Automatic grinding mechanism for welding gun electrode cap

An electrode cap and welding torch technology, which is applied to the field of automatic grinding mechanism for welding torch electrode caps, can solve the problems of increased cost, reduced production efficiency, poor thermal conductivity, etc., and achieves the effects of high degree of automation, long service life and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

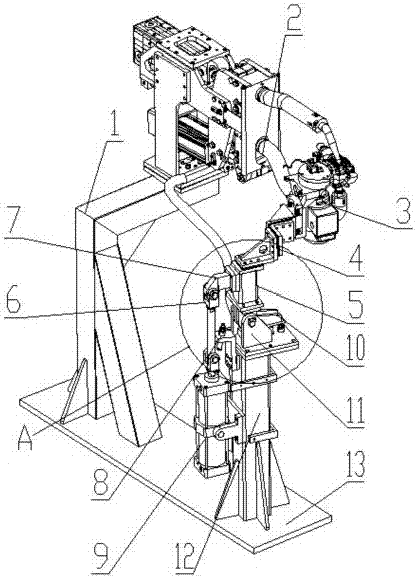

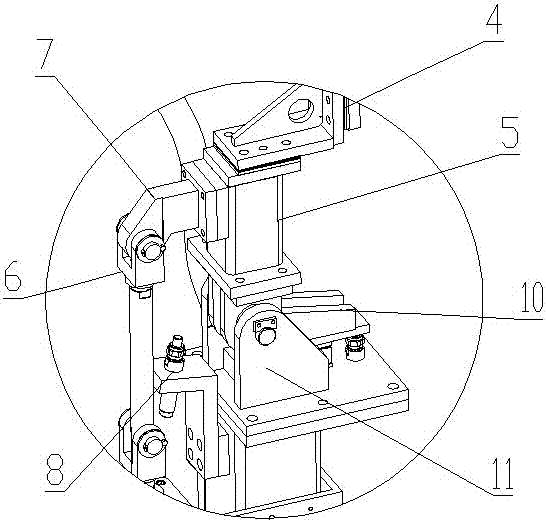

[0012] see figure 1 , figure 2 , a welding torch electrode cap automatic grinding mechanism, comprising: a welding torch dresser 3, an adjustment block 4, an adapter block 5, and a top block 7; it is characterized in that: the welding torch dresser 3 is fixed on the first part of the adjustment block 4 One end, the second end of the adjustment block 4 is fixed on the upper part of the adapter block 5 by bolts, the lower end of the adapter block 5 is hinged with the fixing seat 11 through a connecting pin, and the side of the adapter block 5 is fixed There is a top block 7, the transfer block 5 can rotate along the connecting pin, the top block 7 is an L-shaped structure, the bottom of the top block 7 is hinged with the connector 6, and the connector 6 is fixed on the piston rod of the cylinder 9 superior.

[0013] The cylinder 9 is fixed on the side of the bracket 11 , and the fixing base 11 is fixed on the top of the bracket 11 .

[0014] A second buffer 10 for counteract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com