Patents

Literature

73results about How to "Fully clamped" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

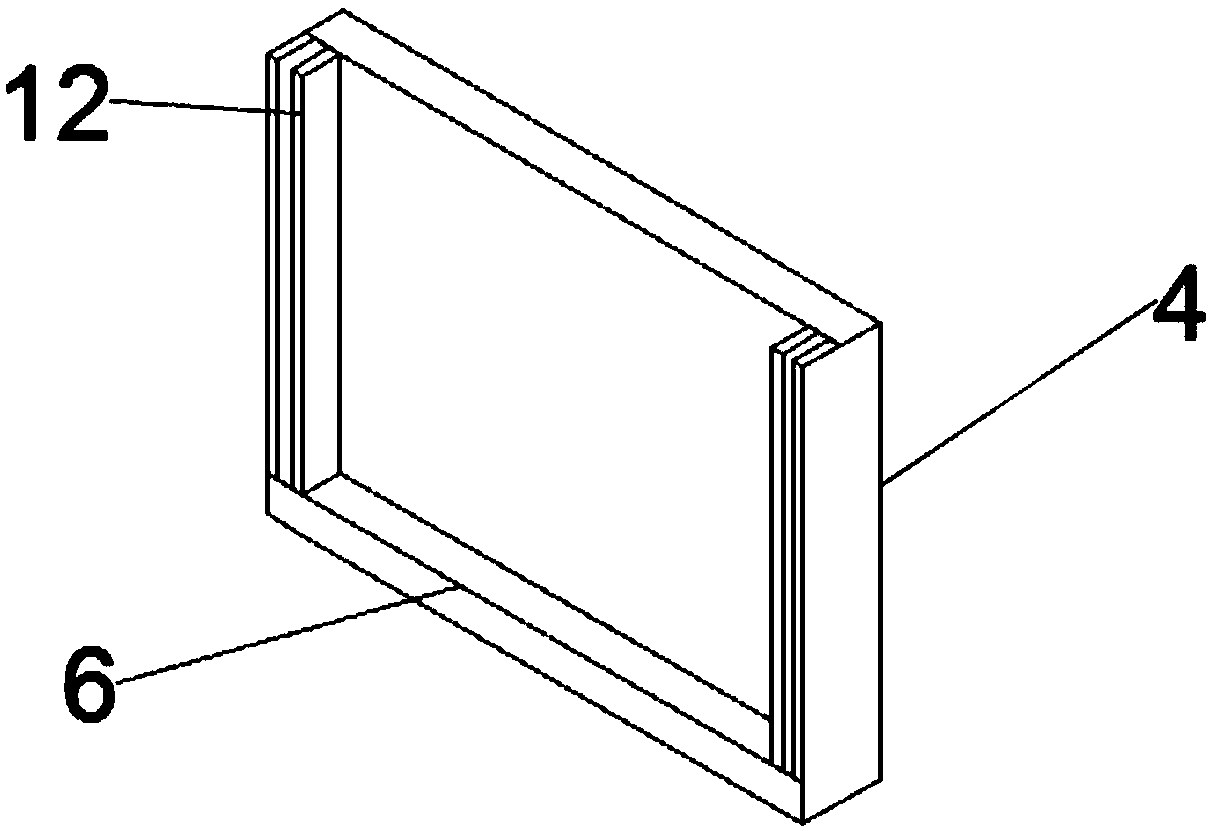

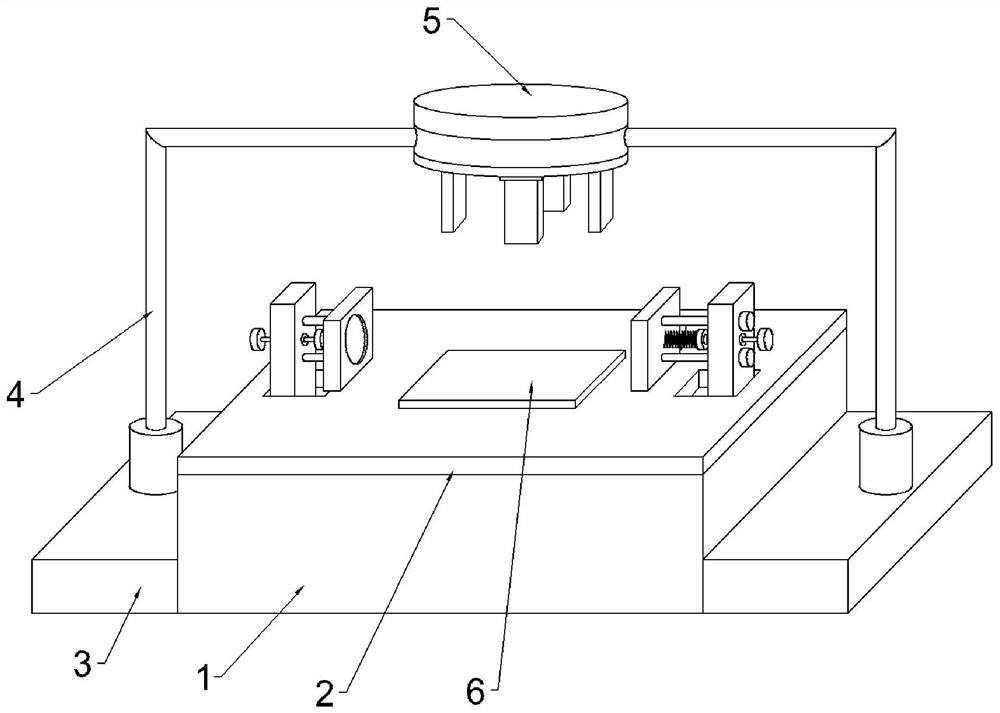

Workpiece clamp

InactiveCN103170847AGuaranteed clampingStable working conditionPositioning apparatusElectrical-based auxillary apparatusWire cuttingEngineering

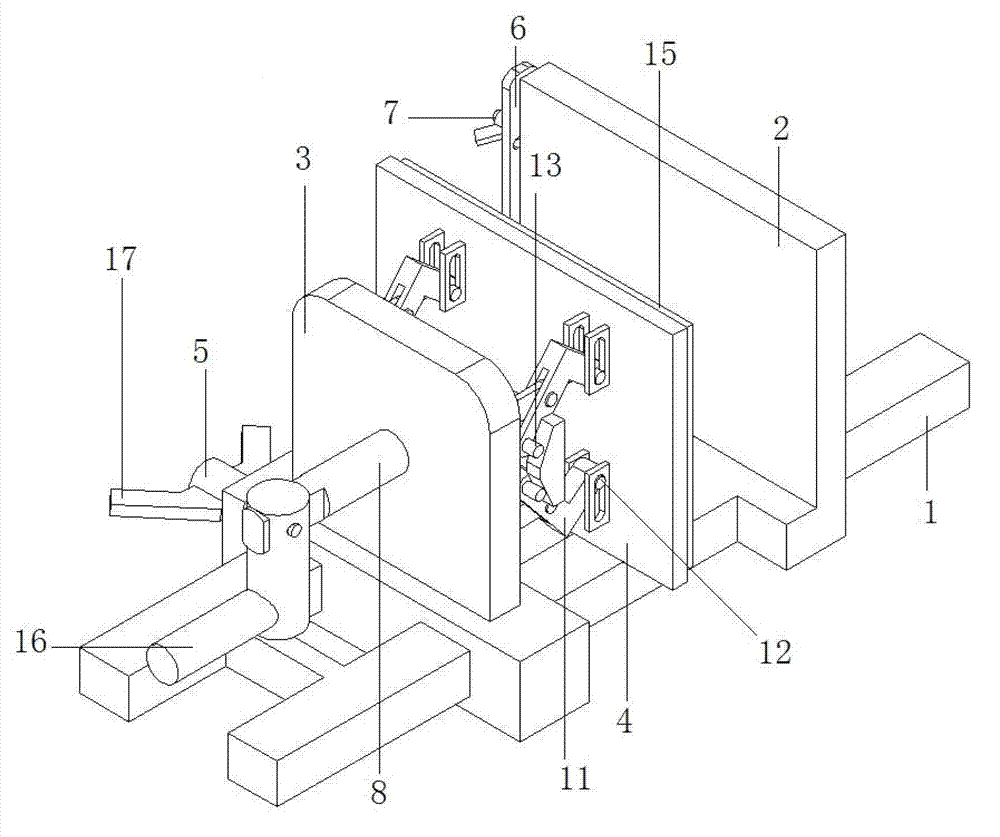

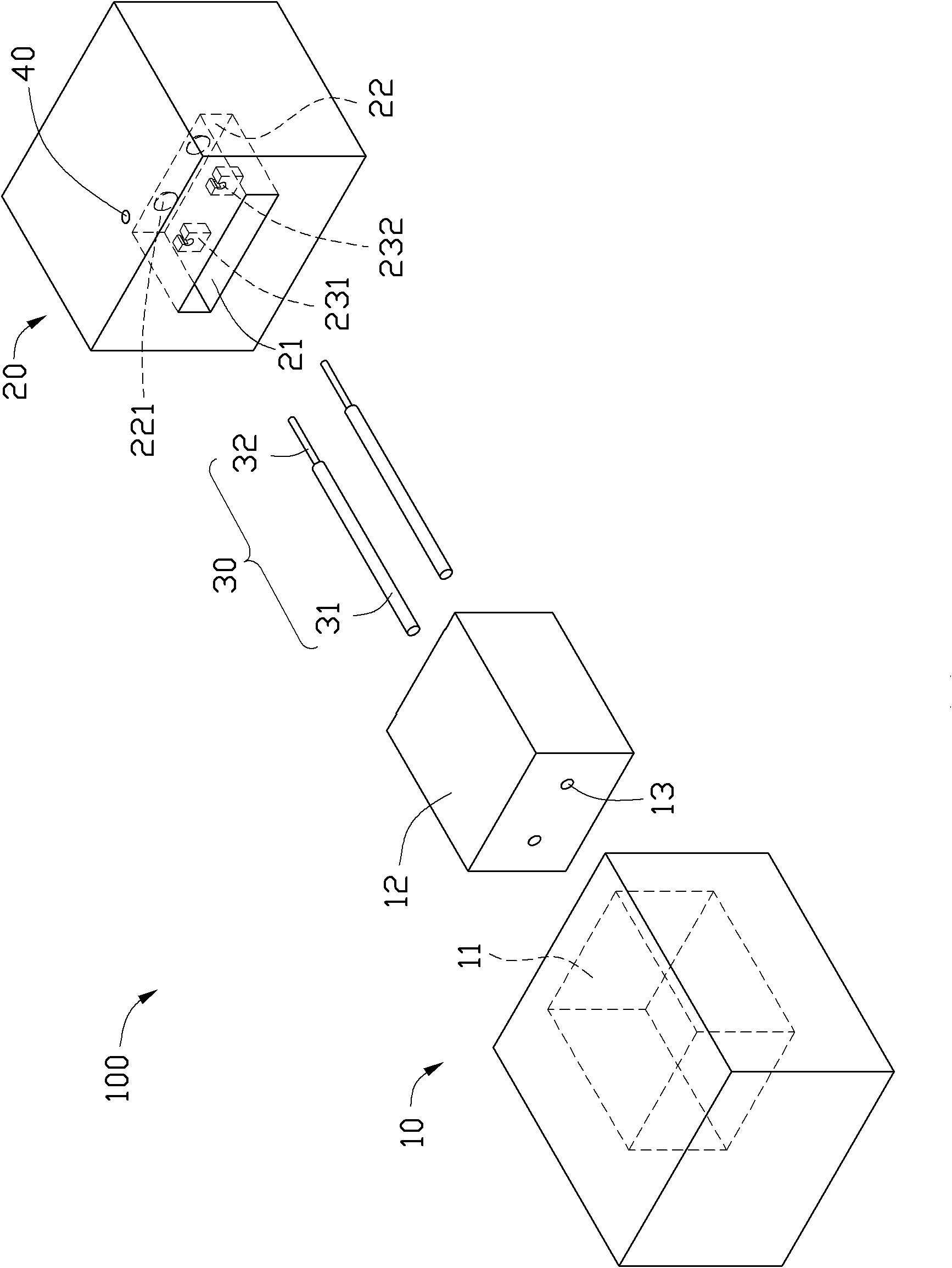

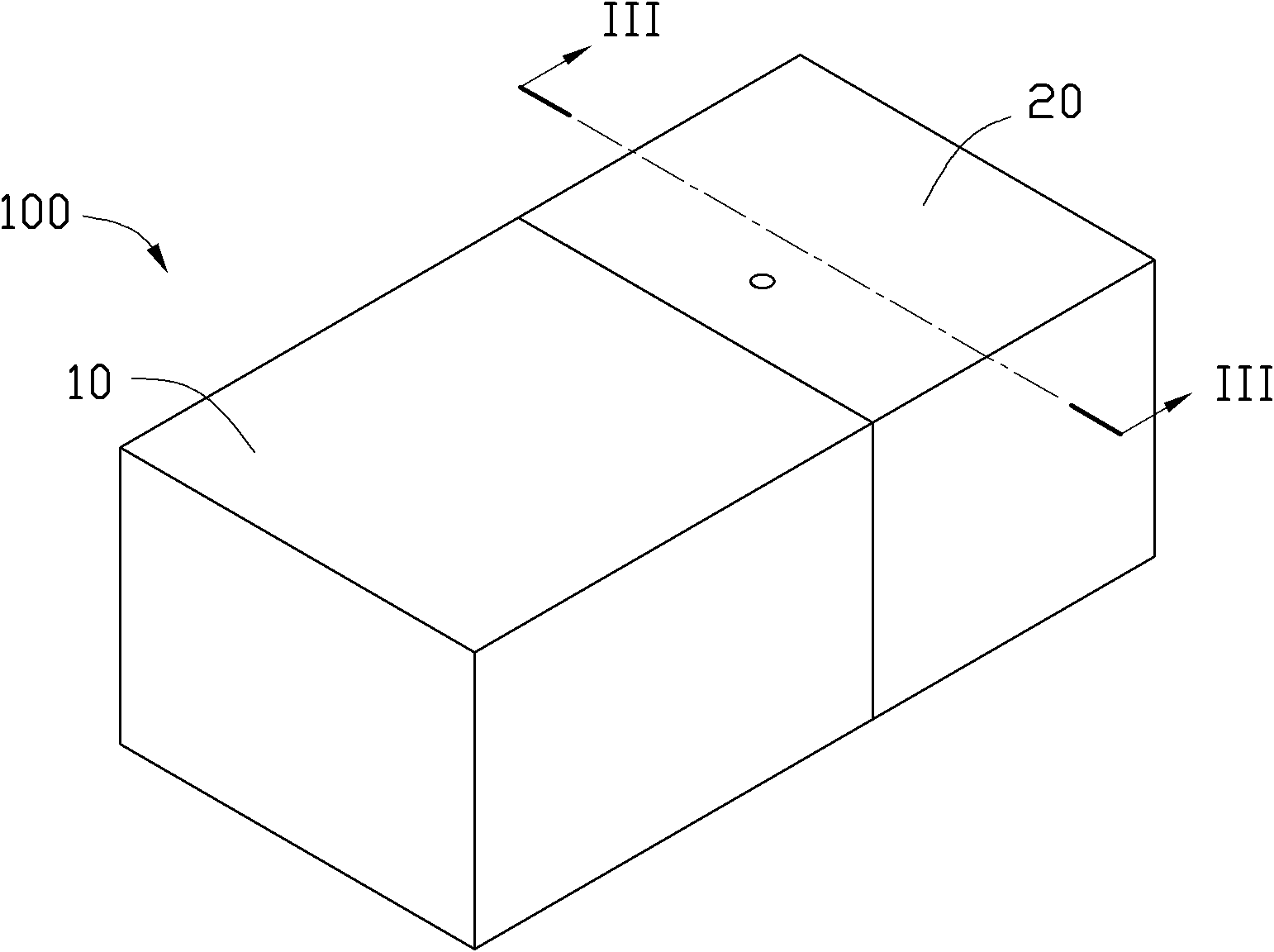

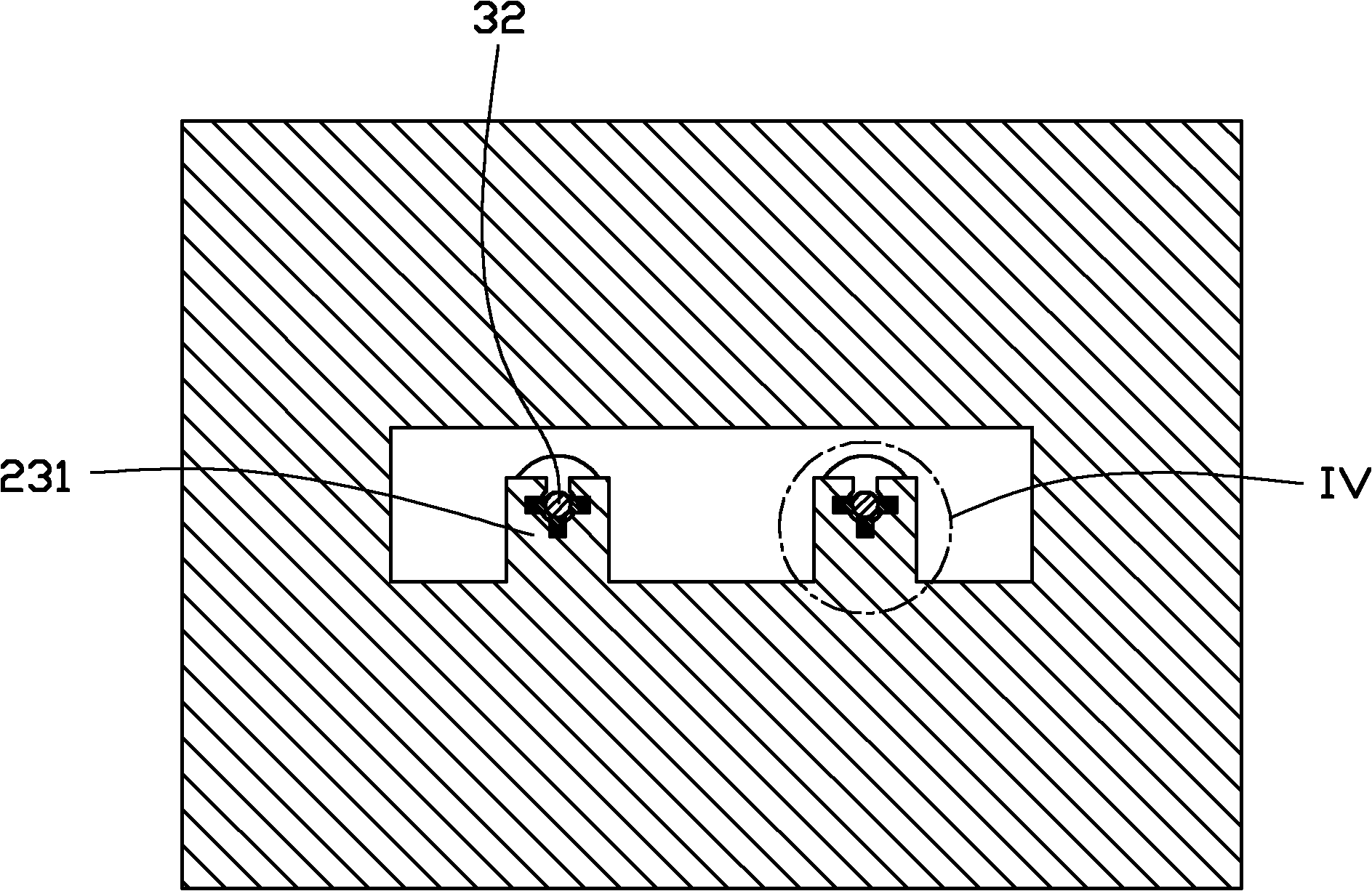

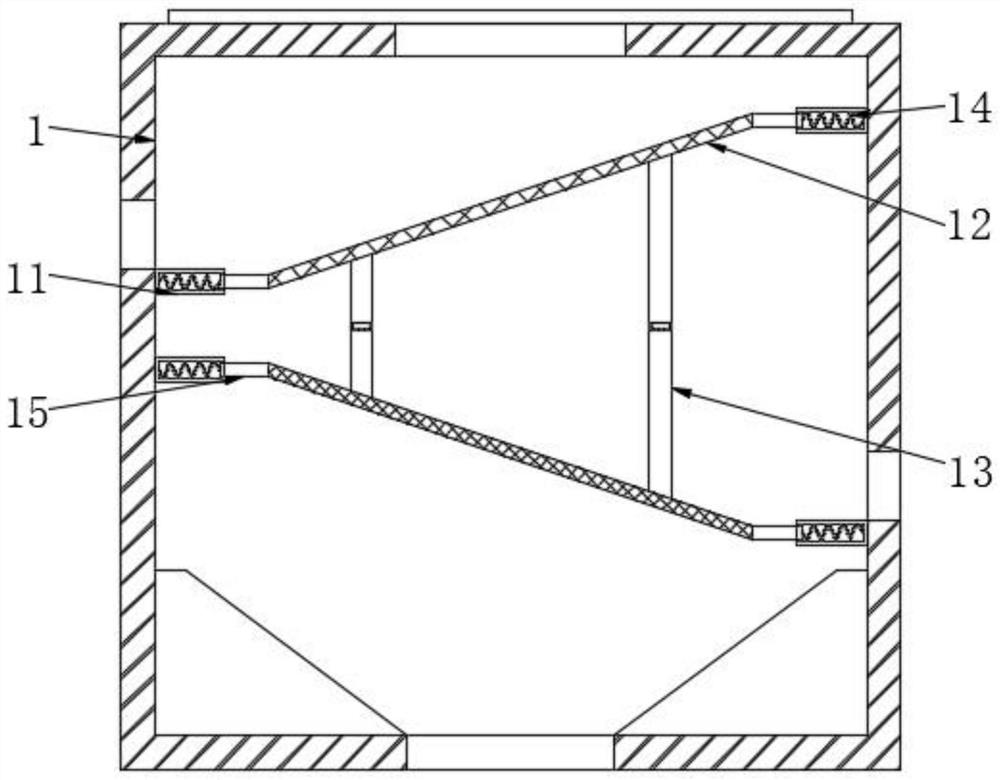

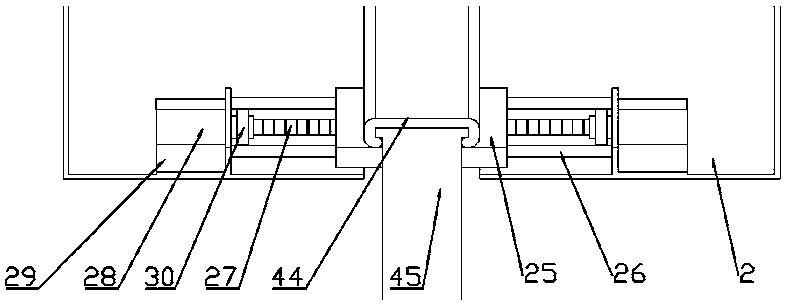

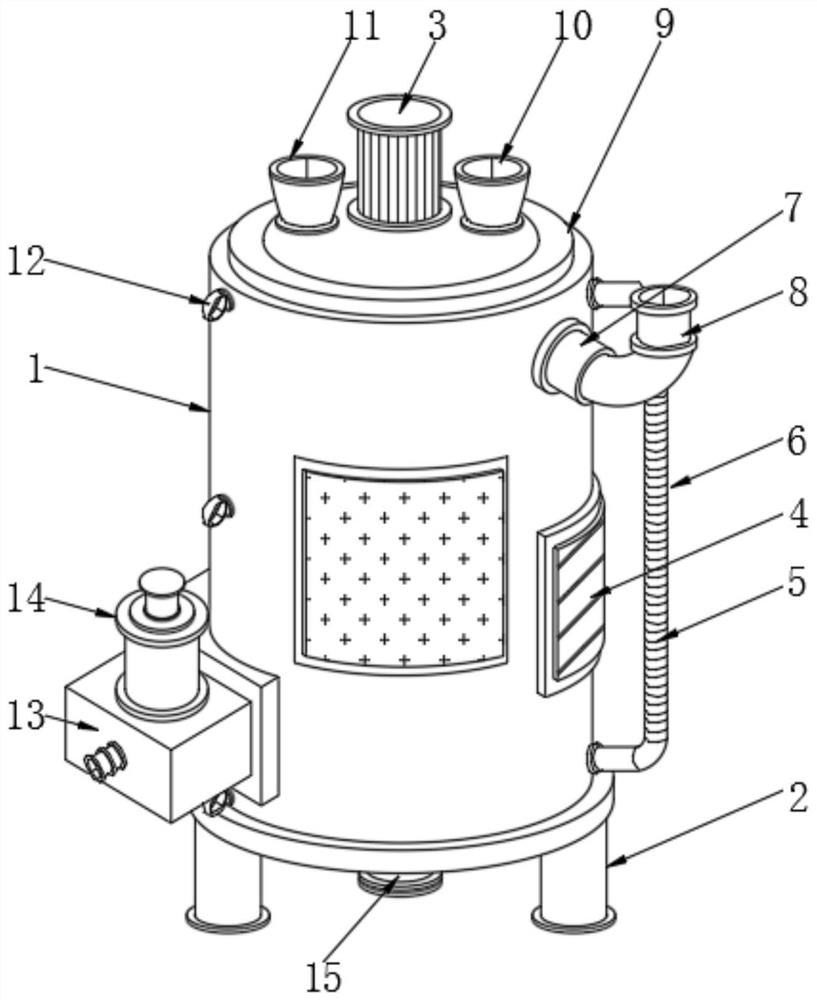

The invention discloses a workpiece clamp capable of directly achieving positioning without depending on workers and extra tools. The workpiece clamp solves the problem that according to a wire cutting clamp in the prior art, horizontal positioning of a workpiece has to depend on extra tools. According to a novel chopstick barrel, the lower end of a barrel body is provided with a water filtering frame, and the bottom of the barrel body is connected with a water collection cup. The workpiece machining clamp comprises a substrate, a standard base plate and a sliding clamping plate which is opposite to the standard surface of the standard base plate and arranged on a sliding clamping base are arranged on the substrate. The sliding clamping base is connected with the substrate in a sliding mode, a positioning bolt is arranged on a side of the sliding clamping base and is tightly attached to the side edge of the substrate under a tightening state, a limit plate which partially extends towards the direction where the sliding clamping base is located is arranged on a side of the standard base plate, and the surface of the limit plate close to the standard base plate is vertical to the standard surface of the standard base plate. The workpiece clamp is suitable for being used in occasions where an original wire-electrode cutting clamp is suitable, and has the advantages of being capable of achieving quick clamping and loosening, capable of clamping multiple workpieces, and the like.

