Clamp device for friction experiment of drum type friction plate

A technology of clamping device and friction plate, which is applied in the field of brake friction, can solve the problems of not being able to meet the test requirements and shortages, and achieve the effect of simple and reliable structure, convenient disassembly and assembly, and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

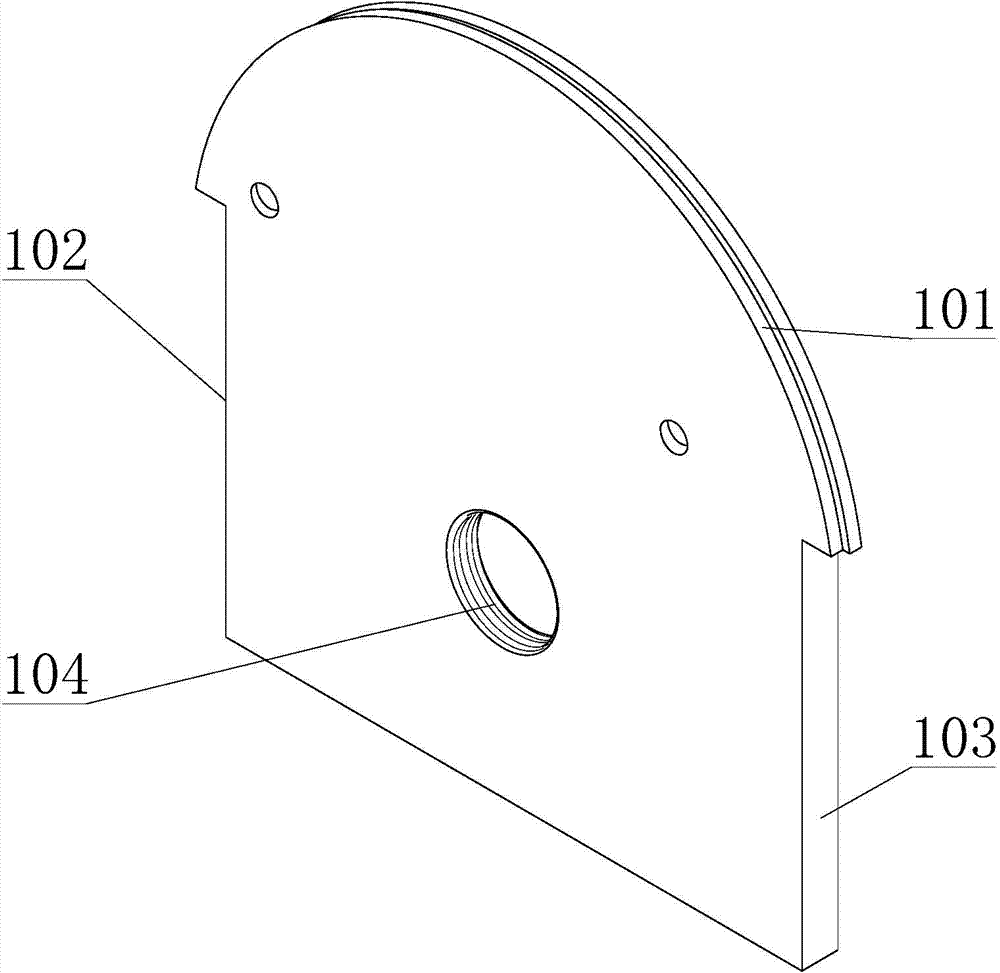

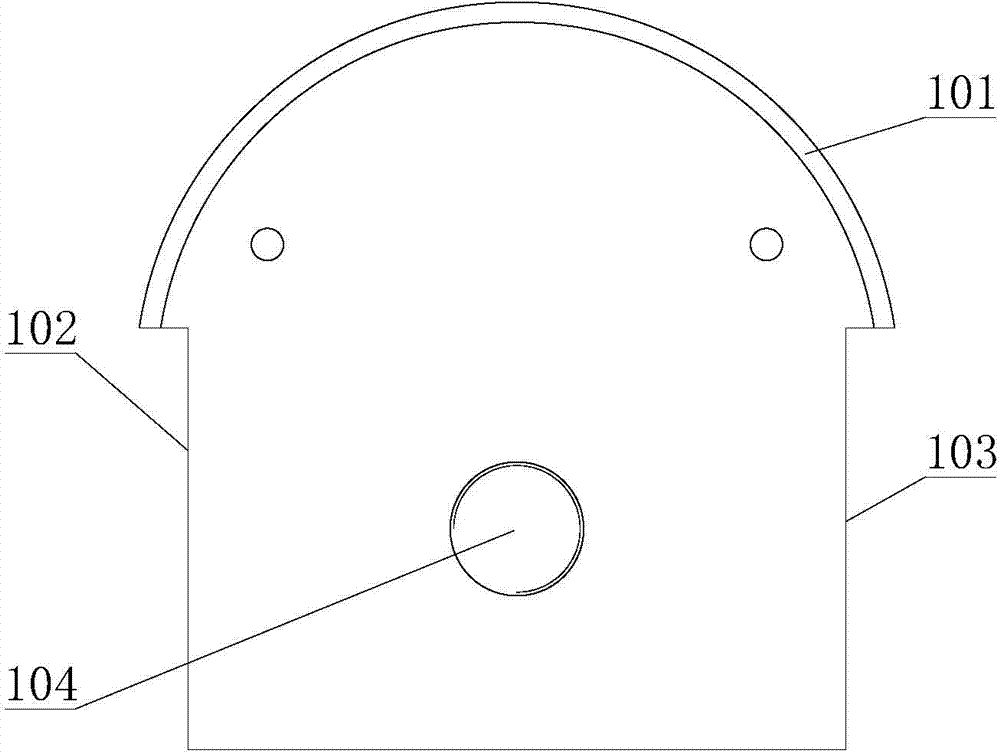

[0027] Such as Figure 1~2 As shown, the horizontally arranged vertical splint 1 is a special-shaped flat plate, and its upper edge 101 is a section of arc-shaped step surface protruding upwards. The left and right ends of the upper edge 