Patents

Literature

52results about How to "Does not affect welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

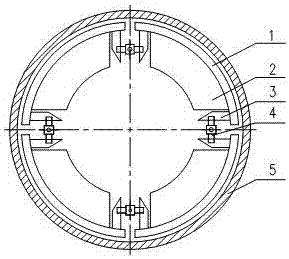

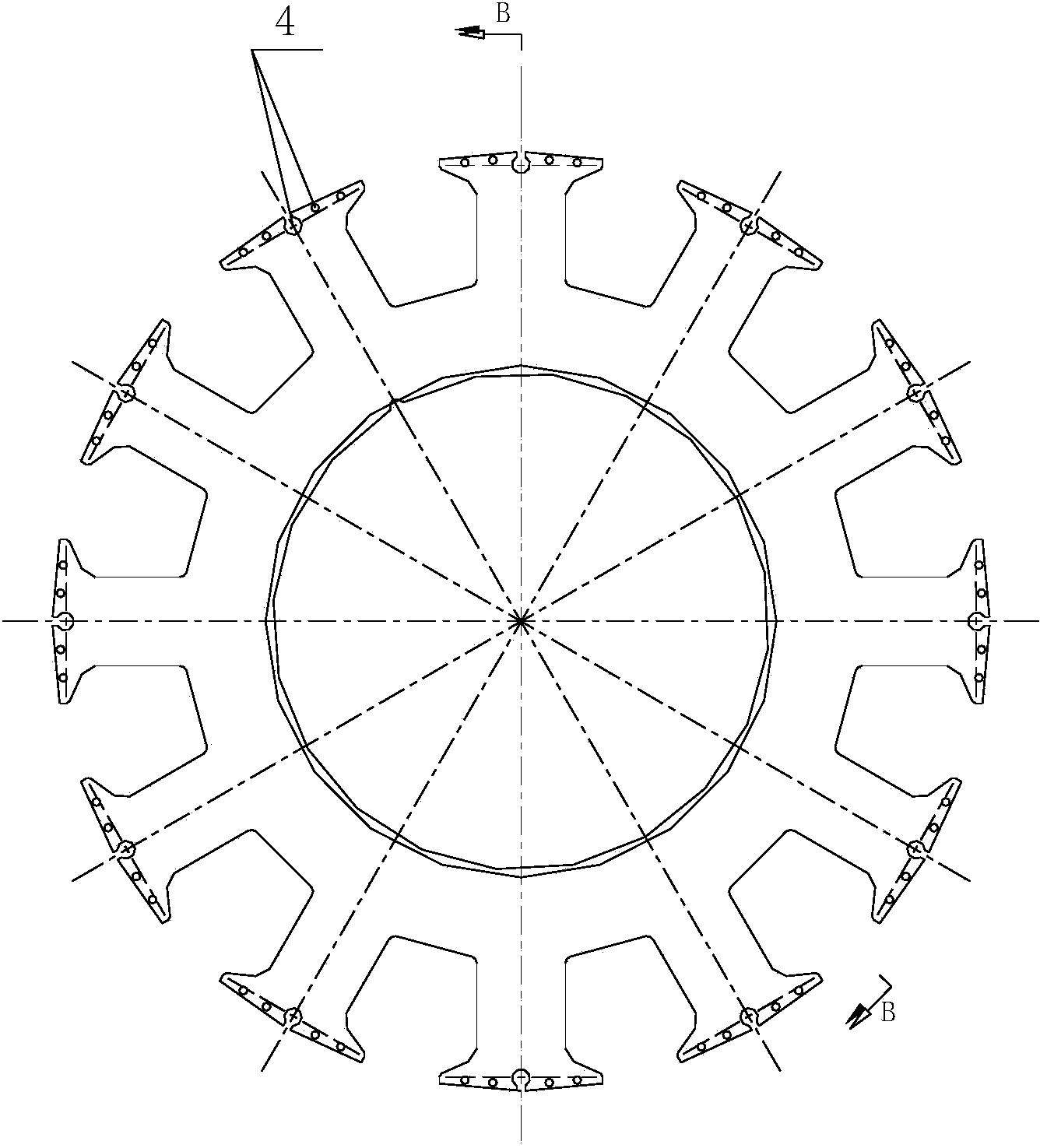

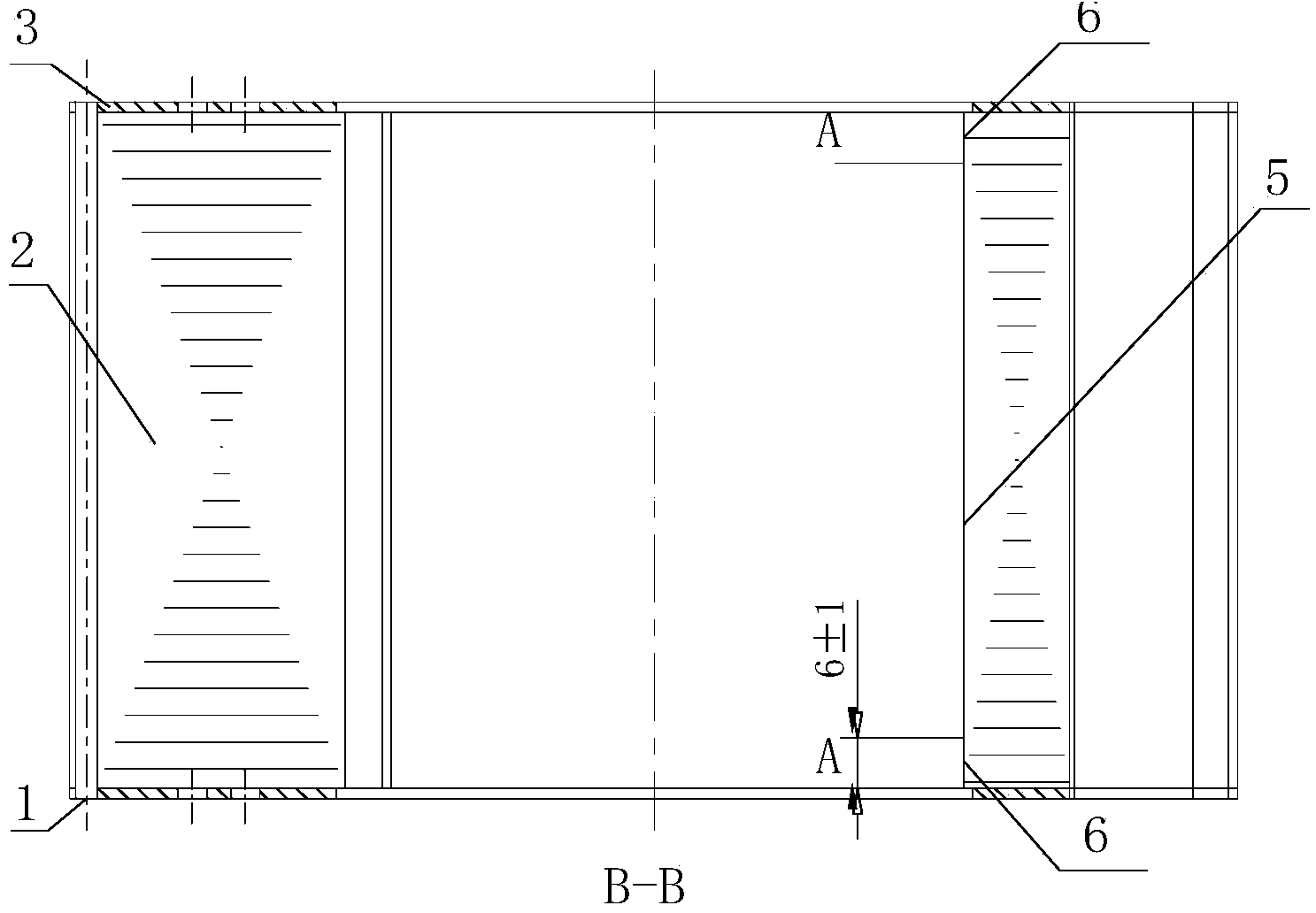

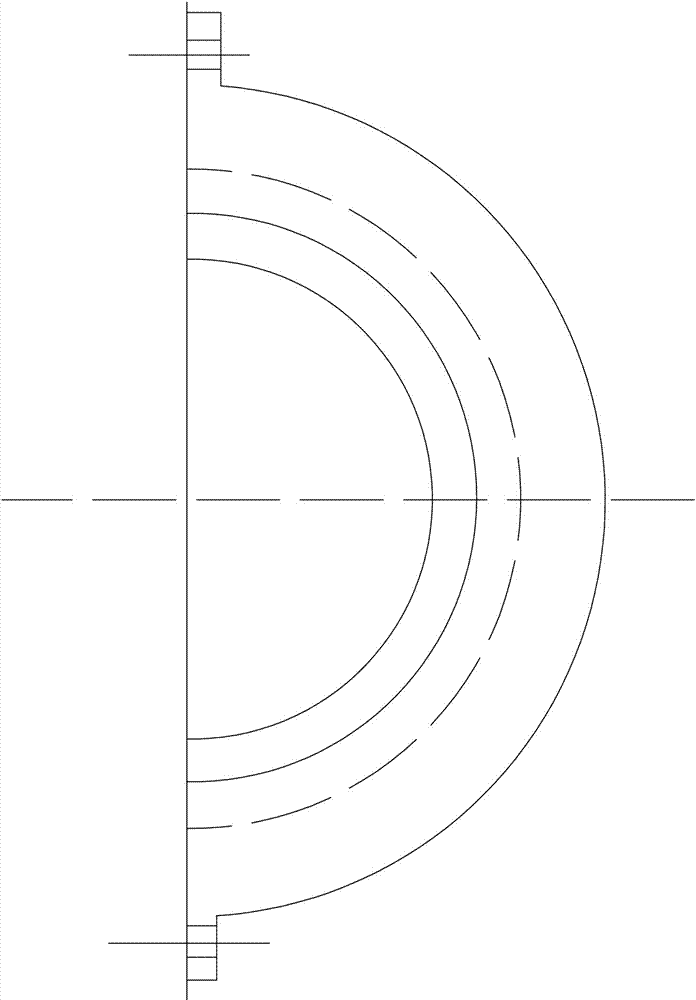

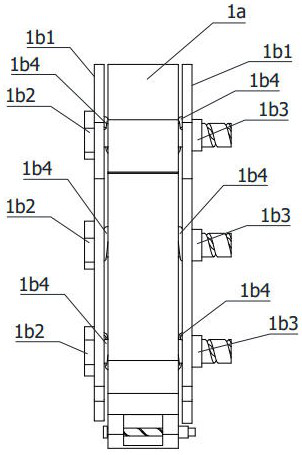

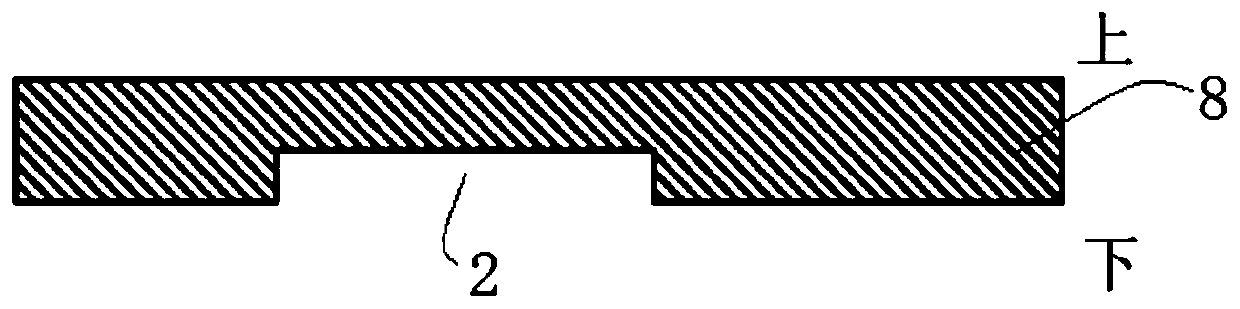

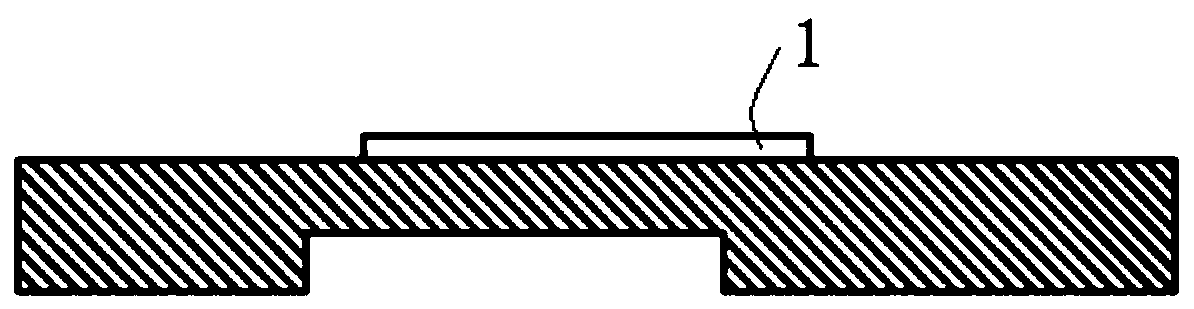

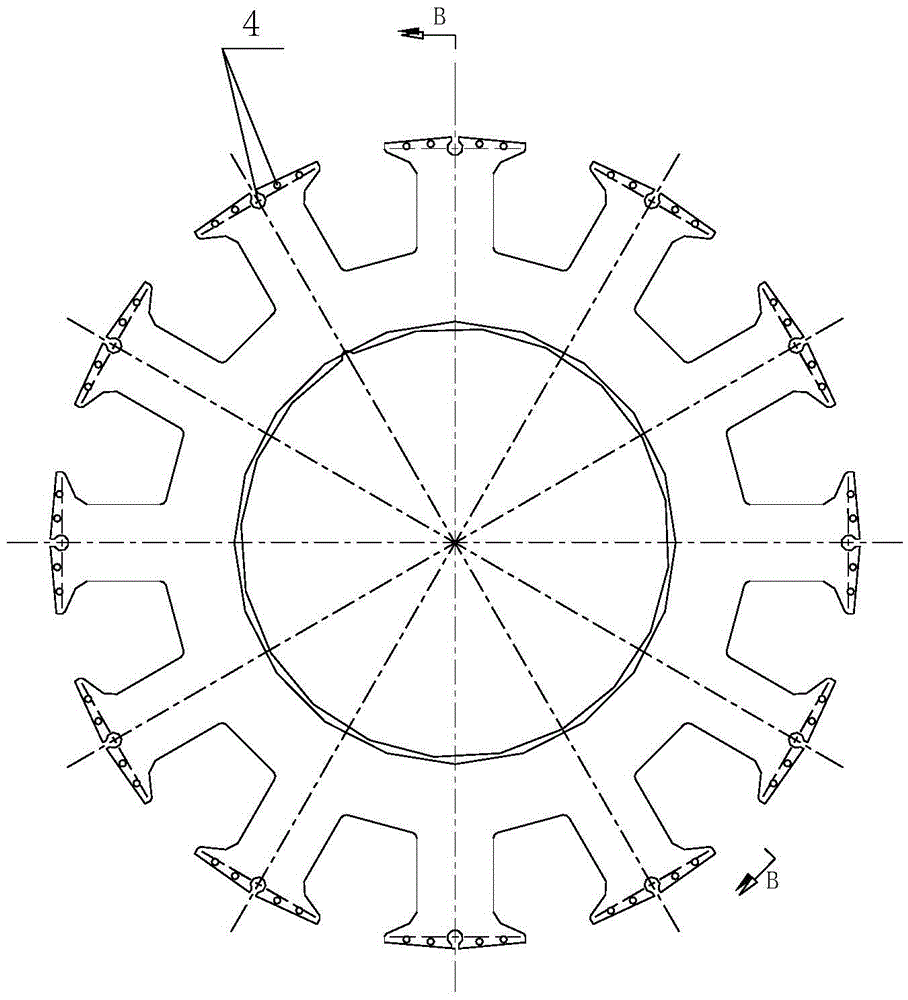

Inner circular expanding tool in thin-wall cylinder circular seam pairing

PendingCN107303633ADoes not affect weldingSimple structureWelding/cutting auxillary devicesAuxillary welding devicesThin walledWelding

The invention discloses an inner circular expanding tool in thin-wall cylinder circular seam pairing. The tool comprises a shell cushion plate, a support arc plate, rib plates and a locking device; the shell cushion plate, the support arc plate and the rib plates are welded and connected as a whole; the rib plates are connected through the locking device; and the locking device is movably connected with two adjacent rib plates through forward and reverse screw buckles. The tool is simple in structure, is adopted without influencing such work as welding of circular seams, is convenient in installation and disassembly, has such advantages as low cost and easiness in operation, is free of influencing the welding work of cylinder circular seams, improves the working efficiency, and effectively prevents such quality problems as easiness in deformation and cylinder waist collapse in welding of the circular seams.

Owner:LANZHOU LS HEAVY EQUIP

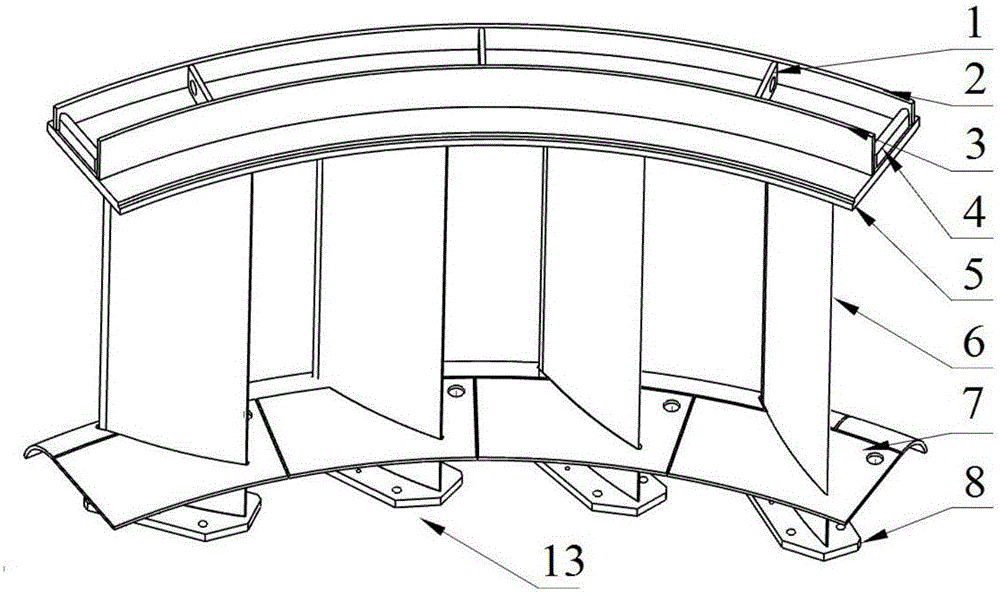

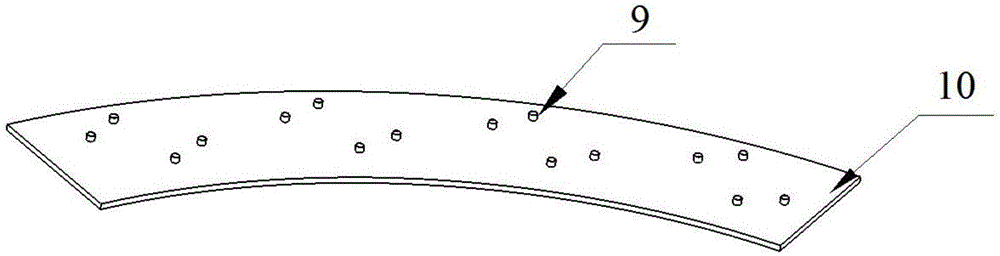

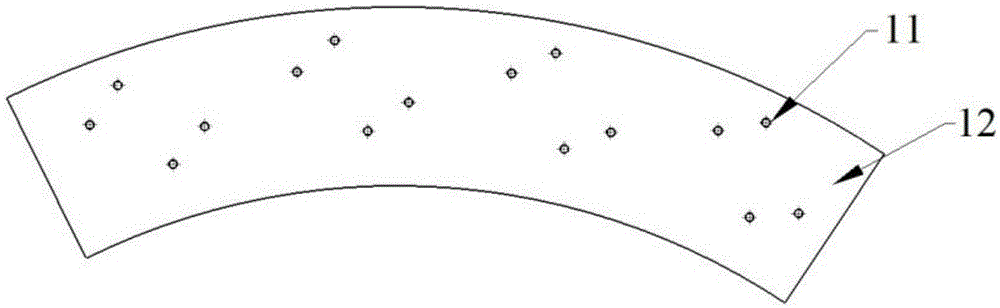

Erecting welding technological method for single-upper-ring type large segmented stand ring with sole plates

ActiveCN105057855AReduce weightReduce difficultyArc welding apparatusProcessing costWelding deformation

The invention relates to an erecting welding technological method for a single-upper-ring type large segmented stand ring with sole plates. A sole plate positioning template and positioning pipes are used for precise positioning; and after splice welding of a lower guide plate, fixed guide vane mounting holes are perforated in a matched mode, and then fixed guide vanes are inserted. The key process problems of stand ring welding deformation, sole plate assembly positioning, sole plate combining through hole processing cost, the production cycle and the like are solved through an auxiliary lower ring, the sole plate positioning templates and the positioning pipes, and the production cost and the production cycle are reduced. According to the stand ring manufactured through the technological method, the problems of assembly positioning, the production cost, welding deformation and the like are effectively solved, and construction site installation requirements are met; the subsequent production cycle and processing cost are greatly reduced, economy and practicability are both considered, and the purposes of lowering cost and improving effects are achieved.

Owner:HARBIN ELECTRIC MASCH CO LTD

PCB structure capable of preventing tin connection of adjacent pads

The invention discloses a PCB structure capable of preventing tin connection of adjacent pads, for solving the problem of tin connection easily generated during welding of pads in a PCB. The PCB structure comprises a PCB main body and the N pads which are arranged on the PCB main body and are provided with welding holes. All the pads are sequentially arranged to form a pad group, the pad arrangement direction is parallel to the furnace direction of a PCB, N is a natural number greater than one, the pads are runway-shaped, the adjacent two pads are arranged in such a way that the runway-shaped straight edges are opposite, and the PCB main body area between the adjacent pads is provided with a silkscreen white oil layer whose length is not smaller than the length of the pads; and tin dragging pads connected with the pads at edges are disposed at the two ends of the pad group on the reverse surface of the PCB main body. The design is ingenious, the problem of tin connection between the tail portions of the pads and between the adjacent pads can be effectively solved, the labor cost is saved, and the production efficiency is also substantially improved.

