Method for preparing coated carbon aluminum foil of lithium-ion battery current collector by employing metallurgical coke powder as raw material

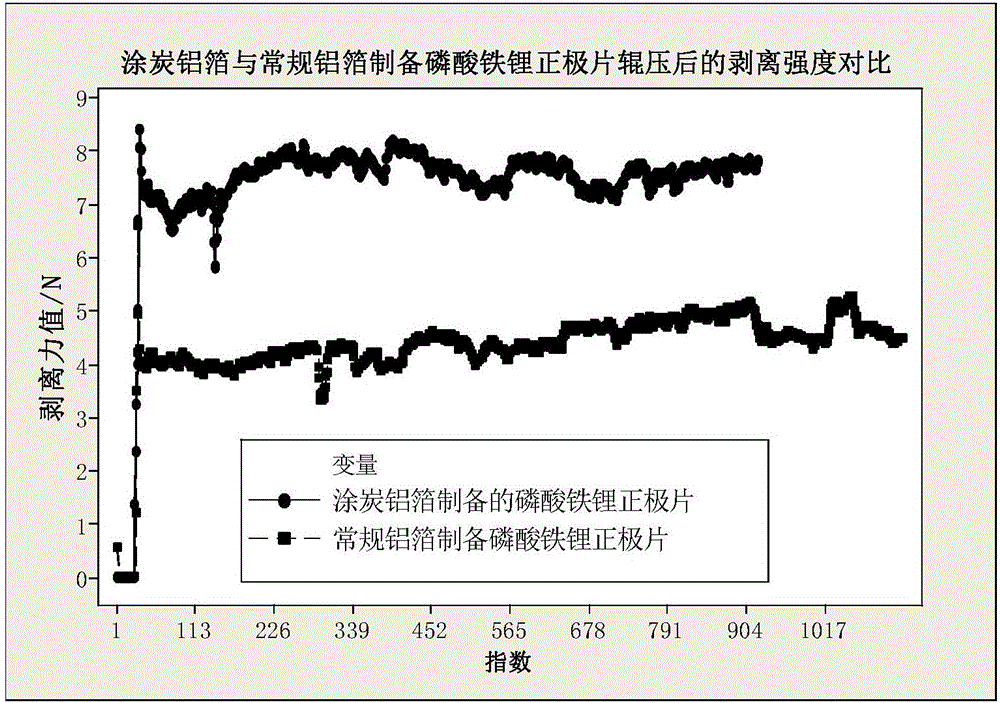

A lithium-ion battery and metallurgical coke powder technology, applied in battery electrodes, secondary batteries, electrode carriers/collectors, etc., can solve problems such as overcapacity, environmental pollution, resource waste, etc., to improve electrical performance and reduce manufacturing costs , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

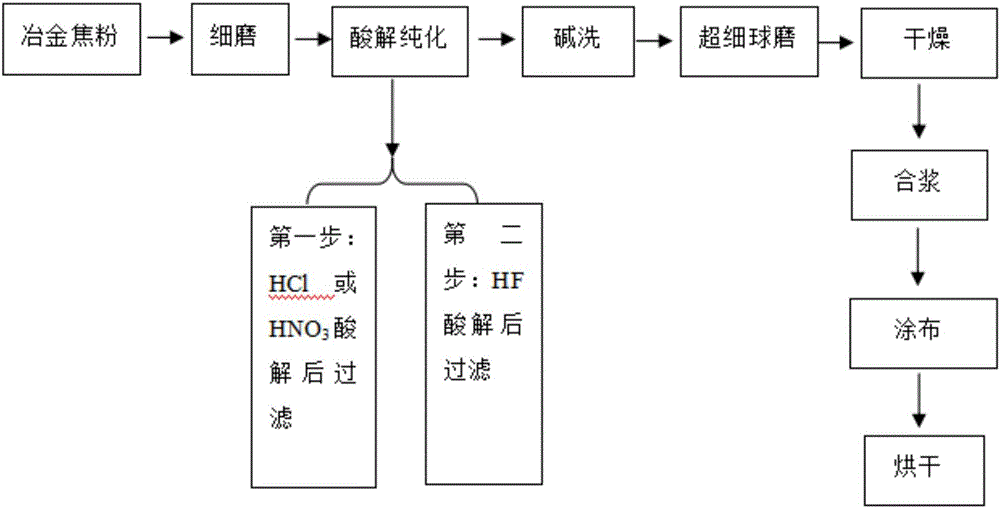

[0031] Such as figure 1 Shown, a kind of method that is raw material with metallurgical coke powder is prepared carbon-coated aluminum foil of lithium-ion battery current collector, comprises the following steps:

[0032] The first step is to take 100g of metallurgical coke powder transported from iron and steel enterprises, put it into a pendulum grinder for grinding for 180s, and use a laser force meter to test the particle size of the metallurgical coke powder after grinding, if the particle size is still large Secondary grinding is required until the particle size of the coke powder is reduced to 1-10 μm;

[0033] In the second step, configure 350ml of 1mol / L dilute hydrochloric acid solution, place it in a water bath at 80°C, slowly add fully ground metallurgical coke powder and keep stirring for 1-2 hours. After fully reacting, use the Buchner funnel Suction filtration is carried out, and the filtrate can be purified to prepare other chemical reagents. After the filter ...

Embodiment 2

[0049] The first step is to take 100g of metallurgical coke powder transported from iron and steel enterprises, and put it into a planetary ball mill for ball milling for 5 hours at a ball milling speed of 350r / min. Use a laser particle size analyzer to test the particle size of the metallurgical coke powder after grinding, such as particle size If it is still too large, a second ball mill is required until the particle size of the coke powder is 1-10 μm;

[0050] The second step is to configure 350ml of 1mol / L dilute HNO3 solution, place it in a water bath at 80°C, slowly add fully ball-milled metallurgical coke powder and keep stirring for 1-2h. After fully reacting, use a Buchner funnel to carry out Suction filtration, the filtrate can be purified to prepare other chemical reagents, after the filter cake is collected, carry out secondary acid hydrolysis; configure 700ml of 1mol / L dilute hydrofluoric acid solution, place it in a 50°C water bath, slowly add The decomposed met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com