Bottle blowing machine provided with clamping mechanism

A technology of clamping mechanism and bottle blowing machine, which is applied in the field of bottle blowing, can solve problems such as hidden dangers in operation stability and complex motion trajectory of manipulator, and achieve the effects of reducing design difficulty, reducing tracking stroke, and simplifying motion trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

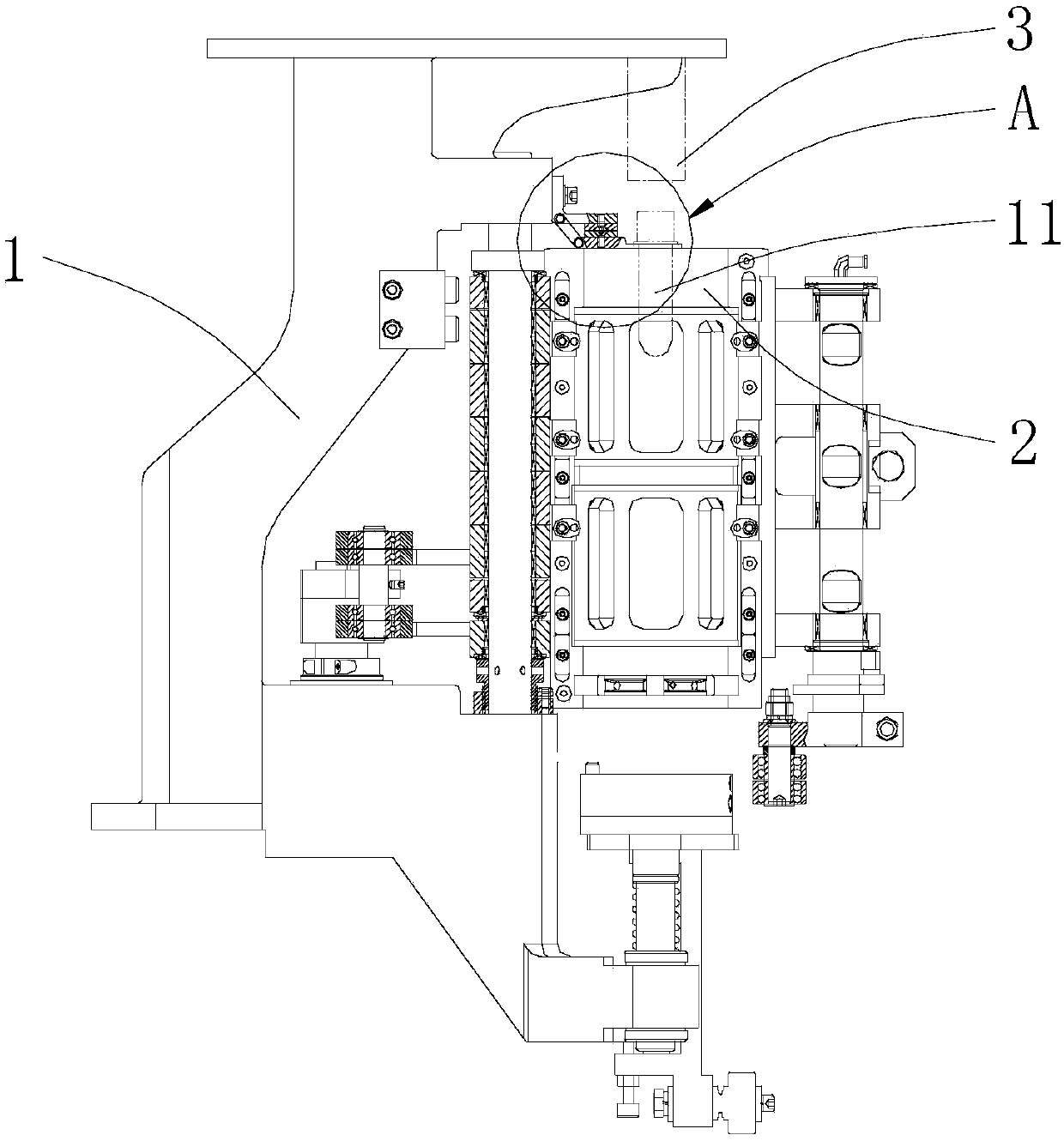