Owner:ZHEJIANG GEELY POWERTRAIN CO LTD +2

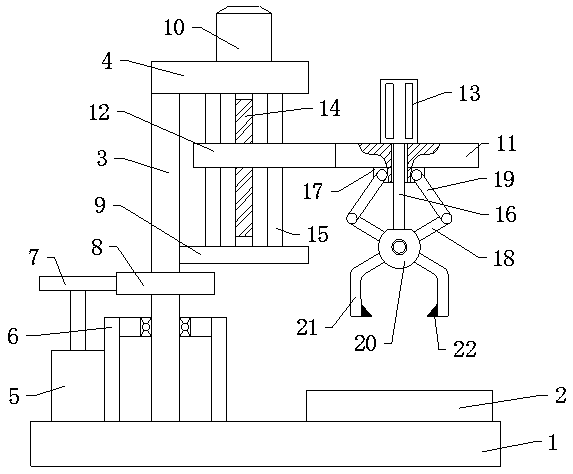

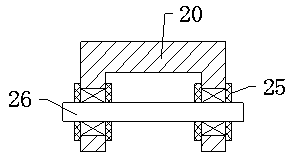

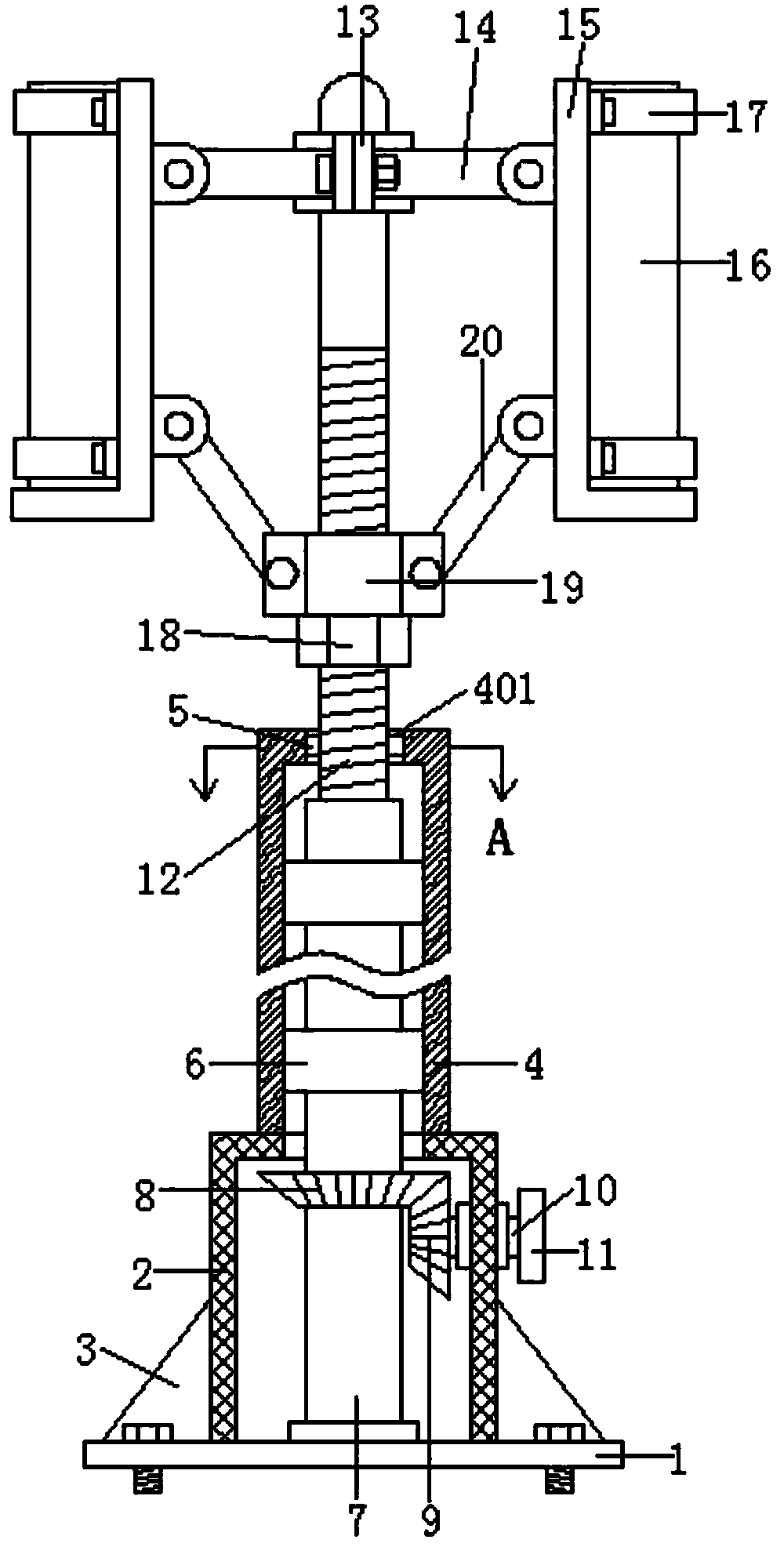

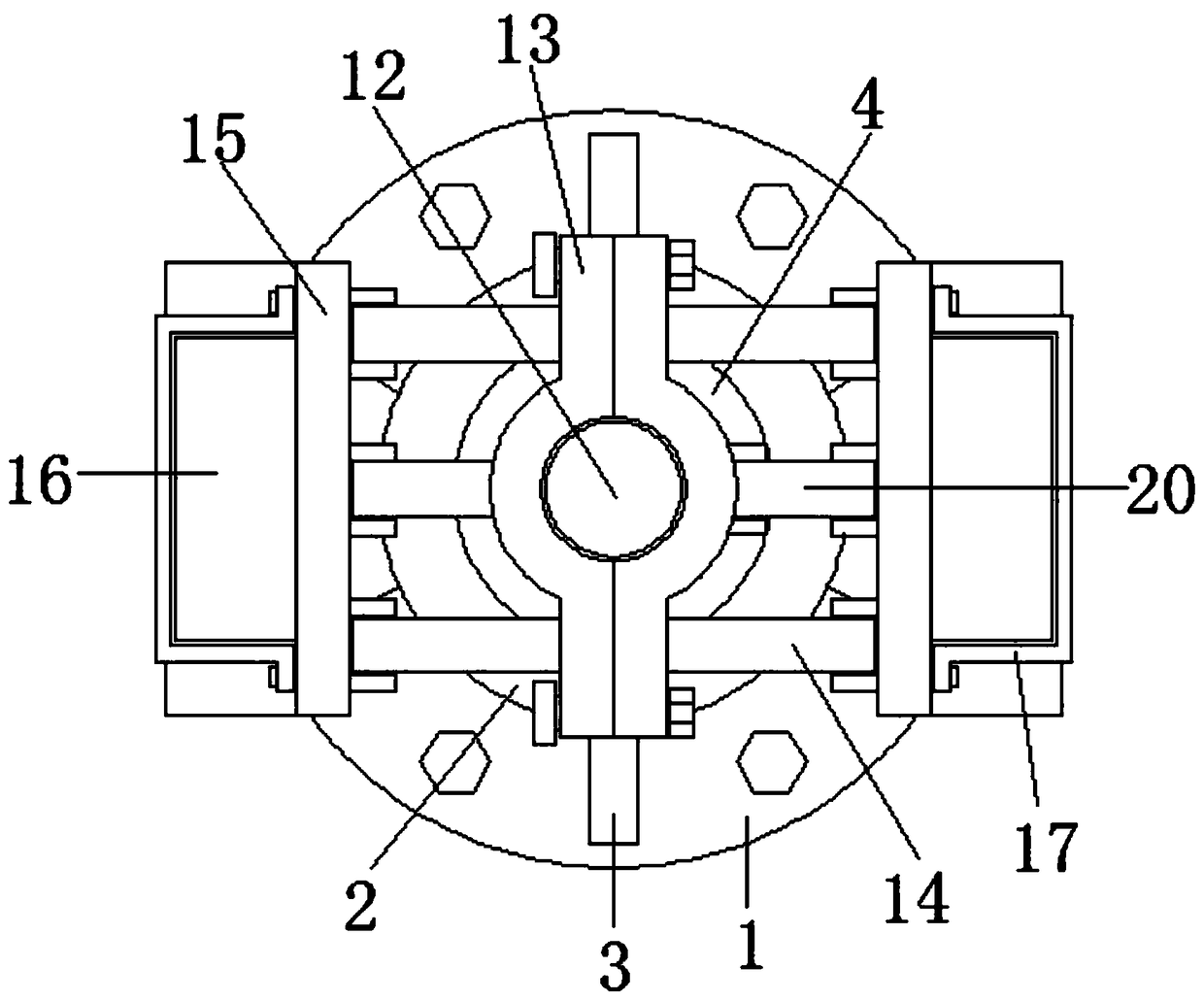

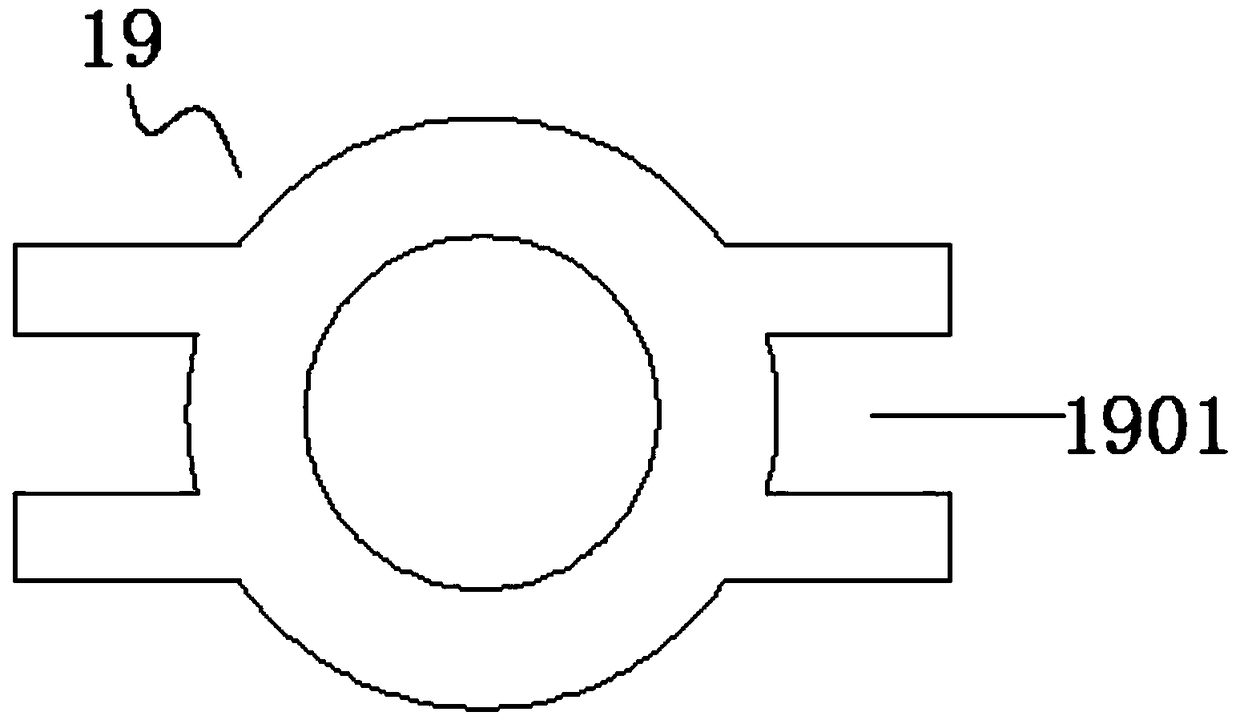

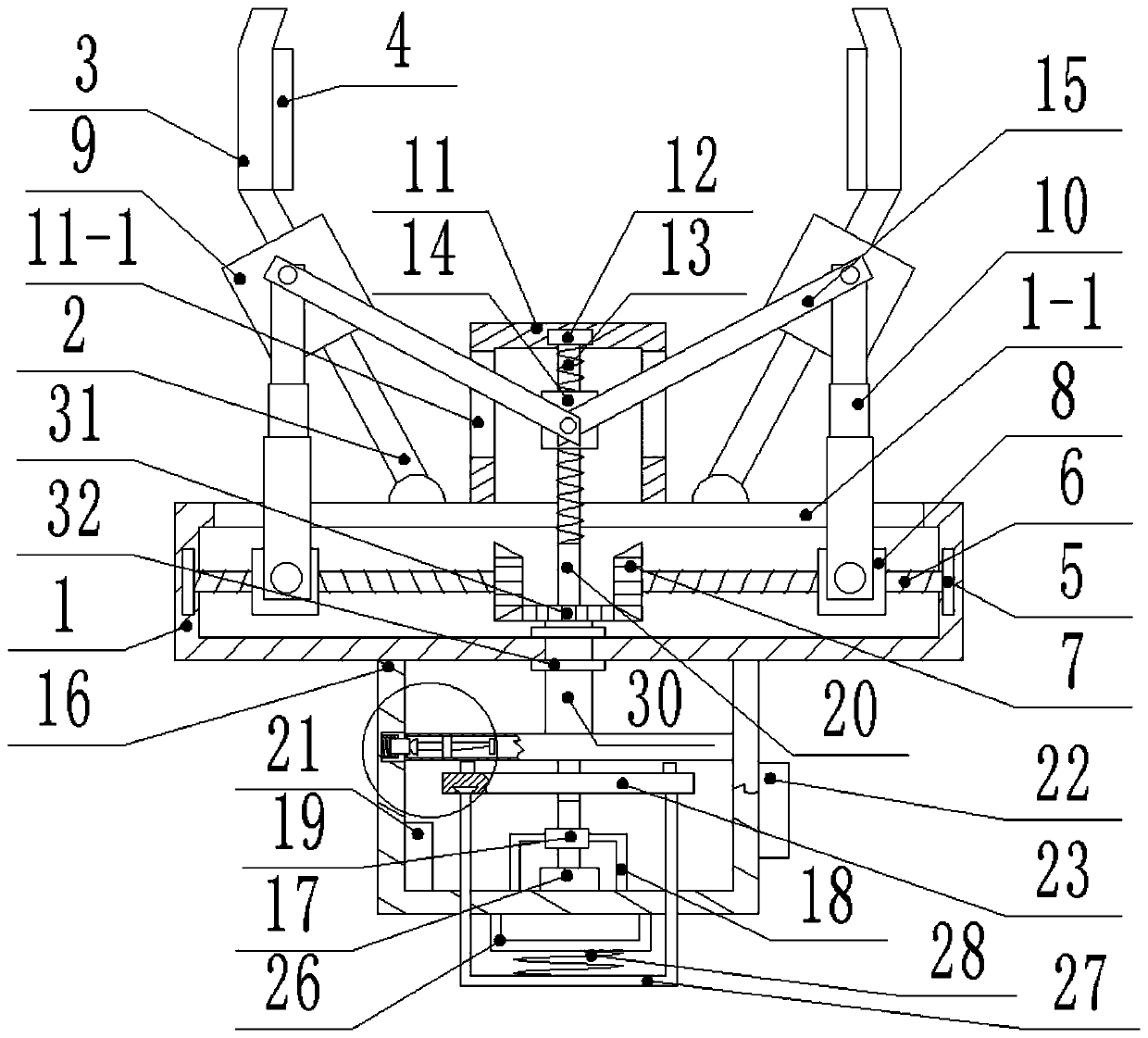

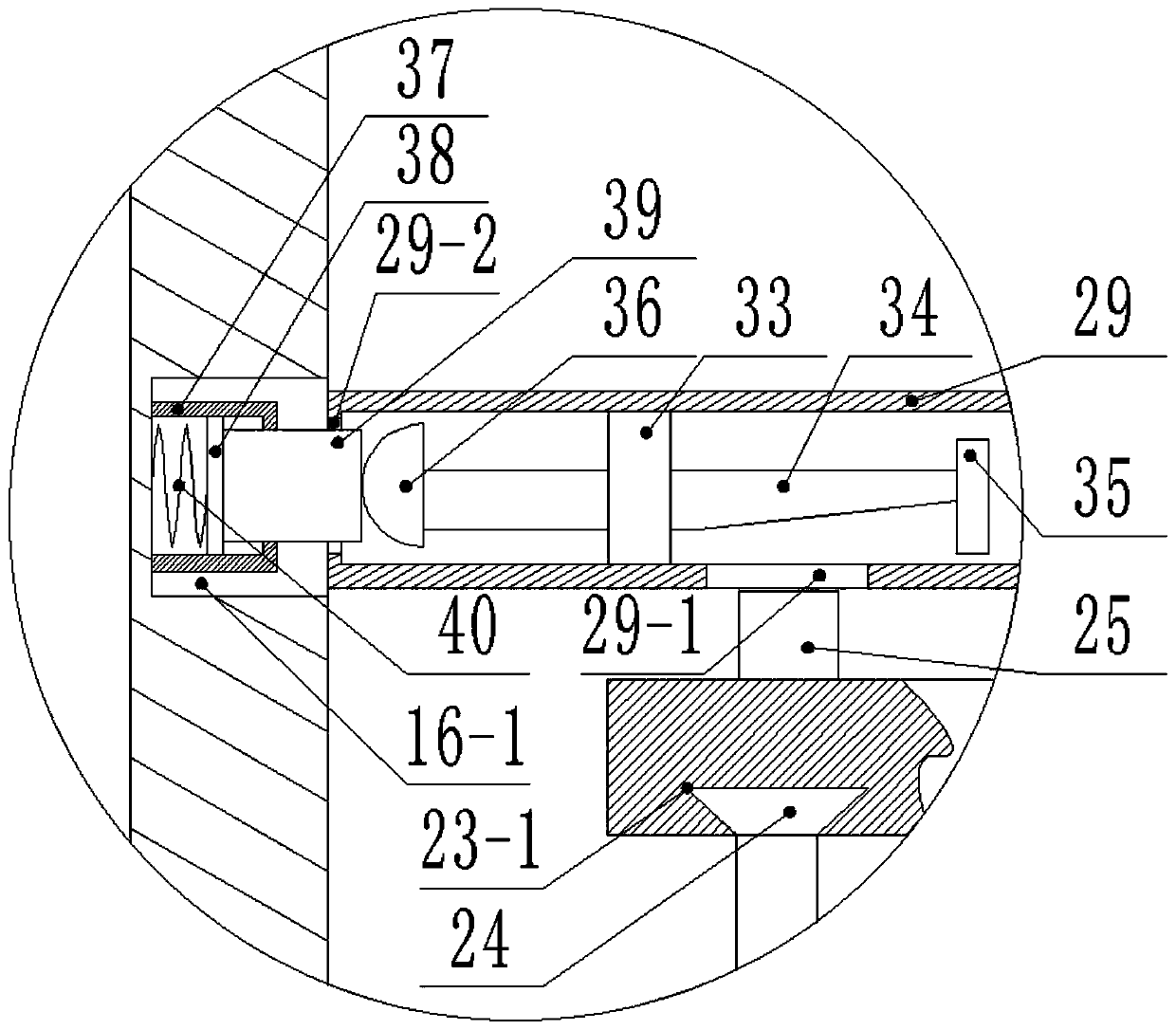

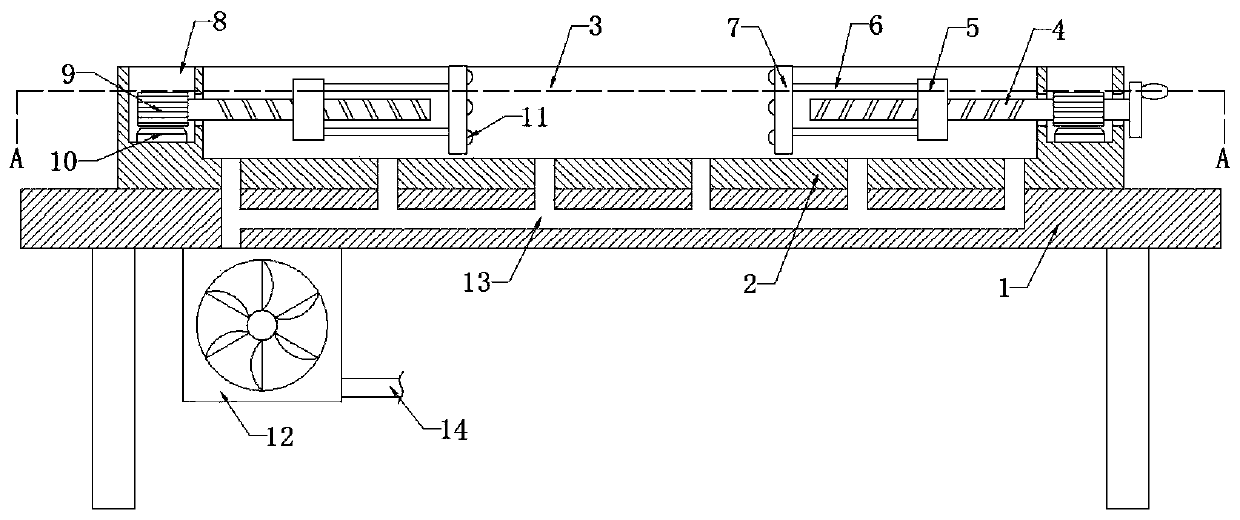

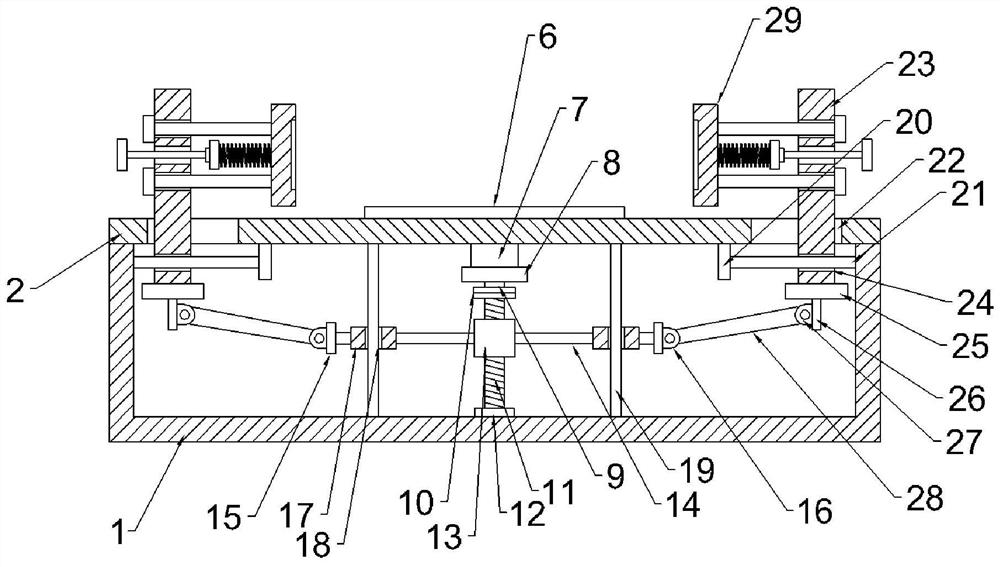

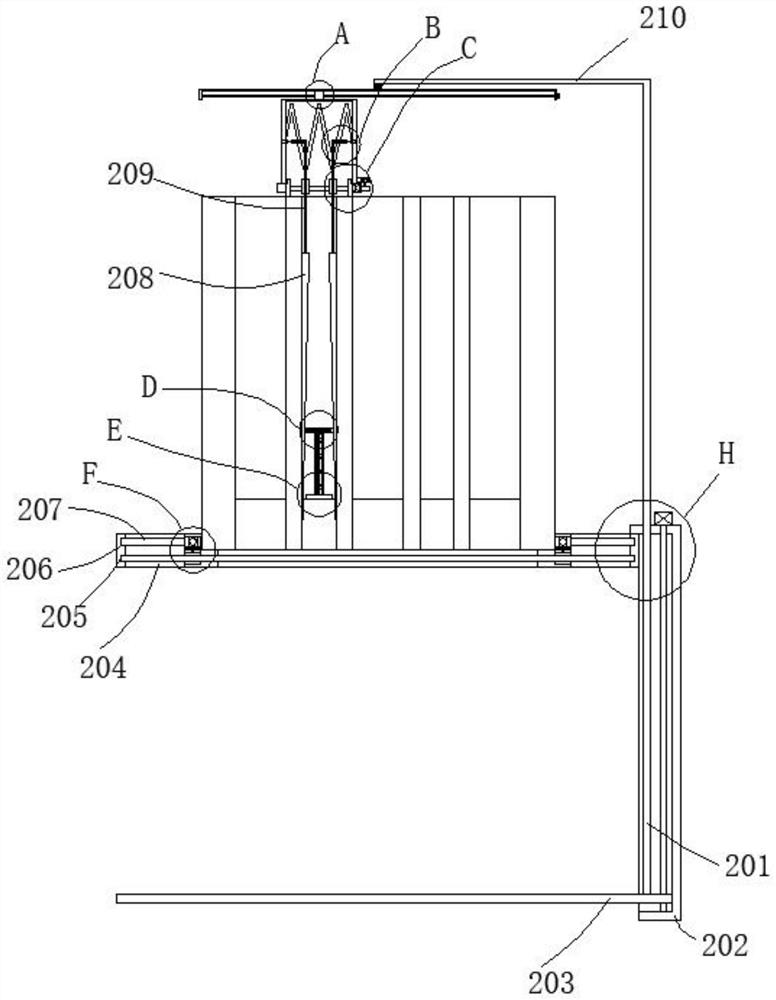

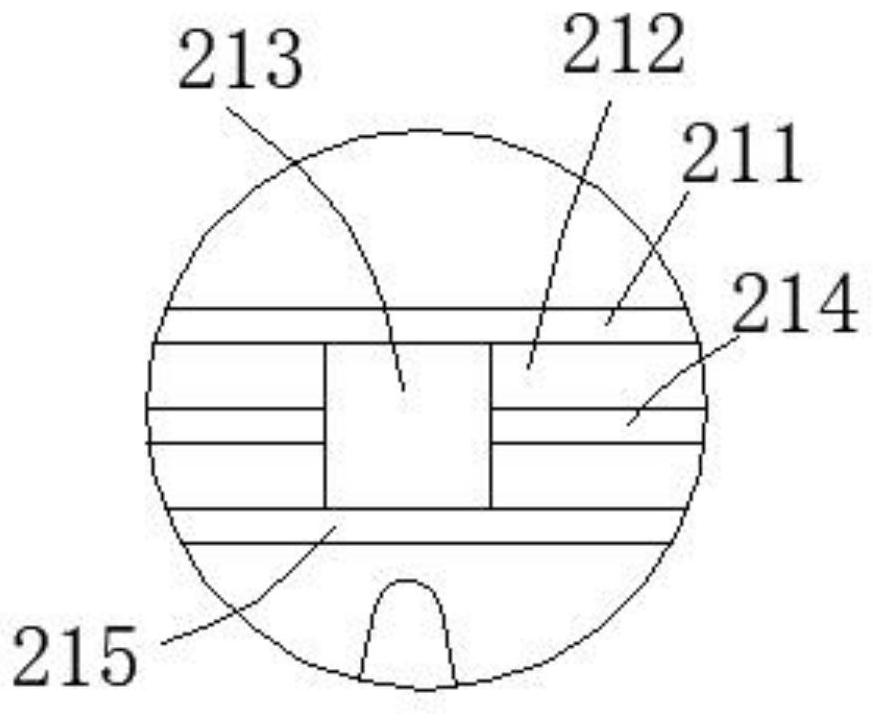

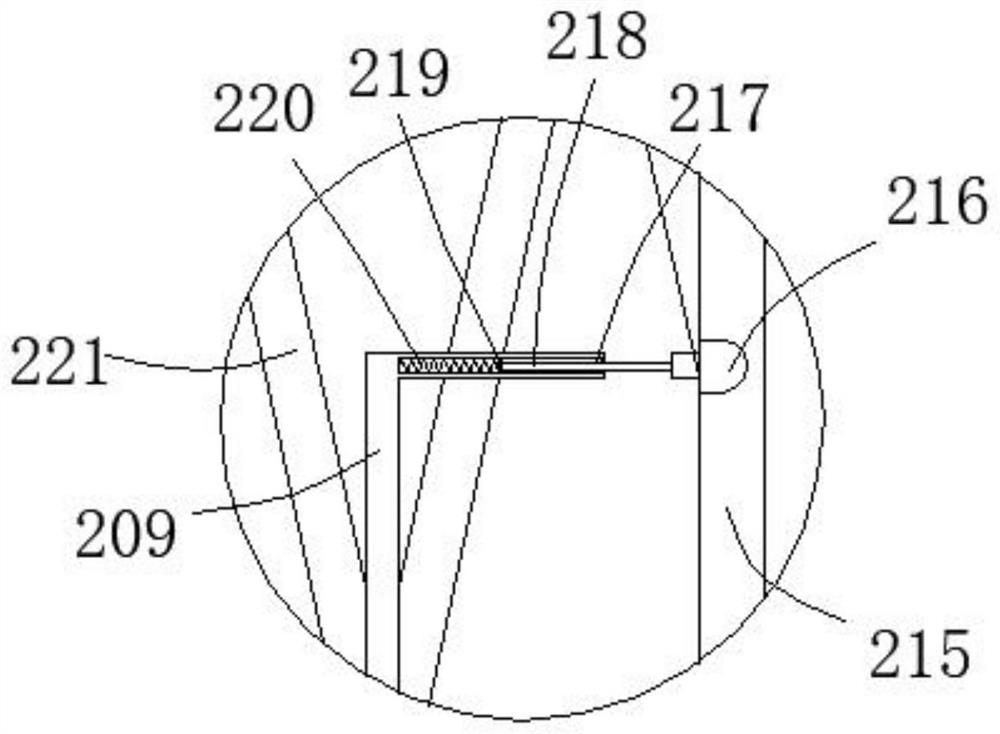

Workpiece clamping transfer device for machining

The invention discloses a workpiece clamping transfer device for machining. The device comprises a base, a working platform, a support column, a lifting plate, a movable plate, a lead screw, a connecting piece and mechanical clamping plates; a support top plate is erected on the right side wall of the top end of the support column; a support base plate is arranged on the right side wall of the middle part of the support column; the lead screw is rotationally erected between the middle part of the support top plate and the middle part of the support base plate; the middle part of the movable plate sleeves the lead screw through a threaded connecting mode; the lifting plate is fixedly welded and erected at the right end of the movable plate; a hinge base is fixedly mounted on the lower surface of the lifting plate; two first hinge rods are rotationally arranged at the two ends of the hinge base; the other ends of the two first hinge rods are rotationally connected with two second hinge rods; and the other ends of the second hinge rods are provided with the integrally molded mechanical clamping plates. The device is simple in structure, reasonable in design, flexible in use, excellentin workpiece clamping effect, convenient to transfer workpieces and high in practicability.

