Patents

Literature

56results about How to "Simple motion track" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

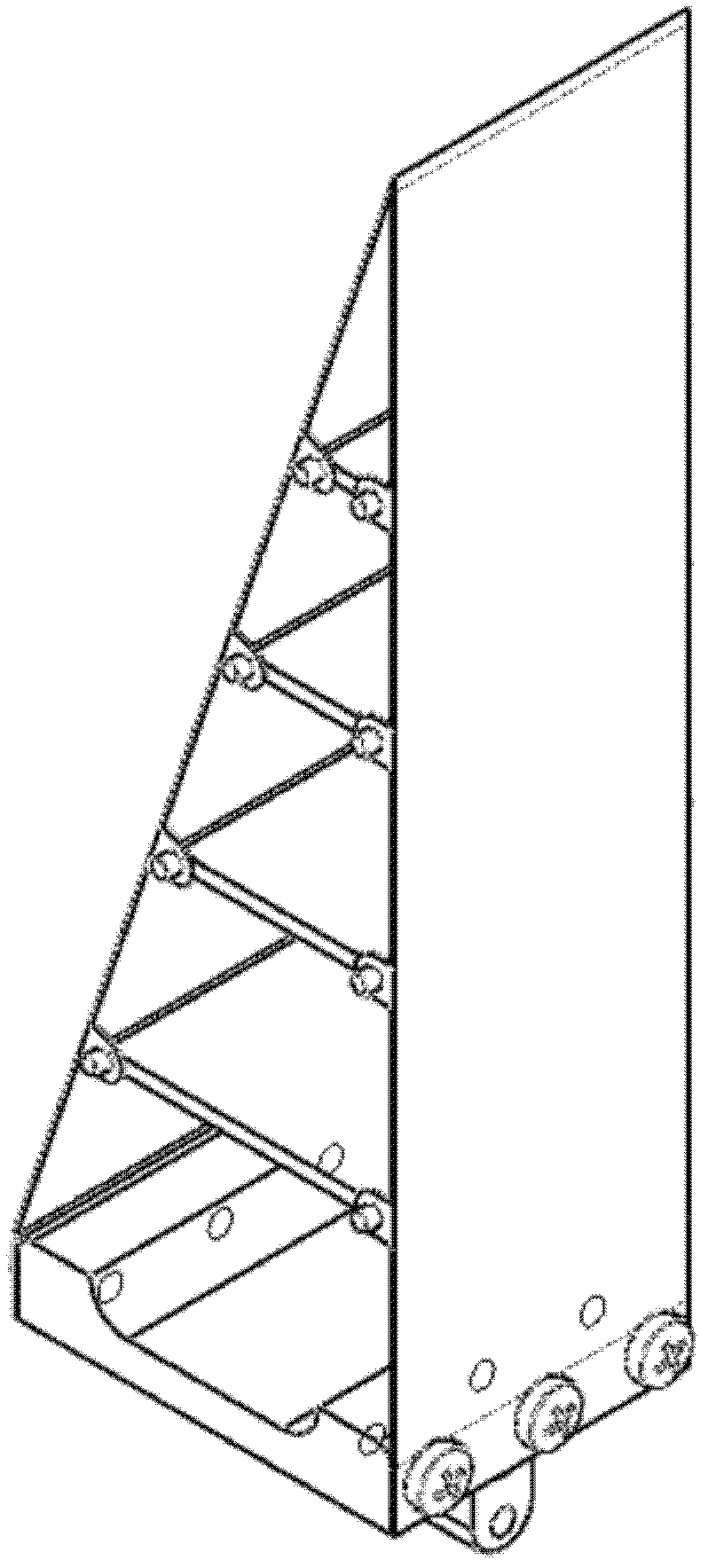

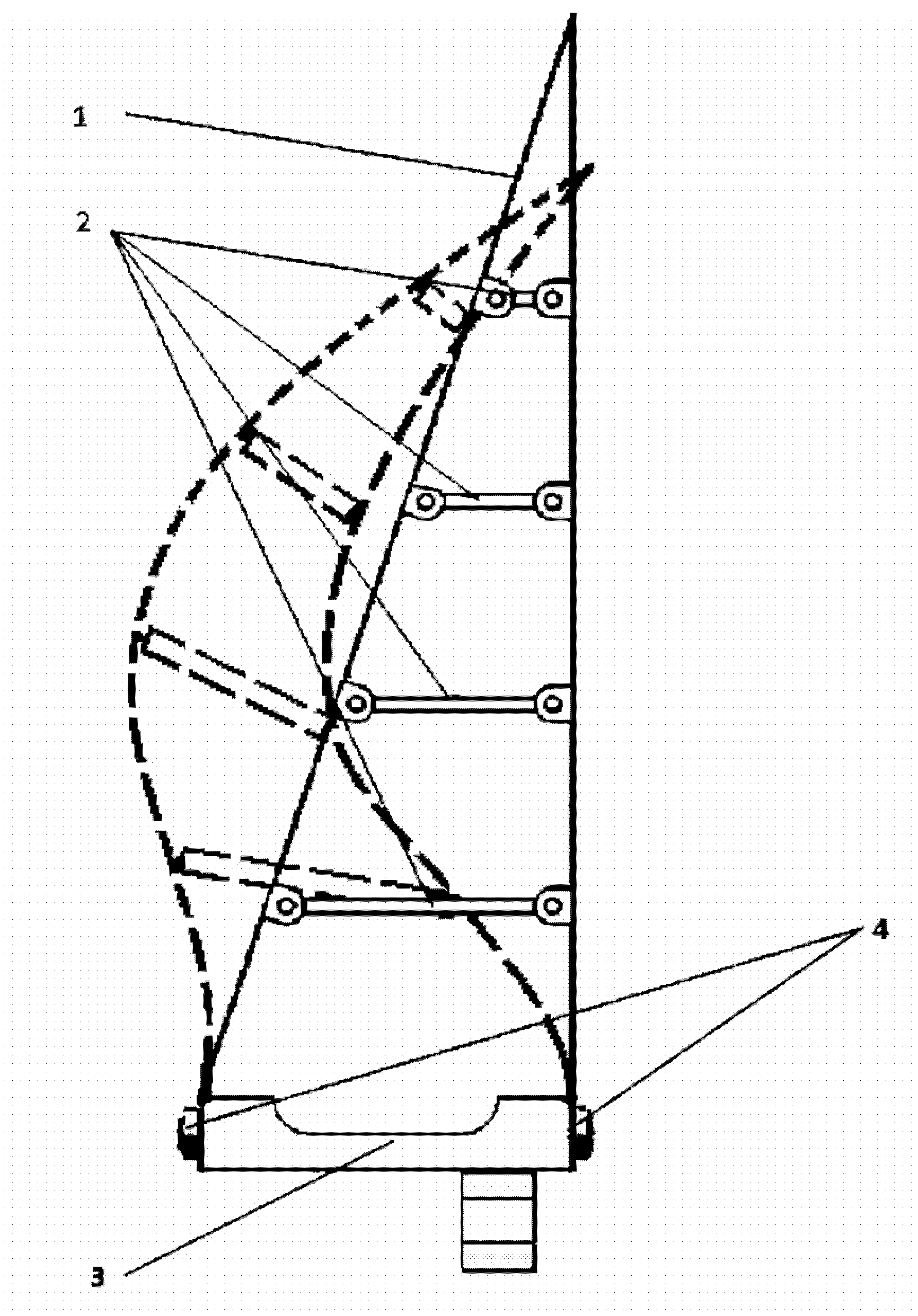

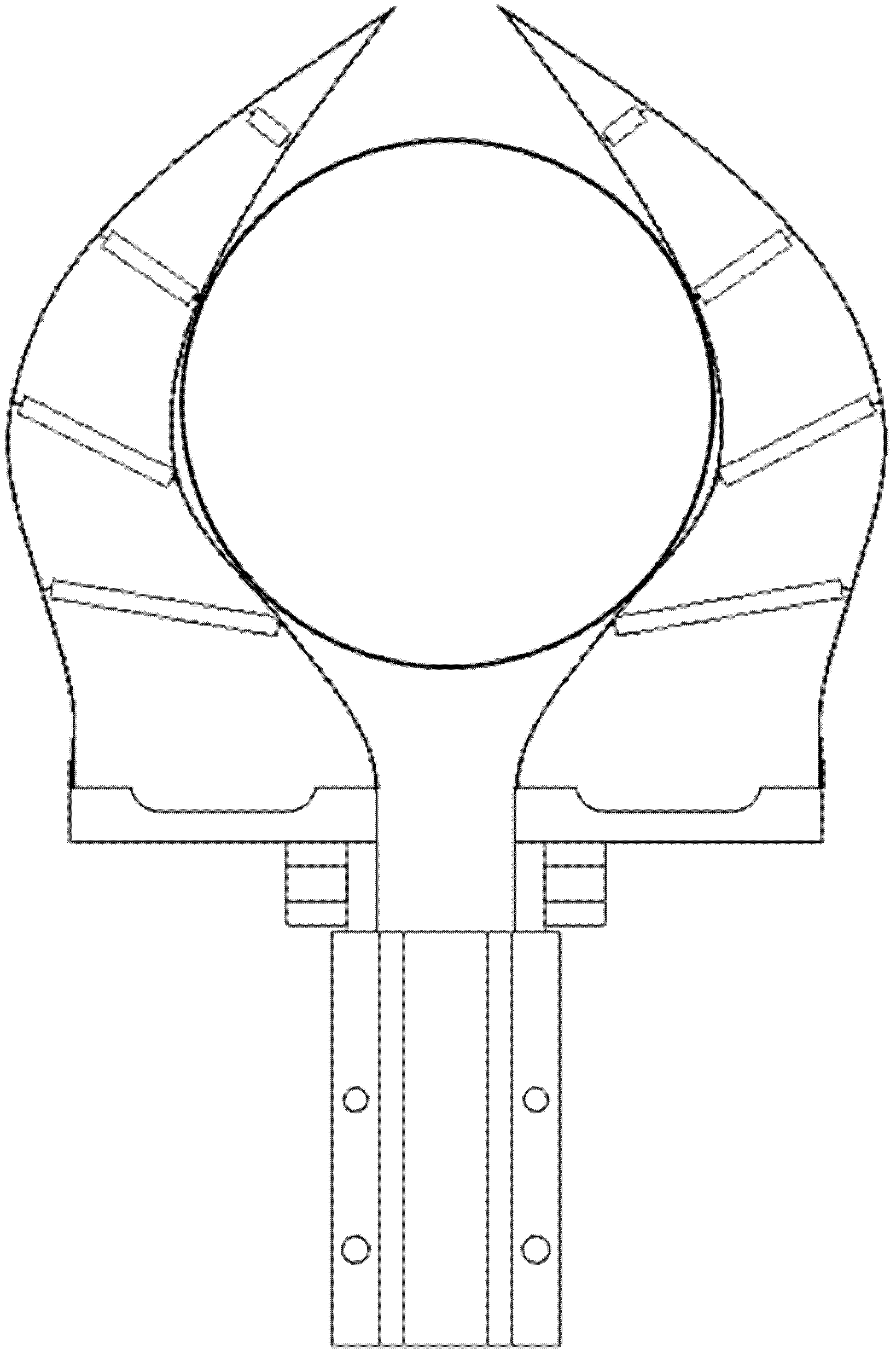

Flexible mechanical finger adaptive to shapes of clamped objects

A flexible mechanical finger adaptive to shapes of clamped objects belongs to the technical field of intelligent robots and comprises a flexible outer wall, a multi-stage rigid beam, a finger base and a screw. The finger is triangular, two edges, except for the bottom edge, of the triangular finger are made of high-elasticity materials, and high elastic deformation can be realized under the effect of external force. The multi-stage rigid beam and the finger base are made of rigid materials unsuitable for elastic deformation. Two or a plurality of mechanical fingers are selected to act fittingly. When the mechanical fingers grab a workpiece, vertical surfaces of flexible outer walls of the mechanical fingers contact with the workpiece by the aid of an external power source and elastically deform, stress on the workpiece is uniform due to the fact that the flexible outer walls are tightly attached to the surface of the workpiece, multi-stage rigid plates rotate relative to the flexible outer walls when the flexible outer walls deform, accordingly, the top ends of triangular structures of the flexible outer walls are closed downwards, and the workpiece is wrapped. The fingers are separated from the workpiece by the aid of the external power source, and initial states of the fingers are restored. The flexible mechanical finger is simple in structure and is adaptive.

Owner:BEIJING UNIV OF TECH

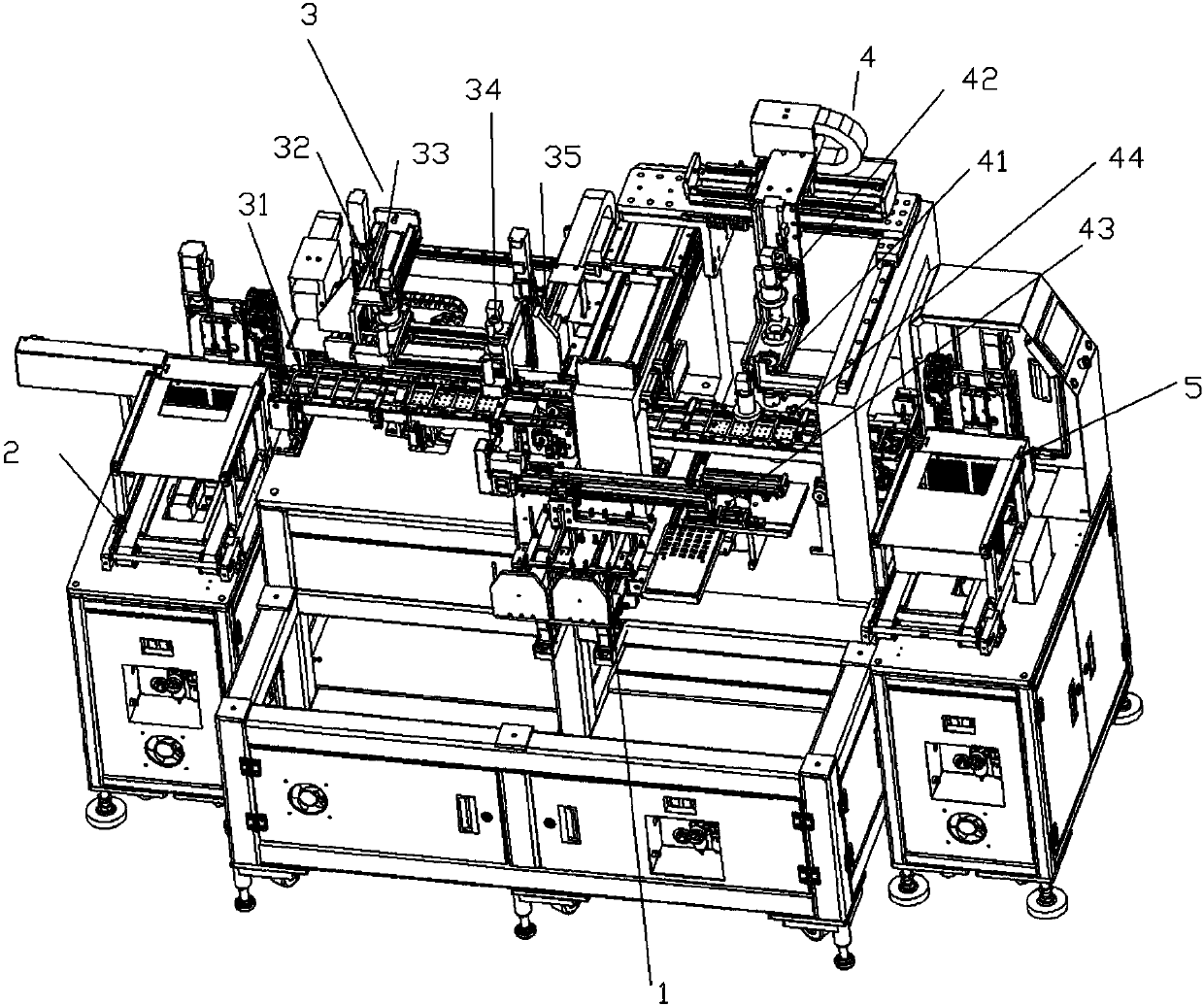

Full-automatic surface-mounting machine electrically connected with controller

ActiveCN105120608ASimple structureLow costPrinted circuit assemblingElectrical and Electronics engineeringSurface mounting

Disclosed in the invention is a full-automatic surface-mounting machine electrically connected with a controller. The machine is used for pasting a specially-shaped element to a substrate; and a connecting sheet enabling the specially-shaped element and the substrate to be in contact tightly is arranged between the specially-shaped element and the substrate. The full-automatic surface-mounting machine comprises a substrate transmitting device, a connecting sheet fetching and delivery device, a specially-shaped element fetching and delivery device, a film tearing device, and an identification and positioning device. The connecting sheet and the specially-shaped element are in contact based on cooperation of the specially-shaped element fetching and delivery device with the connecting sheet fetching and delivery device. The film tearing device tears a protection film of a specially-shaped element to expose a bonding layer of the specially-shaped element; and the part, with the exposed bonding layer, of the specially-shaped element is pasted to the substrate by the bonding layer and the connecting sheet based on cooperation of the specially-shaped element fetching and delivery device with the substrate transmitting device. The identification and positioning device carries out identification and positioning on pasting mounting of the connecting sheet and the specially-shaped element and the pasting mounting of the specially-shaped element and the substrate when the specially-shaped element is pasted to the substrate. The machine has advantages of simple and compact integrated structure, effectively reduced cost, and improved pasting precision.

Owner:DONGGUAN WORLD PRECISION MACHINERY

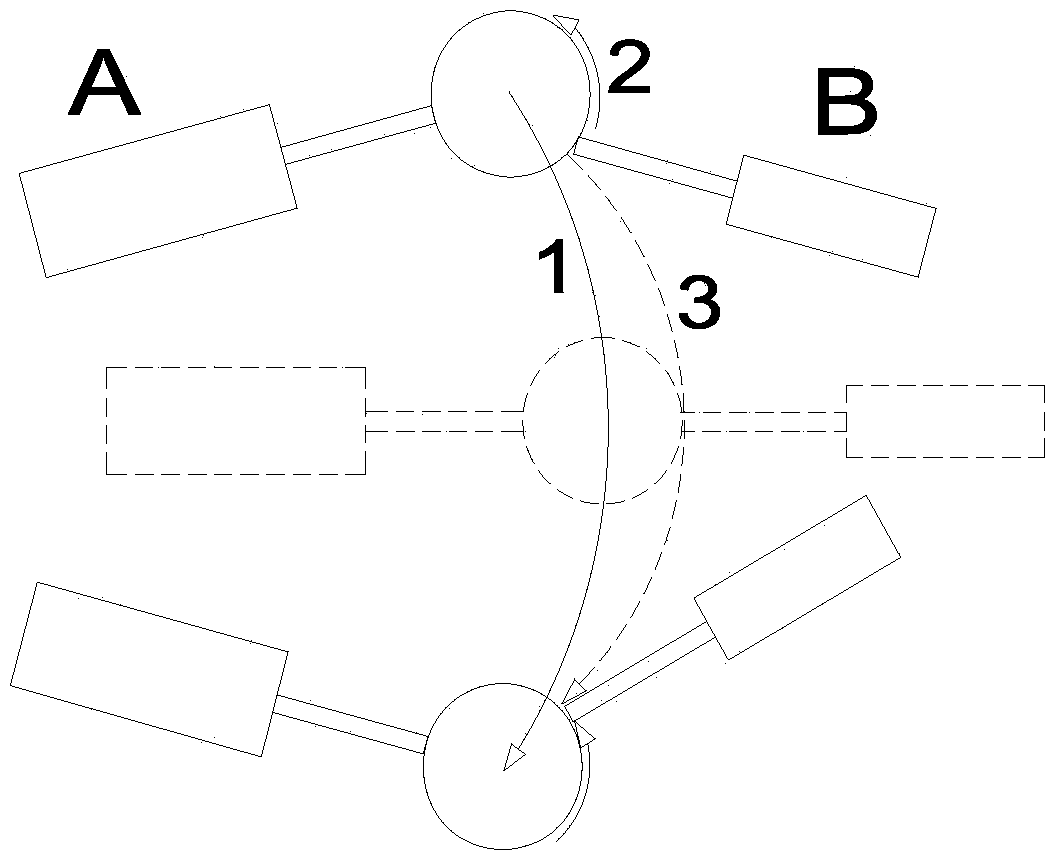

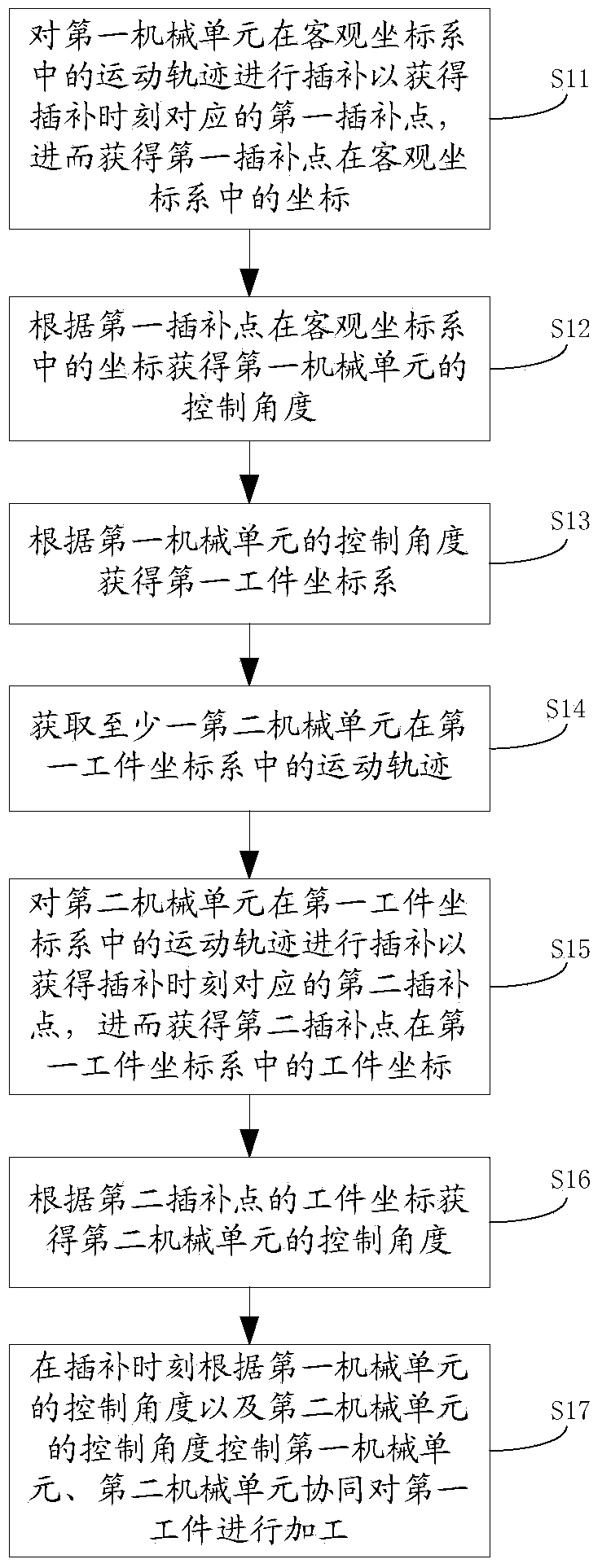

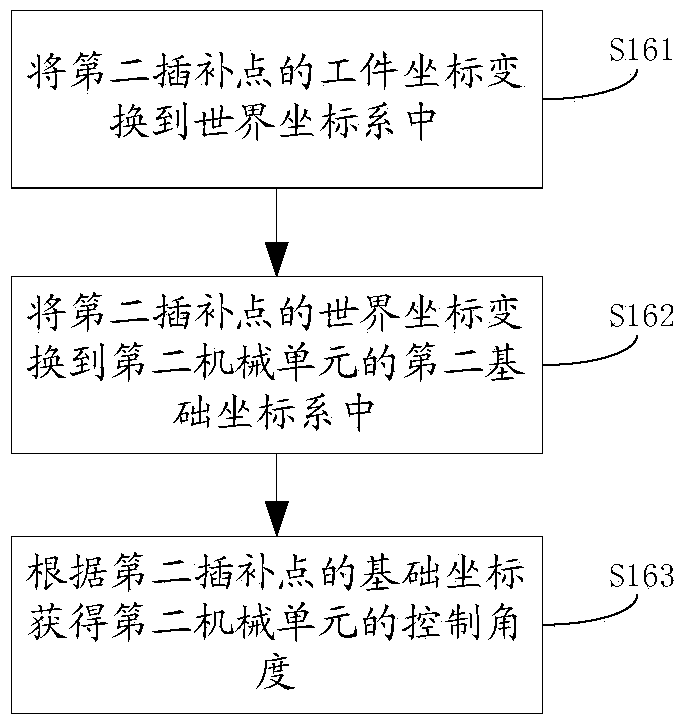

Workpiece collaborative machining method and system and collaborative control method and device

InactiveCN104238460ARealize synchronous control motionReduce complexityNumerical controlSynchronous controlEngineering

The invention discloses a workpiece collaborative machining method. The workpiece collaborative machining method comprises the steps that interpolation is carried out on the motion trail of a first mechanical unit in an objective coordinate system so that a first interpolation point can be obtained, and then the control angle of the first mechanical unit and a first workpiece coordinate system are obtained; interpolation is carried out on the motion trail of a second mechanical unit in the first workpiece coordinate system so that a second interpolation point corresponding to the interpolation moment can be obtained, and then the workpiece coordinates of the second interpolation point in the first workpiece coordinate system are obtained; the control angle of the second mechanical unit is obtained according to the workpiece coordinates of the second interpolation point; the first mechanical unit and the second mechanical unit are controlled to collaboratively machine a first workpiece at the interpolation moment according to the control angle of the first mechanical unit and the control angle of the second mechanical unit. The invention further discloses a workpiece collaborative machining system and a collaborative control method and device for multiple mechanical units. According to the workpiece collaborative machining method and system and the collaborative control method and device for multiple mechanical units, synchronous control over the multiple mechanical units can be easily achieved so that the machining efficiency can be improved, and practicability is high.

Owner:BEIJING A&E TECH

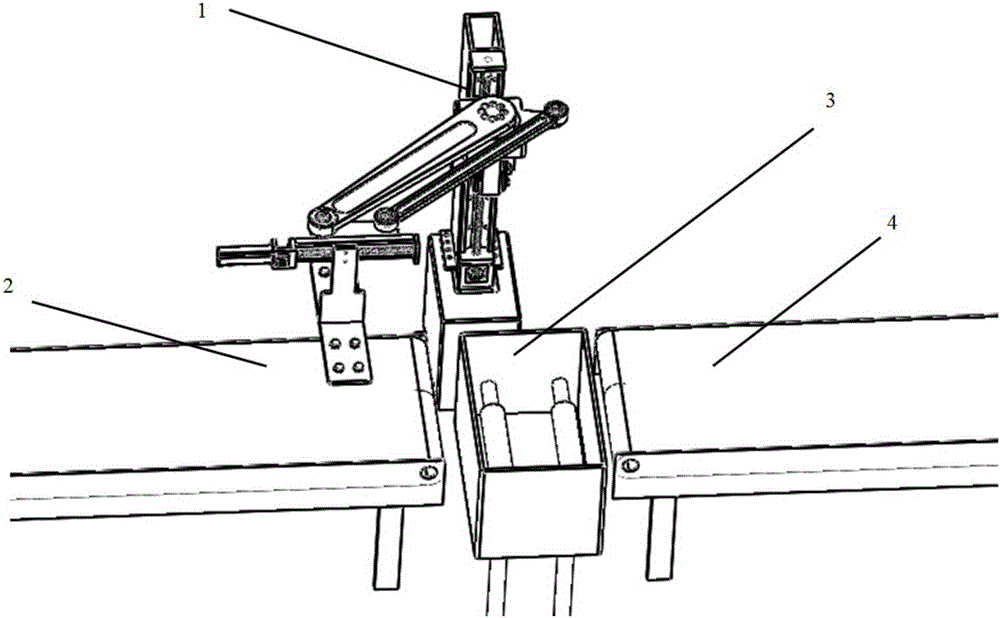

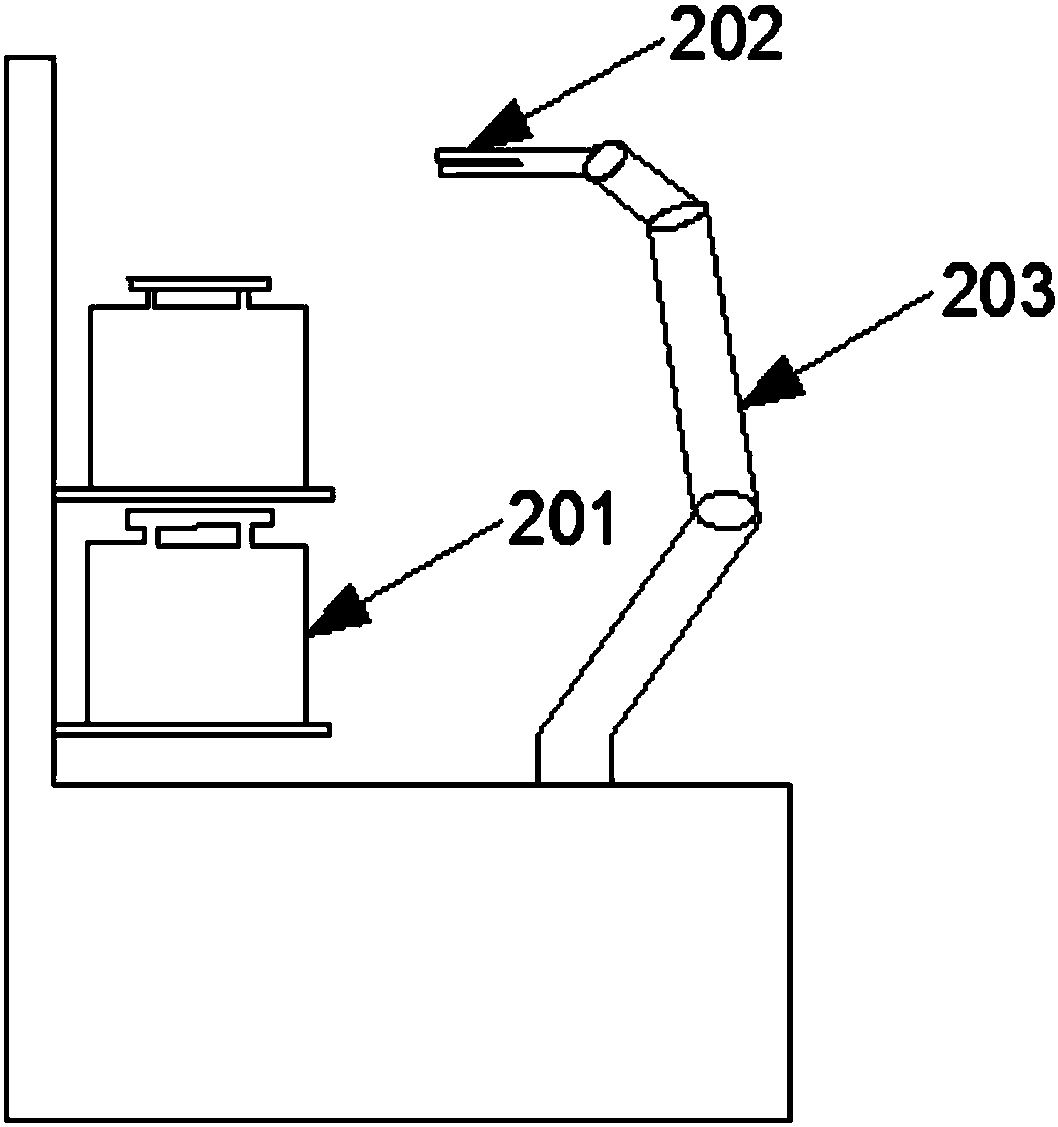

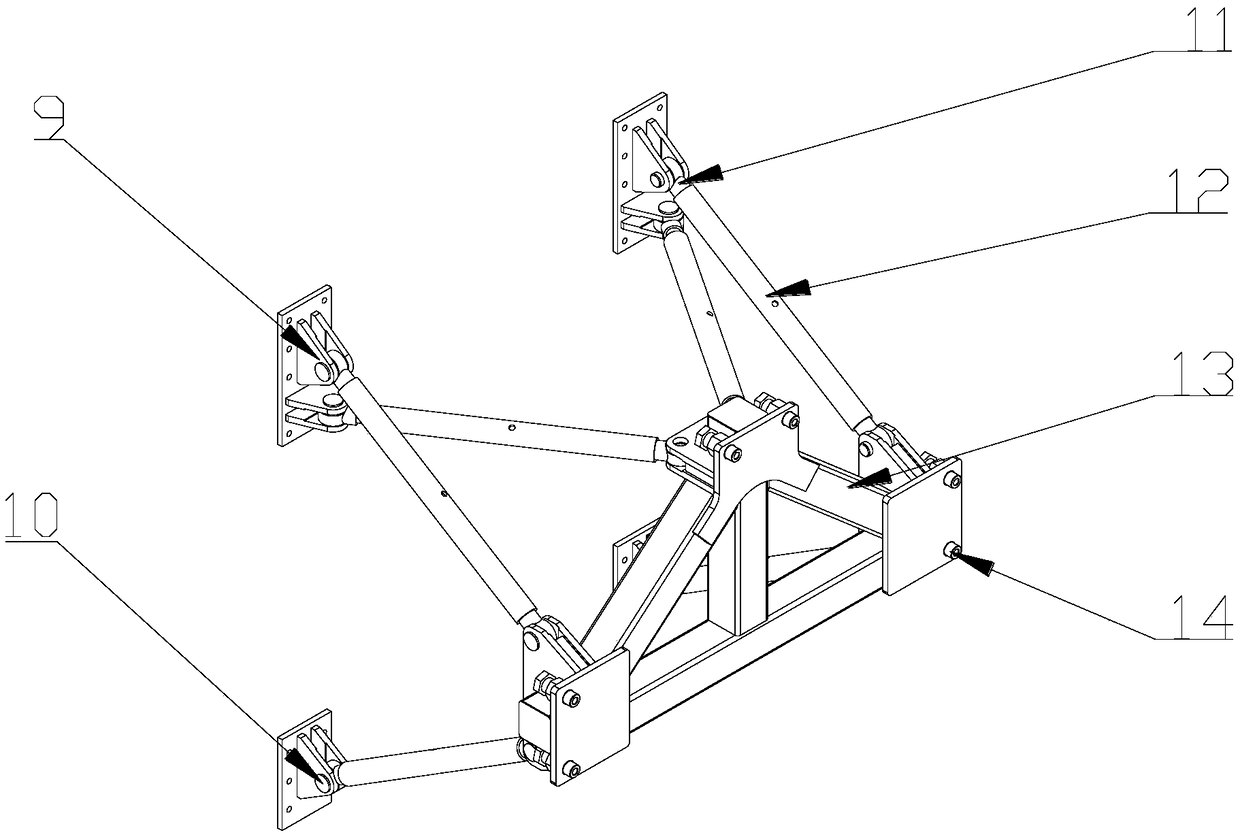

Grabbing and placing device for deburring

InactiveCN105196165ASmall inertiaIncrease freedomGrinding feedersThree degrees of freedomEngineering