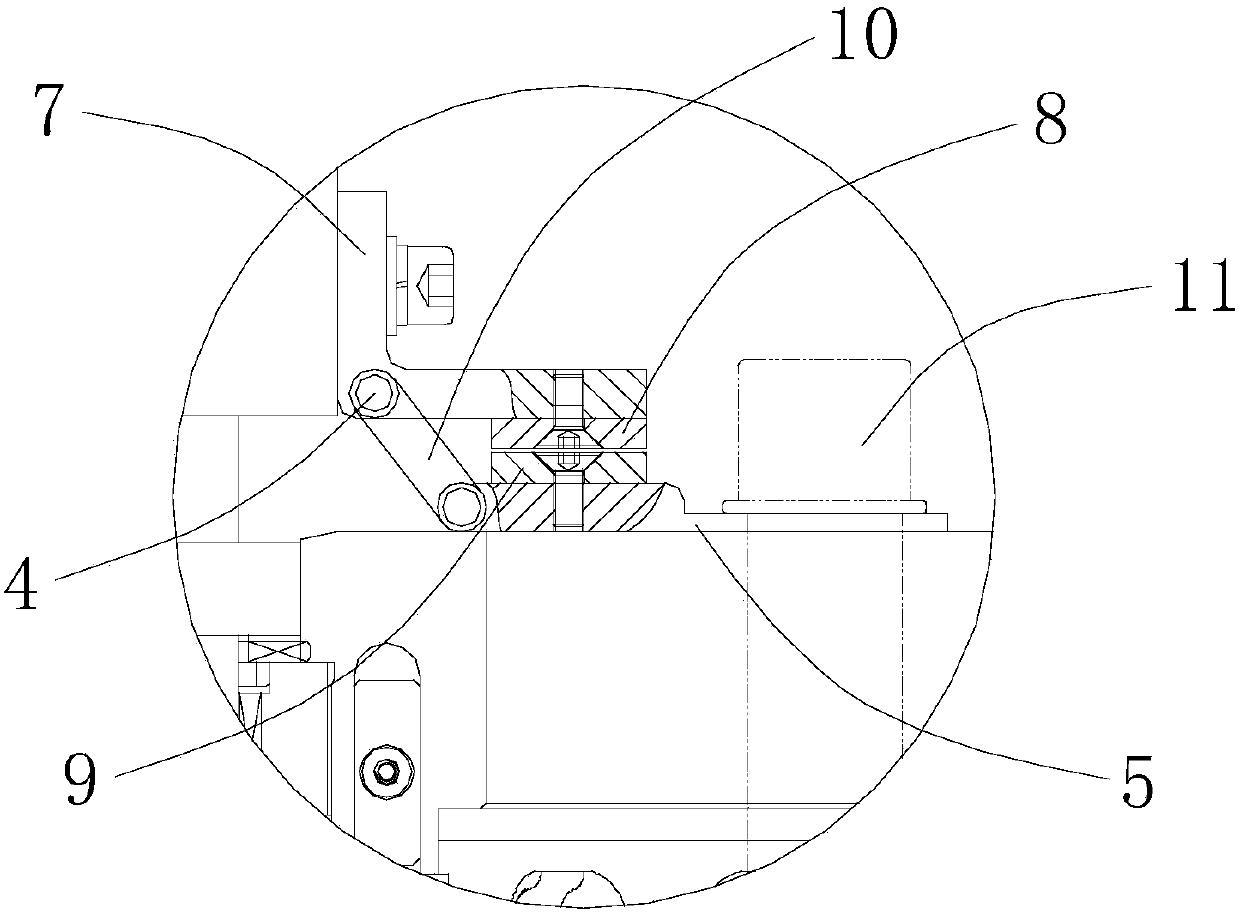

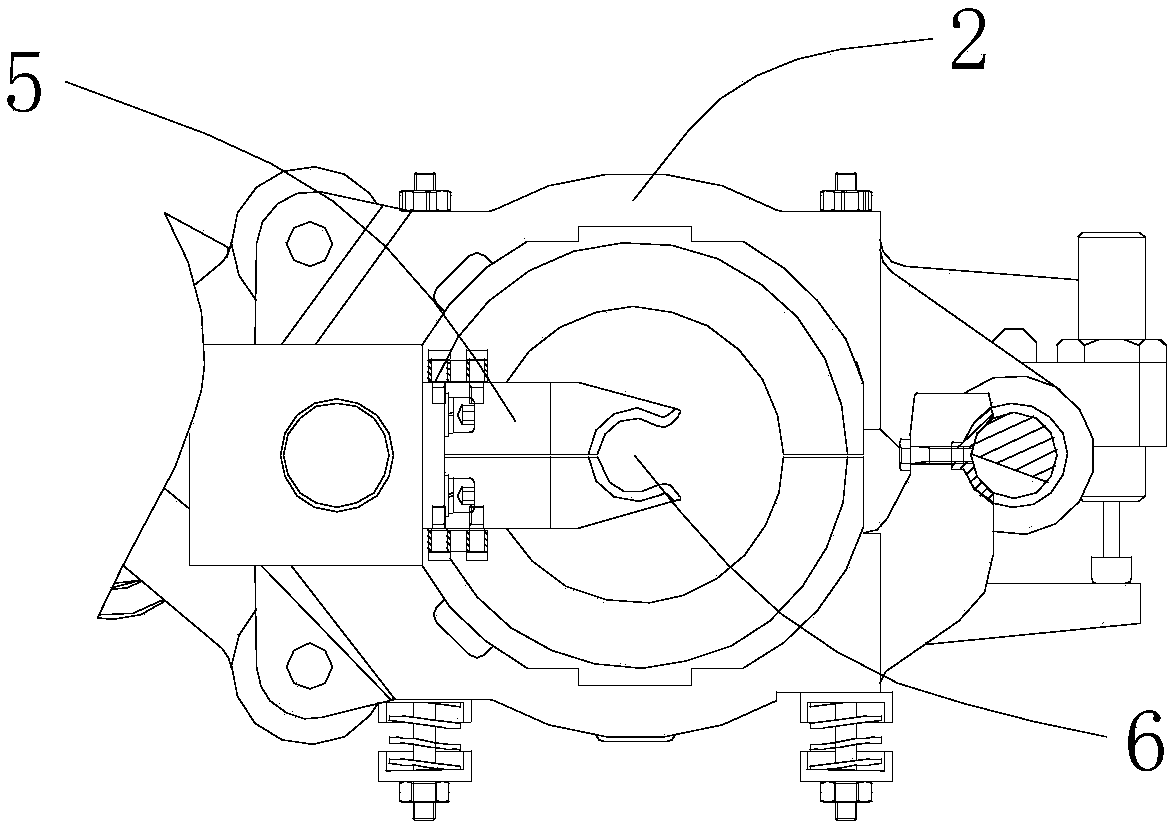

[0018] see Figure 1-3 As shown, the above-mentioned bottle blowing machine with a clamping mechanism includes a frame 1, an opening and closing mold frame 2 arranged on the frame 1, and a mold frame located on the frame 1 that moves up and down in the vertical direction. The sealing mechanism 3 above the opening and closing mold frame 2 is described above. In this embodiment, the sealing mechanism 3 is also used to blow compressed air into the bottle blank 11 .

[0019] The clamping mechanism includes a clamping part 5 which is arranged on the frame 1 with one end rotating around the horizontal axis 4, and the clamping part 5 is located between the sealing mechanism 3 and the opening and closing mold frame 2 in the vertical direction. In this embodiment, the clamping member 5 is around its left end (see figure 2 as shown, figure 2 The le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com