A fixing fixture and welding method for welding buttons on a button board

A technology for fixing fixtures and key boards, applied in electrical components, electrical switches, circuits, etc., can solve the problems of low welding accuracy, interference, and keys are prone to skew, so as to improve welding accuracy, avoid sliding or offset, and improve the finished product. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

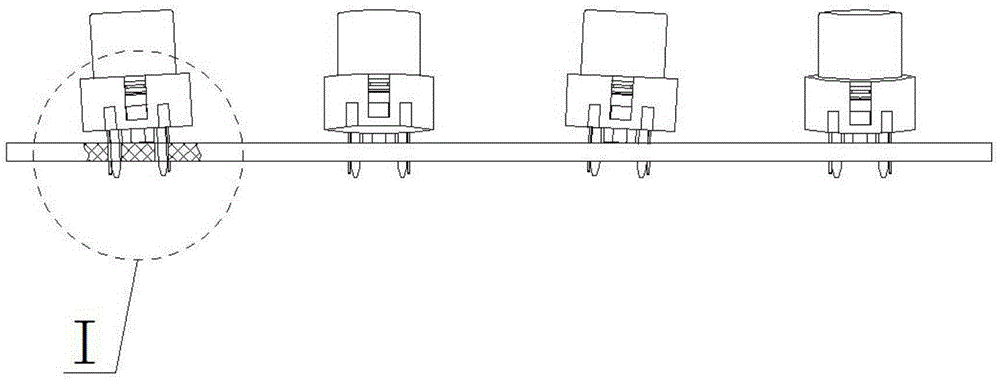

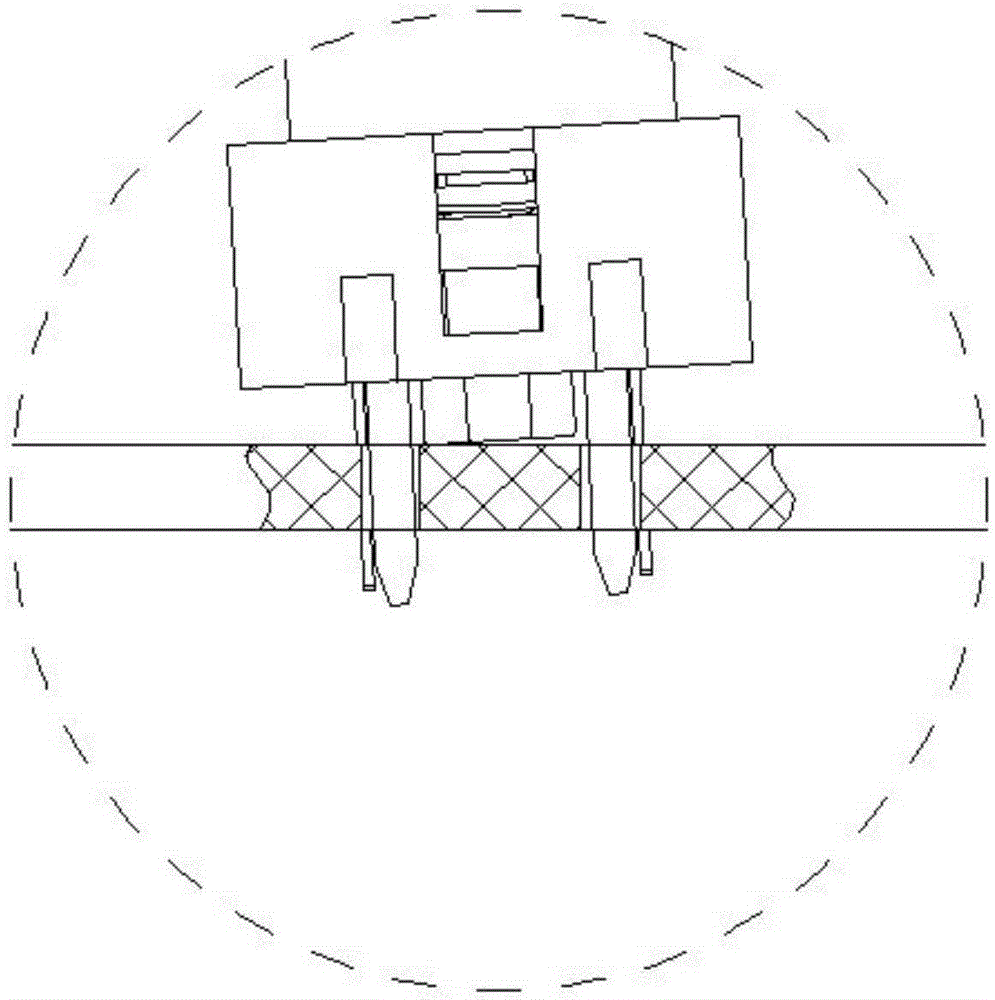

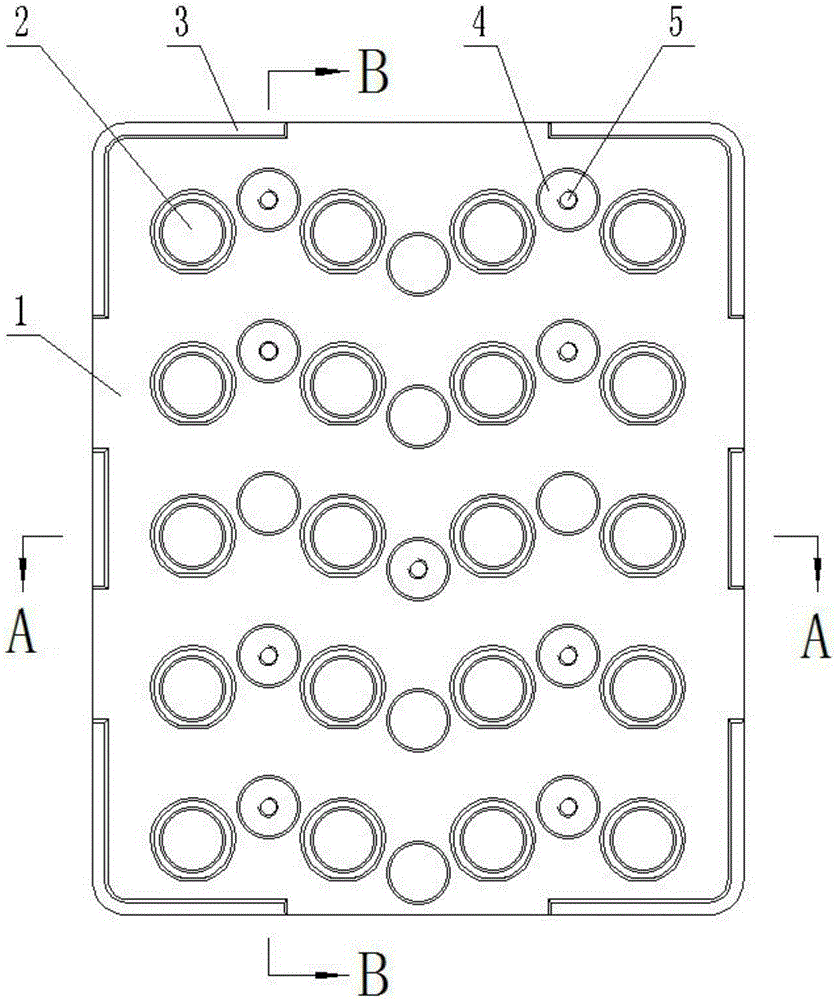

[0050] Example 1: When it is necessary to weld 20 keys 7 distributed in 4×5 on the five-slice key board, take the pin 9 of the key 7 and insert it into the center of the via hole to compress the height after welding, the length of the key board 10 and the five-screw key The width of plate, remove seat plate 1 height with the distance greater than button 7 height 1mm, but the length and width of seat plate 1 with the distance of 5mm more than key plate 10 length and five spell key plate width respectively. The extra 5mm side of length and width divides the two sides equally, leaving a 0.1mm installation gap for each, and then designing a limit side 3 with a width of 2.4mm and a height 0.5mm higher than the thickness of the keypad 10, to limit the placement range of the keypad 10, The key board 10 needs to print a metal edge with a width of about 2 mm on the side board and the mounting hole 5 to prevent the key board 10 from being damaged by static electricity.

[0051] When in ...

Embodiment 2

