Mask ear strap welding machine

A technology for welding machines and earbands, which is applied to household components, tools for sewing clothes, household appliances, etc., can solve problems such as low production efficiency, inefficiency, and inability to meet the production needs of enterprises, achieving high success rate, The effect of improving production efficiency and reducing product defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

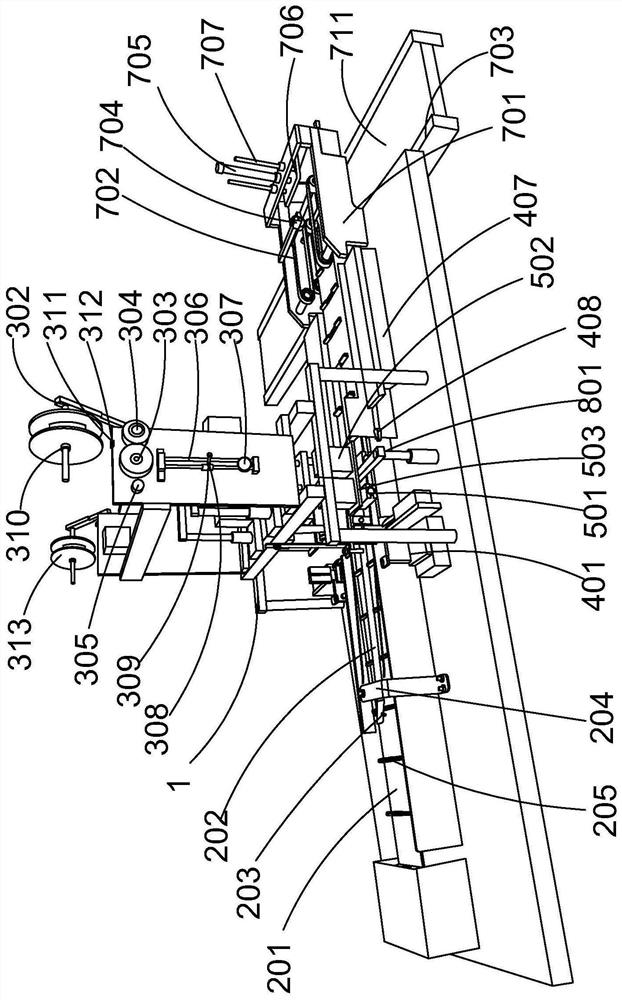

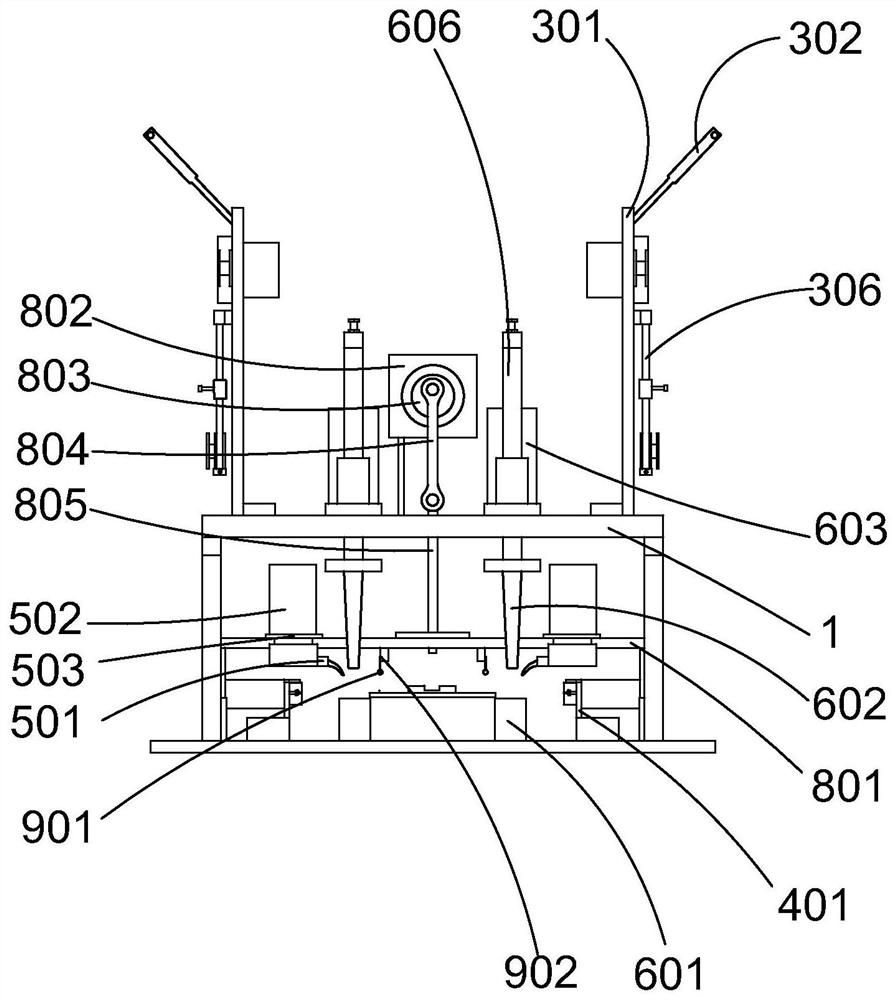

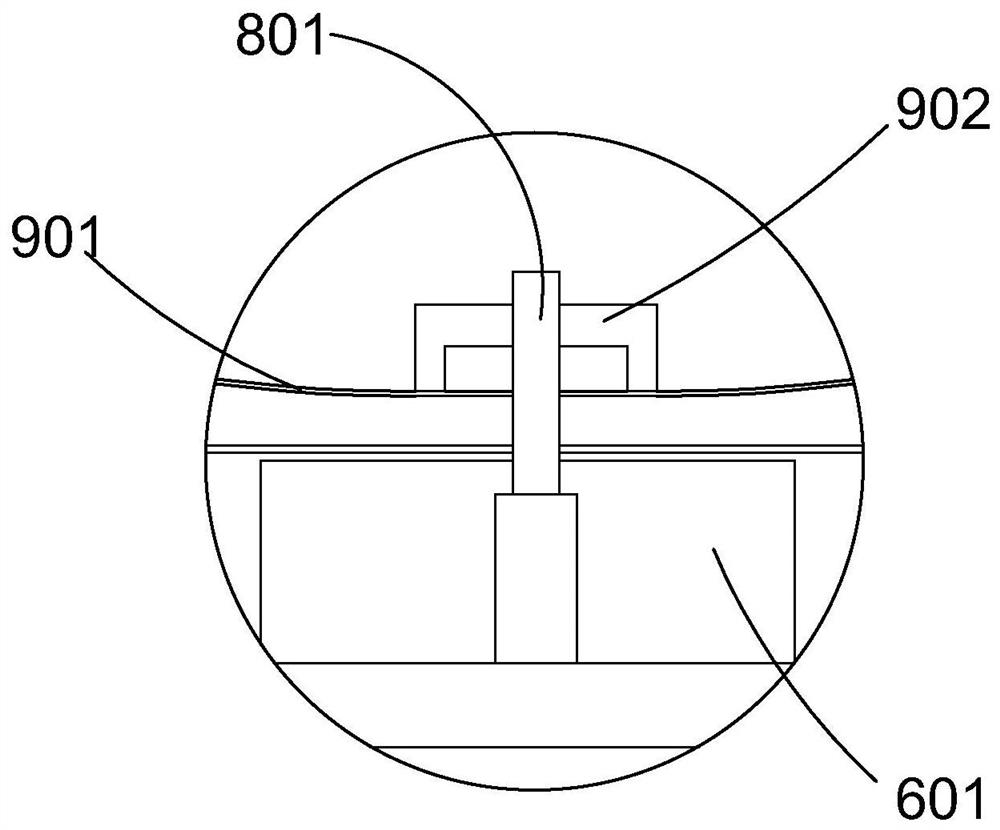

[0044] refer to Figure 1 to Figure 8 , a mask earband welding machine, comprising a frame 1, wherein, according to the assembly line, the input device for inputting the mask body is arranged on the frame successively, and the earband ropes for pulling the earband rope are arranged on both sides of the frame The traction device, the ear strap cord positioning device that guides the ear strap cord into both sides of the input device, and the ear strap that bends the ear strap cord into a U shape and guides it into the end of the mask body on one side of each ear strap cord positioning device. The strap turning device, the welding device installed on the frame to weld the U-shaped ear straps to the mask body, and the output device to output the masks with the ear straps welded, the frame is equipped with controls to turn over the ear straps The device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com