Shift cylinder, drive device, work machine as well as method for operating a work machine

A driving device and control cylinder technology, which is applied in the direction of transmission, fluid transmission, transmission control, etc., can solve problems such as undesired switching, multi-plate clutch accident, transmission hydraulic motor damage, etc., so as to avoid unwanted Effects of decoupling, light weight, and avoidance of switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

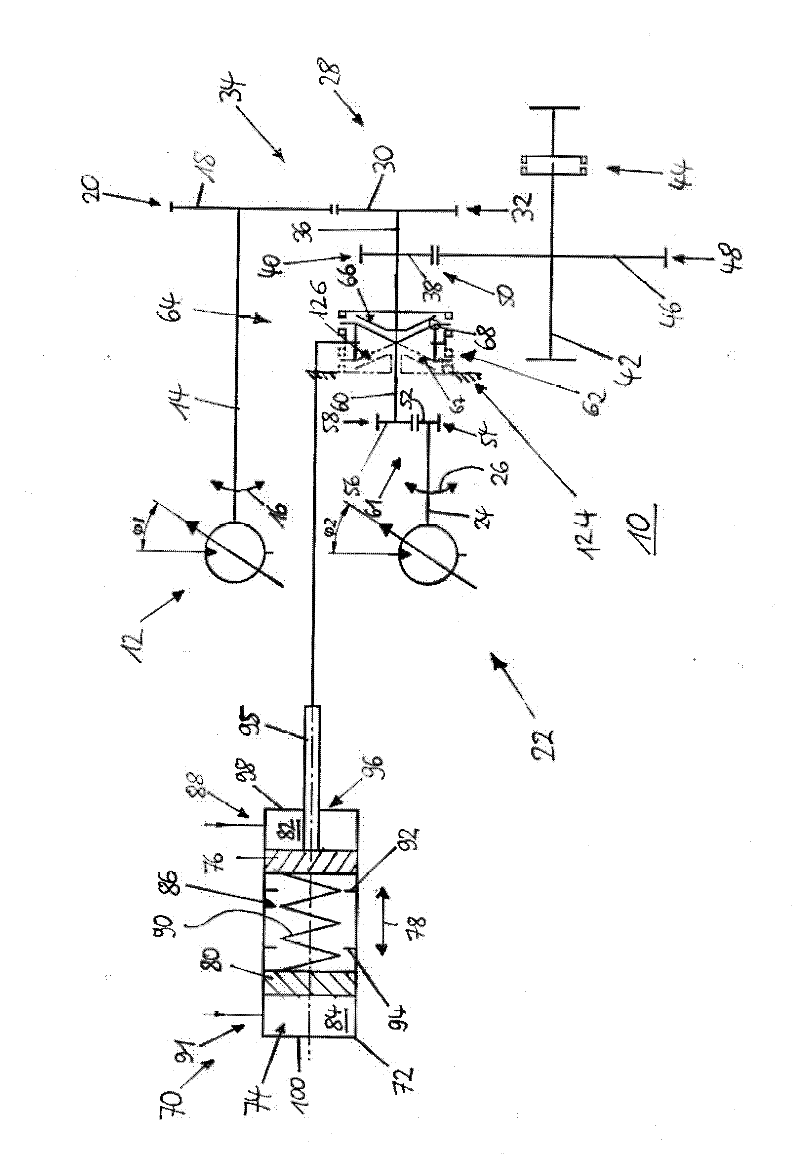

[0057] figure 1 A drive 10 for a self-propelled agricultural machine is shown. The drive device 10 includes a first hydraulic motor 12 which can be driven by hydraulic oil. The hydraulic motor 12 comprises a driven shaft 14 which is rotatable about a rotational axis in a first rotational direction and in a second rotational direction opposite to the first rotational direction. The rotation of the driven shaft is indicated by directional arrow 16 . A gear wheel 18 is connected in a rotationally fixed manner to the output shaft 14 , and has a toothing 20 . The gear 18 is formed as a spur gear, for example.

[0058] The drive device 10 includes a second hydraulic motor 22 which can be driven by hydraulic oil. To drive the first hydraulic motor 12 and the second hydraulic motor 22 , the two hydraulic motors 12 and 22 are supplied with hydraulic oil via only one pump device of the drive device 10 which is common to the hydraulic motors 12 and 22 . The drive device 10 thus has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com