Special-shaped boat for controlling sintering flexural deformation of long trumpet-shaped hard alloy nozzle pipe

A hard alloy, bending deformation technology, applied in the field of hard alloy manufacturing, can solve problems such as bending deformation, achieve good bending deformation, and control the effect of bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

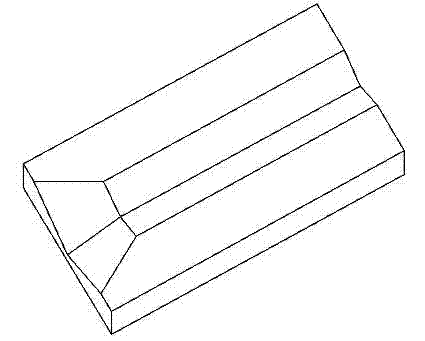

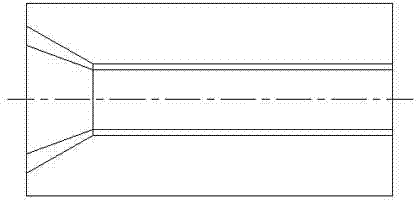

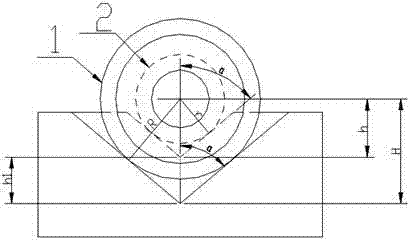

[0055] Such as Figure 9 The shape and material are YG6, and the bell mouth long pipe is sintered. The boat material is made of graphite with a high degree of graphitization, a bright iron black color, a semi-metallic luster, a smooth and greasy feel, and a low knocking sound. The roughness of the V-groove is above 0.8, which can reduce the bending deformation of the blank caused by frictional resistance during the cooling and contraction process.

[0056] Assume Figure 9 The one-half taper angle β of the long pipe with the shape of the bell mouth is 20°, and the angle α is set to 50°. According to the formula:

[0057] tgγ=tgβ / Sinα tgγ=tg20° / Sin50°

[0058] Calculated: γ=25.41°

[0059] tgθ=tgα / Cosγ tgθ=tg50° / Cos25.41°

[0060] θ=52.84°

Embodiment 2

[0062] Assume Figure 9 The one-half taper angle β of the horn-shaped long pipe is 10°, and the α angle is set to 45°. According to the formula:

[0063] tgγ=tgβ / Sinα tgγ=tg10° / Sin45°

[0064] Calculated: γ=14°

[0065] tgθ=tgα / Cosγ tgθ=tg45° / Cos14°

[0066] θ=45.864°

[0067] According to the above-mentioned α, β, γ and θ values, the special-shaped boat suitable for the sintering of the tungsten carbide bell mouth long pipe is manufactured. At any moment during the cooling and contraction process of the blank, there are two different busbars and two busbars at both ends of the blank. The V-shaped grooves of the special-shaped boat are supported by contact, so the bending deformation of the blank is controlled. In the actual production process, as long as the graphite boat material is properly selected, the roughness of the V-shaped groove is above 0.8, and the product length is within 250mm, most of its bending deformation can be controlled within 0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com