A kind of waterproof and antibacterial zipper and preparation method thereof

A zipper and chain belt technology, applied in the field of special clothing, can solve the problems of low waterproof strength and life, low antibacterial performance, etc., and achieve the effects of preventing water infiltration and wetting, improving strength and toughness, and strong sterilization ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

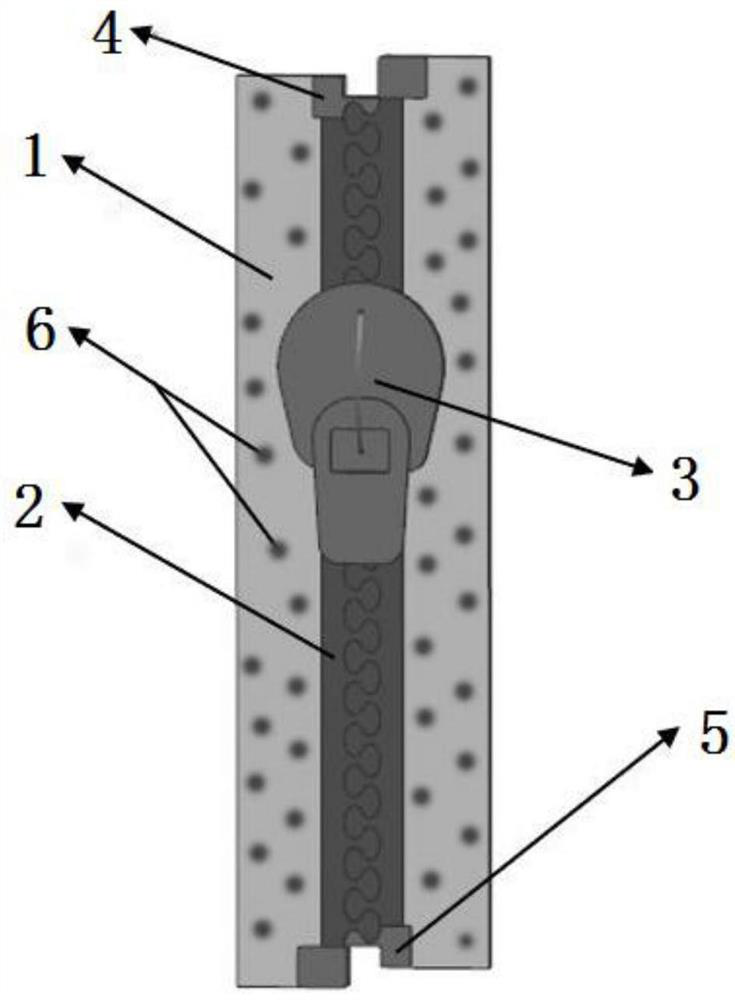

[0031] The preparation method of the zipper specifically comprises the following steps:

[0032] Step 1: Use silica and polydimethylsiloxane composite materials to make two chain belts, and use fluorosilicone resin to make chain elements;

[0033] Step 2: Treat the surface of the silica and polydimethylsiloxane composites with 3-aminopropyltriethoxysilane to obtain an interfacial chemical structure that is favorable for the deposition of nano-silver, and then magnetron sputtering on the surface of the chain band The metal nano-silver particles are deposited by the method of radiation, so that the nano-silver particles grow tightly on the surface of the chain belt, and the fastener elements are respectively fixed on both sides of the chain belt to form a chain belt with fastener elements;

[0034] Step 3: Configure the puller for the chain belt with the fastener elements in step 2, set the front and rear ends of each chain belt respectively, and connect the front end of one cha...

Embodiment

[0036] The preparation method of a kind of waterproof and antibacterial zipper of the present invention is explained in detail below by specific embodiment:

