Construction method of long-span composite beam bridge with steel truss and corrugated steel web

A technology of corrugated steel webs and steel trusses, applied to long-span composite girder bridges and their construction fields, can solve problems such as web height, buckling instability, and loss in negative moment areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

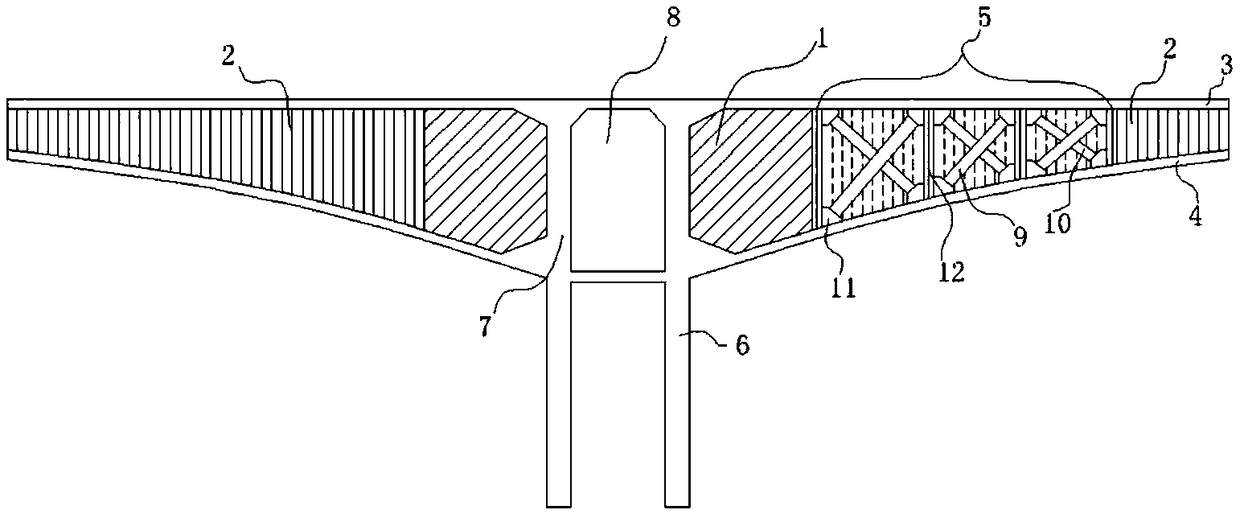

[0042] 1. Basic structure and principle of steel truss-corrugated steel web long-span composite girder bridge

[0043] Steel truss-corrugated steel web mixed shear is adopted, and steel truss-corrugated steel web beam section is set outside the lining concrete section of the bridge middle fulcrum, and the length of the beam section is L h , to share the problem of excessive shearing of the corrugated steel web of the beam section ( figure 1 ). Steel truss-corrugated Steel web beam section length L h It should be satisfied that the net height of the corrugated steel web is greater than 5m, and the stability safety factor of the corrugated steel web of the beam section is greater than 2.0.