The invention discloses a grabbing and placing device for deburring, which belongs to the technical field of industrial robot application. The grabbing and placing device comprises an input conveyor belt, a brush machine, an output conveyor belt and a moving support three-degree-of-freedom transfer robot, wherein the input conveyor belt is horizontally arranged; the brush machine is positioned under a sucking disc mounting plate when an active arm of an arm conveying device of the moving support three-degree-of-freedom transfer robot is positioned at the middle position; the output conveyor belt and the input conveyor belt are symmetrically arranged relative to the brush machine. The grabbing and placing device disclosed by the invention has the advantages of high production efficiency, high automatic degree and capabilities of realizing full-automatic collection, conveying and grabbing operations.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

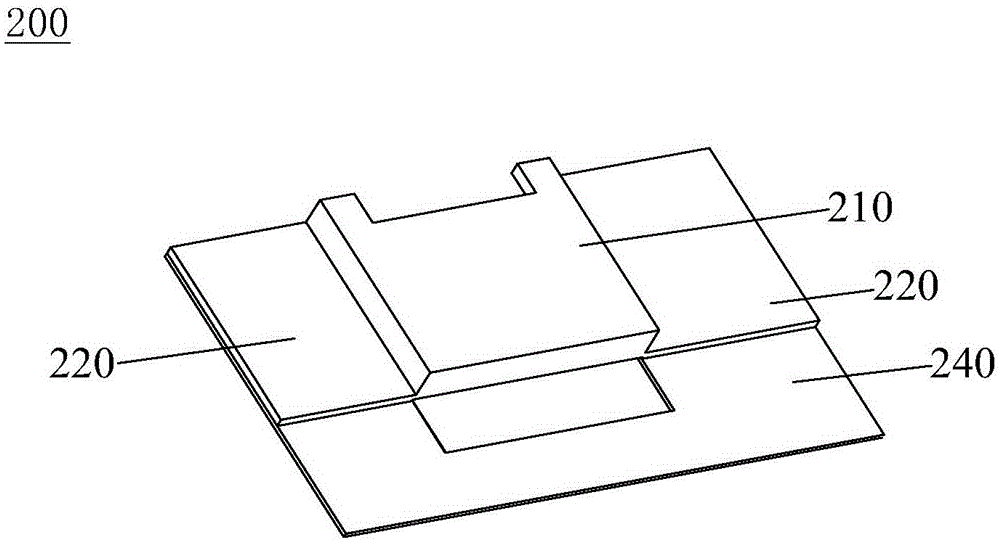

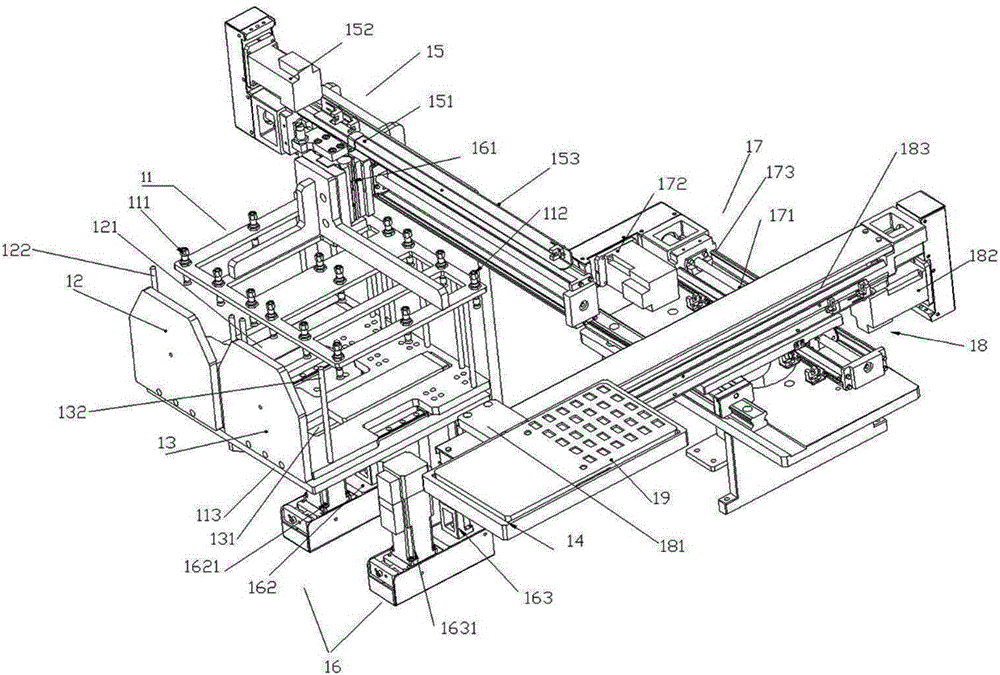

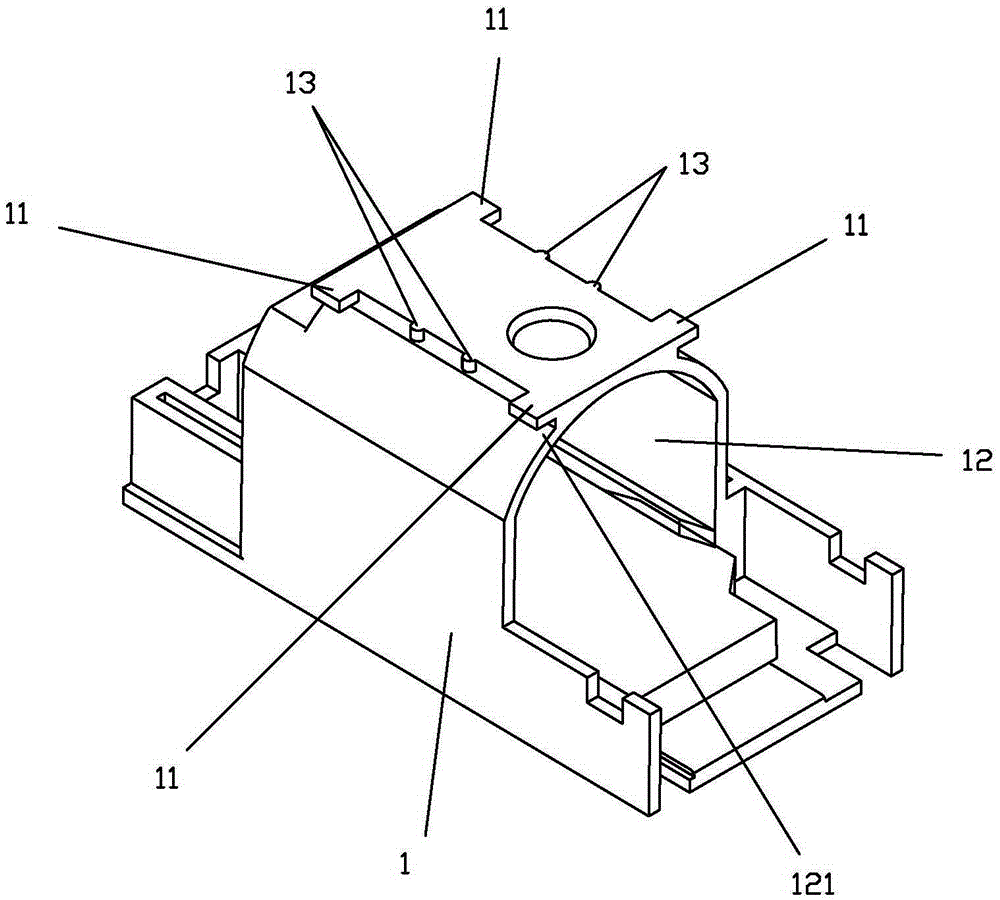

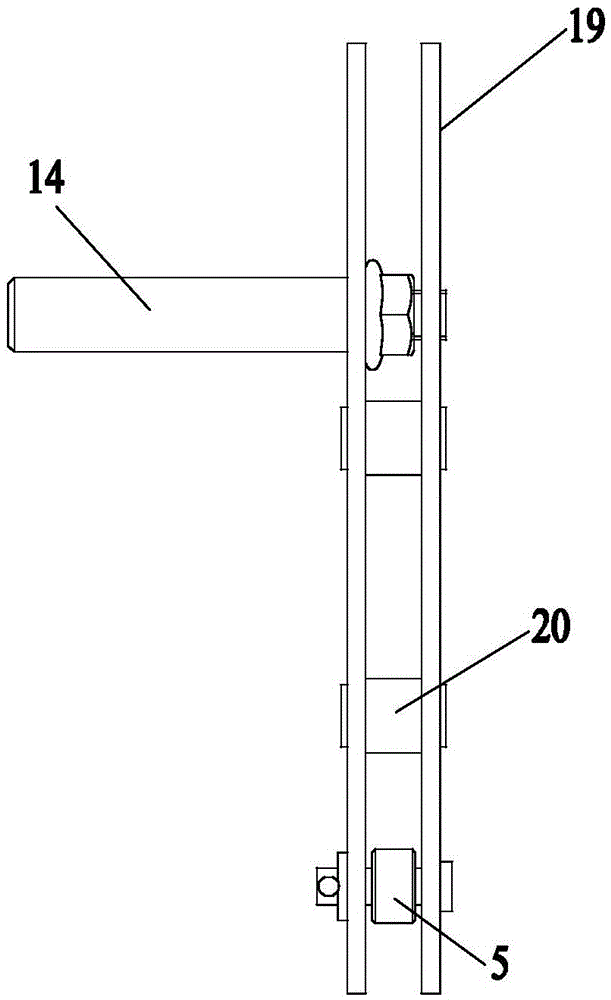

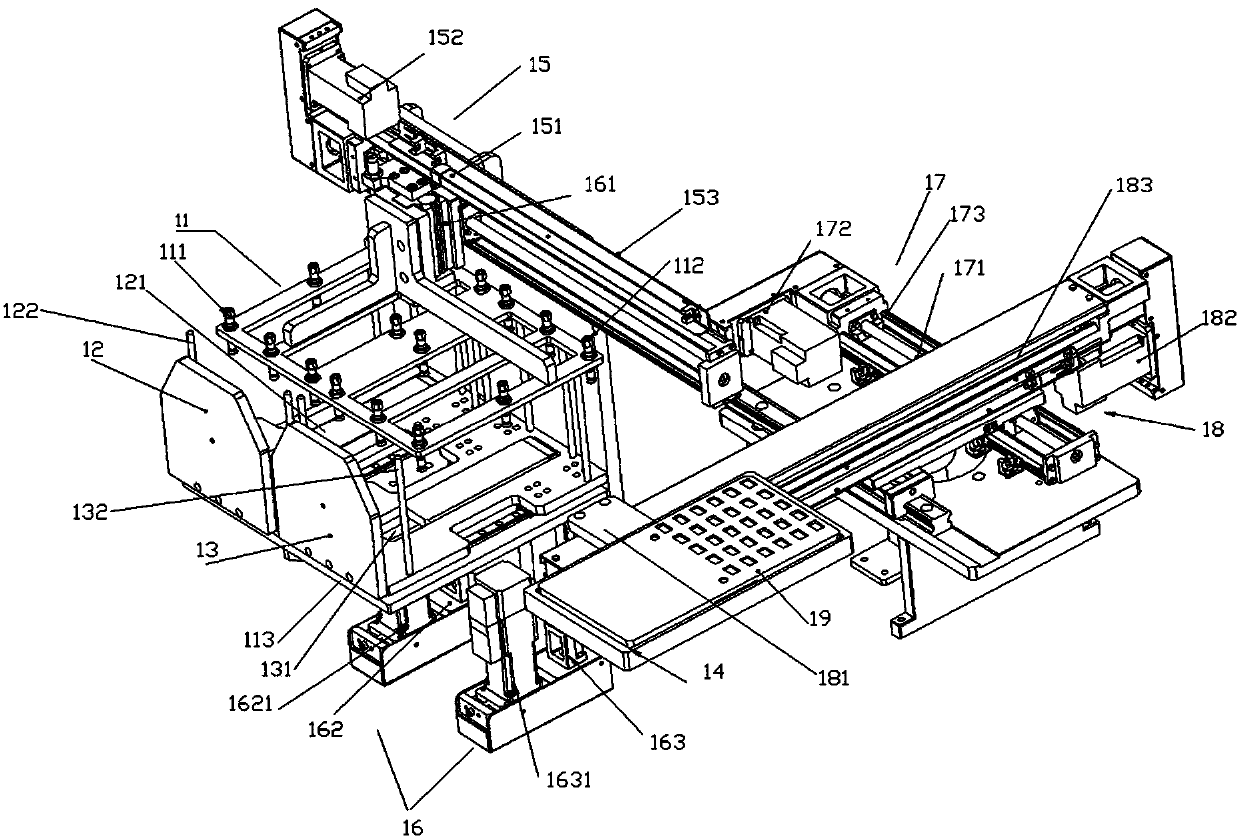

Attaching device for automatic feeding mechanism and fingerprint identification module

The invention discloses an attaching device for an automatic feeding mechanism and a fingerprint identification module. The attaching device comprises a sucker (11), a feeding bin(12), a receiving bin (13), a work plate (14), an X-direction driving mechanism (15) and Z-direction driving mechanisms (16), wherein a group of feeding suckers (111) arranged relative to the feeding bin (12) and a group of receiving suckers (112) arranged relative to the receiving bin (13) are arranged on the sucker (11). According to the attaching device, the problems in automatic feeding and automatic attaching of a cover plate during an attaching and assembling process of the fingerprint identification module are solved, and the overall production efficiency of the fingerprint identification module can be improved.

Owner:SHENZHEN CEWAY TECH

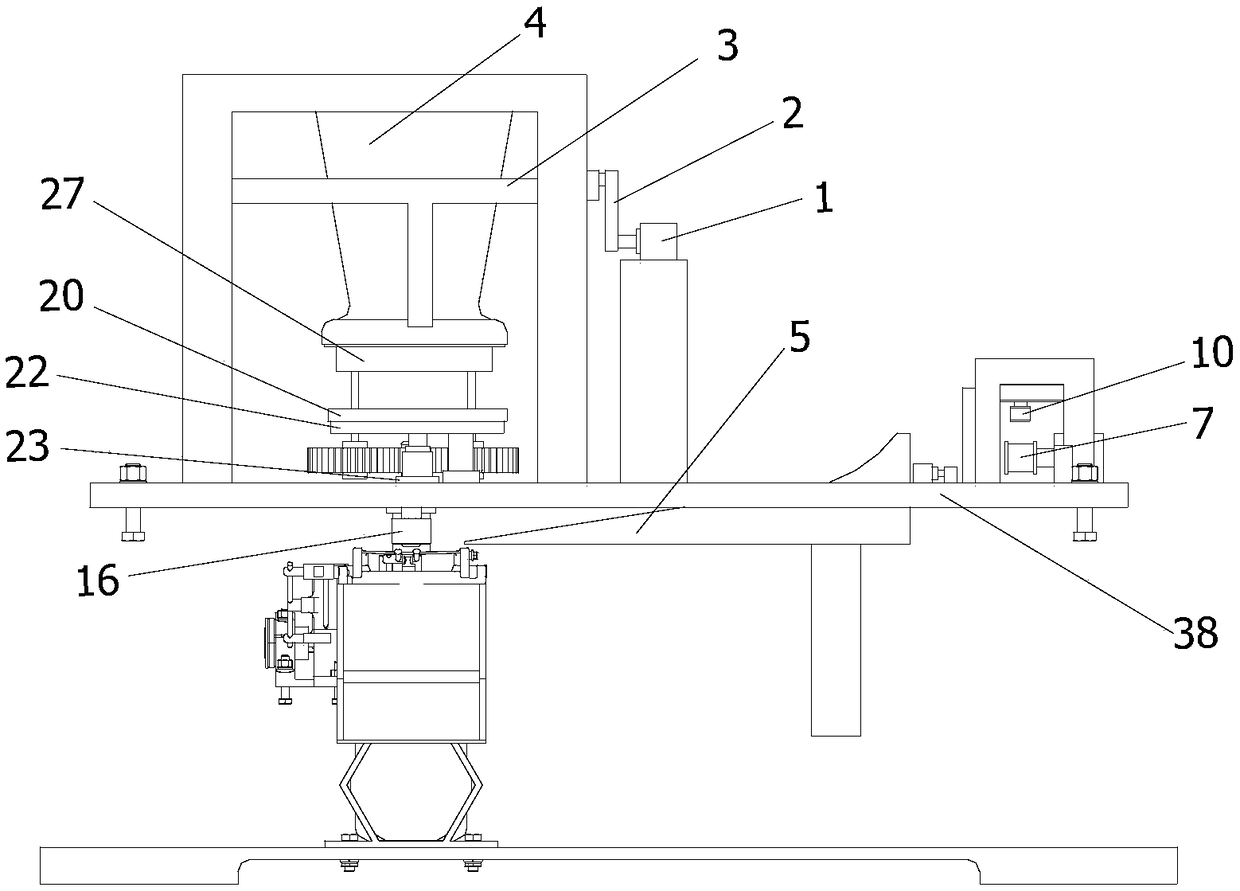

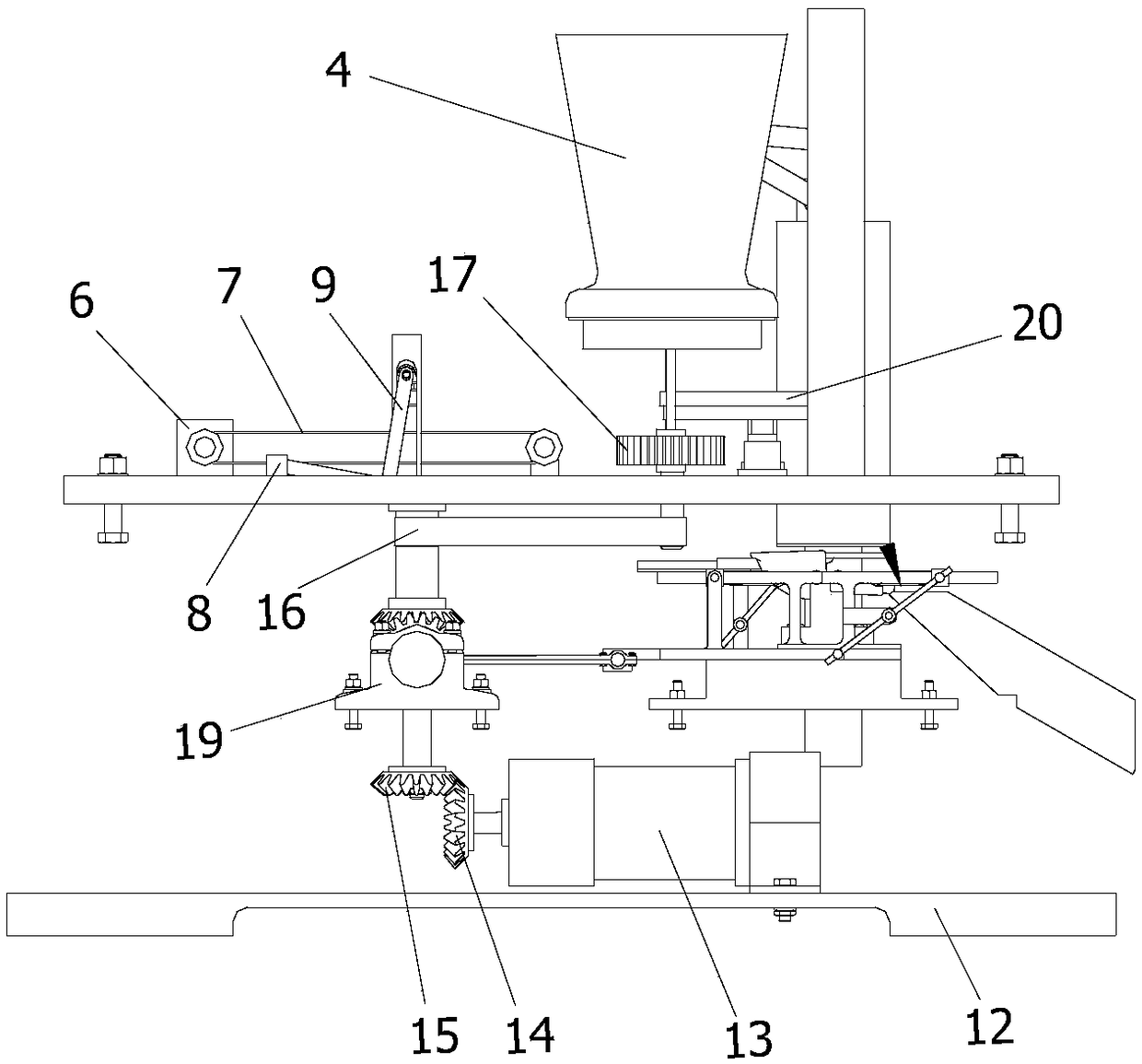

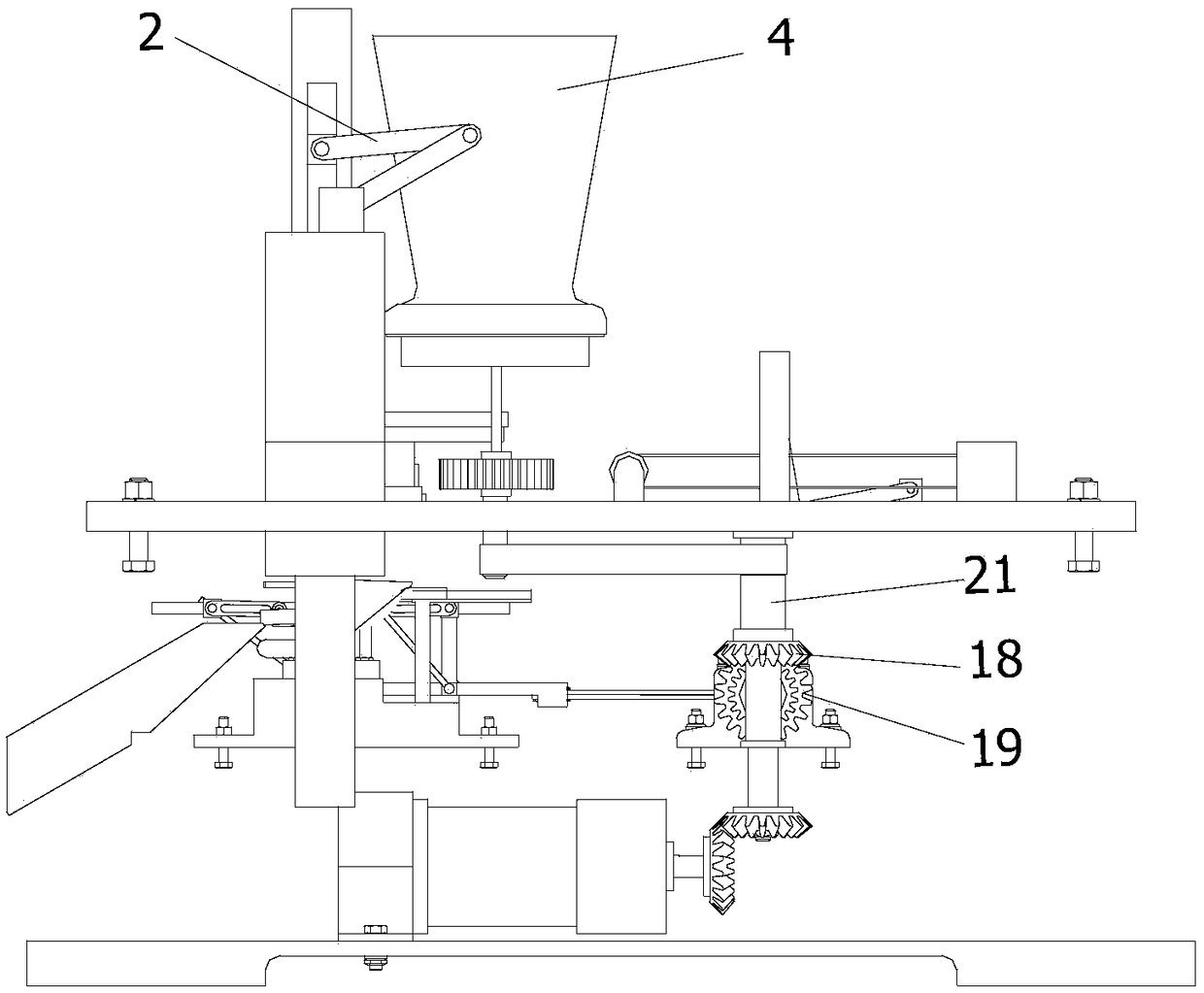

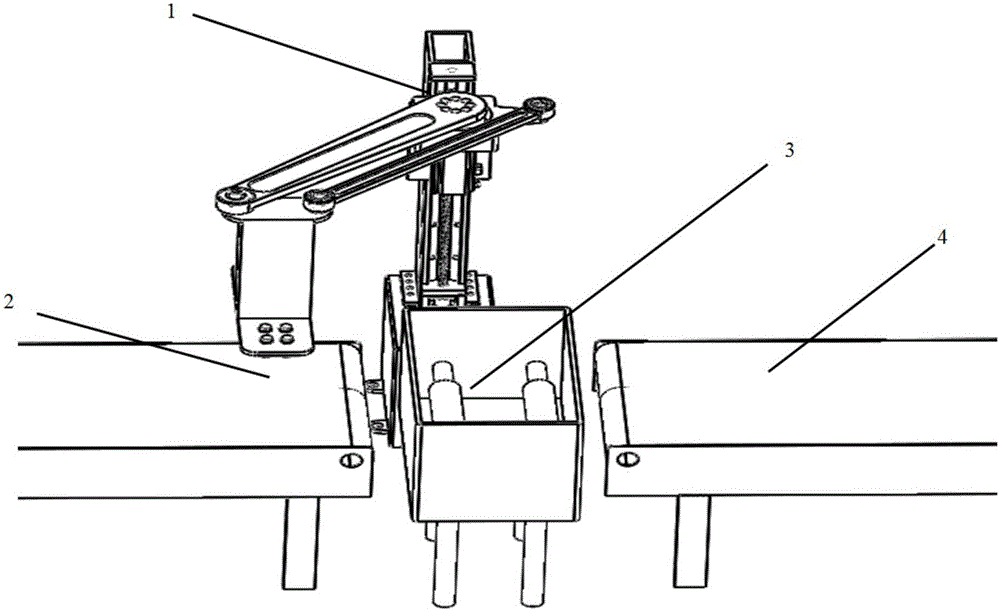

Dumpling machine

PendingCN108835156ASimple motion trackAchieve preparationDough extruding machinesDough processingPush outEngineering

The invention discloses a dumpling machine, and solves the problems of complex structure and high cost of dumpling machines in the prior art. The dumpling machine has the effects of being simple in structure and low in cost and can effectively complete dumpling making. According to the technical scheme, the dumping machine comprises a dumpling wrapper making and transporting device, a stuffing making device and a dumpling forming device, wherein the dumpling wrapper making and transporting device comprises a conveying mechanism, and a dumpling wrapper mold capable of moving up and down is arranged above the conveying mechanism; the stuffing making device comprises a stuffing stirring device, a rotating disc with a groove and a fixed disc are arranged below the stuffing stirring device; thedumpling forming device comprises a first forming die and a second forming die which are opposite and controlled to be opened or closed by a driving mechanism; the closed first forming mold and second forming mold form dumplings and then are opened, and the dumplings are pushed out by a push plate on the side surface.