Owner:KUNMING UNIV OF SCI & TECH

Installation rack for installation of communication antenna

The present invention relates to the field of communication, especially to an installation rack for installation of a communication antenna. The rack comprises a pedestal, the top portion of the pedestal is provided with a fixed bottom barrel, triangular support plates are uniformly arranged at the side wall of the fixed bottom barrel, the triangular support plates are fixed at the top portion ofthe pedestal, the top portion of the fixed bottom barrel is provided with a connection barrel, the top portion of the connection barrel is provided with an opening, spacing blocks are symmetrically arranged at left and right sides of the inner wall of the opening, the connection barrel is internally provided with a fixed block, the fixed bottom barrel is internally provided with an internal threadrotating drum, the bottom portion of the internal thread rotating drum is rotationally connected with the pedestal, the upper end of the internal thread rotating drum penetrates the fixed block, theouter side of the internal thread rotating drum is provided with a driven bevel gear, and the right side of the driven bevel gear is engaged with a drive bevel gear. The installation rack for installation of the communication antenna is novel in design and convenient to use, can achieve high regulation of a communication antenna, can achieve convenient regulation of the angle of the communicationantenna, is high in applicability and is suitable for promotion and application.

Owner:合肥鸿坤通信工程有限公司

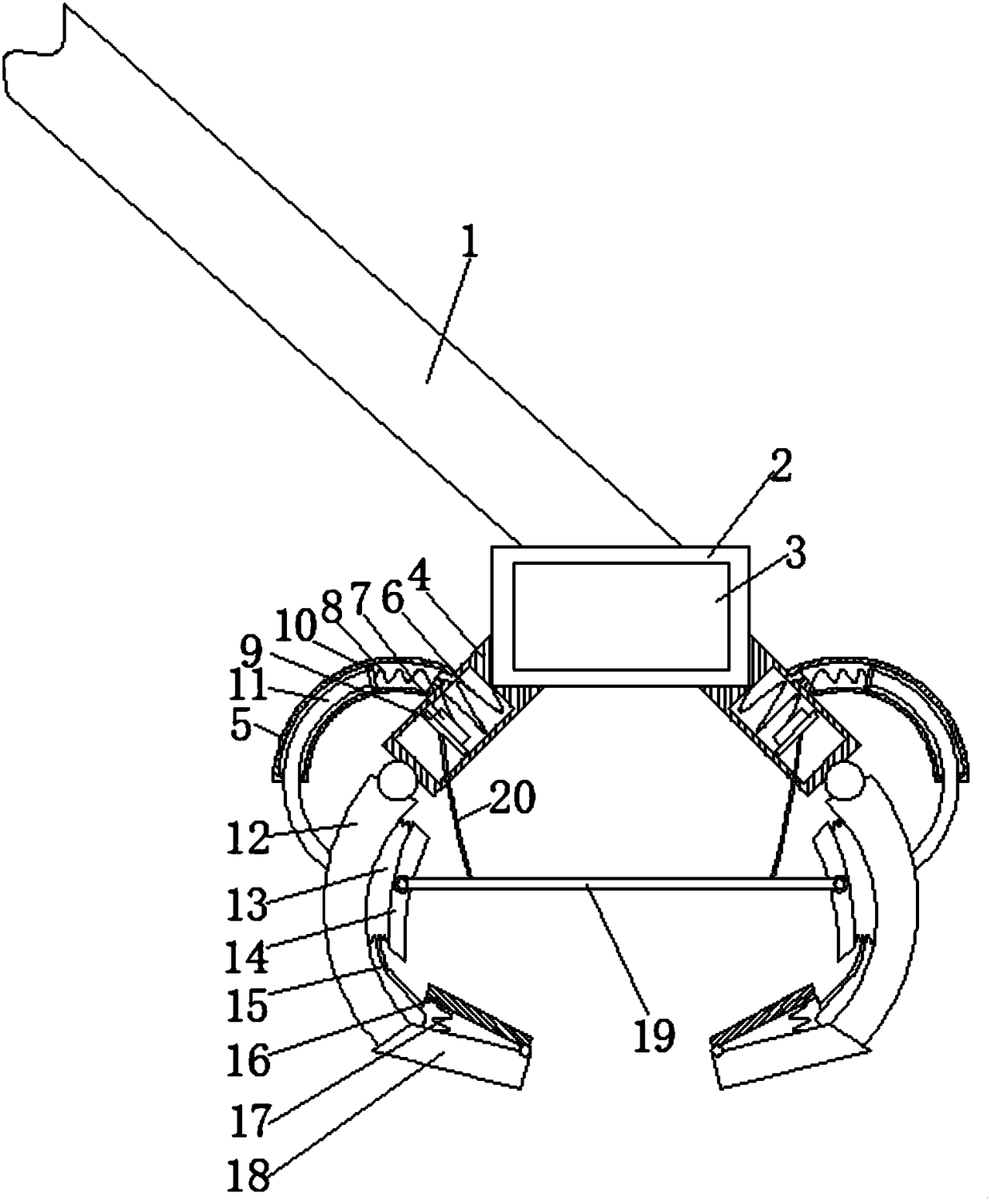

Stable grasping device for crane

InactiveCN108313866ASimple device structurePrevent objects from fallingLoad-engaging elementsPistonEngineering

The invention discloses a stable grasping device for a crane. The stable grasping device comprises a suspension arm, wherein a mounting box is fixedly mounted at the lower end of the suspension arm; afirst electromagnet is mounted in the mounting box; the stable grasping device for the crane is simple in structure; an external power supply is switched on and the first electromagnet is electrifiedto generate a great suction force; after an object to be hoisted is adsorbed among a plurality of rotary plates, the object falls onto the upper sides of a plurality of second supporting plates; a third spring is compressed by the self weight of the object; a first airbag is expanded through the effect of a pipeline and a plurality of rubber plates are close to each other to clamp the object, andfurthermore, the grasping is firm; on the other hand, a second steel rope is pulled along upward movement of a first piston, so that a first steel rope is pulled upward, and furthermore, the rubber plates are dragged and the object is sufficiently clamped; the object is prevented from falling off and the industrial production efficiency is ensured.

Owner:浙江环艺电子科技有限公司

Multifunctional mechanical gripper

The invention provides a multifunctional mechanical gripper. The multifunctional mechanical gripper comprises a clamping component and a driving component. The clamping component comprises first inclined rods, clamping jaws, a first box, a first barrel and a second barrel. At least two first inclined rods are symmetrically hinged to the first box. The top end of each first inclined rod is fixedlyconnected with one clamping jaw. A first sliding block is slidably connected to each first inclined rod. The top surface of the first box is fixedly connected with the first barrel. A second bearing is mounted on the inner top surface of the first barrel. The second bearing is used for supporting one end of a rotary shaft. A second threaded sleeve is connected to the rotary shaft through a screw thread pair. The rotary shaft rotates to drive the second threaded sleeve to do linear motion. The first sliding blocks are hinged to the second threaded sleeve through second inclined rods. The bottomsurface of the first box is fixedly connected with the second barrel. The driving component is fixed to the bottom of the second barrel. The other end of the rotary shaft penetrates through the firstbarrel and the second barrel to be connected with the driving component. The multifunctional mechanical gripper is simple in structure, diversified in function and high in practicality.

Owner:JIANGSU UNIV

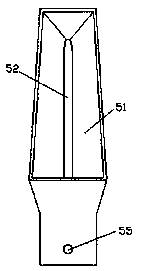

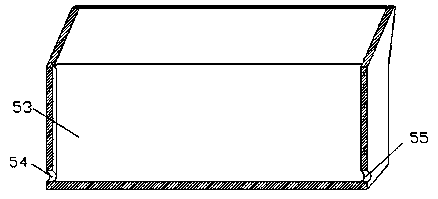

Die for molding fiber coupling connector

ActiveCN102248637AAvoid Collimation EffectsFully clampedOptical articlesMaterials scienceFiber coupling

The invention relates to a die for molding a fiber coupling connector. The die comprises a mold insert which comprises a tail part and a blind hole molding part; a male mold for accepting and fixing the tail part of the mold insert; and a female mold which comprises a molding chamber possessing a lens molding part and a positioning block which is arranged in the lens molding chamber, corresponds to the lens molding part and is used for clamping and positioning the blind hole molding part to aim the blind hole molding part at the center of the lens molding part. Compared with the prior art, the die allows the mold insert to be clamped and positioned through the positioning block, so the collimation of the blind hole is substantially increased.

Owner:JIANGSU STERLITE TONGGUANG FIBER

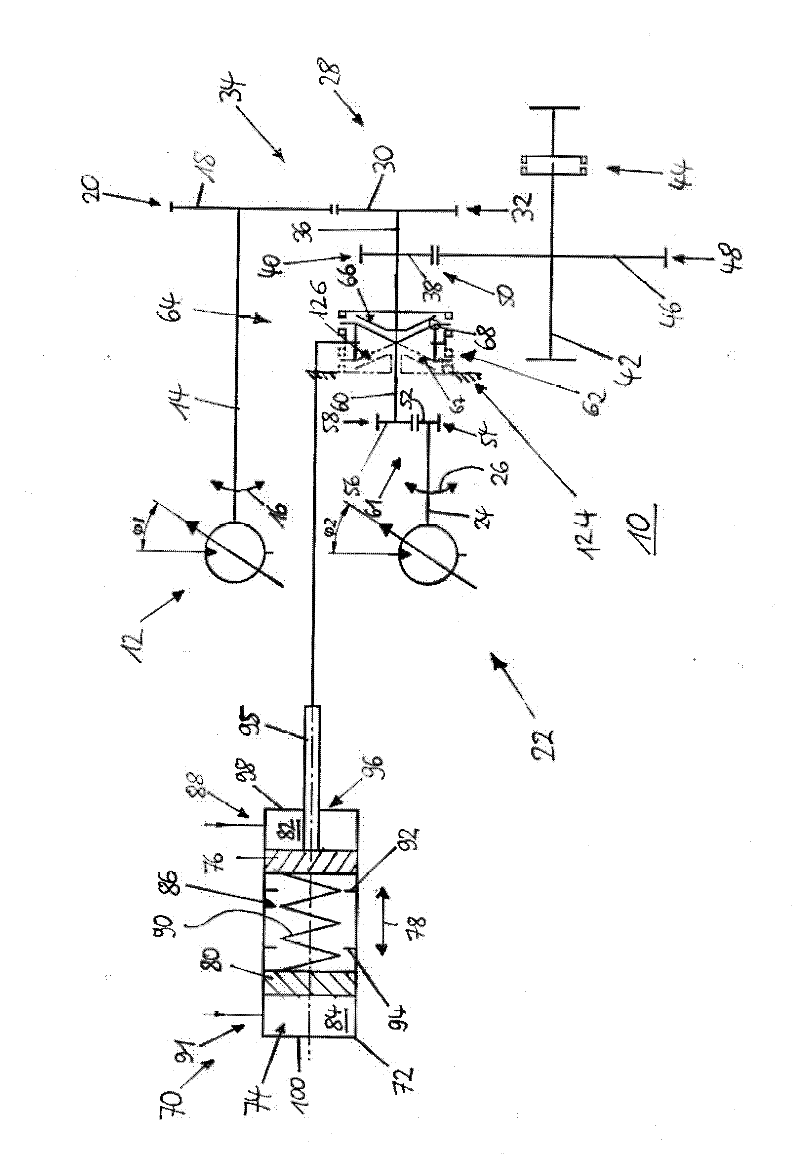

Shift cylinder, drive device, work machine as well as method for operating a work machine

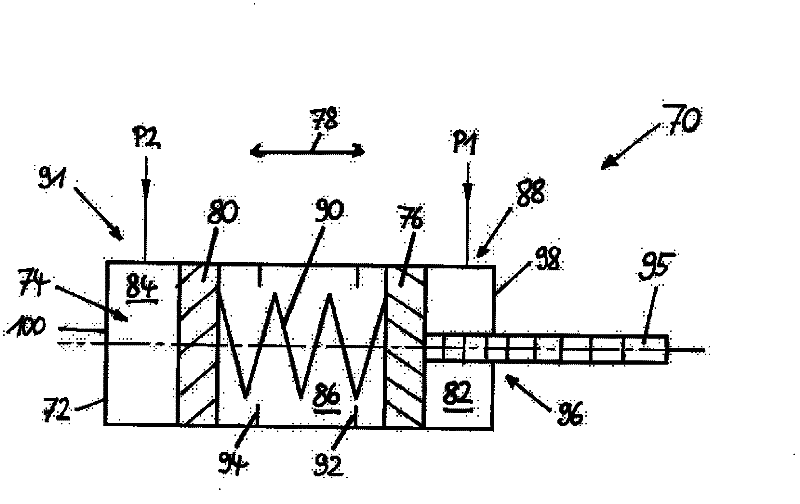

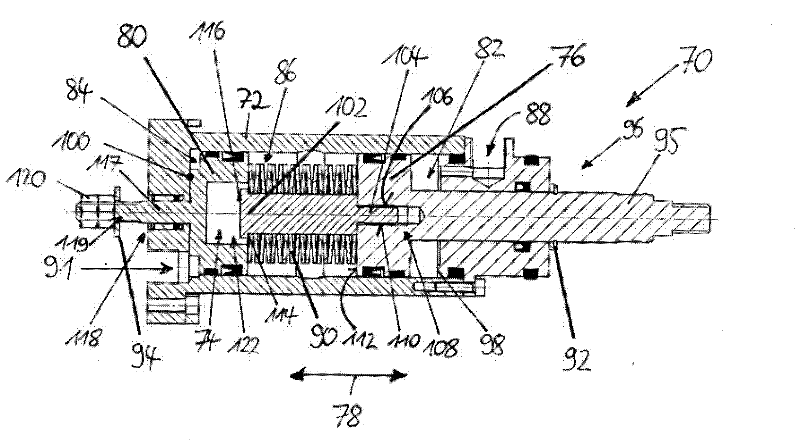

ActiveCN102691690AAvoid undesired conversionsGear effectFluid actuated clutchesGearing controlEngineeringPiston

The invention relates to a shift cylinder (70) including a cylinder element (72) having a working space (74), a first and a second piston (76, 80) received in the working space (74) displaceably relatively to it, by which the working space (74) is divided in a first working chamber (82) capable of being charged with a working medium through a first port (88) of the shift cylinder (70), a second working chamber (84) capable of being charged with a working medium through a second port (91) of the shift cylinder (70) and a third working chamber (86) disposed between the first and the second working chamber (82, 84), including at least one spring member (90) capable of being supported on the first piston (76) on the one hand and on the second piston (80) on the other hand, by means of which a force can be bilaterally applied to the pistons (76, 80), wherein a first stop (92); of the shift cylinder (70) is associated with the first piston (76), by means of which a movement of the first piston (76) towards the second piston (80) is confined, and wherein a second stop (94) of the shift cylinder (70) is associated with the second piston (80), by means of which a movement of the second piston (80) towards the first piston (76) is confined.