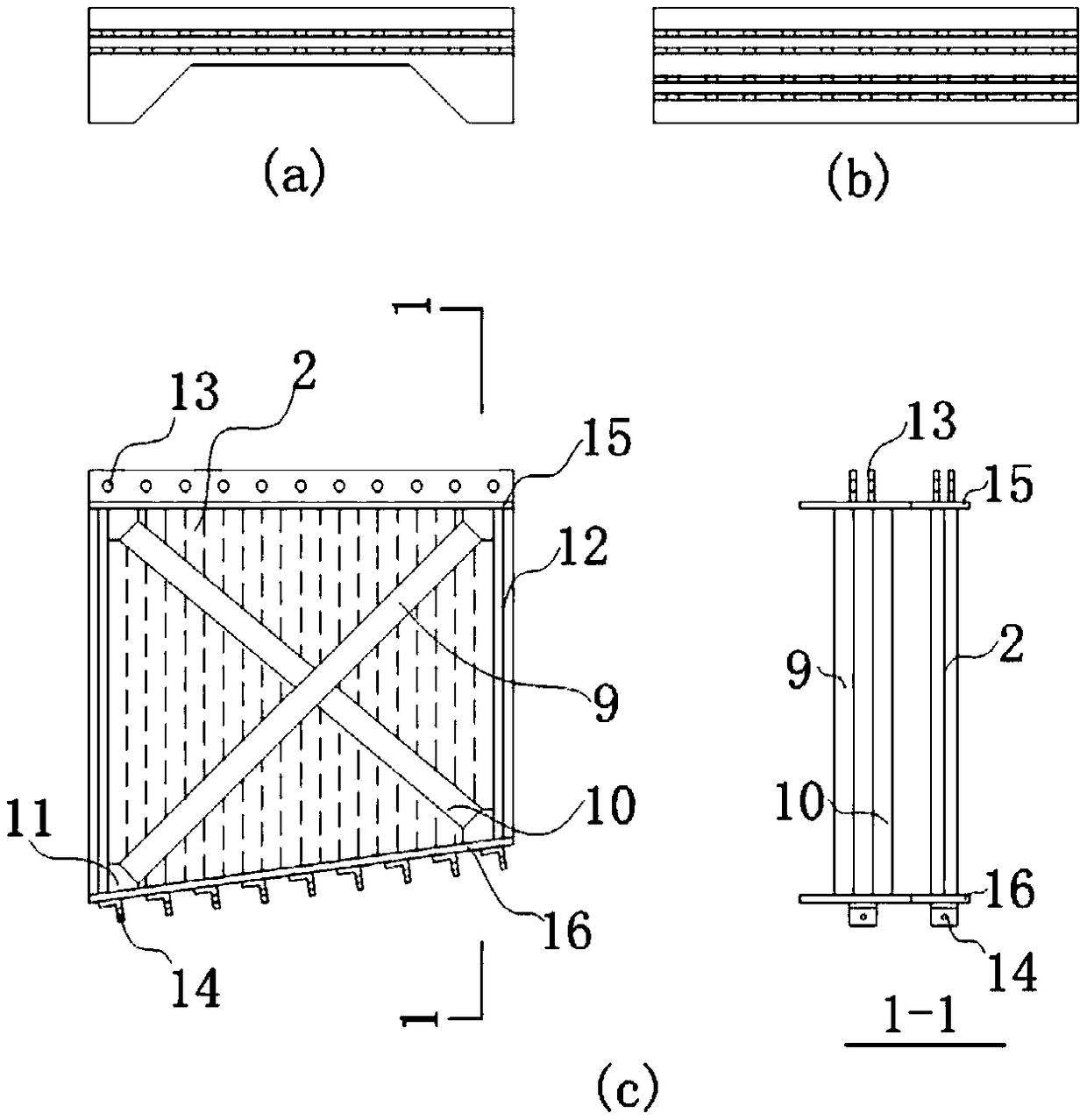

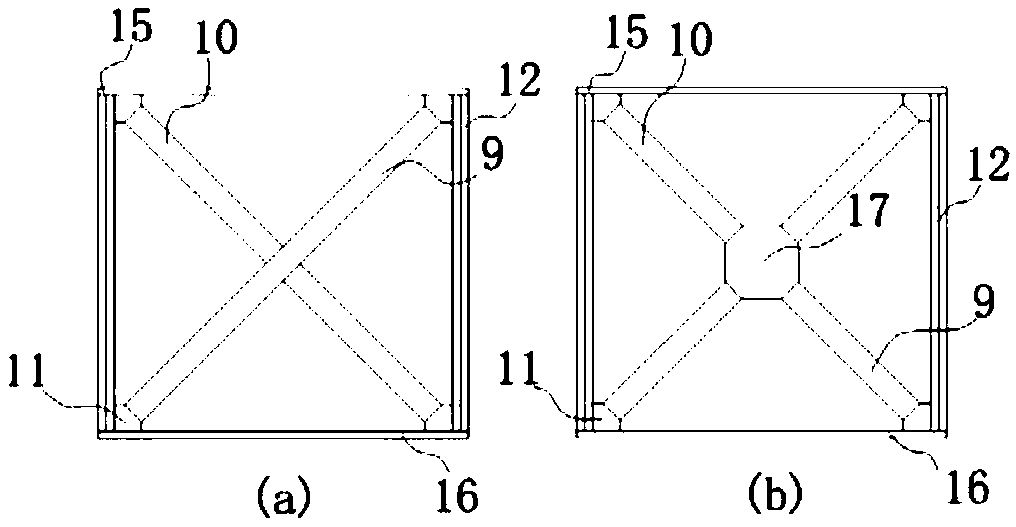

[0044] Such as figure 2 As shown, the steel truss-corrugated steel web beam section is composed of steel columns, compression steel trusses, tension steel trusses, gusset plates, corrugated steel webs, steel upper flange plates, and steel lower flange plates. Among them, the compression...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com