Owner:SHANDONG UNIV

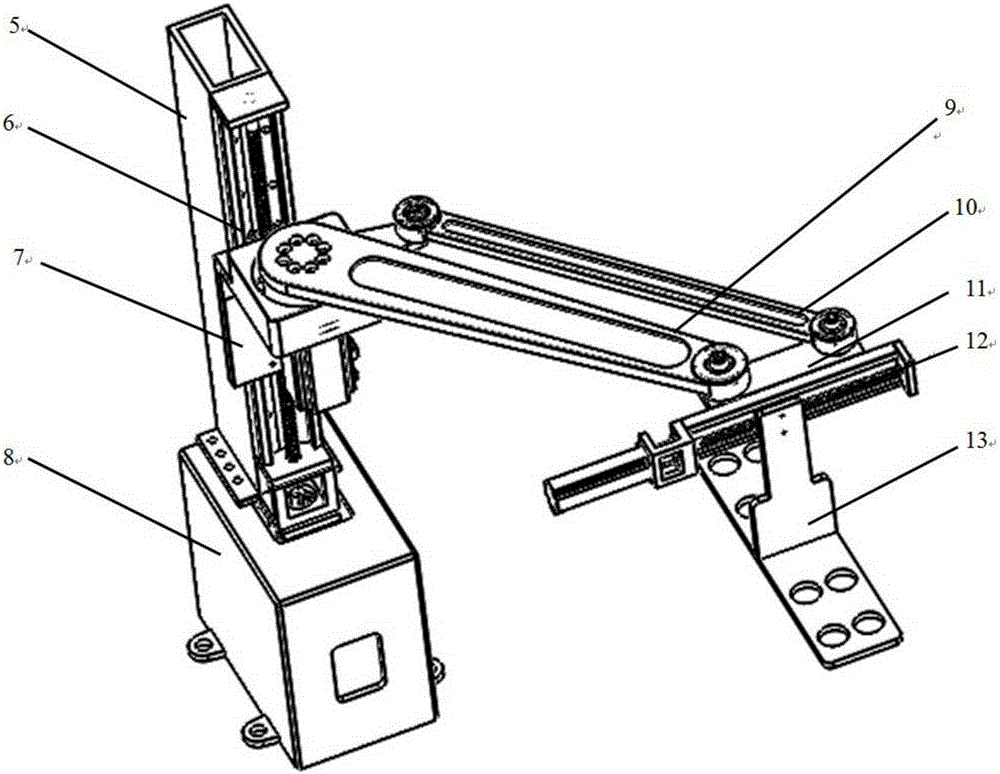

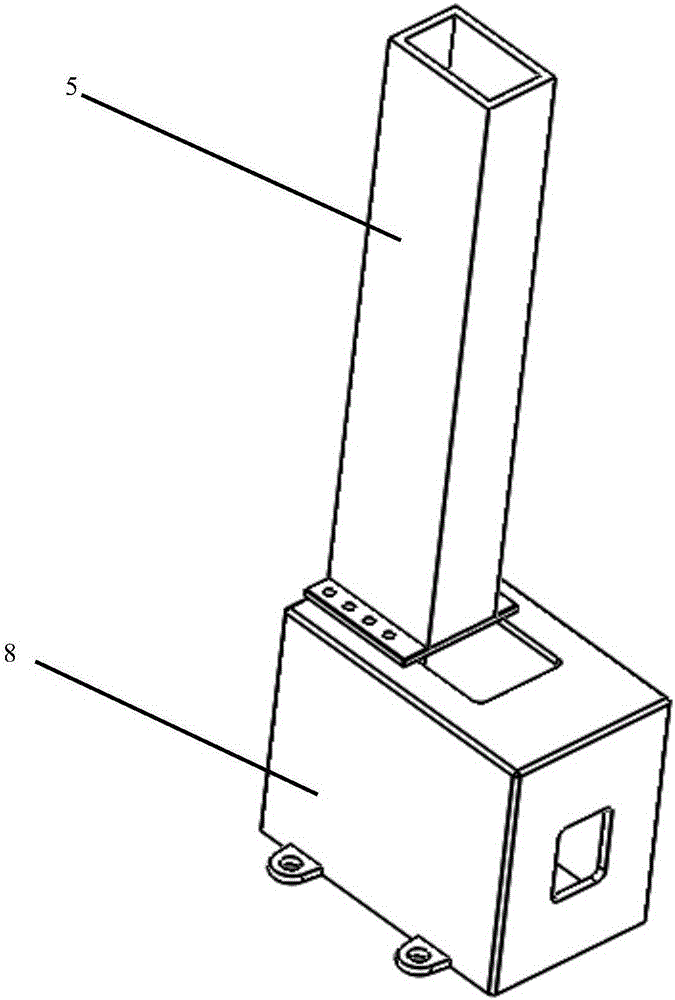

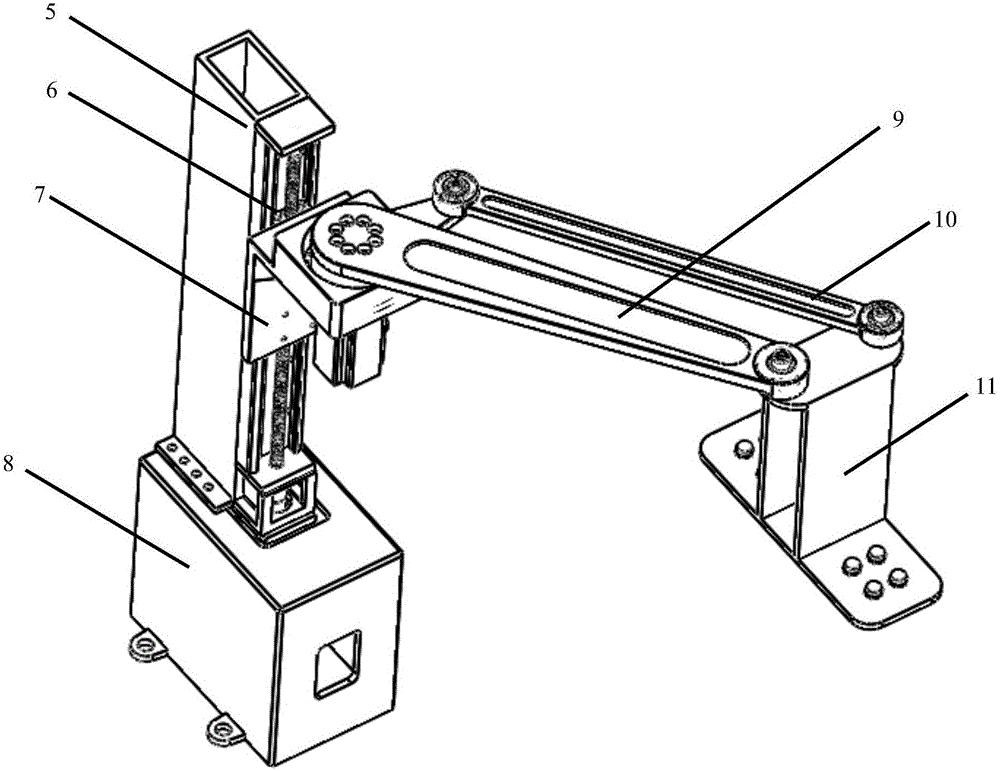

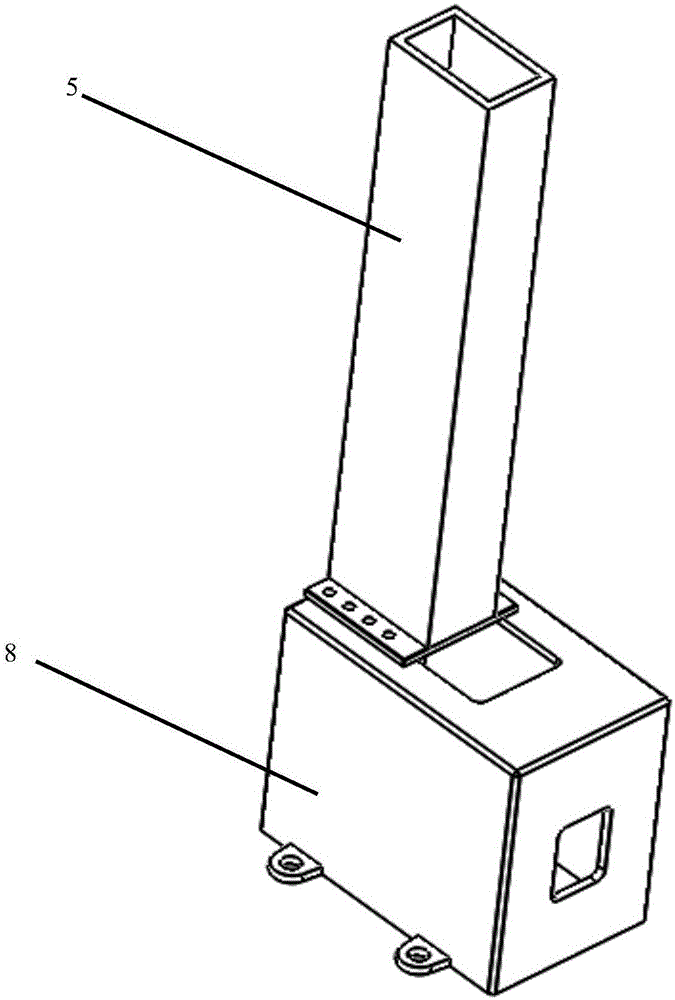

Grabbing and arranging device for deburring

The invention discloses a grabbing and arranging device for deburring, and belongs to the technical field of industrial robot application. The grabbing and arranging device comprises an input conveyer belt, a deburring machine, an output conveyer belt and a movable-support two-degree-of-freedom transfer robot; the input conveyer belt and the output conveyer belt are horizontally arranged; the deburring machine is located right below a suction cup mounting plate when a driving arm of an arm conveyer of the movable-support two-degree-of-freedom transfer robot is arranged at a middle position, and the output conveyer belt and the input conveyer belt are symmetrically arranged about the deburring machine; the movable-support two-degree-of-freedom transfer robot comprises a rack, a linear module, a movable support, the arm conveyer and a tail-end executing mechanism, and the linear module comprises a ball screw rod, a sliding block and a linear sliding rail. The grabbing and arranging device for the deburring has high production efficiency and high automation degree, and can also perform full-automatic collecting, conveying and grabbing operations.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

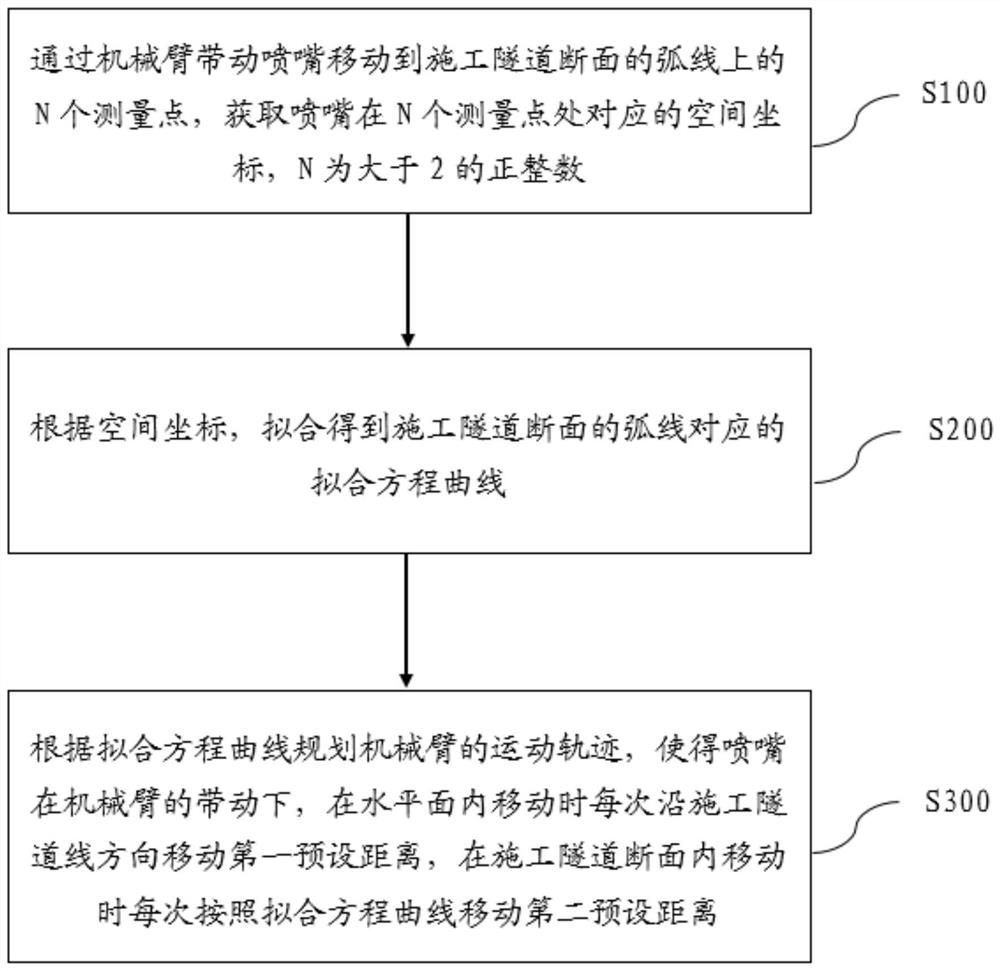

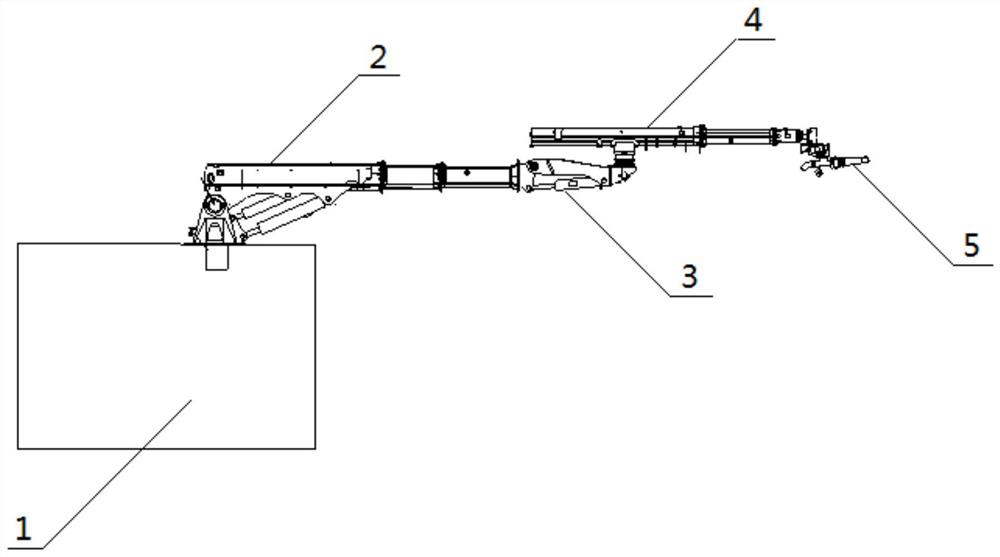

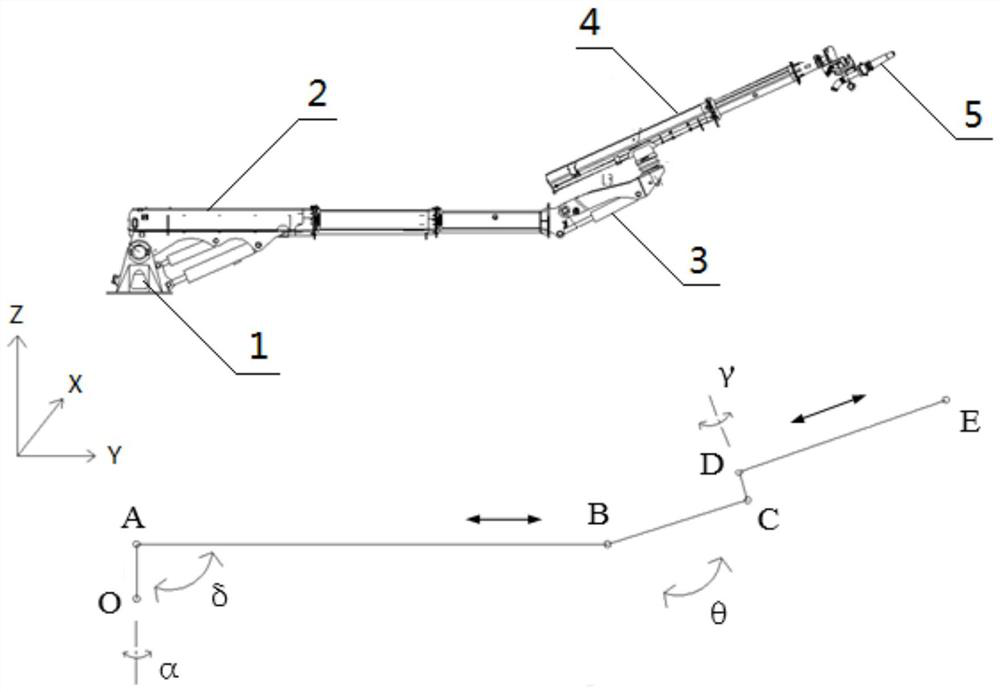

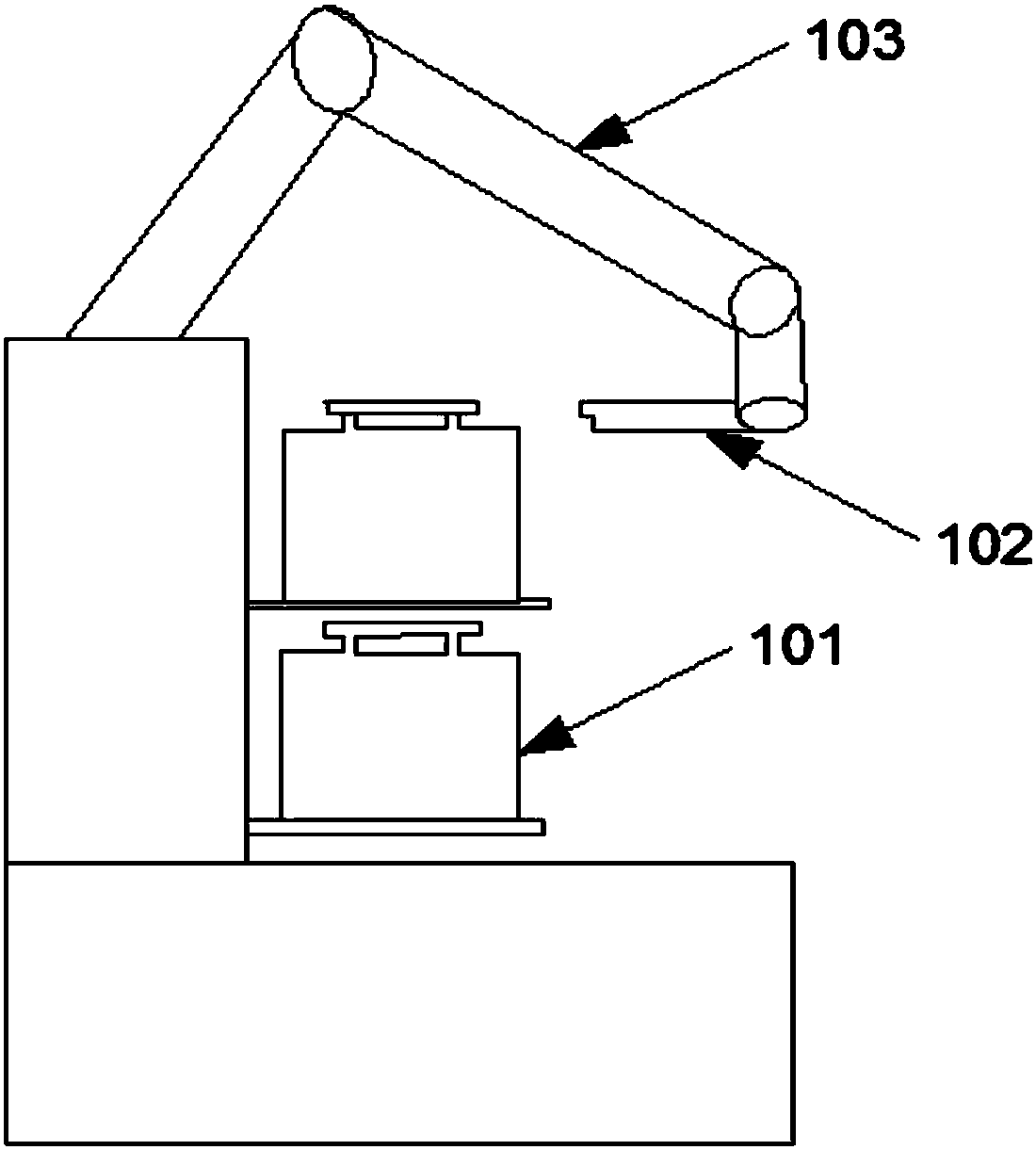

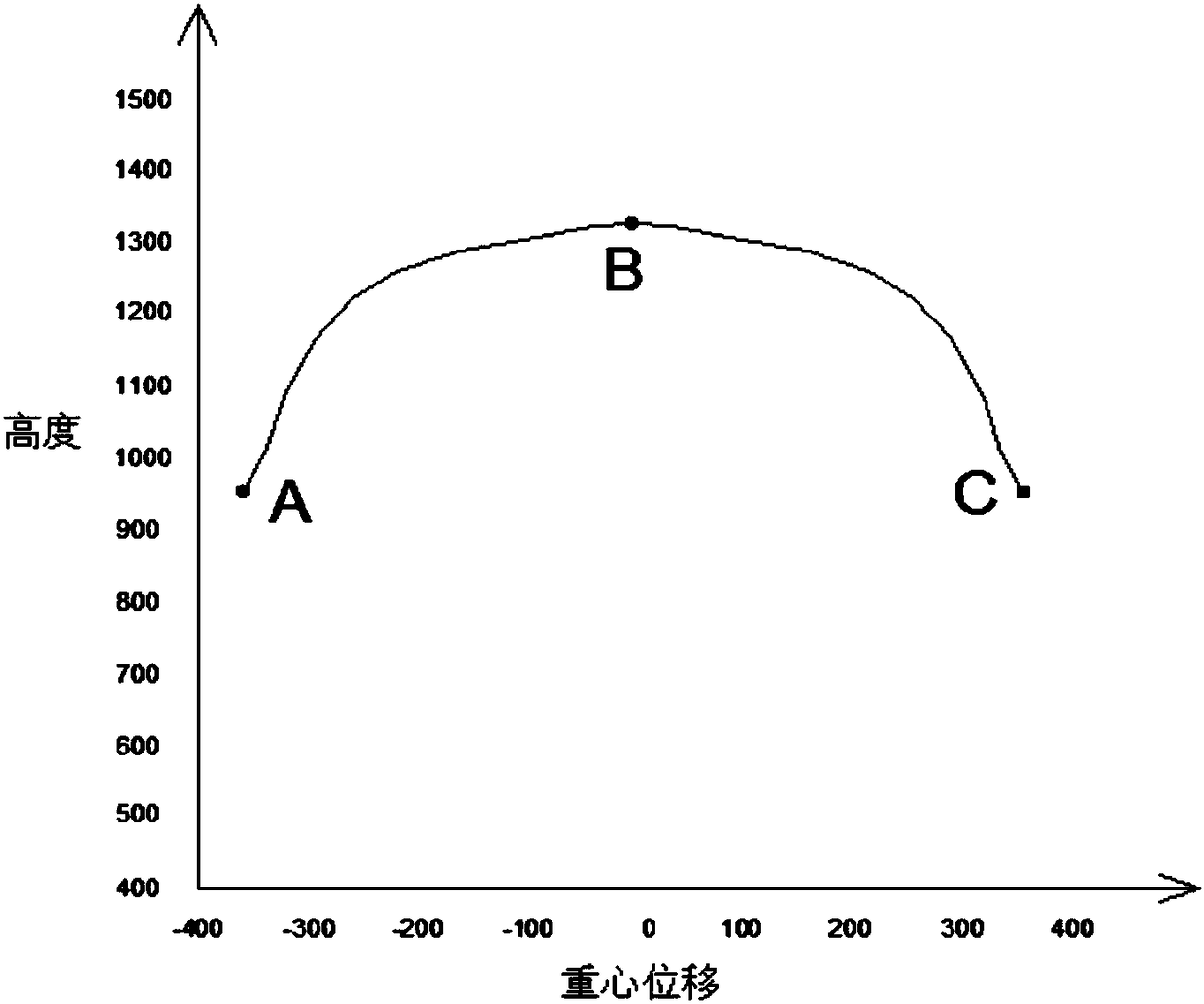

Mechanical arm, and system and method for planning motion track of mechanical arm

InactiveCN111618860ASimple motion trackReduce control difficultyProgramme-controlled manipulatorUnderground chambersStructural engineeringMachine

The invention discloses a mechanical arm, and a system and method for planning a motion track of the mechanical arm. According to the method, a nozzle is driven to move to a plurality of measuring points on an arc line of a construction tunnel section through the mechanical arm, corresponding spatial coordinates of the nozzle at the multiple measuring points are obtained, a fitting equation curvecorresponding to the arc line of the construction tunnel section can be obtained by fitting, and the motion track of the mechanical arm is planned accordingly, so that under driving of the mechanicalarm, the nozzle moves by the first preset distance each time in the direction of a construction tunnel line when moving in the horizontal plane, and moves by the second preset distance each time according to the fitting equation curve when moving in the construction tunnel section, that is, when a wet spraying machine conducts automatic wet spraying, the mechanical arm only needs to be controlledto drive the nozzle to move horizontally in the horizontal plane and make lifting moving in the construction tunnel section. Compared with the prior art, the motion track of the mechanical arm duringautomatic wet spraying of the wet spraying machine can be simplified, the control difficulty of the mechanical arm is lowered, and the construction cost is saved.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

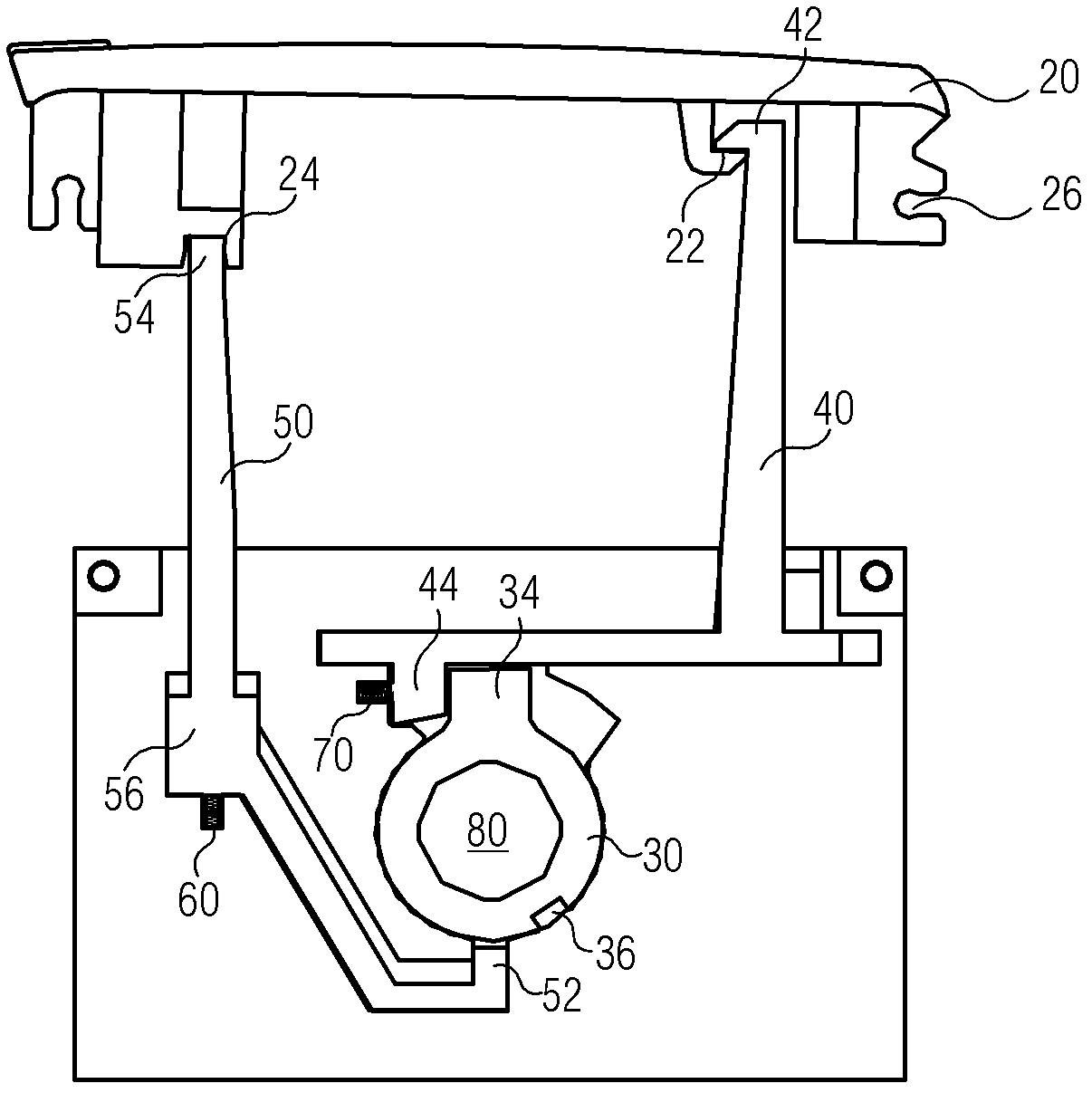

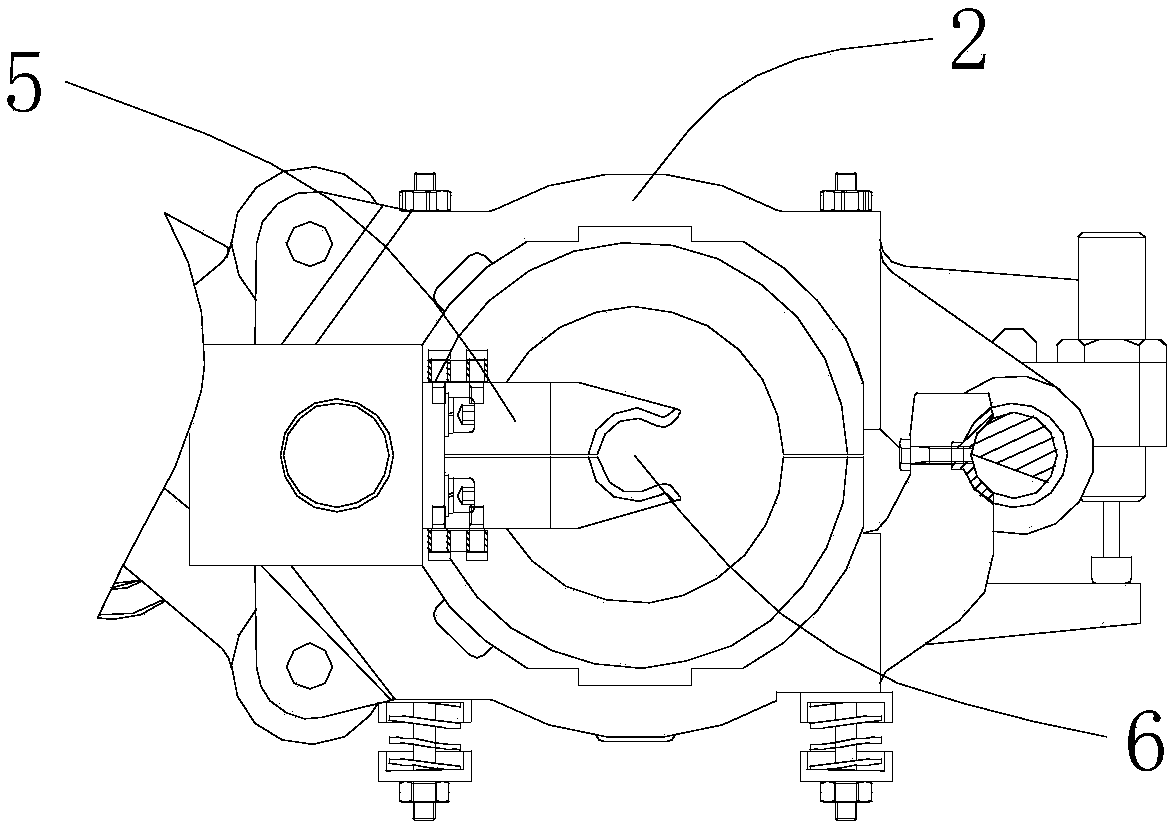

Switching mechanism and interlocking device thereof

InactiveCN103000406AImprove reliabilityIncreased durabilityElectric switchesEmergency protective devicesMechanical engineeringStability of motion

The invention provides an interlocking device of a switching mechanism. The interlocking device comprises a support (10), an annular part (30), a first locking rod (50), a first elastic part (60), a second locking rod (40), an end cover (20) and a second elastic part (70). A clamping portion can be connected with limiting parts so as to limit the annular part during rotation. The first elastic part can push the first locking rod to slide along a locking direction in which the clamping portion is clamped with the limiting parts. A locking portion can be fastened on the end cover, and a contact portion is abutted onto the end cover and further can push the clamping portion to slide along a direction opposite to the locking direction. The second elastic part can push the second locking rod to slide along a direction opposite to a sliding direction in which the locking portion can be clamped on the end cover. The pushing part can push a second driving portion to slide along the sliding direction, so that the locking portion is clamped with the end cover. The interlocking device of the switching mechanism has the advantages that the movement stability and the movement reliability of each locking rod are improved, and the durability of the interlocking device is enhanced. The invention further provides the switching mechanism comprising the interlocking device.

