A processing method for high-speed generator rotor core assembly

A technology of rotor iron core and processing method, which is applied in the direction of electric components, manufacture of motor generators, electrical components, etc., can solve problems such as affecting the normal operation of high-speed generators, punching of rotor iron core components, and breakage of damping copper bars, etc. Achieve the effect of reducing eddy current loss and improving insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

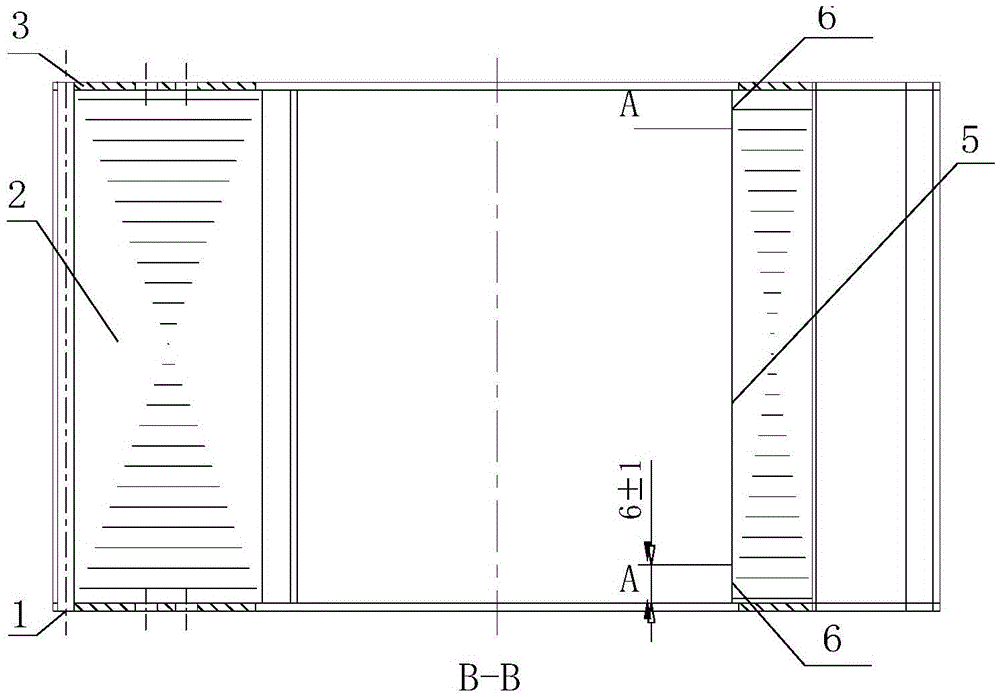

[0035] Step 1: Before lamination of the rotor lamination 2, use CBP-I adhesive to spray one side of the iron core lamination, and preheat at 65±2°C for 15 minutes to form a layer of solid adhesive film on the surface of the 2 before lamination ;

[0036] Step 2: Retain 15-20 pieces of rotor punches with a thickness of 0.35mm on both sides of the rotor core. Glue-coating process is adopted: that is, no adhesive is applied to the pole body and pole shoe parts, and glue is applied to the rest of the parts. Preheat at 65±2°C for 15 minutes to form a solid film on the surface of 2 before lamination;

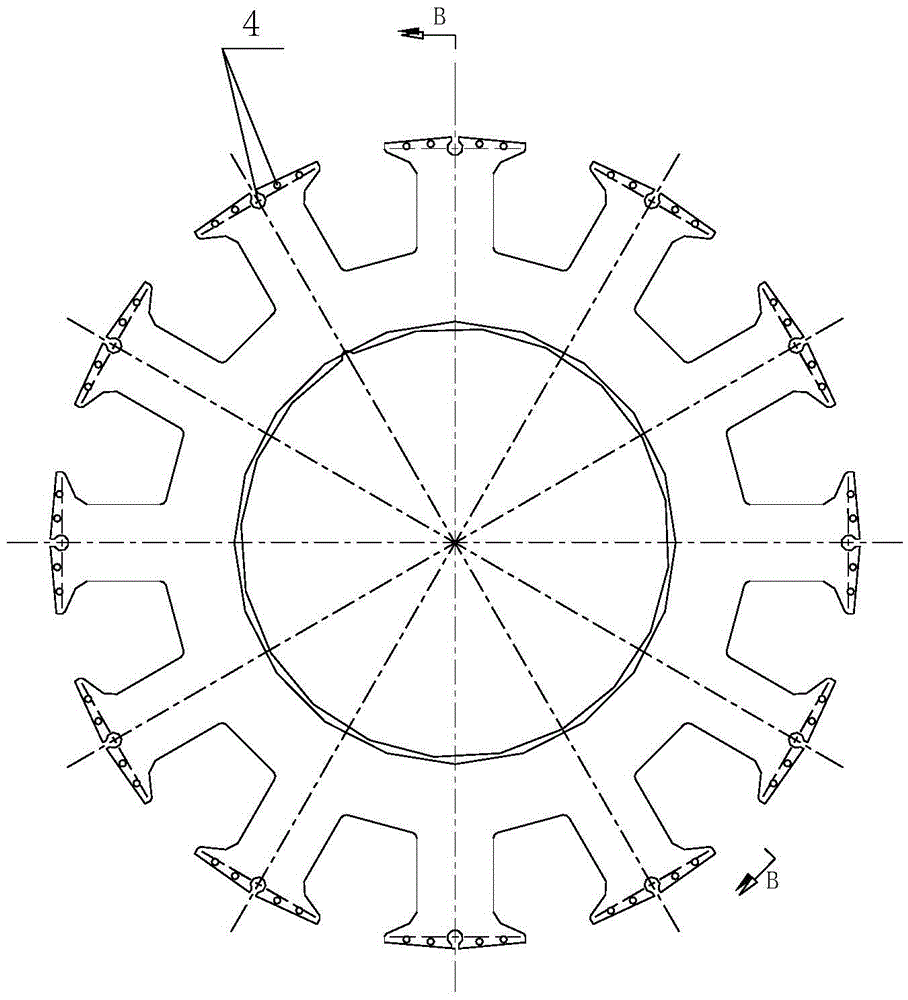

[0037] Step 3: On the rotor core assembly stacking jig, stack in the order of rotor copper end plate 3→glue-coated punch 6→glue-spray punch 5→glue-coated punch 6→rotor copper end plate 3, and press on-board pressurization;

[0038] Step 4: Take out the rotor core assembly, install the damping copper strip and weld it;

[0039] Step 5: After the welding is completed, bake and cure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com