Owner:深圳市磊科实业有限公司

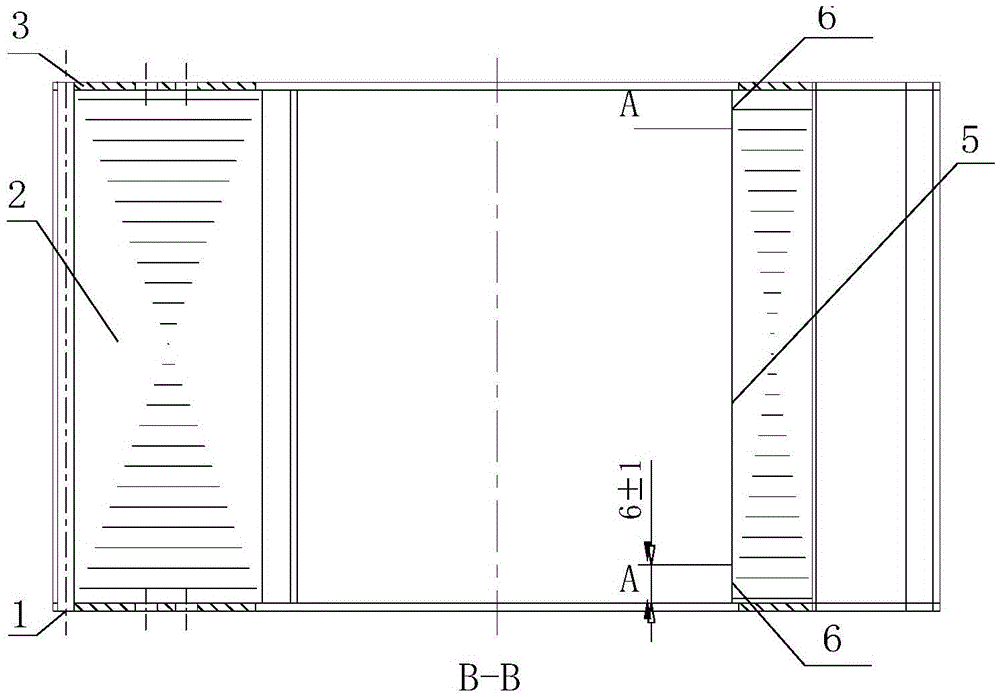

Method for processing high-speed generator rotor core assembly

ActiveCN103490569ADoes not affect linkGuaranteed bondingManufacturing stator/rotor bodiesLiquid stateThin layer

The invention relates to a method for processing a high-speed generator rotor core assembly. A liquid state adhesion agent which can form a solid state adhesive film before solidification is adopted, therefore, a thin layer adhesive film can be formed by conducting good infiltration on the surface of stamped steel, and a copper damper bar can be protected against contamination in follow-up processing. The method that local gluing is conducted on each piece of iron core stamped steel within the range of 6+ / -1 mm apart from a copper end plate is adopted, therefore, the segments of the copper damper bar and the copper end plate are not affected, and adhesive bonding between pieces of iron core stamped steel can be ensured. The method for processing the high-speed generator rotor core assembly has the advantages that the adhesion agent is used for adhesive bonding so that the overall strength of the rotor core assembly can be improved and the damage, caused by welding, to the iron core stamped steel is overcome; the method that local gluing is conducted on each piece of end stamped steel is adopted so that the welding between the copper damper bar and the copper can not be affected; the adhesion agent is used for adhesive bonding between all the pieces of iron core stamped steel, therefore, the insulating property of all the pieces of stamped steel of a rotor core can be improved, and eddy-current loss of the rotor core assembly can be reduced.

Owner:SHAANXI AVIATION ELECTRICAL

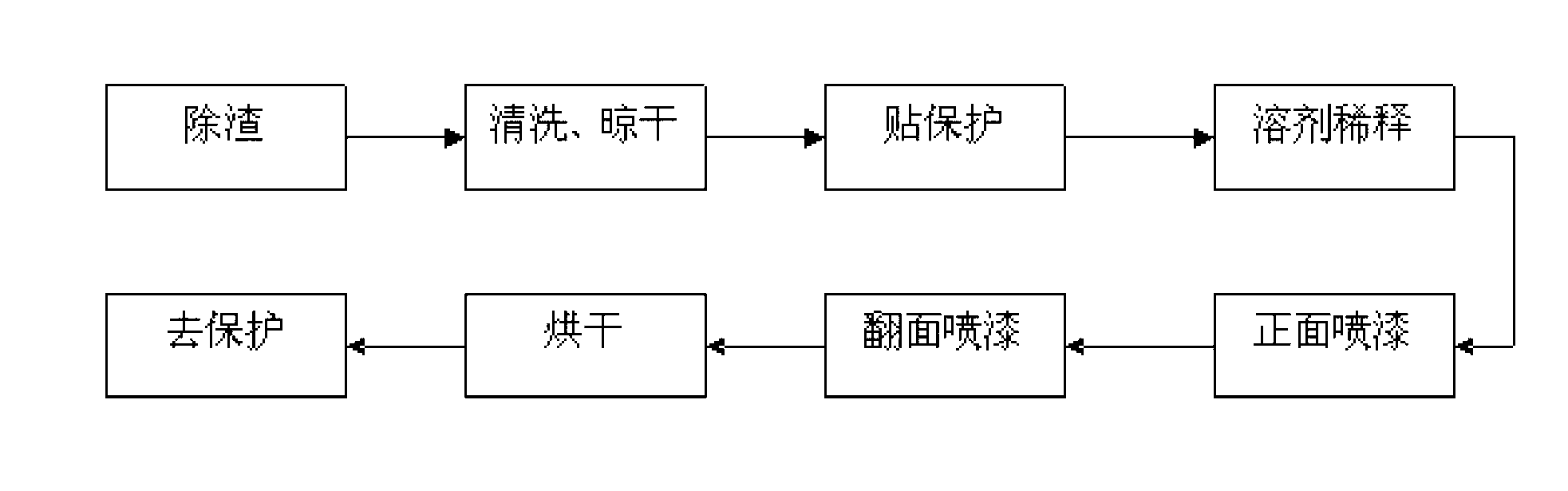

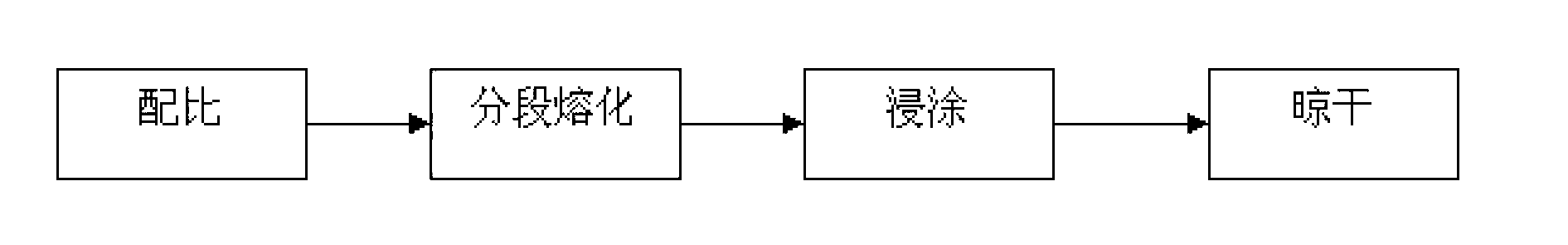

Three proofing method of firefighting electronic product printed circuit board (PCB) through matched electronic wax

InactiveCN103025073AEasy to operateShort cycleNon-metallic protective coating applicationWaxDip-coating

The invention discloses a three proofing method of a firefighting electronic product PCB through matched electronic wax and relates to the technical field of protection of the firefighting electronic product PCB. Soft electronic wax with dropping-melting points of 62 DEG C and 82 DEG C is matched in proportion respectively and heated to be molten and mixed in three sections in a dedicated waxing device; the PCB is placed in the melted and mixed wax liquid for dip coating, and taken out and placed on a board inserting rack vertically when the dip coating time is up; a blowing device is used for accelerating the flow of extra wax fluids; and the next process is performed after the PCB is dried. The three proofing method has the obvious advantages of being simple in operation, short in cycle, low in price, good in 'three proofing' effect, unaffected on welding, lossless in repair and capable of greatly improving the production efficiency.

Owner:蚌埠依爱消防电子有限责任公司

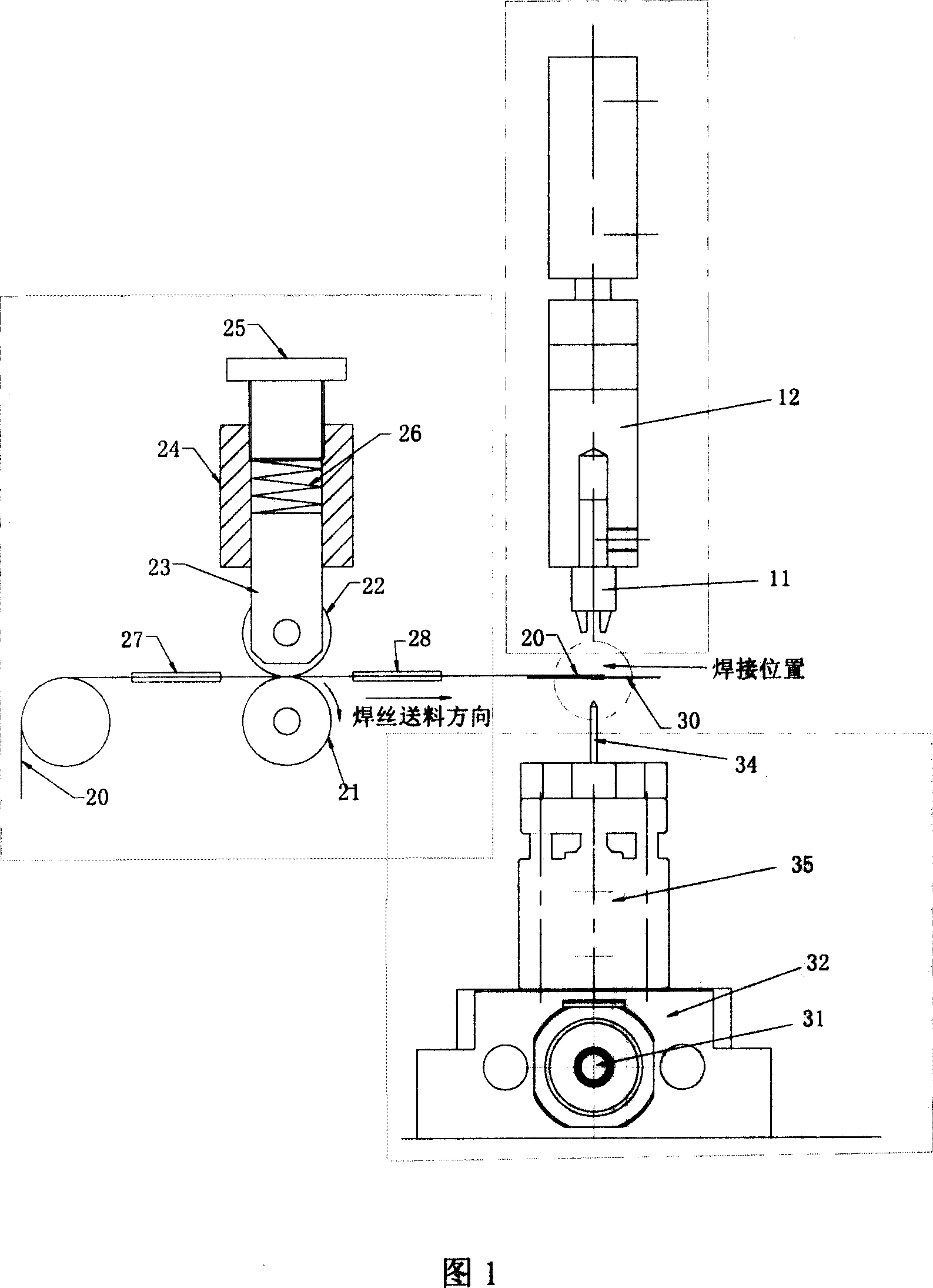

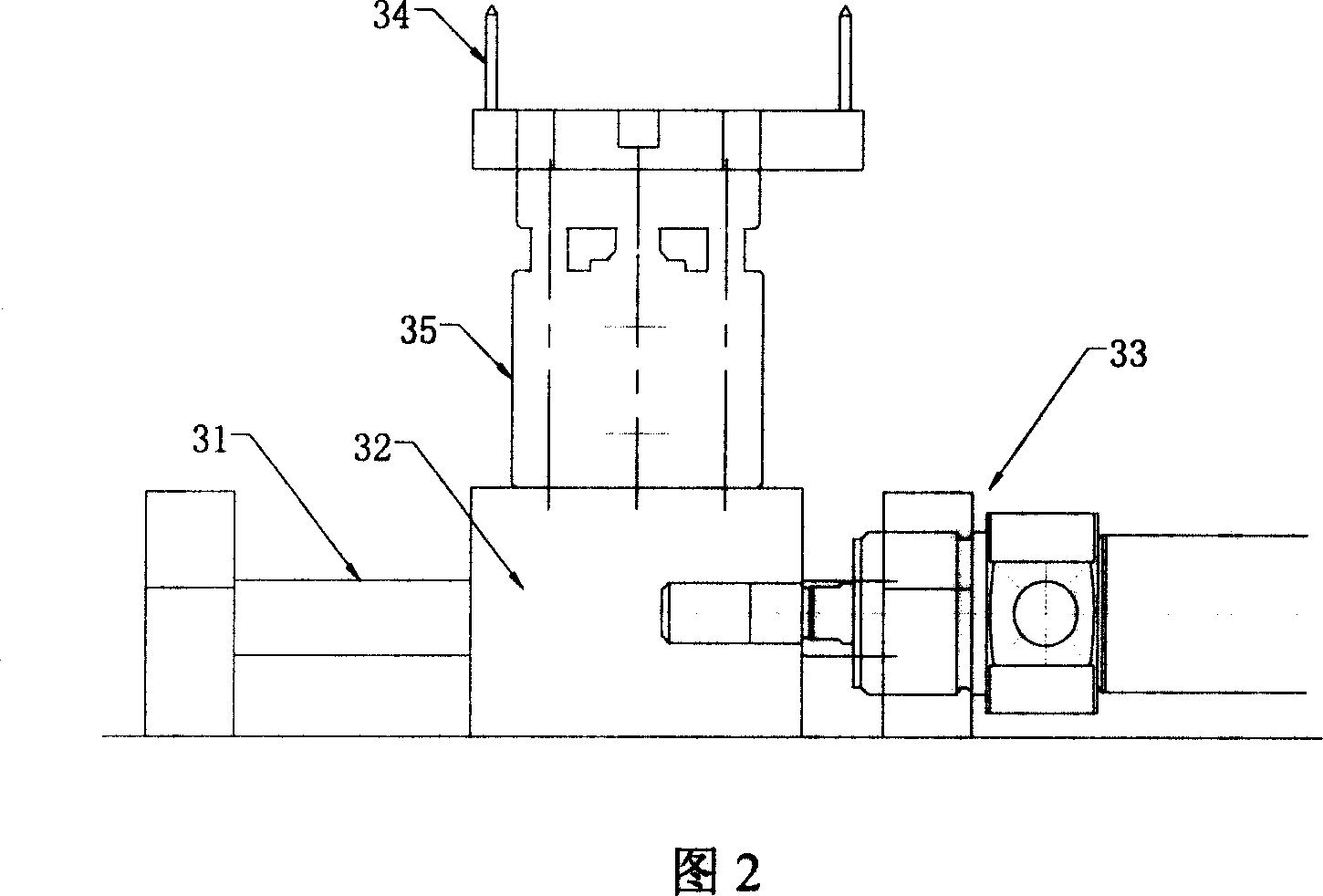

Cold-compression welding wire machine

ActiveCN101053922ADoes not affect weldingImprove welding efficiencyWelding/cutting media/materialsSoldering mediaChemical structureMetallic materials

The invention provides a cold press welding wire machine wherein the welding electrode will not be bonded by welding residual matter. The cold press welding wire machine comprises the welding electrode made of ceramic material which has large difference from metal wire in chemical structure, in addition, the surface of the ceramic material is smooth, thereby the welding electrode will not be bonded by welding residual matter in general case and the welding in next time will not be effected, the welding efficiency and welding quality can be improved.

Owner:惠州臻富机械电子科技有限公司

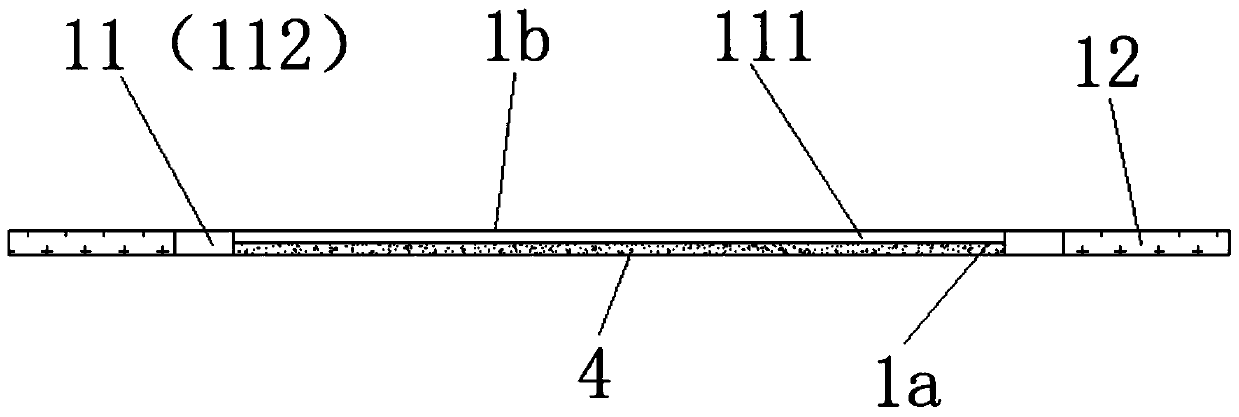

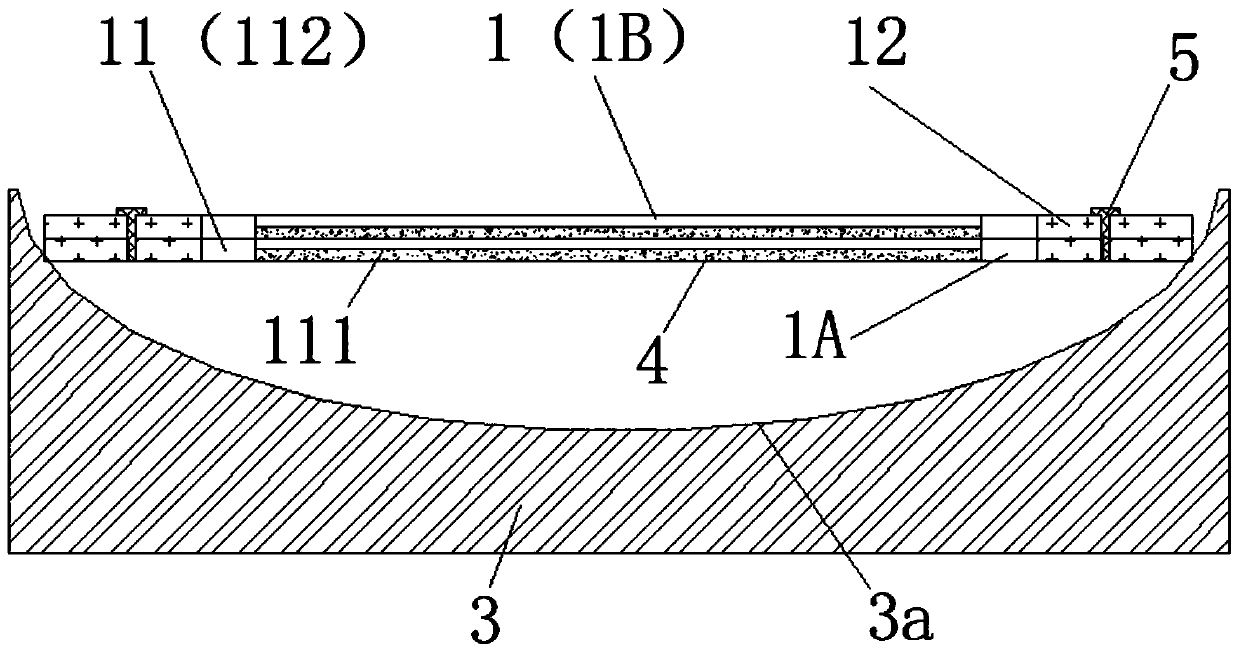

Economical creep aging forming method of large thin-wall component

ActiveCN111195678AInhibition of local buckling instabilitySave materialBuckling instabilityThin walled

The invention discloses an economical creep aging forming method of a large thin-wall component. The economical creep aging forming method comprises the steps that two component plates are firstly cutout; the two component plates are fixed to form a reinforcing plate, and the reinforcing plate is completely covered by ventilated felt and then placed on a mold surface, specifically, the first component plate is close to the mold surface, and the second component plate is away from the mold surface; a vacuum bag is pasted on the edge of a mold to make the vacuum bag and the mold form a closed space; the closed space is vacuumized to make the reinforcing plate approach or keep fit with the mold surface, then the reinforcing plate and the mold are put into a hot-pressing tank to be subjectedto vacuum creep aging forming, and each component plate is separated from the mold after the vacuum creep aging forming is finished; the allowance plate of the first component plate is milled off; andthe process of the vacuum creep aging forming of the reinforcing plate is repeatedly performed on the second component plate to finish a second component. According to the economical creep aging forming method, the precise shape-property integrated forming of the large thin-wall component can be realized, the local buckling instability condition of a component with weak rigidity in the creep aging forming process is effectively inhibited, and meanwhile, the material and the forming time can be saved.

Owner:CENT SOUTH UNIV

Creep age forming method for large thin-wall component

The invention discloses a creep age forming method for a large thin-wall component. The method comprises the following steps that firstly, an aluminum alloy blank is cut into a component plate containing a component unfolding body; a metal plate is cut into an auxiliary plate with an outer contour consistent with an outer contour of the component plate; the component plate and the auxiliary plateare tightly attached and fixed to form a reinforcing plate; the reinforcing plate is placed on a mold face, and the reinforcing plate is completely coated with ventilated felt; a sealant is pasted onthe edge portion of a mold, and a vacuum bag is pasted on the sealant so as to make the vacuum bag and the mold jointly form a closed space; the closed space is vacuumized to make the reinforcing plate be close to or keep attached to the mold face; the reinforcing plate and the mold are put into an autoclave for vacuum creep age forming, and after completion, the component plate, the auxiliary plate and the mold are separated; and an allowance plate is milled. According to the method, precise shape and property integrated forming of the large thin-wall component can be achieved, and a local buckling instability condition of the component with the weak rigidity in the creep age forming process is effectively restrained.

