A Variable Stiffness Leaf Spring Cross-Balanced Suspension

A technology of balanced suspension and variable stiffness, which is applied in the direction of suspension, elastic suspension, vehicle spring, etc., can solve the problem of invariable stiffness of the balance arm, so as to improve ride comfort and comfort, uniform force, and reduce the number of pieces Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

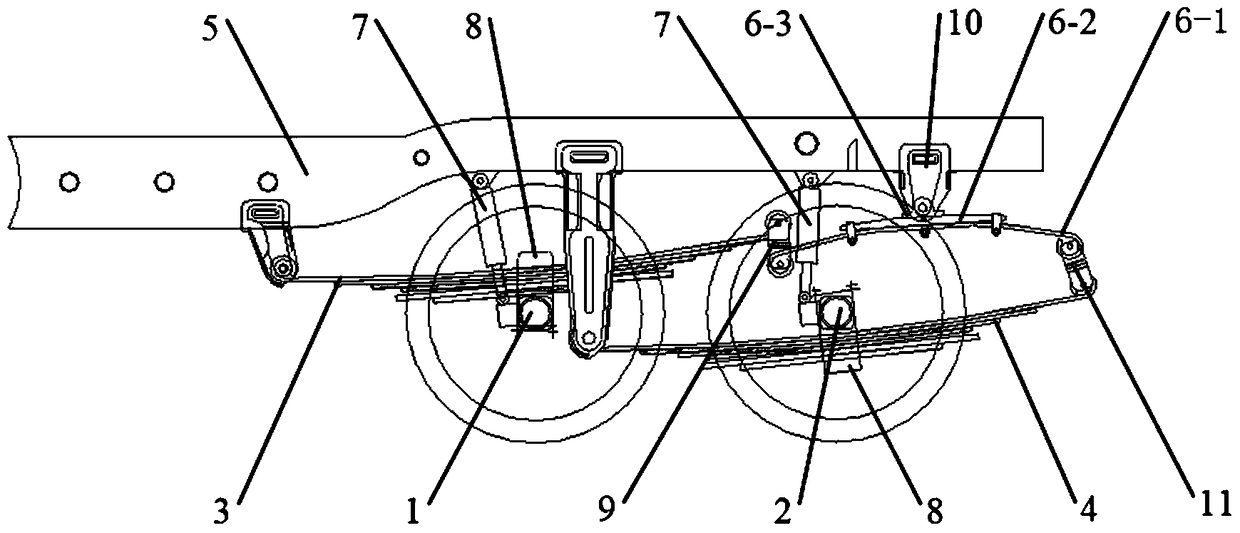

[0018] Such as figure 1 As shown, the variable stiffness leaf spring cross balance suspension includes front axle 1, rear axle 2, front leaf spring 3, rear leaf spring 4, vehicle frame 5, shock absorber 7, U-shaped bolt 8, front spring hanger 9. The balance arm bracket 10 and the rear spring lug 11 are characterized in that it also includes a composite leaf spring balance arm 6, and the composite leaf spring balance arm 6 includes a main plate spring 6-1, a secondary leaf spring 6- 2 and leaf spring clamp 6-3; the front end of the main plate spring 6-1 is hinged with the lower end of the front spring lug 9, and the rear end of the main plate spring 6-1 is hinged with the upper end of the rear spring lug 11; the sub-plate The spring 6-2 is arranged on the main board spring 6-1 through the leaf spring clip 6-3; the balance arm bracket 10 is fixedly connected to the vehicle frame 5, and the leaf spring clip 6-3 is hinged with the balance arm bracket 10; The front leaf spring 3 i...

