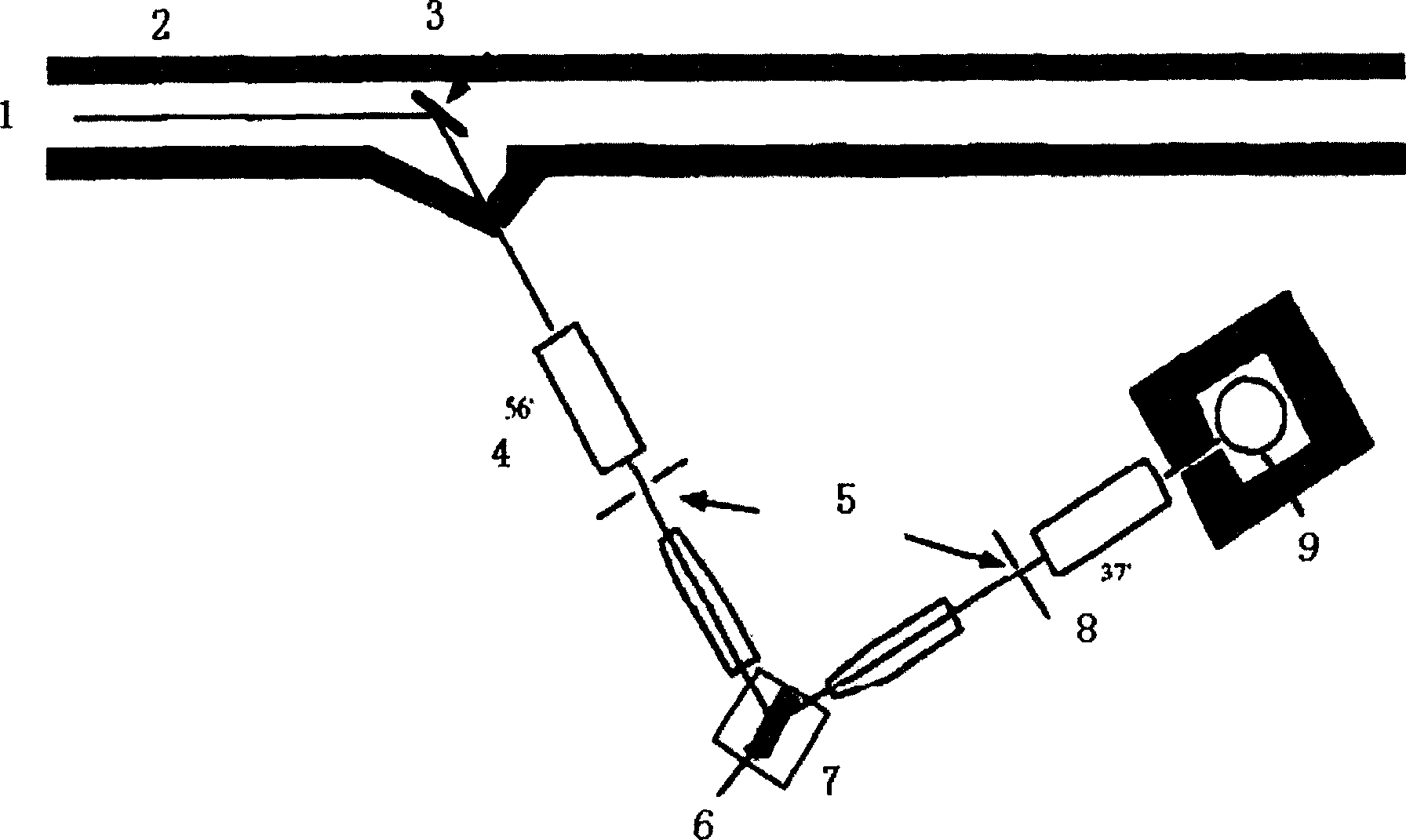

[0028]Put the dried glass frit into the prepared mold and put it into a high-temperature experimental furnace to raise the temperature from room temperature to 1120 °C at a rate of 3 °C / min, and keep it warm for 2 hours to make the glass particles crystallize and flatten, and then cool to room temperature after annealing , A glass-ceramic sample of 20 mm x 20 mm x 8 mm was prepared. The sample is divided into two pieces: the surface of one sample is ground and polished, and the surface of the other sample remains in the original state of automatic flattening. The neutron diffraction measurements were carried out on a two-axis neutron powder diffractometer next to the Heavy Water Research Reactor of the China Institute of Atomic Energy. The wavelength of incident neutrons is 0.1159 nanometers, the scattering angle is 25°-105°, and the step distance is 0.1°. The diffraction ...

Embodiment 2

[0031] Embodiment 2: prepare CaO-Al by the aforementioned method 2 o 3 -SiO 2 System glass-ceramic.

[0032] Put the dried glass frit into the prepared mold and put it into a high-temperature experimental furnace to raise the temperature from room temperature to 1120°C at a rate of 3°C / min, and keep it warm for 2 hours to make the glass particles crystallize and flatten, and set different annealing rates . Specimens with different annealing regimes were prepared for stress testing. The crystal plane constant under the stress state is tested, and the micro-strain in each axial direction is calculated, and the average strain result is obtained as follows: ϵ ‾ = 1 3 ( ϵ 11 + ϵ 22 + ϵ 33 ) . The ...

Embodiment 3

[0033] Embodiment 3: prepare CaO-Al by the aforementioned method 2 o 3 -SiO 2 System glass-ceramic. Changing CaO and Al of glass-ceramics 2 o 3 Glass-ceramic samples of different oxides were prepared. The crystal plane constant under the stress state is tested, and the micro-strain in each axial direction is calculated, and the average strain result is obtained as follows: ϵ ‾ = 1 3 ( ϵ 11 + ϵ 22 + ϵ 33 ) . The corresponding volume average strain is Δ = 1 V ∫ V ϵ ‾ dV , Substitute into the stress formula σ = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com