Owner:CENT SOUTH UNIV

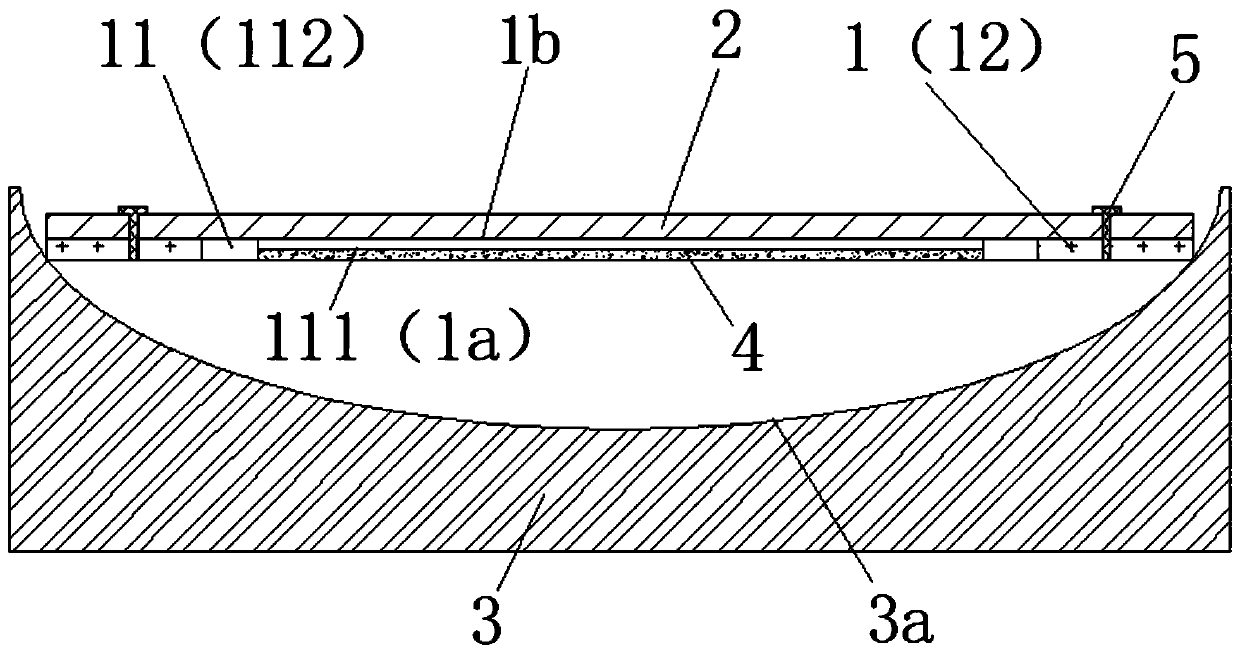

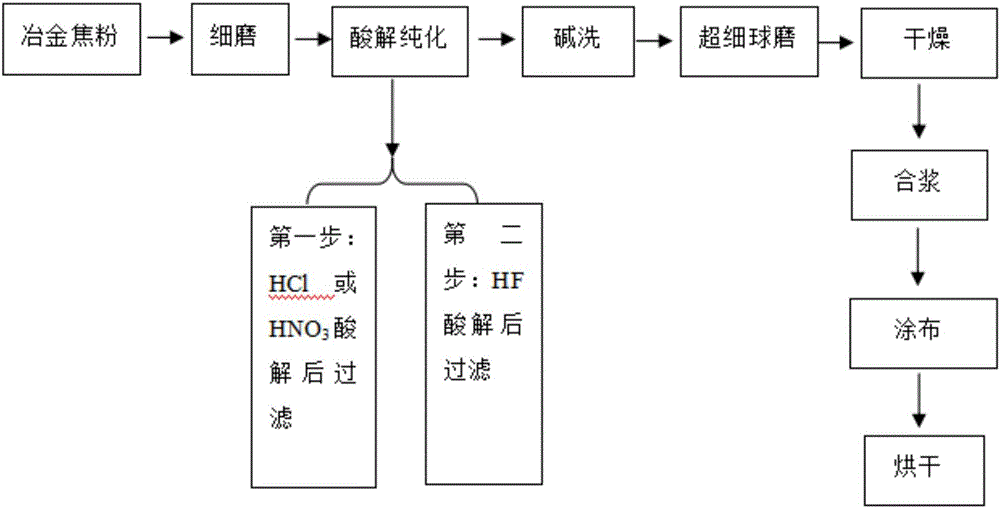

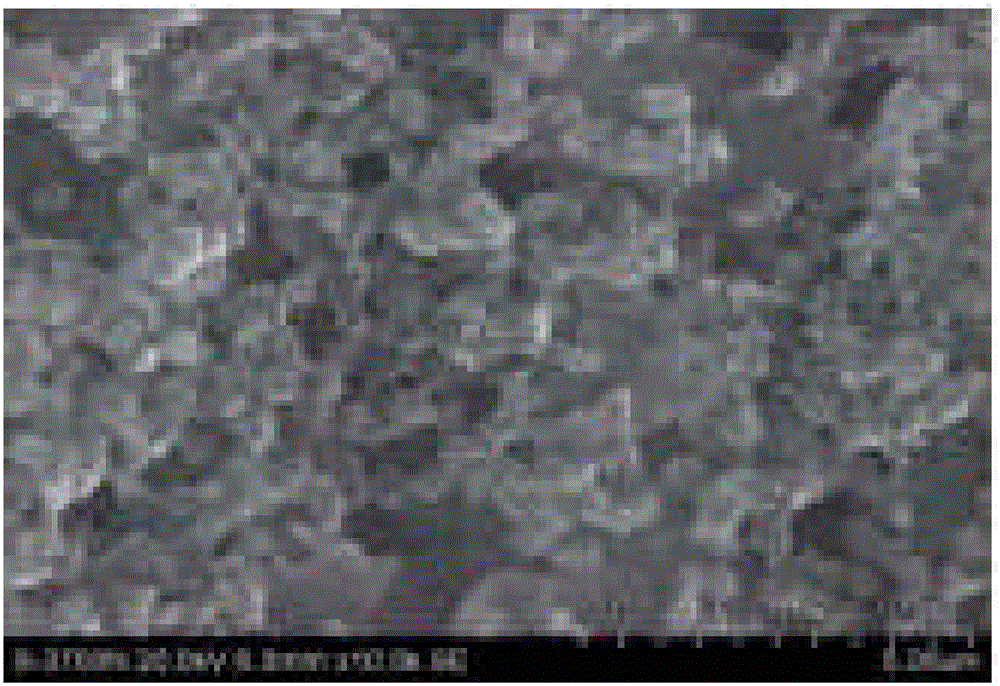

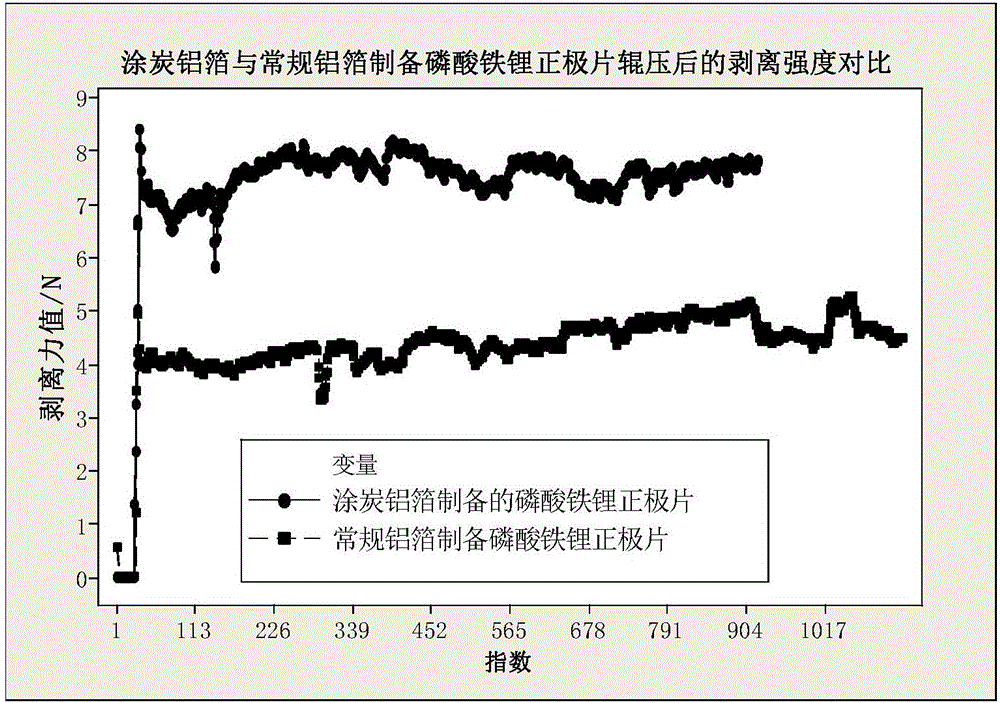

Method for preparing coated carbon aluminum foil of lithium-ion battery current collector by employing metallurgical coke powder as raw material

InactiveCN106505206AIncrease contact areaDoes not affect weldingElectrode carriers/collectorsSecondary cellsHydrofluoric acidElectricity

The invention discloses a method for preparing coated carbon aluminum foil of a lithium-ion battery current collector by employing metallurgical coke powder as a raw material. The method comprises the steps of pulverizing large-grained metallurgical coke powder of which the particle sizes are smaller than or equal to 3mm into the powder of which the particle sizes are 1-10 microns; adding an acid liquid to the metallurgical coke powder for primary acidolysis, putting the liquid into a hydrofluoric acid solution for secondary acidolysis, and sequentially putting the solution into an alkali solution and deionized water for washing and filtering; mixing the filtered metallurgical coke powder and a grinding aid for ultrafine ball-milling for 5-10 hours until the particle sizes of the metallurgical coke powder are 20-50nm; carrying out drying and slurry mixing; and uniformly coating aluminum foil with slurry to obtain the coated carbon aluminum foil of the lithium-ion battery current collector. The particles of the metallurgical coke powder are refined to the maximum extent by adopting an ultrafine ball-milling technology; the contact area of the coke powder particles and the current collector is increased; and the electric property of a lithium-ion battery is significantly improved. The method has the advantages that: on one hand, the manufacturing cost of the coated carbon aluminum foil of the lithium-ion battery current collector is reduced, and on the other hand, a new way is opened up for high added value utilization of the metallurgical coke powder.

Owner:ANHUI ANKAI AUTOMOBILE

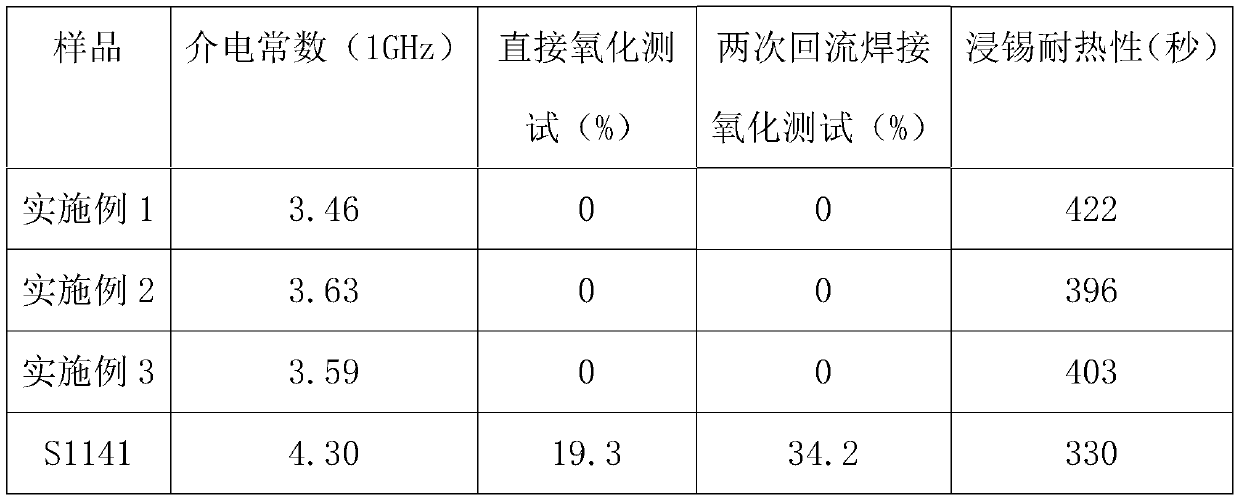

Production process for copper-clad plates

ActiveCN110254025ALow dielectric constantLow dielectric lossLamination ancillary operationsLaminationDielectric lossCopper foil

The invention discloses a production process for copper-clad plates, and belongs to the technical field of production of the copper-clad plates. The production process has the advantages that through a scientific and reasonable formula and an advanced extraction process, dielectric constants of the copper-clad plates are well reduced, so that the dielectric loss is reduced, and the copper-clad plates have high heat resistance; the possibility of oxidation of the copper-clad plates is greatly lowered, and the welding efficiency is improved.

Owner:JIANGXI PROVINCE HANGYU NEW MATERIAL CO LTD

Water-soluble metal short-term antirust liquid and preparation method thereof

The invention discloses a water-soluble metal short-term antirust liquid which is prepared from the following raw materials in parts by weight: 2-3 parts of alkyl polyglucoside, 1-2 parts of an emulsifier OP-10, 2-3 parts of sodium metaborate, 1-2 parts of ascorbic acid, 2-3 parts of butyl hydroxyanisole, 0.5-1.5 parts of urotropine, 1.1-1.7 parts of trioleic acid tallow diamine, 0.5-1 part of silicon nitride, 10-12 parts of acrylonitrile, 5-7 parts of water glass, 1-2 parts of EDTA disodium, 4-5 parts of an auxiliary agent, and 300 parts of water. The antirust liquid can form a thin film on a metal surface, so as to isolate air and prevent oxidation; the thin film is easy to clean up, and can be immediately removed by water washing; the antirust liquid has good oxidation resistance and corrosion inhibition effects, can form the oxidation protective film on the metal surface, and has lasting antirust effect; and the antirust liquid is suitable for short-term rust prevention of hardware, automobile parts and other metal products, and does not affect welding and other performance.

