Stacked paper folding structure with variable stiffness characteristic

An origami structure, stacking technology, applied in cardboard articles, railway car body parts, motor vehicles, etc., can solve the problems of few structural parameters, limited engineering application potential, etc., and achieves a wide range of stiffness changes, good application prospects, and stable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

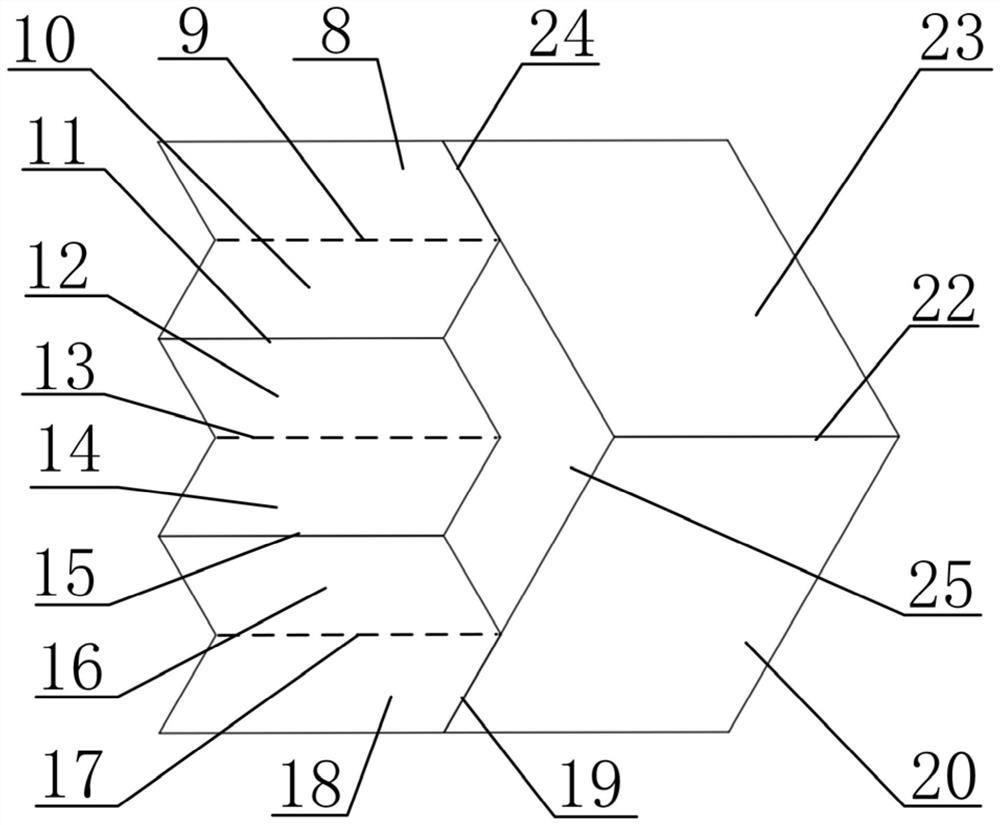

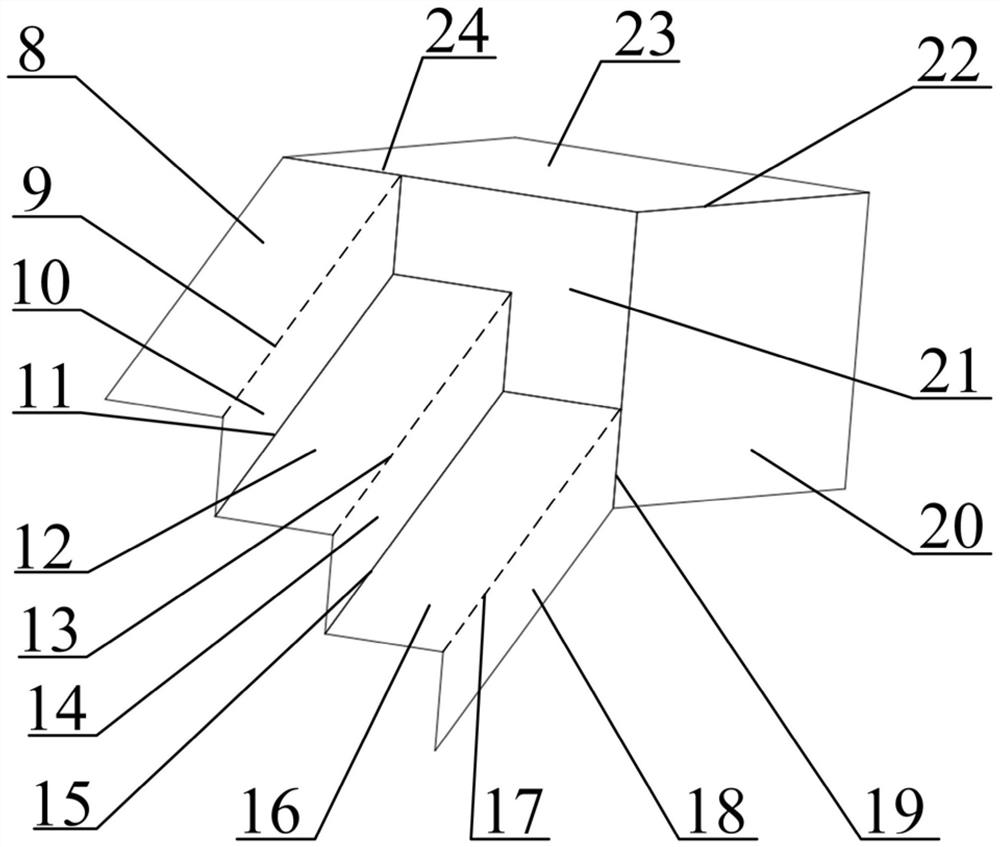

[0042] In order to facilitate a unified review of the various reference signs in the drawings of the specification, the unified description of the reference signs appearing in the drawings of the specification is as follows:

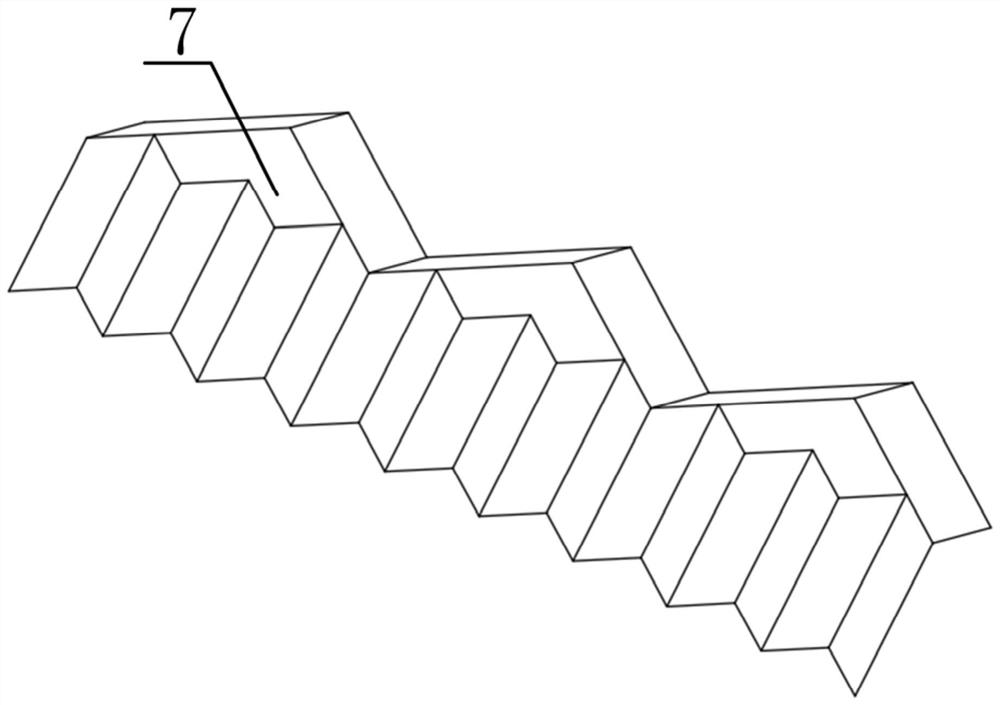

[0043] 1 is the first origami tube, 2 is the second origami tube, 3 is the third origami tube, 4 is the fourth origami tube, 5 is the first origami board, 6 is the second origami board, 7 is the basic unit , 8 is the first facet, 9 is the first valley fold, 10 is the second facet, 11 is the first mountain fold, 12 is the third facet, 13 is the second valley fold, 14 is the fourth facet, 15 is the second mountain fold line, 16 is the fifth facet, 17 is the third valley fold line, 18 is the sixth facet, 19 is the third mountain fold line, 20 is the first large plane, 21 is the folded hexagonal plane, 22 is the fourth mountain fold line, 23 is the second largest plane, and 24 is the fifth mountain fold line. 25 is to expand the hexagonal plane.

[0044] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com