Chinese chestnut opening device

An opening device and chestnut technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of poor control of opening depth and poor adjustability, so as to improve adjustability, good flexibility, prevent The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

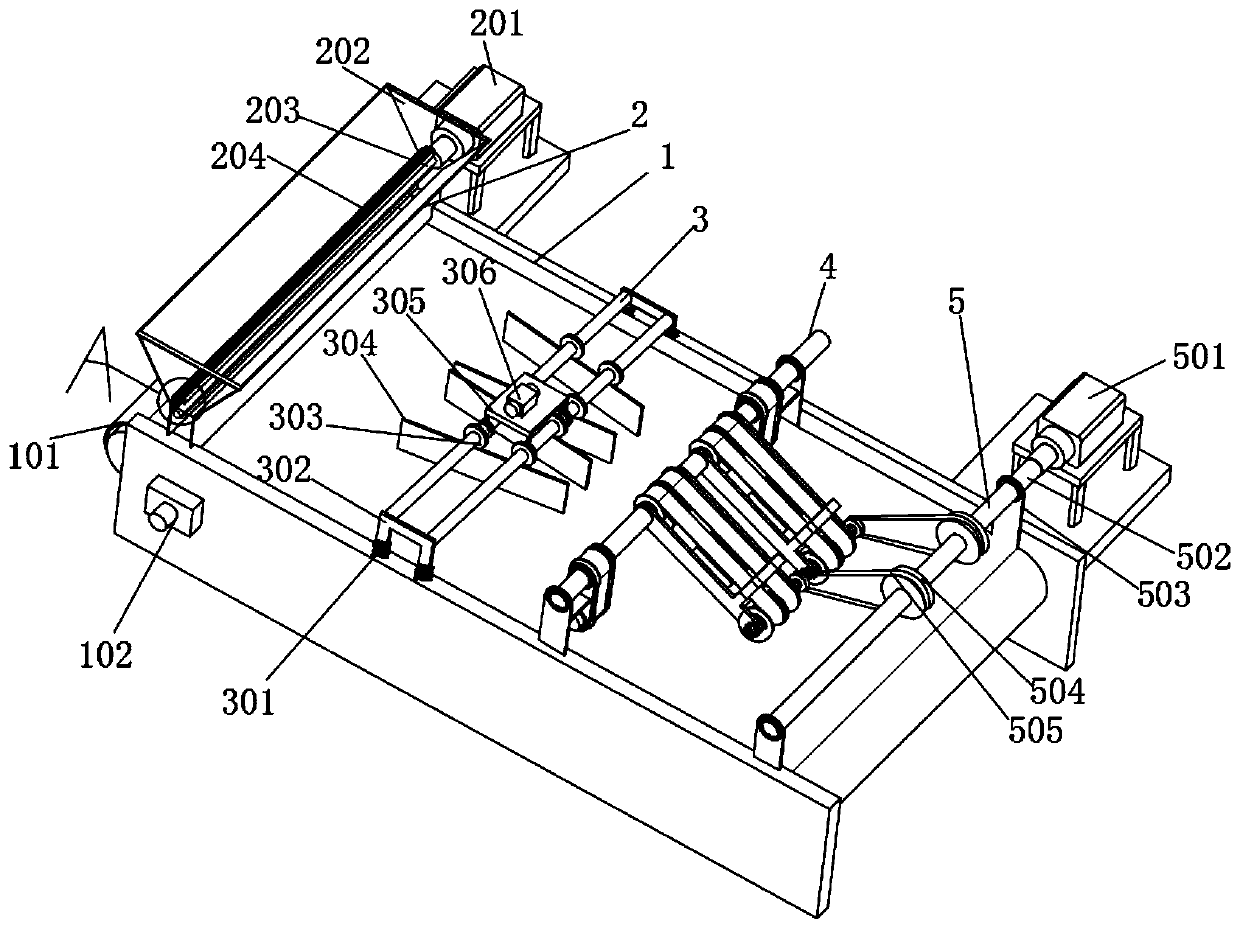

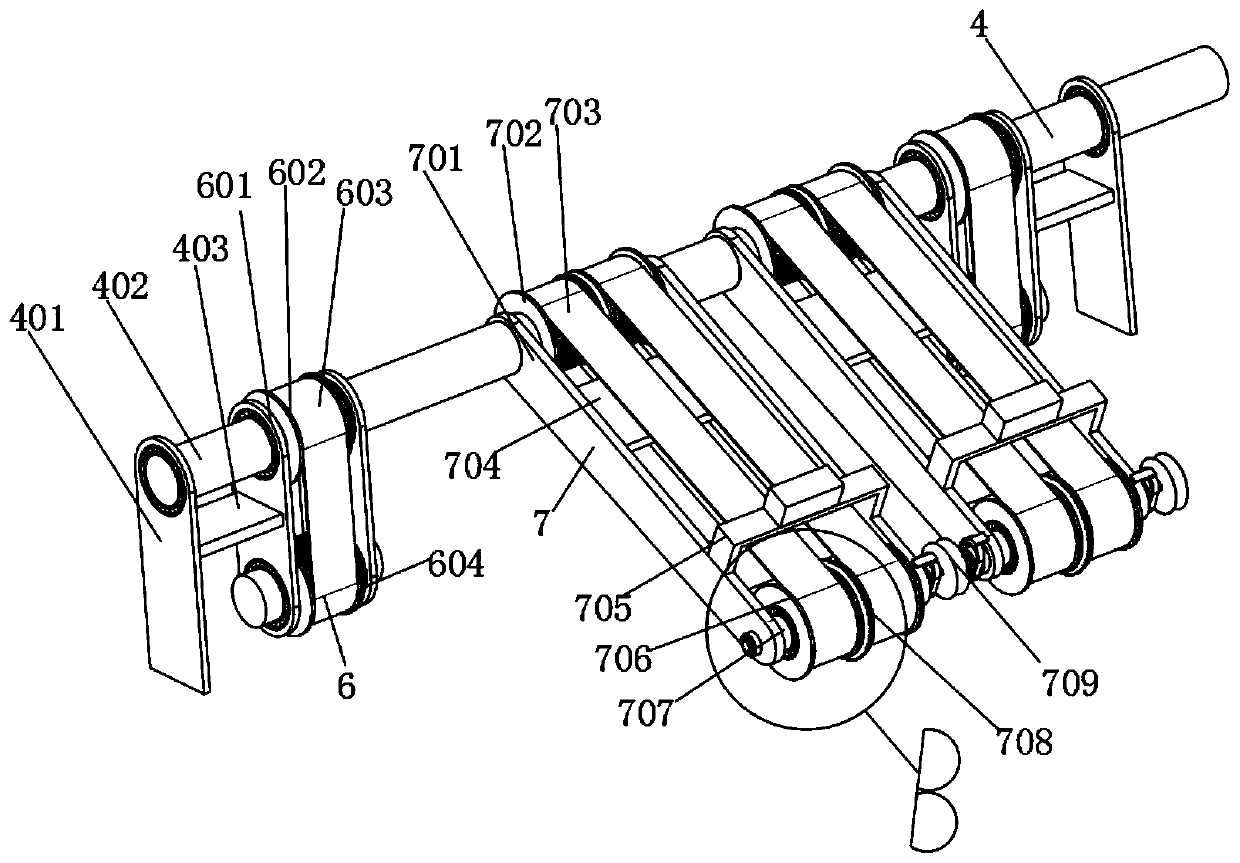

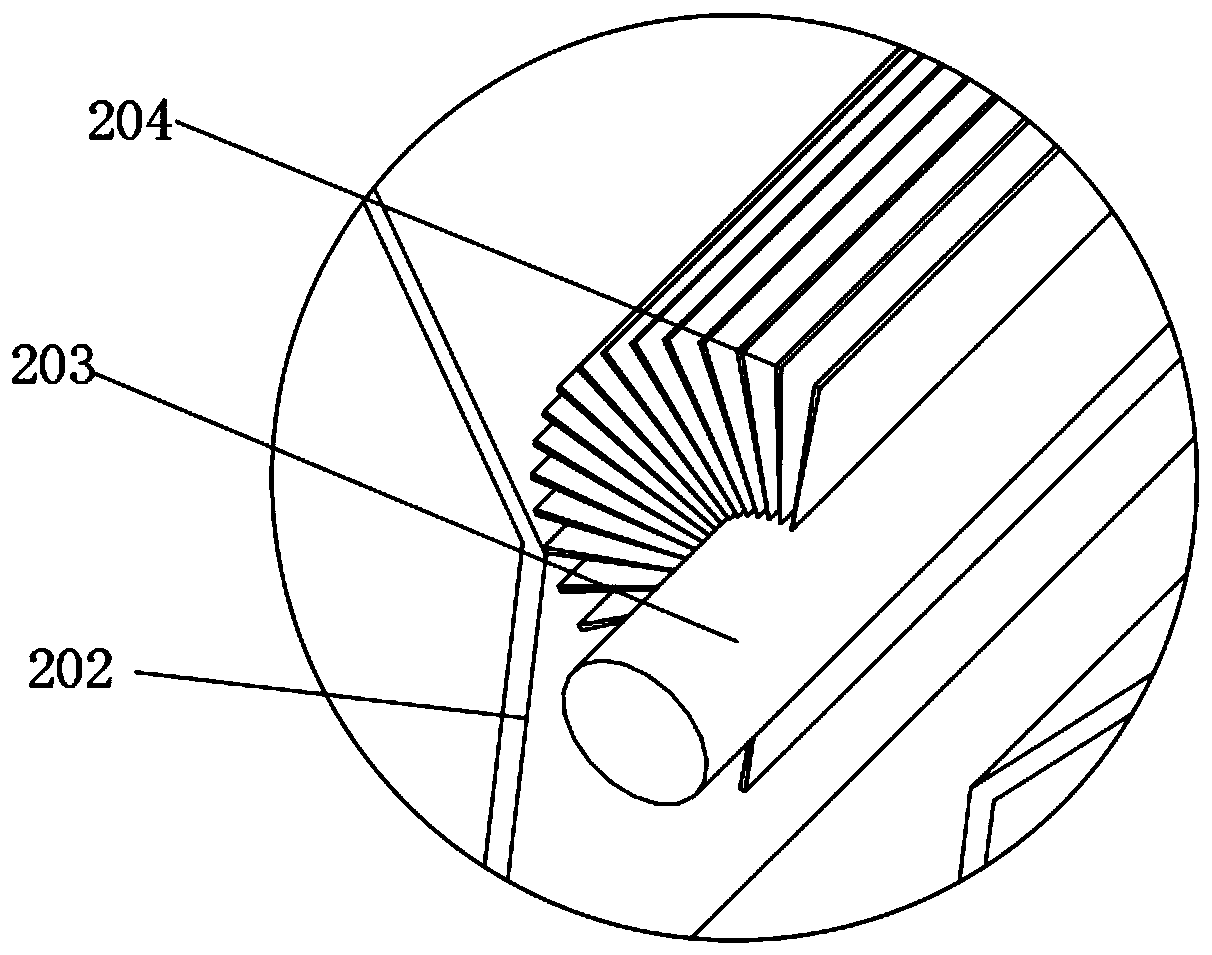

[0040] refer to Figure 1-4 , a chestnut opening device, including two support plates 1, a main conveyor belt 101 is arranged between the two support plates 1, and a switch 102 is fixed on one side of the support plate 1 by bolts, and a switch 102 for controlling the feeding speed is also included. Unloading device 2, carding device 3 for combing chestnuts, cutting device 4 for opening and power device 5 for providing power, cutting device 4 includes central shaft 402, first connecting plate 403 and two fixing plates 401 , and the two fixing plates 401 are respectively fixed on the tops of the two supporting plates 1 by bolts, and one side of the fixing plate 401 has a first installation opening, and a