Owner:MINGGUANG CITY LIUXIANG PUMP IND

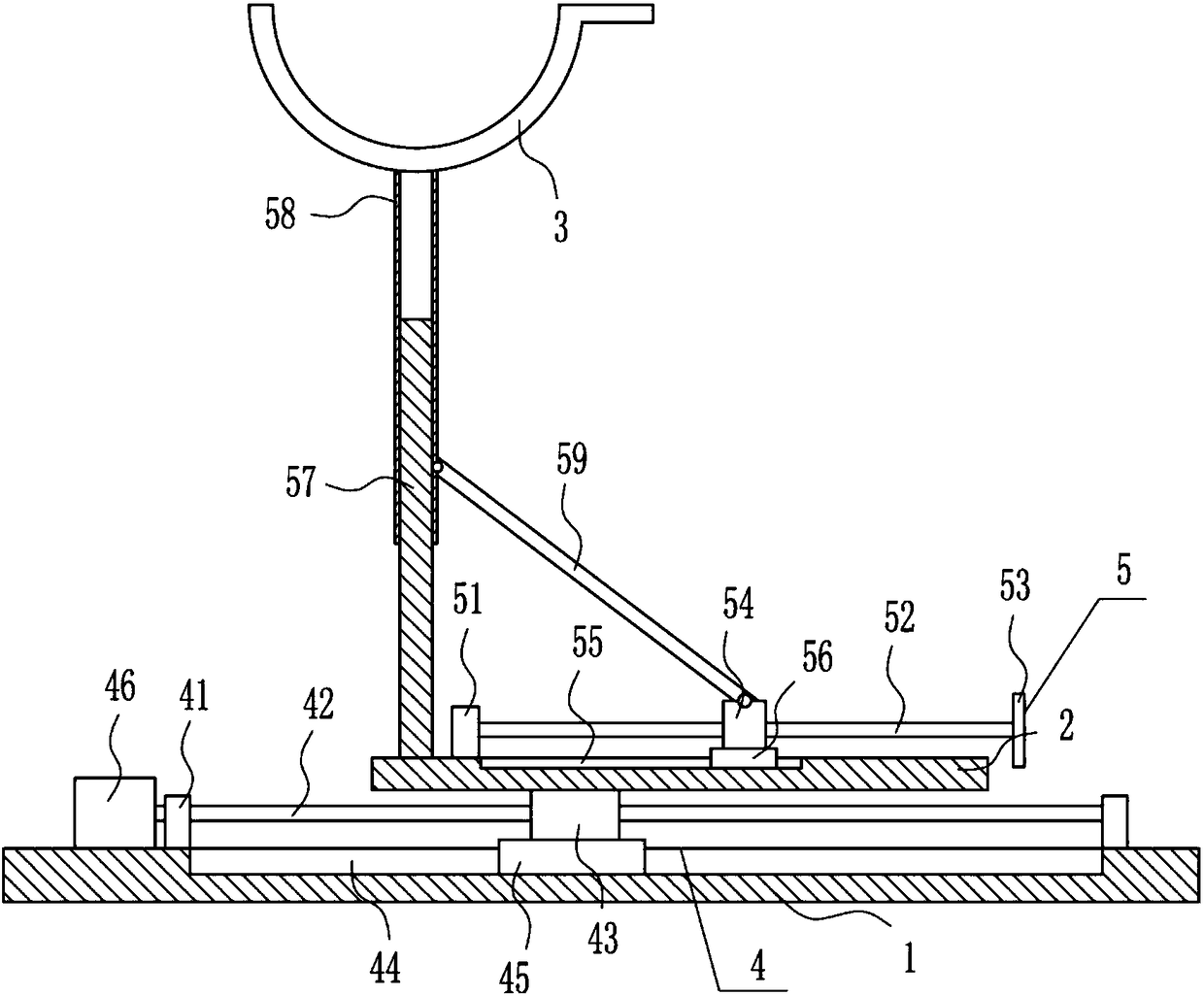

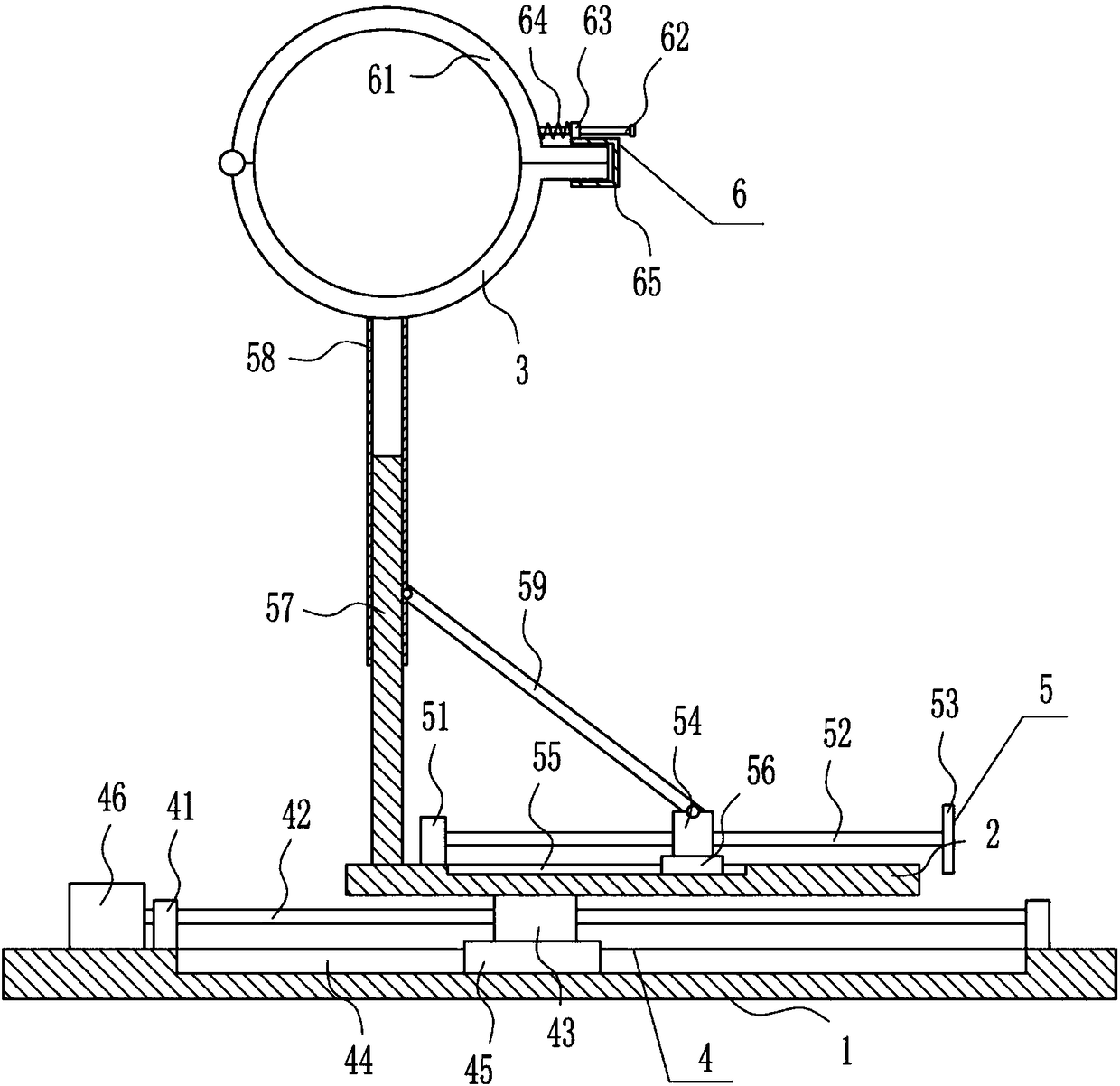

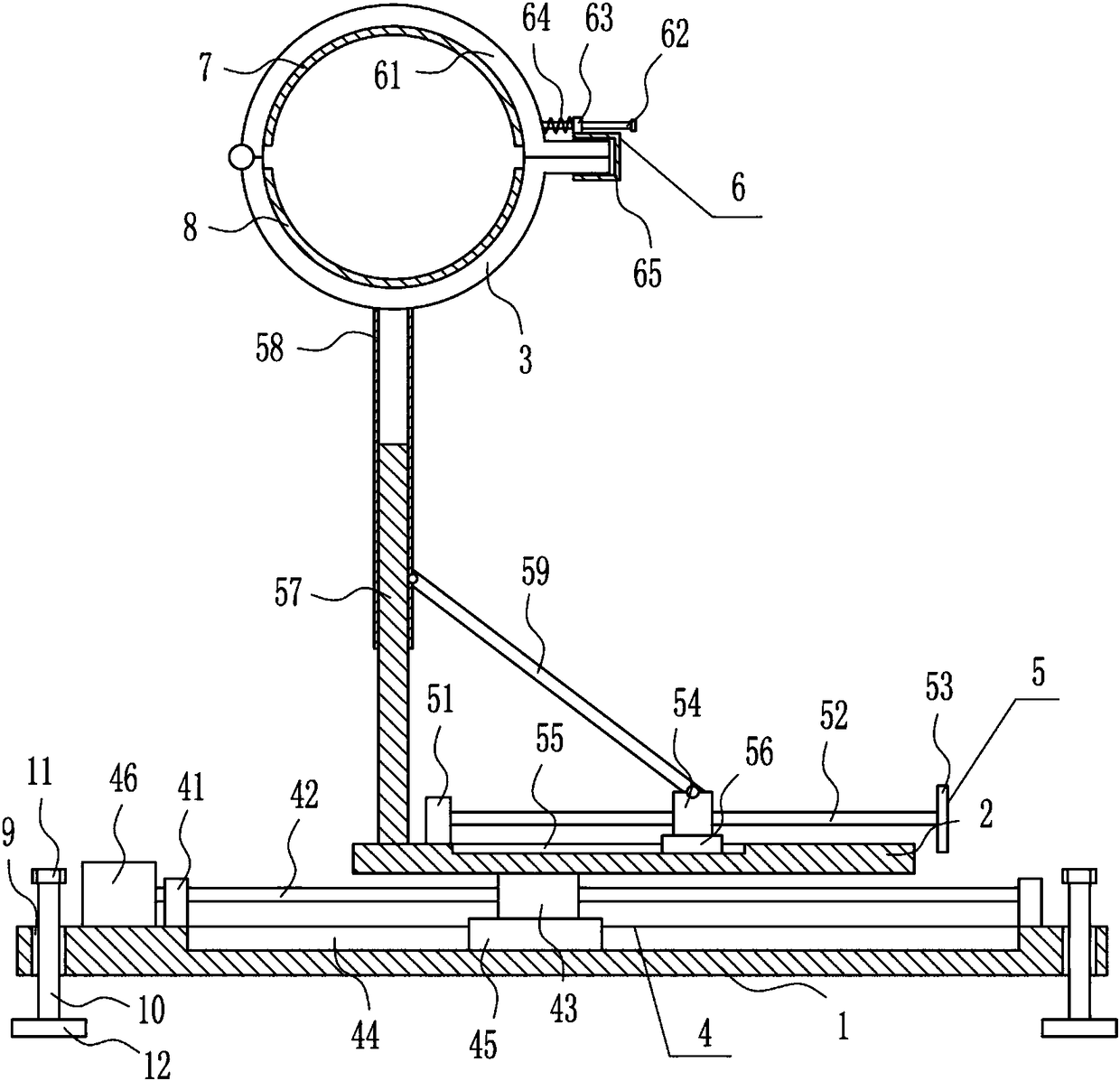

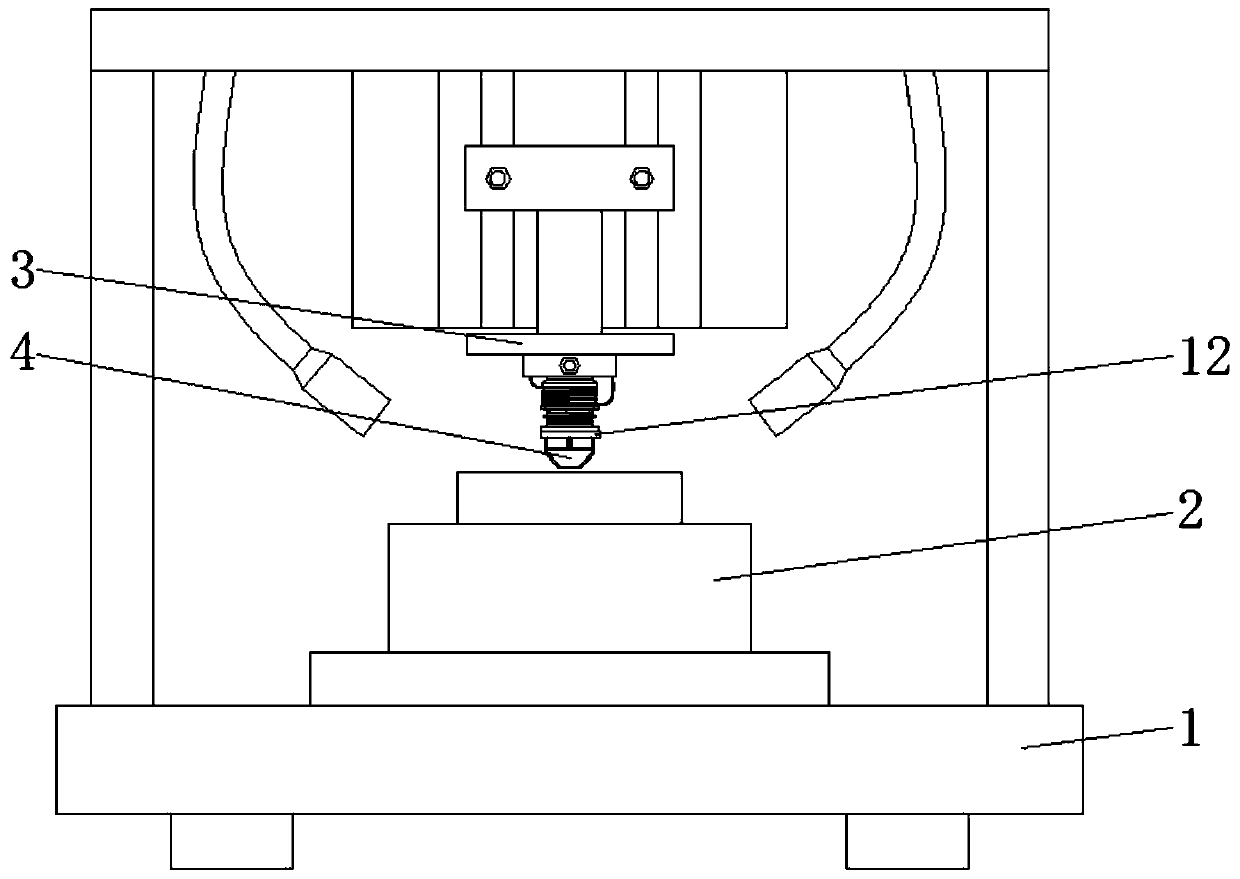

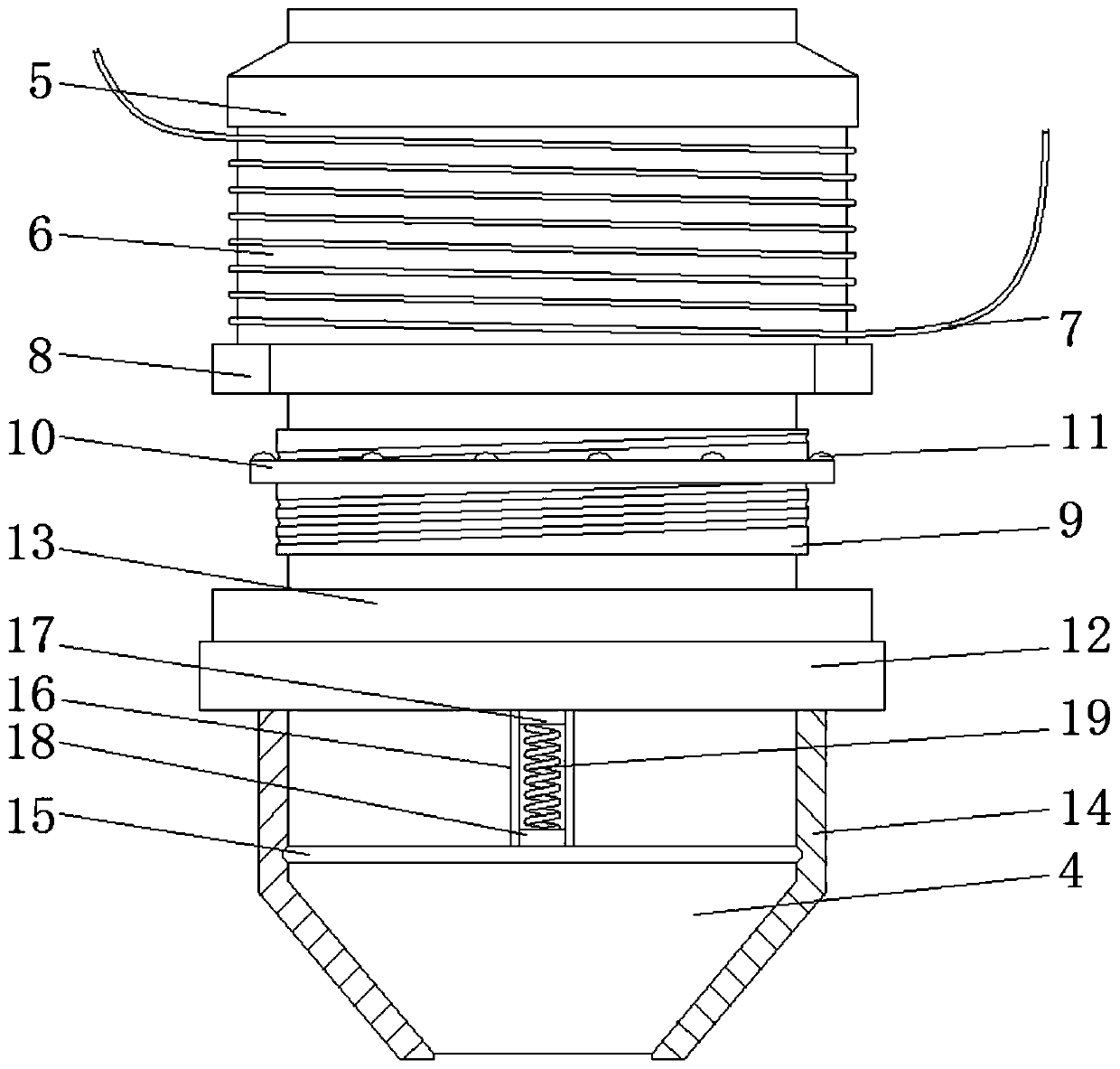

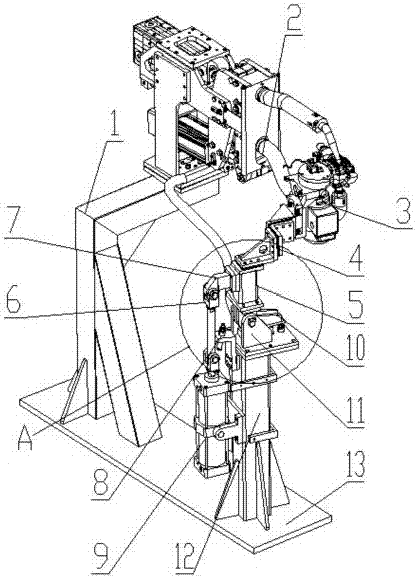

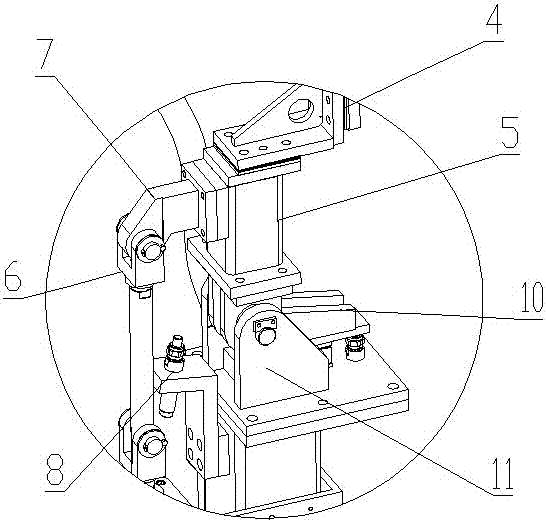

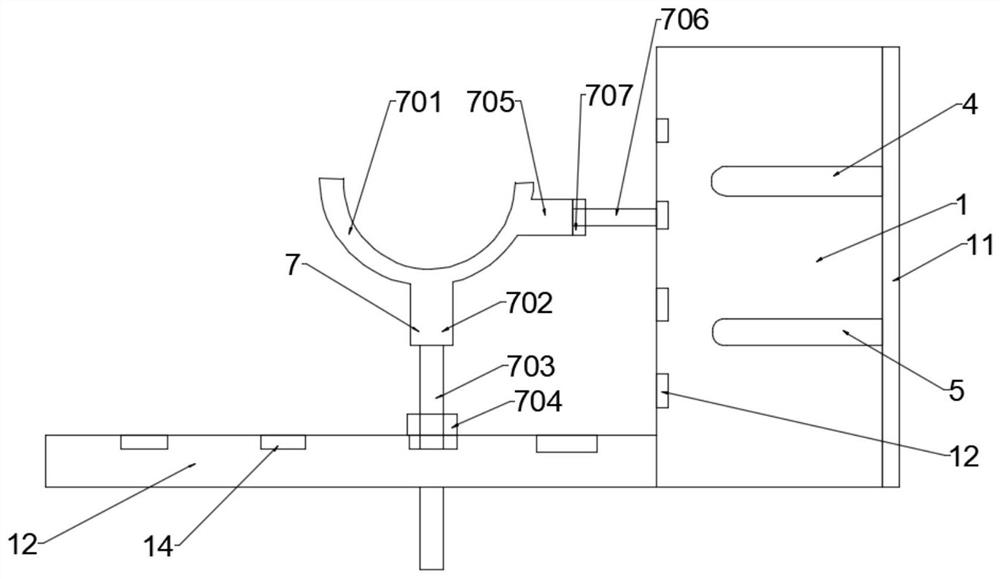

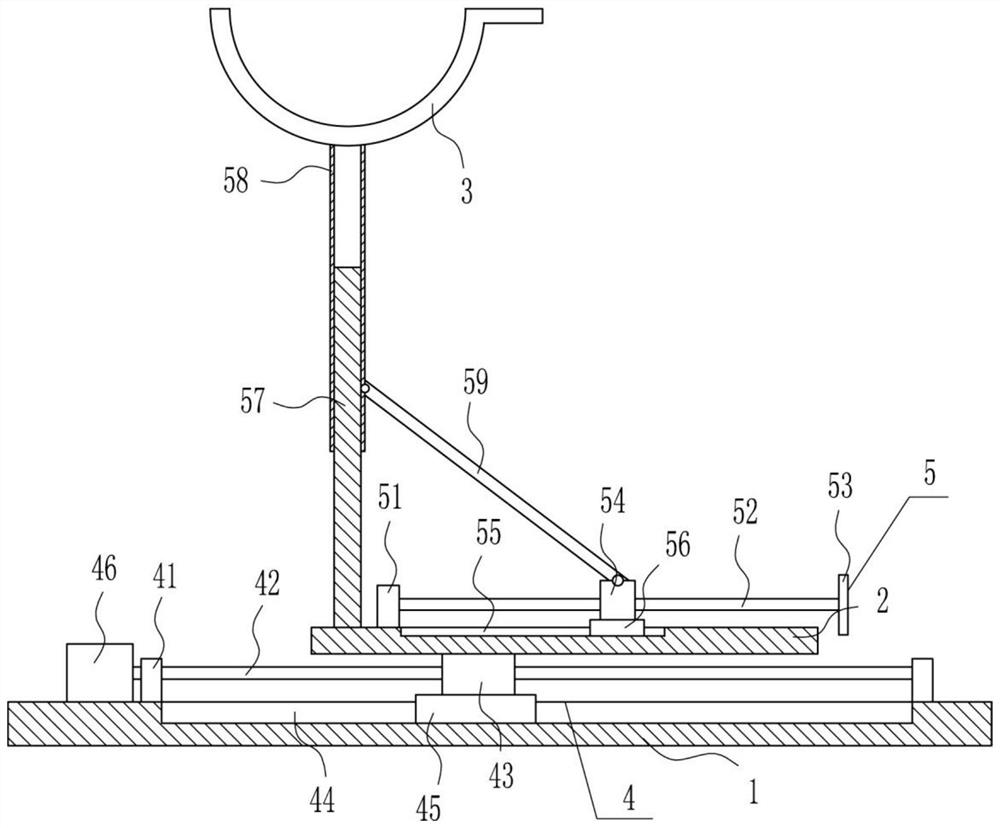

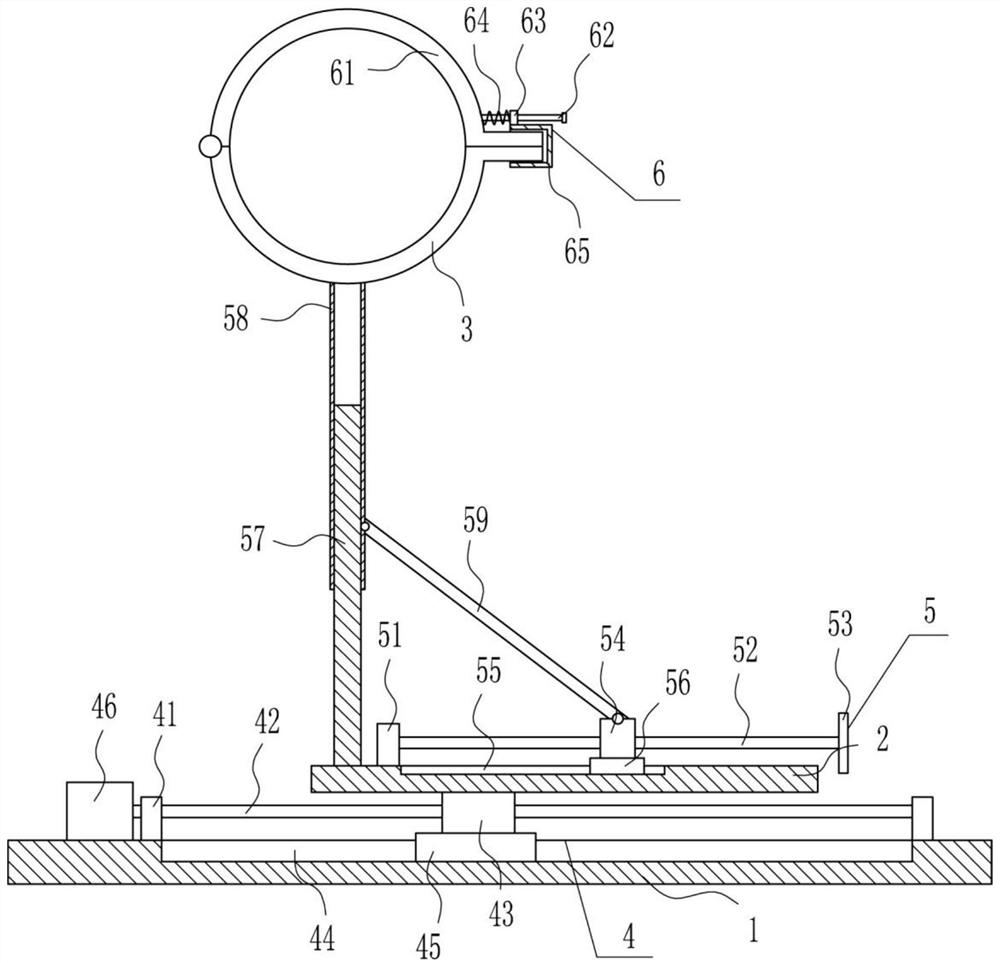

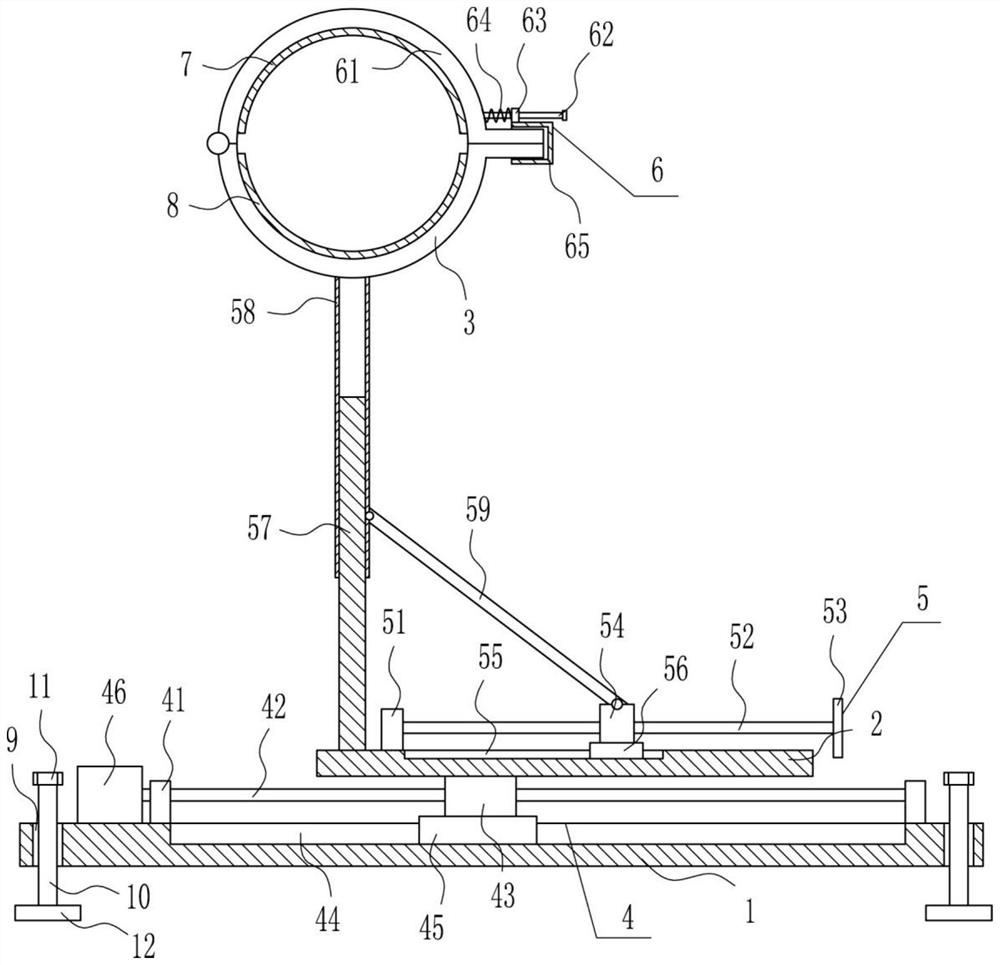

Supporting frame convenient to adjust and used for petroleum pipeline installation

ActiveCN108581358AProtects against welding effectsEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesPetroleumPetroleum engineering

The invention relates to a supporting frame, in particular to a supporting frame convenient to adjust and used for petroleum pipeline installation. According to the technical purposes, the supportingframe convenient to adjust and used for petroleum pipeline installation can play a supporting role, and can also adjust a petroleum pipeline, so that welding is facilitated, the petroleum pipeline isnot likely to move during welding, and welding is not affected. According to the technical scheme, the supporting frame convenient to adjust and used for petroleum pipeline installation comprises a bottom plate and the like; a moving device is arranged on the top of the bottom plate, and a cross plate is connected to the moving device; the top of the cross plate is provided with an adjusting device; and an arc-shaped plate is connected to the adjusting device. According to the supporting frame convenient to adjust and used for petroleum pipeline installation, due to the moving device and the adjusting device, the position of the petroleum pipeline can be adjusted, so that welding is facilitated; due to a fixed device, the petroleum pipeline can be fixed, so that it is prevented that because of moving of the petroleum pipeline, welding is affected, and the effects that the supporting role is played, the petroleum pipeline can also be adjusted, so that welding is facilitated, the petroleum pipelines is not likely to move during welding, and welding is not affected are achieved

