Thin plate weld with trailing deformation control device and method with dynamic hot stretching and chilling combined

A deformation control and thermal stretching technology, applied in the direction of manufacturing tools, welding equipment, welding/welding/cutting items, etc., can solve the problems of limited application, large and complex temperature difference stretching device, etc., to achieve convenient energy adjustment and small size , the effect of the small size of the heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1, thin plate with welding deformation control device

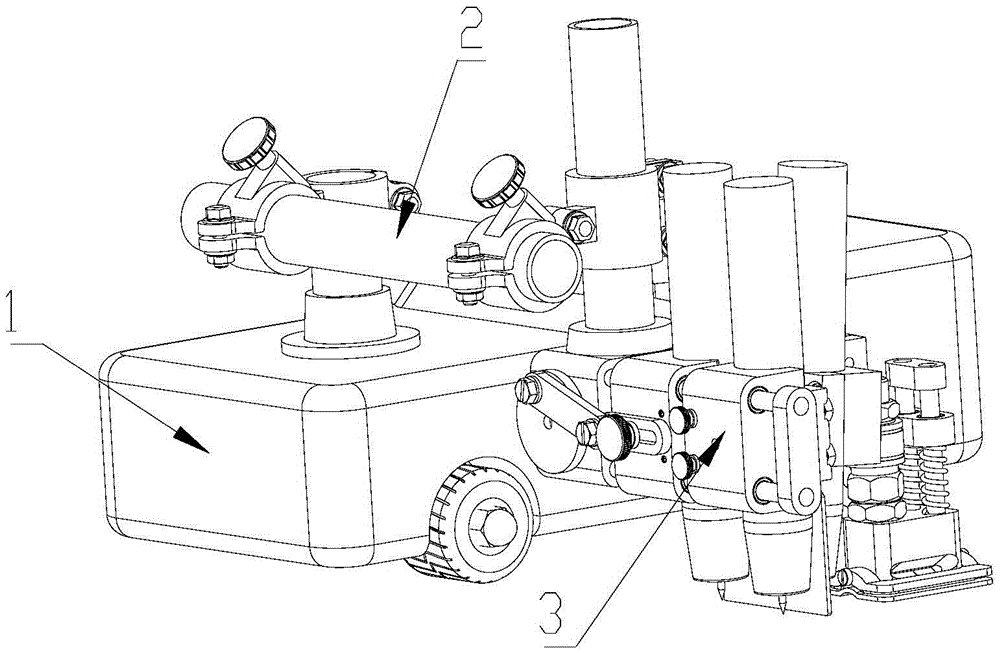

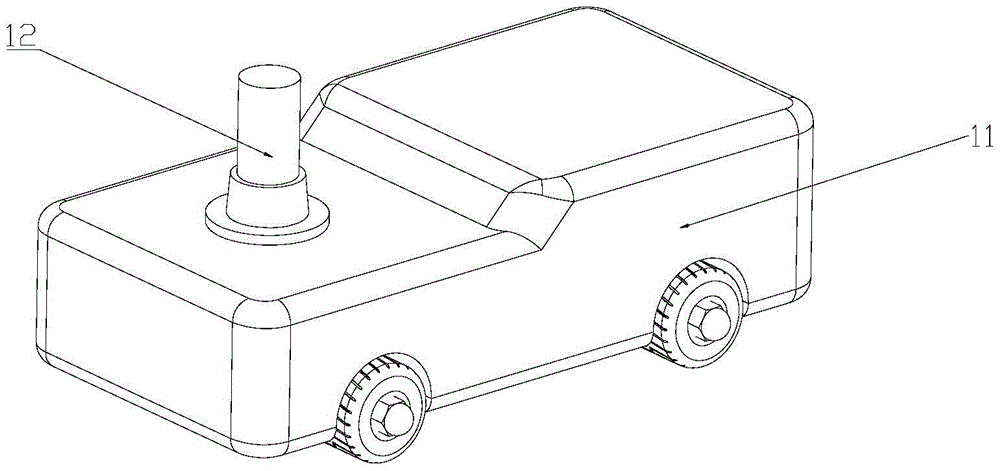

[0048] refer to figure 1 and figure 2 In this example, the thin plate welding deformation control device combined with dynamic thermal stretching and chilling includes a walking module 1, a connecting device 2 and a welding deformation control module 3, and the walking module 1 carries the welding deformation through the connecting device 2 control module 3. Wherein, the walking module 1 is an automatic walking trolley, which includes a body 11 and a connecting device mounted vertical pipe 12 arranged on it, and the body 11 is provided with a counterweight to ensure the stability of the welding deformation control module 3 during the working process. The walking module 1 can move automatically and the speed can be adjusted, and the walking direction is the same as the longitudinal direction of the welding seam.