Owner:NAF NEUNKIRCHENER ACHSENFABRIK

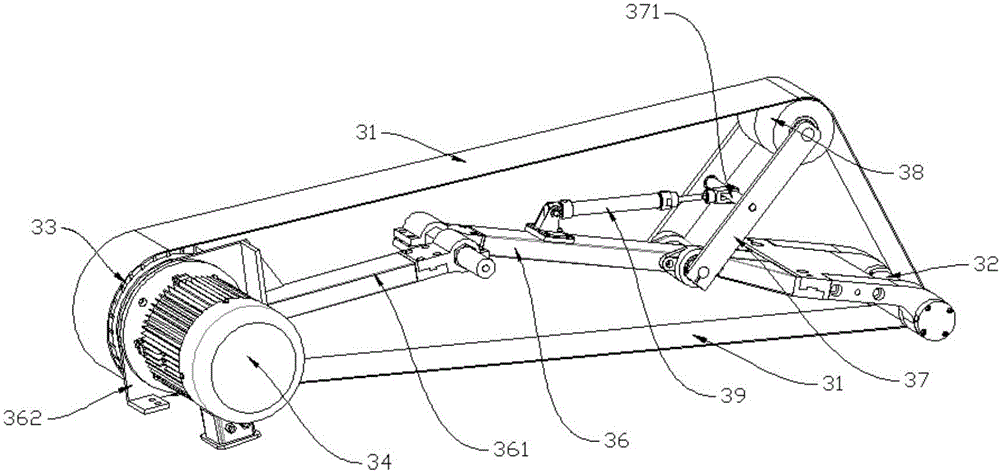

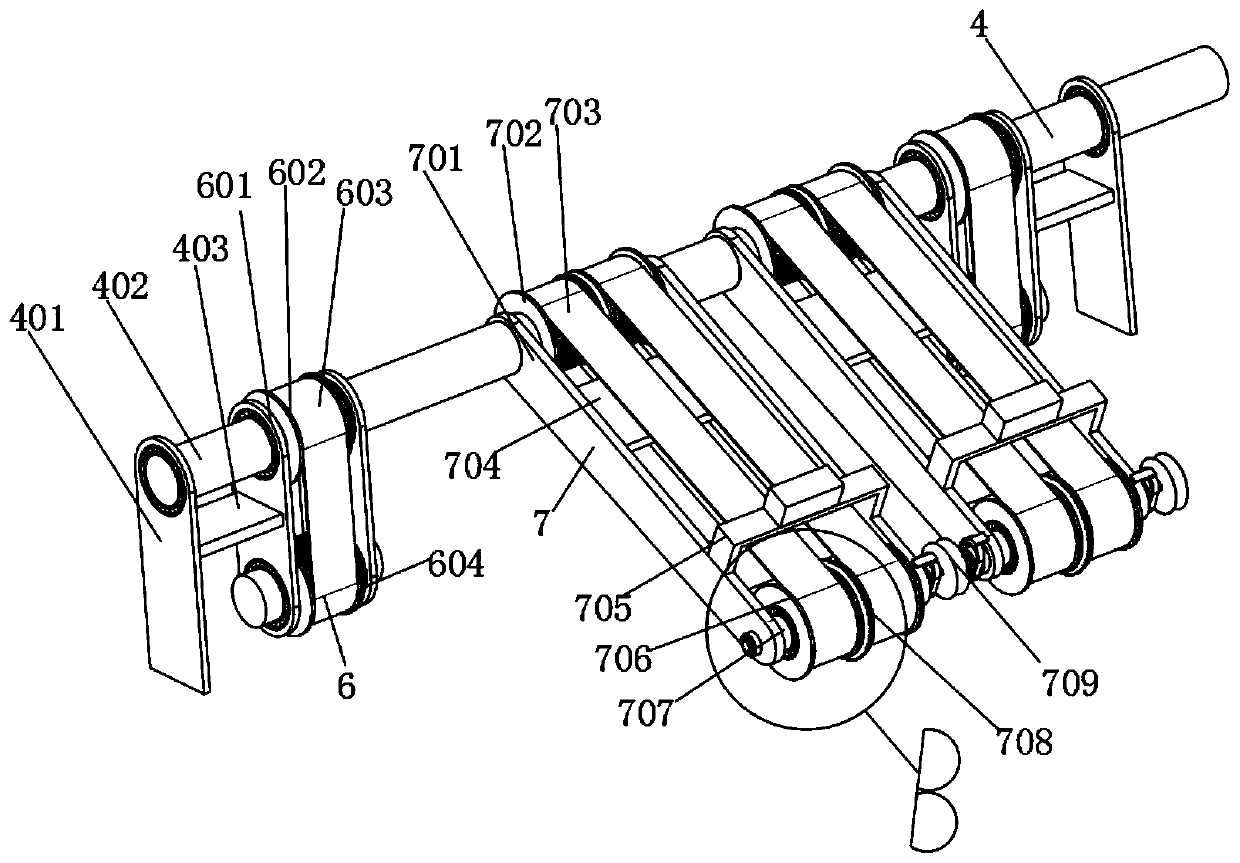

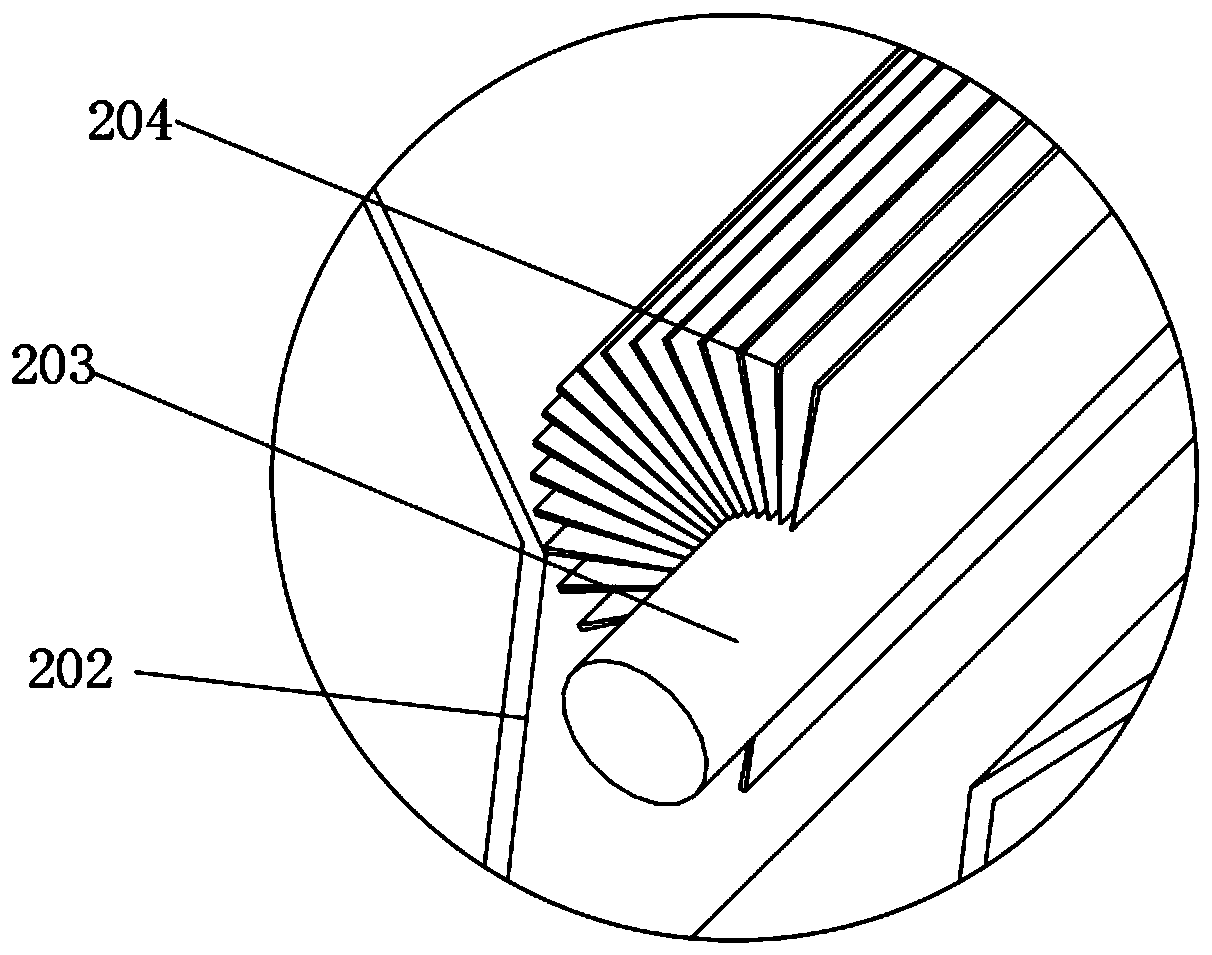

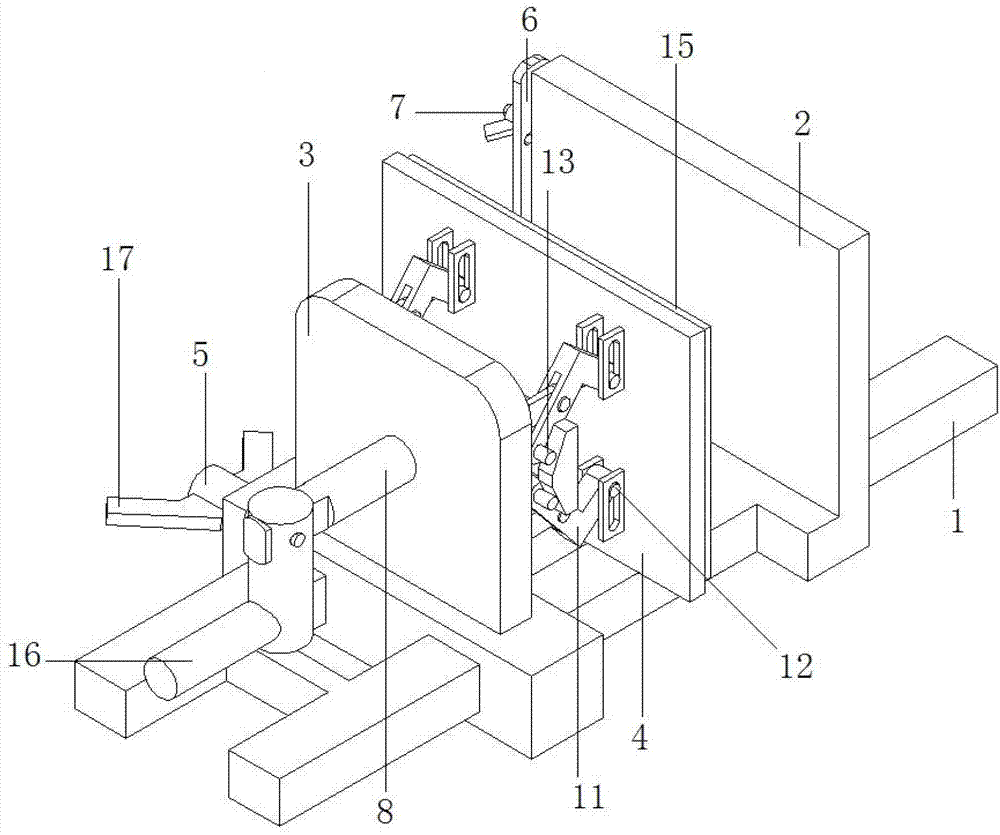

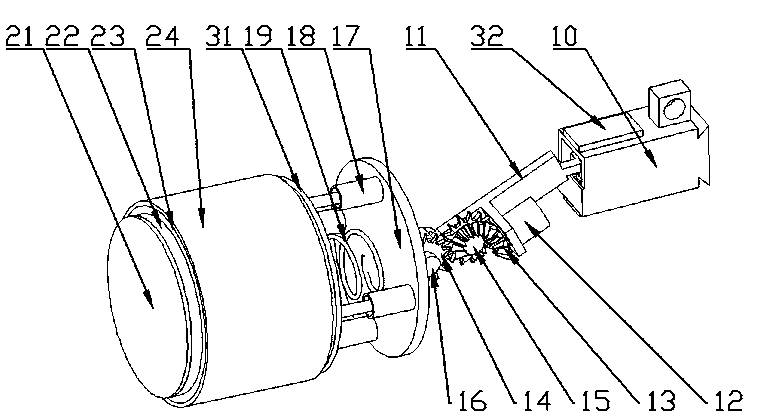

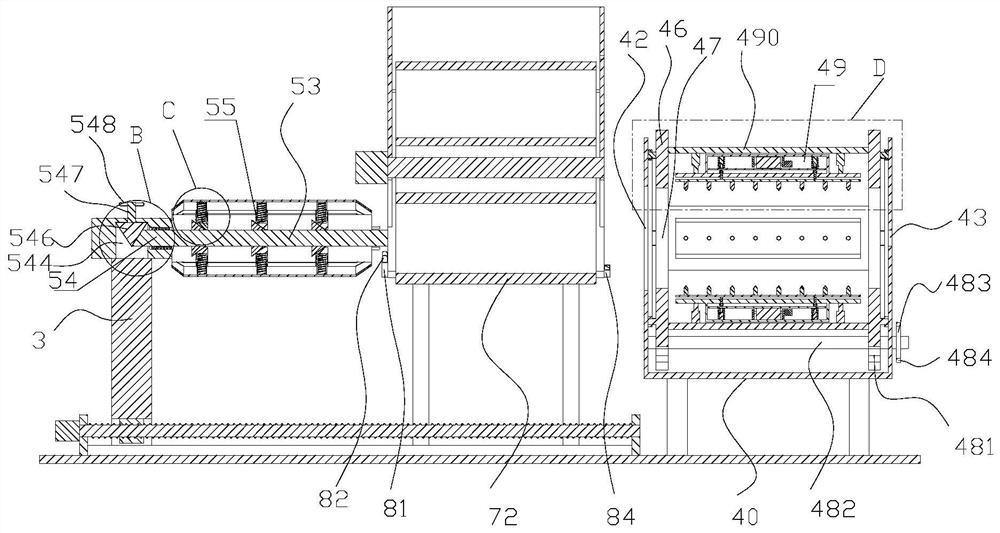

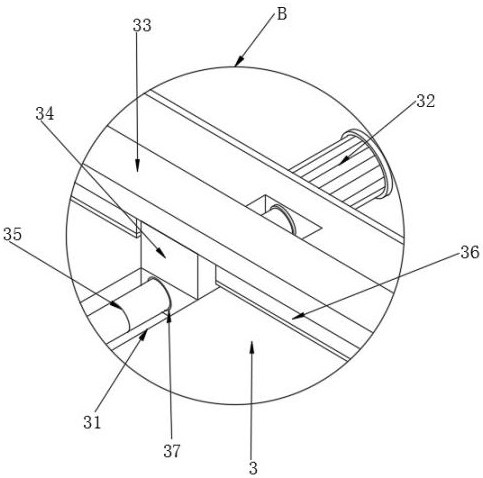

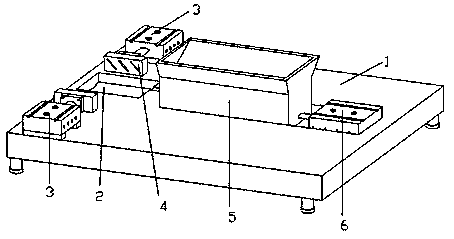

T-shaped ring edge belt sander

ActiveCN106514465AGuaranteed grinding forceFully clampedBelt grinding machinesGrinding work supportsSanderDrive wheel

The invention provides a T-shaped ring edge belt sander and belongs to the field of tableware processing equipment. The T-shaped ring edge belt sander comprises a sanding belt, a shell, a grinding wheel, a driving wheel and a driving motor, wherein the grinding wheel, the driving wheel and the driving motor are fixed to the shell. The sanding belt sequentially winds around the outer ring of the grinding wheel and the outer ring of the driving wheel, the driving motor drives the driving wheel to rotate, and the shell can move forwards and backwards in the transmission direction of the sanding belt. The grinding wheel is fixed to the shell through a grinding arm, the grinding arm is arranged on the inner ring of the sanding belt, locking arms are hinged to the two sides of the grinding arm, the ends, away from the grinding arm, of the locking arms are rotationally connected with an adjusting wheel, the adjusting wheel is tangent to the sanding belt, a connection rod is arranged in the middles of the locking arms located on the two sides of the grinding arm, the end, away from the sanding belt, of the grinding arm is provided with an adjusting air cylinder, and a force output shaft of the adjusting air cylinder is fixedly connected with the middle of the connection rod. The T-shaped ring edge belt sander is simple in structure, convenient to adjust and debug, automatic in production and high in efficiency.

Owner:TIANJIN TTX GROUP

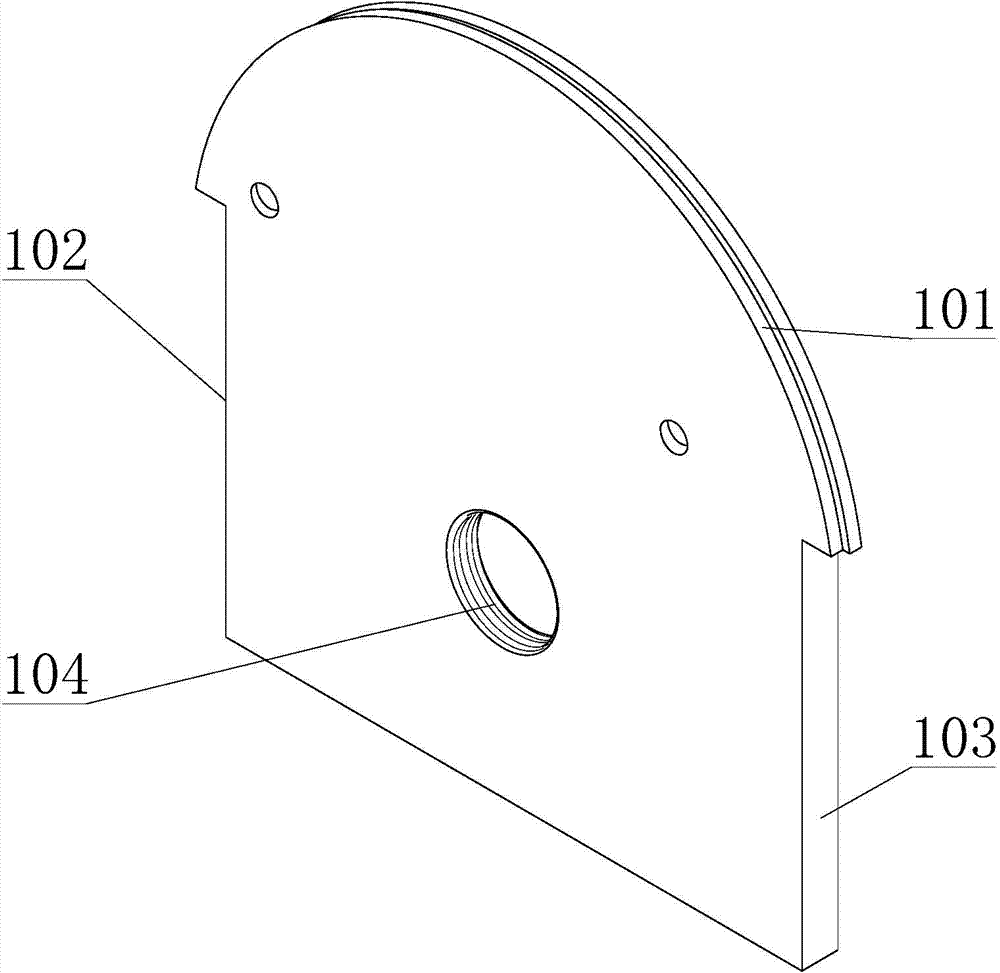

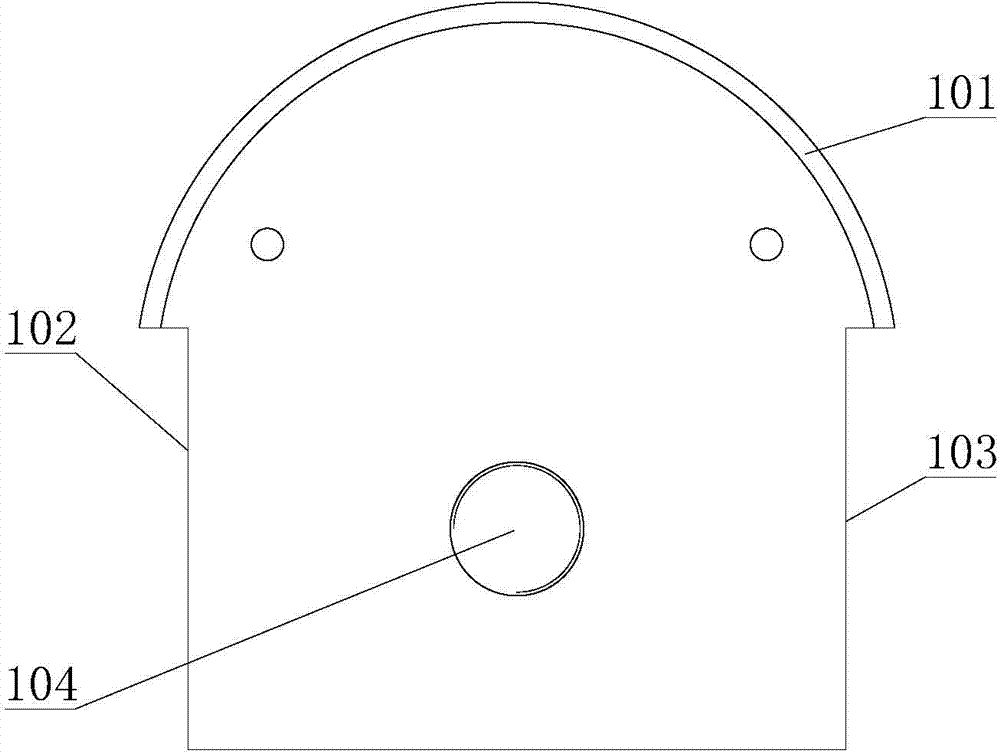

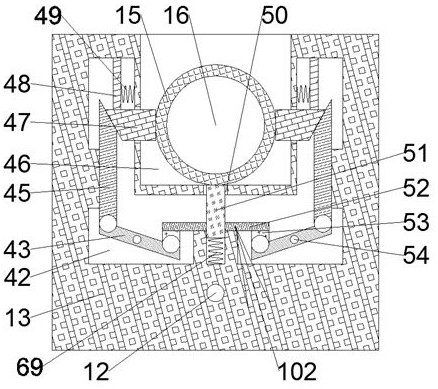

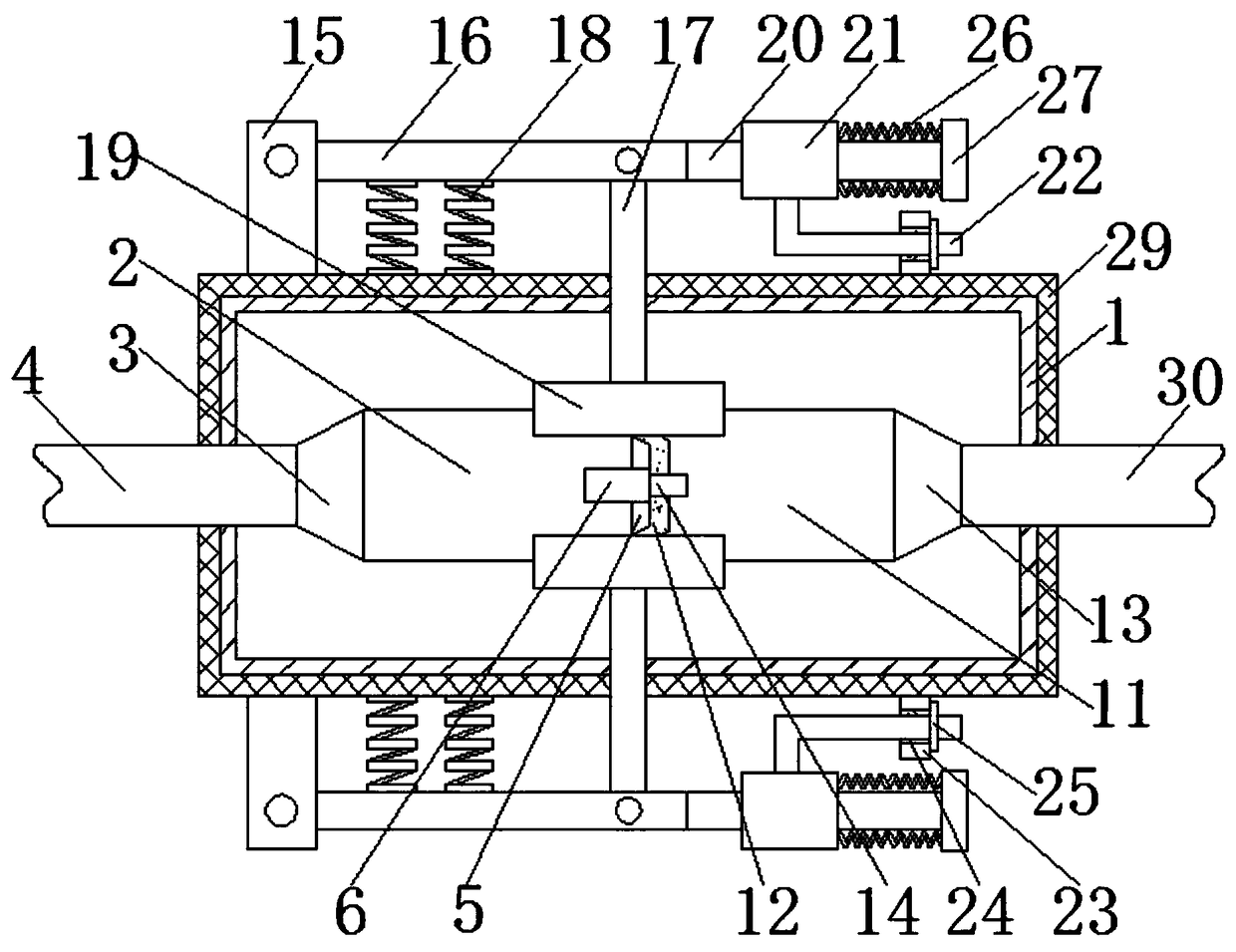

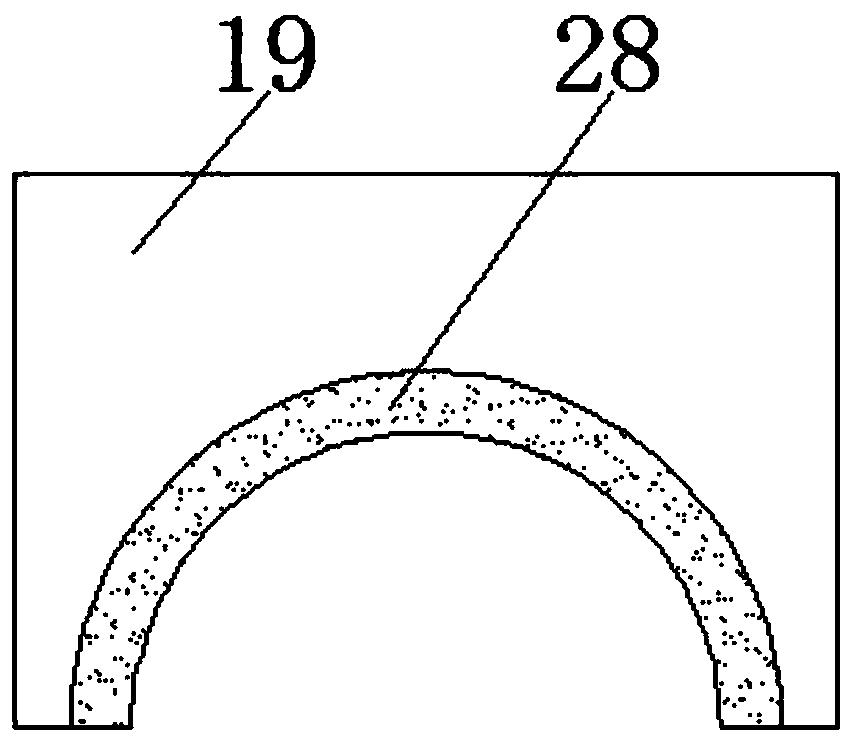

Clamp device for friction experiment of drum type friction plate

InactiveCN103940732AFully clampedRealize multi-purpose with one clipUsing mechanical meansStrength propertiesVertical edgeEngineering

The invention discloses a clamp device for a friction experiment of a drum type friction plate. A transversely arranged vertical clamp plate is an irregular flat plate; a section of arc-shaped stair surface which protrudes upwards is arranged on the upper edge of each vertical clamp plate; the left and right end parts of each upper edge are connected with two left and right vertical edges of the corresponding clamp plate; each two vertical edges are positioned on the inner sides of the two end parts of the corresponding upper edge; the stair surfaces of the upper edges of the two clamp plates are kept opposite and parallel to each other; the two clamp plates are integrally locked; the two upper edges define an arc-shaped clamping groove; two left and right opening ends of the clamping grooves are exposed out of the outer sides of two side edges, respectively; a vertical clamp strip is configured close to each of the two side edges below two ends of the clamp groove; positioning grooves are formed in two upper end parts of the two clamp strips towards two ends of the clamp groove; each positioning groove is internally provided with an elastic propping element which stretches out to the opening of the groove. The clamp device can sufficiently clamp the drum type friction plate according to experiment requirements, and is applicable to friction plates with different thicknesses, so that multiple purposes of one clamp are achieved; the device is good in connection with a universal friction experiment machine and convenient to assemble and disassemble, and the experiment can be accomplished by the device and the universal experiment machine.

