Tunnel primary support structure with built-in steel pipe frame

A primary support and steel frame technology, applied in tunnels, tunnel linings, mining equipment, etc., can solve problems such as buckling instability of medium-sized steel frames, large differences in bending stiffness, and primary support damage. Symmetrical flexural rigidity, increase section flexural rigidity and strength, and ensure the effect of gripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

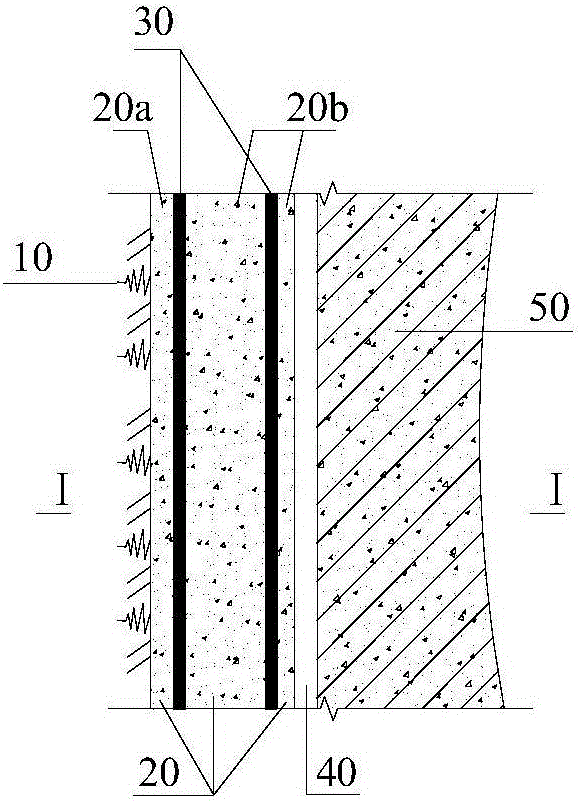

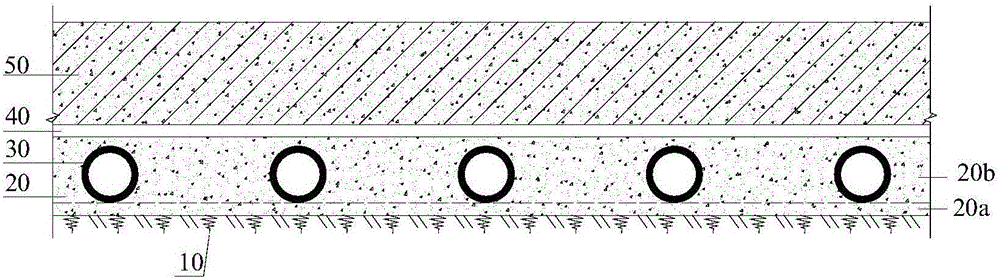

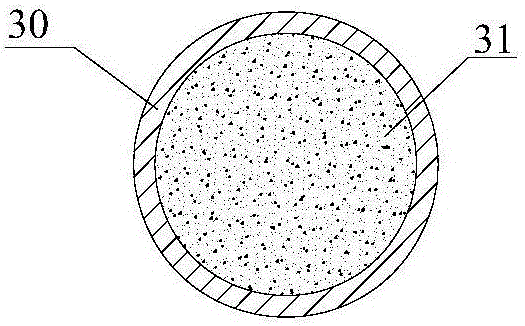

[0017] refer to figure 1 and figure 2 , a kind of tunnel initial support structure with steel pipe steel frame built in the present invention, comprises the shotcrete layer 20 covering the rock 10 around the hole, and the steel frames embedded in the shotcrete layer 20 at intervals along the tunnel excavation direction. refer to image 3 , the steel frame is a steel pipe steel frame 30 with a circular cross section. refer to Figure 4 , the steel pipe steel frame 30 is composed of the butt left side wall section 33 , the vault section 32 and the right side wall section 34 , and the left side wall section 33 and the right side wall section 34 are filled with concrete 31 . refer to Figure 5 , the steel pipe steel frame 30 is composed of the butt left side wall section 33, the vault section 32, the right side wall section 34 and the inverted arch se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com