Production process for copper-clad plates

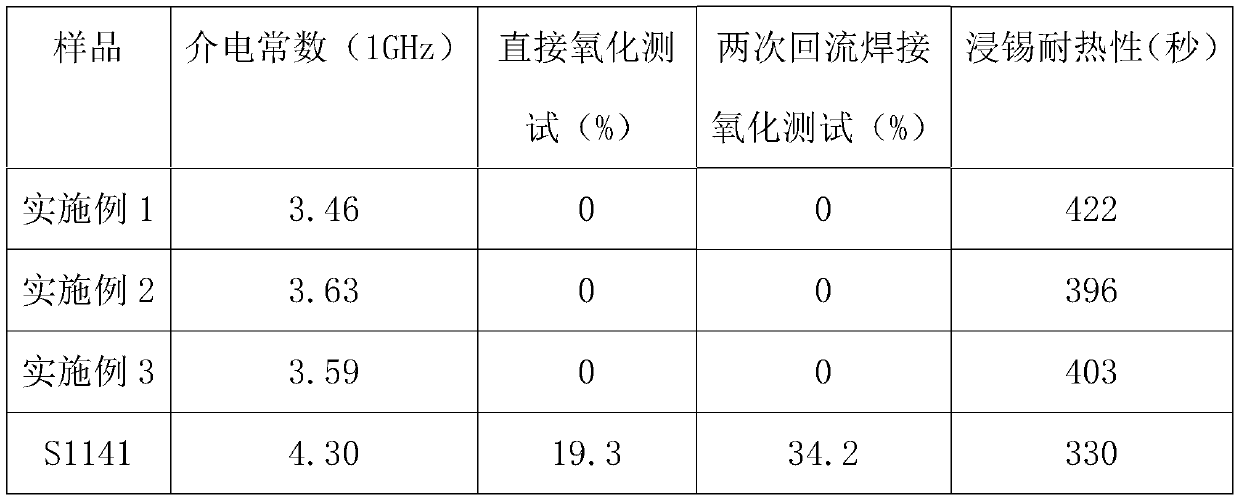

A treatment process and copper clad laminate technology, which is applied in the field of copper clad laminate production and treatment process, can solve the problems of false soldering, easy oxidation, virtual soldering, etc., and achieve good heat resistance, low dielectric constant, and reduce dielectric loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of copper-clad laminate production process is provided in embodiment 1,

[0045] S1: Provide copper foil, glass fiber paper, glass fiber cloth, and prepare the first resin glue, the second resin glue, and OSP prepreg;

[0046] The second resin glue is composed of the following components in parts by weight:

[0047] 23 parts of phosphorus-containing epoxy resin, 8 parts of spherical silicon powder, 6 parts of phenolic epoxy resin, 7 parts of polyarylate, 15 parts of alicyclic epoxy resin and 7 parts of graphene;

[0048] The first resin glue is composed of the following components in parts by weight:

[0049] 12 parts of phenol, 6 parts of cardanol, 2 parts of spherical silicon powder, 7 parts of alicyclic epoxy resin and 5 parts of formaldehyde; the epoxy equivalent of the alicyclic epoxy resin is 150g / eq;

[0050] Described OSP prepreg is made up of following components by weight:

[0051] 25 parts of 2,3-dihydro-1,4 naphthoquinone, 4 parts of ethylenediamin...

Embodiment 2

[0066] Embodiment 2 provides a kind of copper-clad laminate production process,

[0067] S1: Provide copper foil, glass fiber paper, glass fiber cloth, and prepare the first resin glue, the second resin glue, and OSP prepreg;

[0068] The second resin glue is composed of the following components in parts by weight:

[0069] 20 parts of phosphorus-containing epoxy resin, 5 parts of spherical silicon powder, 5 parts of phenolic epoxy resin, 6 parts of polyarylate, 10 parts of alicyclic epoxy resin and 5 parts of graphene;

[0070] The first resin glue is composed of the following components in parts by weight:

[0071] 11 parts of phenol, 5 parts of cardanol, 2 parts of spherical silicon powder, 6 parts of cycloaliphatic epoxy resin and 3 parts of formaldehyde; the epoxy equivalent of the cycloaliphatic epoxy resin is 100g / eq;

[0072] Described OSP prepreg is made up of following components by weight:

[0073] 20 parts of 2,3-dihydro-1,4 naphthoquinone, 3 parts of ethylenedi...

Embodiment 3

[0088] Embodiment 3 provides a copper clad laminate production process,

[0089] S1: Provide copper foil, glass fiber paper, glass fiber cloth, and prepare the first resin glue, the second resin glue, and OSP prepreg;

[0090] The second resin glue is composed of the following components in parts by weight:

[0091] 25 parts of phosphorus-containing epoxy resin, 10 parts of spherical silicon powder, 10 parts of phenolic epoxy resin, 8 parts of polyarylate, 20 parts of alicyclic epoxy resin and 10 parts of graphene;

[0092] The first resin glue is composed of the following components in parts by weight:

[0093] 13 parts of phenol, 8 parts of cardanol, 2 parts of spherical silicon powder, 8 parts of alicyclic epoxy resin and 4 parts of formaldehyde; the epoxy equivalent of the alicyclic epoxy resin is 200g / eq;

[0094] Described OSP prepreg is made up of following components by weight:

[0095] 30 parts of 2,3-dihydro-1,4 naphthoquinone, 5 parts of ethylenediamine, 40 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com