Preparation method of super-sliding block

An ultra-slippery, slider technology used in the manufacture of microstructure devices, processes for creating decorative surface effects, piezoelectric/electrostrictive or magnetostrictive motors, etc. damage, the buckling and unstable structure of the slider, etc., to achieve the effect of simple and convenient method, wide applicability, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

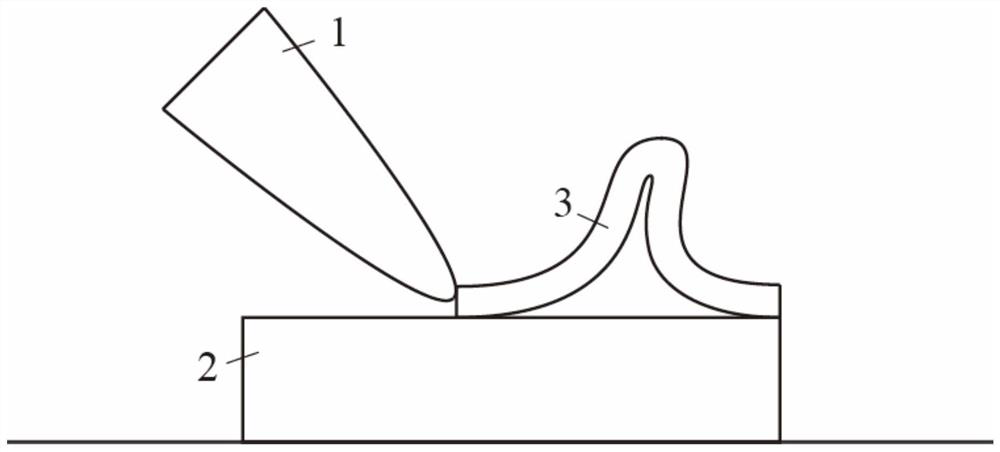

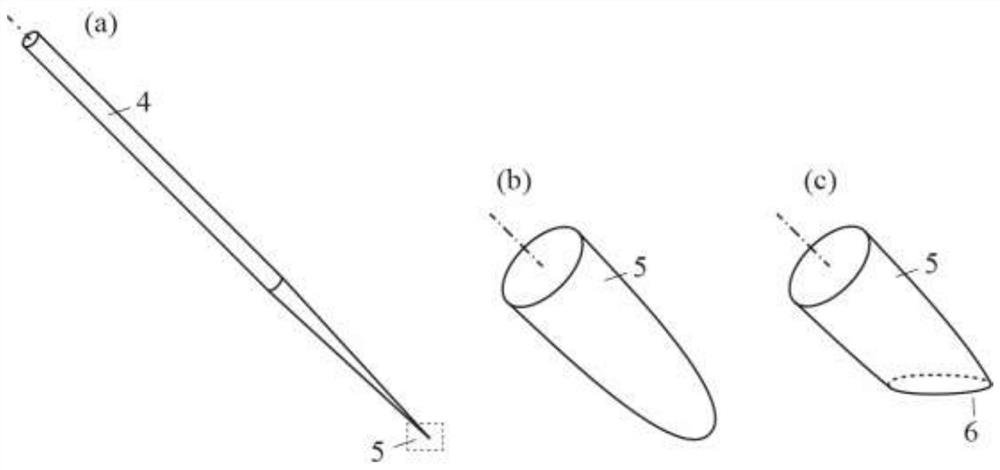

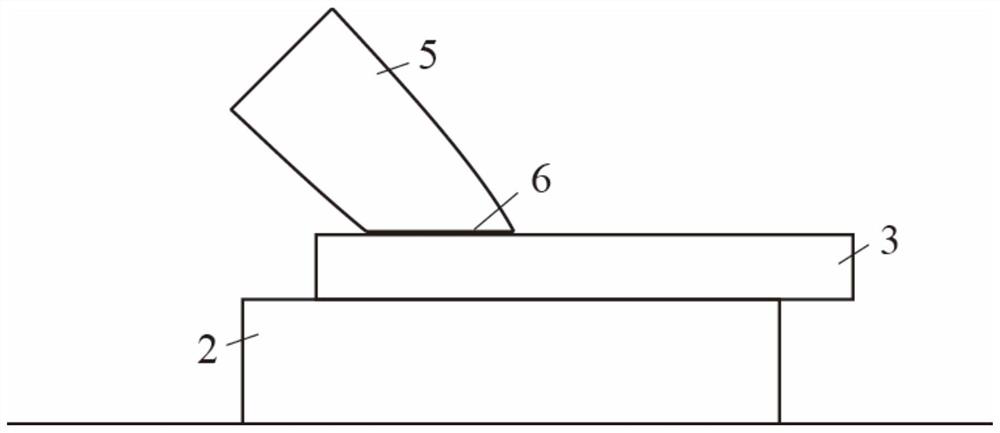

[0032] The preparation method of the ultra-slippery slider that can avoid buckling instability and structural damage of the present invention will be described in detail below with reference to the accompanying drawings.

[0033] Step 1, covering the photoresist on the HOPG, and the photoresist may be covered by spin coating.

[0034] Step 2, patterning the photoresist, and retaining a plurality of photoresist islands. The step of patterning the photoresist determines the layout of the island structure formed in the subsequent steps, for example, the photoresist can be patterned by electron beam etching, and the formed photoresist island can be, for example, the average diameter is 1 μm to 30 μm, and the average interval between photoresist islands is 1 μm to 100 μm, so that the etched island structure also has a corresponding average diameter and average interval.

[0035] Step 3, etching the substrate to remove a portion of the substrate not protected by the photoresist, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com