Owner:SIEMENS AG

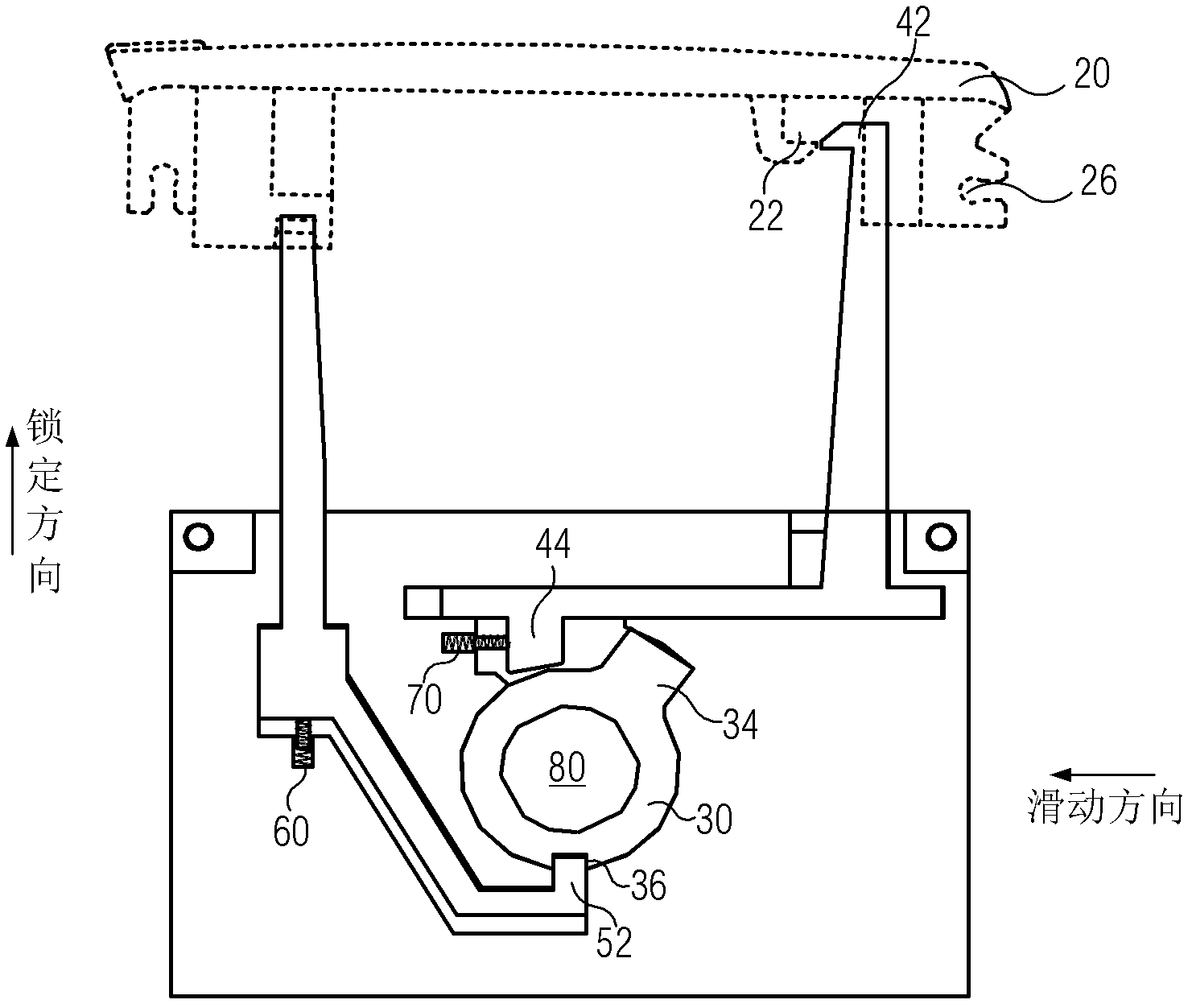

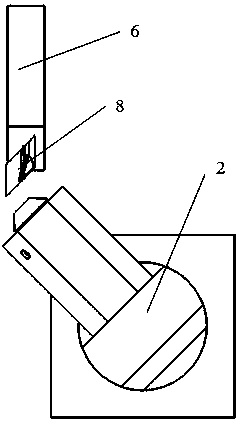

Carrying device and carrying method thereof

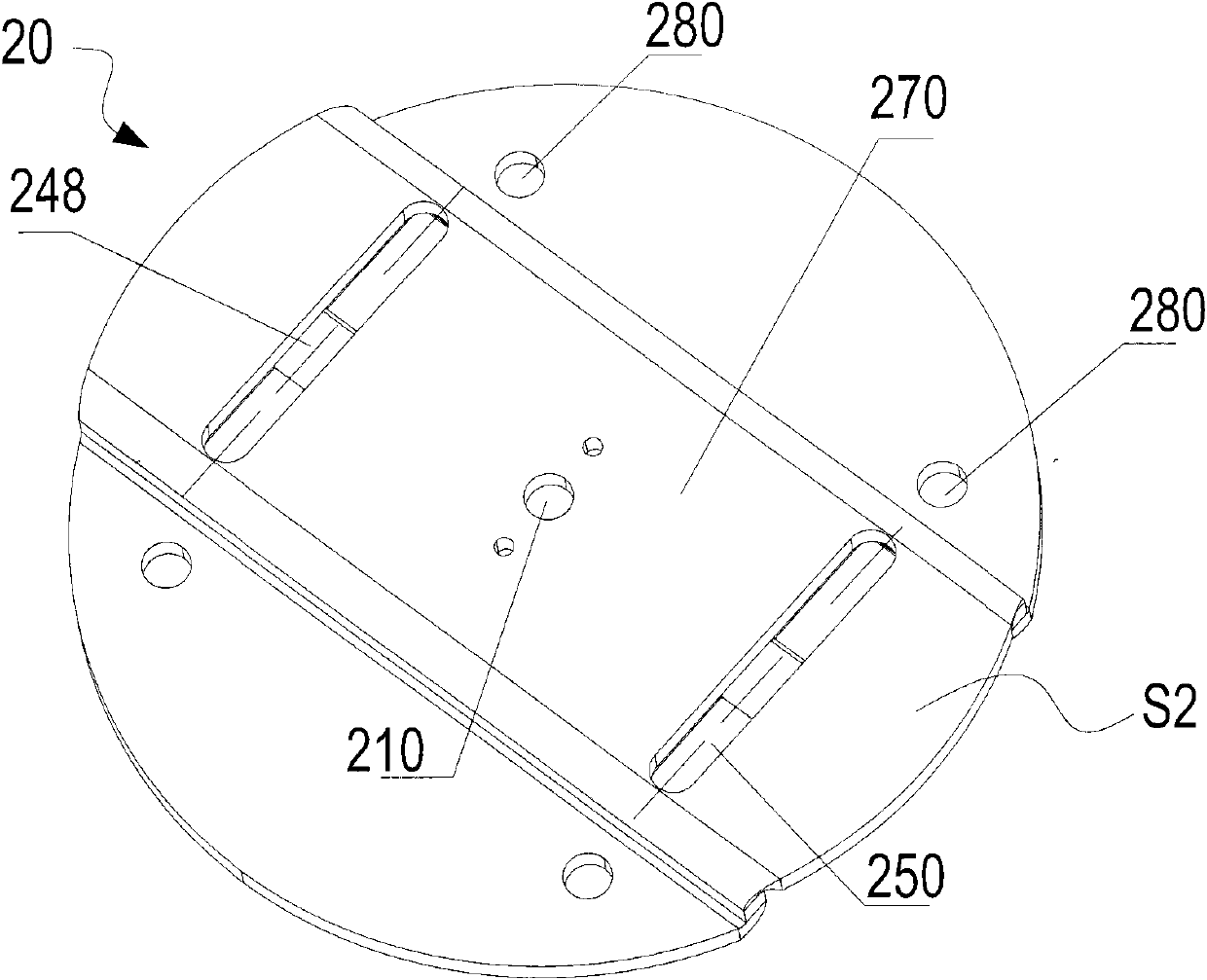

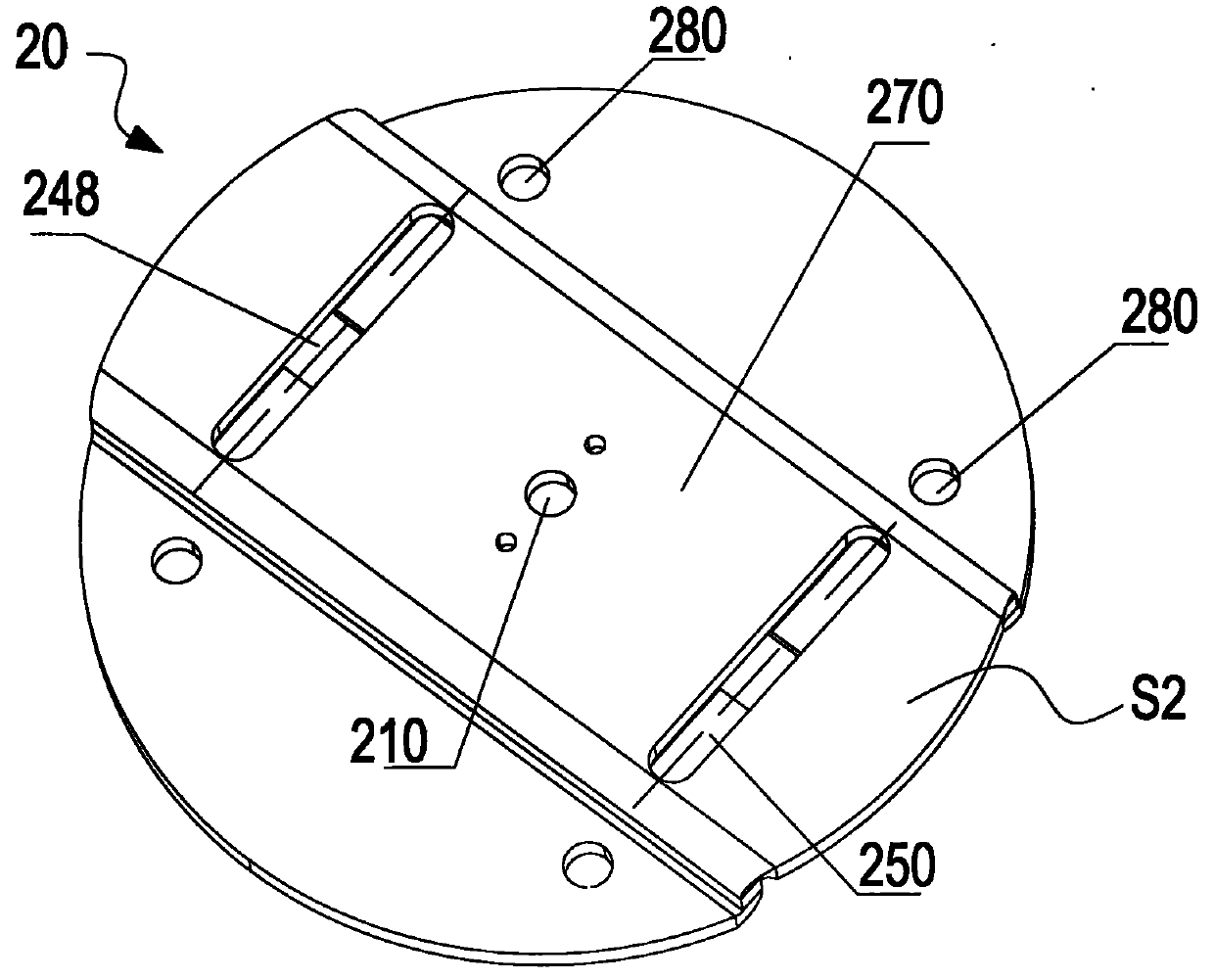

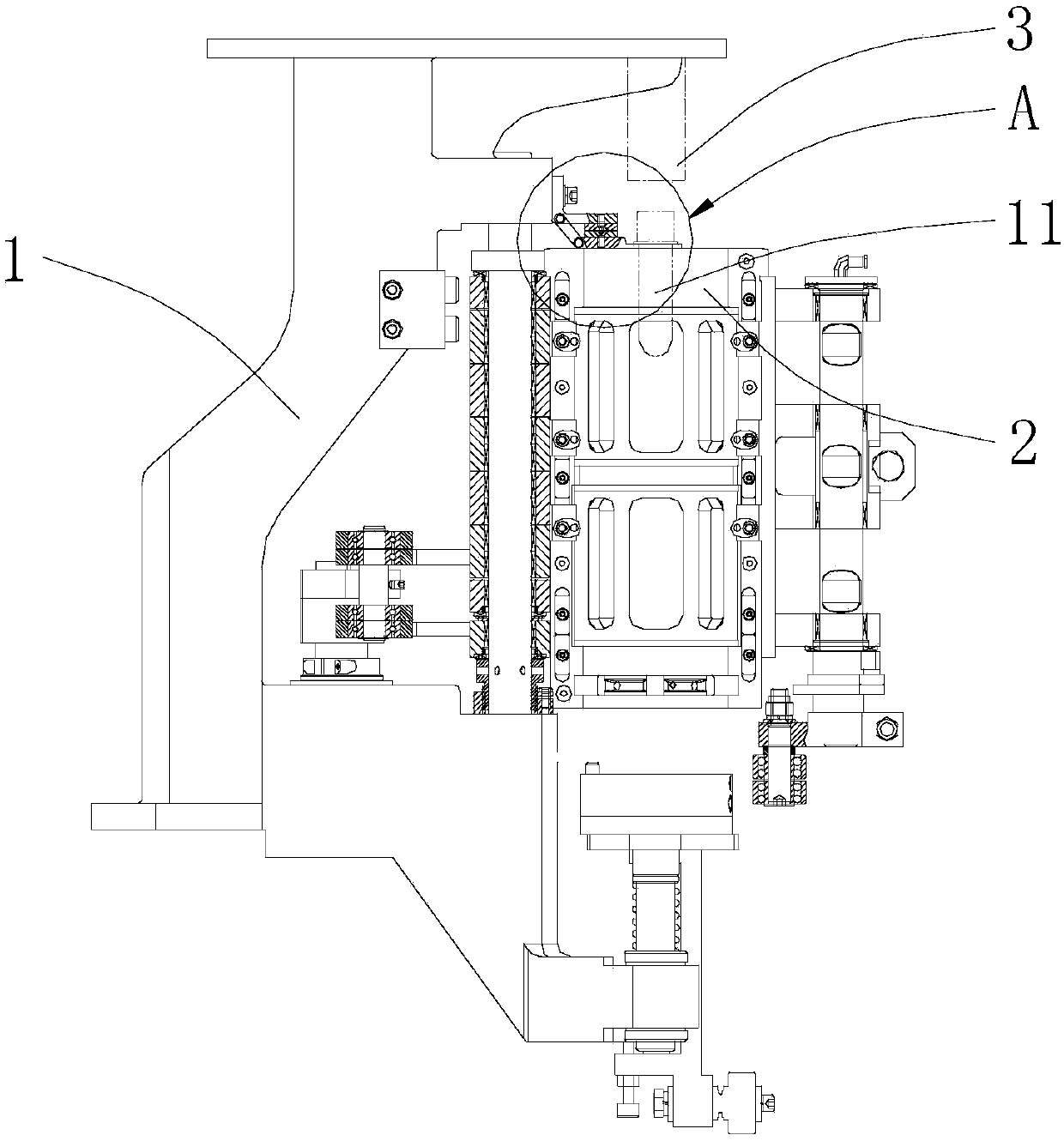

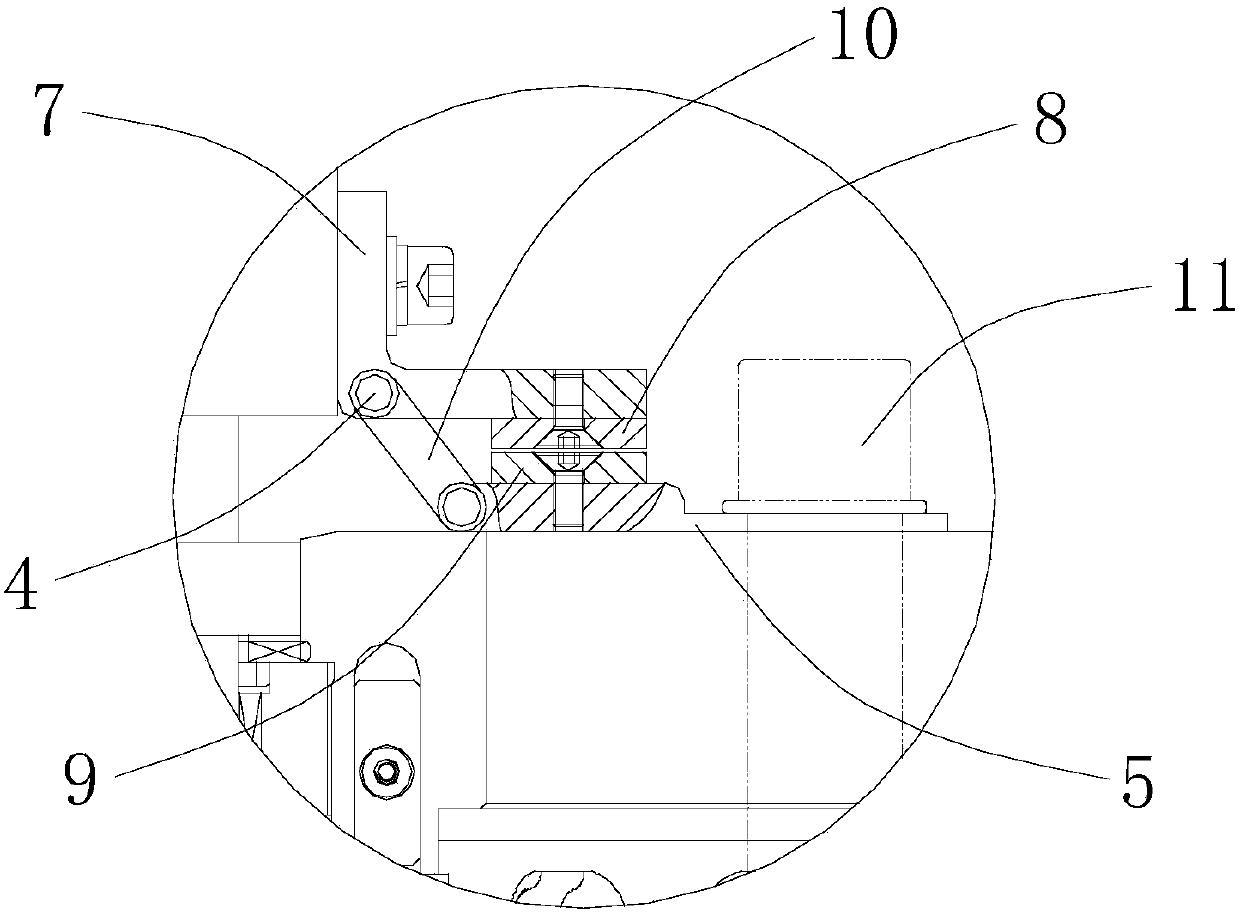

ActiveCN108987318AImprove handling efficiencyShort pathSemiconductor/solid-state device manufacturingConveyor partsControl theoryBearing surface

The invention provides a carrying device and a carrying method thereof. The carrying device comprises a movable transport mechanism, a grabbing mechanism, a bearing bench and a driving mechanism. Thecarrying method comprises the following steps: when the carrying device grabs an object to be carried from an object storage place or transfers the object to be carried to the object storage place, the transport mechanism moves to the object storage place, and a position, facing the object storage place, on a bearing surface is selected as a target pick-and-place area; the driving mechanism can drive the bearing bench to rotate horizontally and enables the bearing station meeting requirements to rotate to the target pick-and-place area; and the grabbing mechanism always picks and places the object to be carried on the bearing station of the target pick-and-place area. The carrying device and the carrying method thereof enable movement track of the grabbing mechanism to be same every time the grabbing mechanism grabs the object to be carried on the bearing station of the target pick-and-place area, thereby improving carrying efficiency of the carrying device.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

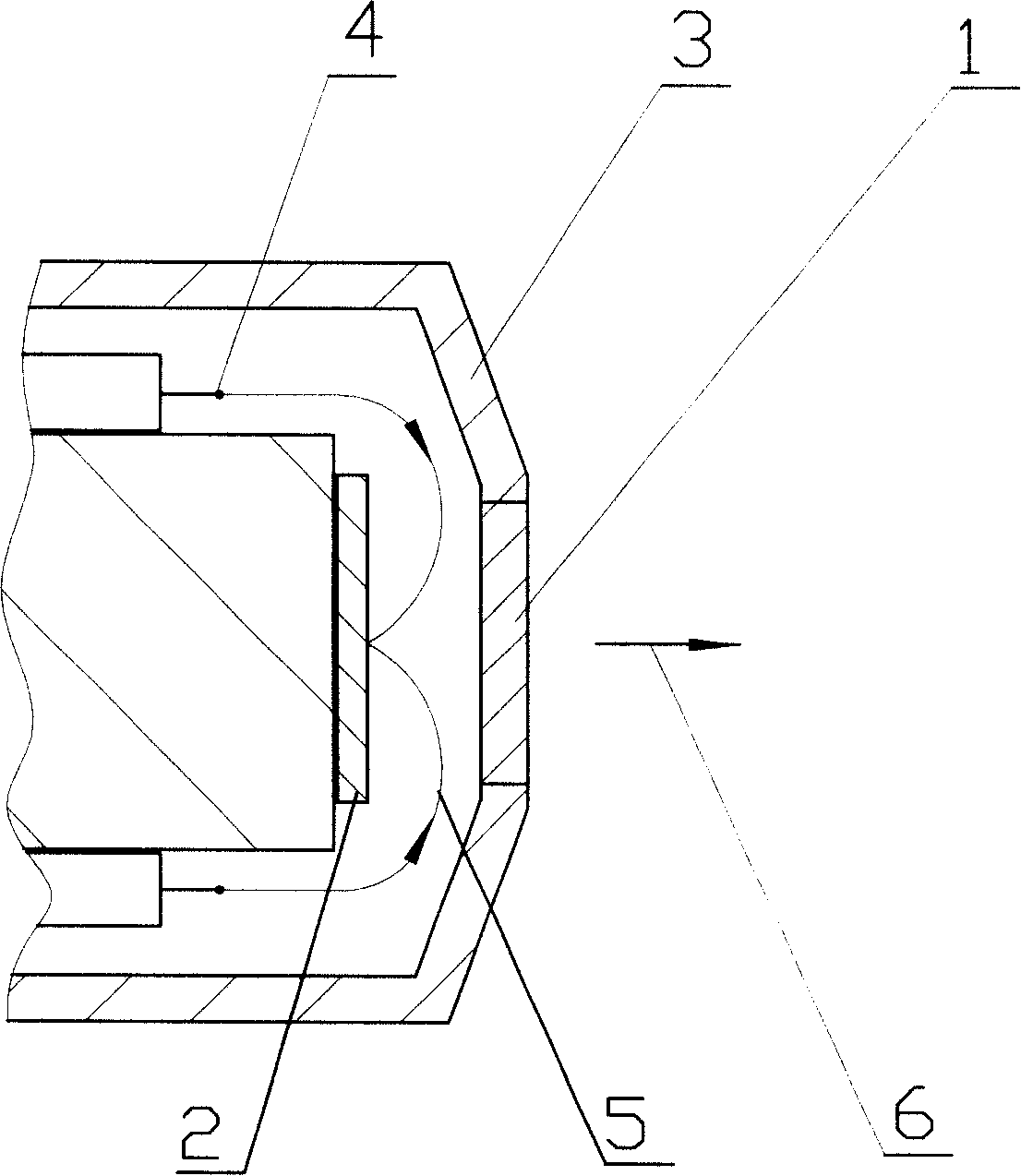

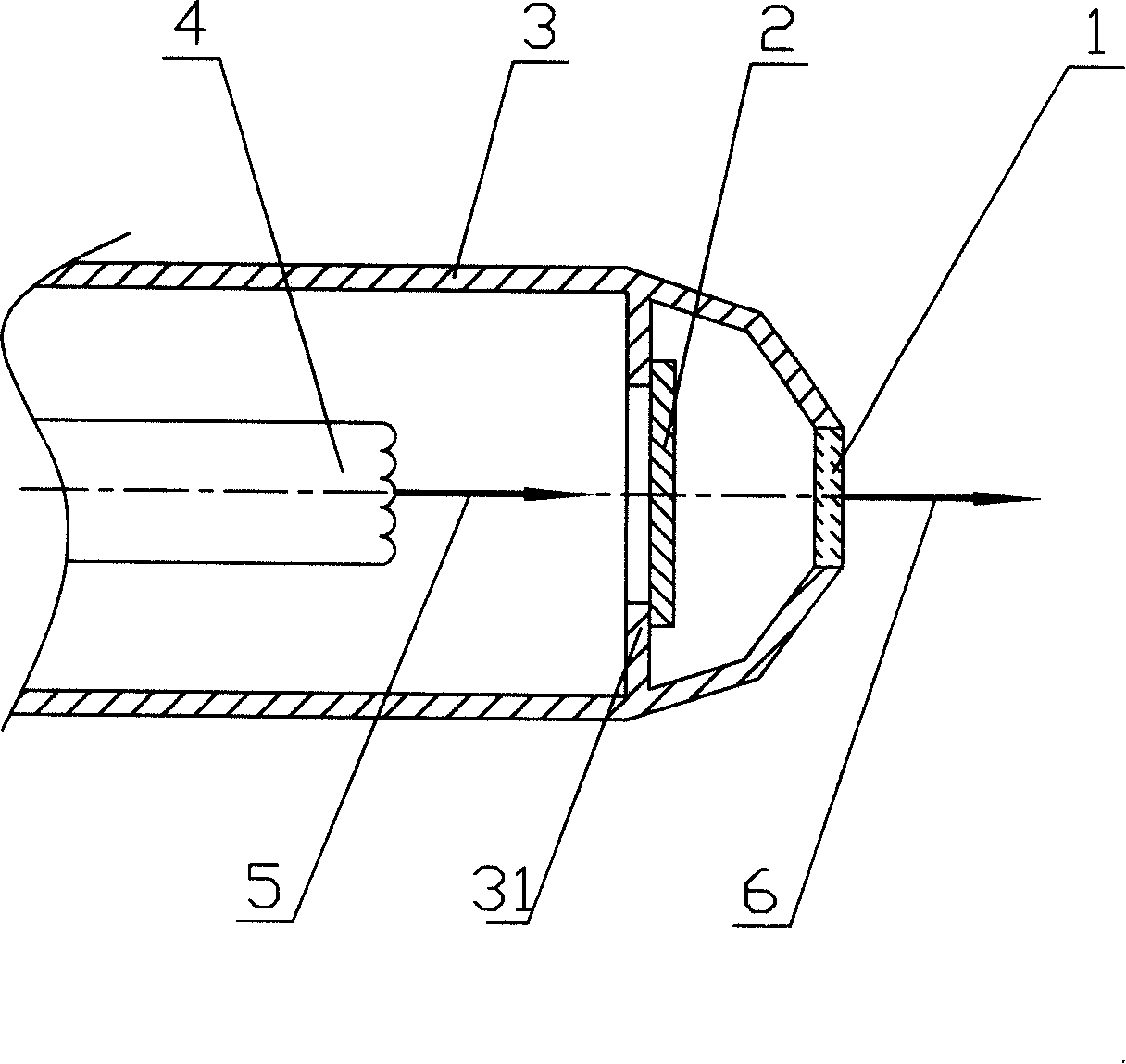

End-window X ray tube

InactiveCN101174533AHigh sensitivityReduce difficultyX-ray tube electrodesX-ray tube vessels/containerSoft x rayHigh energy

The invention provides an end window X ray tube, which comprises a casing, a cathode filament used for transmitting electron beams, a thin film anode target and a berylium window. The cathode filament is encapsulated in the casing, the berylium window is arranged on the end face of the casing and positioned in front of the electron beam, the thin film anode target is arranged between the cathode filament and the berylium window, and the thin film anode target are fixedly connected inside the casing. Simultaneously, the invention adopts the earthing of casing and the negative high-voltage power supply mode of the cathode filament, and the casing which is electrically insulated and protected is avoided, thus being beneficial to the radiation of the X ray tube. The invention has the advantages that firstly, because X ray is required to penetrate through a thin film anode, and the X ray can emit from the end window, the low energy part of the X ray is filtered and weakened, the high energy part of the X ray is influenced little, thereby an X ray spectrum with weaker background is obtained; secondly, a more complex electric field is not required to control the deflection direction of an electron, thus being beneficial to the product-forming and the mass of the end window X ray tube.

Owner:BEIJING PURKINJE GENERAL INSTR

Container closing apparatus

ActiveCN103373680AAvoid lifting strokePreserve Overlap OrientationCapsThreaded caps applicationMechanical engineeringEngineering

