PCB structure capable of preventing tin connection of adjacent pads

A technology for PCB boards and pads, applied in the field of PCB structure that can prevent adjacent pads from connecting tin, can solve problems such as easy soldering, achieve reliable solder joints, prevent soldering, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

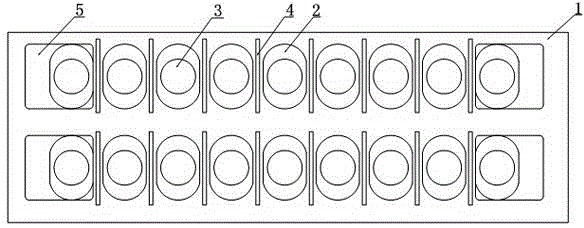

[0023] like figure 2 As shown, the present invention includes a PCB board main body 1 , solder pads 2 and a silk screen white oil layer 4 . The pad 2 is arranged on the PCB board main body 1, and the pad 2 is provided with a solder hole 3 for the insertion of the solder leg of the plug-in component, and the solder pad 2 is penetrated into the solder hole 3 by the solder leg of the plug-in component Finally, the plug-in components are welded to the main body of the PCB board. There are multiple pads 2, and all the pads are arranged in sequence to form a pad group. The direction of the pad arrangement is parallel to the direction of the PCB board going through the furnace. Each pad is in the shape of a racetrack, and two adjacent pads are arranged in such a way that the straight sides of the raceway face face each other, which can effectively increase the distance between adjacent pads and prevent tin connection.

[0024] Further, since two adjacent pads are arranged in a race...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com