Owner:SHANGHAI UNIV OF ENG SCI

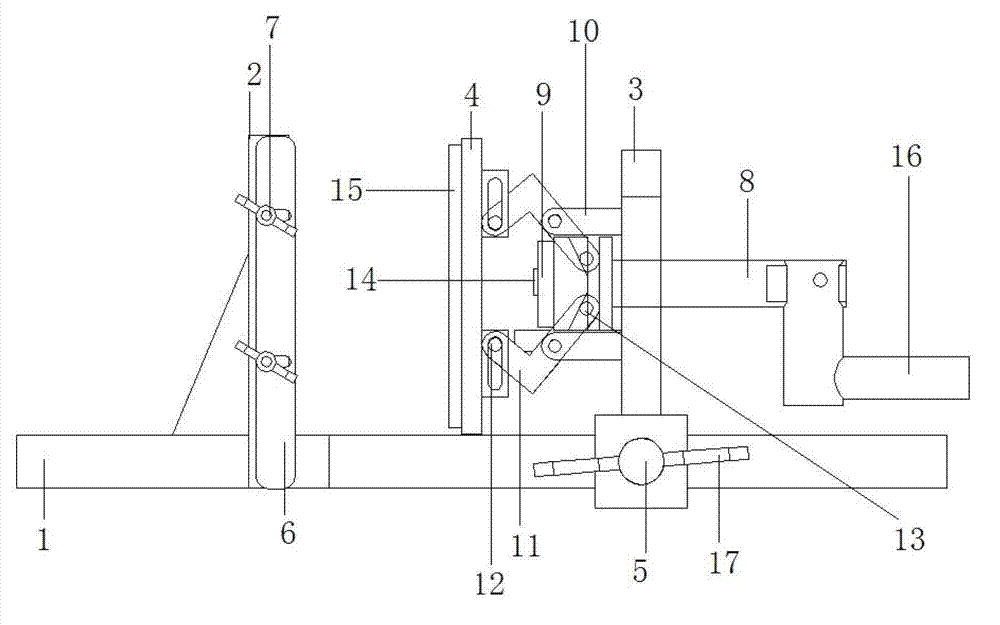

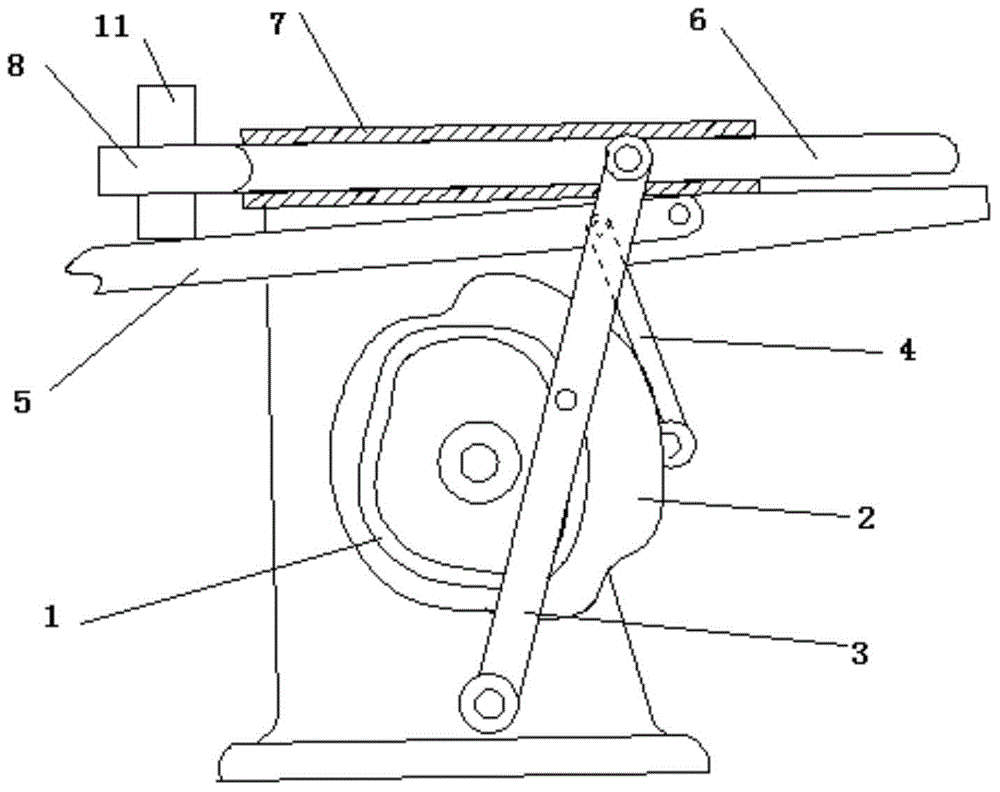

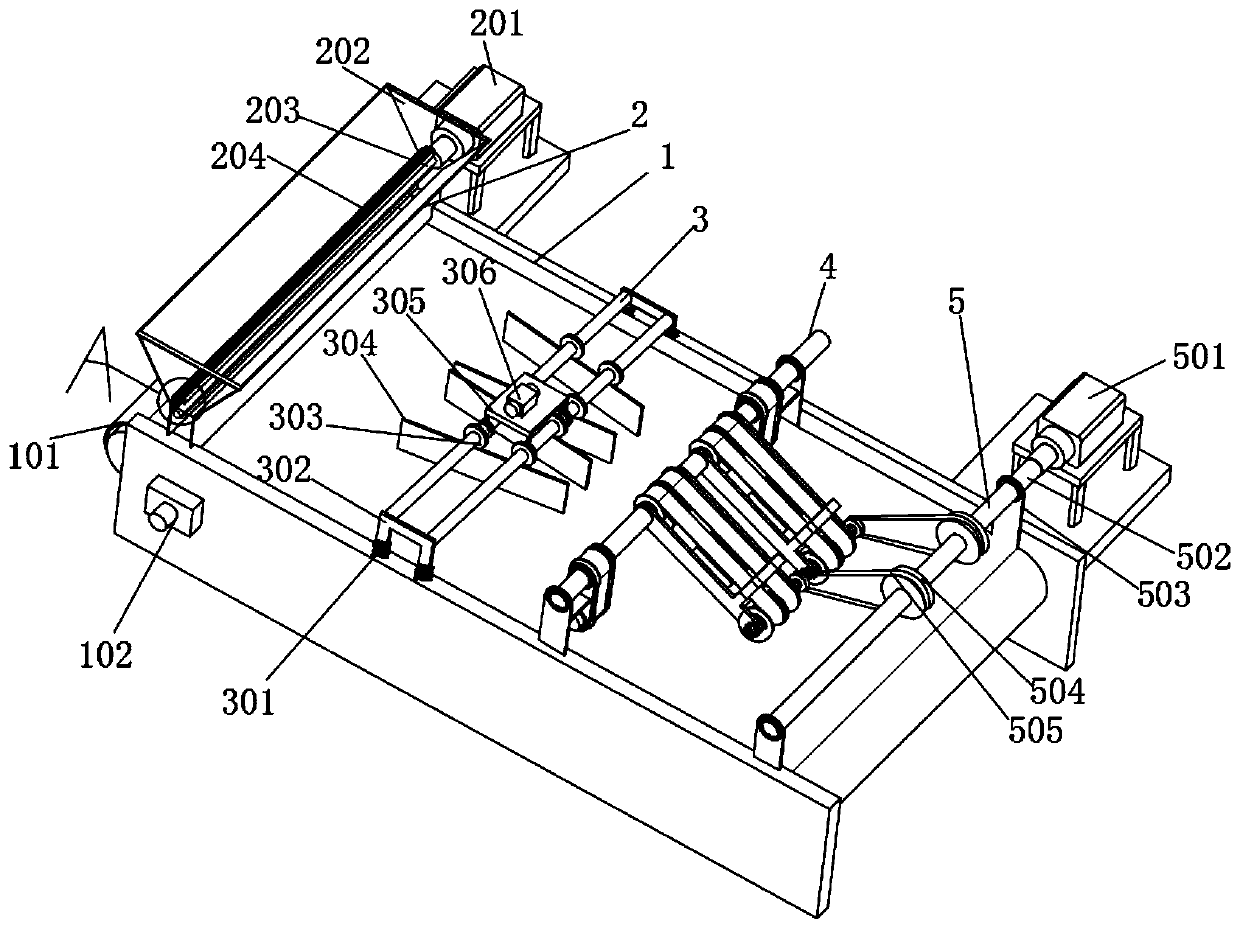

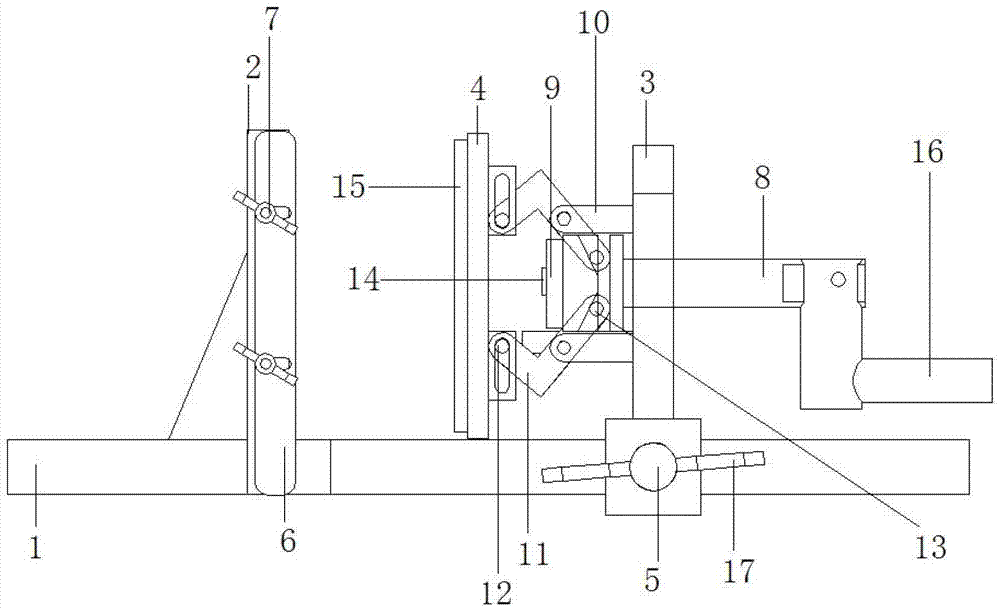

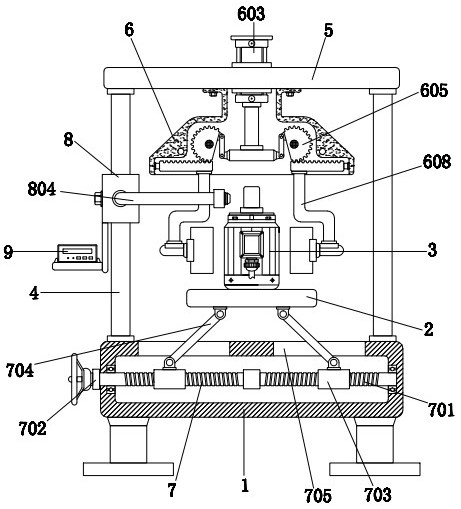

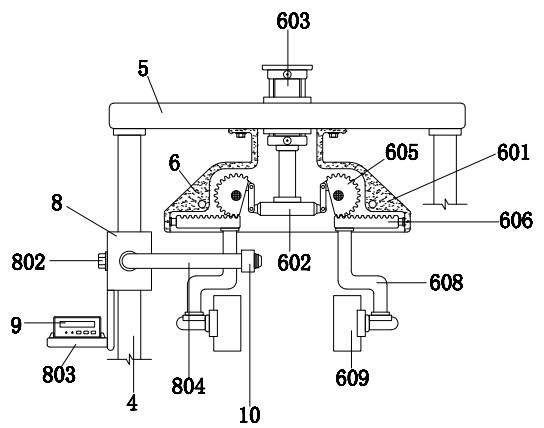

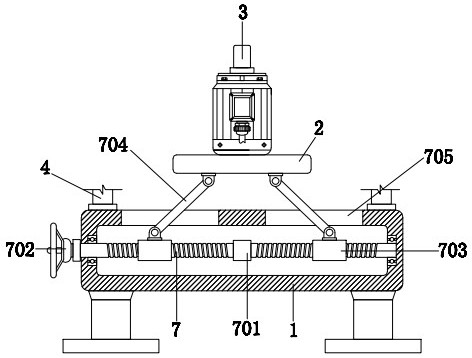

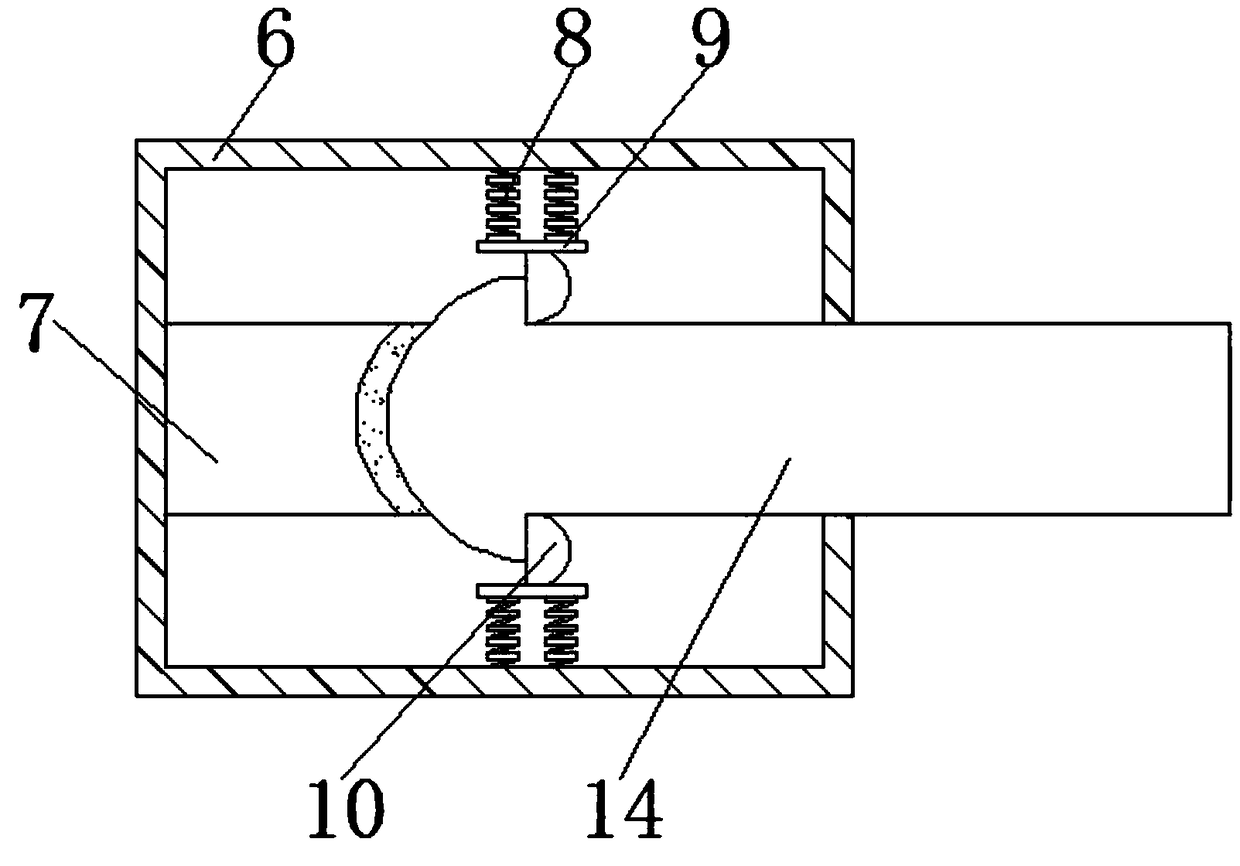

Machining device for workpiece clamping

InactiveCN104607991AGuaranteed stabilityAvoid wear and tearMetal working apparatusPush pullControl rod

The invention relates to a machining device for workpiece clamping. The machining device comprises a machine frame, a conveying device and a control device. The conveying device comprises two cam mechanisms, a rotating swinging rod, a pushing-pulling control rod, a supporting plate and a sliding clamping device. A guiding rod is horizontally arranged on the machine frame. A sliding clamping body is connected into the guiding rod in a sliding mode. One end of the sliding clamping body is provided with a left clamping body and a right clamping body which are hinged and are connected through a compressed spring. The middle portion of the rotating swinging rod is connected with a first cam. The two ends of the rotating swinging rod are hinged to the machine frame and the sliding clamping device. A supporting plate is placed below the sliding clamping device. The right end of the supporting plate is hinged to the machine frame. The middle portion of the supporting plate is hinged to the pushing-pulling control rod. The middle portion of the pushing-pulling control rod is hinged to the machine frame. The lower end of the pulling-pushing control rod is connected to a second cam mechanism. The problem that during an existing workpiece clamping conveying process, conveying is not stable, or equipment cost is high is solved.

Owner:CHONGQING CHAOLIAN IND

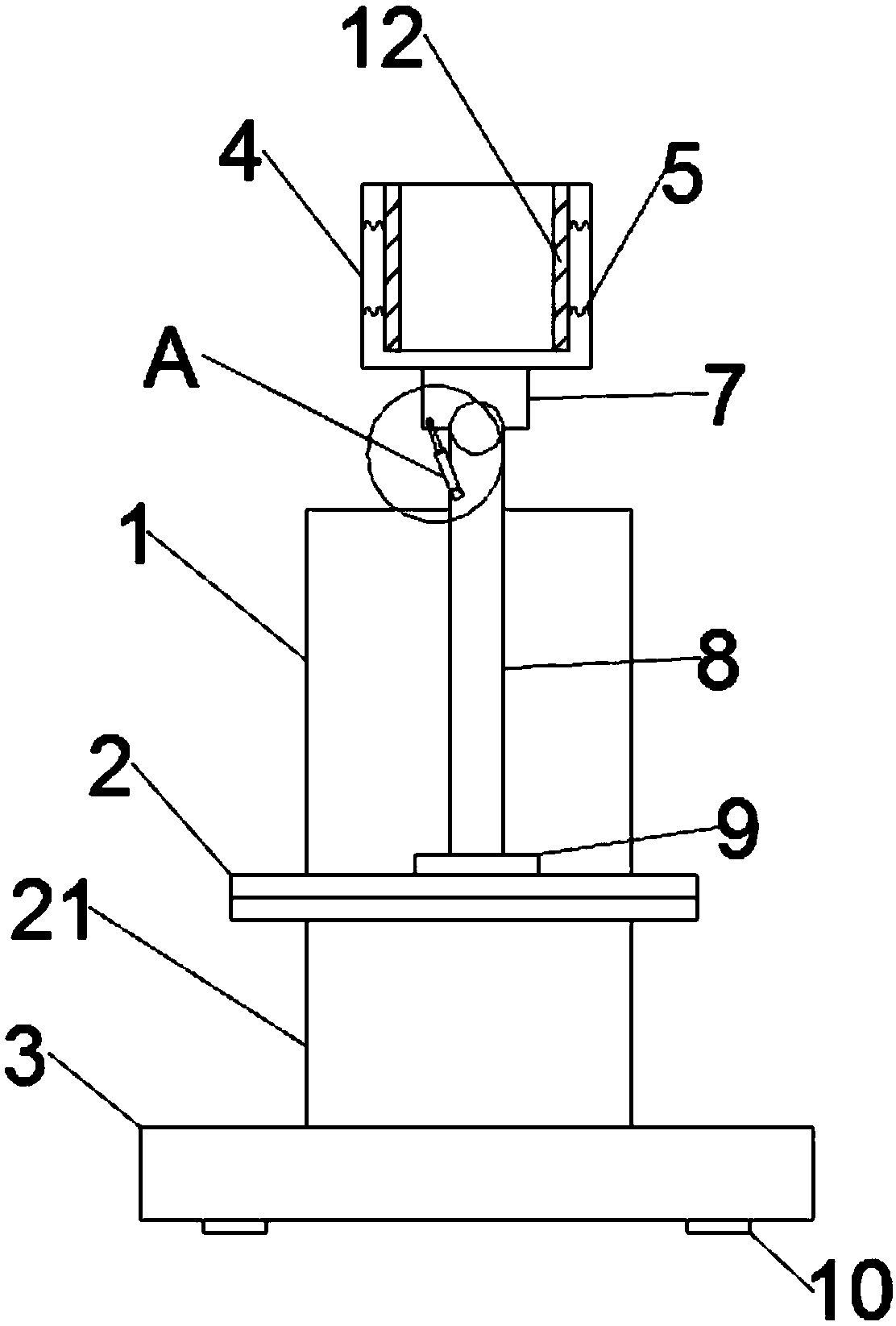

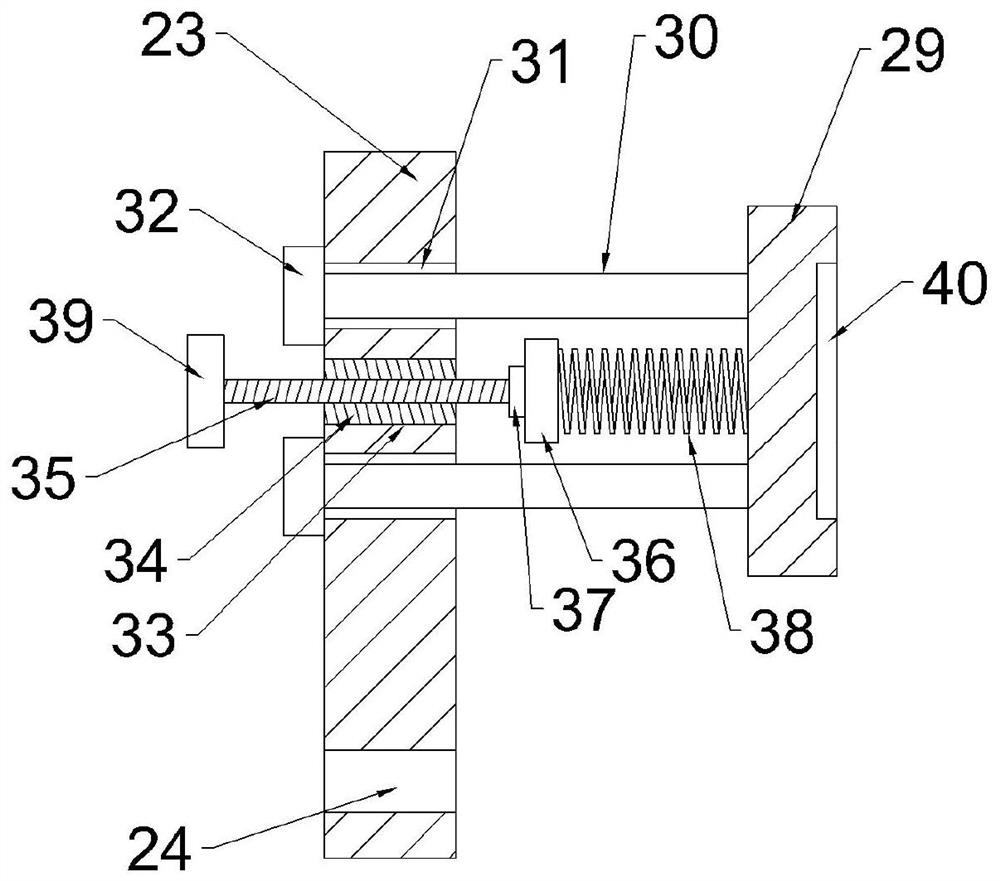

Rotatable mobile phone holder capable of raising adjustment angle

ActiveCN108769337ALarge adjustment rangeFully clampedTelephone set constructionsEngineeringMobile phone

The invention discloses a rotatable mobile phone holder capable of raising adjustment angle. The mobile phone holder comprises an upper support pillar body, a base, a locking plate and a lower supportpillar body; suckers are arranged at the bottom of the base; a connection rod is arranged in the upper support pillar body; the upper end of the connection rod is hinged with the middle of the bottomsupported by the locking plate; the side of the upper end of the connection rod, under which the locking plate supports, is hinged with one end of a telescopic rod; the other end of the telescopic rod is hinged with the outer surface of the bottom supported by the locking plate; the top supported by the locking plate is fixedly connected with the bottom of the locking plate; the locking plate consists of a spring, a first support rod and a clamp plate; the first support rod is fixedly connected at the bottom of the front side of the locking plate; and, the clamp plate is symmetrically arranged on the opposite sides of the left and right walls of the locking plate. The mobile phone holder provided by the invention is simple in structure, is capable of adjusting the height manually, can beadjusted manually so that the locking plate can rotate on the horizontal direction and the vertical direction, and has wide adjustable range; and, the base is provided with the four suckers, so that the device is fixed sufficiently.

