Multifunctional mechanical gripper

A multi-functional machine and claw technology, applied in the field of robotic hands, can solve the problems of time-consuming and labor-intensive, single practical function, and increase the cost of picking and placing, and achieve the effect of improving work efficiency, improving time-consuming and laborious, and increasing the scope of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

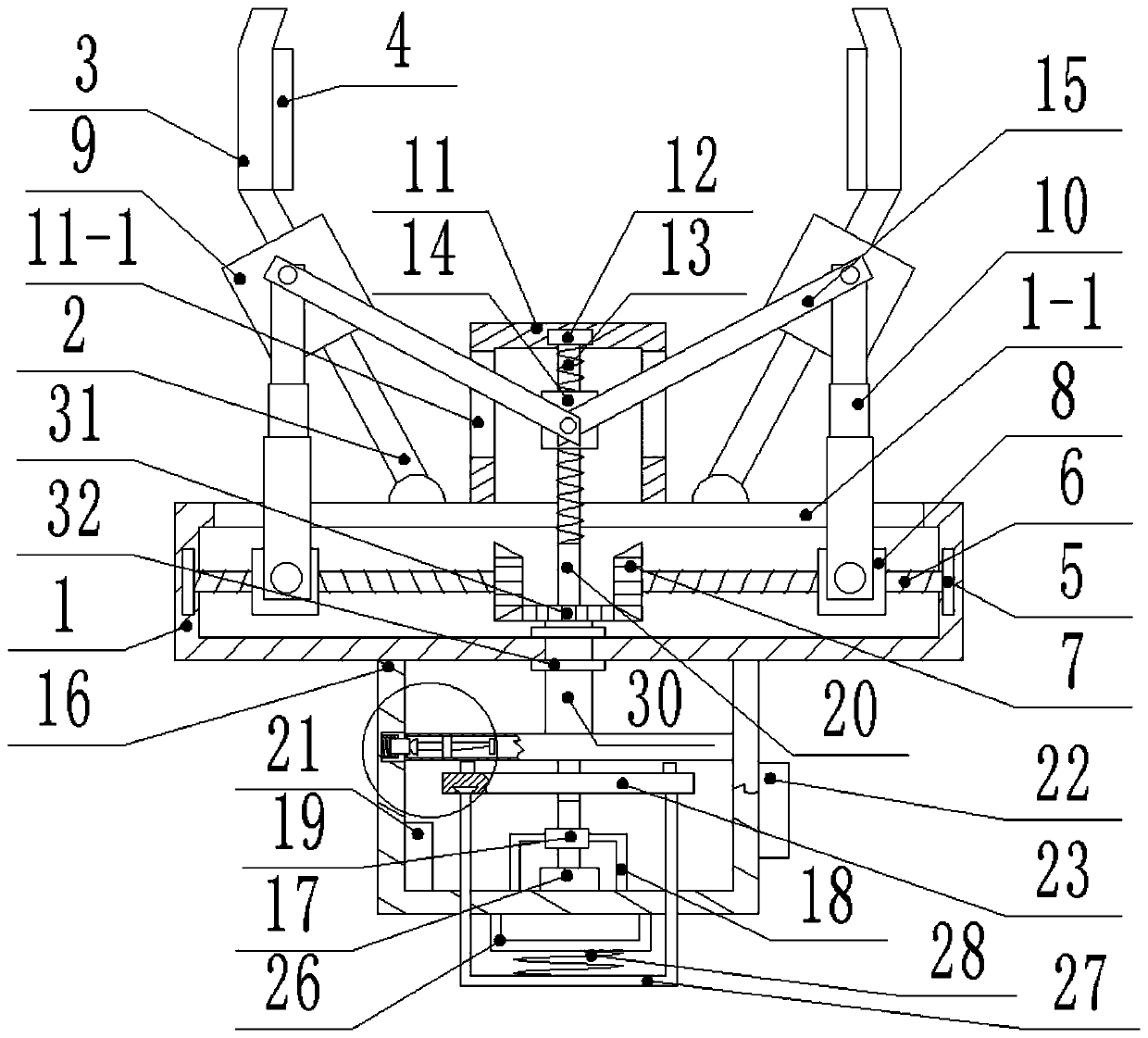

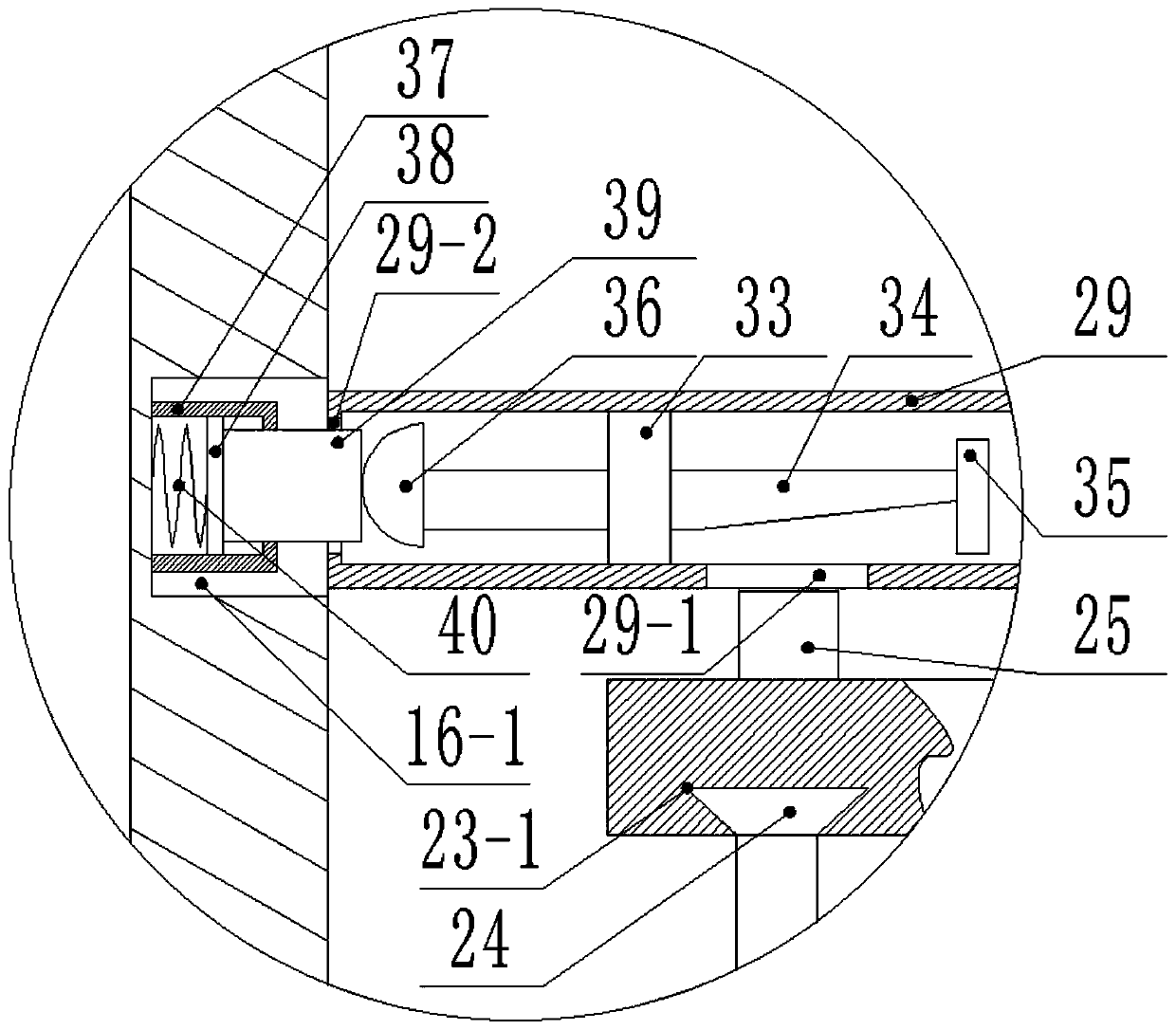

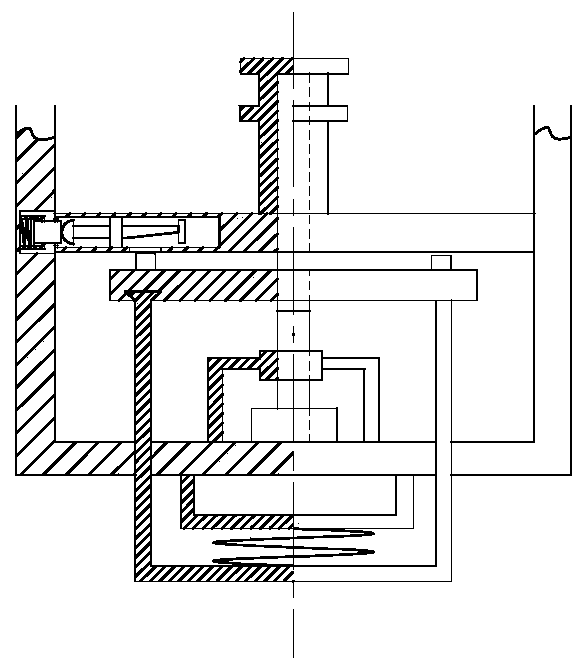

[0021] Such as figure 1 , figure 2 and image 3 As shown, the multifunctional mechanical claw of the present invention includes a clamping part, a transmission part, a traverse part and a clutch part;

[0022] The clamping part includes a first inclined bar 2, claws 3, a first box body 1, a first barrel body 11 and a second barrel body 16; at least two first barrel bodies are symmetrically hinged on the first box body 1. Slanting rods 2, the top of each first slanting rod 2 is fixedly connected with claws 3, and the side walls of the claws 3 are fixedly connected with frosted layers 4, the cross section of the first slanting rods 2 is square, and the first The first sliding block 9 is slidably connected to the inclined rod 2; the top surface of the first box body 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com