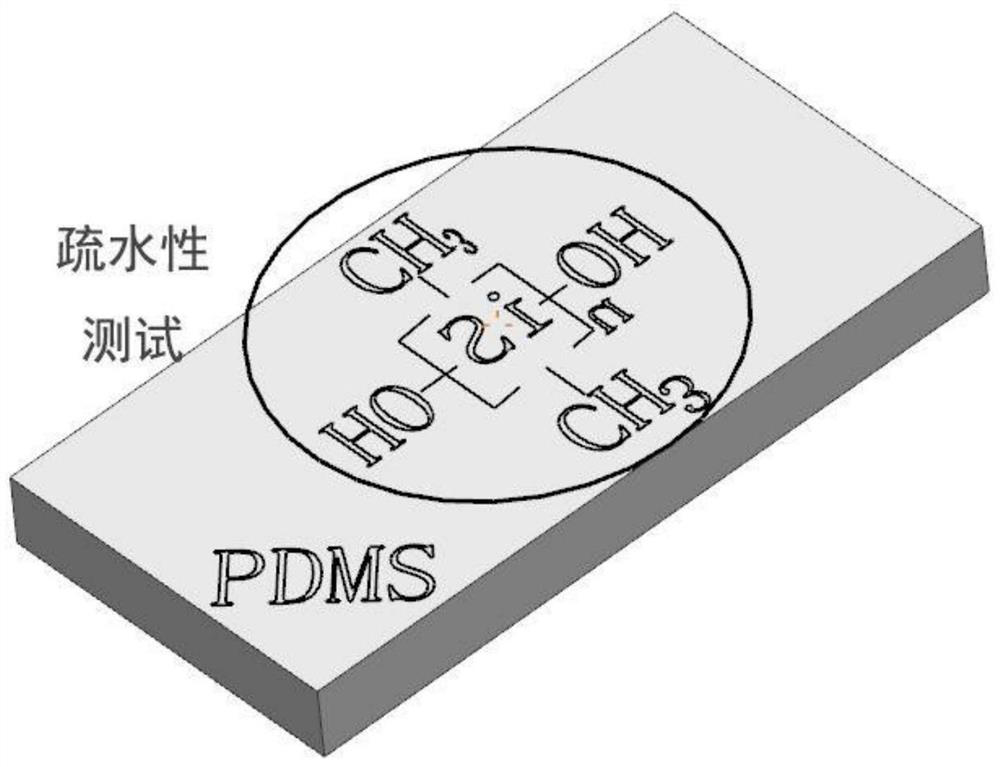

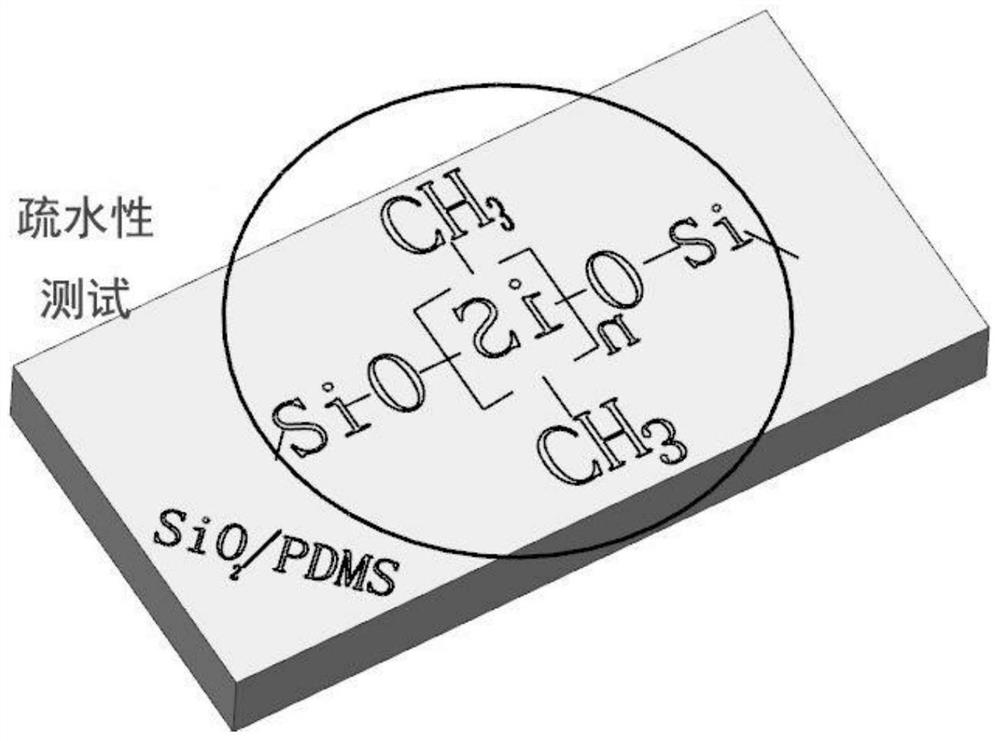

[0037] Step 1: Use silica and polydimethylsiloxane composite materials to make two chain belts, use fluorosilicone resin to make fastener elements, and form fastener elements of fluorosilicone resin material and corresponding fastener elements Silica and polysiloxane Chain tapes of methyl siloxane composites,

[0038] Step 2: Treatment of Silica and Dimethicone SiO with 3-aminopropyltriethoxysilane (APTES) 2 @PDMS surface, obtaining an interfacial chemical structure that is favorable for nanosilver deposition. Then, through the deposition of metal nano-silver on the surface of the chain belt, the silver particles are grown closely on the surface of the chain belt. The superhydrophobic surface of the SiO2@PDMS composite material specifically means that the static contact angle to water is less than 150°, and the rolling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com