first bearing is clipped in the first installation opening, and the first bearing and the center The shaft 402 is rotatably connected to facilitate the rotation of the central shaft 402, and the fixed plate 401 can play a good role in fixing and supporting. Both sides of the cen...

Embodiment 2

[0046] refer to Figure 5-6 , a chestnut opening device. Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, the fourth bearing is deleted, and a plurality of adjustment devices 8 are also included. The adjustment devices 8 are located on one side of the clamping frame 701, and the adjustment The device 8 includes an adjustment frame 801, a fixed block 803 and an adjustment bearing 805. The fixed block 803 is welded on one side of the clamping frame 701, and the fixed block 803 is welded to the adjustment frame 801. The two ends of the adjustment frame 801 are arc-shaped structures, and the fixed The upper and lower ends of the block 803 and the adjustment frame 801 are all provided with threaded holes, the threaded holes are internally threaded with a threaded rod 802, the threaded rod 802 can rotate in the threaded hole according to different needs, adjust the position of the bearing 805 and fix it, The bottom of the threaded rod 80...

Embodiment 3

[0049] refer to Figure 7-8 , a chestnut opening device. Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, the transmission device 6 and the first connecting plate 403 are deleted, and a motor plate, a driving motor 103 and a second transmission wheel 107 are also included. , the motor plate is fixed on one side of the support plate 1 by bolts, and the top of the motor plate is fixed to the active motor 103 by bolts, and one end of the output shaft of the active motor 103 is fixed with a drive roller 105 by bolts for driving the main conveyor belt 101. The roller 105 is connected to the main conveyor belt 101 by transmission, the output shaft of the driving motor 103 is sleeved with a first transmission wheel 104, the outer wall of the first transmission wheel 104 is connected with a power belt 106, and the second transmission wheel 107 is sleeved on the central shaft 402 outside, drive the first transmission wheel 104 to rotate thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com