Preliminary tunnel support structure with internal box type steel frames

An initial support and steel frame technology, applied in tunnels, tunnel linings, mining equipment, etc., can solve problems such as large difference in bending stiffness, buckling instability of supporting medium-shaped steel frames, and initial support failure, etc. Increase the bending stiffness and compressive strength of the section to ensure the effect of gripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

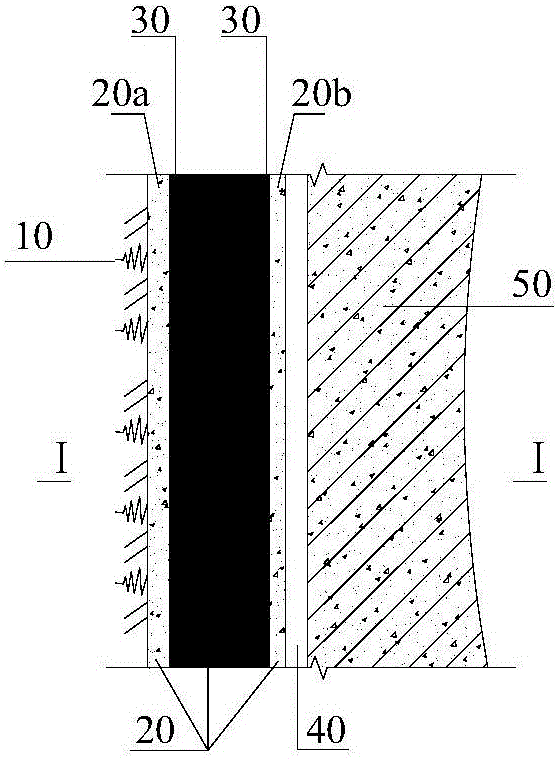

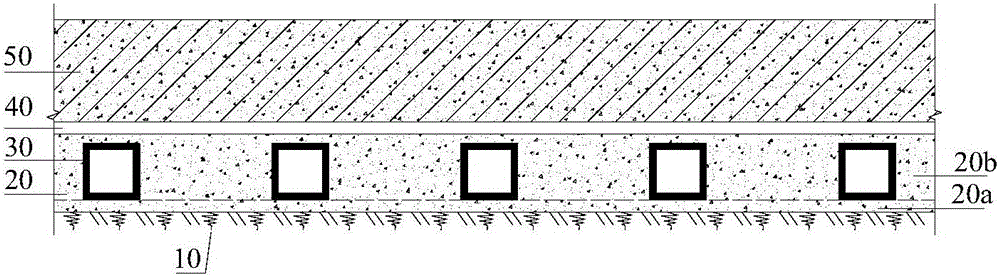

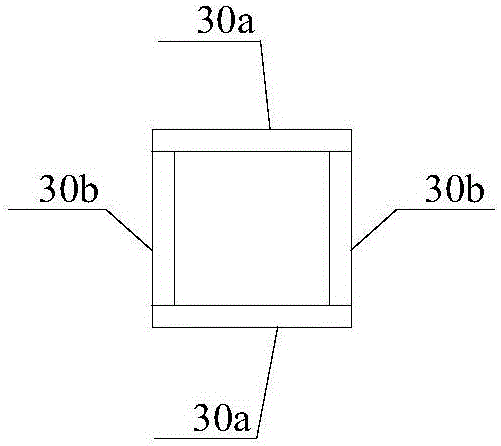

[0017] refer to figure 1 and figure 2 , a tunnel primary support structure with a box-shaped steel frame inside, including a shotcrete layer 20 covering the rock 10 around the hole, and steel frames buried in the shotcrete layer 20 at intervals along the tunnel excavation direction. refer to image 3 , the steel frame is a box-shaped steel frame 30 whose cross section is rectangular, and the box-shaped steel frame 30 is composed of a pair of flange plates 30a and webs 30b that are perpendicular to each other and welded as one. The box-shaped steel frame 30 Filling concrete (31) is poured inside except the vault section 32.

[0018] refer to Figure 4 , the box-shaped steel frame 30 is composed of a buttted left side wall section 33 , a vault section 32 and a right side wall section 34 , and the left side wall section 33 and the right side wall sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com