Machining method for tin target

A processing method and tin target technology, which is applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of reduced performance of tin targets and high surface roughness of tin targets, and achieve good lubrication and cooling effects And good lubrication effect, improve the effect of process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

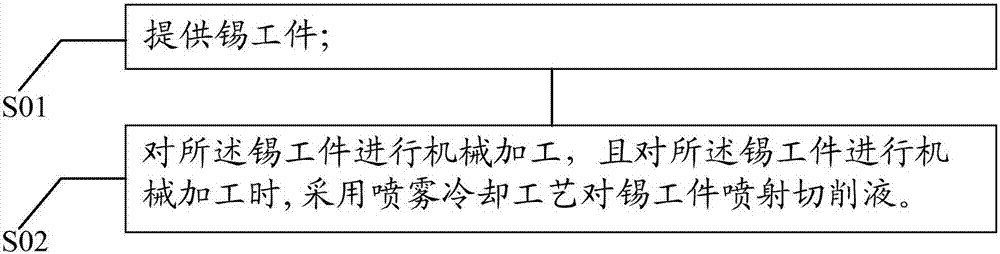

Method used

Image

Examples

Embodiment Construction

[0033] As mentioned in the background art, currently formed tin targets have relatively high surface roughness, which degrades the performance of the tin targets.

[0034] In one embodiment, during the machining process of the tin workpiece, a cutting fluid is poured into the cutting area of the tin workpiece, and the material of the cutting fluid is grease.

[0035] The function of cutting fluid includes lubrication and cooling.

[0036] The research found that the roughness of the tin target formed by the method of the above embodiment is high because:

[0037] Tin is a kind of soft metal material. When the tin workpiece is machined, the tin workpiece is very easy to deform and has a large friction with the corresponding tool, so that the tin adheres to the tool used; at the same time , due to the deformation and friction of the tin workpiece, a large amount of heat will be generated, making the surface of the tin workpiece softer, which intensifies the degree of tin adhe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com