[0052] Example 2: When it is necessary to weld 40 keys 7 distributed in 8×5 on the five-slice key board, take the pin 9 of the key 7 and insert it into the center of the via hole to compress the height after welding, the length of the key board 10 and the five-screw key The width of plate, remove seat plate 1 height with the distance greater than button 7 height 1.5mm, but the length and width of seat plate 1 with respectively more than 5mm of key plate 10 lengths and five spell key plate widths. The extra 5mm side of length and width divides the two sides equally, leaving a 0.1mm installation gap for each, and then designing a limit side 3 with a width of 2.4mm and a height 0.5mm higher than the thickness of the keypad 10, to limit the placement range of the keypad 10, The key board 10 needs to print a metal edge with a width of about 2 mm on the side board and the mounting hole 5 to prevent the key board 10 from being damaged by static electricity.

[0053] When in use, firs...

Embodiment 3

[0054] Example 3: When it is necessary to weld 30 keys 7 distributed in 6×5 on the five-slice key board, take the pin 9 of the key 7 and insert it into the center of the via hole to compress the height after welding, the length of the key board 10 and the five-screw key The width of plate, go seat plate 1 height with the distance greater than button 7 height 2mm, but the length and width of seat plate 1 with the distance of 5mm more than key plate 10 length and five spell key plate width respectively. The extra 5mm side of length and width divides the two sides equally, leaving a 0.1mm installation gap for each, and then designing a limit side 3 with a width of 2.4mm and a height 0.5mm higher than the thickness of the keypad 10, to limit the placement range of the keypad 10, The key board 10 needs to print a metal edge with a width of about 2 mm on the side board and the mounting hole 5 to prevent the key board 10 from being damaged by static electricity.

[0055] When in use,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com