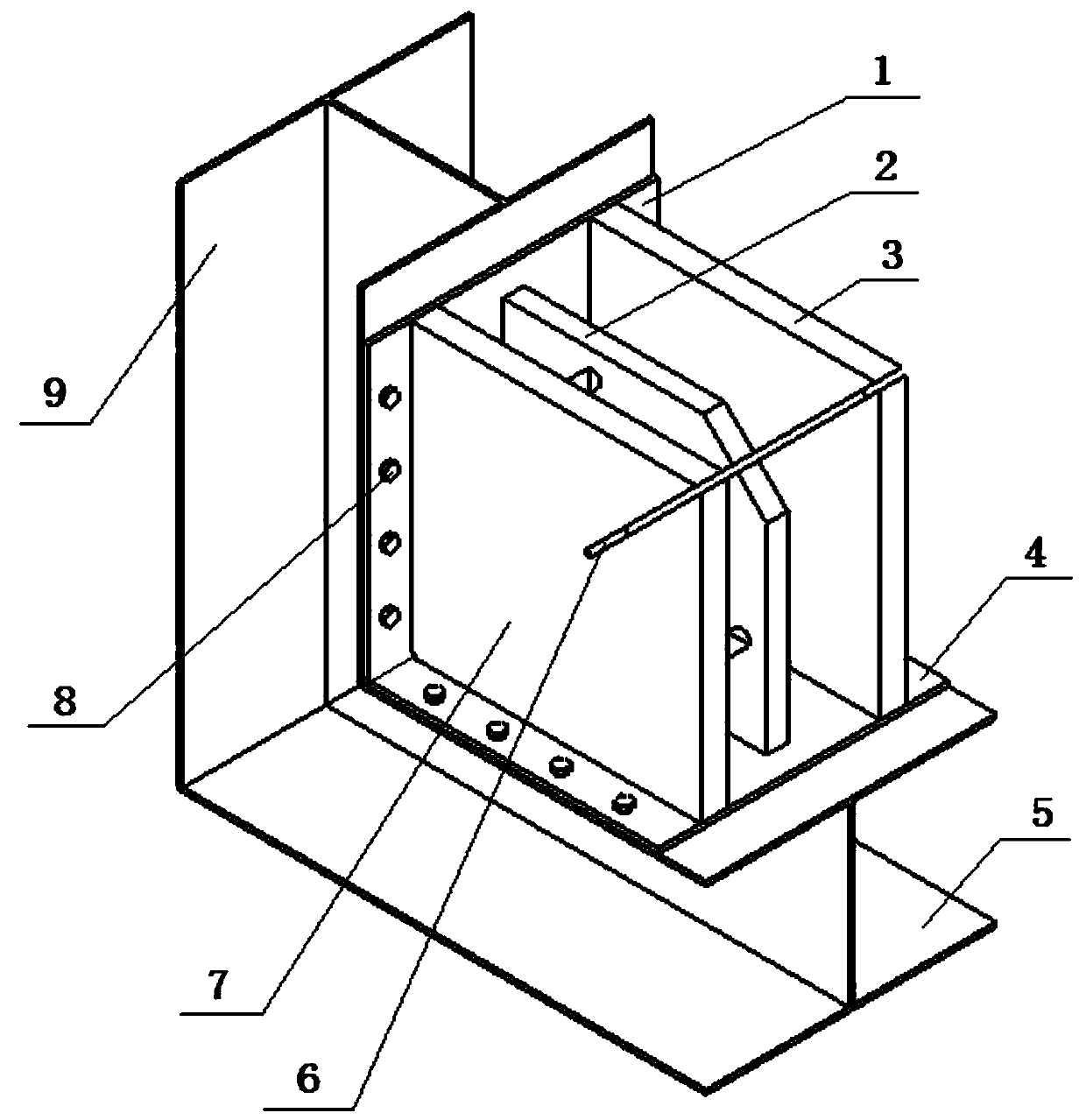

Combined type buckling-restrained joint component

A buckling restraint, combined technology, applied in building components, building structures, protective buildings/shelters, etc., can solve the problems of low repair economy, reduced ductility of frame beam-column joints, and high support cost. Avoid support buckling, reduce repair difficulty and repair cost, and facilitate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

