Inner circular expanding tool in thin-wall cylinder circular seam pairing

A technology of rounding tooling and thin-walled cylinder, which is applied to auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of difficulty in repeated use and difficult to adjust the curvature locally, and achieves simple structure, low cost, and avoidance of deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

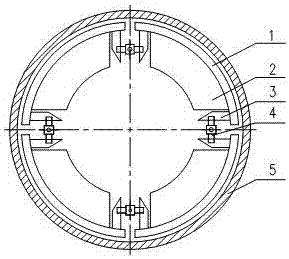

[0012] Such as figure 1 A kind of thin-walled cylinder ring seam group timing internal support circle tooling, which includes shell backing plate 1, support arc plate 2, rib plate 3 and locking device, shell backing plate 1, support arc plate 2 and rib The plate 3 is welded together, and the inner radius curvature of the shell backing plate 1 and the cylinder body 5 drawing requirements tends to be consistent; the supporting arc plate 2 and the shell backing plate 1 are welded to rigidly fix the shell backing plate 1 The role; the ribs 3 are connected by a locking device.

[0013] The locking device is flexibly connected with two adjacent ribs 3 through positive and negative threaded buttons 4 . The two ends of the positive and negative threaded buttons are respectively connected with the rib plate 3, which is threaded connection; wherein, there is a circular perforation in the middle of the positive and negative threaded button 4, and a section of bar is added to rotate and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com