Economical creep aging forming method of large thin-wall component

A technology of creep aging forming and thin-walled components, which is applied in the field of thin-walled component manufacturing, can solve problems such as buckling instability of large thin-walled components, and achieve the effects of preventing deformation, reducing weight, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The invention provides a large-scale thin-walled component economical creep aging forming method, which is described by taking a large-scale thin-walled double-curvature component as an example.

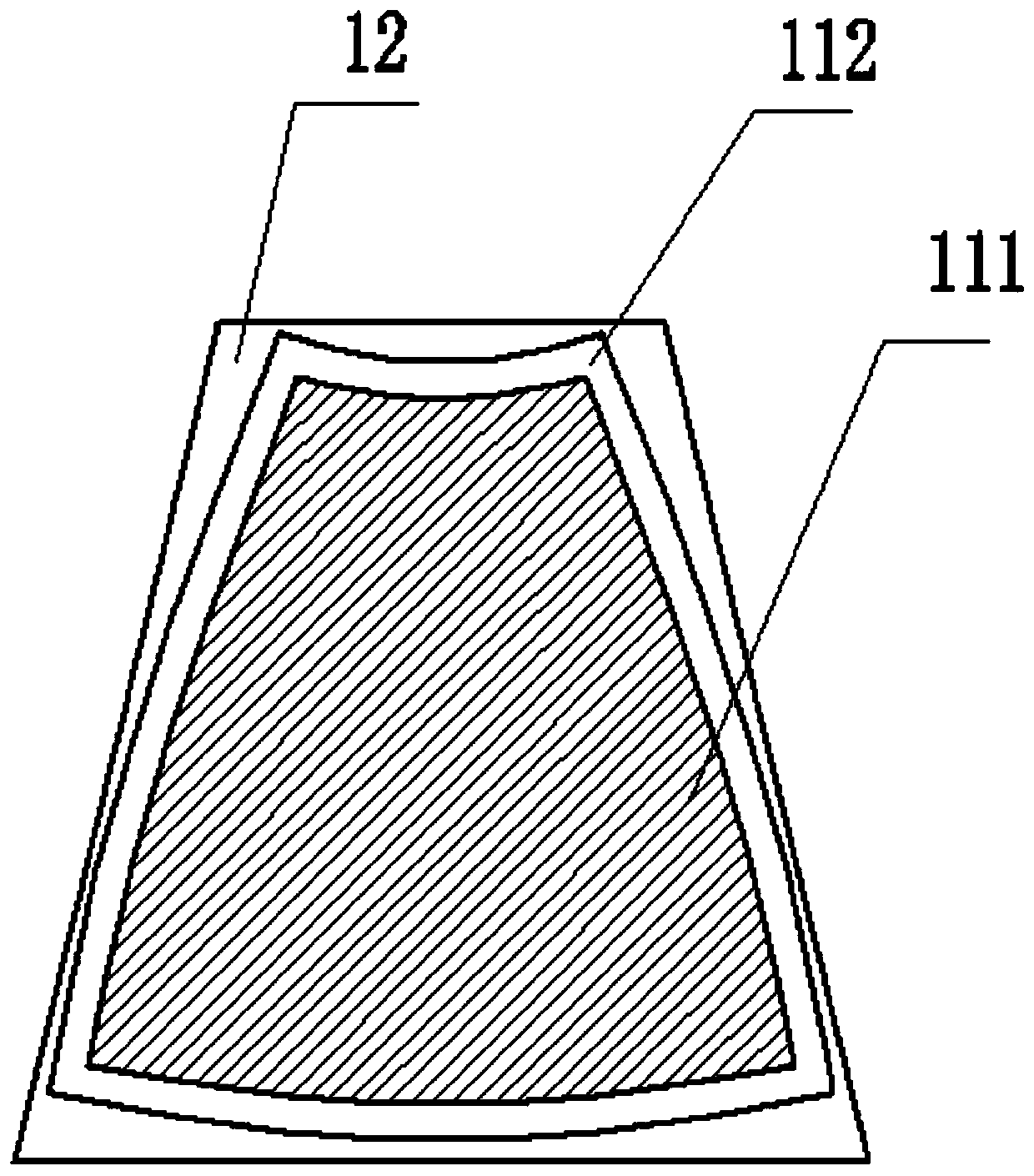

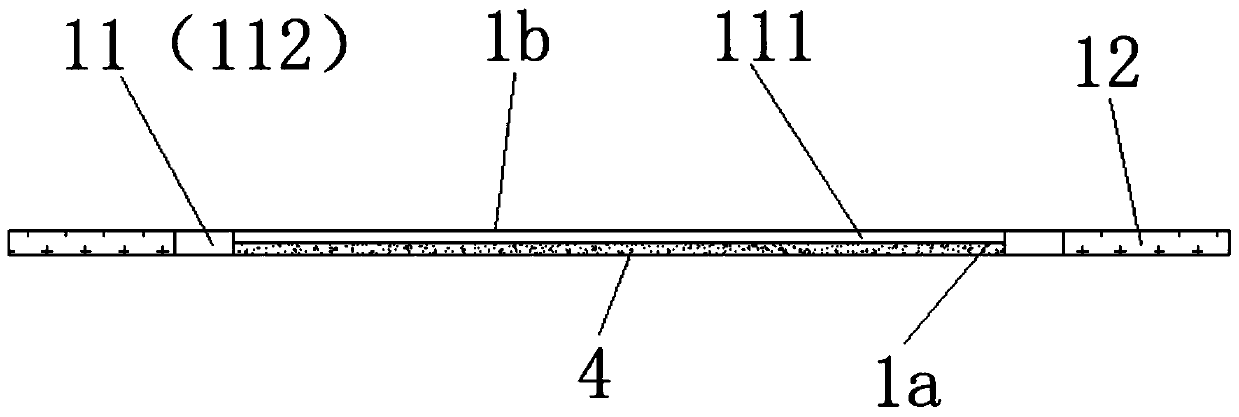

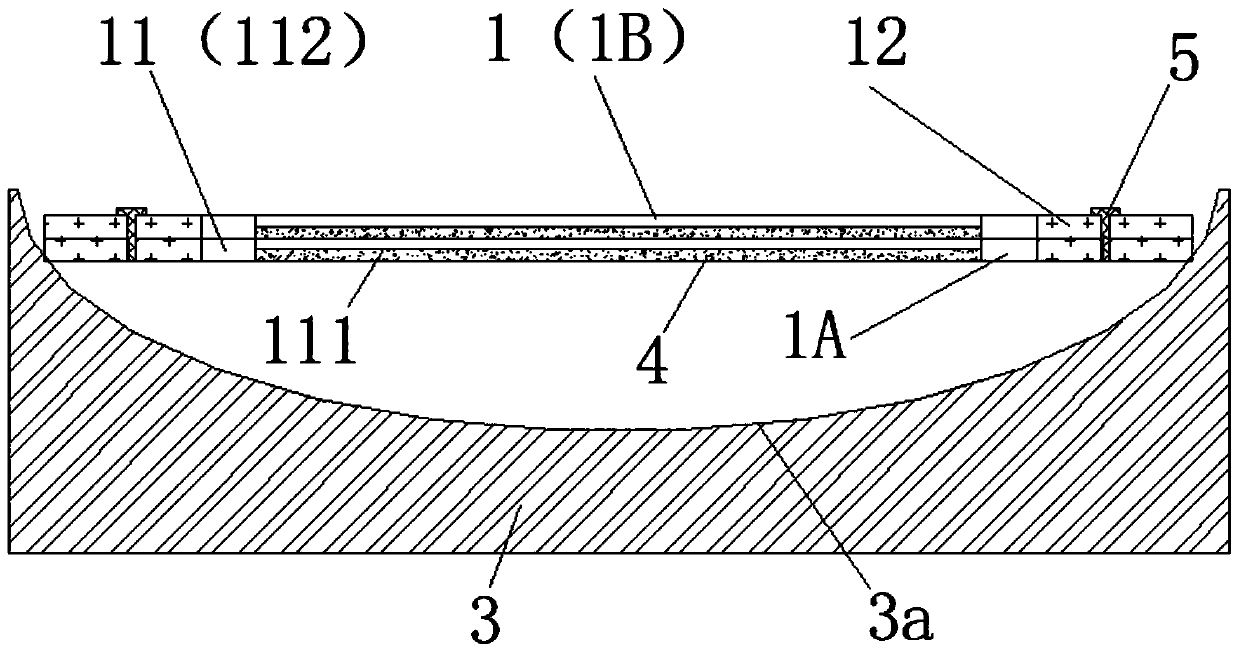

[0028] S1. First, cut out the factory-made aluminum alloy sheet stock with a thickness of 5 mm and a brand name of 2219, and cut out two component sheet materials 1 including the component expansion body 11, preferably two pieces with an upper bottom of 743 mm and a lower bottom of 743 mm. Isosceles trapezoidal plate with a height of 1419mm and a height of 1394mm. like figure 1 shown. Mark the area of the component expansion body 11 in the two component sheets 1, and reserve a circle of 50 mm wide outer grid area 112 inward along the edge of the area of the component expansion body 11. For the external grid area 112 of the component expansion The area is milled to form a thinned area 111 of 2 mm thickness by 3 mm. The side of the component plate 1 that has been milled i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com