Owner:东营睿港投资服务有限责任公司

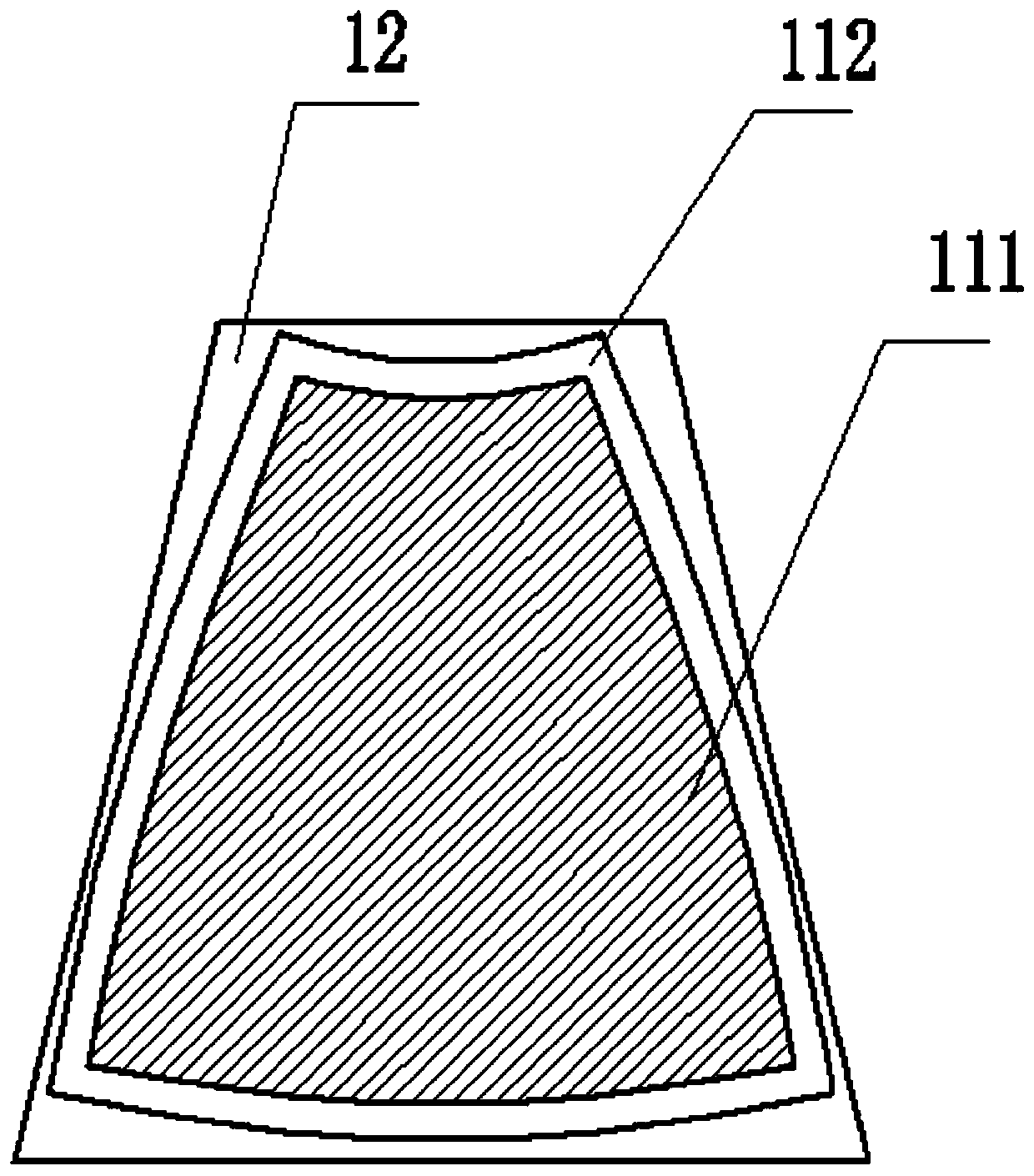

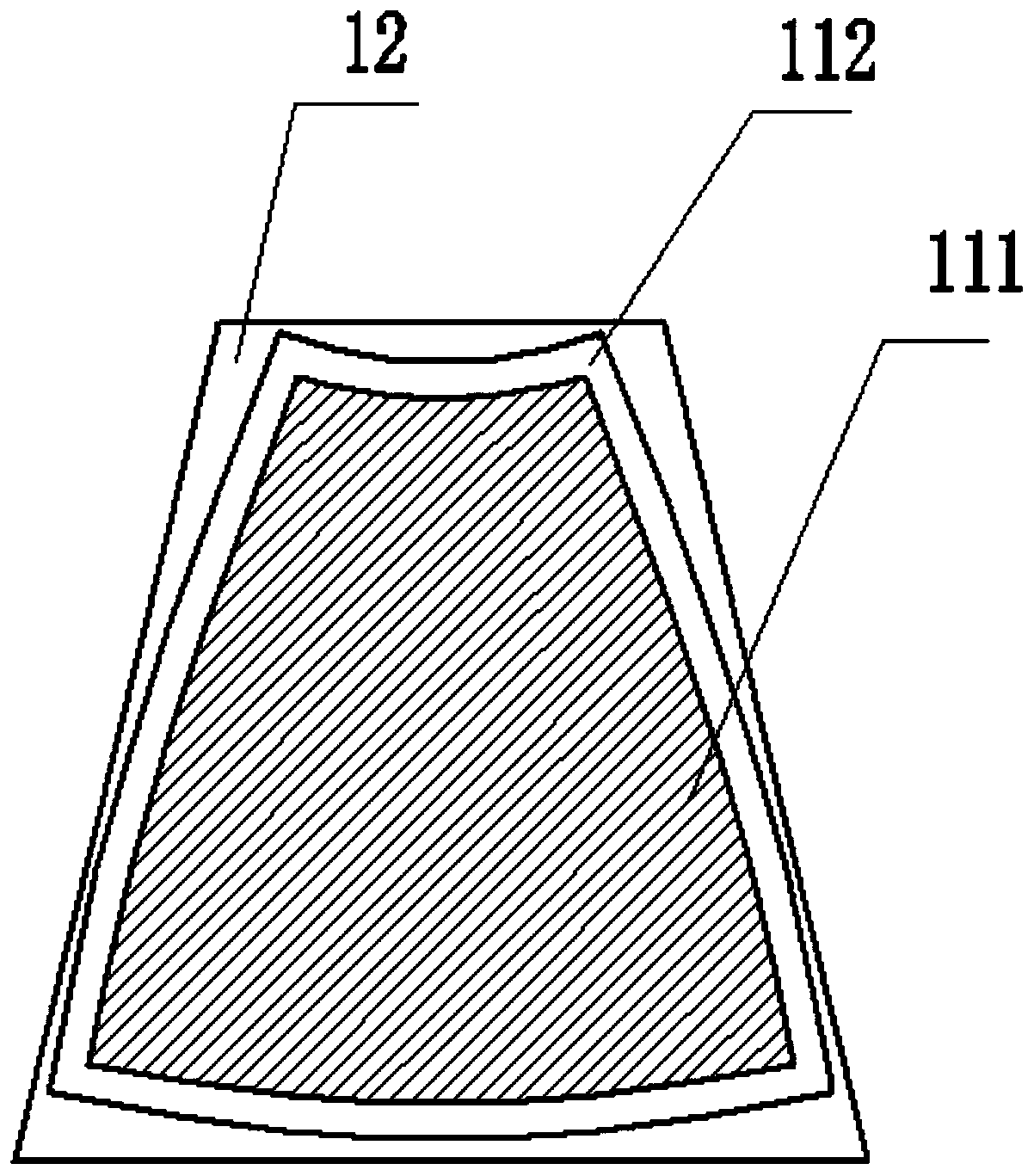

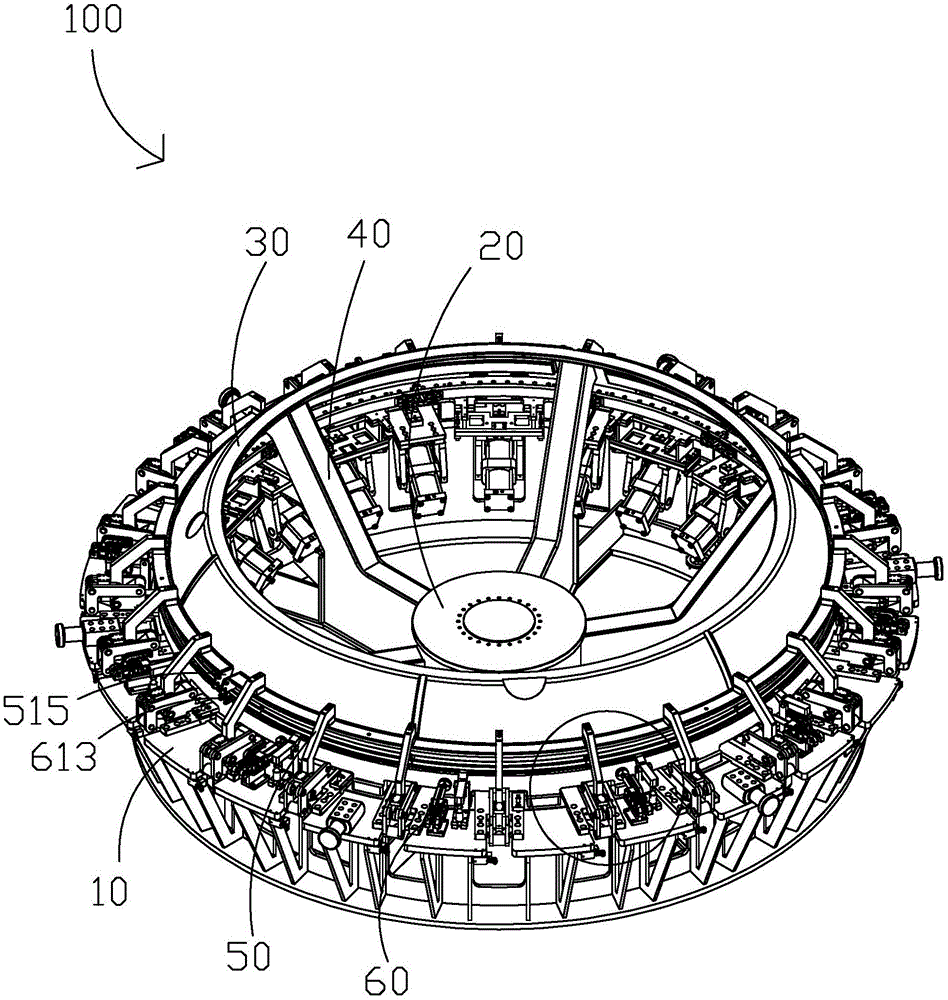

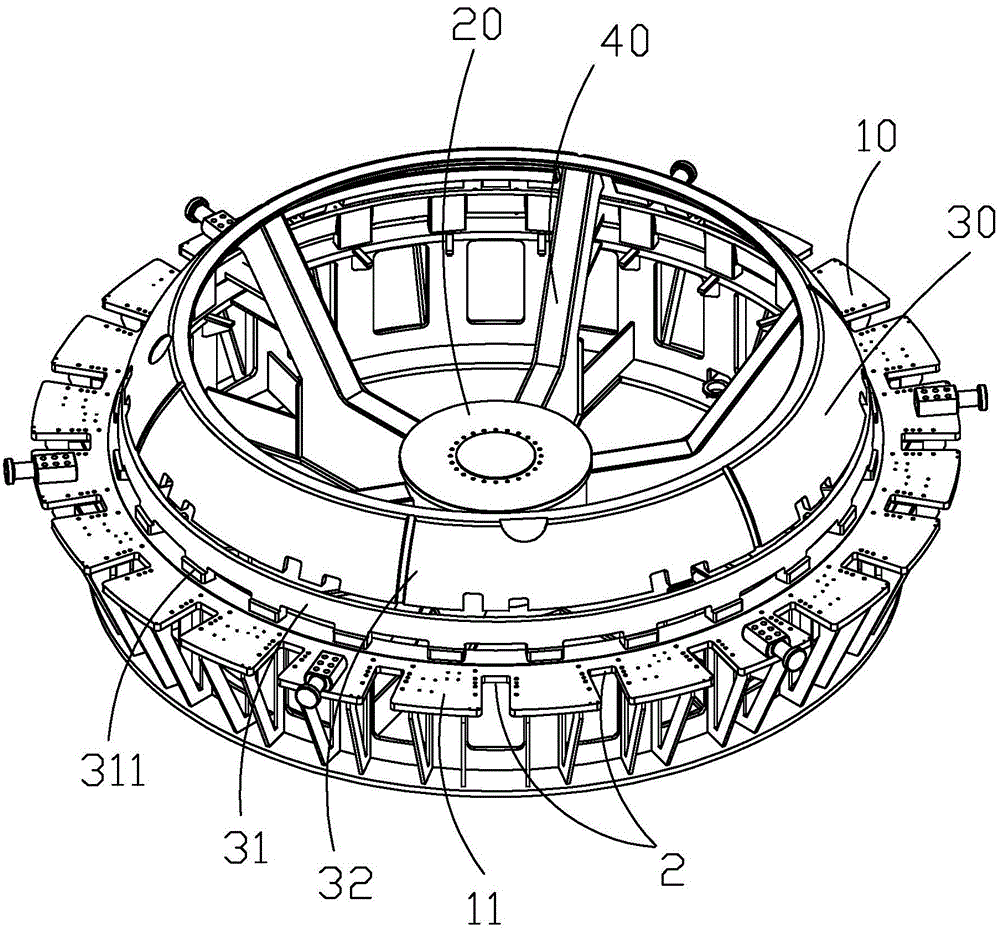

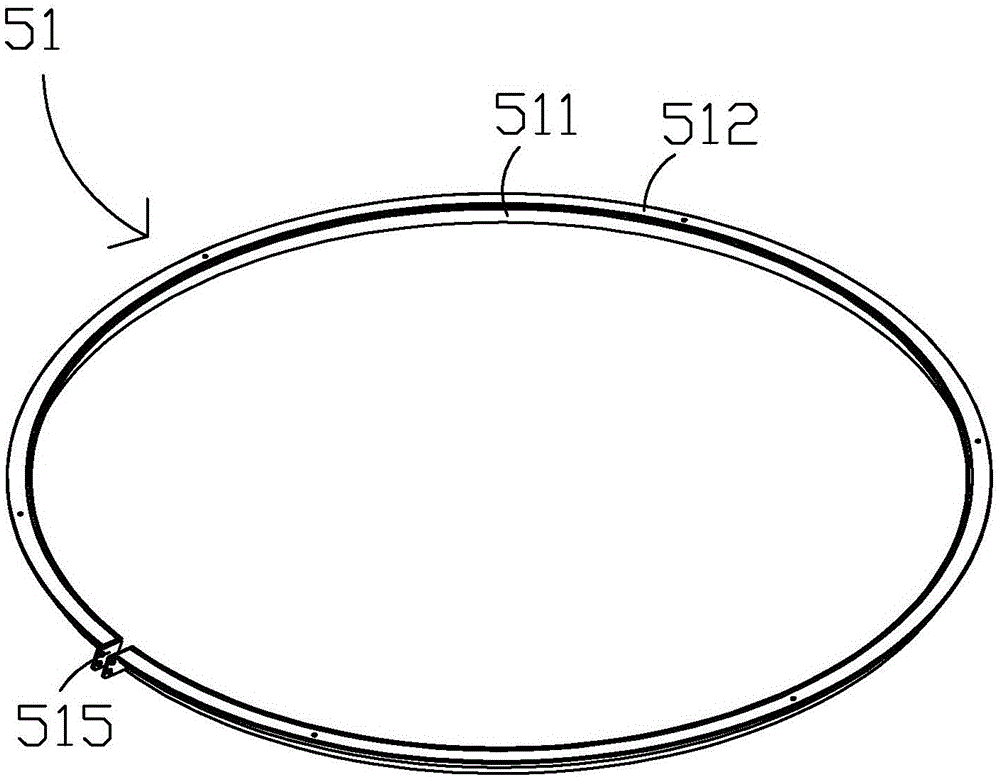

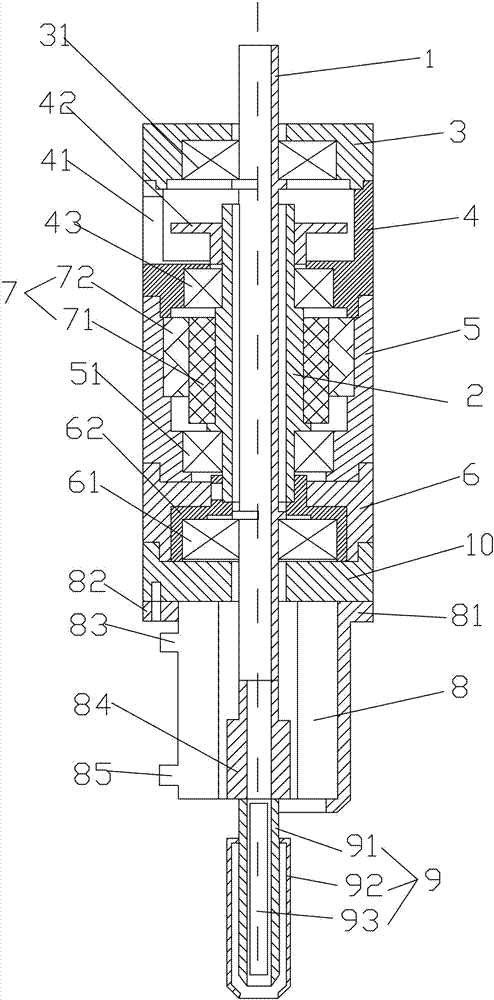

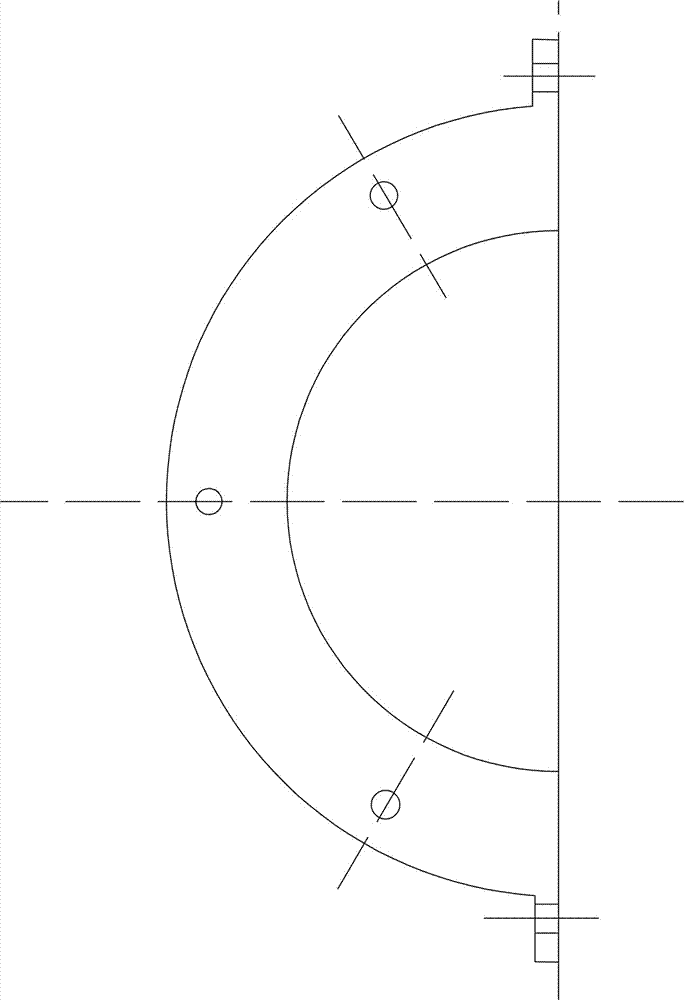

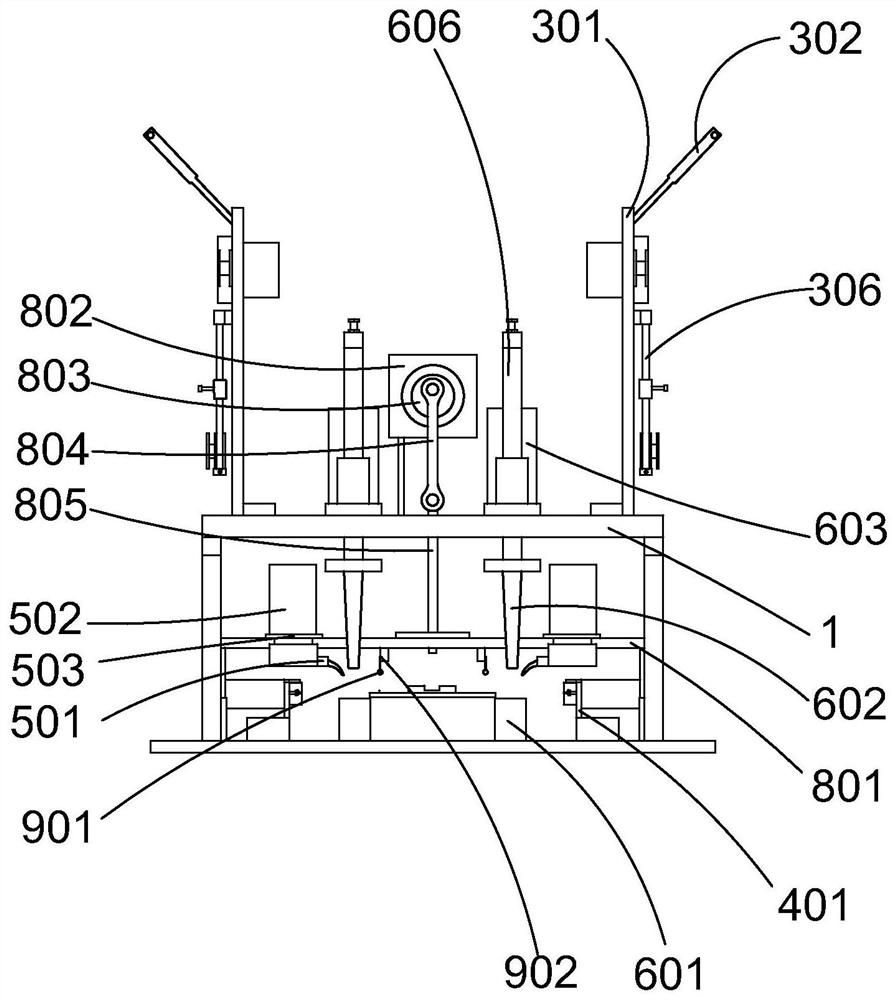

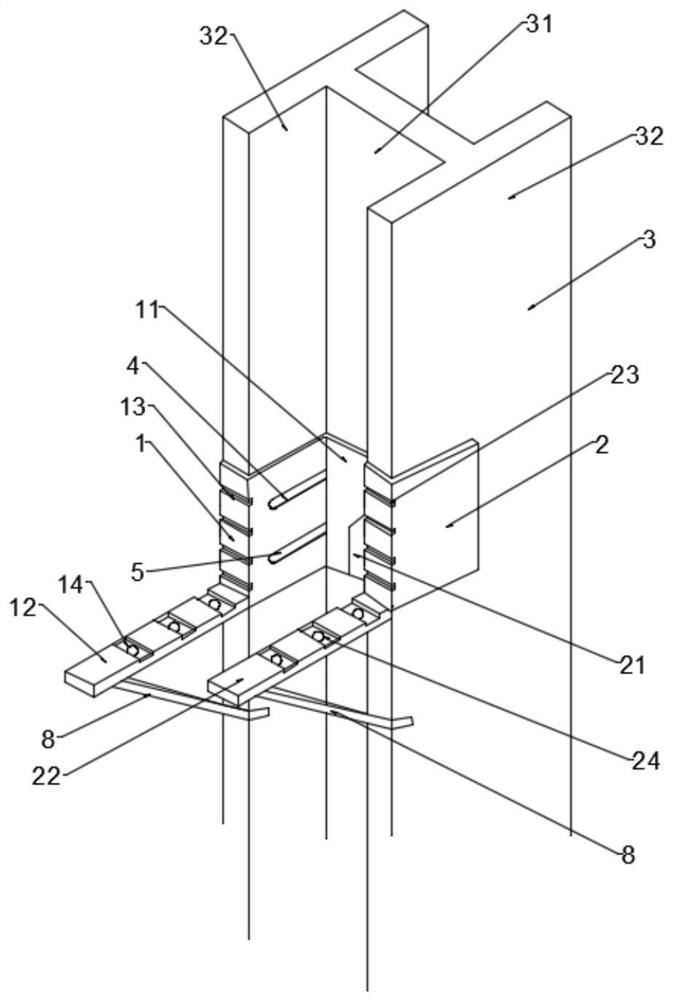

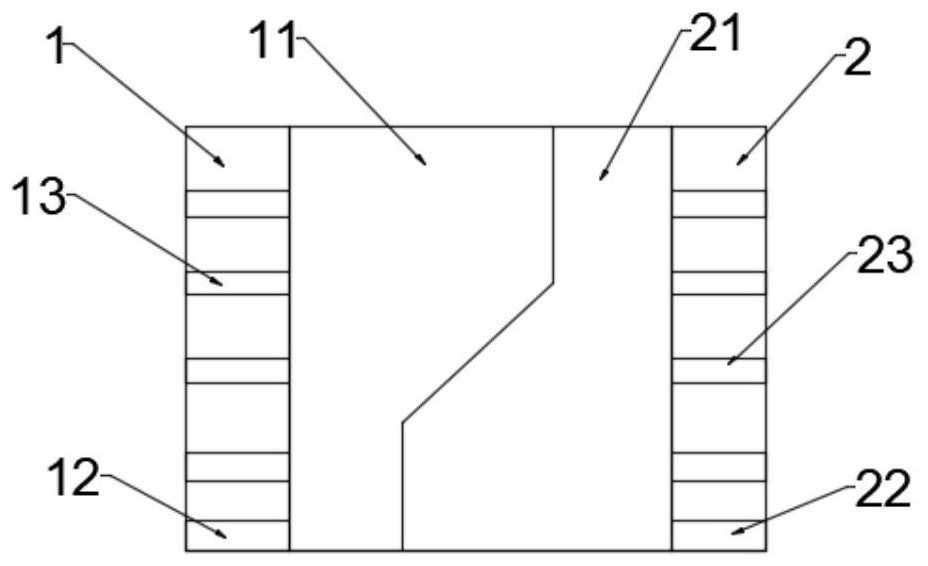

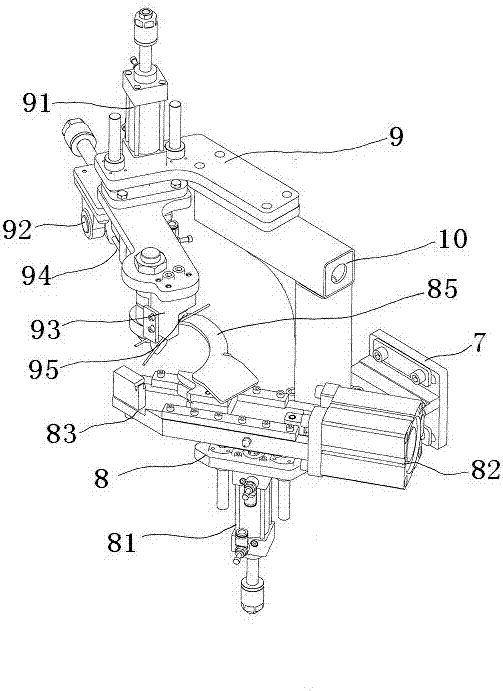

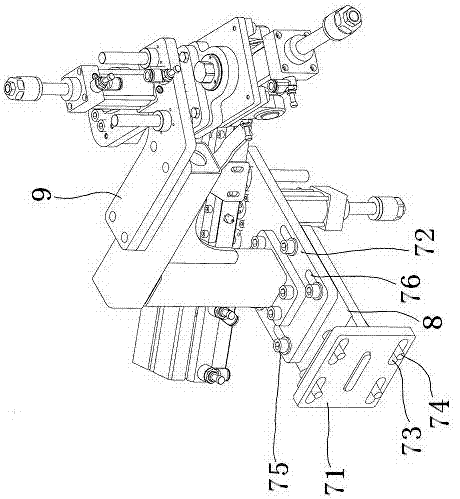

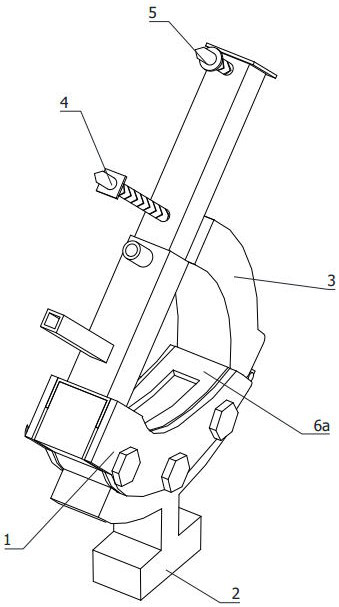

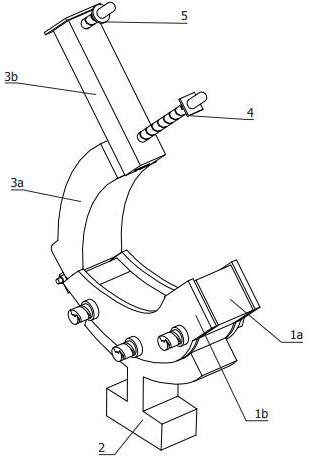

Positioning fixture and storage case girth welding equipment

ActiveCN105127656AAvoid deformationPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention provides a positioning fixture for positioning a circular ring and a section frame at the bottom of a storage case. The positioning fixture comprises a base, a mould fixed on the base and used for positioning the circular ring and the section frame from the inner side, a first pressing assembly used for pressing the circular ring from the outer side and a second pressing assembly used for pressing the section frame; the first pressing assembly comprises a first pressing ring sleeving the circular ring from the outer side and a first pressing mechanism acting on the first pressing ring; the second pressing assembly comprises a second pressing ring sleeving the section frame from the outer side, a second pressing mechanism acting on the second pressing ring, and a third pressing mechanism used for pressing the section frame inwards from the outer side; the first pressing mechanism, the second pressing mechanism and the third pressing mechanism are fixed on the base and positioned on the outer side of the mould. The positioning fixture has good positioning effect on the circular ring and the section frame, cannot affect welding, and can provide guarantee for achieving high-quality welding.