Embodiment 2

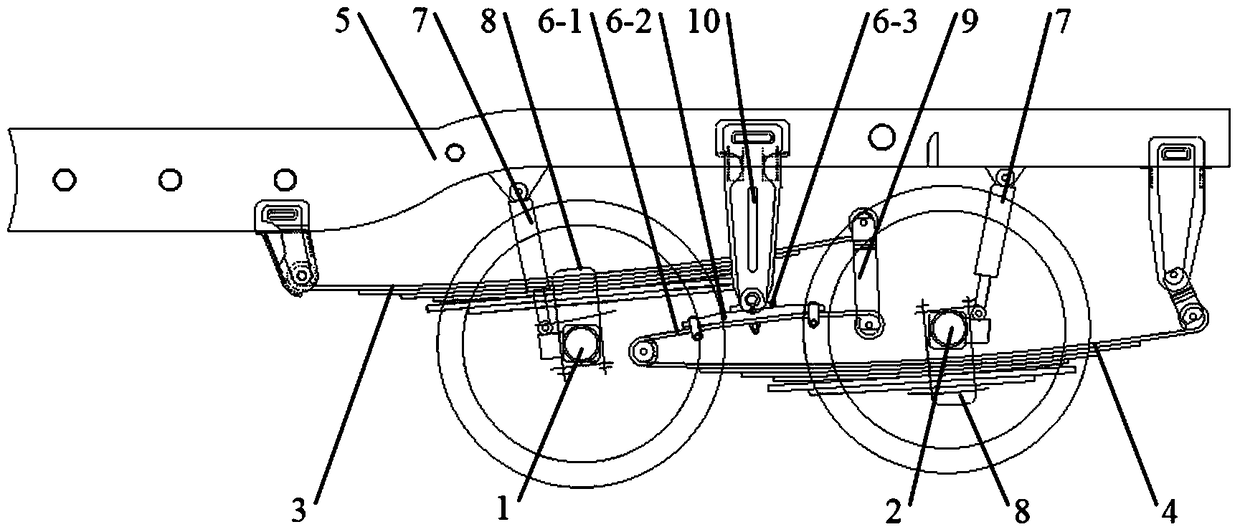

[0020] Such as figure 2 As shown, the variable stiffness spring cross balance suspension includes a front axle 1, a rear axle 2, a front leaf spring 3, a rear leaf spring 4, a vehicle frame 5, a shock absorber 7, U-shaped bolts 8, and front spring hangers 9 And balance arm bracket 10, it is characterized in that: it also comprises a composite leaf spring type balance arm 6, and described composite leaf spring type balance arm 6 comprises main board spring 6-1, secondary leaf spring 6-2 and leaf spring clip 6- 3. The rear end of the main plate spring 6-1 is hinged with the lower end of the front spring lug 9, and the front end of the main plate spring 6-1 is hinged with the front end of the rear leaf spring 4; the auxiliary leaf spring 6-2 is clamped by the leaf spring 6-3 is arranged above the main board spring 6-1; the balance arm bracket 10 is fixedly connected to the vehicle frame 5, and the leaf spring clip 6-3 is hinged with the balance arm bracket 10; the front leaf spr...

Embodiment 3

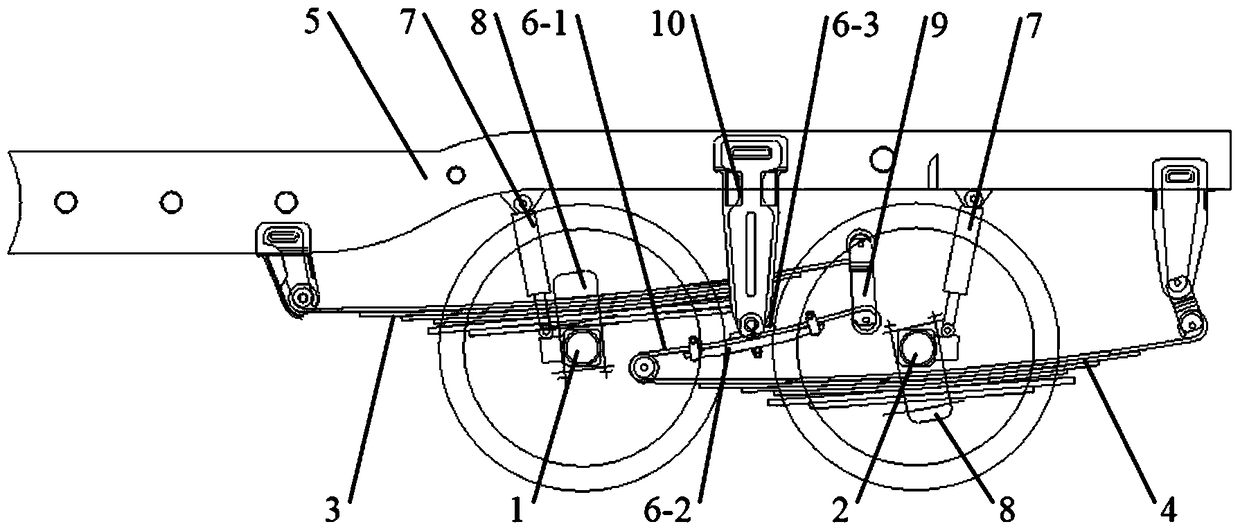

[0022] Such as image 3 As shown, the variable stiffness leaf spring cross balance suspension includes front axle 1, rear axle 2, front leaf spring 3, rear leaf spring 4, vehicle frame 5, shock absorber 7, U-shaped bolt 8, front spring hanger 9 and the balance arm bracket 10, characterized in that: it also includes a composite leaf spring type balance arm 6, and the composite leaf spring type balance arm 6 includes a main plate spring 6-1, an auxiliary leaf spring 6-2 and a leaf spring clip 6 -3; the rear end of the main plate spring 6-1 is hinged with the lower end of the front spring lug 9, and the front end of the main plate spring 6-1 is hinged with the front end of the rear leaf spring 4; the secondary leaf spring 6-2 passes through the leaf spring Clip 6-3 is arranged under the main board spring 6-1; the balance arm bracket 10 is fixedly connected on the vehicle frame 5, and the leaf spring clip 6-3 is hinged with the balance arm bracket 10; the front leaf spring 3 passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com