Owner:滁州宇美塑业有限公司

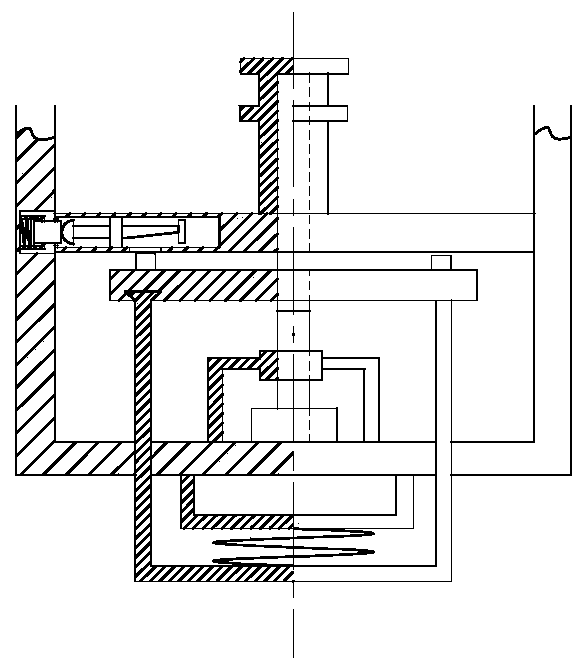

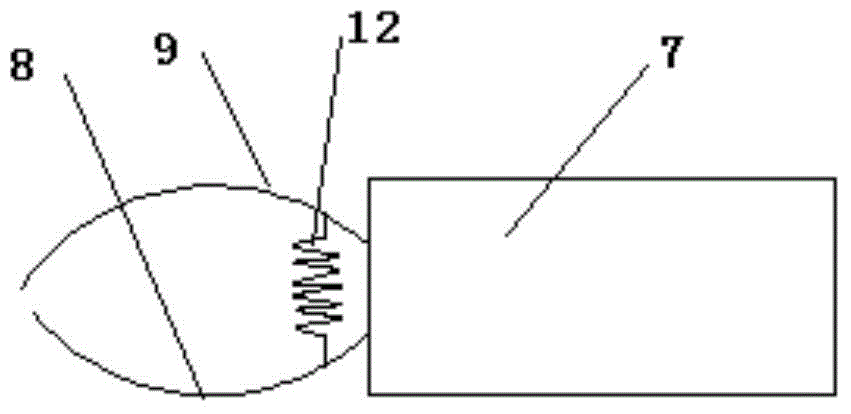

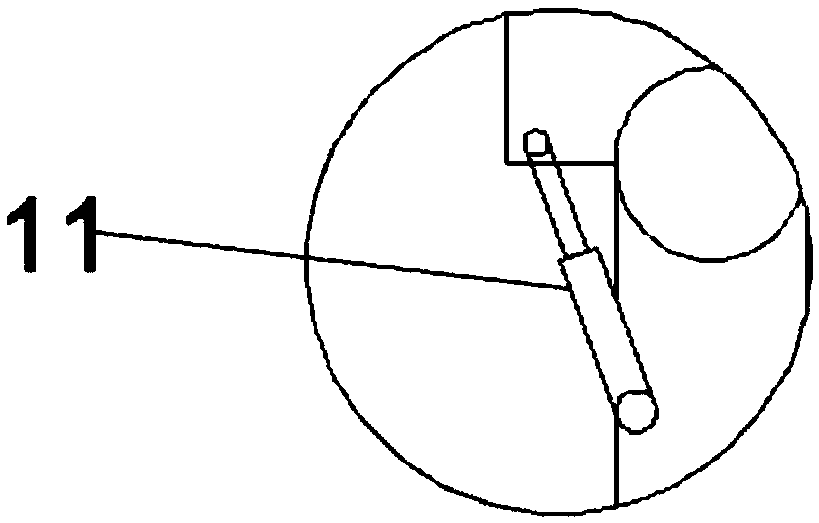

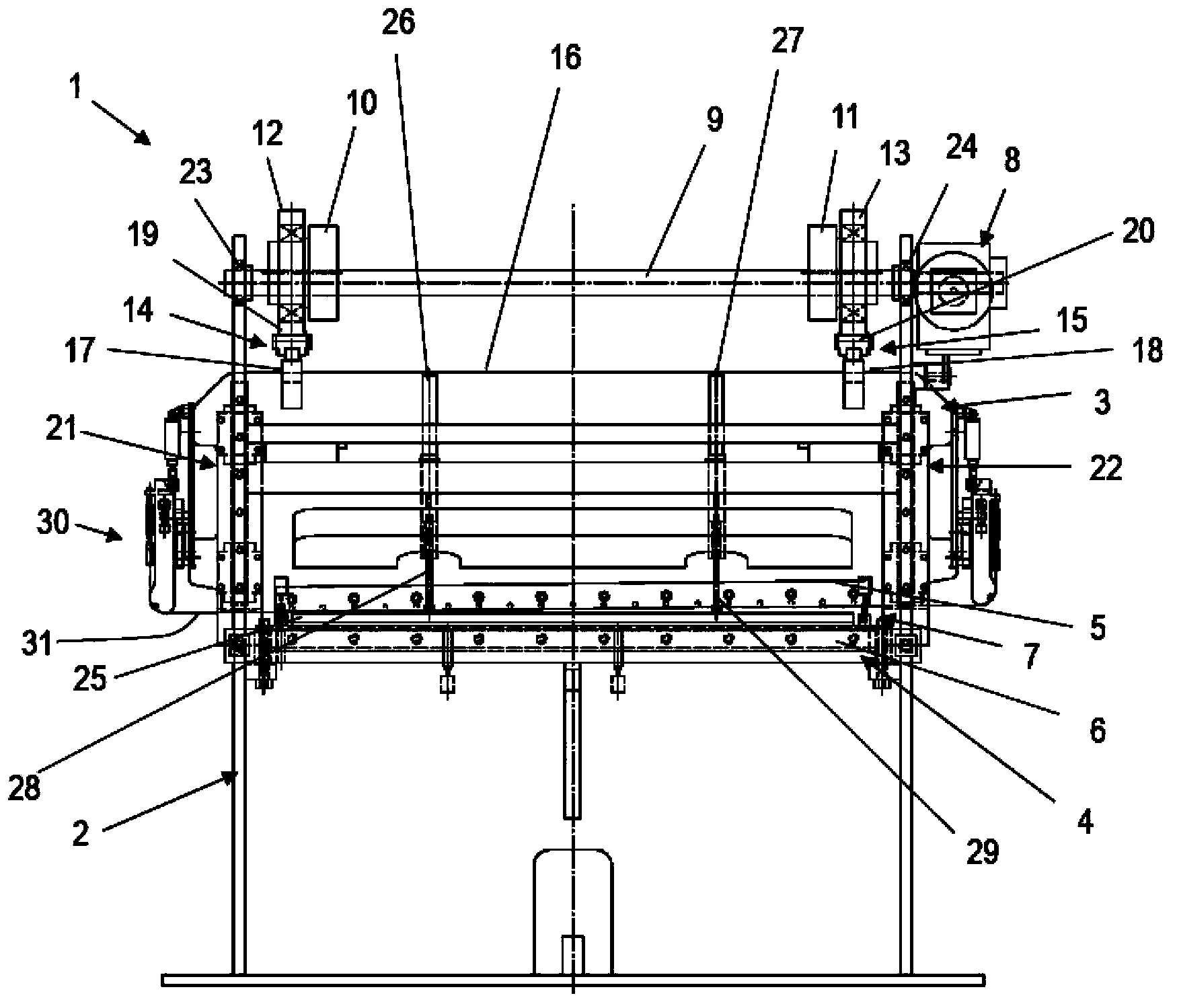

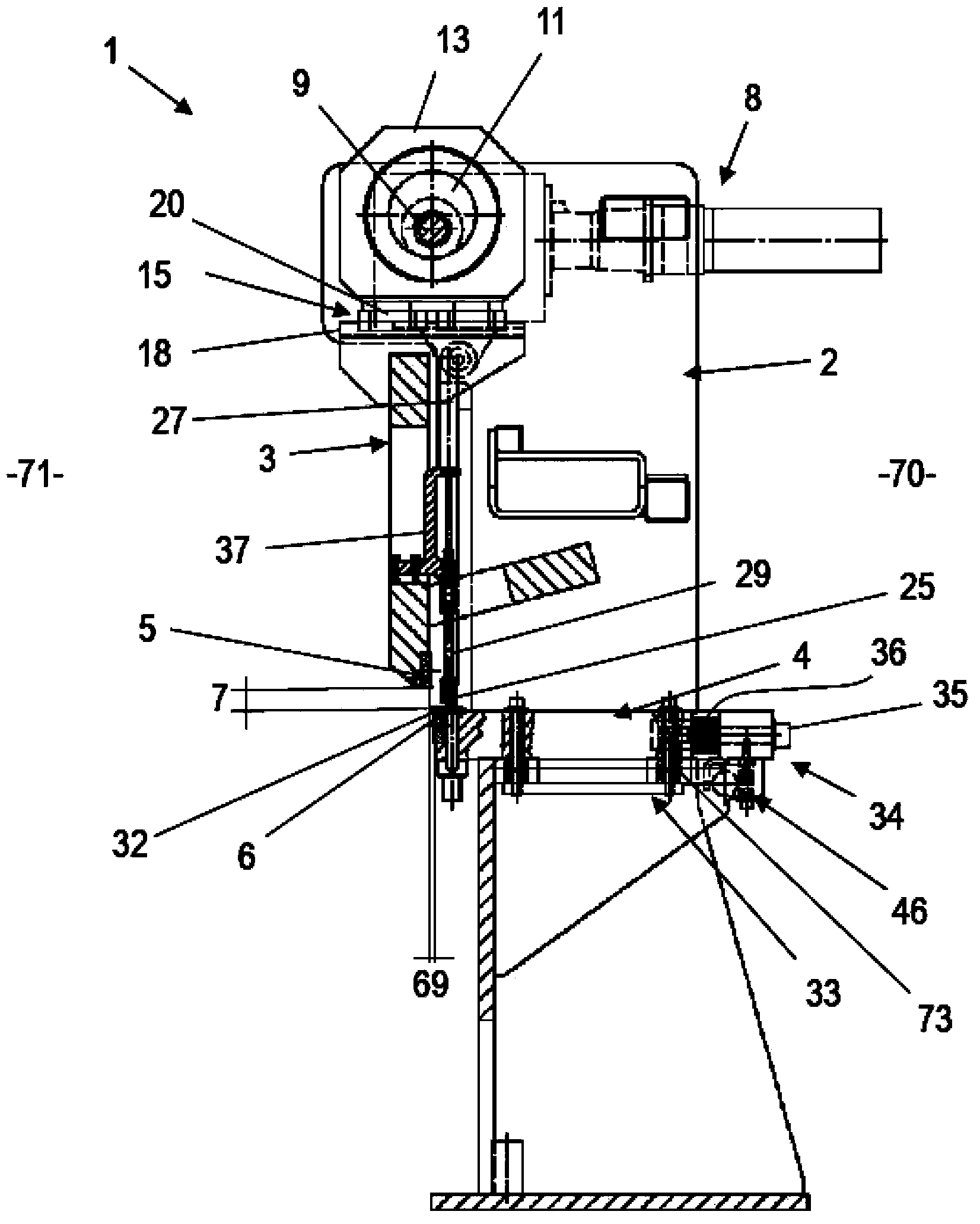

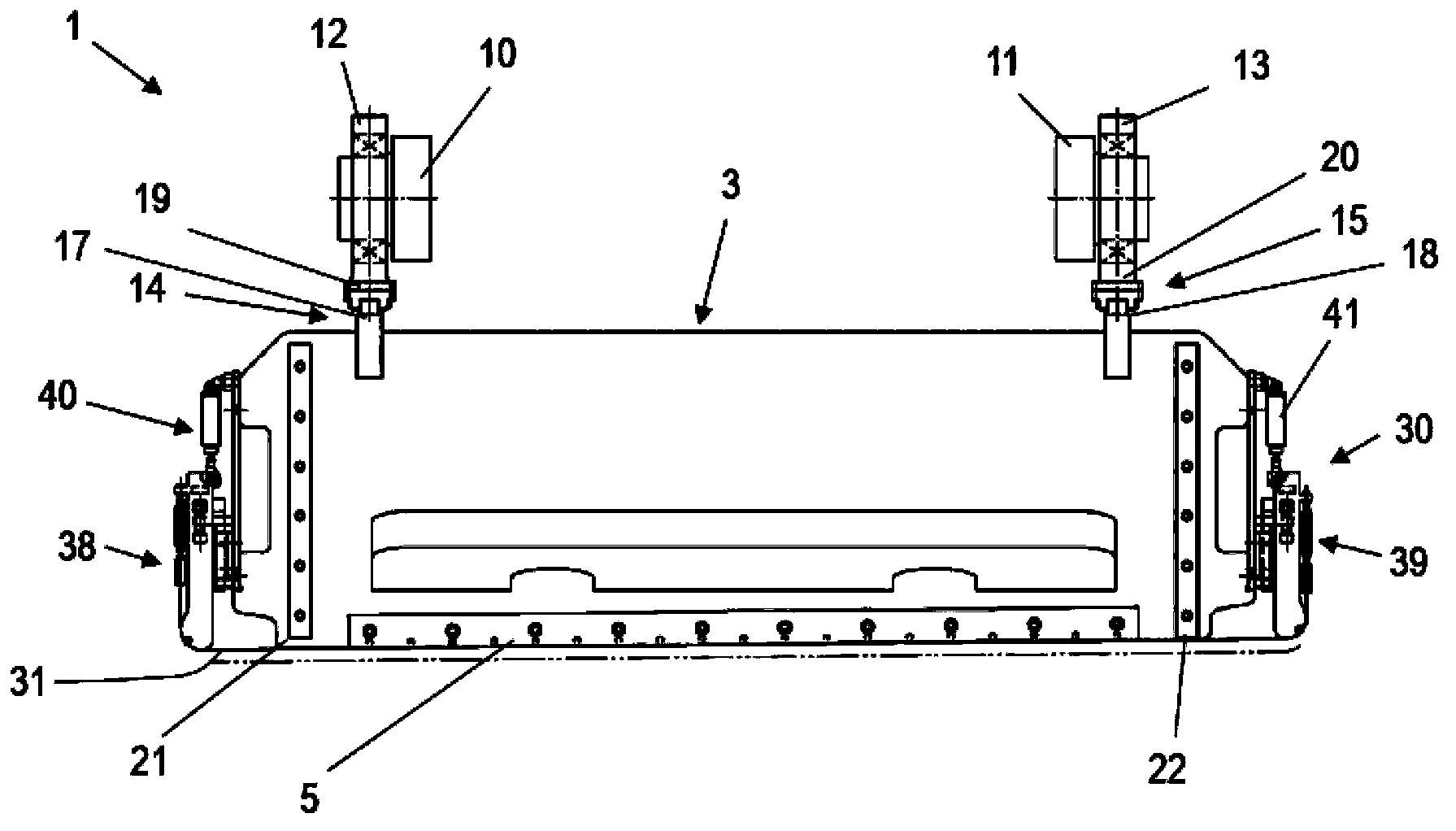

Cutting machine

The invention relates to a cutting machine for cutting sticky ribbons, particularly the ribbon comprises sticky thin cord fabric material comprising spinning silk and / or steel wire. The cutting machine comprises a main frame (2), a knife rest (3), a platen (4) with a lower blade (6), and a driving device (8) with a driving shaft (9), wherein the knife rest (3) with an upper blade (5) can vertically move and support on the main frame (2), a knife edge (7) is arranged between the upper blade (5) and the lower blade (6), the driving device (8) is used for driving the knife rest (3) with the upper blade (5) to vertically move relative to the main frame (2). In order to realize high hardness, the driving shaft (9) eccentrically supports in at least one bearing shell (12 or 13), and the bearing shell only can horizontally move and support on the knife rest (3) through linear guide parts (14 and 15).

Owner:KARL EUGEN FISCHER GMBH

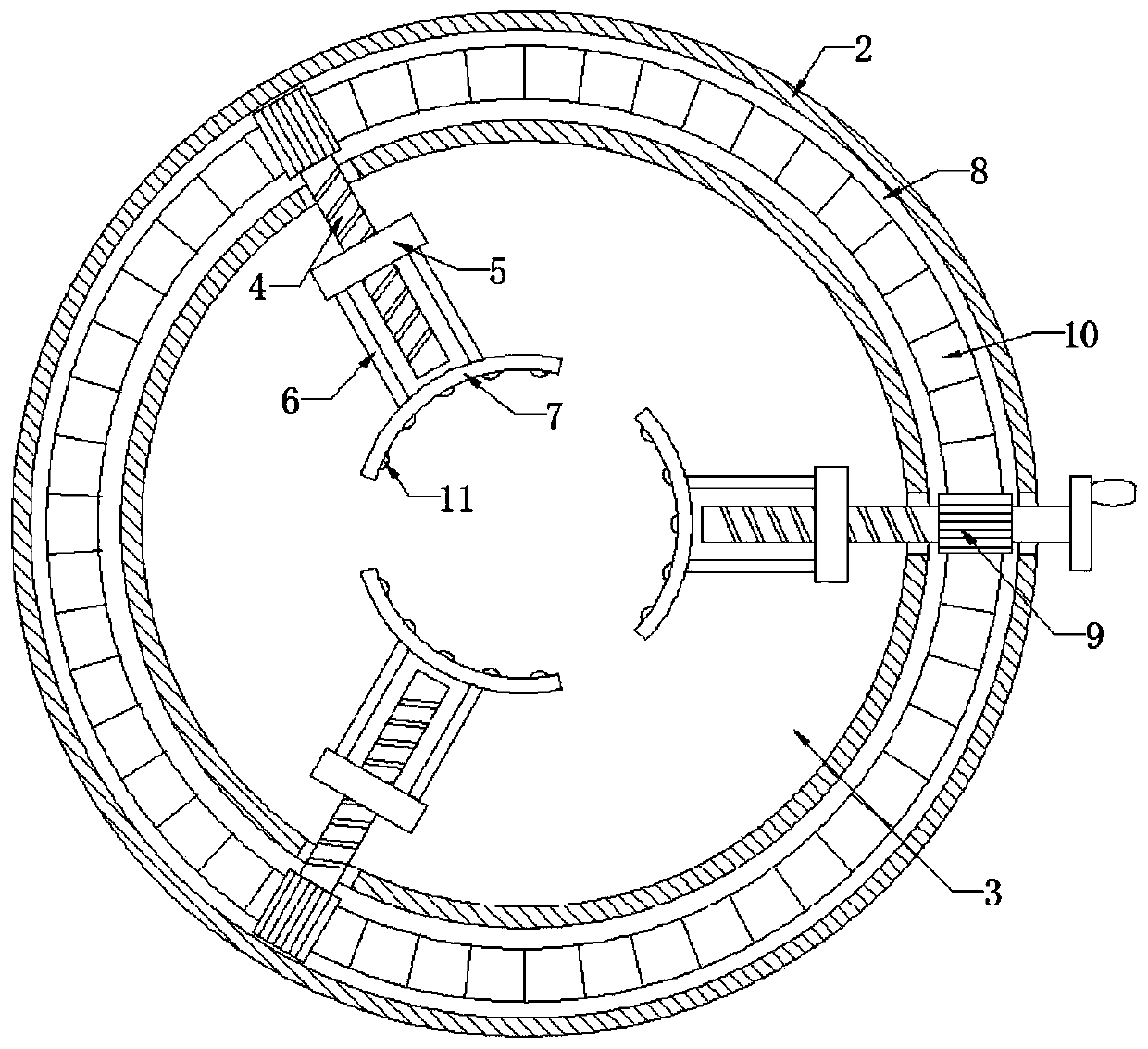

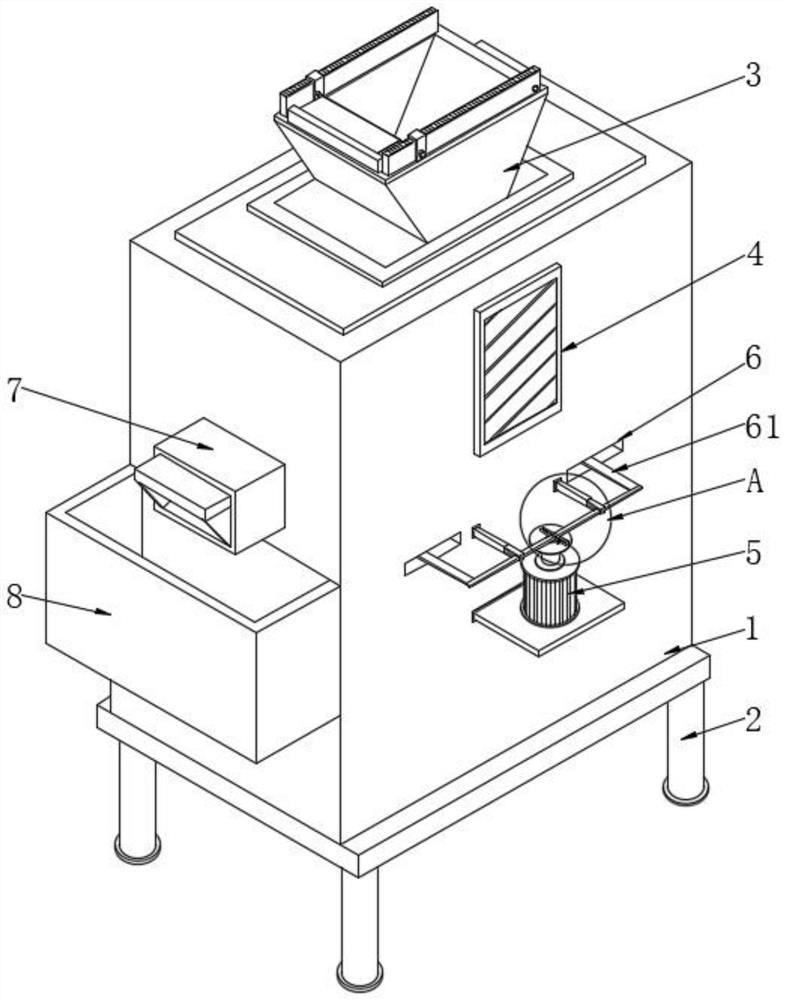

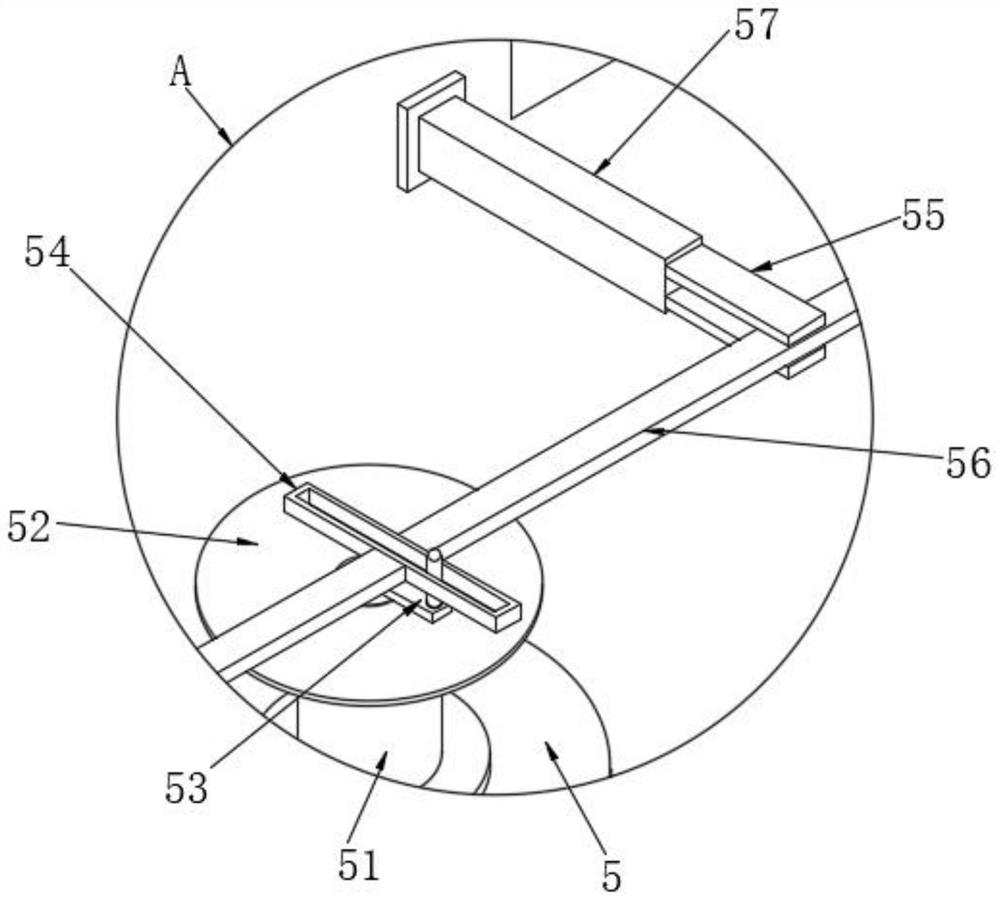

Special-shaped part polishing device for machining

InactiveCN111376147AFully clampedAffect judgmentGrinding carriagesGrinding machinesPhysicsAbnormal shaped

The invention discloses a special-shaped part polishing device for machining. The device comprises a base; a disc is fixedly connected to the upper end of the base, a circular groove is formed in theupper end of the disc, a plurality of lead screws are uniformly and rotatably connected to the inner wall of the circular groove, an annular groove is formed in the upper end of the disc, and a driving device for driving the plurality of lead screws to rotate synchronously is installed in the annular groove. According to the special-shaped part polishing device, annular racks, gears, hand wheels,the screw rods, sliding blocks, connecting rods and arc-shaped clamping plates are arranged, the hand wheels are rotated to enable the screw rods rotatably connected to the inner wall of the circulargroove to rotate synchronously, the special-shaped part is clamped in all sides, the problem that the position of the special-shaped part is shifted during polishing of the special-shaped part, causing polishing errors of the special-shaped part to influence the appearance and the use of the special-shaped part is avoided, scraps in the polishing process of the special-shaped part can be sucked through a fan, and the judgment of the polishing position of the special-shaped part is prevented from being influenced by the scraps.

Owner:合肥锦鑫隆机械制造有限公司

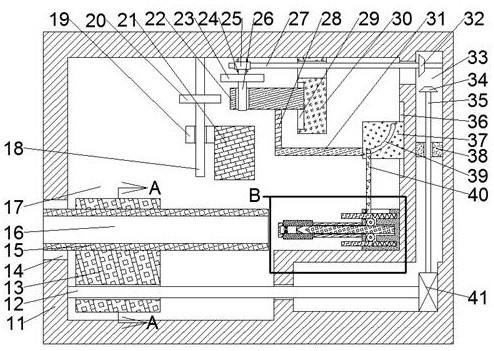

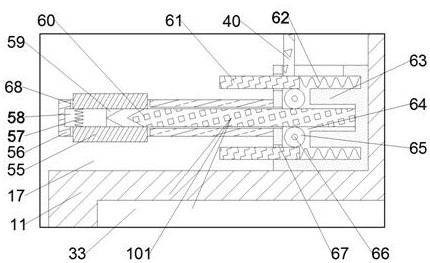

Device for efficiently detecting compressive strength of plastic pipes

InactiveCN112067453AFully clampedWith stamping effectMaterial strength using tensile/compressive forcesGear wheelClassical mechanics

The invention discloses a device for efficiently detecting the compressive strength of plastic pipes. The device comprises a detection machine body. Thedevice of the invention is mainly applied to detection of the compressive strength of a plastic pipe; in the detection process, a pressed block abuts against the plastic pipe so as to trigger a clamping mechanism, and then the plastic pipe can be fully clamped; meanwhile, a large motor operates to drive the plastic pipe to move, then the plastic pipe abuts against a pushed rod, and then a sliding abutting mechanism is triggered to drive a pressure measuring sensor to be tightly attached to the inner wall of a pressure measuring cavity, so that pressure testing is conducted; a driving rod can move so as to drive a driving gear and a driven gear to be engaged, and drive a driven bevel gear and a driving bevel gear to be engaged, and then a threaded sliding block is driven to move, and therefore, a stamping block has a stamping effect, itis guaranteed that the surface of the plastic pipe is subjected to stamping testing, and a pressure measuring main block senses a pressure value on the inner wall, and the compressive strength grade of the plastic pipe can be detected.

Owner:杭州容旗科技有限公司

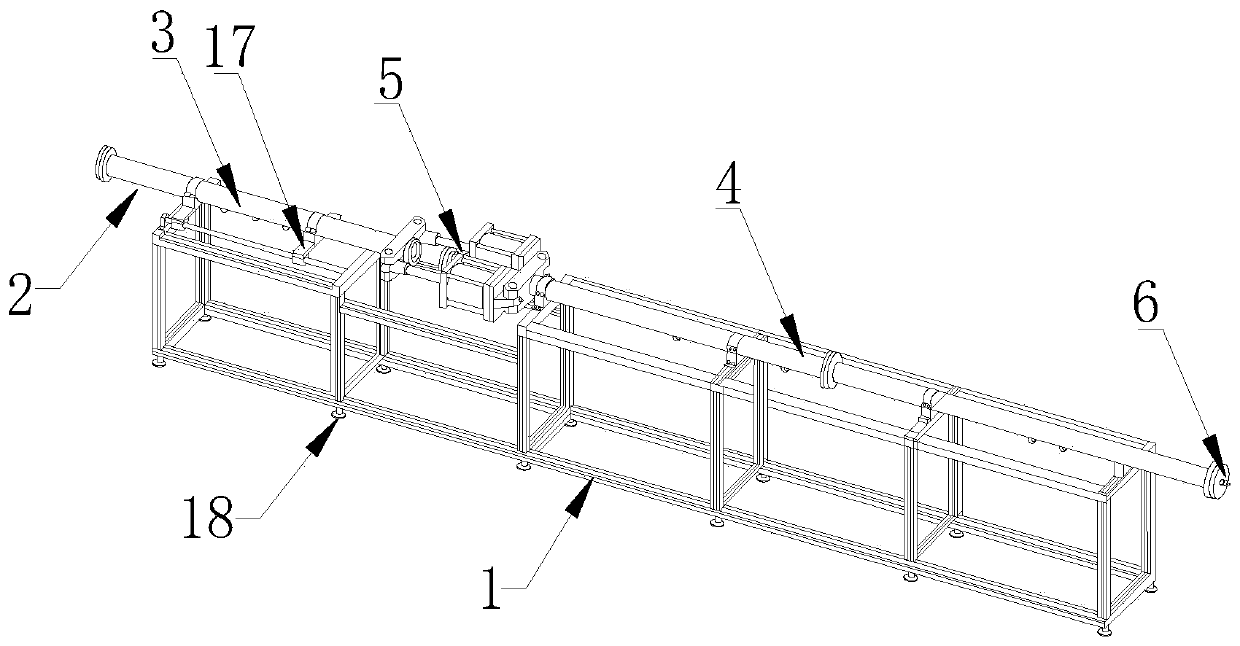

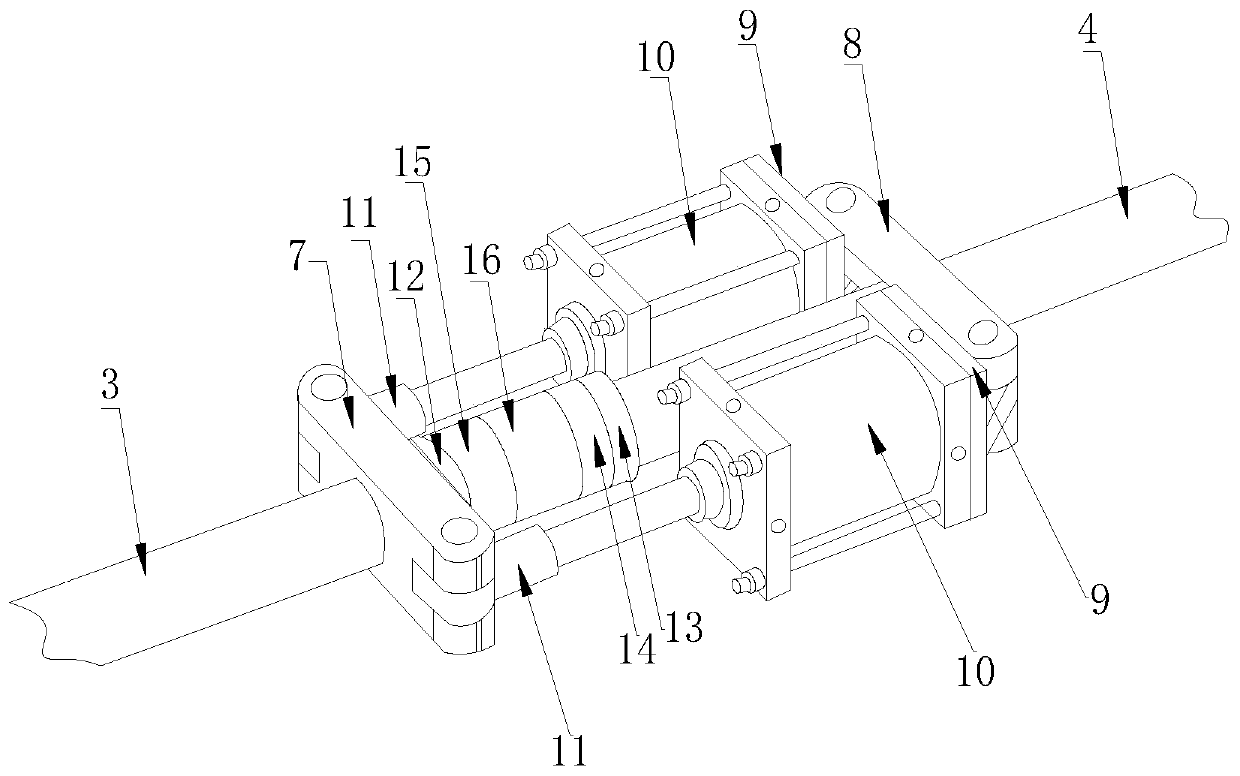

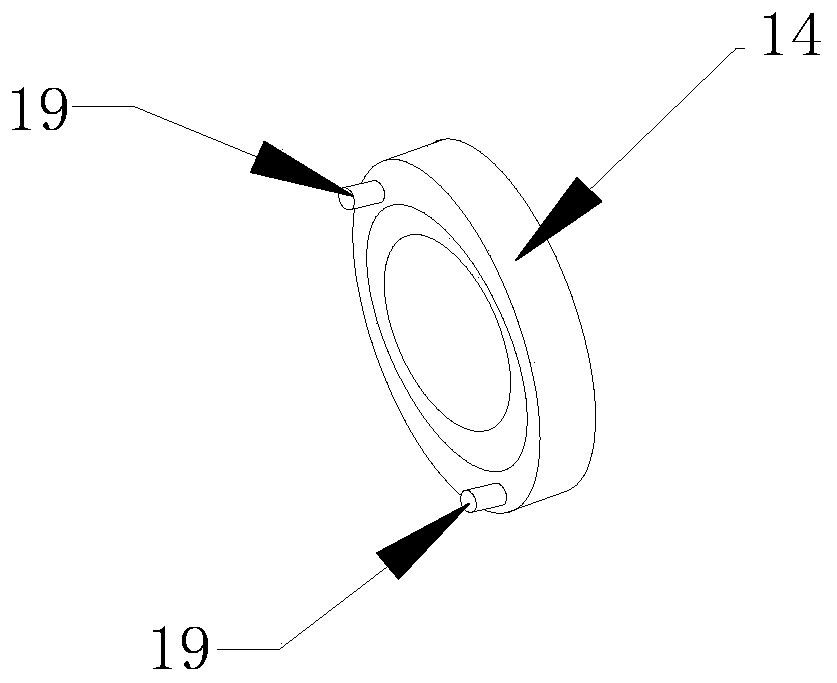

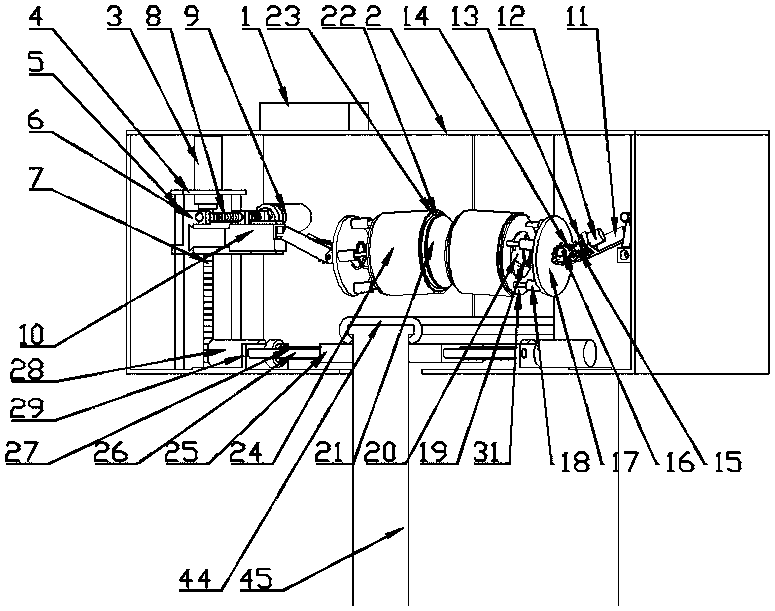

Shock tube for dynamic pressure calibrating device

ActiveCN111076889AEasy loading and unloadingThe membrane rupture method is simpleSustainable transportationAerodynamic testingPhysicsTrunnion