Owner:JIANGSU BEIREN ROBOT SYST CO LTD

Leading wire bonder

ActiveCN111299880AQuality improvementIncrease smoothnessWelding/cutting auxillary devicesAuxillary welding devicesMagnetic tension forceLead bonding

The invention relates to the technical field of semiconductor machining, and discloses a leading wire bonder. The bonder comprises a chopper, a sliding sleeve is slidingly mounted on the chopper, thebottom of the sliding sleeve is fixedly connected with an iron bar, the iron bar is wound with a wire, the end of the wire is connected with a power source in a driving device, the bottom of the ironbar is fixedly connected with an iron ring, an adjusting device is bonded on the chopper, through connection between the wire and the power source of the driving device, the running speed of the chopper is higher, the higher the speed is, the rapier the contact between the chopper and a welding disc is, the larger the friction coefficient is, the rapier the wear of the chopper is, the larger the generated current is, the larger the magnetic force generated by the iron ring is, through the principle of homopolar repulsion of a magnet, a magnetic block is ejected, a rubber cylinder moves downwards, the end of the chopper is covered, when the chopper makes contact with a welding disc each time, through elastic strength of the rubber cylinder, the contact area and the contact strength betweenthe chopper and the welding disc can be reduced, and friction between the chopper and the welding disc is reduced.

Owner:江苏微邦电子有限公司

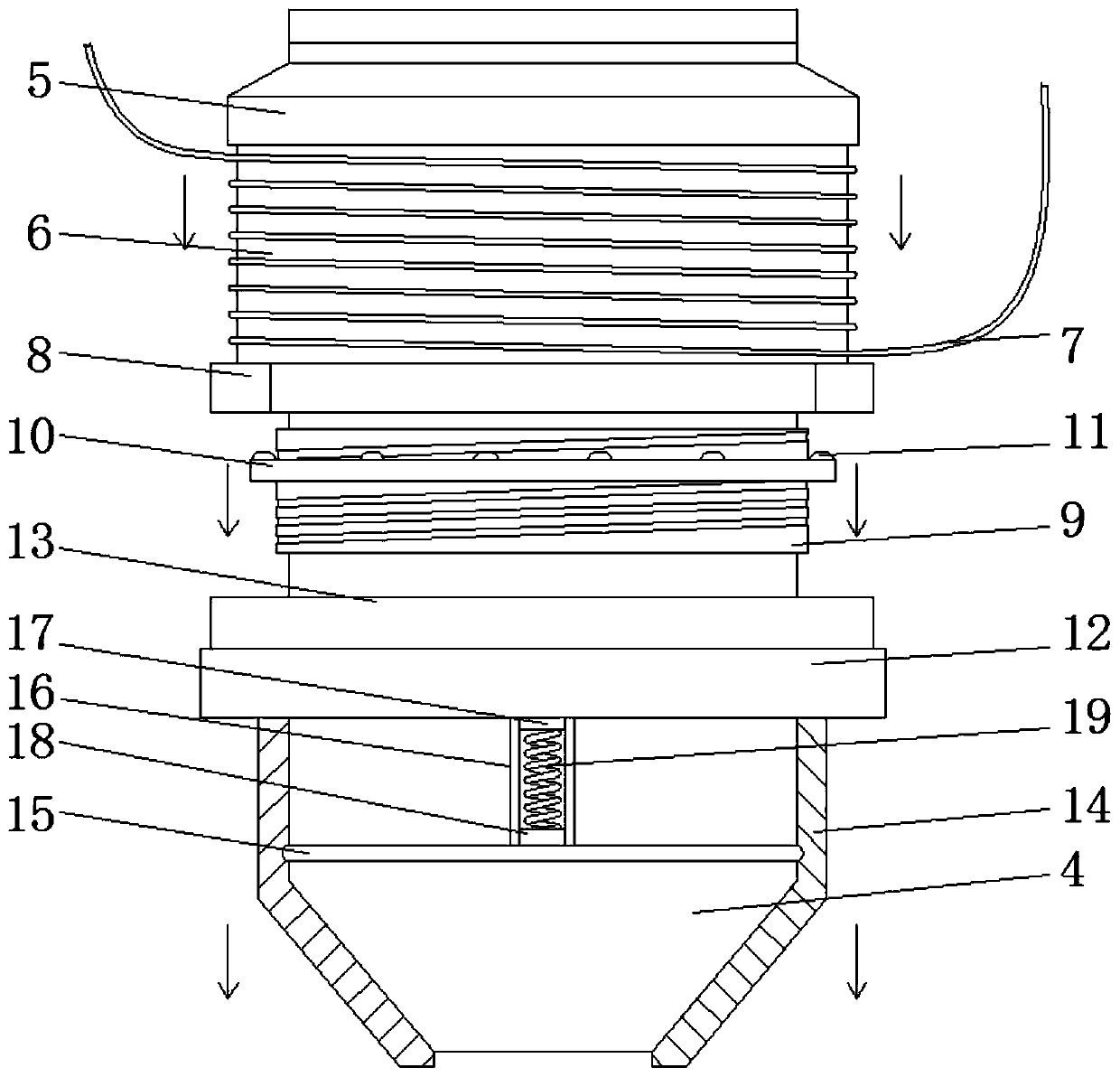

Water-cooled TIG welding rotating arc sensor

PendingCN107414257ADoes not affect weldingReduce quality problemsCooled electrode holdersWelding accessoriesPhysicsSpeed measurement

The invention relates to the technical field of electrowelding, in particular to a water-cooled TIG welding rotating arc sensor. The water-cooled TIG welding rotating arc sensor is used for large-current TIG automatic welding. The sensor comprises an external fixed shell, a middle conductive rod and an internal conductive rotating device. The fixed shell is composed of an end cover, a speed measurement chamber, a power chamber, an eccentric chamber, a bottom cover and a cold water chamber which are arranged from top to bottom. An optical coded disc in the speed measurement chamber is connected to a hollow shaft through set screws. A photoelectric sensor is placed on an opening of the speed measurement chamber. A power device is mounted in the power chamber. An eccentric block is mounted in the eccentric chamber. The cold water chamber is mounted on the lower portion of the base cover. A welding device is mounted at the bottom of the hollow shaft. According to the water-cooled TIG welding rotating arc sensor, the water-cooled cooling manner is adopted for a welding gun, the use range of the rotating arc sensor is broadened, protective gas passes the hollow conductive rod, and therefore the mass of the sensor is reduced, and welding is facilitated.

Owner:NANCHANG UNIV

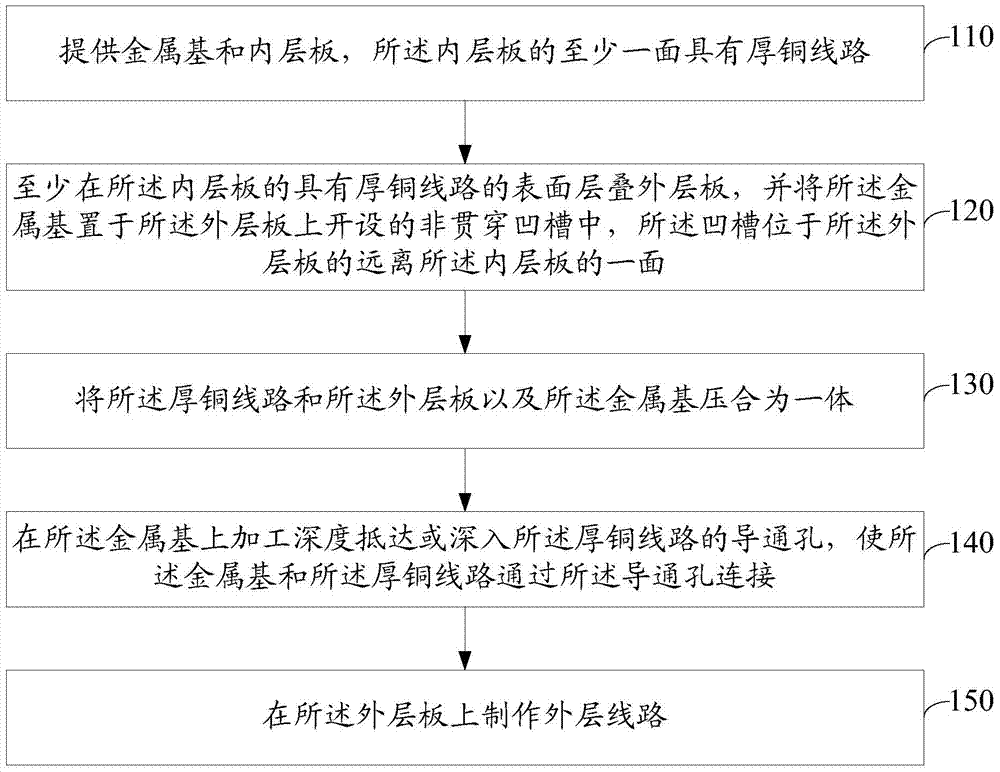

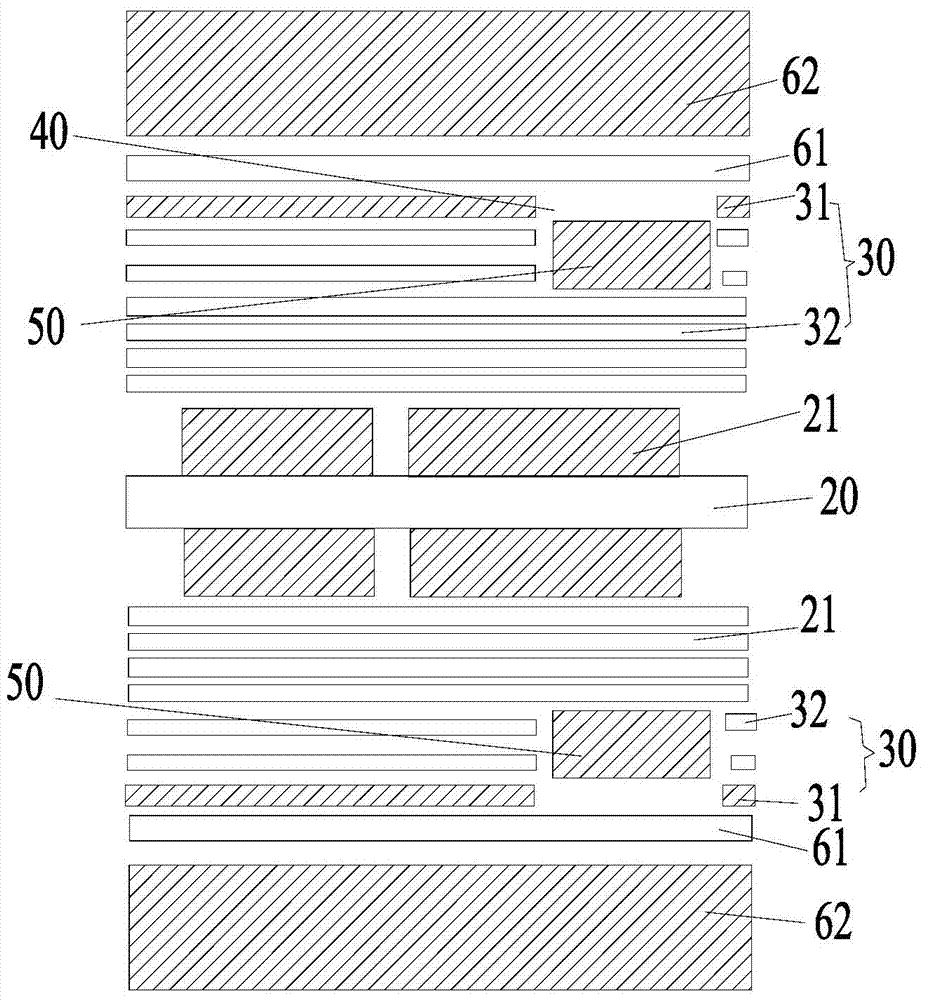

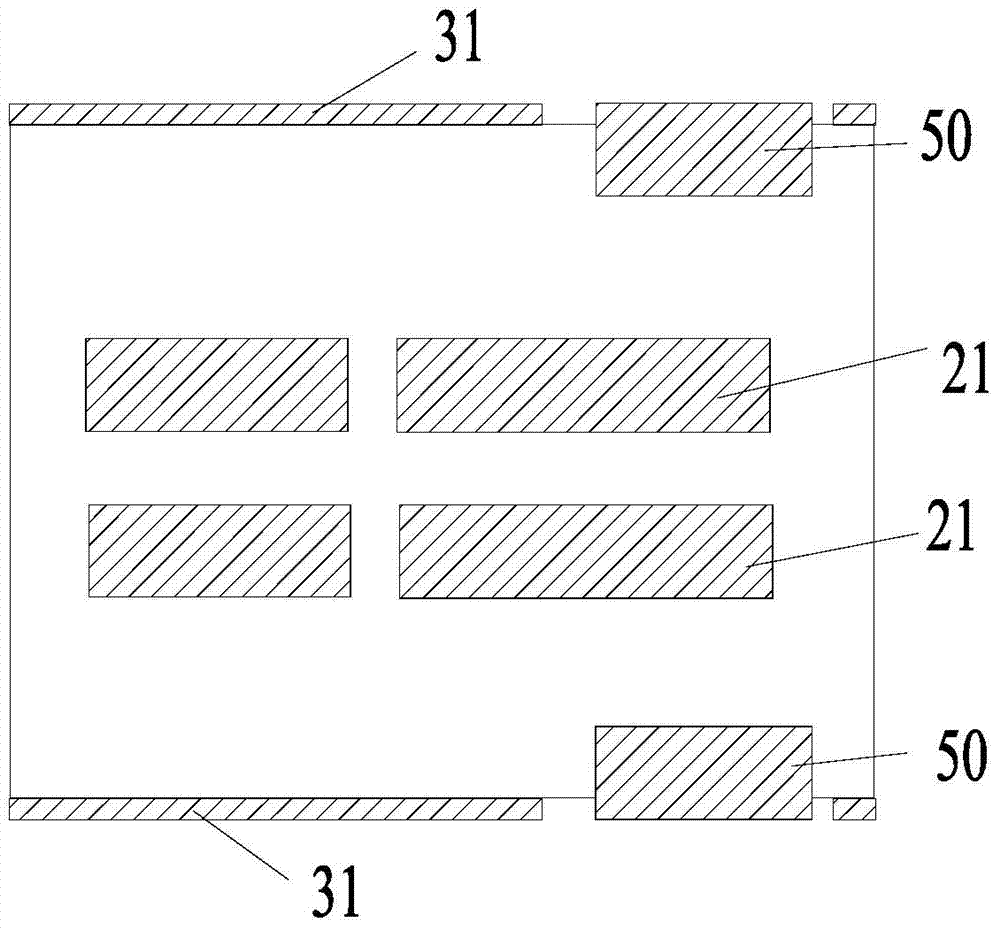

Circuit board manufacturing method and circuit board with embedded metal matrix

ActiveCN104853522AGood surface smoothnessNot corrosivePrinted circuit manufacturePrinted circuit non-printed electric components associationCopperElectroplating

The invention discloses a circuit board manufacturing method and a circuit board with an embedded metal matrix, thereby settling multiple defects caused by manufacture of partial thick copper through partial electroplating or partial micro-corrosion technology in prior art. In some embodiments of the invention, the circuit board manufacturing method comprises the steps of supplying the metal matrix and an inner layer board, wherein at least one surface of the inner layer board is provided with a thick copper line; laminating an outer layer board on the surface with the thick copper line on the inner layer board, placing the metal matrix in a non-through trough which is arranged on the outer layer board, wherein the trough is arranged on the surface which is far from the inner layer board on the outer layer board; pressing the thick copper line, the outer layer board and the metal matrix for integrating; machining at least one conducting hole which arrives at or penetrates deeply into the thick copper line on the metal matrix, so that the metal matrix is connected with the thick copper line through the conducting hole; and manufacturing an outer layer line on the outer layer board.

Owner:SHENNAN CIRCUITS

Environment-friendly waterborne antirust agent and preparation method thereof

InactiveCN109666407ANo pollutionDoes not affect cuttingRosin coatingsAnti-corrosive paintsPEG 400Organic solvent

The invention discloses an environment-friendly waterborne antirust agent. The environment-friendly waterborne antirust agent is prepared by proportioning the following components in parts by weight:7 parts of rosin polymer, 5 parts of heterocyclic antirust agent, 20 parts of triethanolamine borate, 12 parts of ethanolamine (MEA), 0.3 part of ethylenediamine tetraacetic acid disodium (EDTA disodium), 0.2 part of polyethylene glycol 400 and 55.5 parts of pure water. The antirust agent made of the rosin polymer has good post-cleaning performance and better antirust capability than conventionalwaterborne antirust agent, has very high absorptivity and spreadability on the surface of steel and iron, and has performance similar to that of oily products, and the raw materials for preparing theantirust agent are easily available and low in price; and meanwhile, the environment-friendly waterborne antirust agent does not contain organic solvents such as benzene, toluene, xylene, formaldehydeand the like and heavy metals, is incombustible and non-explosive, does not pollute the environment, and belongs to an environment-friendly product.

Owner:扬州新东方金属材料制造有限公司

Automatic grinding mechanism for welding gun electrode cap

The invention discloses an automatic grinding mechanism for a welding gun electrode cap. The automatic grinding mechanism for the welding gun electrode cap comprises a welding gun grinder, an adjusting block, a turning-connection block and an ejecting block, and is characterized in that the welding gun grinder is fixed to the first end of the adjusting block; the second end of the adjusting block is fixed to the upper portion of the turning-connection block through a bolt; the lower end of the turning-connection block is hinged to a fixing base through a connecting pin; the ejecting block is fixed to the side portion of the turning-connection block; the turning-connection block can rotate along the connecting pin; the ejecting block is of an L-shaped structure; the bottom of the ejecting block is hinged to a connecting head; and the connecting head is fixed to a piston rod of a cylinder. The automatic grinding mechanism for the welding gun electrode cap has the beneficial effects of being convenient to use, high in automation degree and long in service life.

Owner:WUHU CHANGRUI AUTO PARTS

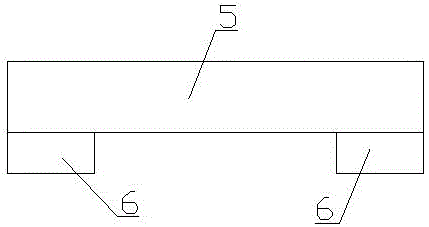

Welding fixture clamping device

InactiveCN106736140AUniform pressureEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention aims at providing a welding fixture clamping device. The welding fixture clamping device comprises a strip-shaped mounting block. The bottom of the left side of the mounting block is provided with a mounting groove. A movable block matched with the mounting groove is mounted in the mounting groove. A movable pin shaft transversely penetrates through the movable block. The right end of the movable pin shaft stretches into the mounting block. The left end of the movable pin shaft penetrates out of the mounting block. The bottom of the movable block is connected with a clamping block. The front end and the rear end of the bottom of the clamping block are provided with clamping heads. The right end of the top of the mounting block is provided with a clamping cylinder. According to the welding fixture clamping device, the front clamping head and the rear clamping head are arranged at the bottom end of the clamping block and used for clamping two identical parts; the clamping block is arranged below the movable block, and the movable block is mounted in the mounting groove through the movable pin shaft; in this way, when the mounting block pressed downwards, the movable pin shaft automatically levels the planes of the two parts, and then the parts are clamped; moreover, the device is provided with a positioning block and a limiting groove for positioning. The welding fixture clamping device is uniform in pressure and easy to operate, does not affect welding and can effectively guarantee the quality of assembly parts.

