White-light emitting diode with vertical structure and manufacturing method thereof

A technology of light-emitting diodes and vertical structures, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of complex production process of vertical structure LEDs, reduce product stability and yield, and increase production costs, and achieves the advantages of separating, The effect of ensuring stability and reducing the difficulty of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

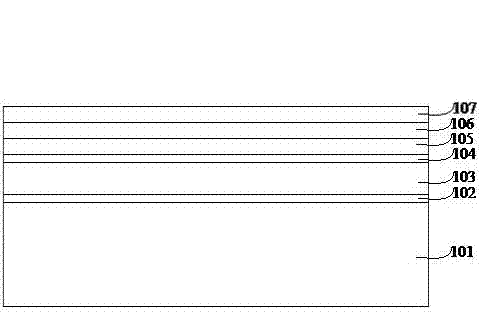

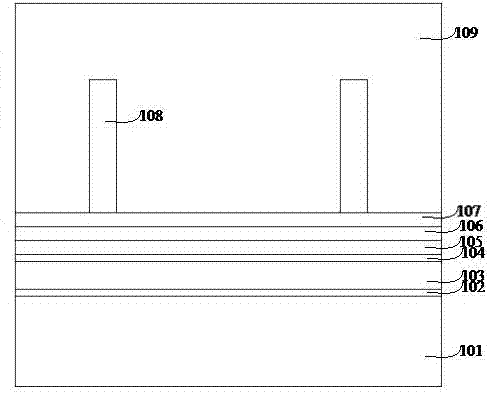

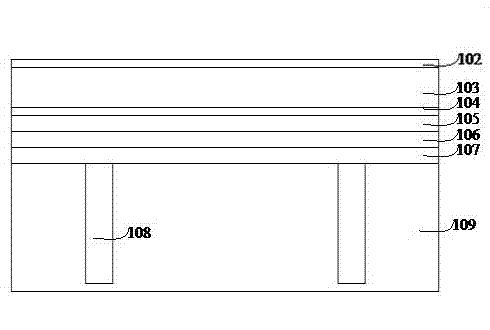

[0031] see Figure 10 The white light vertical light emitting diode of the present invention comprises a metal support substrate 109, a metal seed layer 107, a reflective metal layer 106, a P-type GaN-based semiconductor layer 105, a quantum well active region 104, and an N-type GaN-based semiconductor layer stacked sequentially from bottom to top. The semiconductor layer 103 and the passivation layer 110, a phosphor layer 111 is placed on the passivation layer 110, and an N-face electrode 112 is placed in the electrode groove at the top of the device. The metal supporting substrate 109 is made of Ni, Cu, Au, Fe, Mn, Sn or an alloy of several elements, and the thickness of the metal supporting substrate 109 is 100-500 μm. The material of the metal seed layer 107 is composed of one or more layers of metals among Pd, Pt, Au, W, Ni, Ta, Co, Ru, and the thickness of the metal seed layer 107 is 100-400 nm. The reflective metal layer 106 is made of Al or Ag and their alloys with h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com