The invention discloses a shock tube for a dynamic pressure calibrating device, and relates to the technical field of aerospace experiments. Key points of the technical scheme are that the shock tubeincludes a base support frame and a shock tube body, and the shock tube body includes a high-pressure section, a low-pressure section and a film clamping mechanism; a to-be-detected sensor is arrangedat an end part of the low-pressure section; the film clamping mechanism includes a first fixed seat fixedly connected with an outer wall of the high-pressure section, a second fixed seat connected with the outer wall of the low-pressure section, a lug, two air cylinders fixedly connected with the lug and located on the two sides of the high-pressure section respectively, two trunnions connected with telescopic ends of the two air cylinders respectively, a first flange connected with an end portion of the high-pressure section, and a second flange connected with the end portion of the low-pressure section; a film rupture ring and a film clamping ring are arranged between the first flange and the second flange; and a diaphragm is fixed on the film rupture ring and is attached to the film clamping ring. According to the shock tube, a film clamping structure can be used for fully clamping the diaphragm, the diaphragm is convenient to assemble, disassemble, replace and maintain, a film breaking mode of the diaphragm is simple, test operation is facilitated, and test requirements are met.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

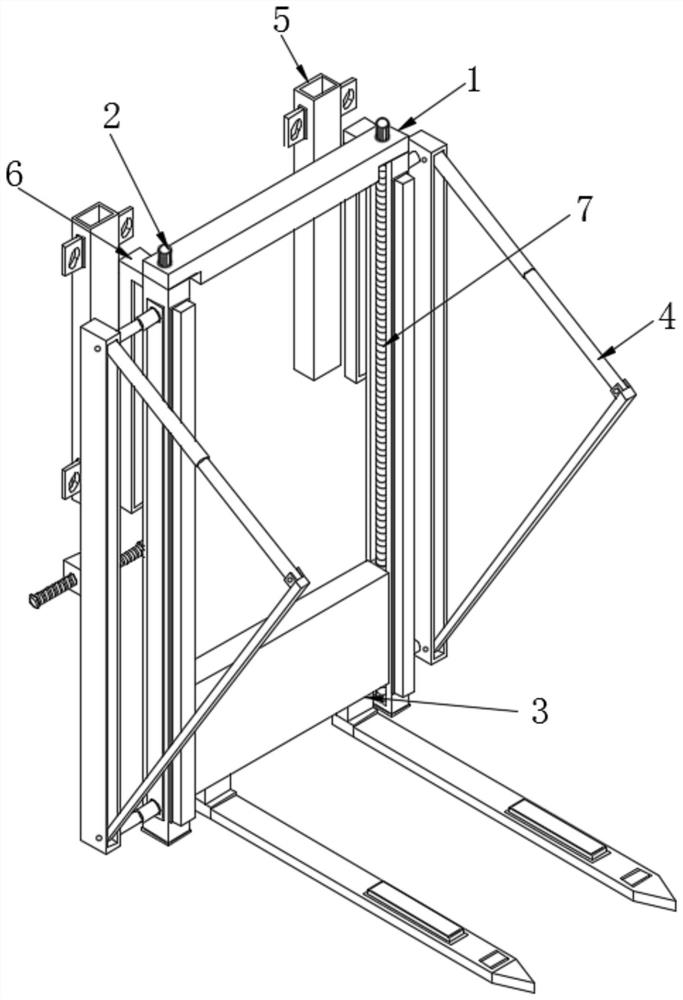

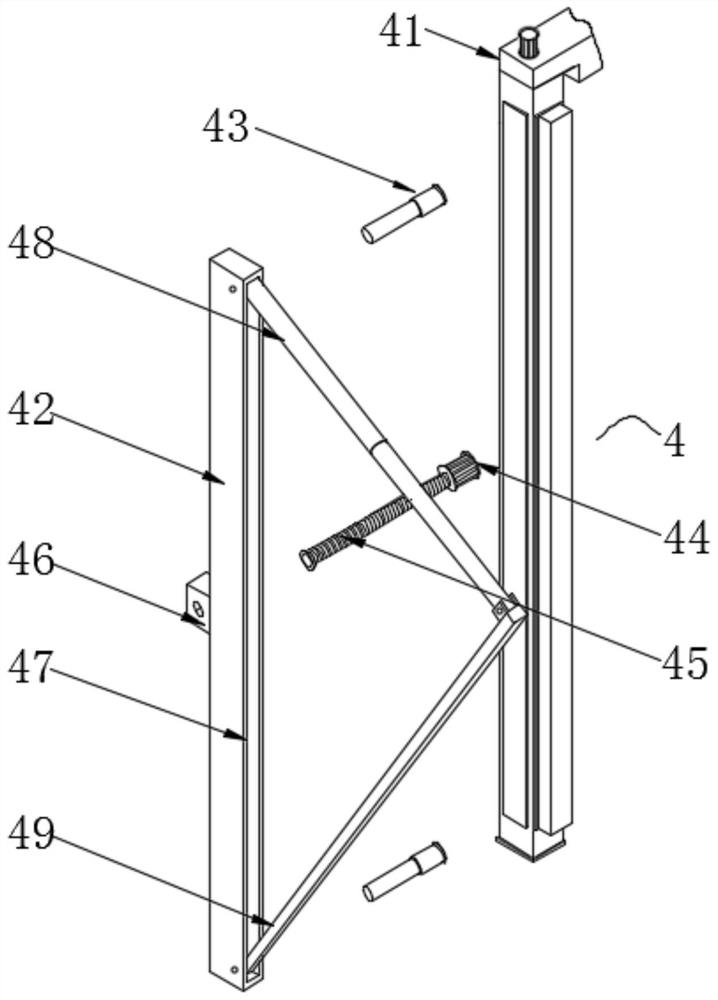

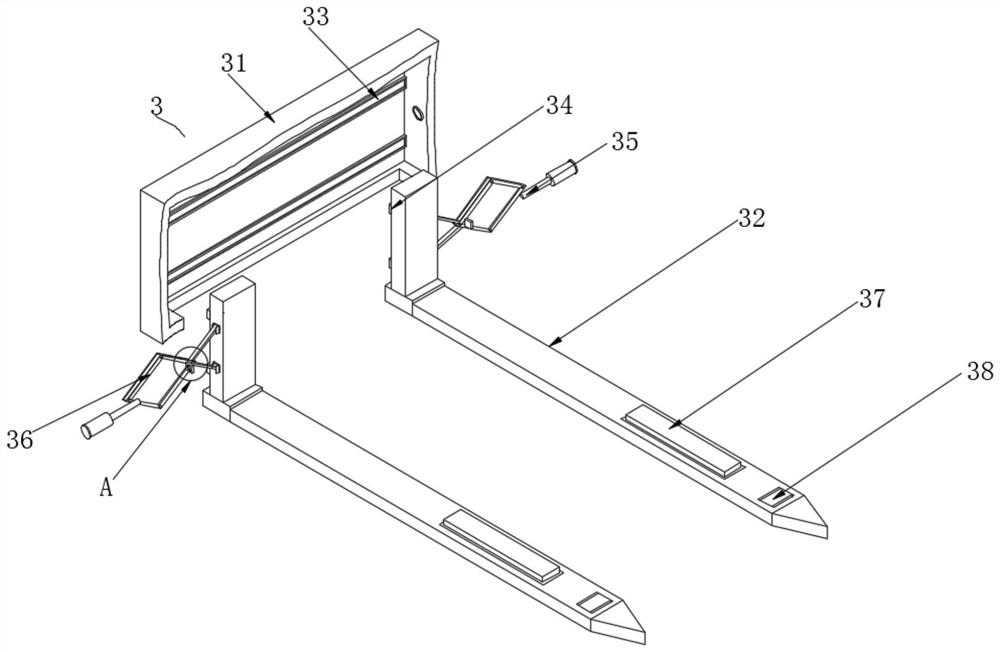

Light-weight front forklift assembly

The invention relates to the technical field of forklifts and discloses a light-weight front forklift assembly which comprises a frame and two sets of rear mounting rods, the two sets of correspondingrear mounting rods are located on the two sides of the rear end of the frame, limiting inserting rods are fixedly mounted on the two sides of the rear end face of the frame, first motors are fixedlyinstalled on the two sides of the upper end face of the frame correspondingly, rotating lead screws are fixedly installed at the output ends of the first motors, blocking mechanisms are arranged on the outer end faces of the two sides of the frame correspondingly, a panel embedding mechanism is fixedly installed in the middle of the interior of the frame, and limiting rods are located on the two sides of the frame. According to the forklift assembly, the conditions that that the goods are fully clamped in the transportation process, shaking and other situations cannot happen are ensured, the distance between the two corresponding fork rods can be effectively changed, and external personnel can conveniently conduct forking treatment work on forklift plates of different sizes.

Owner:ANHUI YUFENG WAREHOUSING EQUIP

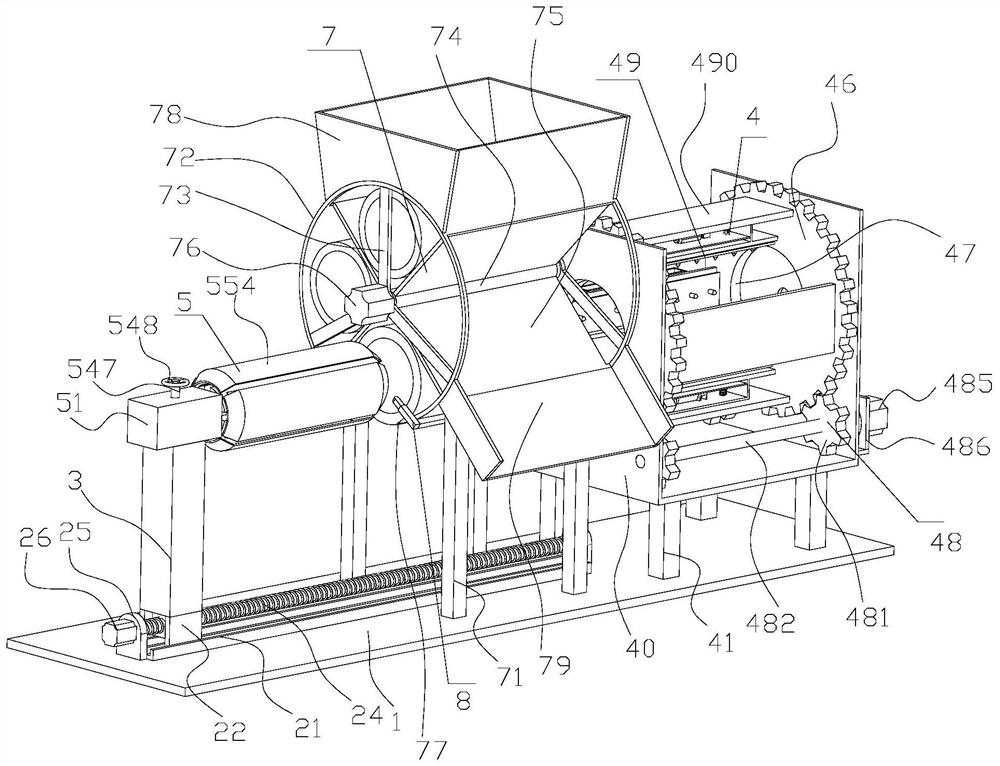

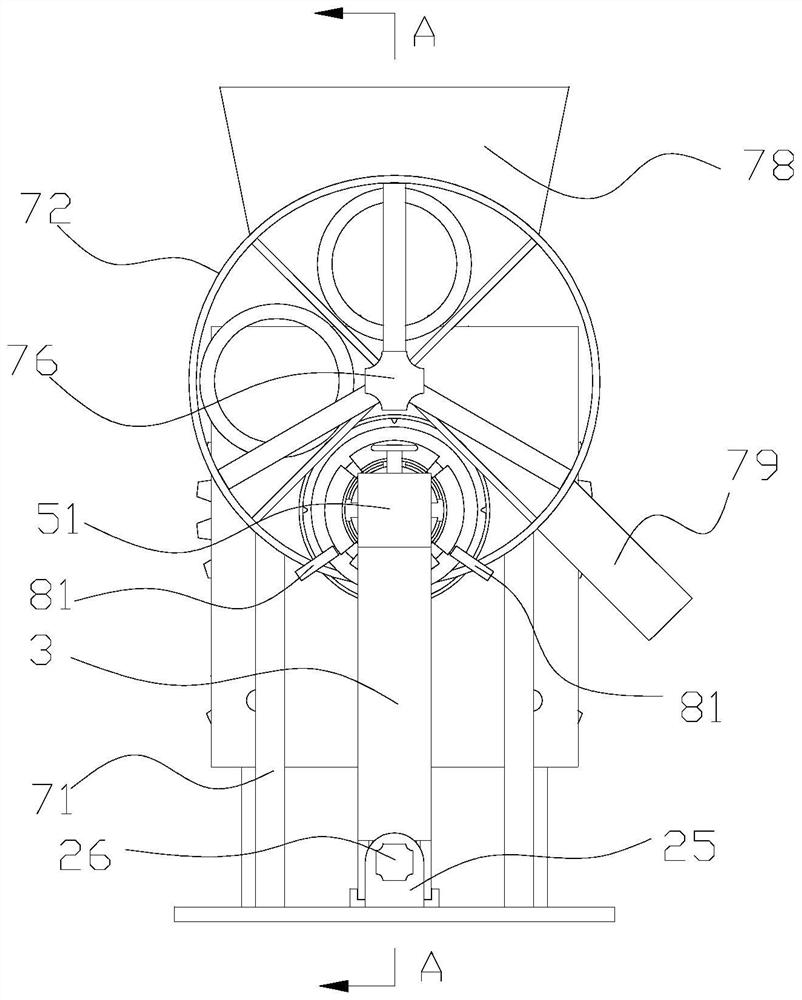

Chinese chestnut opening device

InactiveCN110959875AImprove adjustabilityGood flexibilityHuskingHullingStructural engineeringMechanical engineering

The invention relates to the technical field of chestnut processing and further discloses a Chinese chestnut opening device. The device includes two supporting plates. A main conveyor belt is arrangedbetween the two supporting plates, and a switch is fixed to one side of the supporting plate through bolts. The device further comprises a blanking device, a carding device, a cutting device and a power device. And the cutting device comprises a center shaft, a first connecting plate and two fixed plates. The two fixed plates are fixed to the tops of the two supporting plates through bolts correspondingly, and a first mounting opening is formed in one side of each fixed plate. A first bearing is clamped in each first mounting opening, and the first bearings are rotatably connected with the center shaft. According to the Chinese chestnut opening device, Chinese chestnuts can be clamped under the cooperation of the gravity of a balancing weight when passing through the Chinese chestnut opening device, which facilitates the subsequent opening work; and when Chinese chestnuts of different sizes pass through the Chinese chestnut opening device, a clamping frame can rotate around the centershaft to automatically adjust the position, so that each Chinese chestnut can be fully clamped, and the flexibility of the device is improved.

Owner:李旋

Crushed material collecting device for rice crust production

PendingCN114833066AEase of screening and processingFully clampedSievingFouling preventionProcess engineeringWaste material

The invention discloses a crushed material collecting device for rice crust production, relates to the technical field of rice crust production, and solves the technical problems that when a traditional screening mechanism is used, only waste materials of a single size can be screened, the multiple screening effect cannot be achieved, and operation and treatment by external personnel are not facilitated. A circuit switch of the servo motor is turned on, the servo motor drives the rotating shaft to rotate, the sliding guide rod can be fully clamped in the rotating process of the rotating shaft, therefore, when the sliding guide rod shakes, the movable through rod is driven to slide back and forth in the movable through groove, and the movable through rod is driven to move back and forth through the limiting pushing effect of the limiting center piece. The built-in screen cloth on the upper side and the lower side can be effectively driven to shake back and forth through the driving device, in the shaking process, the built-in abutting piece is driven to deform, the built-in abutting piece resets after being deformed, the built-in screen cloth can abut against the built-in screen cloth, the built-in screen cloth can screen crushed materials, the screening effect is improved, and external personnel can conveniently conduct screening treatment work.

Owner:马鞍山永阳食品有限公司

Workpiece clamp

InactiveCN103170847BStable working conditionNot prone to problems such as large vibrationsPositioning apparatusElectrical-based auxillary apparatusWater filterWire cutting

Owner:ZHEJIANG GEELY POWERTRAIN CO LTD +2

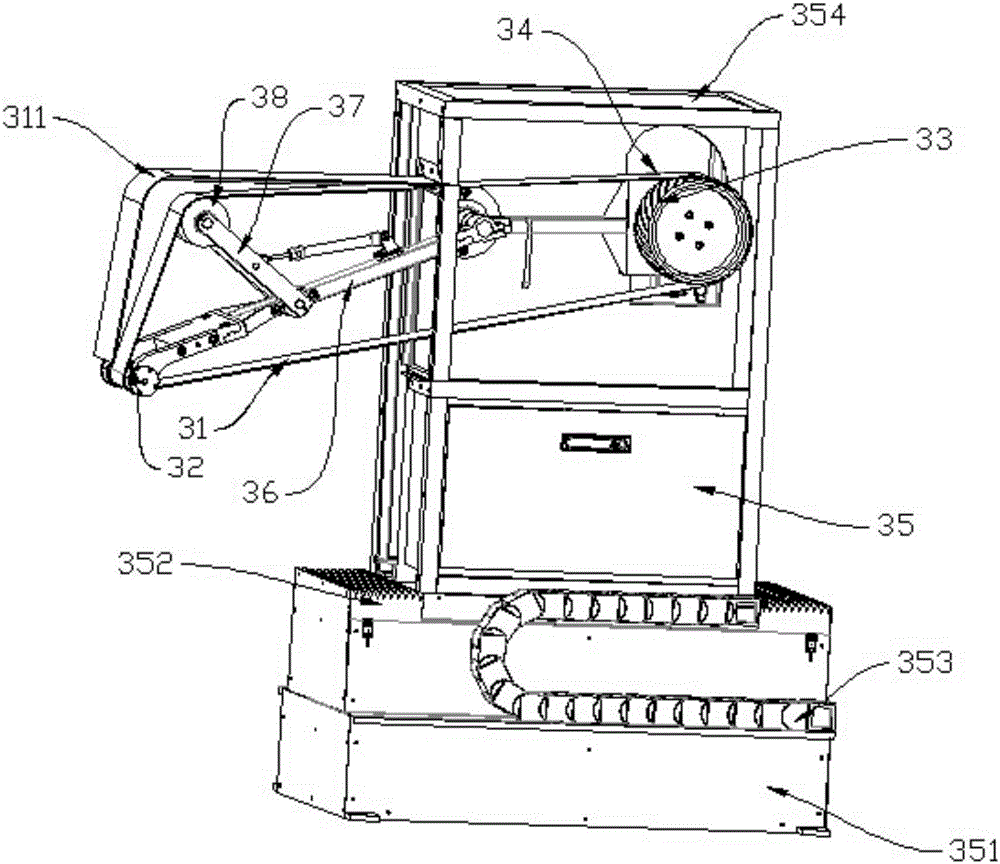

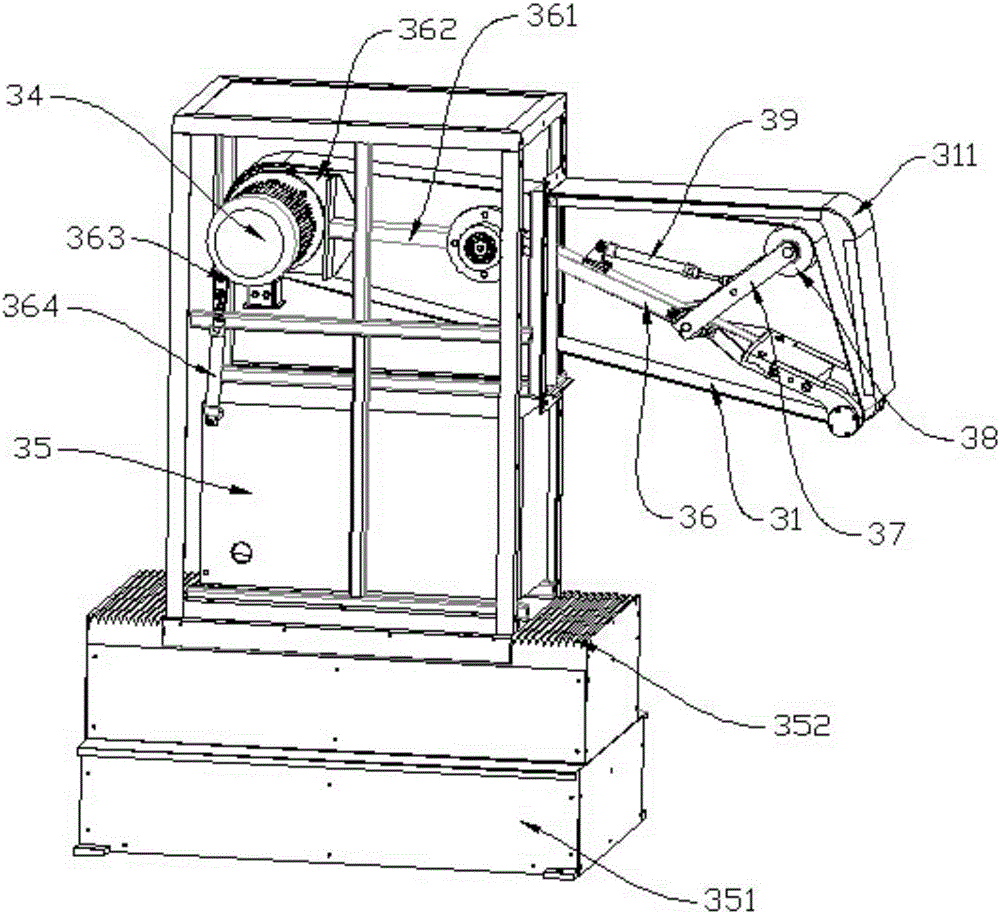

Elevator automatic handrail belt washing robot

The invention provides an elevator automatic handrail belt washing robot which comprises a control box, an overall machine shell, a lifting guide rail, a lifting lead screw, an up-and-down moving block, a transverse movement lead screw and the like. A clamping part comprises a clamping lead screw, a clamping block, a clamping guide rail, a clamping motor and the like, a washing part comprises a transverse movement movable block, an up-and-down swing arm, an electric cylinder round disc, an electric cylinder, a buffer spring, a positive brush support, a side brush support, a brush head base, abrush support shaft, a side brush support connecting piece, a brush head motor, a rotating motor and the like. The overall machine shell is adopted to serve as a shell of the overall device, the overall device is provided with one clamping device and two washing devices, the washing devices can move up and down along the lifting lead screw and the horizontal lead screw, and a handrail belt can bewashed with the washing devices after the overall machine is clamped to an escalator through the clamping device.

Owner:绍兴市晟途环保科技有限公司

High-precision punching equipment for PVC film processing

InactiveCN112847628AWide range of applicationsSmall footprintMetal working apparatusStructural engineeringManufacturing engineering

The invention discloses high-precision punching equipment for PVC film processing. The high-precision punching equipment comprises a base, a support and a punching part arranged above the right side of the base, and further comprises a supporting component, an anti-sliding assembly, a feeding assembly, and a limiting assembly; the supporting component is fixedly arranged above the support; the anti-sliding assembly is arranged on one side of the supporting component; the feeding assembly is arranged on the right side of the supporting component; the limiting assembly is arranged on the lower side of the feeding assembly; the supporting component comprises a fixed block, a fan-shaped supporting shaft, a sliding shaft slidably arranged in the middle of the fan-shaped supporting shaft, an adjusting assembly used for controlling the sliding shaft to slide left and right, and a clamping piece arranged on the sliding shaft. According to the equipment, through the arrangement of the adjusting assembly, via sliding of the sliding shaft, a clamping piece can clamp PVC film barrels with different inner diameters, the application range is wide, and the occupied space is small; through the arrangement of the anti-sliding assembly, a PVC film barrel is fully clamped, deviation is prevented during punching, and the punching precision is improved; and the feeding assembly is matched with the limiting assembly, automatic feeding and discharging are achieved, and the working efficiency is improved.