Owner:KRONES AG

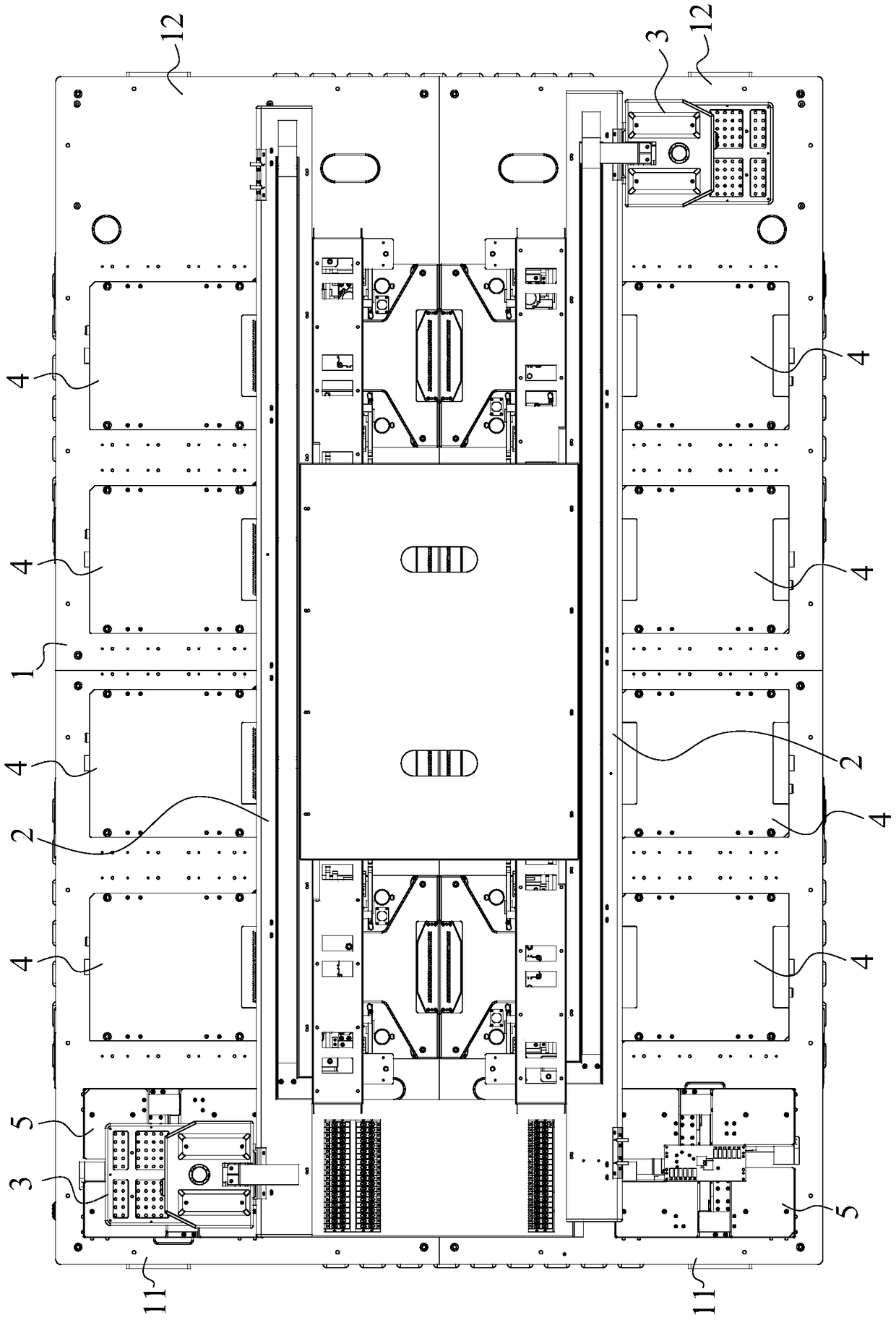

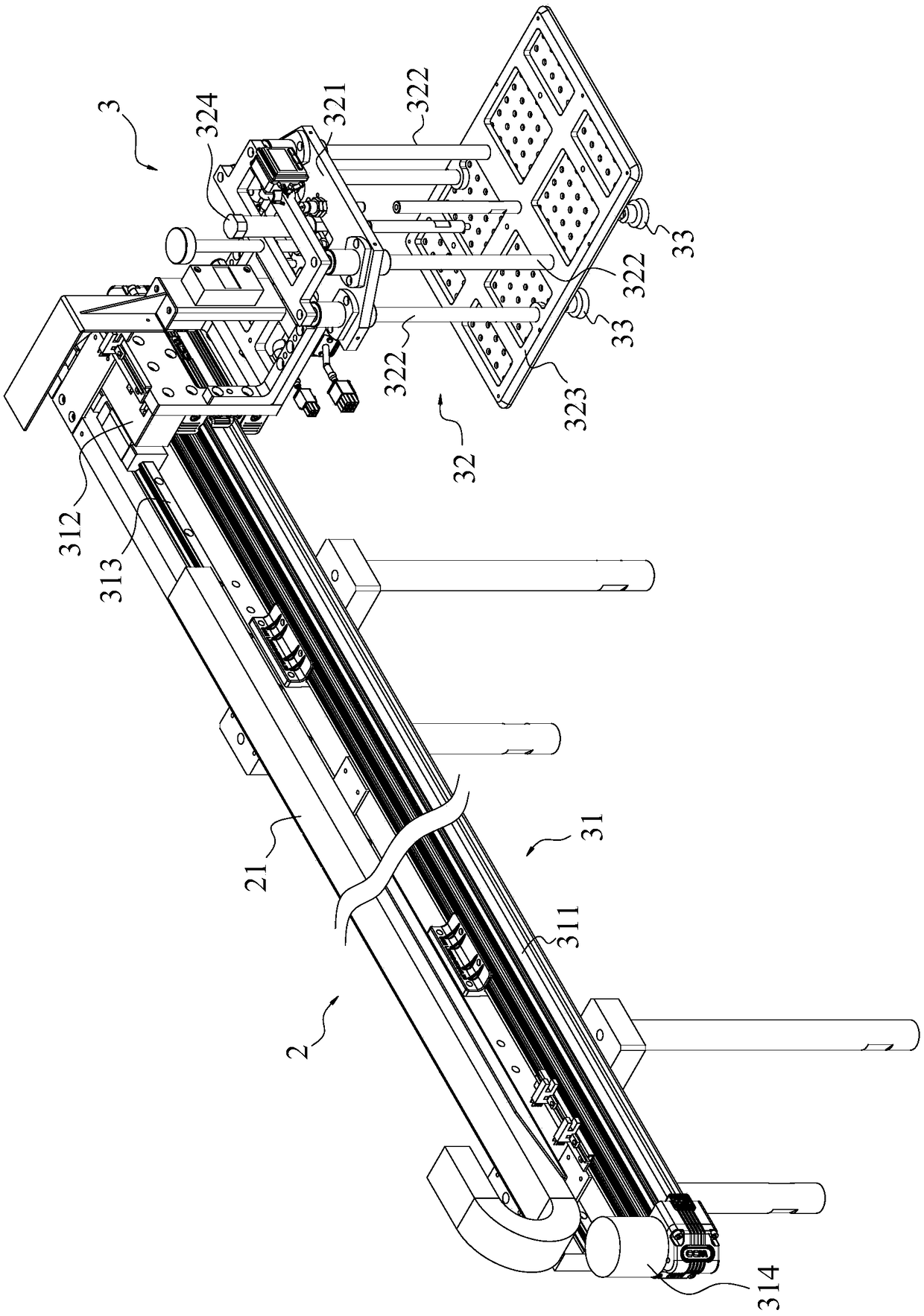

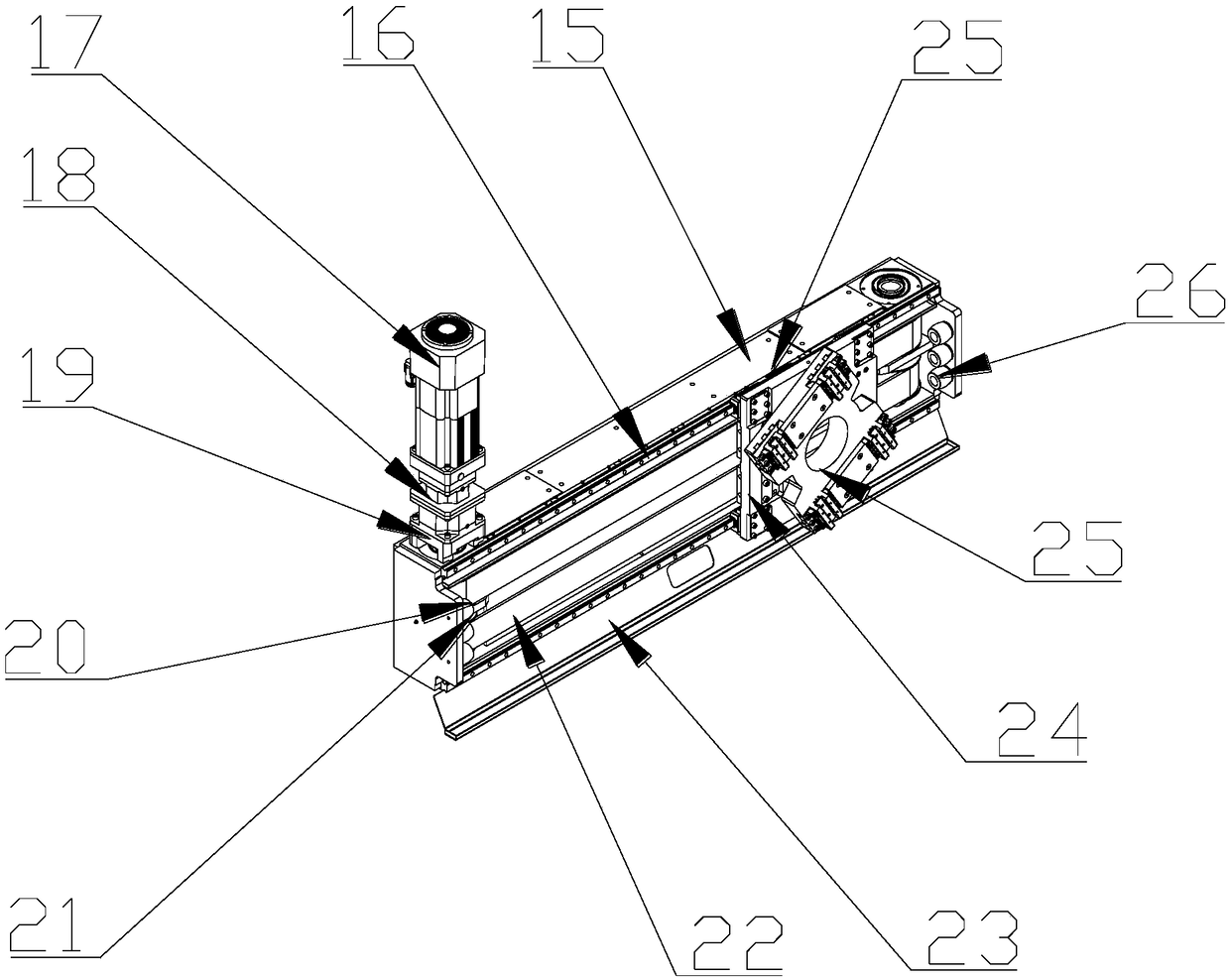

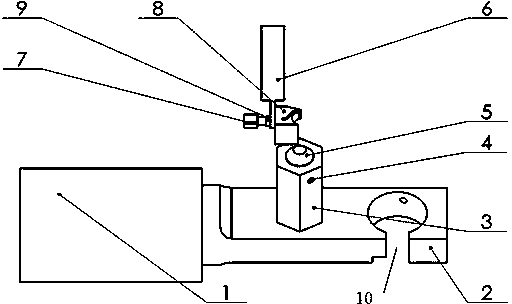

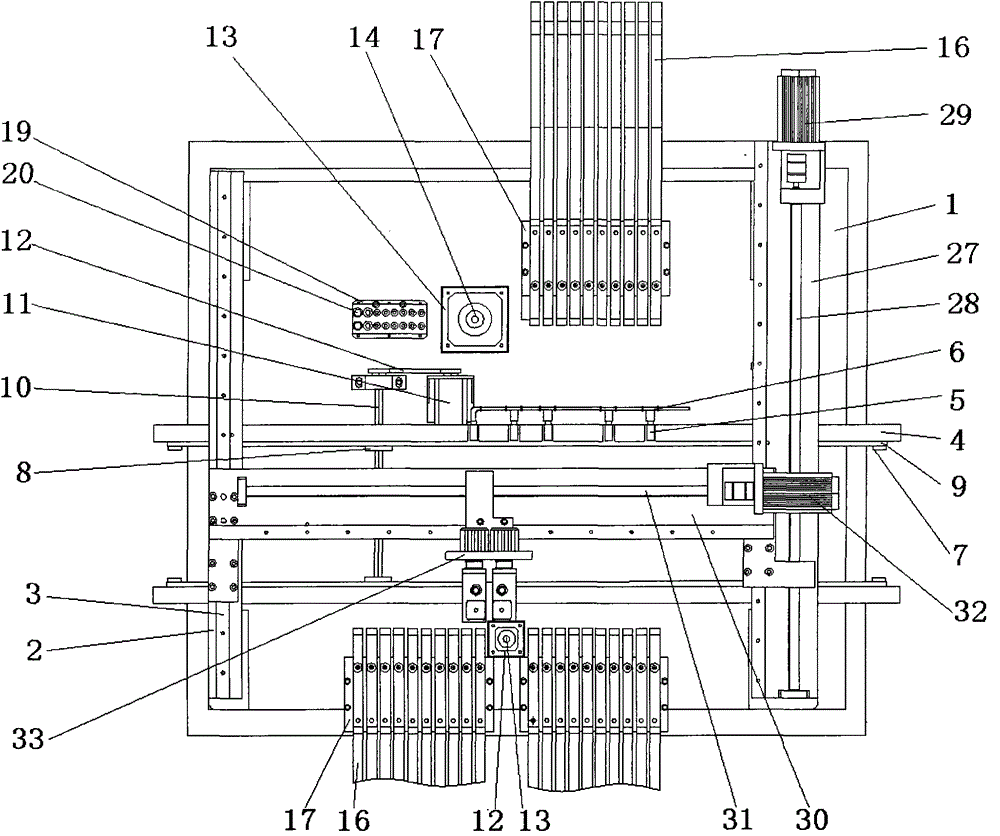

Program burn test machine

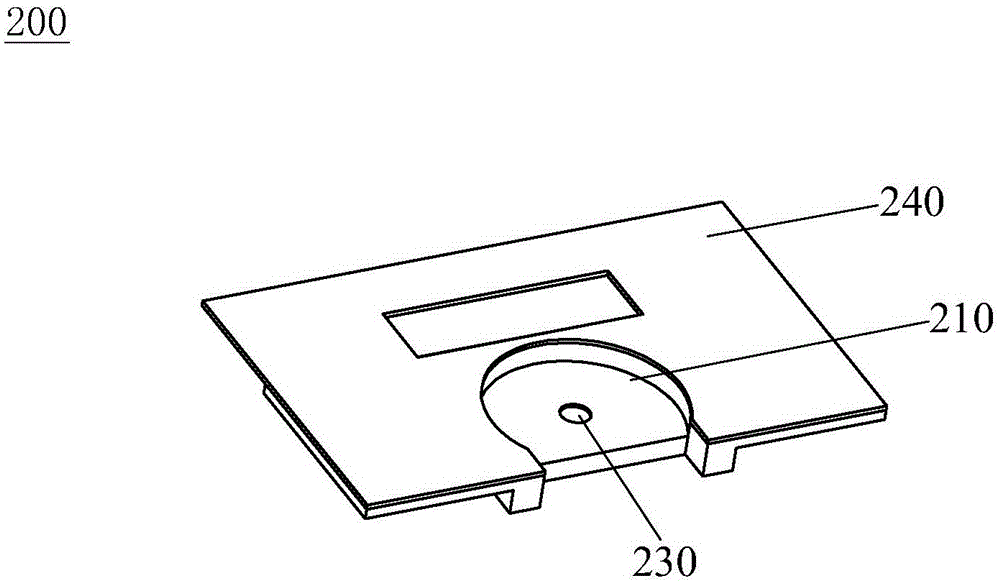

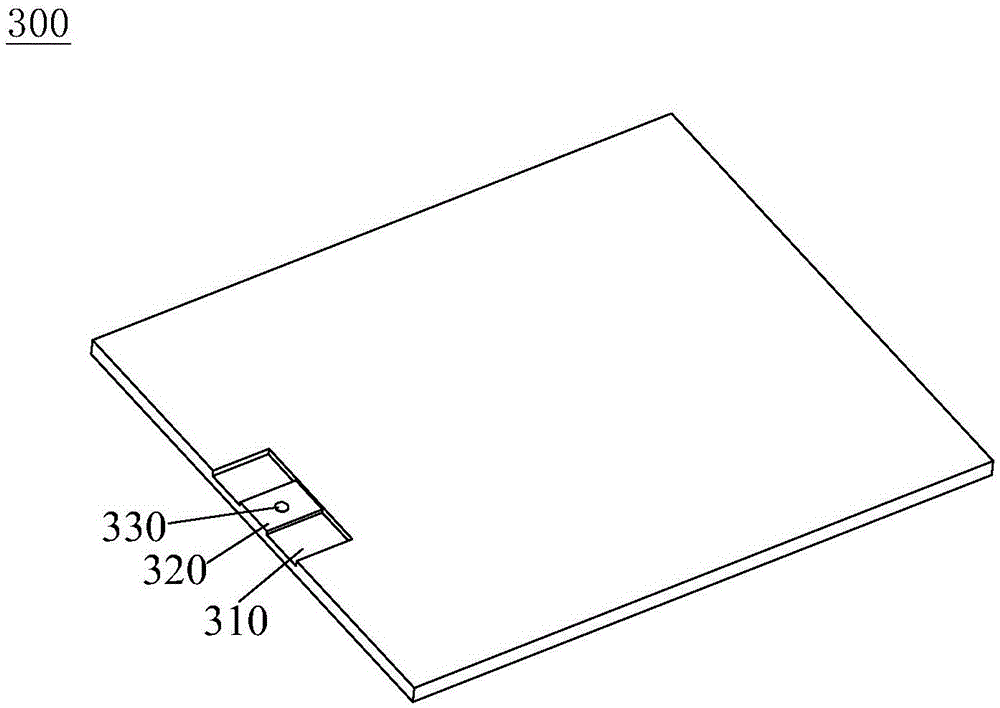

PendingCN108919101AFast testSimple motion trackElectronic circuit testingSoftware deploymentLinear motionEngineering

The invention belongs to the technical field of PCB production testing equipment, and particularly relates to a program burn test machine. The program burn test machine comprises a working platform. Afeeding area and a discharging area are correspondingly arranged at the two ends of the working platform, the working platform is provided with two operation groups, and each operation group comprises a portal frame, a carrying mechanism, a plurality of PCB board test modules and a central positioning mechanism. The two portal frames are arranged between the feeding area and the discharging areaside by side, and each PCB board test module includes a lifting mechanism, an upper module, a linear motion module and a lower module. The first end of the linear motion module is located below the upper module, and the second end of the linear motion module extends out of the upper module, and the second ends of the linear motion modules of the operation groups and the corresponding central positioning mechanisms are located on the same straight line parallel to transverse beams. The PCB board test modules are densely distributed on the working platform, the test speed of the PCB boards is greatly improved, the working efficiency is improved, the movement track of the carrying mechanism is simplified, and the working efficiency is improved.

Owner:深圳市仕科达精密设备技术有限公司

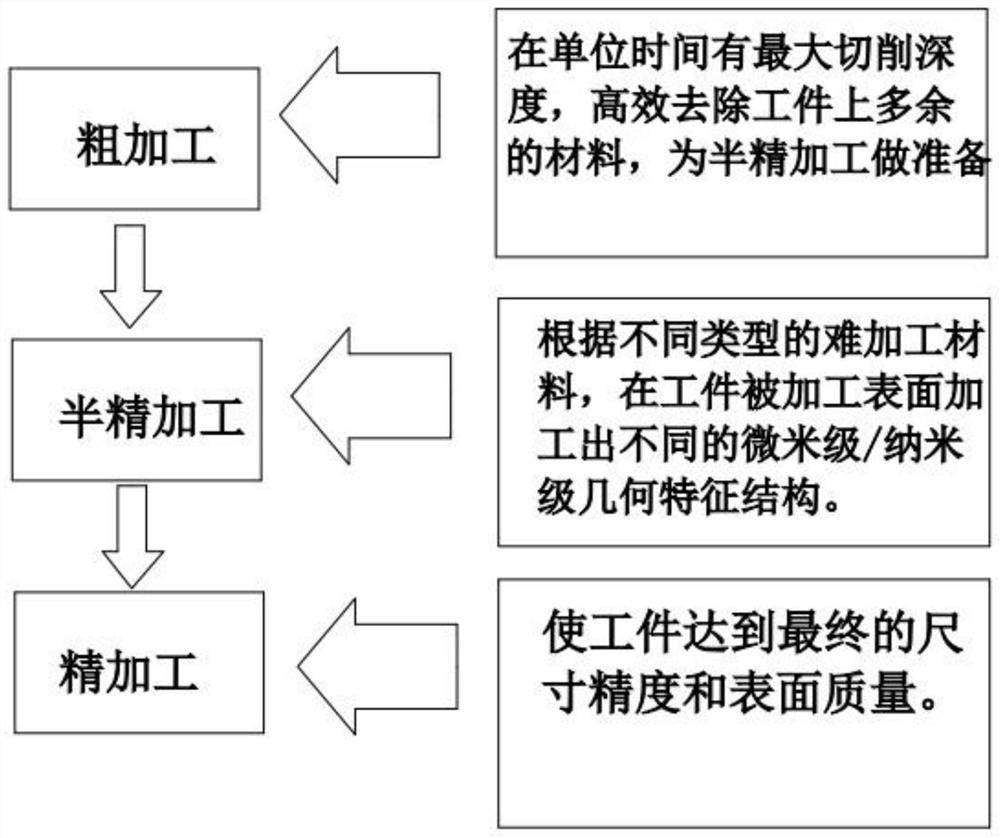

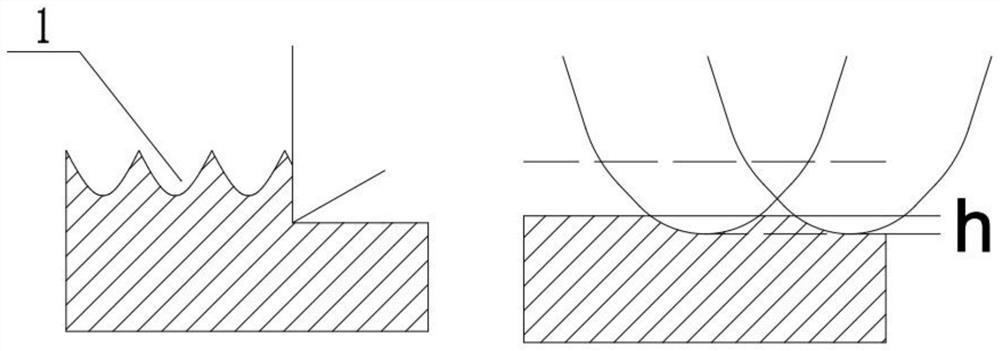

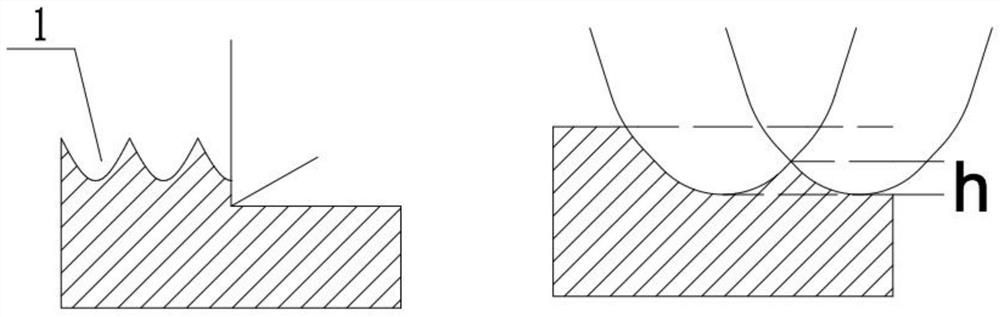

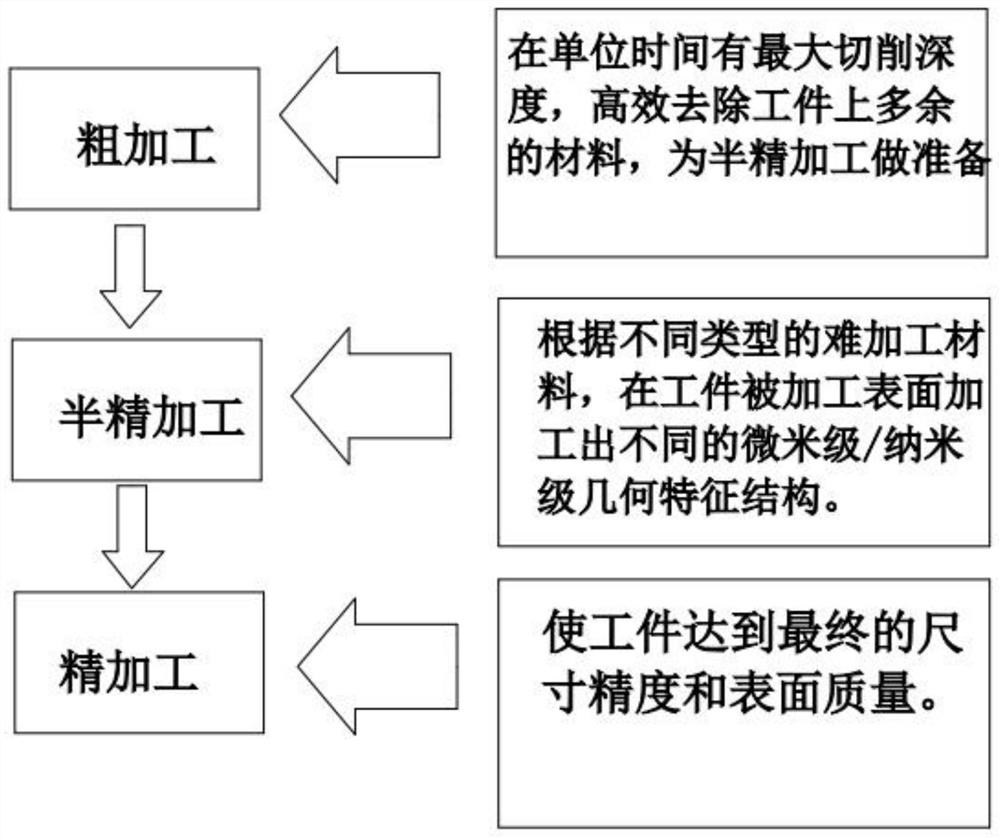

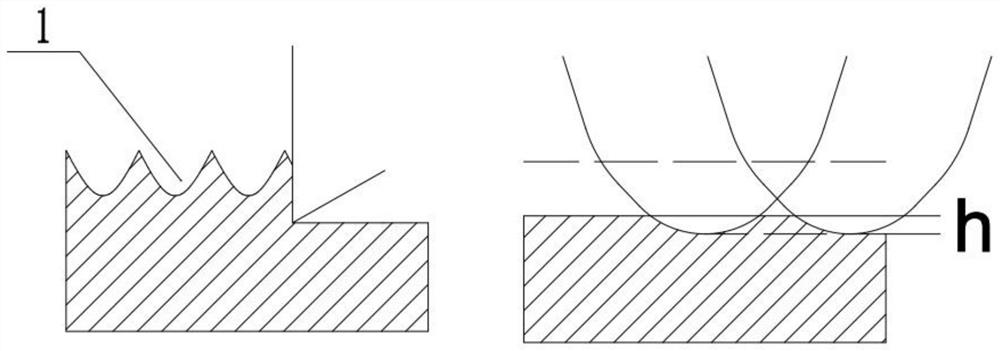

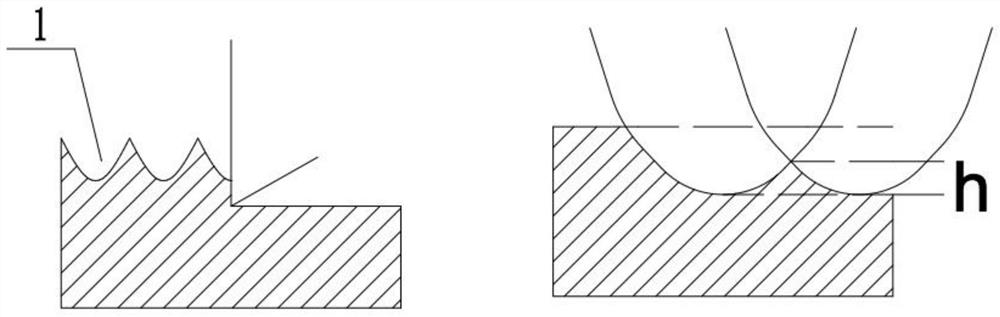

Ultra-precision cutting method based on surface microstructure design

The invention provides an ultra-precision cutting method based on surface microstructure design. The method comprises the following steps that rough machining is conducted, redundant materials on a workpiece are removed by utilizing a machine tool, the geometric contour of the workpiece can be prepared for semi-finish machining, and the machining allowance is left on the to-be-machined surface of the workpiece, and the thickness of the machining allowance is micron-sized; semi-finish machining is conducted, a plurality of densely-arranged defect structures are machined on the to-be-machined surface of the workpiece subjected to rough machining through the machine tool, namely, micro structures with the geometric dimensions being micron-scaled or nano-scaled are machined, and the depth of each micro / nano structure is smaller than the machining allowance; and finish machining is conducted, the micro / nano structure machined in the semi-finish machining process and the remaining machining allowance are removed through the machine tool, the cutting depth is equal to the thickness of the machining allowance reserved in the rough machining process, and the designed micro / nano structure is obtained on the to-be-machined face of the workpiece by comprehensively controlling the finish machining process and the semi-finish machining process. Therefore, the ultra-precision machining purposes of controlling the cutting force borne by a cutter in finish machining, reducing heat generated in the cutting process, prolonging the service life of the cutter and obtaining ultra-precision machining with nanoscale surface roughness on materials difficult to machine are achieved.

Owner:GUANGDONG UNIV OF TECH

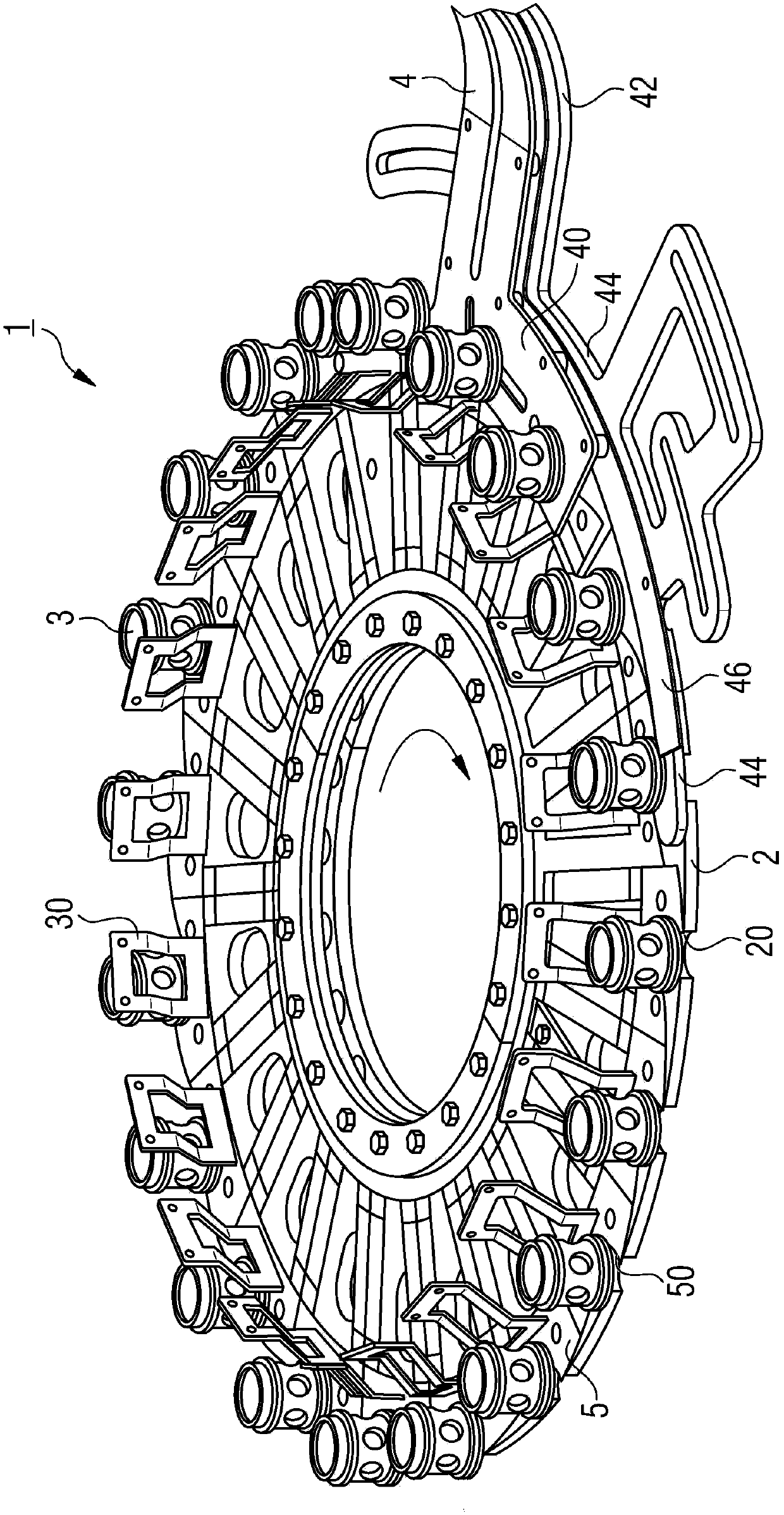

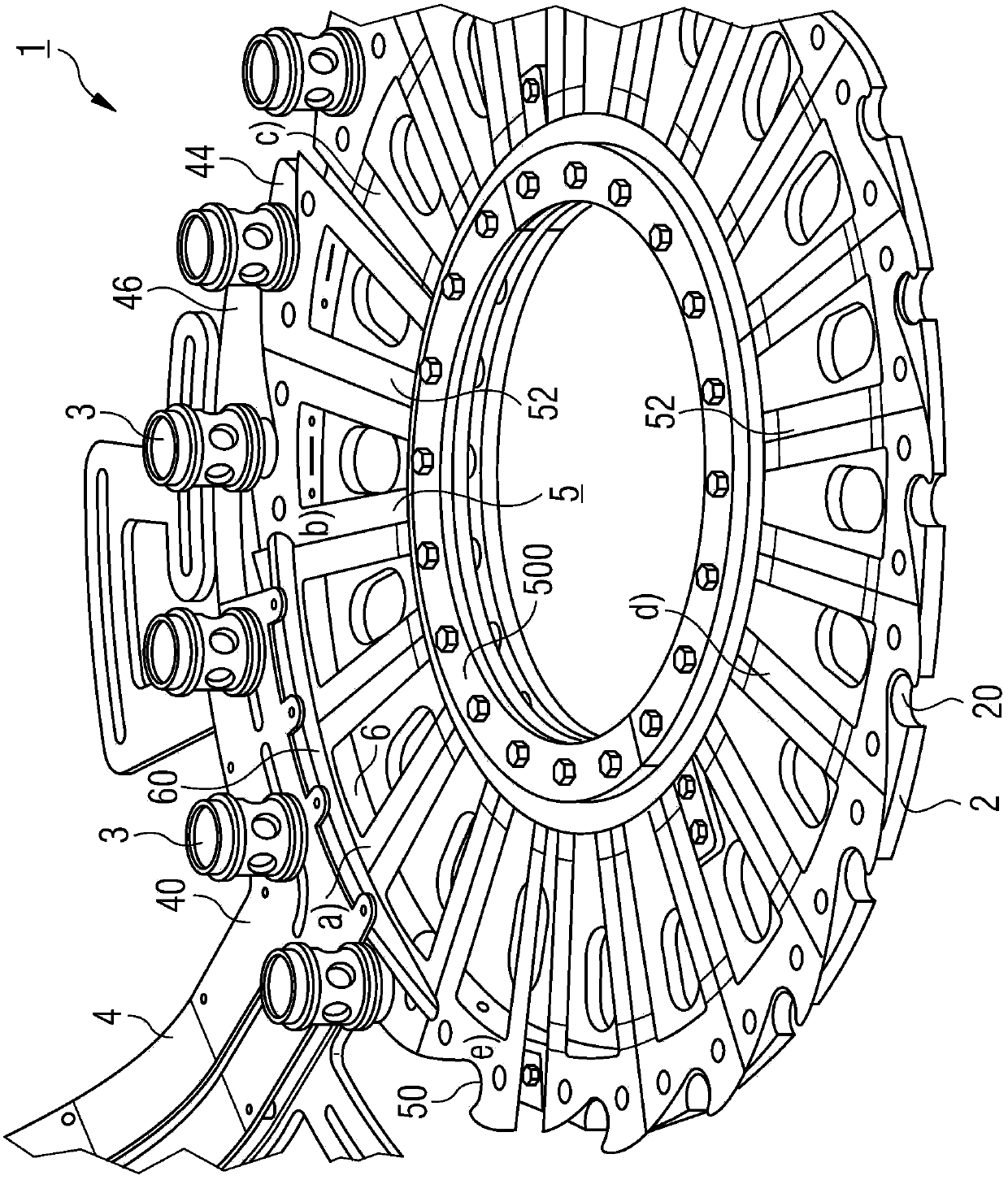

Variable-cycle engine injector valve driving mechanism

The invention belongs to the field of aero-engines, and particularly relates to a variable-cycle engine injector valve driving mechanism. The driving mechanism comprises an annular injector valve, anactuator, transmission rods, an inner-end driving rocker arm and an inner-end driven rocker arm; the annular injector valve is provided with a rocker arm slideway, one end of the actuator is connectedwith a support, and the other end of the actuator is connected with an outer transmission rocker arm; the transmission rods comprise the outer transmission rod and the inner transmission rod, one endof the outer transmission rod is connected with the outer transmission rocker arm, the middle of the outer transmission rod is rotationally arranged on a bypass duct casing, the other end of the outer transmission rod is connected with one end of the inner transmission rod through a spline, and the other end of the inner transmission rod is rotationally arranged on a core driven fan stage casing;one end of the inner-end driving rocker arm is fixedly connected with the inner transmission rod, and the other end of the inner-end driving rocker arm is arranged in the rocker arm slideway througha spherical structure; and one end of the inner-end driven rocker arm is fixed on the core driven fan stage casing, and the other end of the inner-end driven rocker arm is arranged in the rocker arm slideway through a spherical structure.

