Processing table for tension spring production

A technology of tensioning springs and processing tables, applied in the direction of wire material processing, manufacturing springs from wires, applications, etc., to achieve the effect of strong practicability, multi-faceted, convenient and multi-directional processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

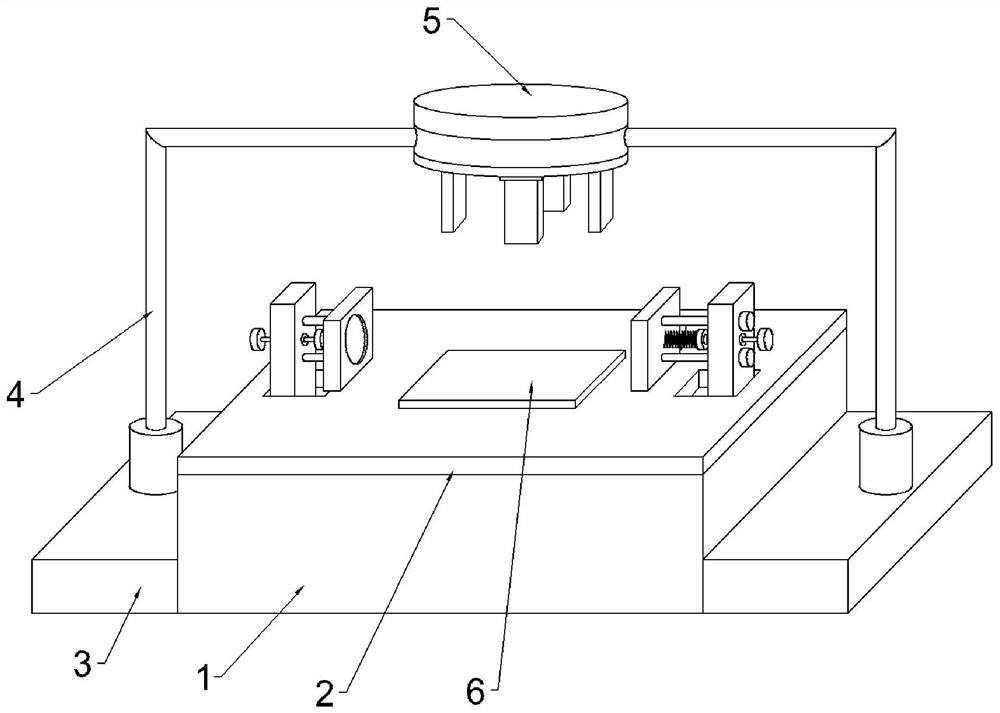

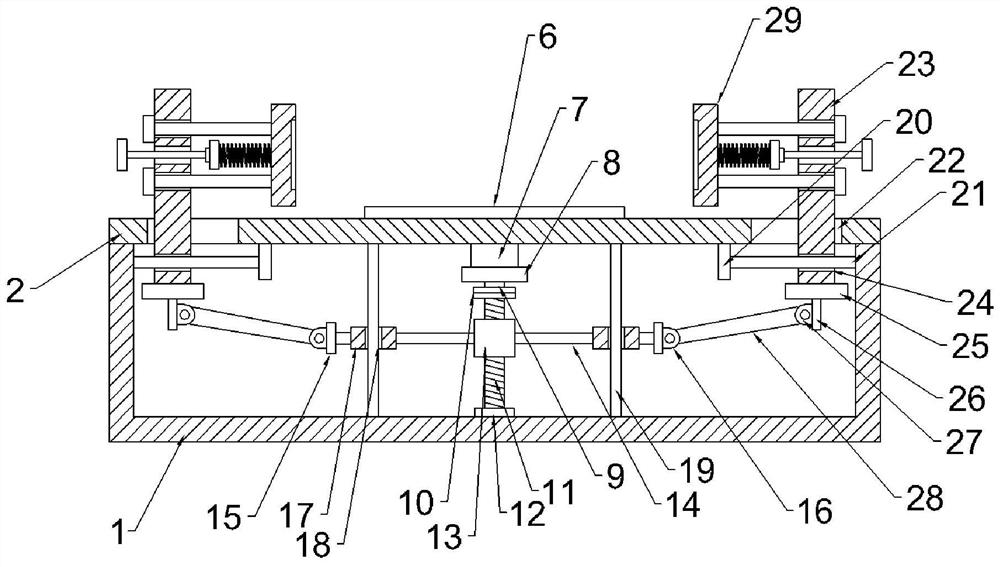

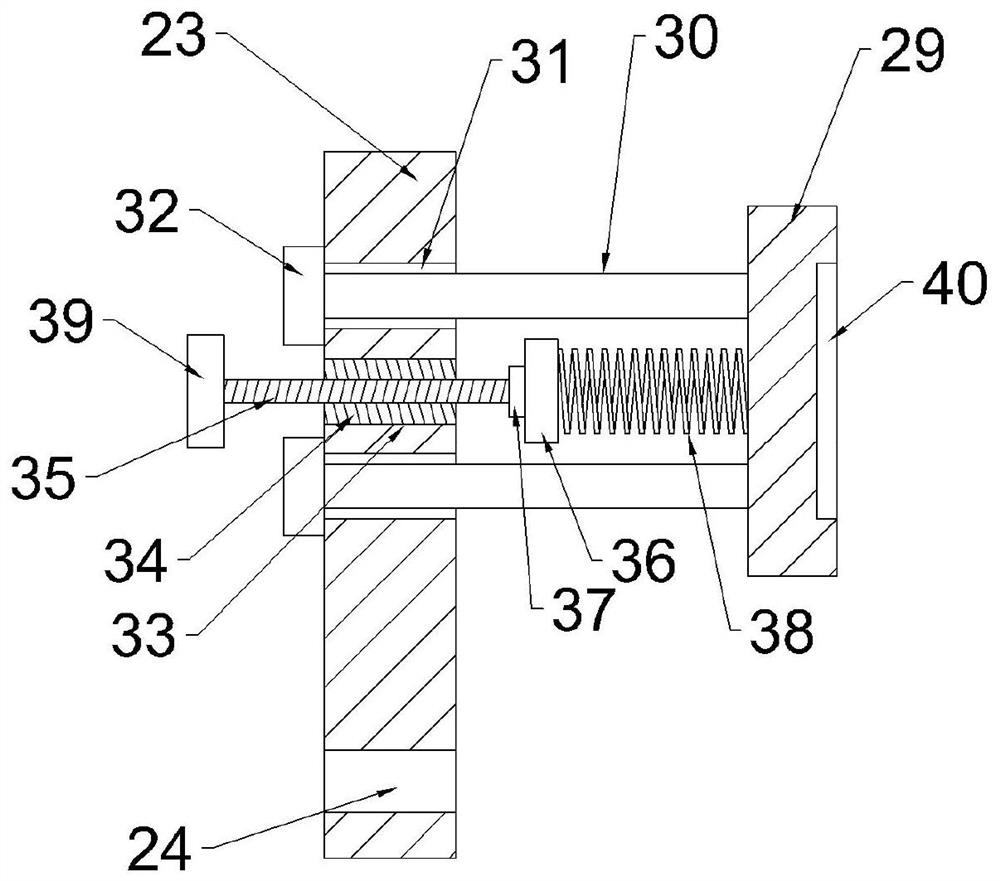

[0024] see Figure 1-Figure 3 , the present invention provides the following technical solutions: a processing table for tension spring production, including a support shell 1, the interior of the support shell 1 is hollow, the top opening, and a support horizontal plate 2 is fixedly installed at the top opening of the support shell 1, An extension plate 3 is fixedly installed on the bottom of the two side walls of the support shell 1 along its width direction, the bottom end surface of the extension plate 3 is flush with the bottom end surface of the support shell 1, and the top center of the extension plate 3 is fixedly installed with The support frame 4, the top center of the support frame 4 is fixedly equipped with a grasping mechanism 5, the grasping mechanism 5 is located di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com