Owner:杭州雷力信息科技有限公司

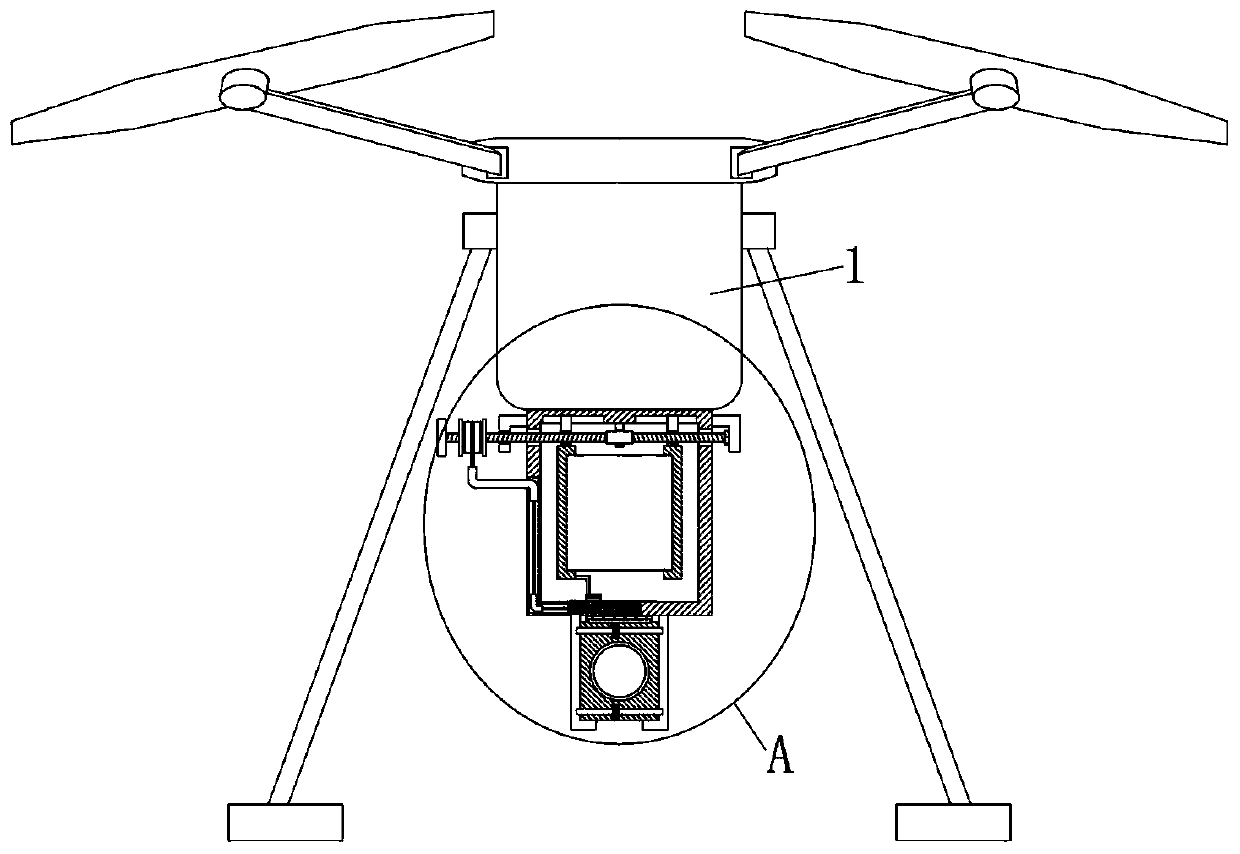

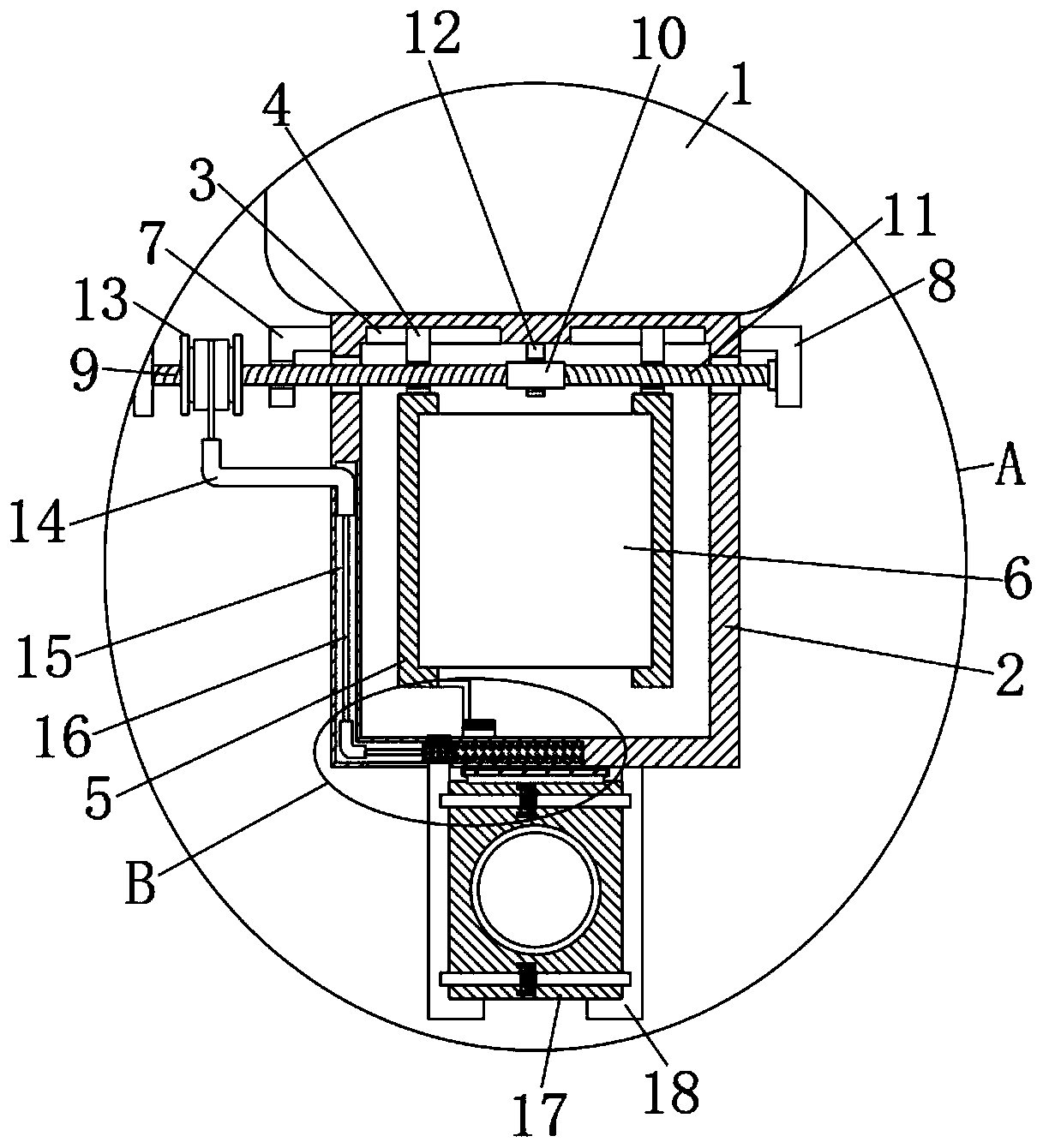

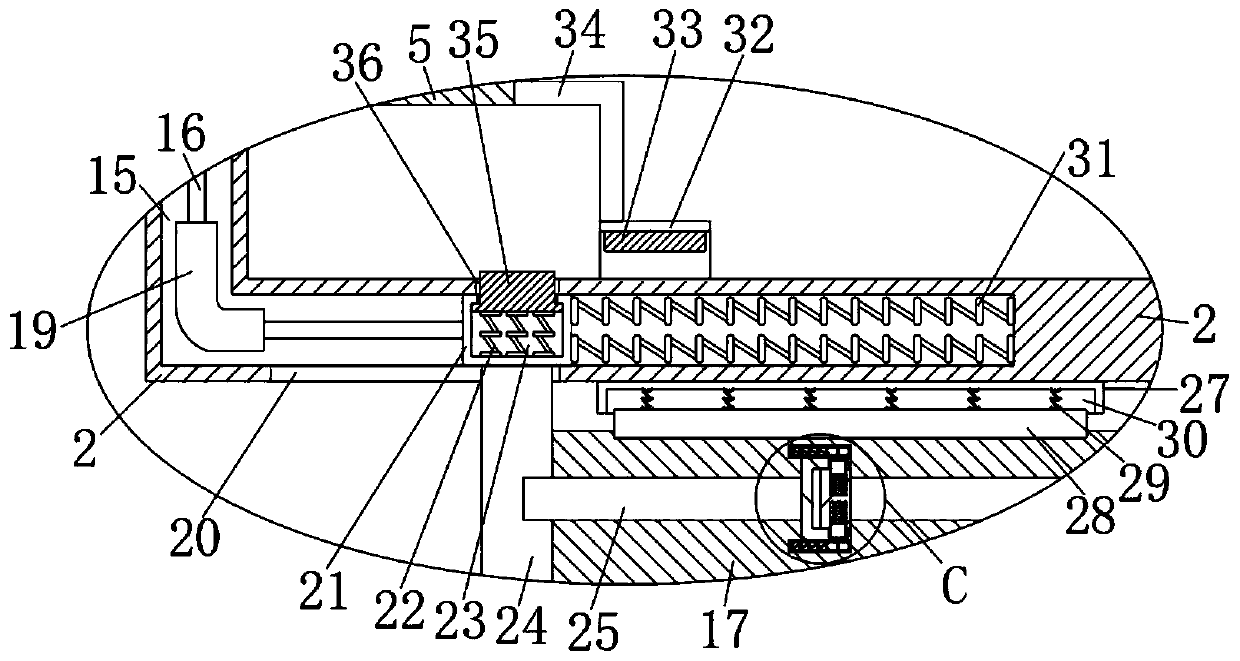

Unmanned aerial vehicle for emergency rescue and disaster relief

InactiveCN110203390ARealize synchronous limit clampingFully clampedAircraft componentsAircraftsEmergency rescueEngineering

The invention discloses an unmanned aerial vehicle for emergency rescue and disaster relief. The unmanned aerial vehicle comprises a machine body, wherein a frame body is fixedly connected to the bottom of the machine body, a clamping mechanism is arranged in the frame body, a transfer piece is clamped in the clamping mechanism, a reset mechanism is fixedly connected to the bottom of the clampingmechanism, the outer side of the clamping mechanism is fixedly connected with a winding wheel, an elastic rope is wound around the winding wheel, an L-shaped cavity is formed in the frame body, a first rope passing pipe communicating with the L-shaped cavity is arranged in the outer side wall of the frame body in a penetrated mode, a second rope passing pipe is fixedly connected with the inner side wall of the L-shaped cavity, and a limiting groove communicated with the L-shaped cavity is formed in the bottom of the frame body in a penetrating mode. The unmanned aerial vehicle has reasonable structural design, not only can fully limit and clamp the transfer piece and a camera at the same time, but also can facilitate rescue personnel to take out the transfer piece, thereby facilitating thenormal operation of rescue work.

Owner:徐晔

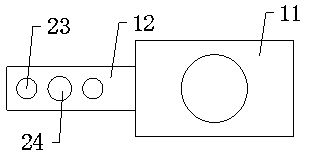

Finished product rotating speed detection device and detection method for motor production

InactiveCN113092806AConducive to efficient inspection operationsReduce energy consumptionLinear/angular speed measurementSpeed/acceleration/shock instrument detailsElectric machineEngineering

Owner:杨洋

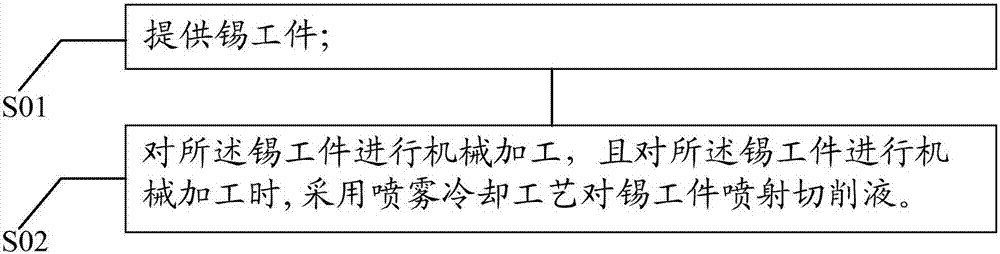

Machining method for tin target

InactiveCN107303634AImprove cooling effectImprove the lubrication effectMaintainance and safety accessoriesSurface roughnessSpray cooling

The invention provides a machining method for a tin target. The method comprises the steps that a tin workpiece is provided; and the tin workpiece is machined, and cutting fluid is sprayed to the tin workpiece through a spray cooling process when the tin workpiece is machined. Due to the fact that the spray cooling process is adopted when the tin workpiece is machined, the tool sticking degree of the tin workpiece is lowered, and the surface roughness of the formed tin target is lowered.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

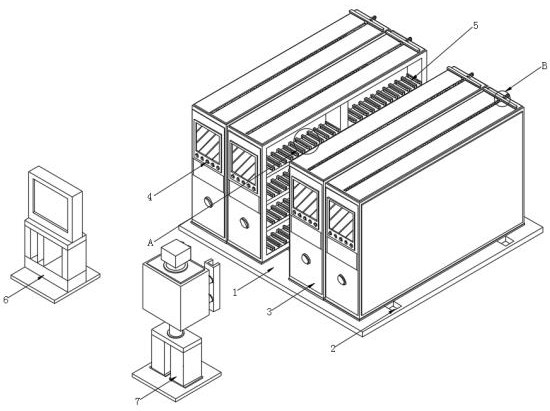

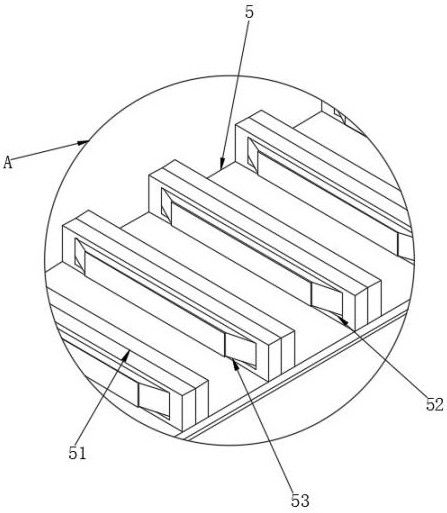

Intelligent robot automatic storing and taking compact shelf

ActiveCN112545198APrevent fallingFully clampedProgramme-controlled manipulatorBook cabinetsControl engineeringStructural engineering

The invention discloses an intelligent robot automatic storing and taking compact shelf and relates to the technical field of file automatic storing and taking. The intelligent robot automatic storingand taking compact shelf comprises a bottom plate, wherein sliding grooves are formed in the two sides of the upper end face of the bottom plate, a plurality of shelving bodies are slidably arrangedbetween every two corresponding sliding grooves, and control panels are fixed to the positions, close to the upper ends, of the front end faces of the shelving bodies; a plurality of overhead plates are fixedly installed in the frame body, and a plurality of limiting blocks are fixed to the periphery of the upper end face of each overhead plate; a built-in movable groove is formed in the middle ofthe interior of the limiting block, and a slope abutting plate is movably connected to the interior of the built-in movable groove. According to the compact shelf, files can be well clamped, so thatthe good clamping effect is achieved, the files are prevented from falling off, external personnel can conveniently conduct clamping operation treatment work, dust on the upper end face of the shelf body can be well removed, and the external personnel can conveniently remove the dust on the upper end face of the shelf body.

Owner:广东振越智能家具有限公司

Device for inserting barbecue sticks into chicken middle wings

InactiveCN109006948AReduce labor intensityReduce manual operationsPutting meat on skewersAerospace engineering

The invention discloses a device for inserting barbecue sticks into chicken middle wings. The device comprises a base, a barbecue stick inserting mechanism and a chicken middle wing storage groove, the barbecue stick inserting mechanism is mounted on the base, the chicken middle wing storage groove is arranged on the front side of the barbecue stick inserting mechanism and formed by sinking of thebase, air cylinders A are arranged on two sides of the storage groove respectively, clamp plates are mounted on air cylinder shafts of the air cylinders A, the barbecue stick inserting mechanism consists of a barbecue stick box and an air cylinder B, and an air cylinder shaft of the air cylinder B is used as a push rod to provide acting force for insertion of barbecue sticks into chicken middle wings. The device for inserting barbecue sticks into chicken middle wings can easily insert the barbecue sticks into chicken middle wings to replace manual operation, the labor intensity is reduced, several openings can be cut in the chicken middle wings for flavoring while the barbecue sticks are inserted into the chicken middle wings, and manual operation procedures are reduced.

Owner:BEIHAI YISHENGYUAN AGRI TRADE CO LTD

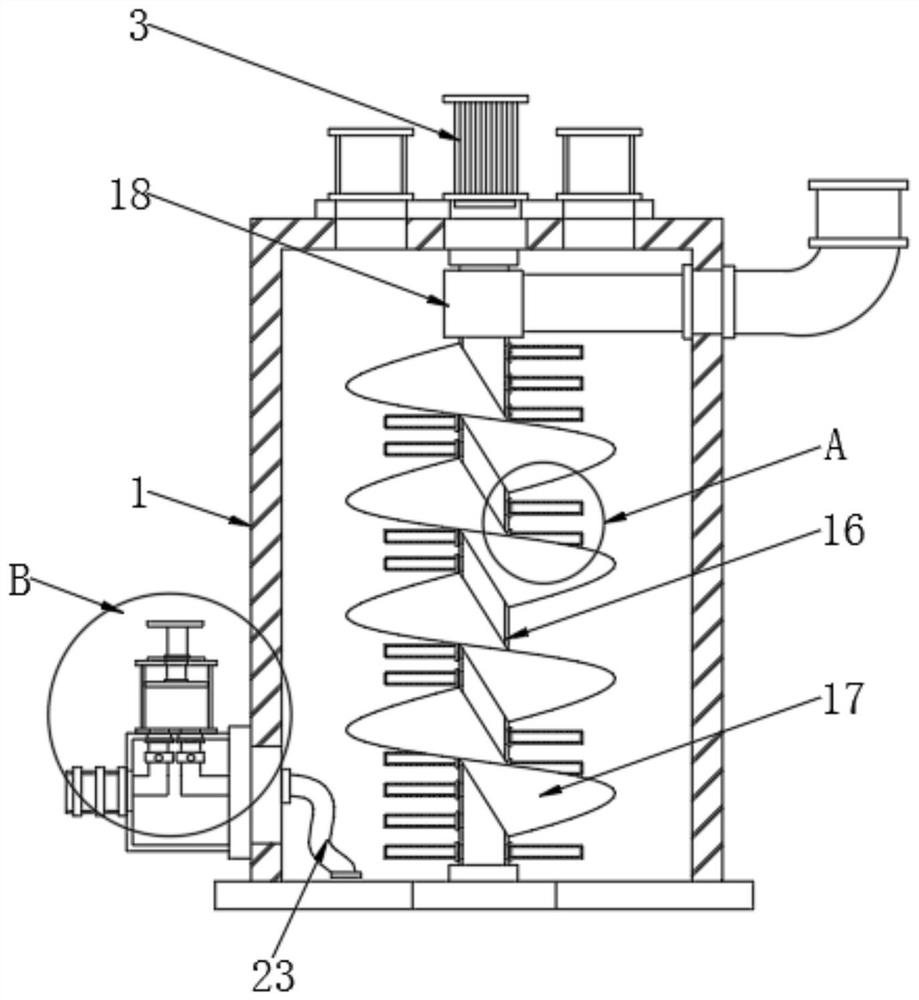

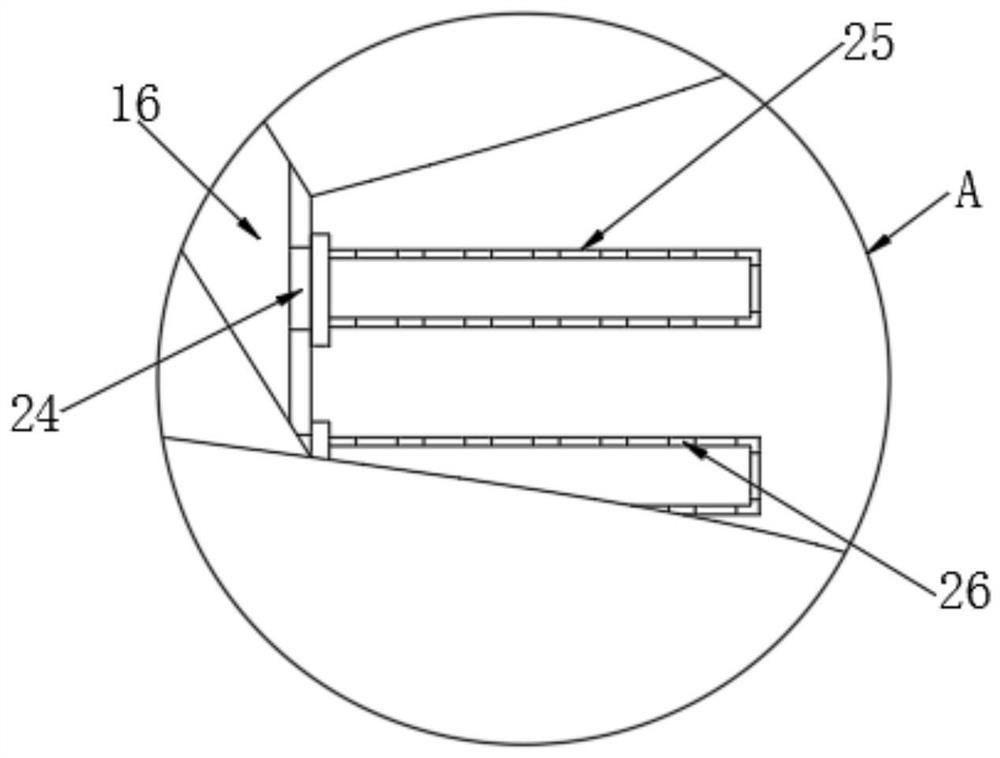

Gallium nitride crystal production equipment

InactiveCN112126981AImprove reaction efficiencyFull mixing efficiencyPolycrystalline material growthFrom chemically reactive gasesGallium nitrideMaterials science

The invention discloses gallium nitride crystal production equipment, and relates to the technical field of gallium nitride crystal production. The gallium nitride crystal production equipment comprises a barrel body, supporting columns are fixedly installed at the corners of the periphery of the lower surface of the barrel body, and a servo motor is fixedly installed in the middle of the upper surface of an upper cover plate. A first feeding pipe is fixedly installed at the position, located on one side of the servo motor, of the upper surface of the upper cover plate, a second feeding pipe is fixedly installed at the position, located on the other side of the servo motor, of the upper surface of the upper cover plate, and a discharging pipe is fixedly installed in the middle of the interior of the barrel body. According to the equipment, the reaction efficiency between the material bodies is improved, meanwhile, the mixing of the material bodies is more sufficient, the quality of theprepared material bodies is better, an operator can fully check the mixing rate of liquid in the barrel body conveniently, the material bodies in the barrel body can be monitored in real time, and the operator can operate and treat the material bodies conveniently.

Owner:高元琴

Processing table for tension spring production

The invention discloses a processing table for tension spring production. The processing table comprises a supporting shell, a supporting transverse plate, an extending plate, a supporting frame, a grasping mechanism and a working table plate, wherein an adjusting screw rod, a first threaded sleeve, a transverse rod, a first connecting plate, a first hinge seat, a limiting rod and a push plate are arranged in the supporting shell, a mounting plate, a second connecting plate and a second hinge seat are mounted at the bottom of the push plate, the first hinge seat and the second hinge seat located on the same side of the adjusting screw rod are connected by means of a connecting rod, and a first clamping plate is arranged on the side face, facing the working table plate, of the push plate. According to the processing table, selective operation can be conducted on a processed portion of a tension spring according to an actual situation, fine adjustment can be conducted on clamping of the tension spring under the condition that an adjusting motor is not started after adjustment of the adjusting motor is completed, the tension springs of different sizes can be easily clamped through the arrangement of the grasping mechanism, and the processing table is high in practicability and suitable for popularization and application.

Owner:山东现大精密机械有限公司

Connecting wire positioning clip suitable for high voltage

ActiveCN108767518AImprove clamping effectAvoid the phenomenon of detaching from the inside of the positioning clipElectric connection structural associationsClamped/spring connectionsEngineeringHigh pressure

The invention discloses a connecting wire positioning clip suitable for high voltage, comprising an insulating casing, wherein a first wire clamp plate is disposed on the left side of the inner cavityof the insulating casing, a first wire guiding cylinder is connected to the left side of the first wire clamp plate, the inner cavity of the first wire guiding cylinder is provided with a first wire,and the right side of the first wire clamp plate is connected with a dovetail shaped bump. Due to the matching of the first wire clamp plate, the first wire guiding cylinder, the first wire, the dovetail shaped bump, the fixing block, the limiting block, the first snap spring, the fixing plate, the semi-arc snap block, the second wire clamp plate, the dovetail shaped groove, the second wire guiding cylinder, the snapping rod, the supporting seat, the cross bar, the blocking bar, the second snap spring, and the fixture block, the invention may fully clamp the first wire and the second wire toenhance the clamping effect of the positioning clip, which solves the problem that the clamping function of the existing positioning clip is poor, avoids the phenomenon that the wire is separated fromthe inside of the positioning clip, and is worthy of popularization.

Owner:GULIFA ELECTRIC +1

Firework paper tube recovery device

The invention discloses a firework paper tube recovery device. The firework paper tube recovery device comprises a middle box body, wherein a penetrating cross rod is arranged in the middle box body, a plurality of clamping grooves are formed in the end wall of the cross rod in a communicating mode, the clamping grooves are vertically and symmetrically formed, inner cavities are formed between the opposite clamping grooves, the inner cavities located in the clamping grooves are symmetrically formed, sliding connecting blocks are slidably arranged in the staggered areas between the clamping grooves and used for clamping firework tubes, a bottom box body is arranged on the upper side of the middle box body, and a cutting and pushing device capable of stretching into the firework tubes to cut mud pies in the firework tubes and pushing the mud pies out of the firework tubes is arranged in the bottom box body. According to the firework paper tubes with different sizes, the sizes of the firework paper tubes clamped by the sliding connecting blocks can be adjusted, and under the action of a lifting plate and a vertical rod, a top platform can conveniently stretch the firework paper tubes into equipment, and meanwhile, the bottom box body and other structures are separated from the firework paper tubes.

Owner:马依和

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com