Owner:AECC SHENYANG ENGINE RES INST

Lamp turning structure and lamp thereof

InactiveCN101907276AReduce manufacturing costSimple motion trackLighting support devicesEngineeringProcessing cost

The invention relates to a lamp turning structure comprising a support, a turntable, a bolt and a nut, wherein the support and the turntable can be oppositely and rotationally connected through a rotary shaft, and a transverse waist-shaped hole and a longitudinal waist-shaped hole are respectively arranged on the support and the turntable, wherein the transverse waist-shaped hole and the longitudinal waist-shaped hole extend along the direction parallel to the rotary shaft and pass through the support and the turntable; and the bolt sequentially passes through the transverse waist-shaped hole and the longitudinal waist-shaped hole and is assembled with the nut to fix the support and the turntable, one of the transverse waist-shaped hole or the longitudinal waist-shaped hole passes through the rotary shaft along the length direction, and the other one does not passes through the rotary shaft along the length direction. The invention also relates to a lamp with the lamp turning structure. The circumferential rotation of the turntable is decomposed into two straight-line directions forming certain angles on the straight-line transverse waist-shaped hole and the straight-line longitudinal waist-shaped hole through the bolt so that the movement locus of the bolt is simplified, and the straight-line transverse waist-shaped hole and the straight-line longitudinal waist-shaped hole are easy to process so that the processing cost is reduced.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

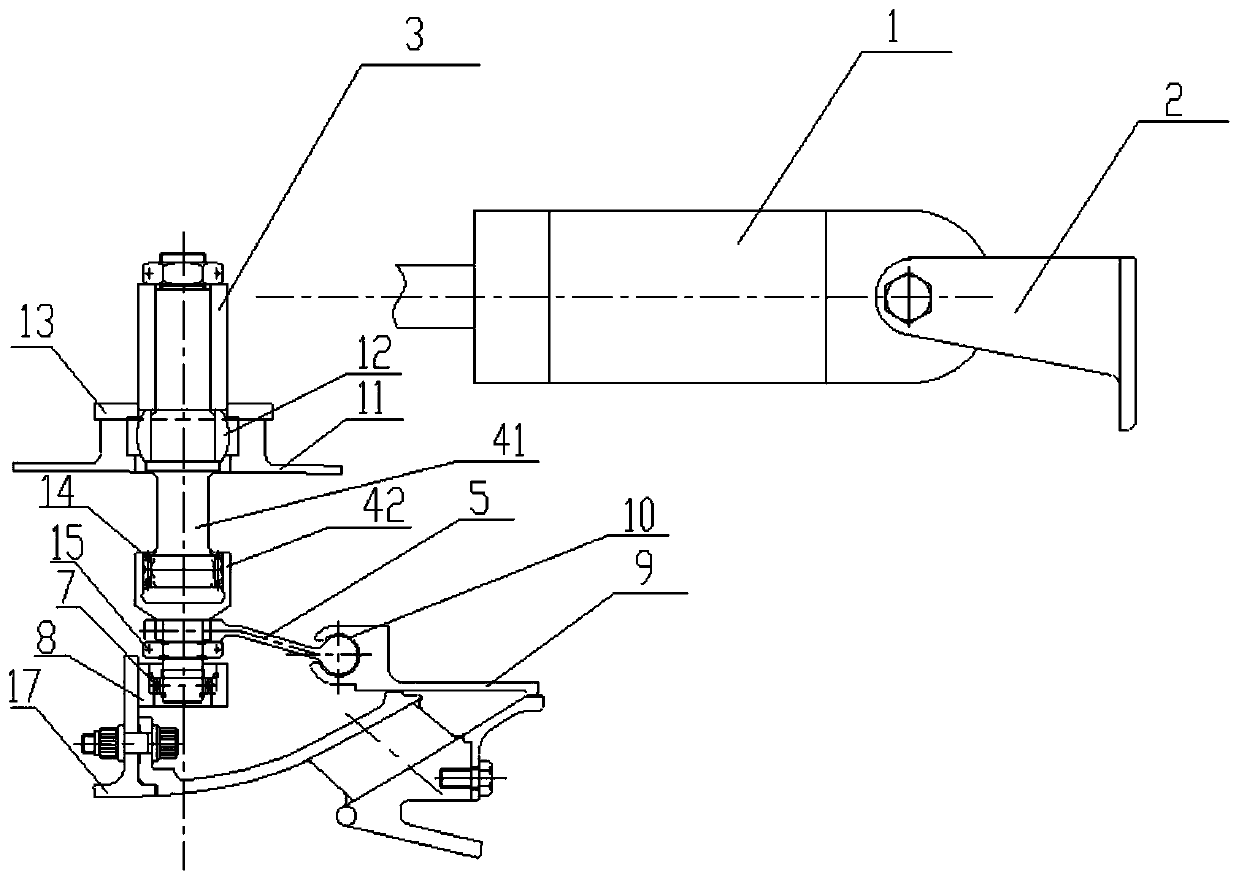

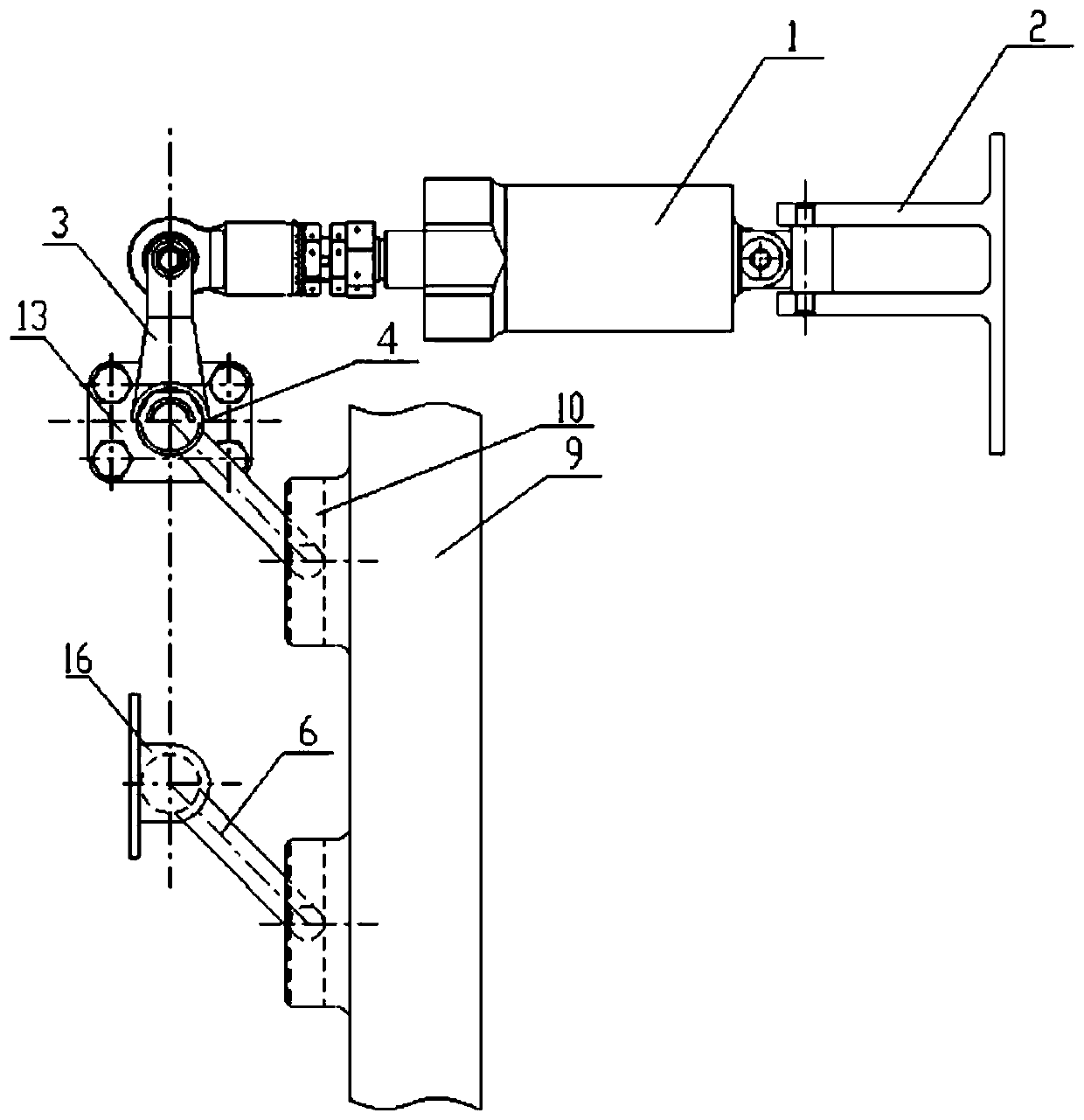

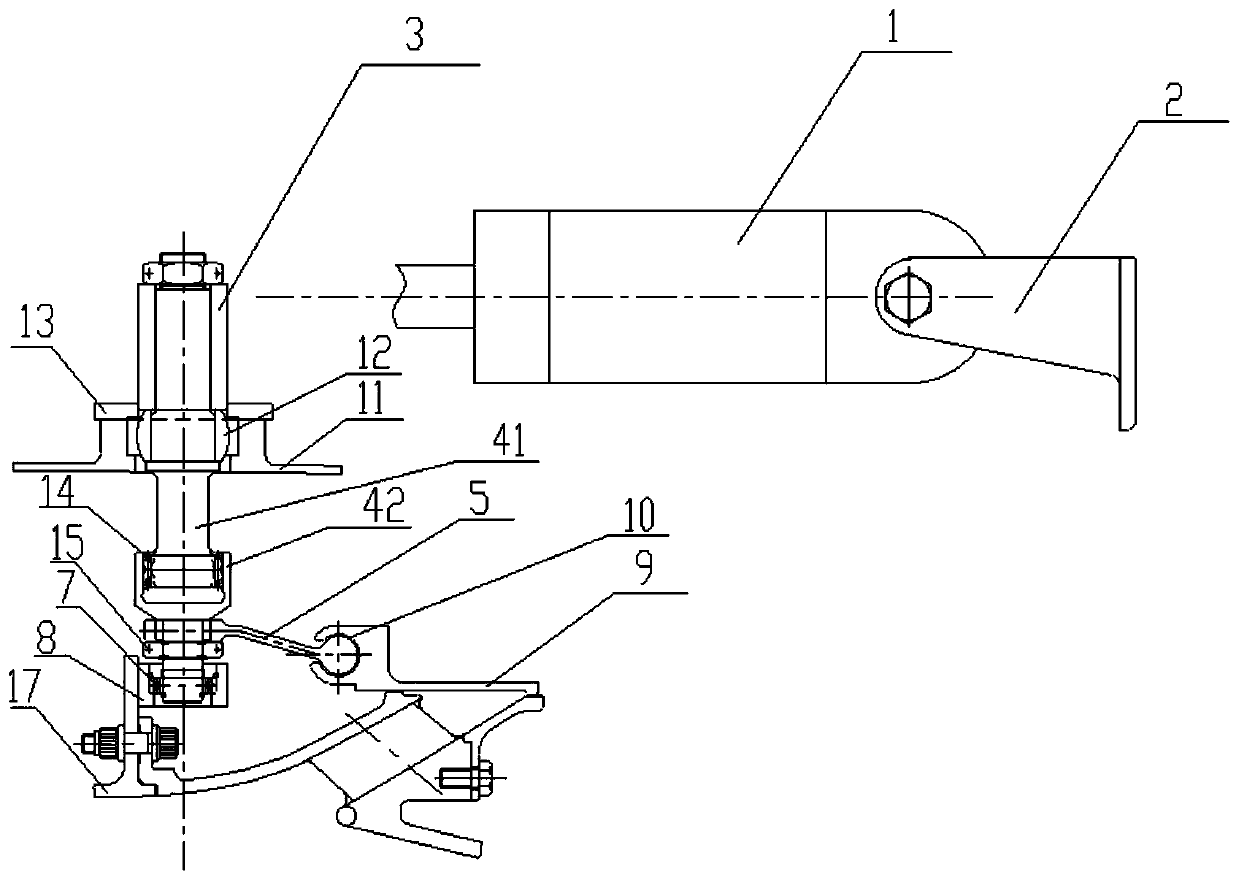

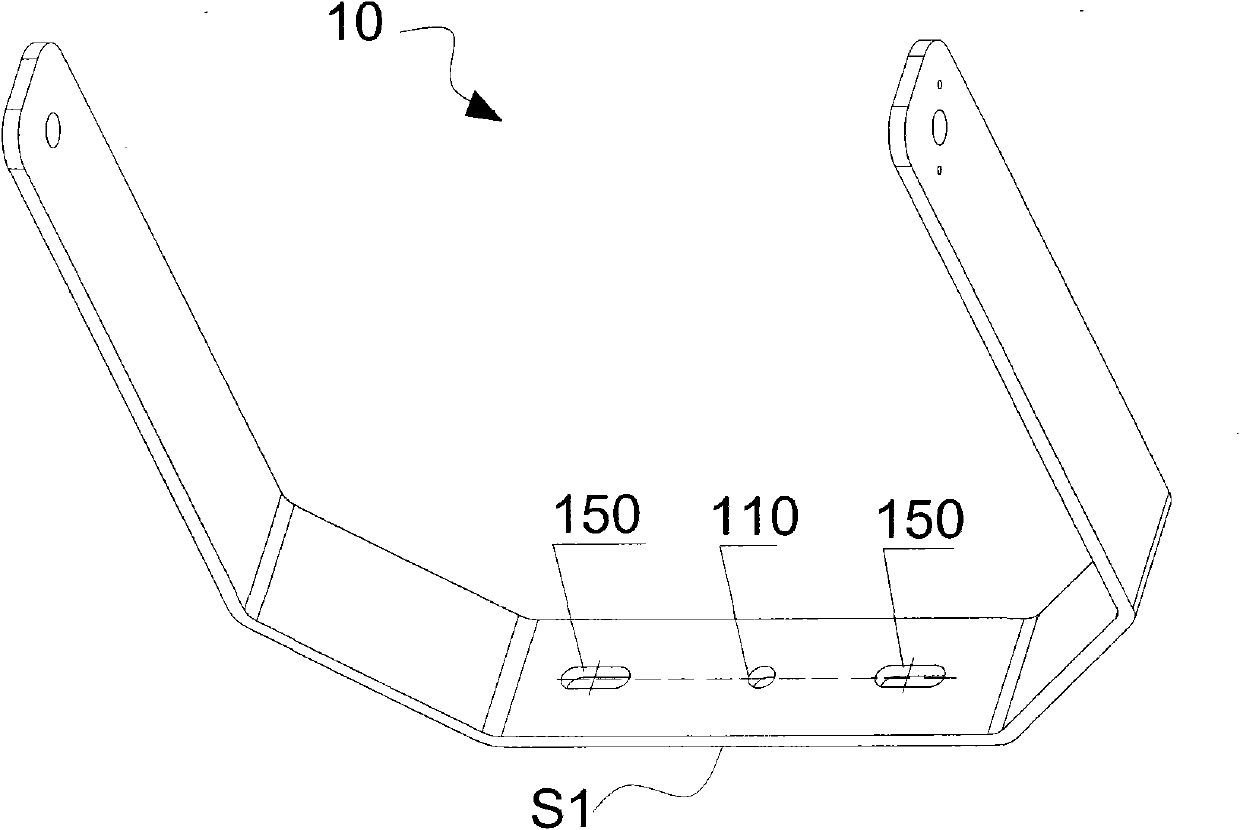

Bottle blowing machine provided with clamping mechanism

The invention discloses a bottle blowing machine provided with a clamping mechanism. The bottle blowing machine comprises a rack, a die opening and closing die-set arranged on the rack and a sealing mechanism which is vertically movable, arranged on the rack and located above the die opening and closing die-set, wherein the clamping mechanism comprises a clamping assembly and a driving device, oneend of the clamping assembly rotates around a horizontal shaft, the clamping assembly is arranged on the rack and located between the sealing mechanism and the die opening and closing die-set, the driving device is arranged on the rack and used for driving the clamping assembly to rotate around the horizontal shaft to be away from the die opening and closing die-set, and a notch for clamping a bottle preform is formed in the other end of the clamping assembly and located under the sealing mechanism. According to the bottle blowing machine provided with the clamping mechanism, the clamping assembly for clamping the bottle preform and the driving device for driving the clamping assembly to be away from the die opening and closing die-set are arranged on the rack, tracking travel of a manipulator is reduced, motion trail of the manipulator is simplified, and operating stability of the manipulator is improved; design difficulty of a manipulator cam is reduced; assistant time for preform feeding and bottle taking is shortened, and single-capacity productivity can be improved effectively.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

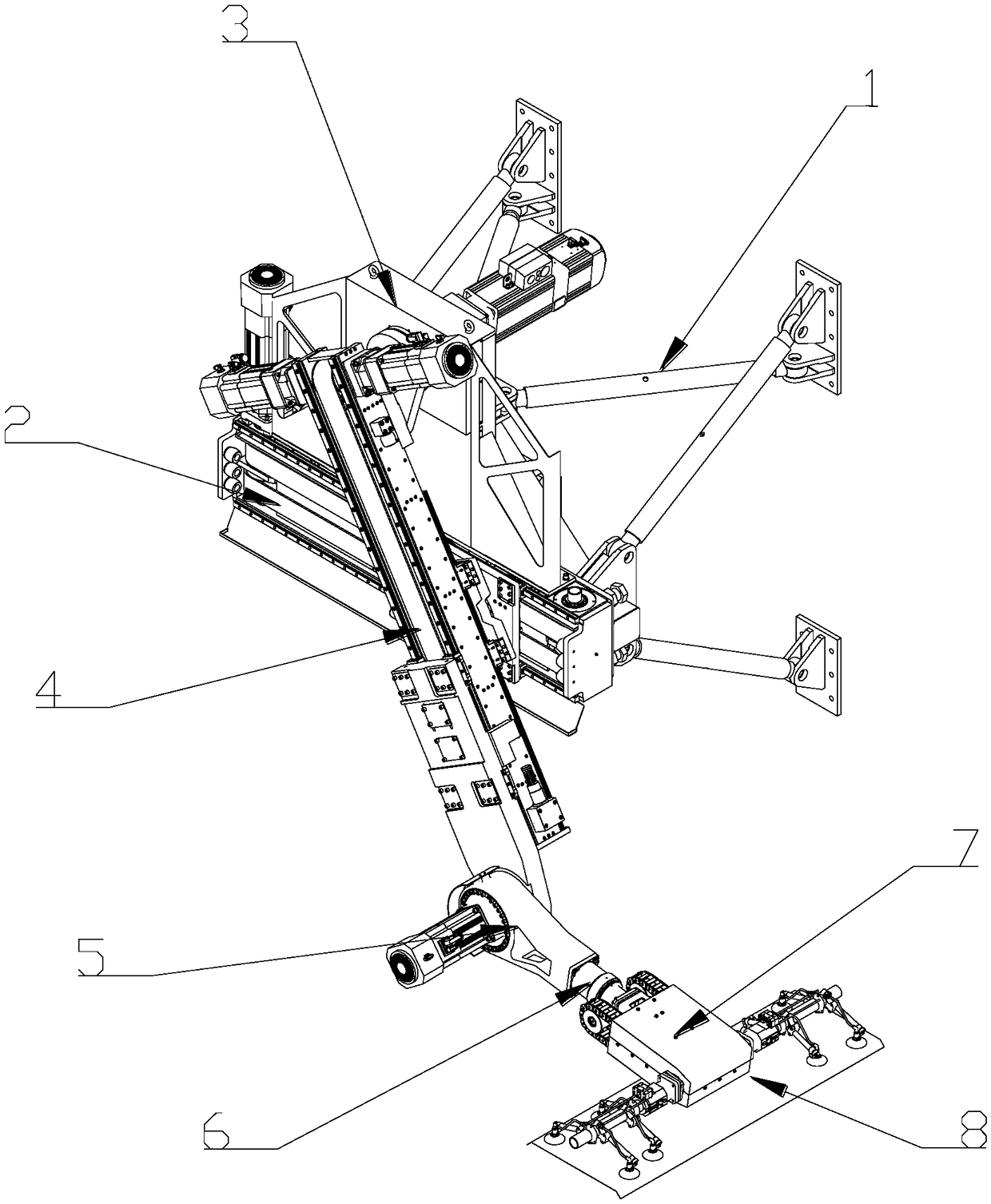

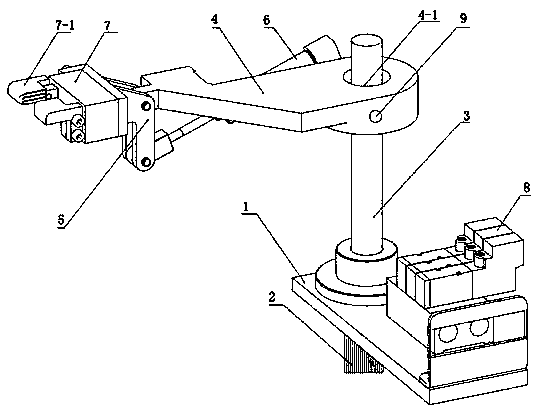

High-speed carrying robot

PendingCN108946160ACompact layoutGuaranteed uptimeConveyorsMetal-working feeding devicesEngineeringRobot

The invention discloses a high-speed carrying robot. The high-speed carrying robot comprises a suspension structure, a large arm structure and a small arm structure; the suspension structure is provided with a displacement adjusting structure; an angle adjusting structure is arranged at the upper part of the displacement adjusting structure; the upper end of the large arm structure is arranged onthe angle adjusting structure; the lower end of the large arm structure is arranged on the displacement adjusting structure; the angle adjusting structure drives the upper end of the large arm structure to perform a swing motion and the lower end of the large arm structure to slide and rotate along the displacement adjusting structure; the end part of the lower end of the large arm structure is connected with the small arm structure; the small arm structure comprises a first rotating structure; the first rotating structure is connected with a second rotating structure; the second rotating structure is connected with a third rotating structure; and the third rotating structure is connected with an end picker structure. Through linkage of all shaft parts, the coordinative reciprocating swingof the large arm and the small arm of the high-speed carrying robot is realized, and the high-speed and high-load stable conveying of plates between presses is achieved.

Owner:JINAN HAOZHONG AUTOMATION

Welding material taking mechanical arm

InactiveCN103506781ASimple structureSimple motion trackProgramme-controlled manipulatorWelding/cutting auxillary devicesCost effectivenessElectric machinery

The invention discloses a welding material taking mechanical arm which comprises a machine base, a motor, a connecting rod, a hanging arm, a connecting block, an air cylinder, a pneumatic finger, pneumatic pipelines and a solenoid directional valve. The connecting rod is vertically arranged on the machine base. The bottom of the connecting rod is in transmission linkage with the motor. The top of the connecting rod is provided with the hanging arm. The end portion of the hanging arm is hinged to the connecting block. One end of the connecting block is provided with the pneumatic finger. A clamping block of the pneumatic finger is made of heat-resisting materials. The air cylinder used for driving the connecting block to turn is connected between the other end of the connecting block and the hanging arm. The air cylinder and the pneumatic pipeline are connected with the solenoid directional valve through the pneumatic pipelines. The welding material taking mechanical arm has the advantages of being simple in structure, high in cost-effectiveness ratio and the like.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

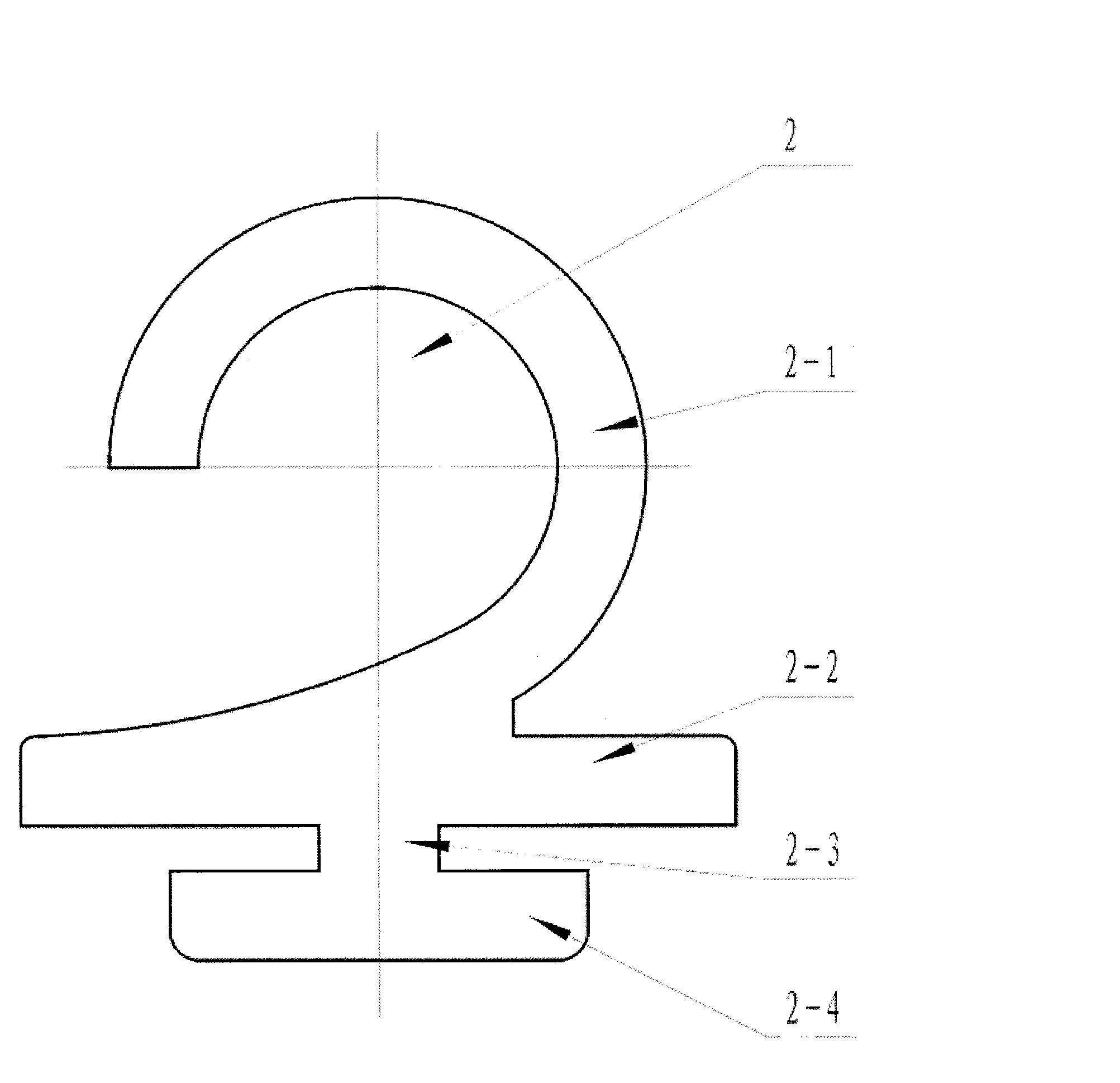

Method for putting hook in textile automatic packaging and hook adopting method

The invention provides a method for putting a hook in textile automatic packaging and the hook adopting the method. The method comprises the steps of clamping the upper part of the hook by a mechanical hand, moving downwards by aligning the hook to a rectangular hook pressing mark which is arranged on an upward-front-surface and horizontally-placed packaging board and is vertical to a folding pressing mark of the packaging board, bursting the rectangular hook pressing mark of the packaging board by a lower beam at the lower part of the hook, and entering into the inner surface of the packaging board; and when the mechanism hand clamps the upper part of the hook and rotates 90 degrees, loosening the hook, and returning back to original position. The hook comprises an upper hook, wherein an upper beam and the lower beam which are mutually paralleled are arranged under the upper hook, and the lower side of the upper beam is connected with the upper side of the lower beam through an upright. According to the method and the hook, which are provided by the invention, the motion trails of a mechanism for putting the hook and the mechanical hand are simplified, and the hook putting success rate is high; no special requirements are required to the packaging board and the hook, and the packaging cost cannot be increased; and the hooking position of a packaged product can be smooth and firm, and the whole packaging effect is increased.

Owner:DONGHUA UNIV +1

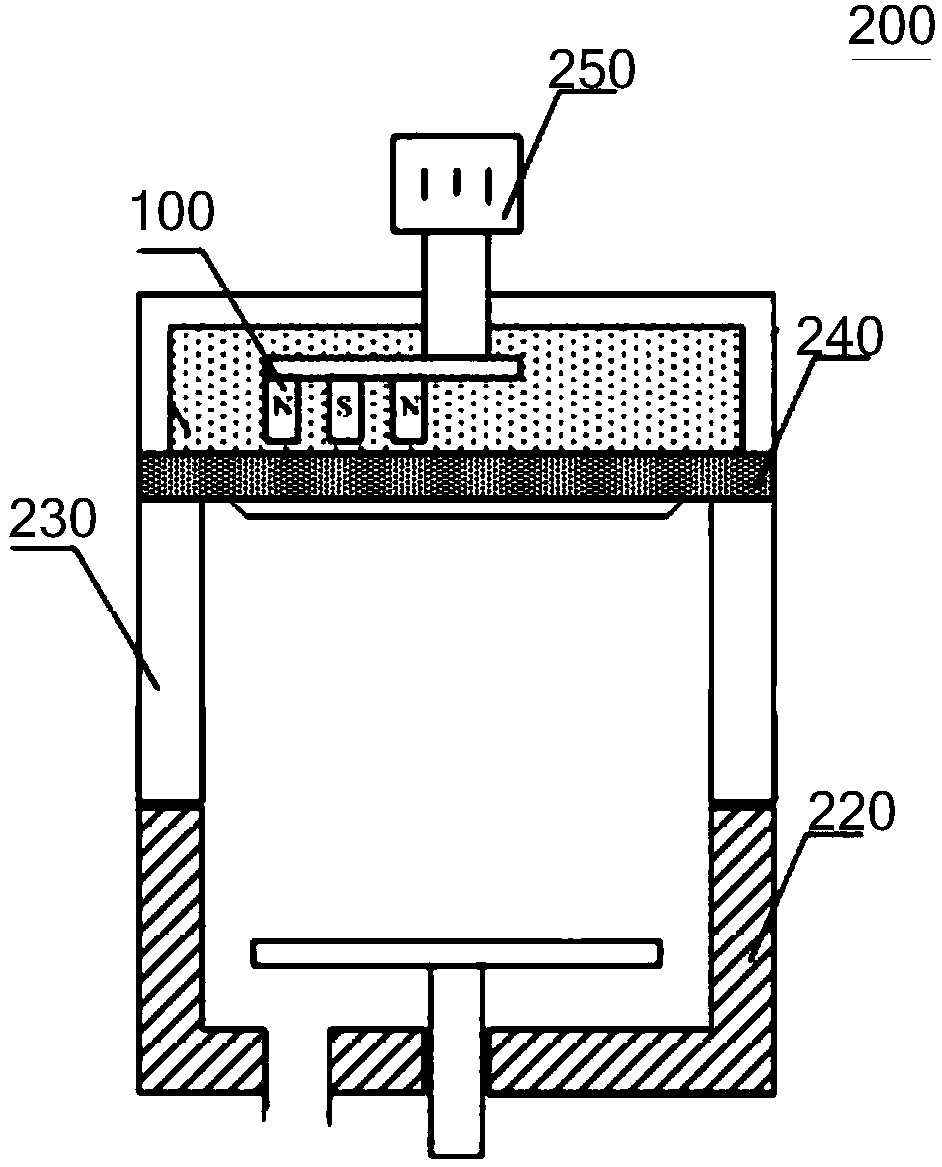

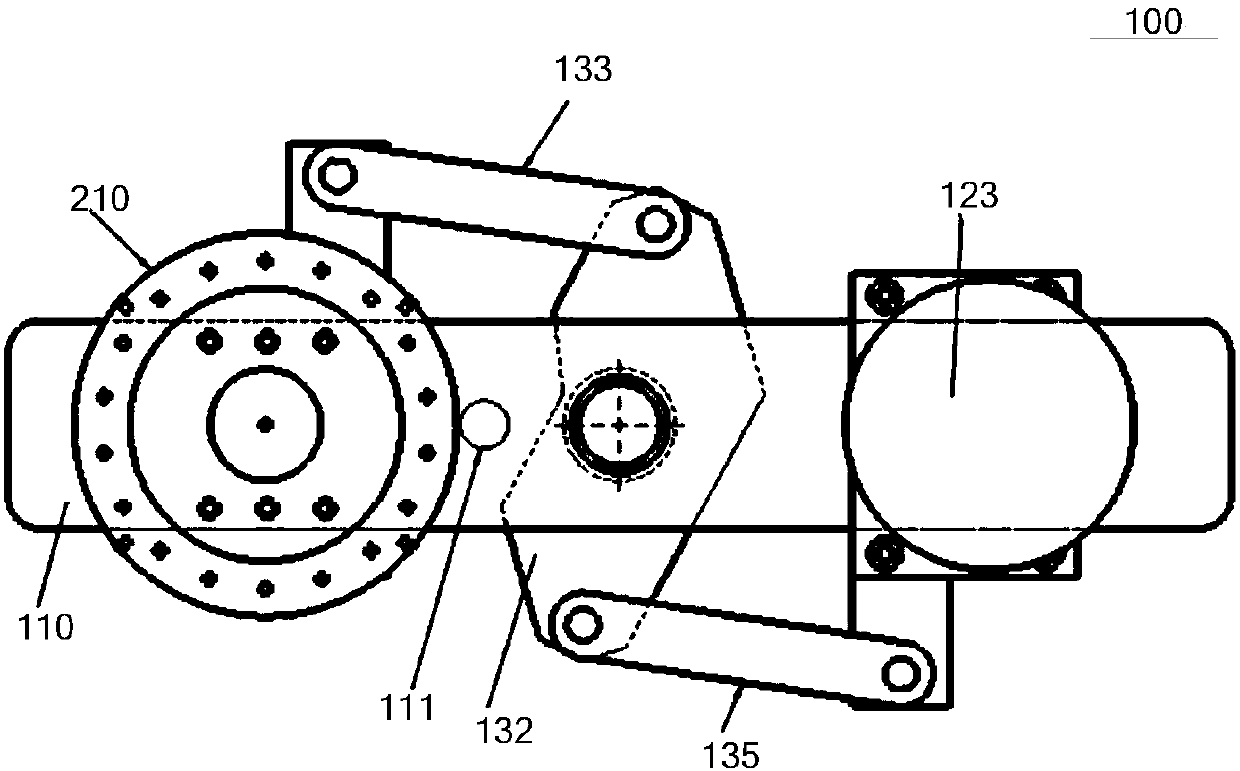

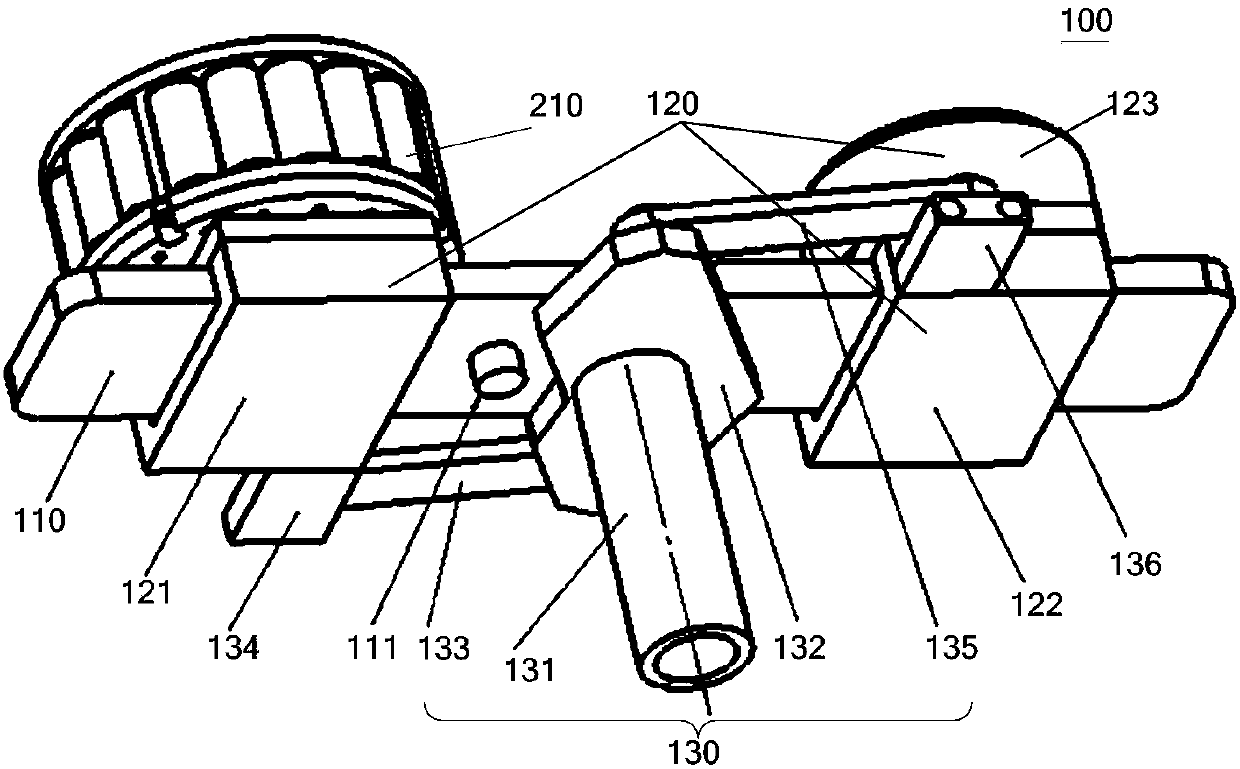

Scanning mechanism for driving magnetron, magnetron source and magnetron sputtering device

