Skipjack meal humidity driving film as well as preparation method and application thereof

A bonito meal and humidity technology, applied in the field of material science, can solve the problems of high cost, complex preparation process, unfriendly environment, etc., and achieve the effects of low material cost, simple preparation method and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

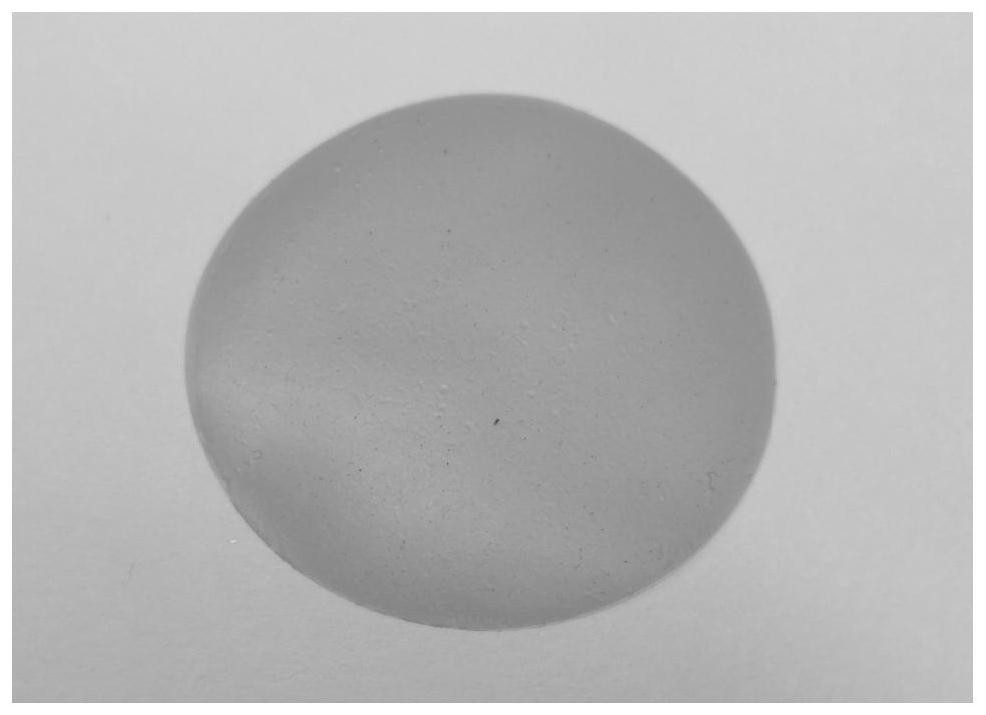

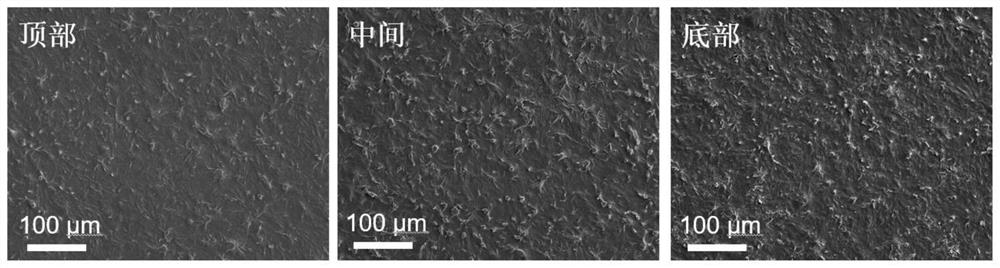

[0030] A bonito meal humidity driving film includes a bonito meal layer, wherein the number of bonito meal particles of the bonito meal layer is distributed in a gradient from top to bottom.

[0031] Further, the thickness of the bonito powder layer is 10-60 μm.

specific Embodiment approach 2

[0032] A preparation method of a bonito meal humidity-driven film is carried out according to the following steps:

[0033] Step 1: Preparation of bonito powder dispersion:

[0034] Dissolve 0.5-5g of bonito powder in 40-80ml of alkaline solution with a concentration of 0.5-5mol / L, the mixed solution is controlled at 20-30°C, magnetically stirred for 0.5-5h, and the magnetic stirring speed is controlled to be 500-1000r / min. Centrifuge the mixed solution for the first time, control the centrifugation speed at 2000-4000r / min, centrifuge time for 10-20min, and collect the supernatant. Centrifuge the supernatant for the second time, control the centrifugation speed at 8000-10000r / min and the centrifugation time for 10-20min, and collect the lower layer precipitate. Dissolve the precipitate in 40-80ml of deionized water and vortex to disperse, control the vortex speed to 1000-3000r / min, and the vortex time to 10-30min to obtain the bonito powder dispersion.

[0035] Step 2: Pre...

specific Embodiment approach 3

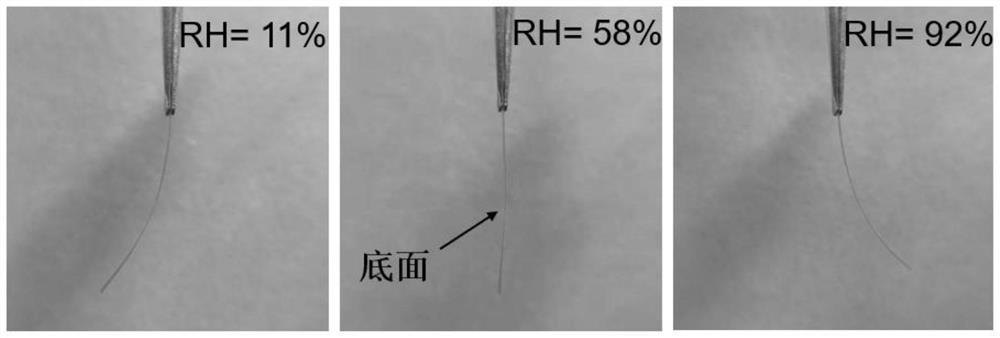

[0041] Embodiment 1 Application of the bonito meal humidity-driven film: when the ambient humidity increases, the bonito meal humidity-driven film bends from the bottom to the top, and when the ambient humidity decreases, the bonito meal humidity-driven film moves from the top to the top. Bottom curved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com