101 and the left and right vertical edges 102 of the splint 1, 103 are connected, and the two vertical edges 102 and 103 are located inside the two ends of the upper edge 101 . The top half of the splint 1 is symmetrically provided with two through holes, and the bottom half is provided with threaded mounting through holes 104 .

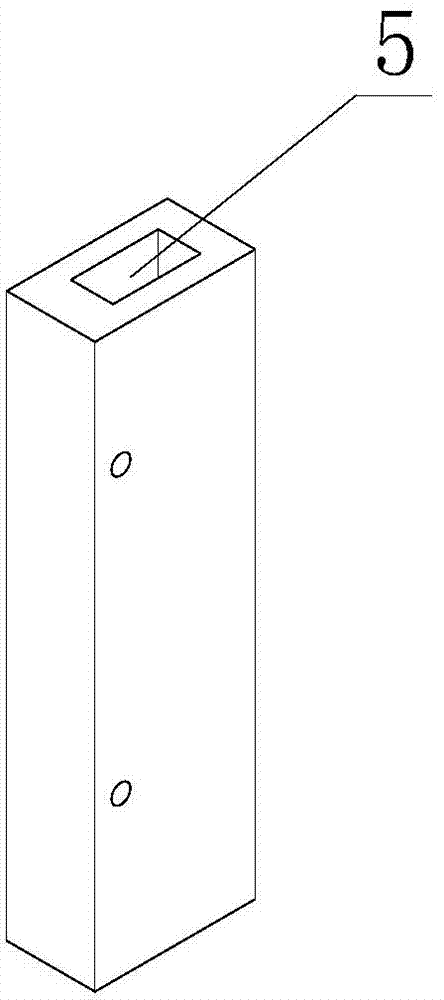

[0028] Such as image 3 , 6 As shown in and 7, a positioning groove 5 is provided at the upper end of the vertical clamping bar 3, and an elastic resisting element 6 protruding toward the notch is loaded into the positioning groove 5. The elastic resisting element 6 in the figure is a coil.

[0029] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com