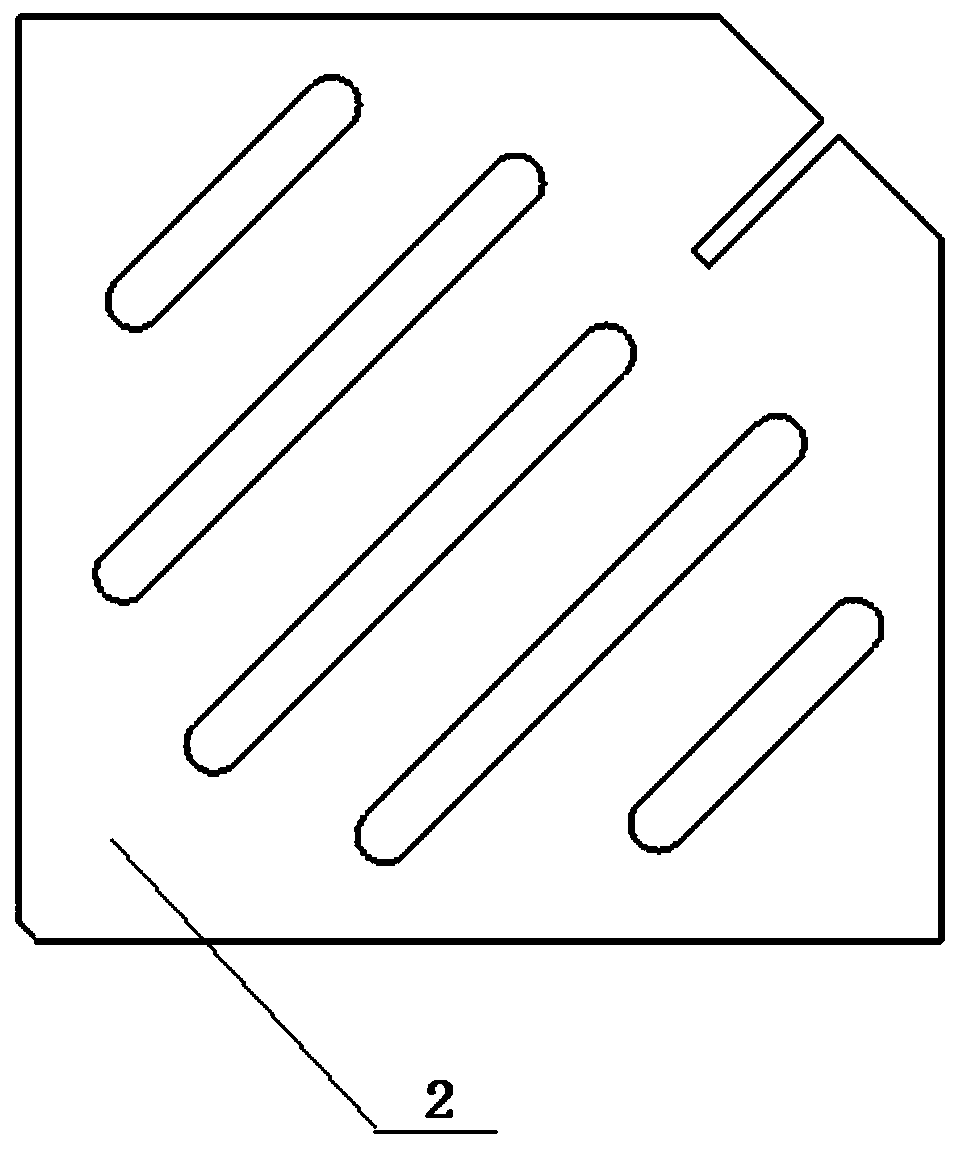

[0018] Refer to attached figure 2 , a corner is cut off on the damping plate 2, the diagonal line of the damping plate 2 is perpendicular to the cutting edge line, and a half-length groove is opened on the vertical direction of the cutting edge line of the damping plate 2, and the center line of the half-length groove is the damping Diagonal line of the plate 2, through holes are symmetrically opened on both sides of the diagonal line of the damping plate 2.

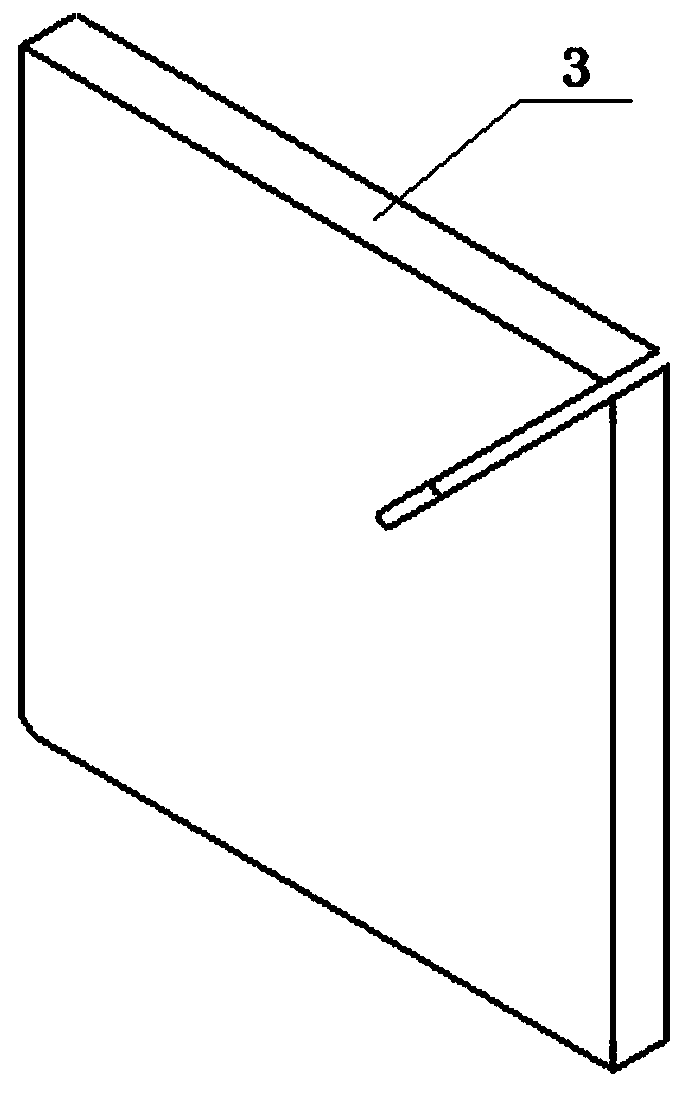

[0019] Refer to attached image 3 , set a half-length groove on one corner of the first guide connecting plate 3, the center line of the half-length groove is the diagonal line of the first guide connecting plate 3, set a half-length groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com