Owner:WUHU POWER TECH

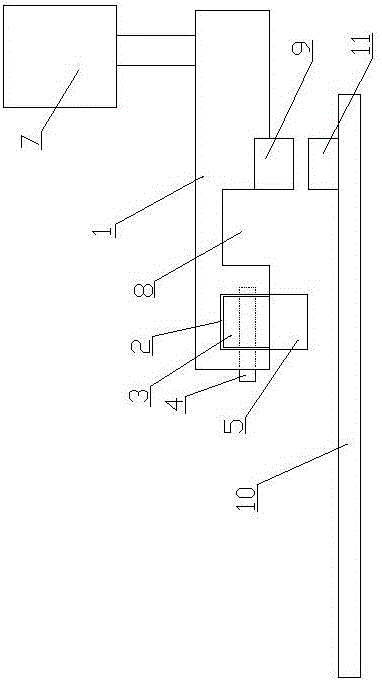

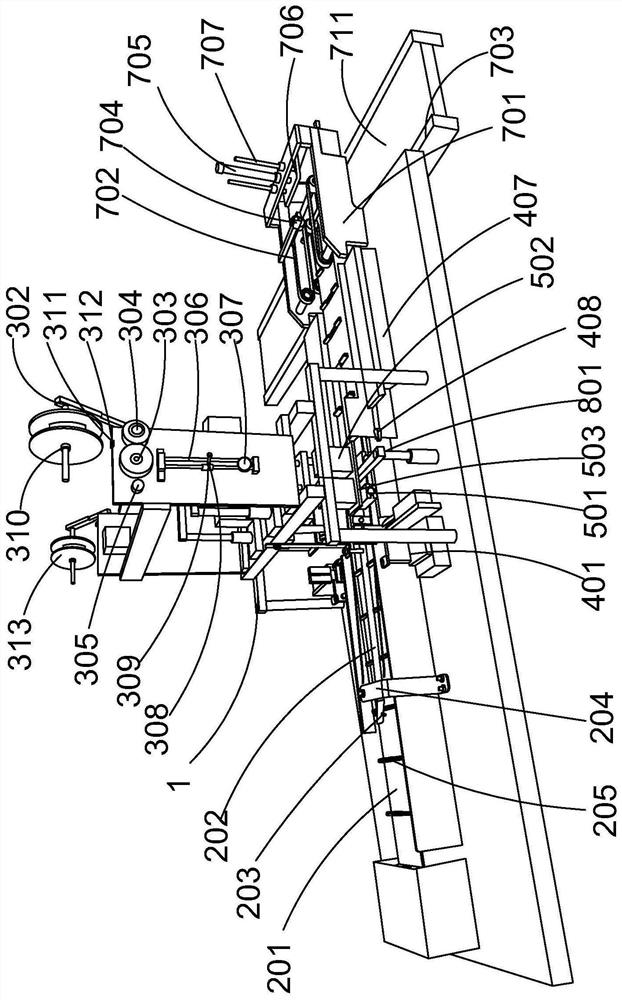

Mask ear strap welding machine

PendingCN111976159ACompact structureHigh degree of automationDomestic articlesClothes making applicancesPhysicsEngineering

The invention relates to the technical field of mask production equipment, in particular to a mask ear strap automatic welding machine. The mask ear strap welding machine comprises a frame, wherein aninput device, ear strap rope pulling devices, ear strap rope pulling wire positioning devices, ear strap rope turning devices, a welding device and an output device are arranged on the frame in sequence according to an assembly line. The input device is arranged on the frame and is used to input a mask body. The ear strap rope pulling devices are arranged on both sides of the frame and are used to pull ear strap ropes. The ear strap rope pulling wire positioning device guides the ear strap ropes into both sides of the input device. The ear strap rope turning devices are arranged on one sidesof the ear strap rope pulling wire positioning device, bend the ear strap ropes into a U-shape and guide U-shaped ear strap ropes into the ends of the mask body. The welding device is installed on theframe and is used to weld the U-shaped ear strap ropes to the mask body. The output device is used to output the masks welded with ear straps. The frame is provided with a first lifting device whichcontrols up and down lifting of each ear strap rope turning device. The two ear strap rope turning devices are respectively arranged on both sides of the first lifting device. The lower two sides of the first lifting device are provided with positioning and pressing devices for positioning the two ends of the mask body.

Owner:QUANZHOU LUOJIANG DISTRICT HUIFENG SANITARY CO LTD

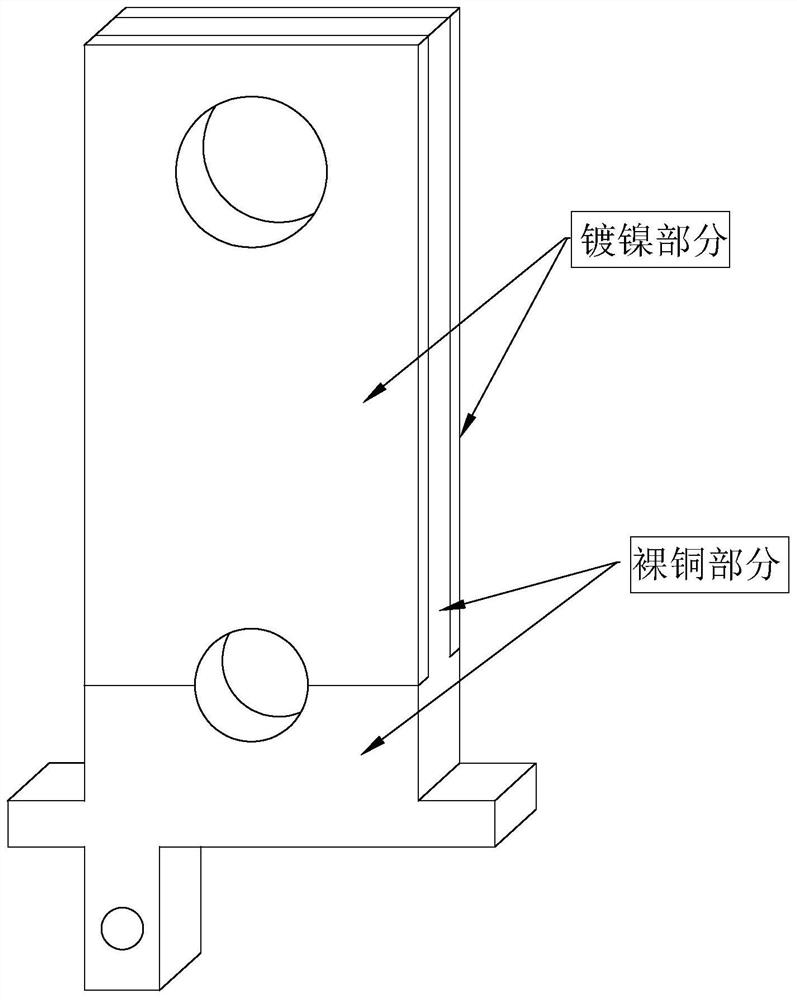

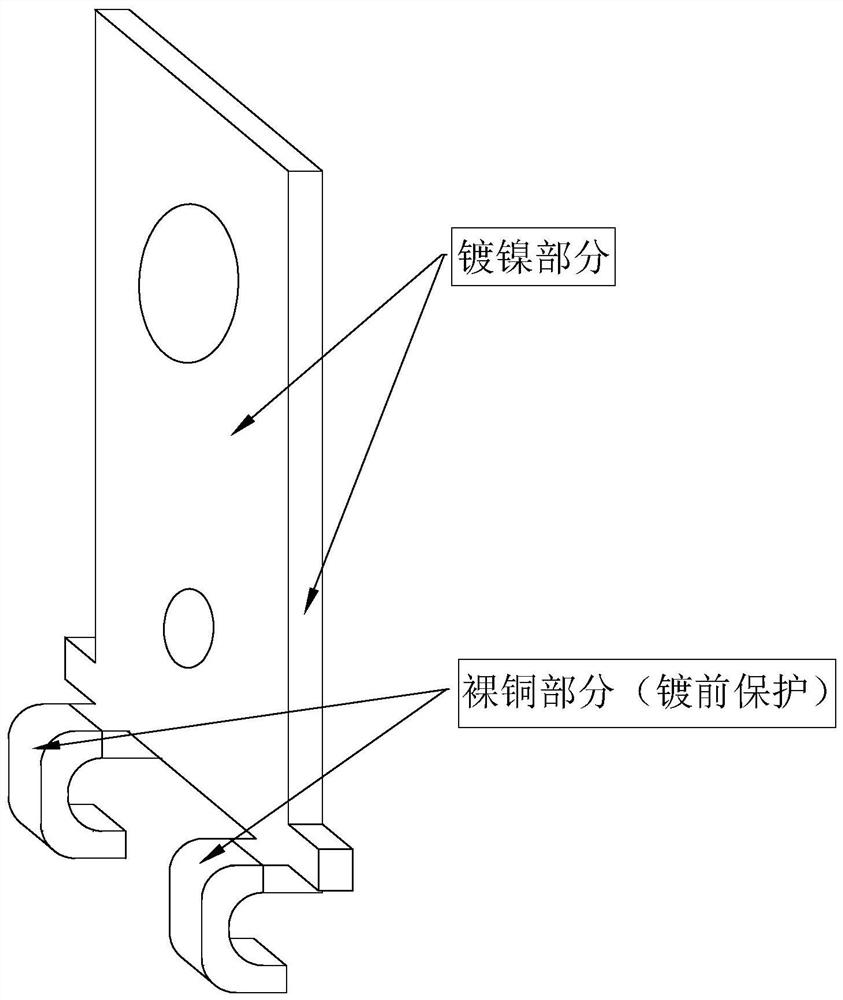

Nickel electroplating process of electrode

ActiveCN112680757AIncrease roughnessEasy plating adhesionLiquid/solution decomposition chemical coatingPolyurea/polyurethane coatingsNickel electroplatingElectrically conductive

The invention provides a nickel electroplating process of an electrode. The nickel electroplating process of the electrode comprises the following specific steps of (1) pre-treating the electrode in sequence; (2) coating a layer of anti-plating protective coating on the position, needing to be welded, of the electrode, and performing protection before plating; (3) hanging the electrode on a hanger made of a material with good conductivity, carrying out preheating, immersing the electrode in the electroplating liquid of a plating tank, connecting a cathode, placing anodes on two sides at a proper distance, and carrying out electrifying to deposit nickel ions on the surface of the electrode; (4) after nickel plating, removing the anti-plating protective coating at the position needing to be welded, and exposing the surface which is not plated with nickel; and (5) carrying out post-treatment on the electrode of which the protection is removed. The welding position of the electrode is protected before plating, nickel plating is conducted through a rack plating technology, protection is removed after plating, the bare copper surface is exposed so that welding can be firm, nickel plating is conducted on the surfaces of other parts so that rust prevention and electric conduction quality of the electrode can be guaranteed, and the selective local electroplating technology is an international advanced technology.

Owner:ZHEJIANG HUAJING RECTIFIER

Orienting device for feet-lock bolt

ActiveCN111720147ADoes not affect weldingUnfix the connectionAnchoring boltsEngineeringStructural engineering

The invention discloses an orienting device for a feet-lock bolt. The end of one side wall of a first U-shaped clamping plate and the end of one side wall of a second U-shaped clamping plate are respectively provided with an abutting plate that extends laterally, U-shaped grooves are arranged on wing plates at the left end and the right end of a web plate of H-shaped steel in a clamping manner respectively, the abutting plate of the first U-shaped clamping plate and the abutting plate of the second U-shaped clamping plate are attached to the web plate of the H-shaped steel respectively, and the opposite side walls of the first U-shaped clamping plate and the second U-shaped clamping plate are respectively provided with opposite upper through grooves and opposite lower through grooves. Theorienting device further comprises supporting frameworks, and the supporting frameworks are supported on the first U-shaped clamping plate and the second U-shaped clamping plate. A transverse caliperof the first U-shaped clamping plate and a transverse caliper of the second U-shaped clamping plate are respectively provided with a bracket assembly detachably clamped with clamping positions A, a clamping part detachably clamped with clamping positions B is arranged on one side of each bracket assembly, and each bracket assembly is also provided with an arc groove with an upward opening.

Owner:贾承志 +2

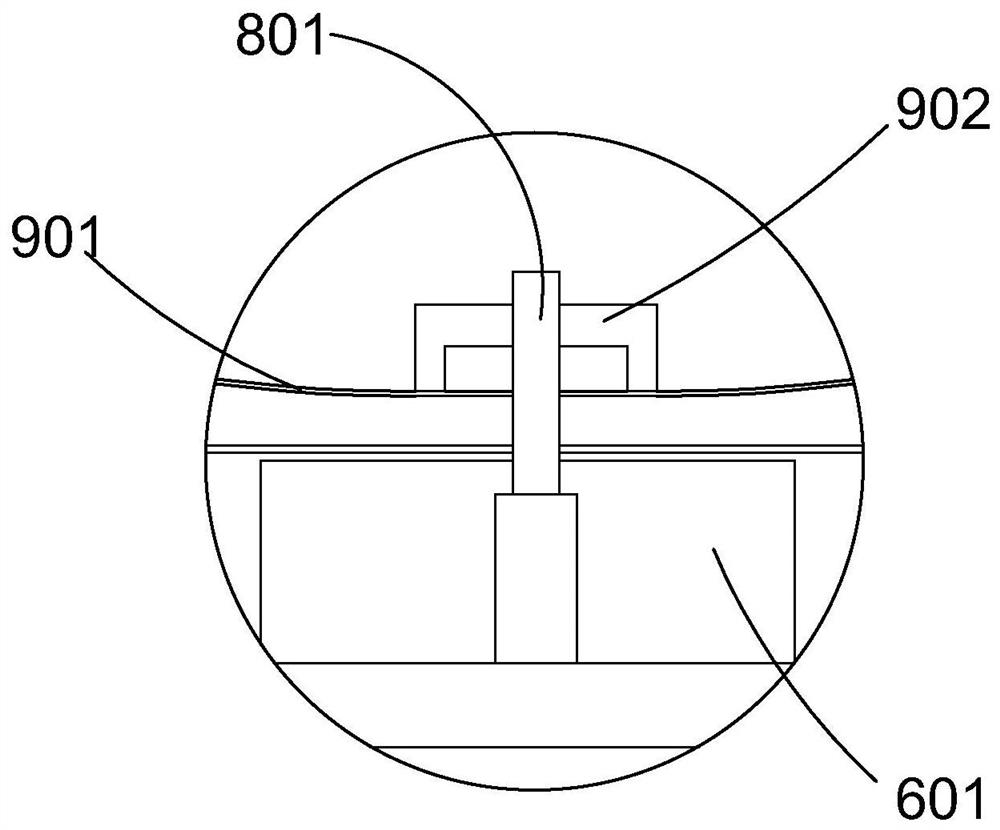

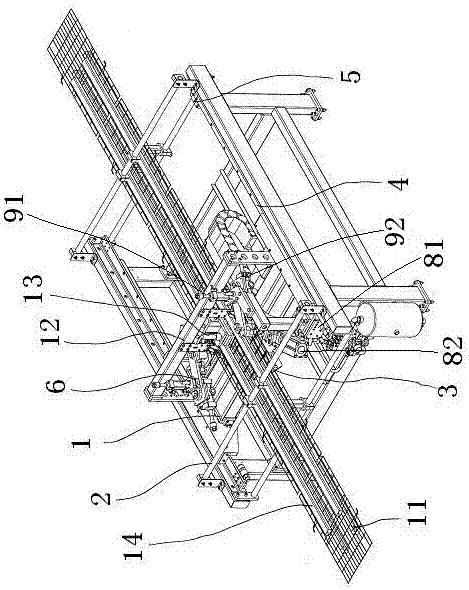

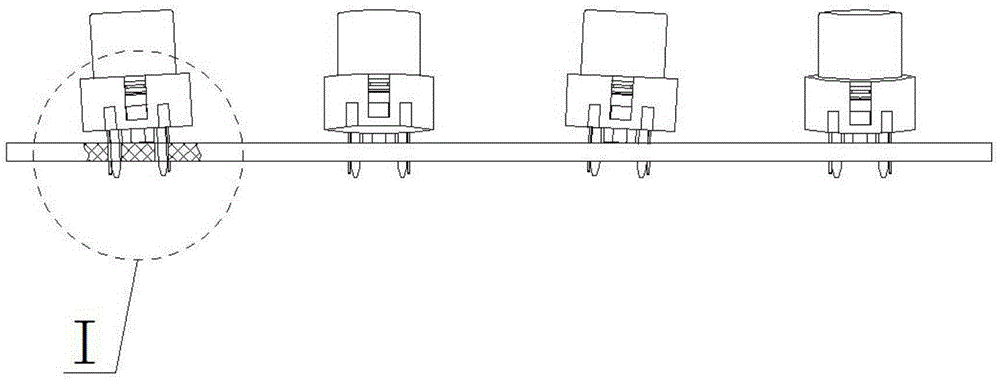

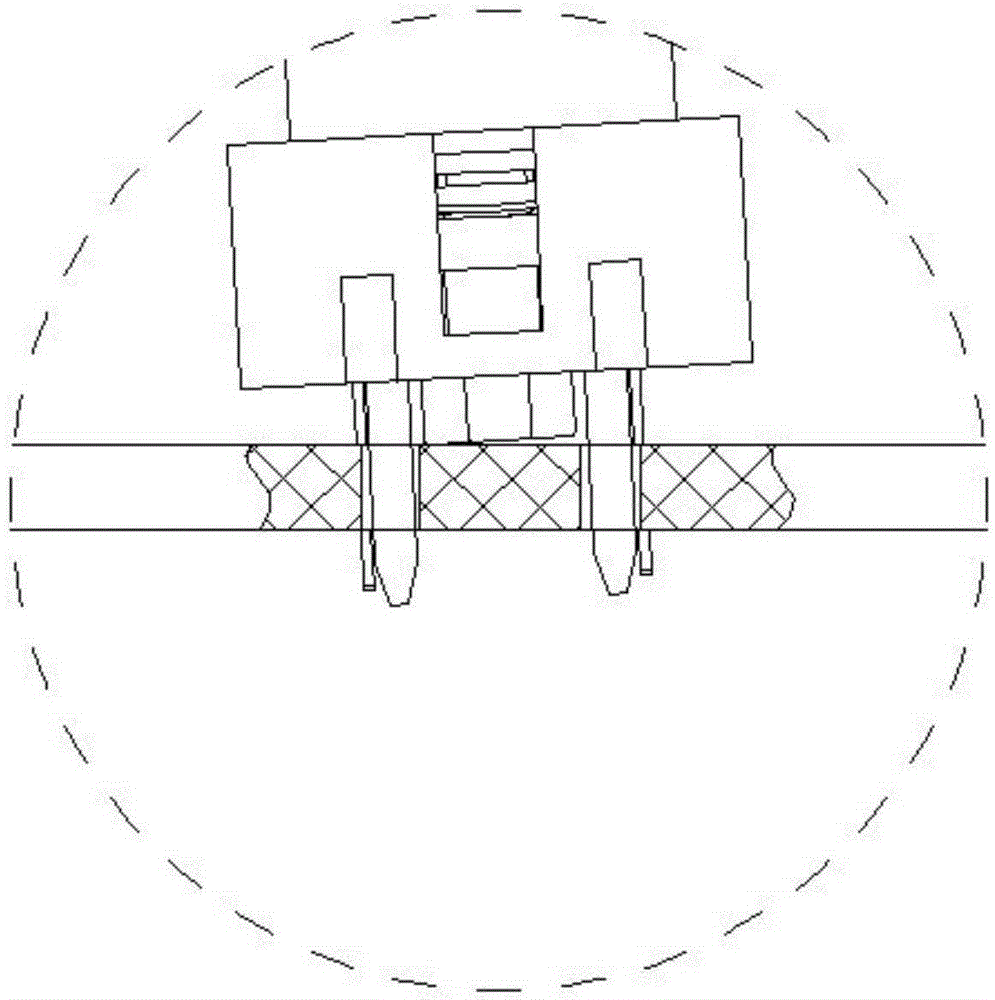

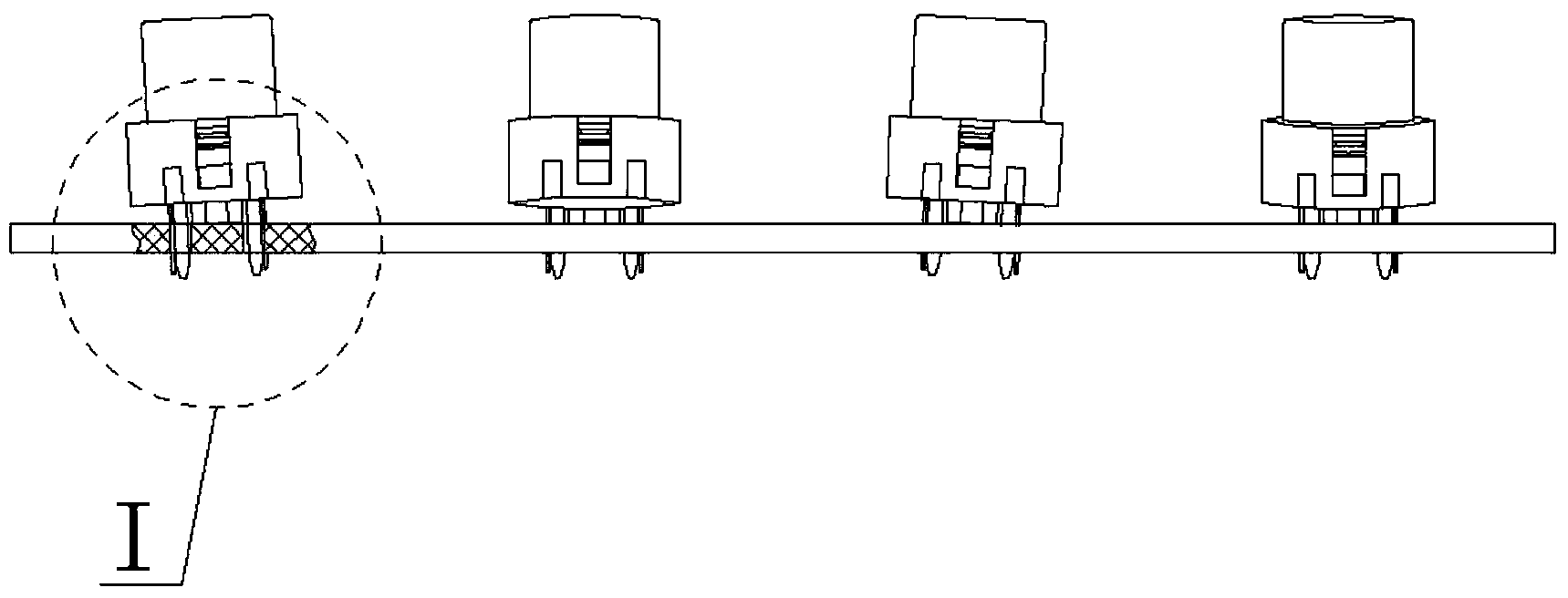

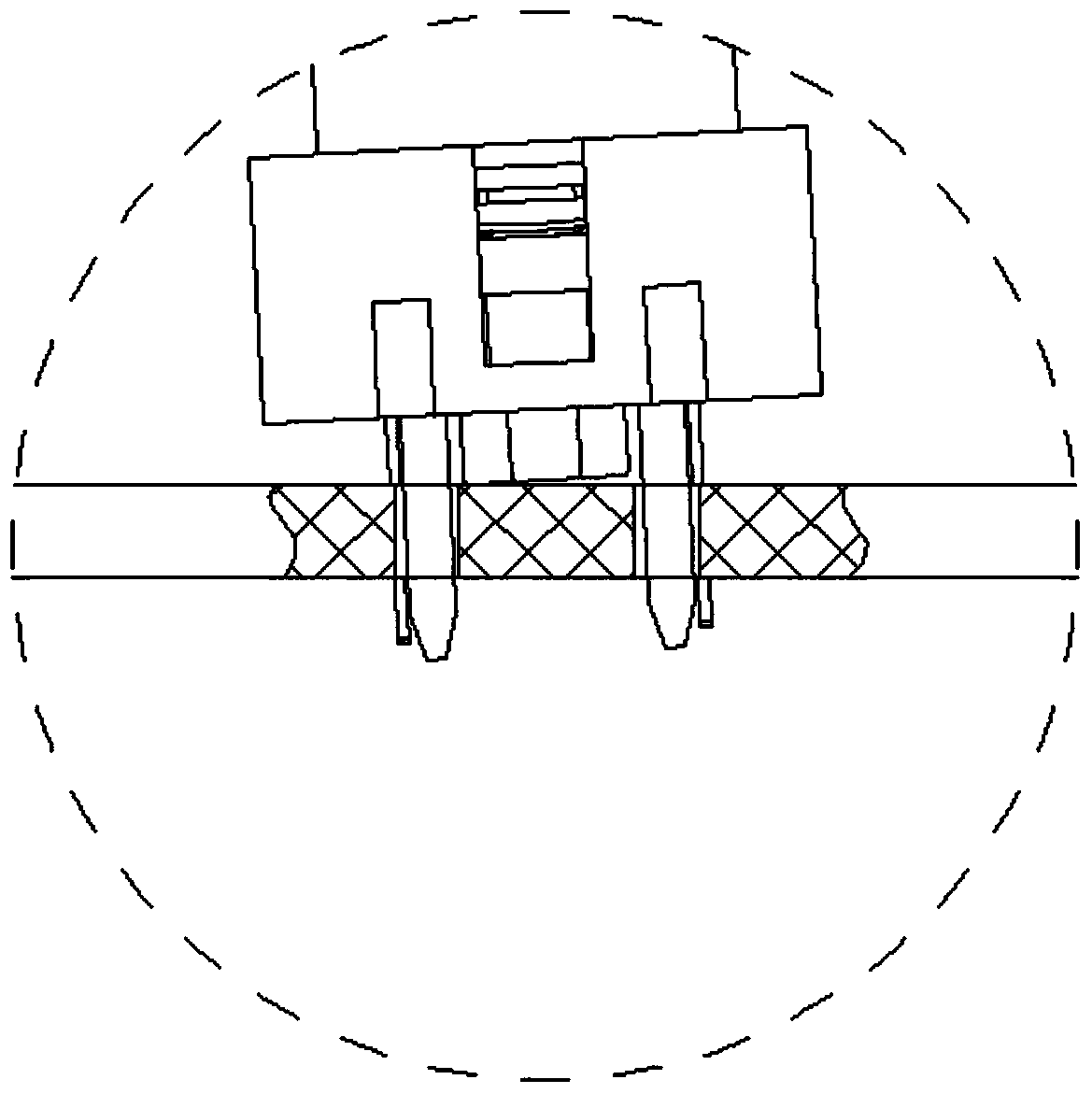

Mesh hauling and bending machine for welding machine and mesh hauling and bending method

ActiveCN107377817ADoes not affect weldingDoes not affect pulling netClimate change adaptationWire networkStructural engineeringIndustrial engineering

The invention belongs to the technical field of mesh hauling mechanisms for wire-mesh welding machines, and discloses a mesh hauling and bending machine for a welding machine and a mesh hauling and bending method. The mesh hauling and bending machine for the welding machine and the mesh hauling and bending method are characterized in that the mesh hauling and bending machine for the welding machine comprises a frame body with a mesh hauling cart, a mesh hauling hook is arranged at the front end of the mesh hauling cart, a cart rail and a hauling mechanism are arranged on the frame body, and a bending mechanism is arranged on the mesh hauling cart. The bending mechanism is arranged on the mesh hauling cart, the mesh hauling cart hauls a mesh to move, when the mesh hauling cart moves, the bending mechanism is in synchronization with the mesh hauling cart, the mesh and the bending mechanism are relatively static, and the mesh is bent when moving, so that no matter how much time bending takes, welding and mesh hauling are not affected, the production efficiency is improved, and the labor intensity is lowered.