ActiveCN109830418ASimple motion trackEasy to controlMagnetronsVacuum evaporation coatingEngineeringMechanical engineering

The invention discloses a scanning mechanism for driving a magnetron, a magnetron source and a magnetron sputtering device. The scanning mechanism comprises a guide rail on which a stopping piece is arranged; a moving structure disposed on the guide rail and capable of reciprocating along the guide rail; a driving component rotatably disposed on the guide rail and used for moving the moving structure on the guide rail to a first predetermined position or second predetermined position and then rotating the moving structure around a target material central axis such that the magnetron is alignedto the edge region or the central region of the target material and then rotates around the target material central axis. Therefore, the scanning mechanism of the present invention is simple in motion trajectory, easy to control, and high in reliability when switching different positions of the magnetron, and can also be applied to various types of magnetrons.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

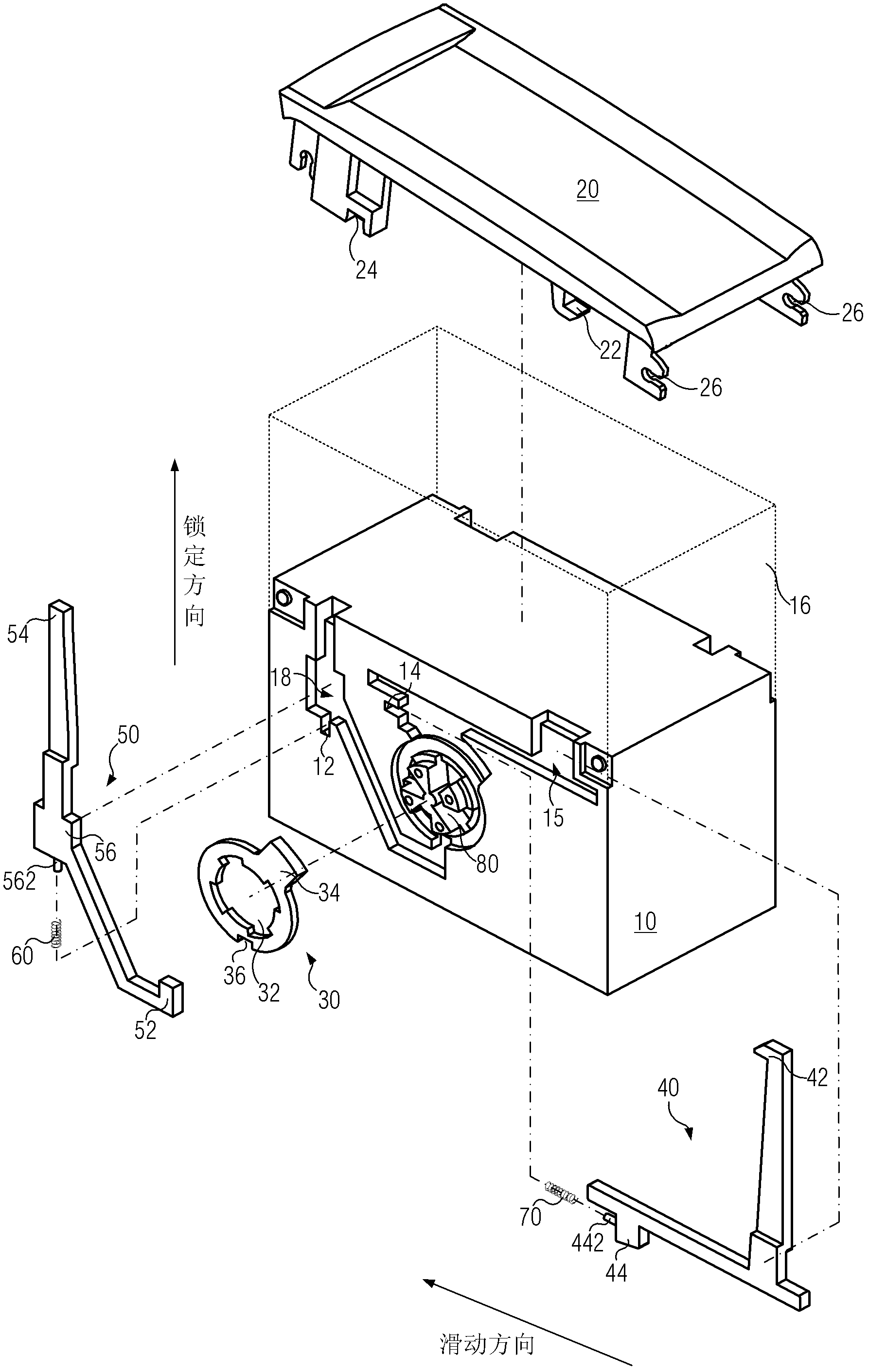

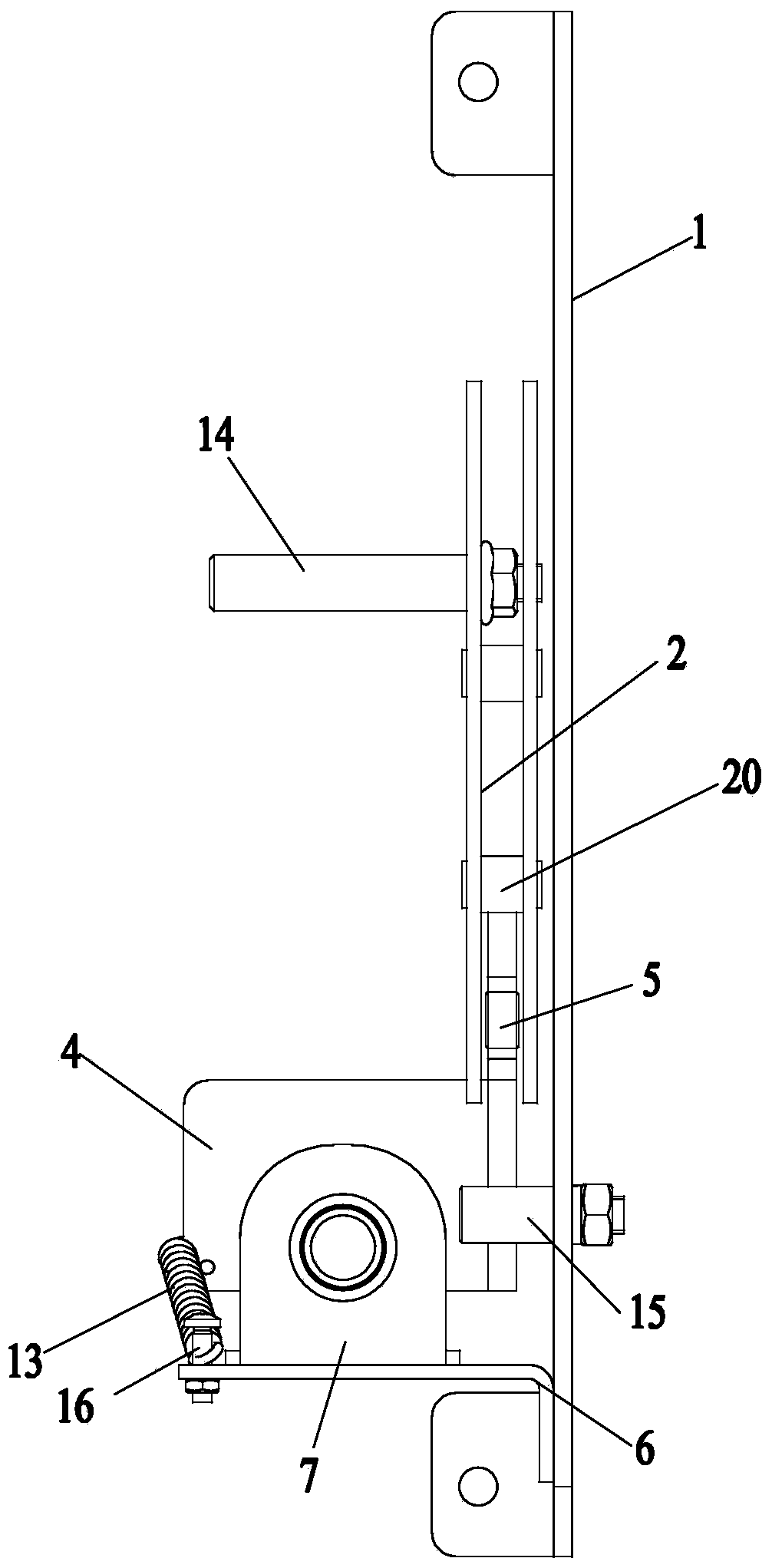

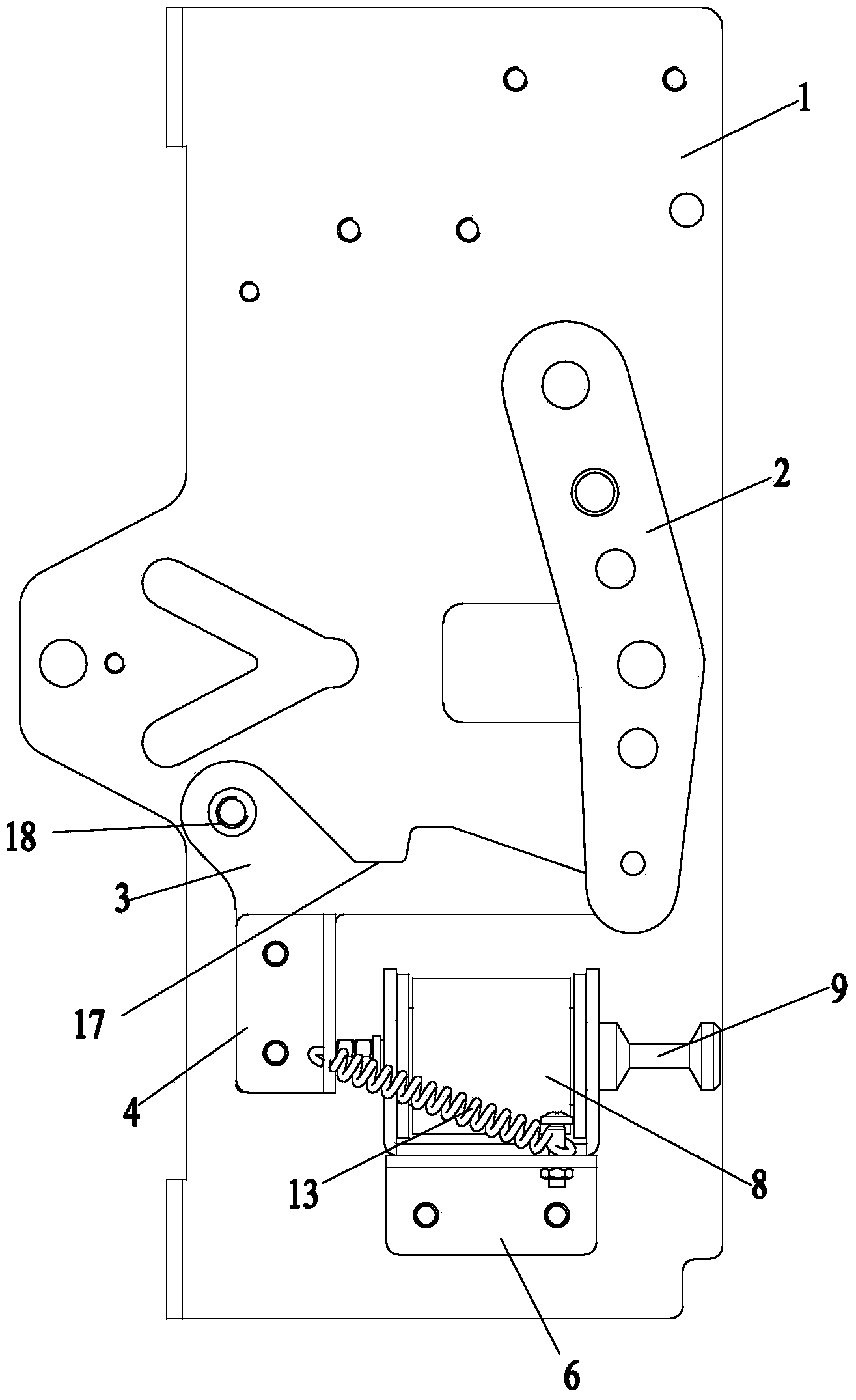

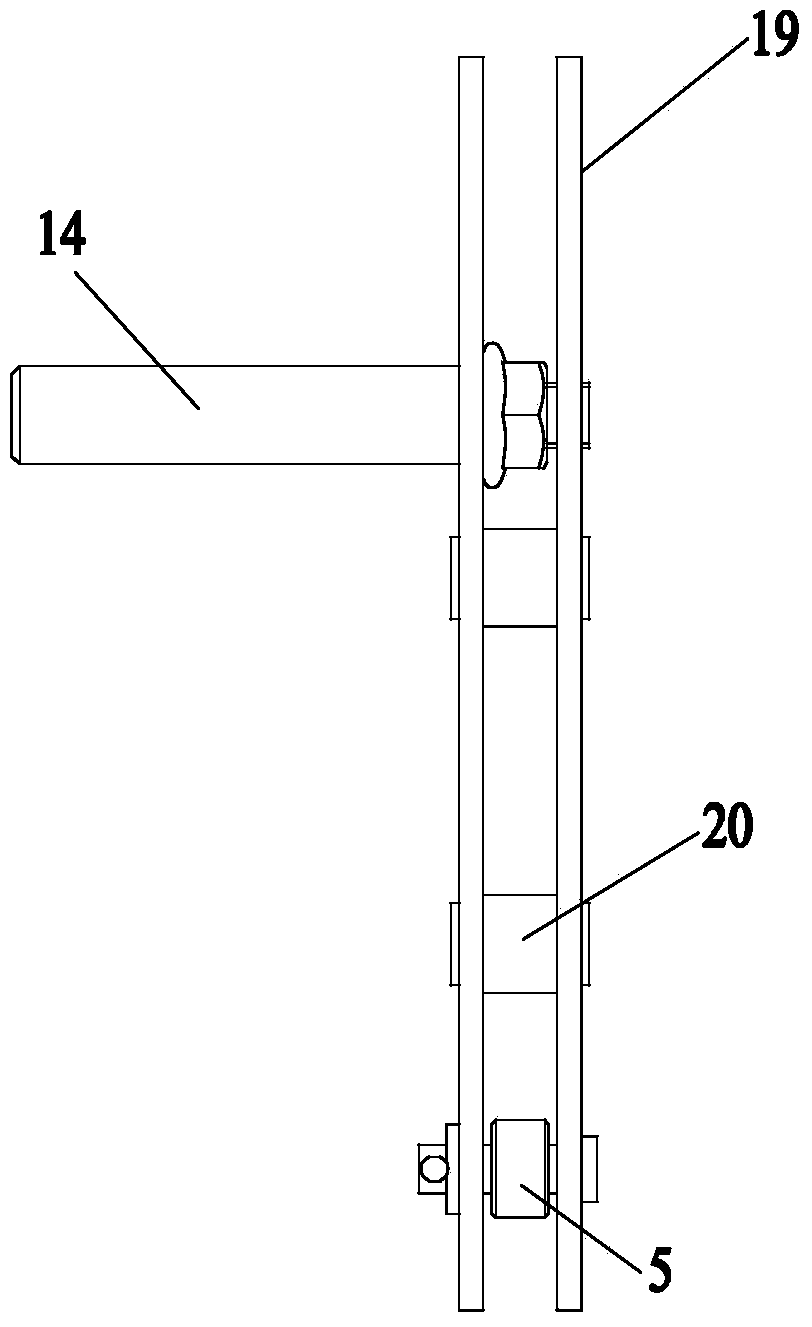

Buckling and tripping device for automatic transfer switching equipment

ActiveCN104282463AImprove closing operationReliable closing operationContact driving mechanismsTransfer switchEngineering

The invention relates to a buckling and tripping device for automatic transfer switching equipment. The buckling and tripping device comprises a base plate, wherein a buckling mechanism and a tripping mechanism. The buckling mechanism comprises a lever plate body and a buckling plate, wherein the lever plate body and the buckling plate are hinged to the base plate, the buckling plate is located at one end of the lever plate body, a roller capable of rolling on the buckling plate and being embedded into a buckling groove formed in the buckling plate is arranged in the lever plate body and the lever plate body rotates on the base plate to enable the roller to be embedded into the buckling groove so as to achieve switching-on control of an automatic transfer switch. The tripping mechanism comprises a connecting plate installed on the buckling plate and a tripping action mechanism, wherein the tripping action mechanism enables the roller to break away from the buckling groove in the buckling plate through the connecting plate so as to achieve switching-off control of the automatic transfer switch. The buckling and tripping device is simple and compact in structure and capable of achieving remote operation on the automatic transfer switch, improving the on-off performance of the automatic transfer switching equipment and ensuring the switching-on and switching-off reliability of the automatic transfer switch.

Owner:WUXI HANKWANG ELECTRIC

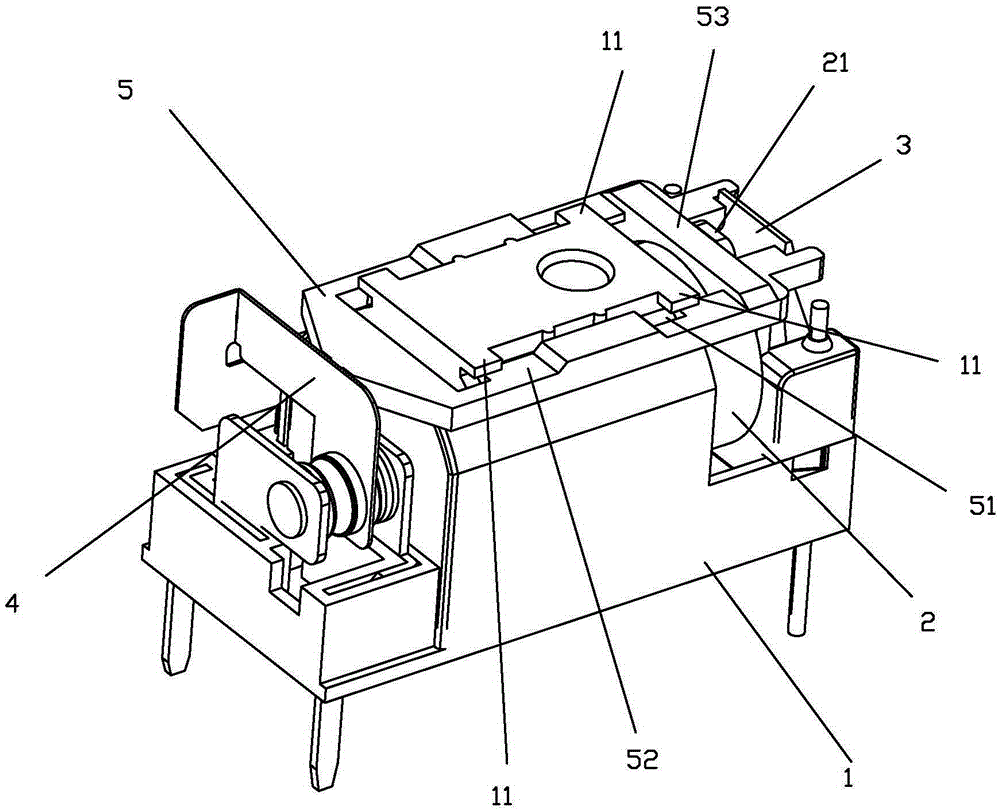

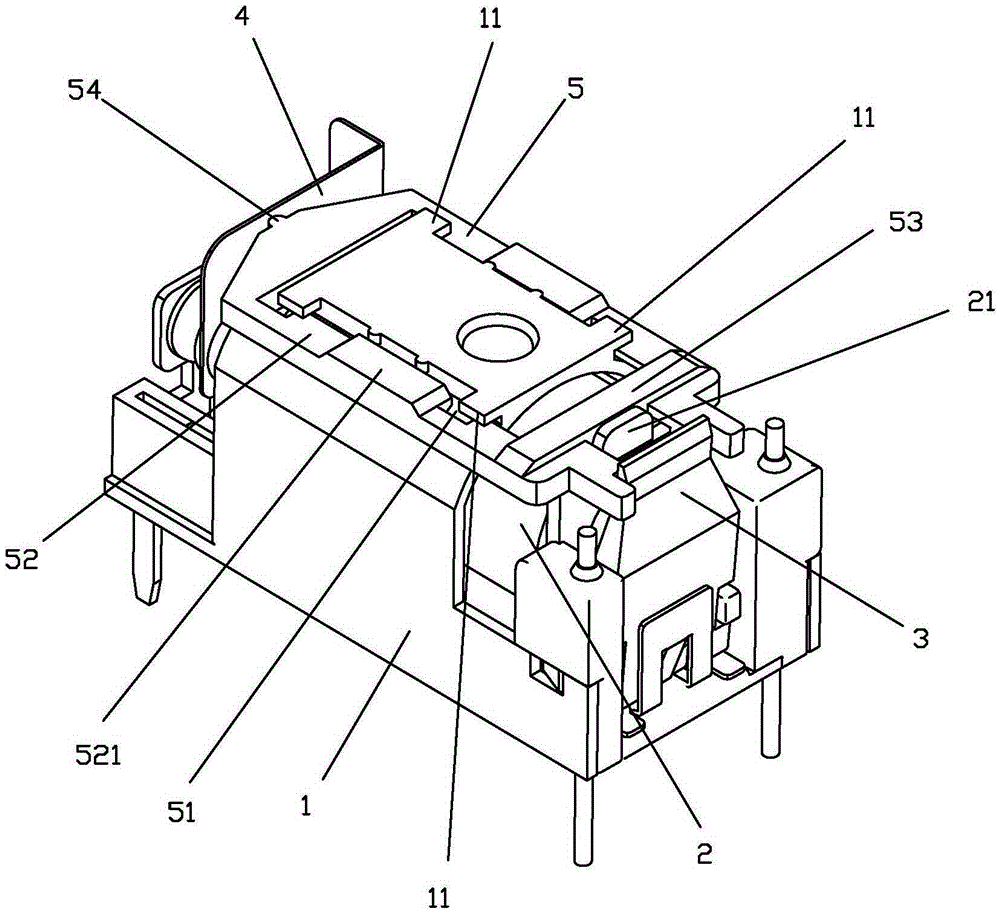

Pushing card chipless assembling electromagnetic relay and assembling method thereof

ActiveCN105575732ANot easy to rubSimple motion trackElectromagnetic relay detailsContact modeEngineering

The invention discloses a pushing card chipless assembling electromagnetic relay and an assembling method thereof. The electromagnetic relay comprises a moving reed, an armature, a pushing card and a pedestal, wherein the pushing card is clamped into a track of the pedestal through an interference-free clamping structure between the pushing card and the pedestal and can only perform linear reciprocating movement along the track limited by the pedestal, the pushing card cooperates with the armature in a contact mode at one end of the linear reciprocating movement to enable the armature to only push the pushing card to move in a single direction, and the pushing card also cooperates with the moving reed at the other end of the linear reciprocating movement in a contact mode to enable the pushing card to also only push the moving feed to act in a single direction. According to the electromagnetic relay provided by the invention, when the pushing card is assembled, interference assembling is not employed, and plastic powder shreds are not generated; the positioning and motion locus of the pushing card of the assembled relay are determined through the pedestal, the plastic powder shreds are not easily generated through friction in normal operation of the relay, the movement locus of the pushing card is quite simple, and the assembling precision is also more accurate.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

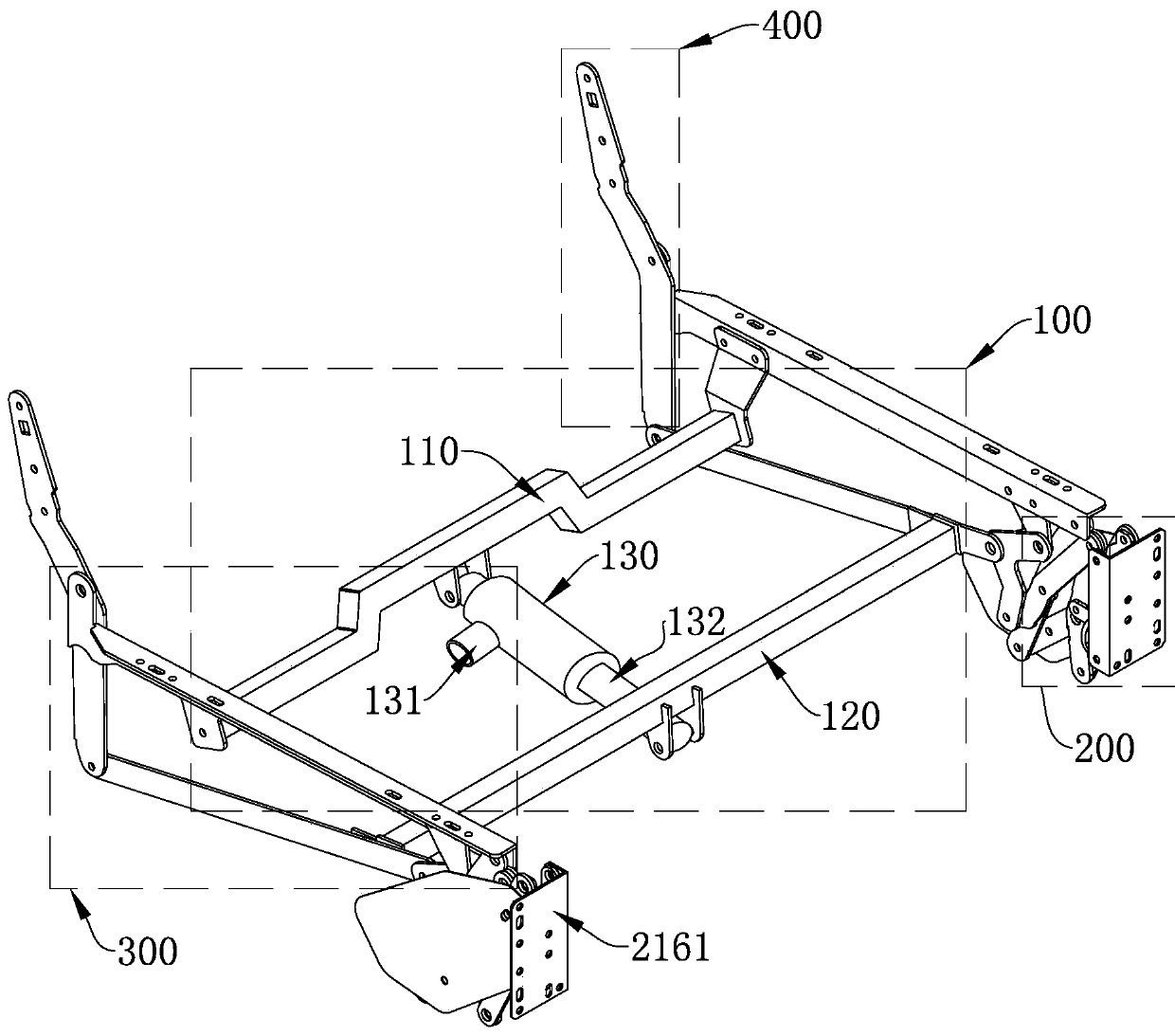

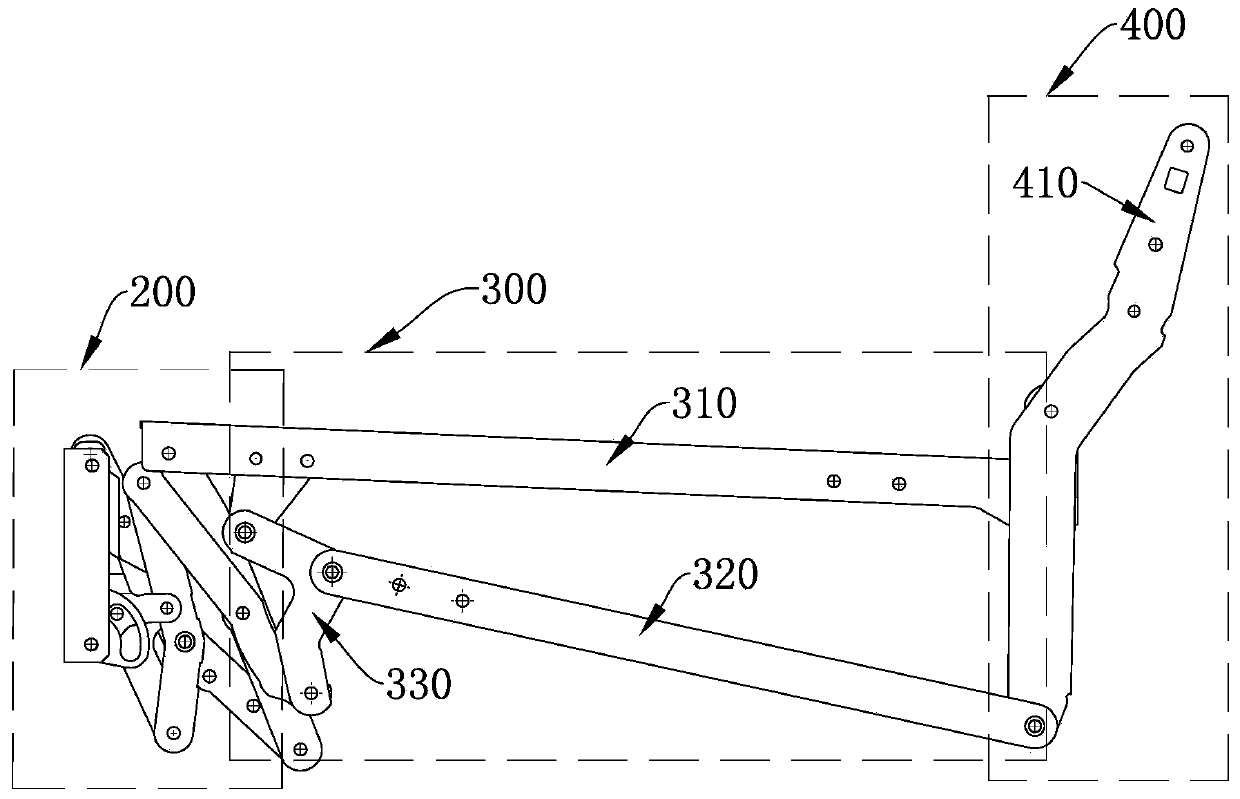

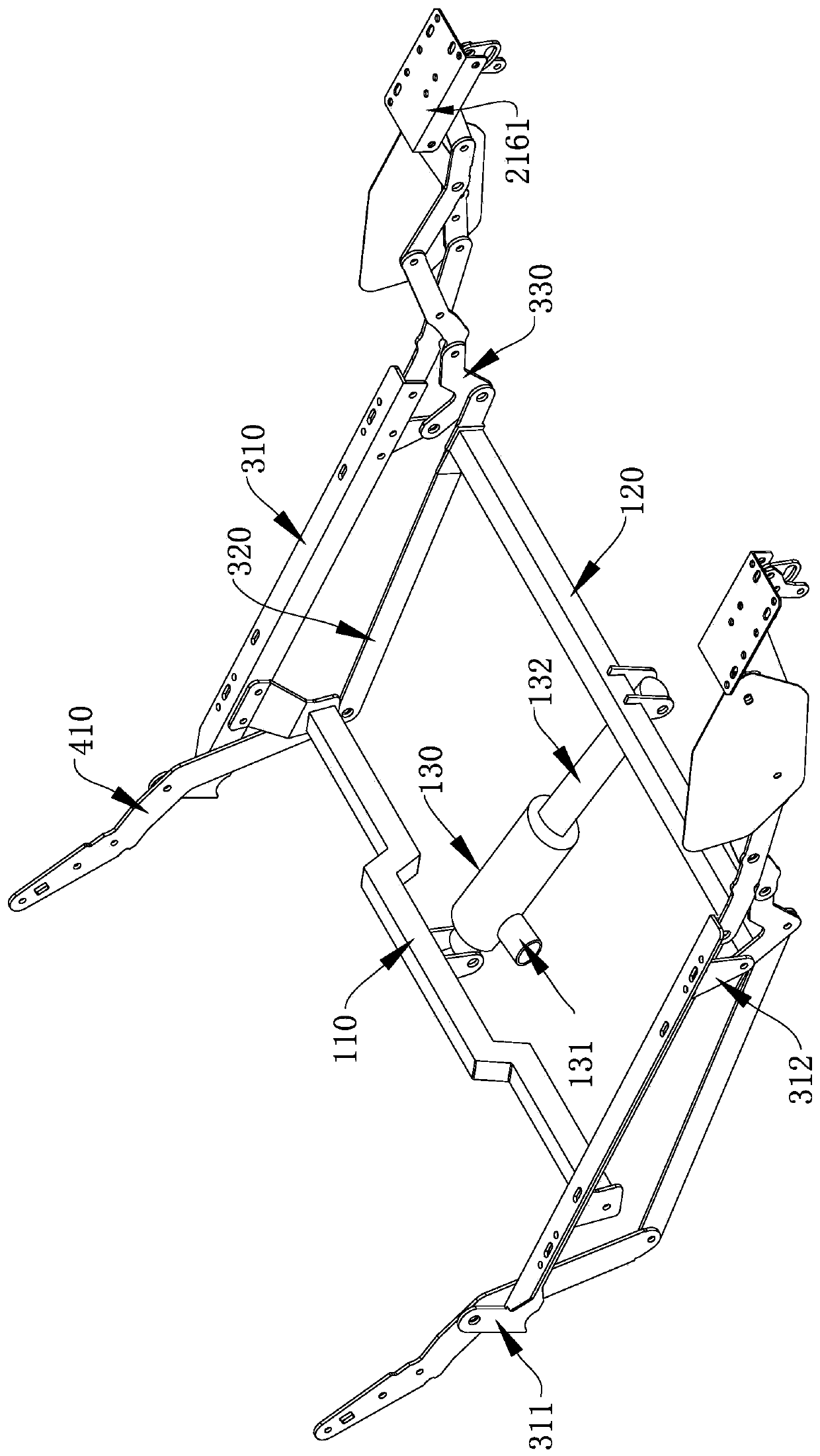

Electric mechanical stretching device

InactiveCN110693227ASimple structureEase of functional designStoolsChairsClassical mechanicsElectric machinery

