X-brace type energy dissipation device

A technology of cross bracing and energy dissipator, which is applied in the direction of building components and earthquake resistance, can solve the problems of affecting the shock absorption effect of the energy dissipator, weakening the stiffness, and buckling outside the surface, so as to achieve simplicity and flexibility, reduce Calculation of length, effect of preventing buckling instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the accompanying drawings.

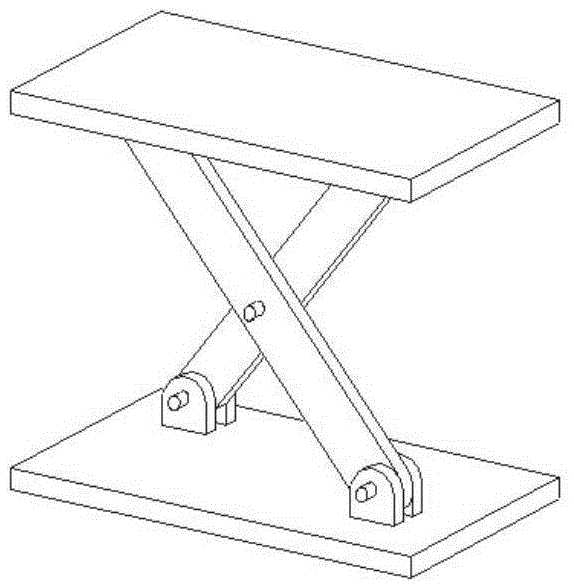

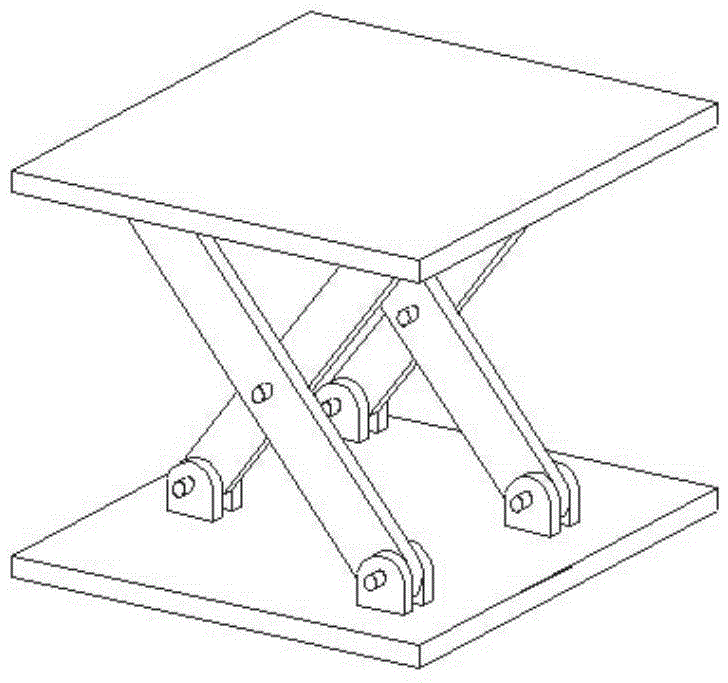

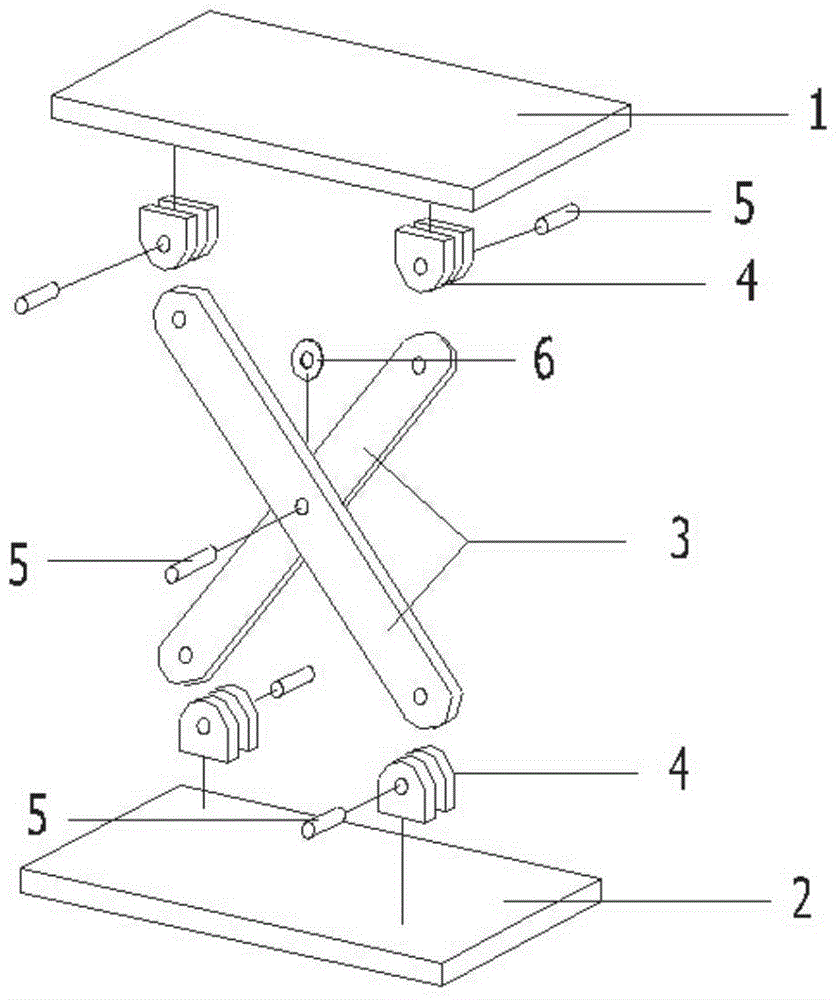

[0021] Such as image 3 A cross-bracing energy dissipator shown includes an upper roof 1, a lower roof 2, a set of core energy-dissipating components, and four ear plates 4, and the two ear plates 4 are connected to the upper roof 1 through full penetration welds. On the lower surface, two lug plates 4 are connected to the upper surface of the lower top plate 2 by welding. Among them, the energy-dissipating parts include two cross-set core slats 3 and a pin 5 made of steel with a low yield point below 225 MPa or steel with a ductility rate of 0.45 to 0.5. The two ends and the middle of each core slat 3 locations provided with through-holes, such as Figure 4 As shown, there are many options for the cross-sectional form of the core slats, which can be selected according to their stability requirements. A gasket 6 is provided between the two core slats 3 , and the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com