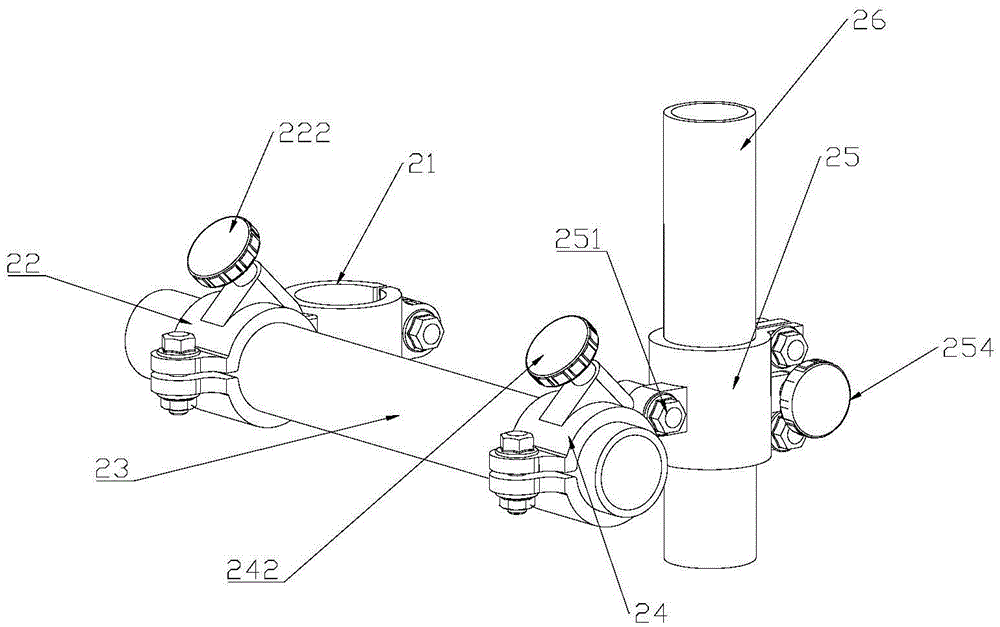

[0049] Such as figure 1 and image 3 As shown, the connecting device 2 includes a firs...

Embodiment 2

[0068] Embodiment 2. Method for controlling deformation of curved thin plates with welding (butt welding of equal thickness curved thin plates)

[0069] The method for controlling deformation of a thin plate with welding in combination with dynamic thermal stretching and chilling of the present invention comprises the following steps:

[0070] (1) Butt the first curved surface thin plate 4 and the second curved surface thin plate 5 of two aluminum alloys with equal thickness of 3mm to be welded, such as Figure 10 As shown, according to the material and thickness process requirements of the thin plate to be welded, the material, thickness and size of the arc starting plate 91 and the arc extinguishing plate 92 are determined, and the arc starting plate 91 and the arc extinguishing plate 92 are fixed on such as Figure 10 location shown.

[0071] (2) Place the self-propelled trolley on the side of the weld so that the traveling direction of the self-propelled trolley is parall...

Embodiment 3

[0077] Embodiment 3, thin plate with welding deformation control method (unequal thickness thin plate welding)

[0078] (1) Butt the third flat plate 6 of 5 mm and the fourth flat plate 7 of 3 mm to be welded, and the material is aluminum alloy. Such as Figure 11 As shown, the arc starting plate 91 and the arc extinguishing plate 92 are fixed on such as Figure 11 location shown.

[0079] (2) Place the self-propelled trolley on the side of the weld so that the traveling direction of the self-propelled trolley is parallel to the longitudinal direction of the weld. Twist the first horizontal adjustment knob 222 and the second horizontal adjustment knob 242 so that the center of the welding torch 322 is located on the arc strike plate 91 and is directly opposite to the center of the welding seam. Adjust the distance between the dynamic thermal stretching module 31 , the welding torch module 32 and the cooling module 8 with welding, and the vertical height between them and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com