Owner:河北骄阳焊工有限公司

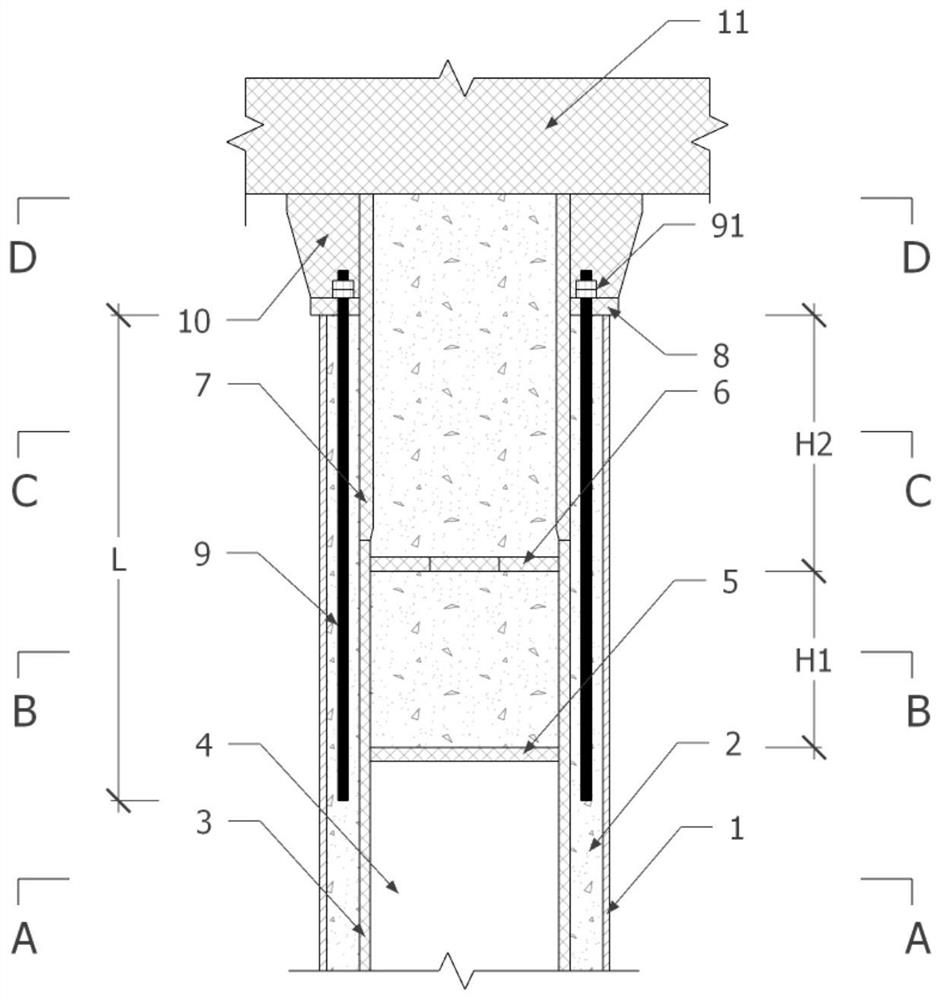

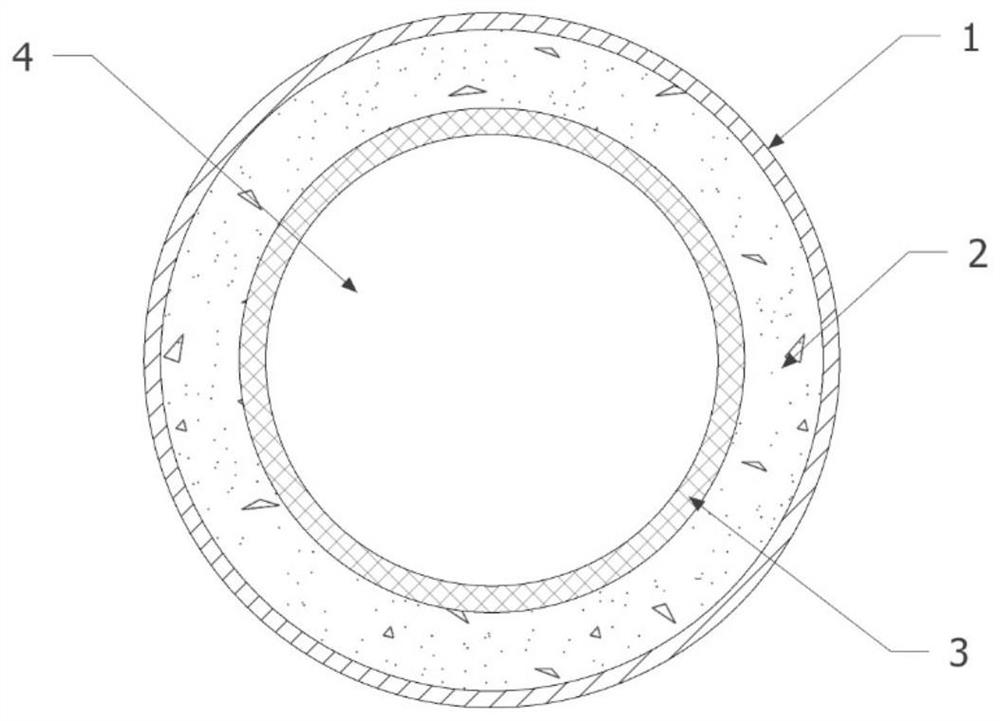

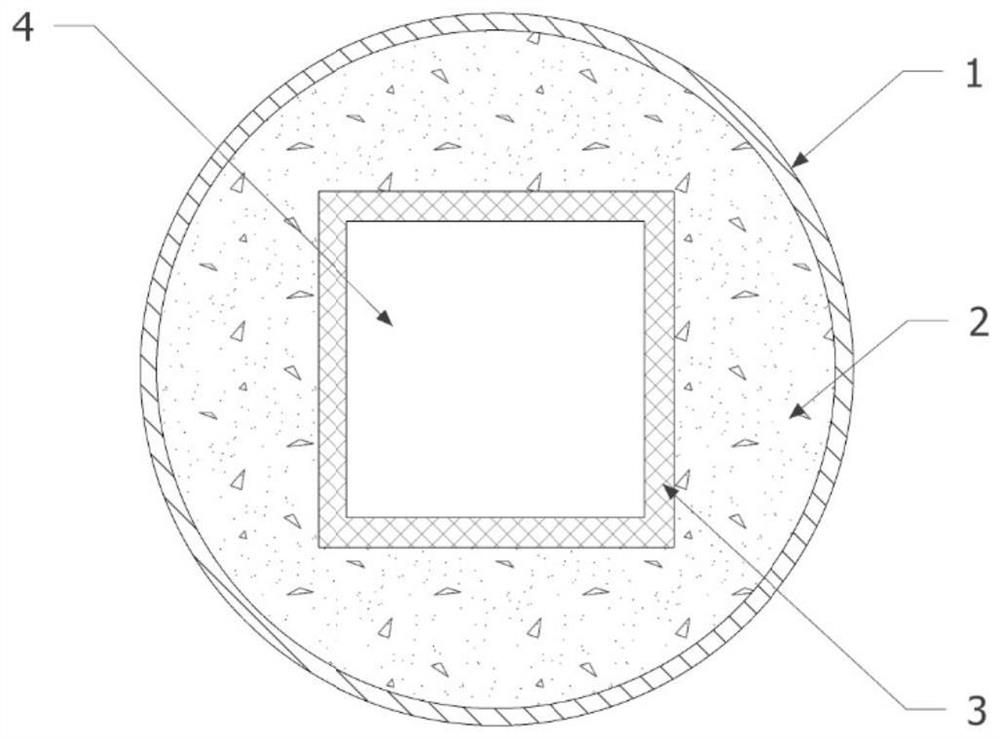

Fixed joint of double-wall hollow pier column and steel bridge and construction method

ActiveCN113832834AEfficient deliveryFirmly connectedClimate change adaptationBridge structural detailsEarthquake resistanceArchitectural engineering

The invention discloses a fixed joint of a double-wall hollow pier column and a steel bridge, which comprises a hollow section, a solid section, a reinforcing section and a conversion section, the hollow section, the solid section and the reinforcing section respectively comprise a composite material pipe, a steel pipe and a concrete layer between the composite material pipe and the steel pipe, and the conversion section comprises a steel pipe and stiffening ribs; the steel pipe and the stiffening ribs of the conversion section are used for being fixedly connected with a steel bridge; a steel inner partition plate is arranged between the steel pipe of the hollow section and the steel pipe of the solid section, a steel inner ring plate is arranged between the steel pipe of the solid section and the steel pipe of the reinforcing section, and a steel outer ring plate is arranged on the outer side of the junction of the steel pipe of the reinforcing section and the steel pipe of the conversion section. And one end of an anchor bolt is fastened on the steel outer ring plate, and the other end of the anchor bolt is anchored into the concrete layer between the composite pipe and the steel pipe of the reinforcing section. The invention further provides a corresponding construction method. The fixed joint solves the technical problem of fixed connection of the double-wall hollow pier column and the steel bridge, and has the advantages of being reliable in connection, gentle in rigidity transition, good in anti-seismic property and the like.

Owner:广州市城建规划设计院有限公司 +1

An easy-to-adjust support frame for oil pipeline installation

ActiveCN108581358BProtects against welding effectsEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesThermodynamicsPetroleum engineering

Owner:东营睿港投资服务有限责任公司

An automobile wheel lock welding tool

ActiveCN110605520BFully clampedDoes not affect weldingWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWelding

Owner:王志伟

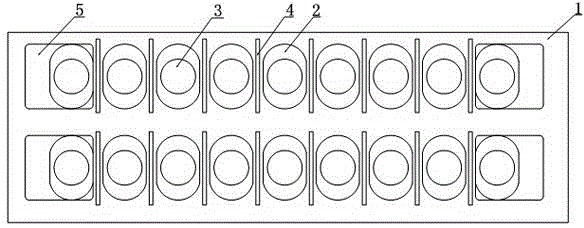

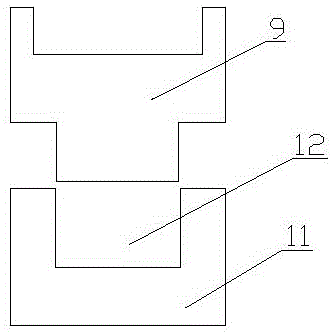

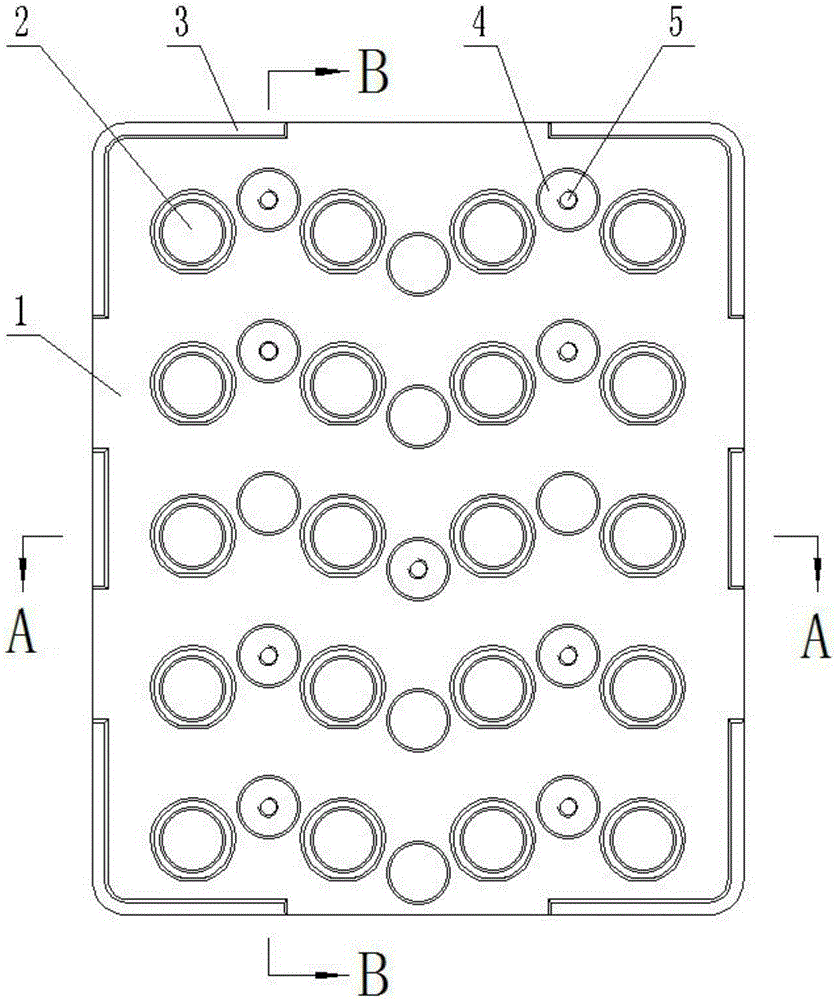

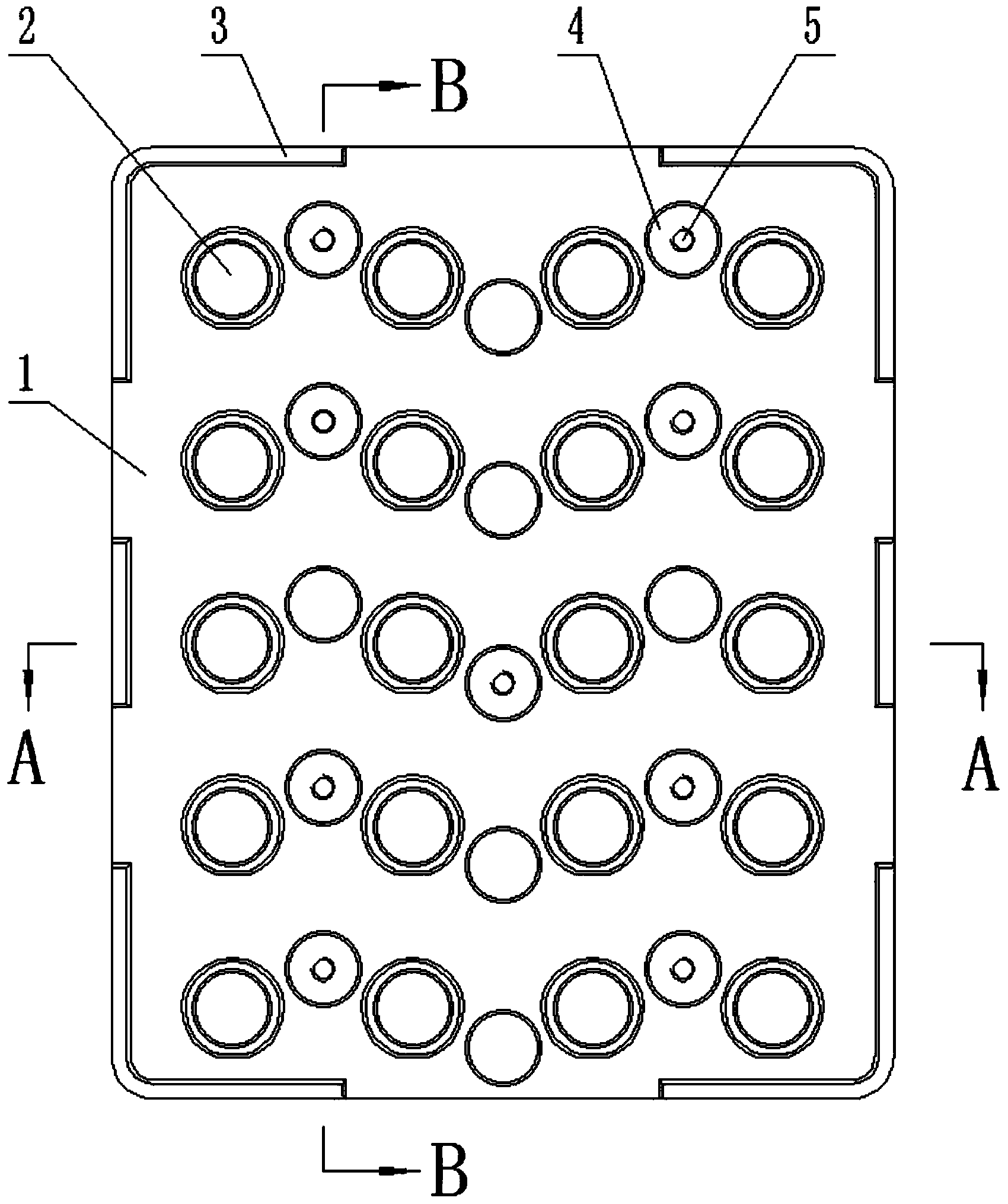

A fixing fixture and welding method for welding buttons on a button board

The invention discloses a fixing clamp used for welding of buttons on a button board and a welding method. The clamp comprises a base plate, wherein a plurality of stepped holes distributed in an array mode are formed in the base plate, the shapes of the stepped holes are matched with the appearances of the buttons needing welding, a row of mounting holes is formed between every two adjacent rows of stepped holes, and the stepped holes and the mounting holes are distributed at intervals. When pins are welded through the clamp, the buttons cannot deflect, and the quality of the welded button board is effectively improved; clamping of the button board can be achieved through limiting edges, the phenomenon that the button board slides or deflects is avoided, and welding precision is improved effectively; the buttons do not interfere with other components; the stepped holes can be used for self-inspection of the buttons; the limiting edges are in a segmented structure, the button board can be taken down rapidly and conveniently from fractured positions, and the situation that the button board is damaged or fractured because the button board bears force unevenly when taken from one corner is avoided.

Owner:贵阳永青智控科技股份有限公司

Fixing clamp used for welding of buttons on button board and welding method

The invention discloses a fixing clamp used for welding of buttons on a button board and a welding method. The clamp comprises a base plate, wherein a plurality of stepped holes distributed in an array mode are formed in the base plate, the shapes of the stepped holes are matched with the appearances of the buttons needing welding, a row of mounting holes is formed between every two adjacent rows of stepped holes, and the stepped holes and the mounting holes are distributed at intervals. When pins are welded through the clamp, the buttons cannot deflect, and the quality of the welded button board is effectively improved; clamping of the button board can be achieved through limiting edges, the phenomenon that the button board slides or deflects is avoided, and welding precision is improved effectively; the buttons do not interfere with other components; the stepped holes can be used for self-inspection of the buttons; the limiting edges are in a segmented structure, the button board can be taken down rapidly and conveniently from fractured positions, and the situation that the button board is damaged or fractured because the button board bears force unevenly when taken from one corner is avoided.

Owner:贵阳永青仪电科技有限公司

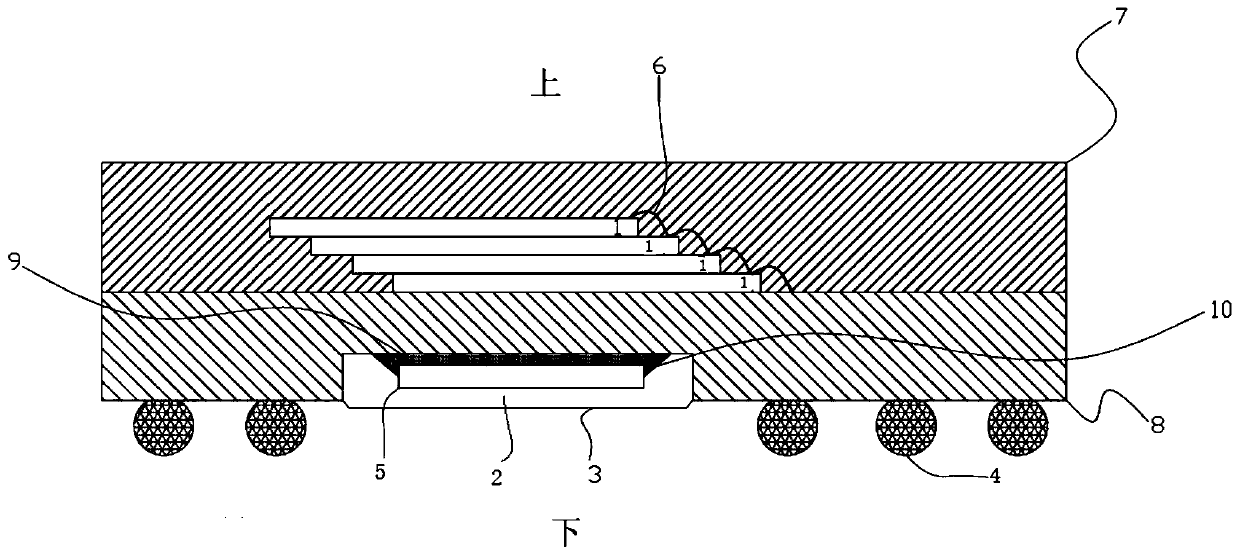

Storage type packaging structure equipped with groove and packaging method

InactiveCN110473791AReduce volumeGood for strong weldingSemiconductor/solid-state device detailsSolid-state devicesMemory chipStorage type

The invention discloses a storage type packaging structure equipped with a groove and a packaging method. The packaging structure is provided with a groove structure on the basis of an existing conventional packaging carrier so that for the structures of a control chip and a memory chip on upper and lower surfaces of a packaging carrier, the control chip can be placed in the groove structure, an entire packaging product volume is reduced and the product becomes light and handy. Because the lower surface of the control chip is also in the groove, a distance between a connection point of a welding surface of the packaging carrier and the surface of the control chip is increased, which is good for firmly welding of the packaging product and a PCB. A condition that disconnection of welding points or a defect caused by the small distance between a connection point and the surface of the control chip can cause circuit impassability is eliminated.

Owner:HUATIAN TECH XIAN

A processing method for high-speed generator rotor core assembly

ActiveCN103490569BDoes not affect linkGuaranteed bondingManufacturing stator/rotor bodiesPunchingCopper contamination

Owner:SHAANXI AVIATION ELECTRICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com