Segmented cotton feeding device of carding machine

A segmented, carding technology, applied in the field of carding machines, can solve the problems of increasing the distance between the gripping jaws, unable to fully and accurately reflect the difference in the thickness of the cotton layer, and affecting the quantitative uniformity of the sliver of the carding machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

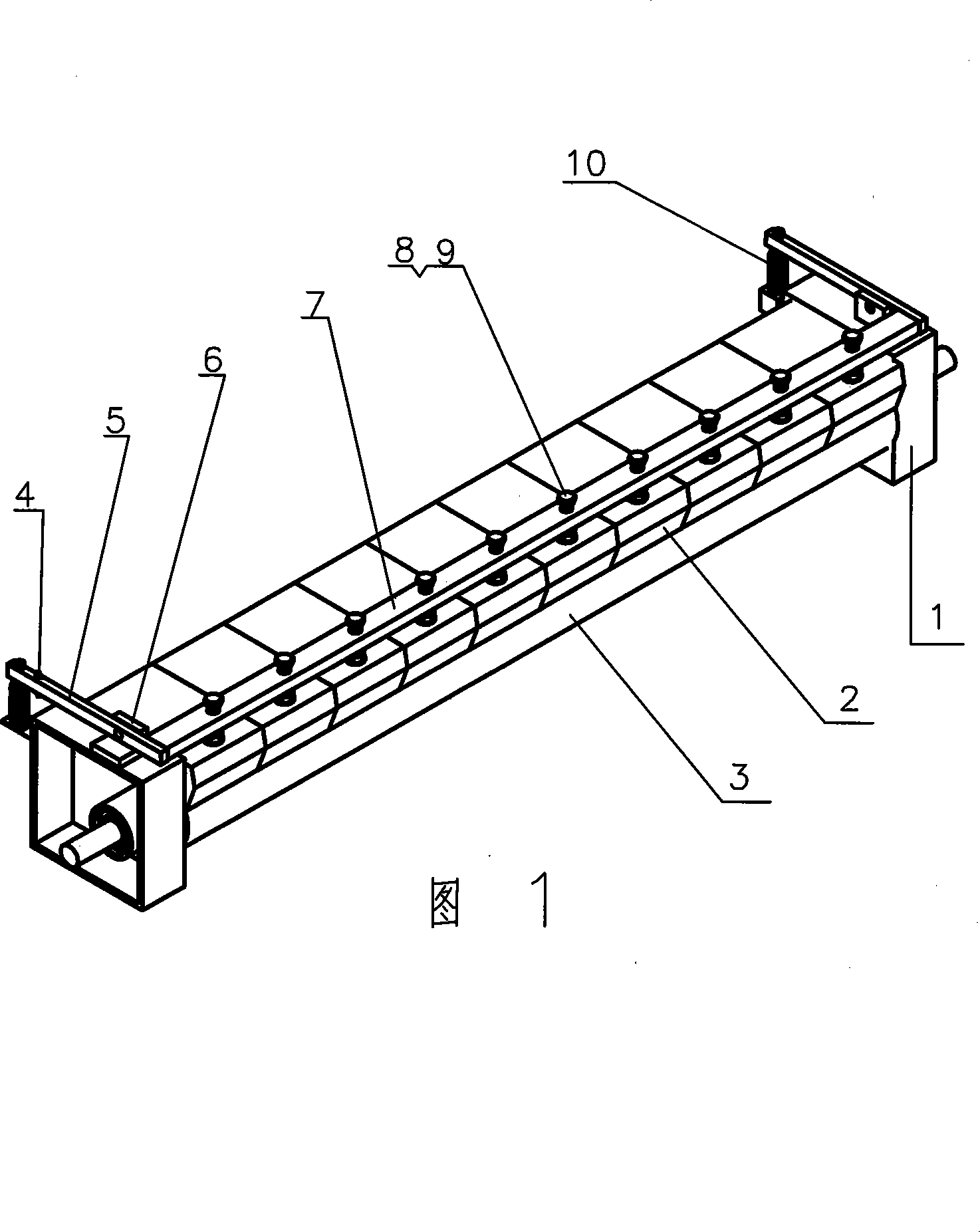

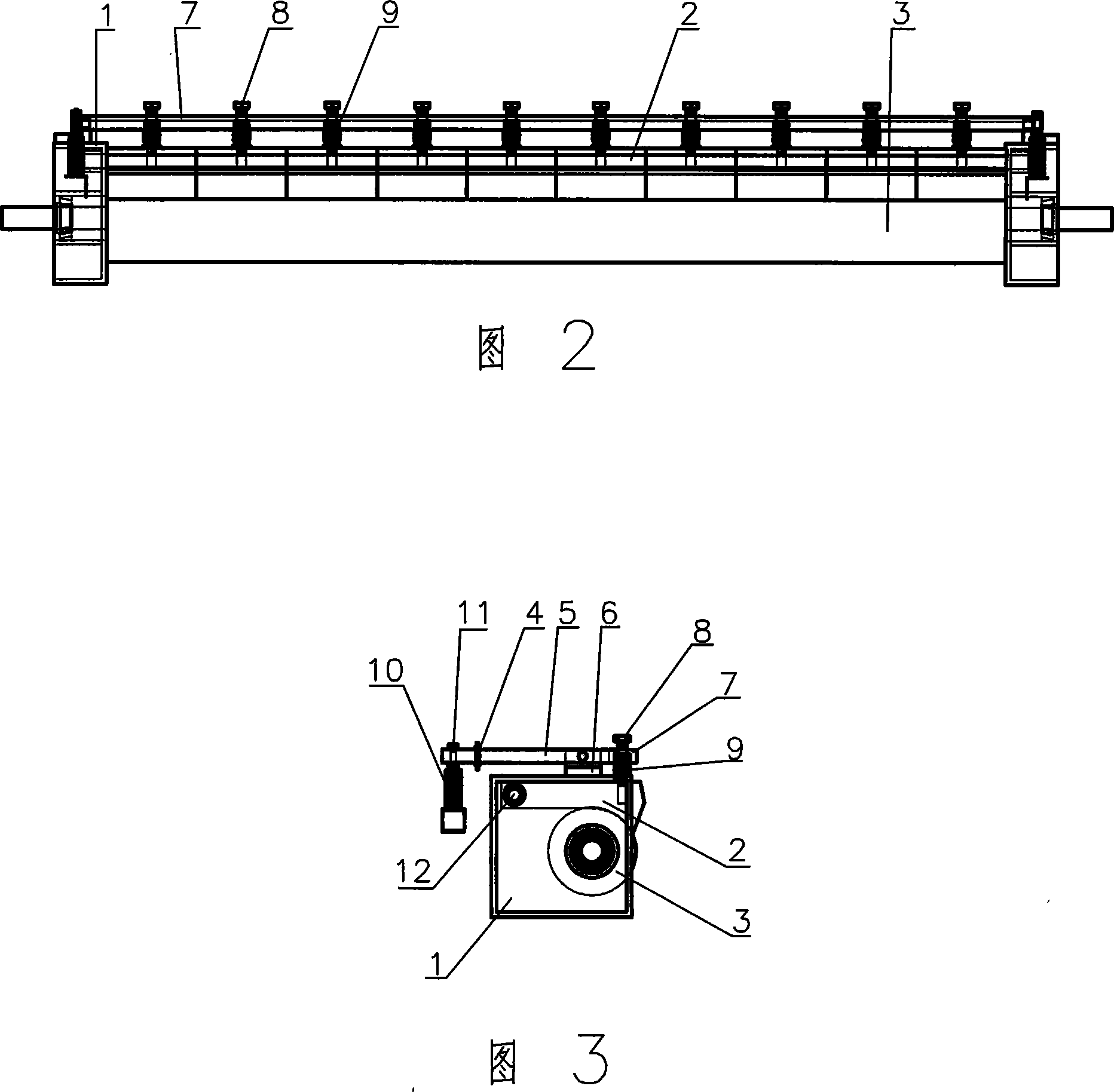

[0016] In the segmented cotton feeding device of the carding machine shown in Figure 1, Figure 2 and Figure 3, the cotton feeding roller 3 is rotatably supported on the frame body 1 through bearings, and the frame body 1 is located at both ends of the cotton feeding roller 3 . Ten cotton feeding boards 2 adjacent to each other are arranged above the cotton feeding roller 3 , and the ten cotton feeding boards 2 are hinged on the support body 1 through the cotton feeding board hinge shaft 12 .

[0017] A pressure beam 7 is also arranged above the cotton feeding plate 2, and two ends of the pressure beam 7 are respectively fixedly connected with a pressure arm 5, and the two pressure arms 5 are hinged on the frame body 1 through the pressure support 6 respectively. On the stretching end of the pressing arm 5, a pressing spring 10 is installed, and the pressing spring 10 adopts a cylindrical helical compression spring. The pressing spring 10 is supported on the frame by a spring s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com