The invention relates to an electric mechanical stretching device that comprises a driving assembly, a leg placing assembly, a seat frame supporting assembly and a backrest assembly; the seat frame supporting assembly comprises supporting fixing rods and supporting transmission rods which are distributed up and down, the rear ends of the supporting fixing rods and the supporting transmission rodsare hinged to the backrest assembly, the front end of the supporting fixing rod is hinged to the leg placing assembly, a linkage rod is hinged to the front end of the supporting transmission rod, andthe two ends of the linkage rod are hinged to the leg placing assembly and the supporting fixing rods respectively; the driving assembly comprises a driving fixing rod with the two ends connected withthe left supporting fixing rod and the right supporting fixing rod correspondingly, a driving transmission rod with the two ends connected with the left supporting transmission rod and the right supporting transmission rod correspondingly, and a push rod motor arranged between the driving fixing rod and the driving transmission rod used for pushing the driving transmission rod to move relative tothe driving fixing rod to achieve stretching and closing of the device. Compared with the prior art, the electric mechanical stretching device has the advantages of simplified structure, conveniencein functional design of the seat, high comfort level, stability, firmness, high universality and low cost.

Owner:UE FURNITURE CO LTD

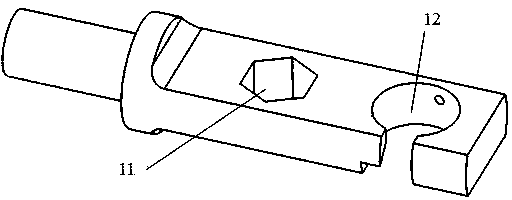

Uniform-section blade-type microscale turbine electric spark machining device and process method thereof

InactiveCN103464988AEliminate conversion errorsImprove processing efficiencyPositioning apparatusMetal-working holdersNumerical controlTurbine blade

The invention discloses a uniform-section blade-type microscale turbine electric spark machining device and a process method thereof, and belongs to the field of microscale turbine processing. The device comprises a clamping rod, an integrated positioning plate, an indexing prism and a standard base. A turbine blade top circular face is processed on a workpiece through numerical-control turning, the workpiece is positioned and clamped on the indexing prism, the workpiece and the indexing prims are enabled to form a rigid body, the indexing prism is mounted on the integrated positioning plate, the integrated positioning plate is mounted on the standard base, and clamped after being positioned by rotating and adjusting by a certain angle, all blades and blade root circular faces are processed symmetrically through electric spark processing. By the uniform-section blade-type microscale turbine electric spark machining device and the process method thereof, the problem of microscale turbine processing is effectively solved, and processing accuracy and stability of a microscale turbine are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

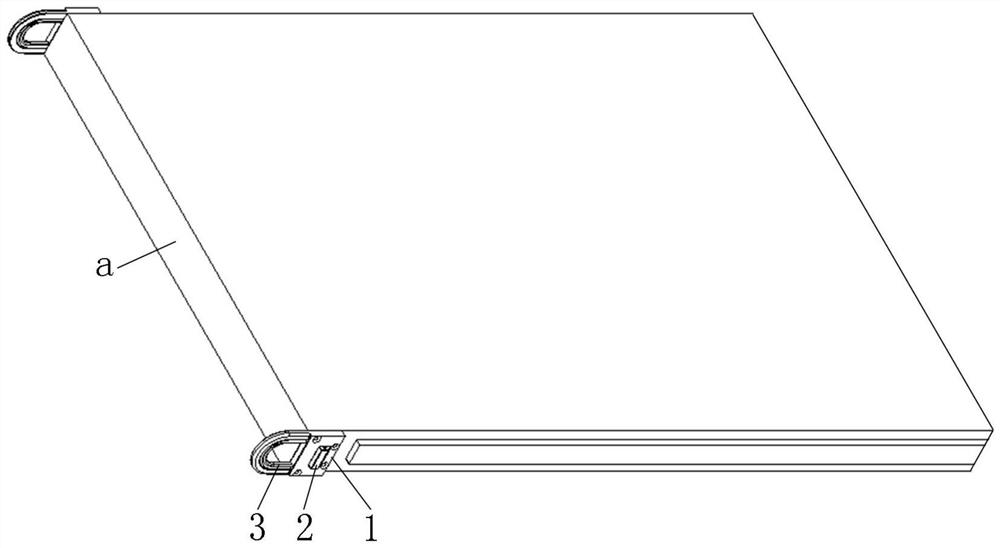

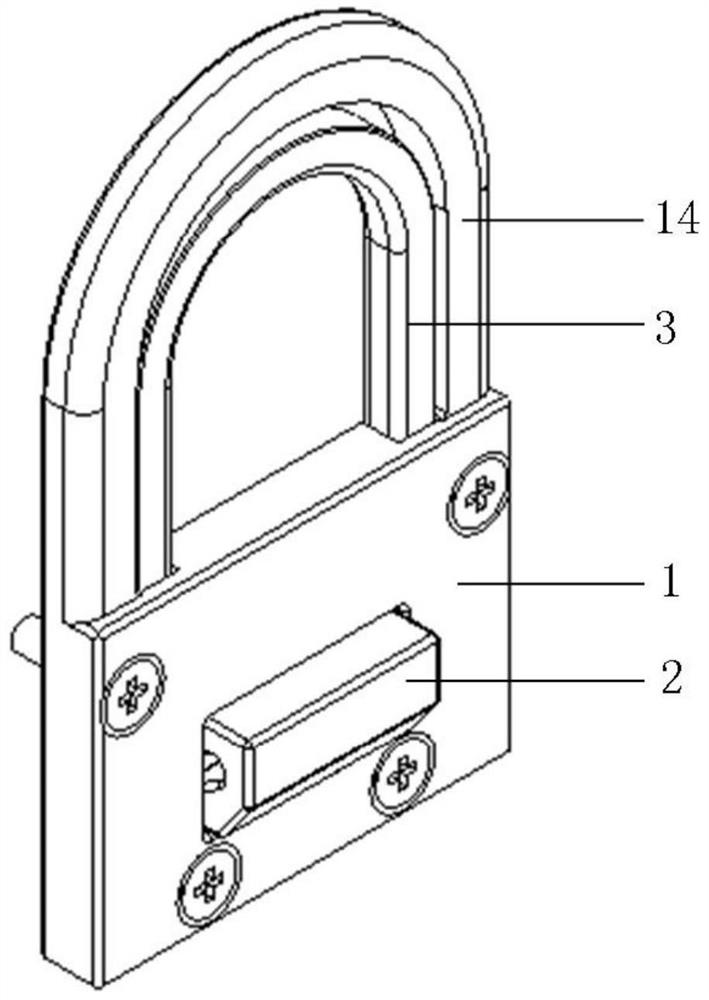

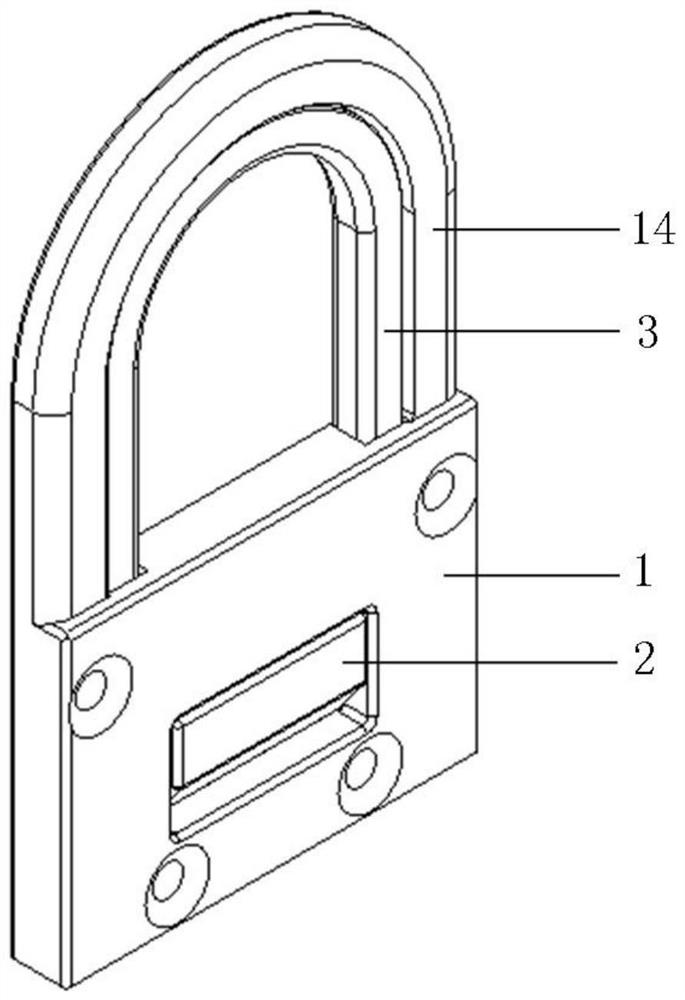

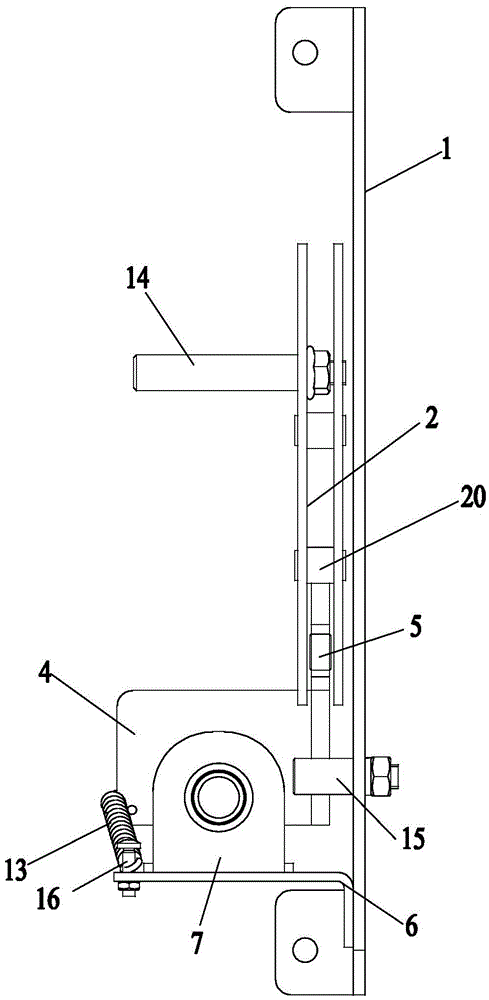

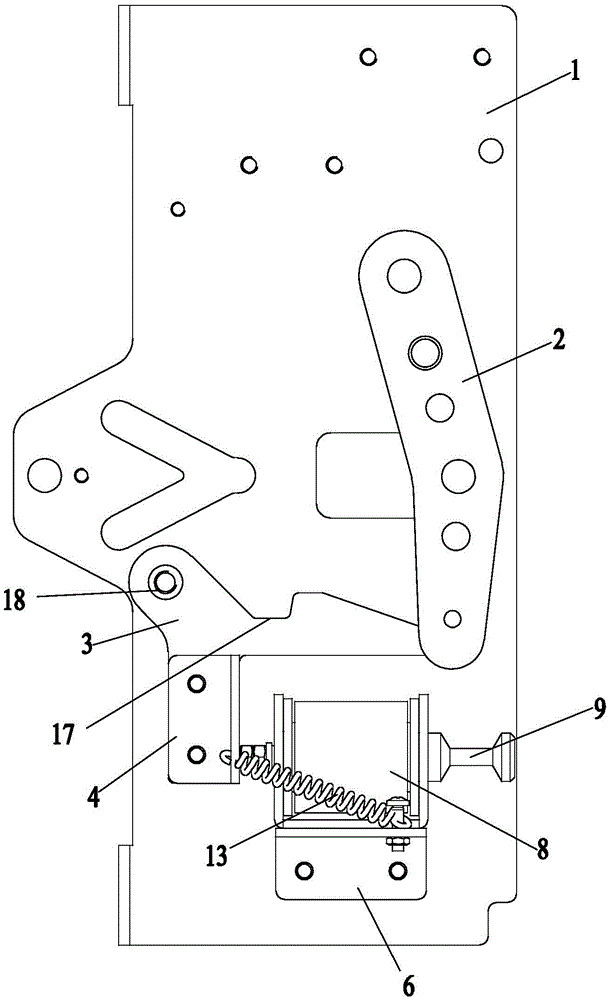

Equipment lock applied to server

PendingCN114165114AImprove the efficiency of plugging and disassemblySimple motion trackWing handlesLocks for portable objectsComputer hardwareEngineering

The invention discloses an equipment lock applied to a server, which comprises a mounting seat arranged on a server case, a lock cylinder telescopically arranged on the mounting seat, and an unlocking handle slidably arranged on the mounting seat and used for driving the lock cylinder to do telescopic motion, and the front end of the unlocking handle extends to the front end of the server case. The sliding direction of the unlocking handle is parallel to the plugging sliding direction of the server case in the server cabinet; and the lock cylinder is matched and locked with a lock catch on the inner wall of the server cabinet when extending out for a preset length. Thus, when the server needs to be unlocked, a user only needs to pull the front end of the unlocking handle towards the outside of the server cabinet, the operation that the lock cylinder retracts into the installation base and the server case is pulled out can be achieved at the same time, the unlocking operation of the server is completed in one step, the unlocking operation of the server in the cabinet can be conveniently and rapidly achieved, and the unlocking efficiency of the server is improved. The plugging, unplugging, dismounting and mounting efficiency of the server in the cabinet is improved, and meanwhile the requirement for the operation space is lowered.

Owner:INSPUR (SHANDONG) COMPUTER TECH CO LTD

Lock and trip device for automatic transfer switch

ActiveCN104282463BImprove closing operationReliable closing operationContact driving mechanismsTransfer switchEngineering

The invention relates to a buckling and tripping device for automatic transfer switching equipment. The buckling and tripping device comprises a base plate, wherein a buckling mechanism and a tripping mechanism. The buckling mechanism comprises a lever plate body and a buckling plate, wherein the lever plate body and the buckling plate are hinged to the base plate, the buckling plate is located at one end of the lever plate body, a roller capable of rolling on the buckling plate and being embedded into a buckling groove formed in the buckling plate is arranged in the lever plate body and the lever plate body rotates on the base plate to enable the roller to be embedded into the buckling groove so as to achieve switching-on control of an automatic transfer switch. The tripping mechanism comprises a connecting plate installed on the buckling plate and a tripping action mechanism, wherein the tripping action mechanism enables the roller to break away from the buckling groove in the buckling plate through the connecting plate so as to achieve switching-off control of the automatic transfer switch. The buckling and tripping device is simple and compact in structure and capable of achieving remote operation on the automatic transfer switch, improving the on-off performance of the automatic transfer switching equipment and ensuring the switching-on and switching-off reliability of the automatic transfer switch.

Owner:WUXI HANKWANG ELECTRIC

An ultra-precision cutting method based on surface microstructure design

The invention provides an ultra-precision cutting method based on surface microstructure design, comprising the following steps: Rough machining: using a machine tool to remove excess material on the workpiece, preparing the geometric profile of the workpiece for semi-finishing, and leaving Machining allowance, the thickness of the machining allowance is micron level; semi-finishing: on the surface of the workpiece to be processed after rough machining, use the machine tool to process several densely arranged defect structures, that is, the geometric size is micron level or nanometer level The depth of various micro / nano structures is less than the machining allowance; finishing: use machine tools to remove the micro / nano structures and remaining machining allowances processed in semi-finishing, and the cutting depth is equal to that in rough machining The thickness of the reserved machining allowance, through comprehensive control of the finishing process and semi-finishing process, the designed micro / nano structure is obtained on the surface of the workpiece to be processed, so as to control the cutting force on the tool during finishing and reduce the cutting process In order to achieve the purpose of improving the life of the tool and obtaining nano-scale surface roughness on difficult-to-machine materials, the generation of medium heat is achieved.

Owner:GUANGDONG UNIV OF TECH

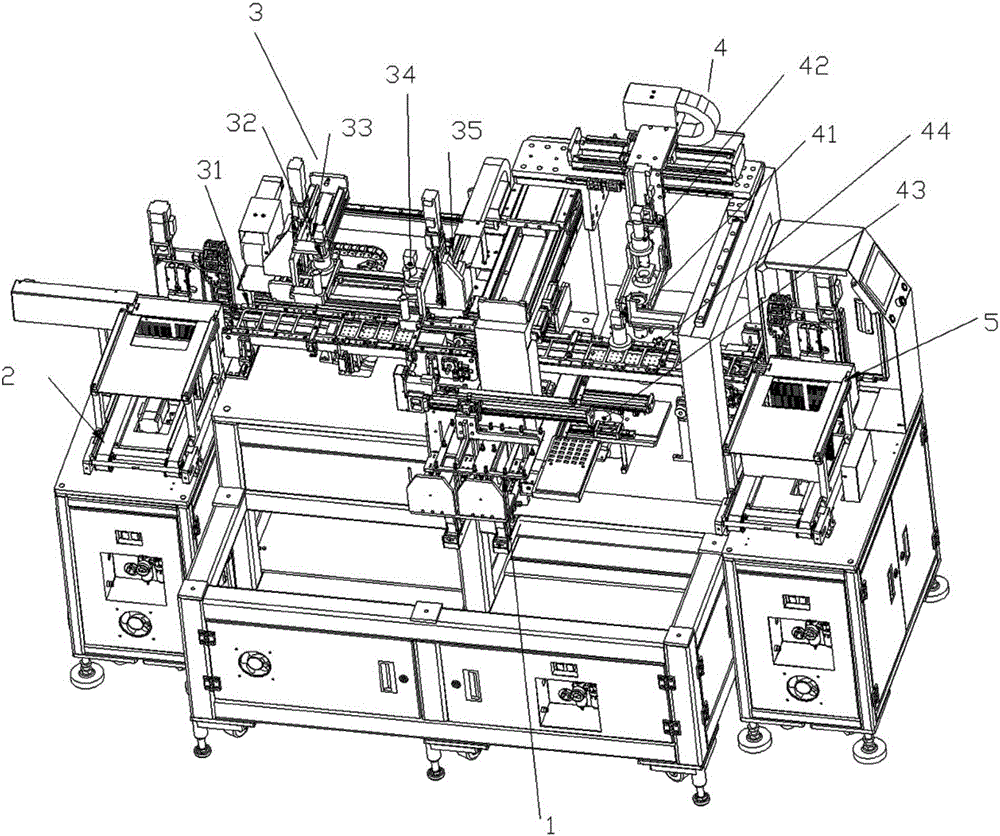

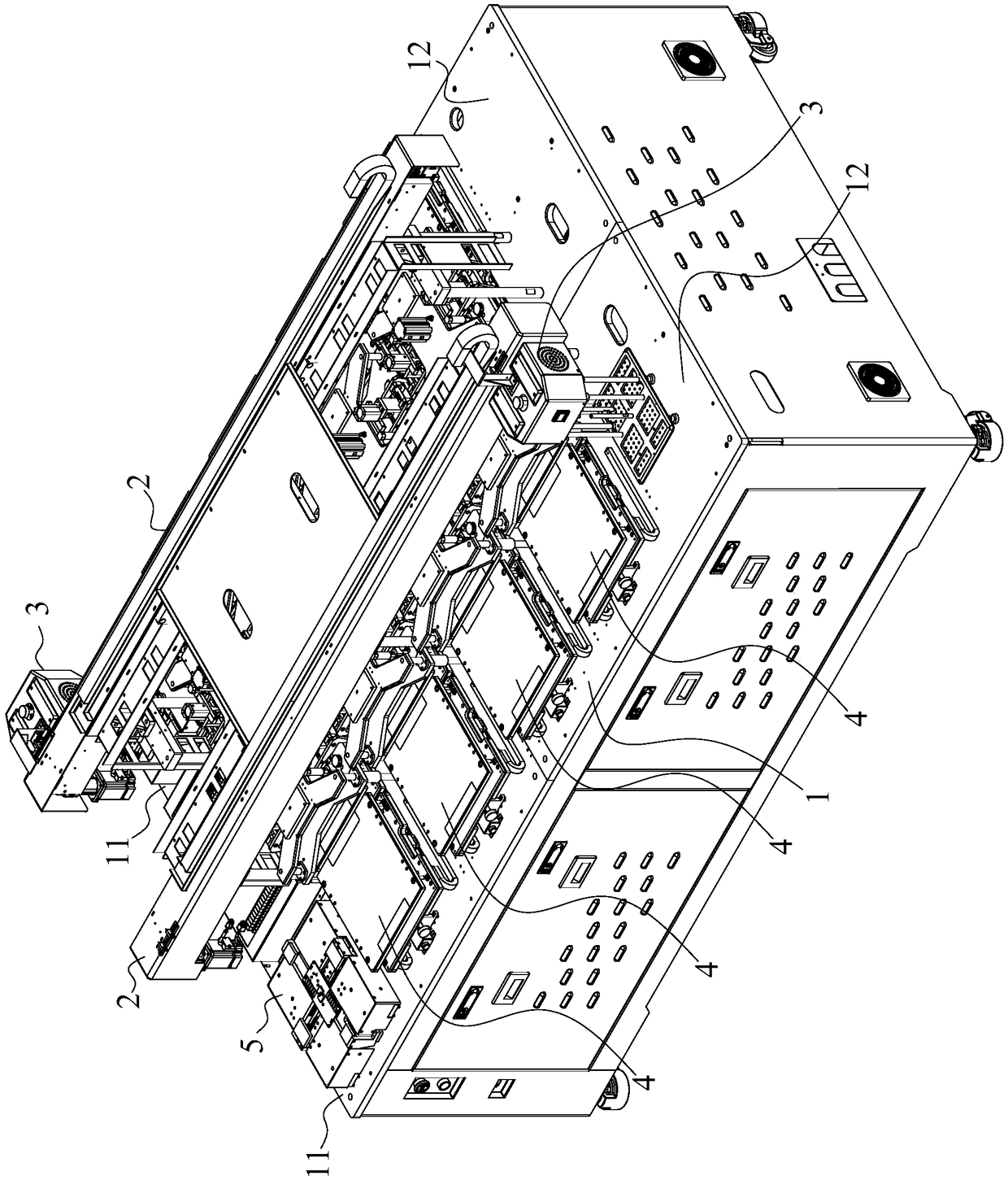

Automatic placement machine

ActiveCN103945655BShorten exercise distanceSimple motion trackPrinted circuit assemblingElectrical componentsVisual recognitionEngineering

The invention relates to a full automatic chip mounter which comprises a base plate. n-shaped base frames are symmetrically arranged on two sides of the base plate, a first linear sliding rail is fixedly connected onto the upper end face of an n-shaped base frame on one side, a first lead screw device is fixedly connected onto the upper end face of an n-shaped base frame on the other side, a second lead screw device is vertically arranged between the first lead screw device and the first linear sliding rail, the second lead screw device is in threaded connection with a double-end mounting mechanism, a conveying track mechanism is vertically arranged under the n-shaped base frames, and visual recognition devices and material supply tables are arranged on two sides of the conveying track mechanism respectively. A material supply device is arranged on each material supply table, and a suction nozzle exchange device is arranged on one side of the conveying track mechanism. Due to the fact that the material supply devices and the visual recognition devices are arranged on two sides of a conveying track, the moving track of the mounting head is simplified, the mounting efficiency is improved, and meanwhile automatic recognition and accurate location of electronic elements are achieved. Mounting of the electronic elements of different sizes can be achieved by arranging suction nozzles of different sizes, and the whole mounter is compact in structure, low in cost and high in mounting accuracy.

Owner:BEIJING TINYO ELECTRONICS

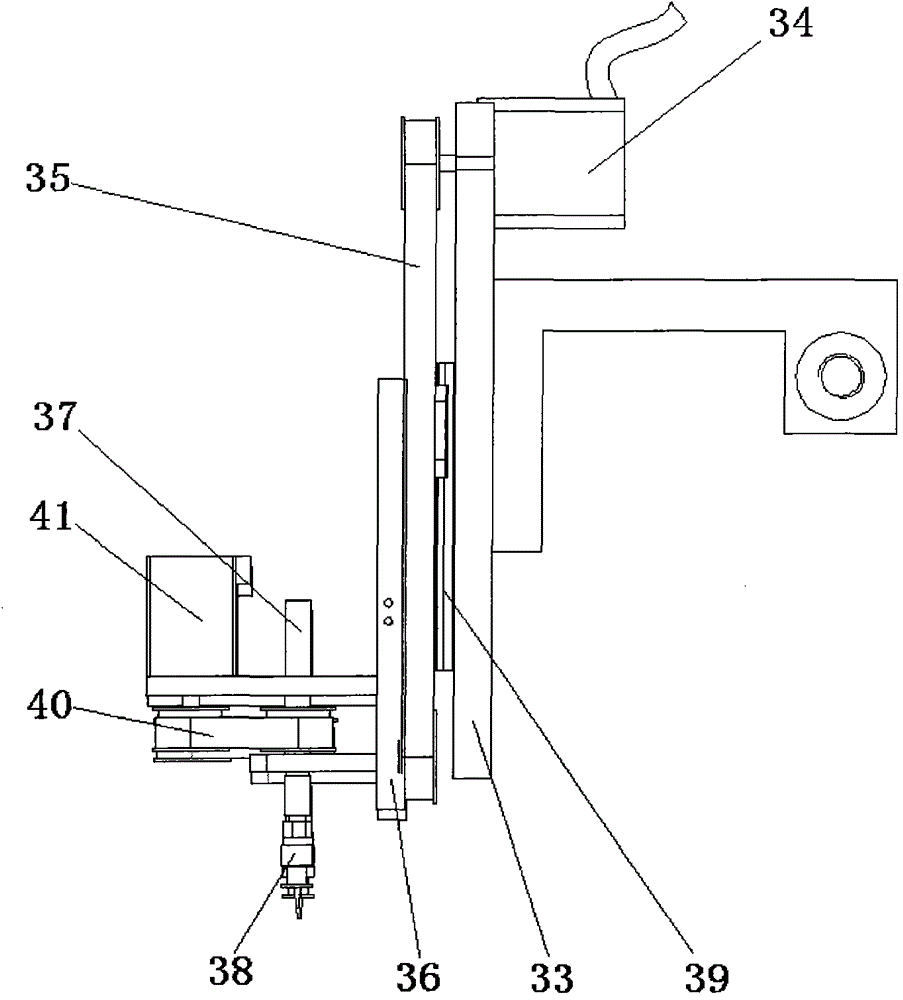

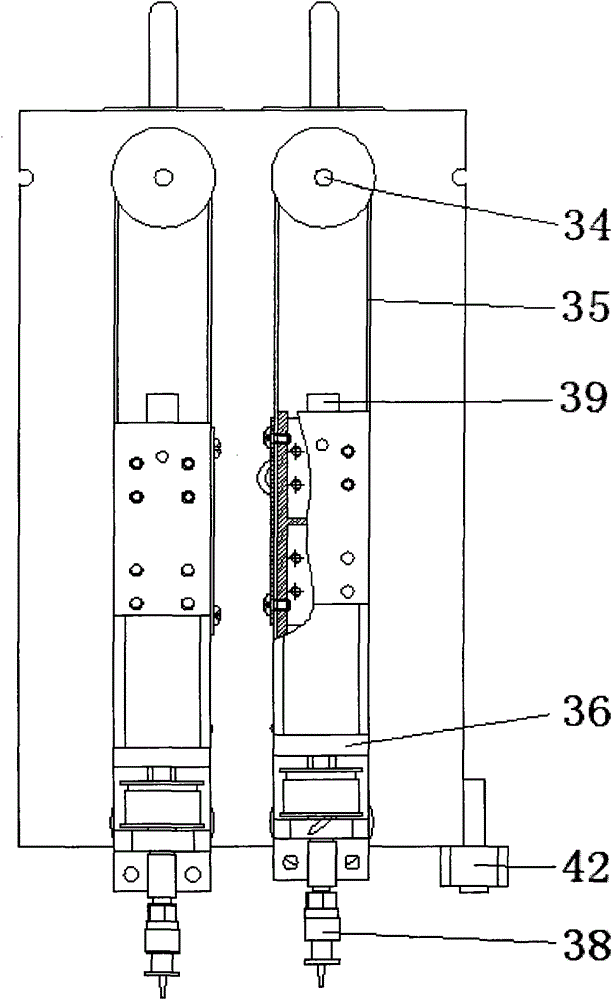

Laminating device for automatic feeding mechanism and fingerprint identification module

The invention discloses an attaching device for an automatic feeding mechanism and a fingerprint identification module. The attaching device comprises a sucker (11), a feeding bin(12), a receiving bin (13), a work plate (14), an X-direction driving mechanism (15) and Z-direction driving mechanisms (16), wherein a group of feeding suckers (111) arranged relative to the feeding bin (12) and a group of receiving suckers (112) arranged relative to the receiving bin (13) are arranged on the sucker (11). According to the attaching device, the problems in automatic feeding and automatic attaching of a cover plate during an attaching and assembling process of the fingerprint identification module are solved, and the overall production efficiency of the fingerprint identification module can be improved.

Owner:SHENZHEN CEWAY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com