Laminating device for automatic feeding mechanism and fingerprint identification module

An automatic feeding and driving mechanism technology, applied in the field of machinery, can solve the problems of low transmission efficiency of feeding and receiving workpieces, complex motion structure and control structure, and inconsistent appearance, so as to facilitate viewing or monitoring and simplify Motion trajectory, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

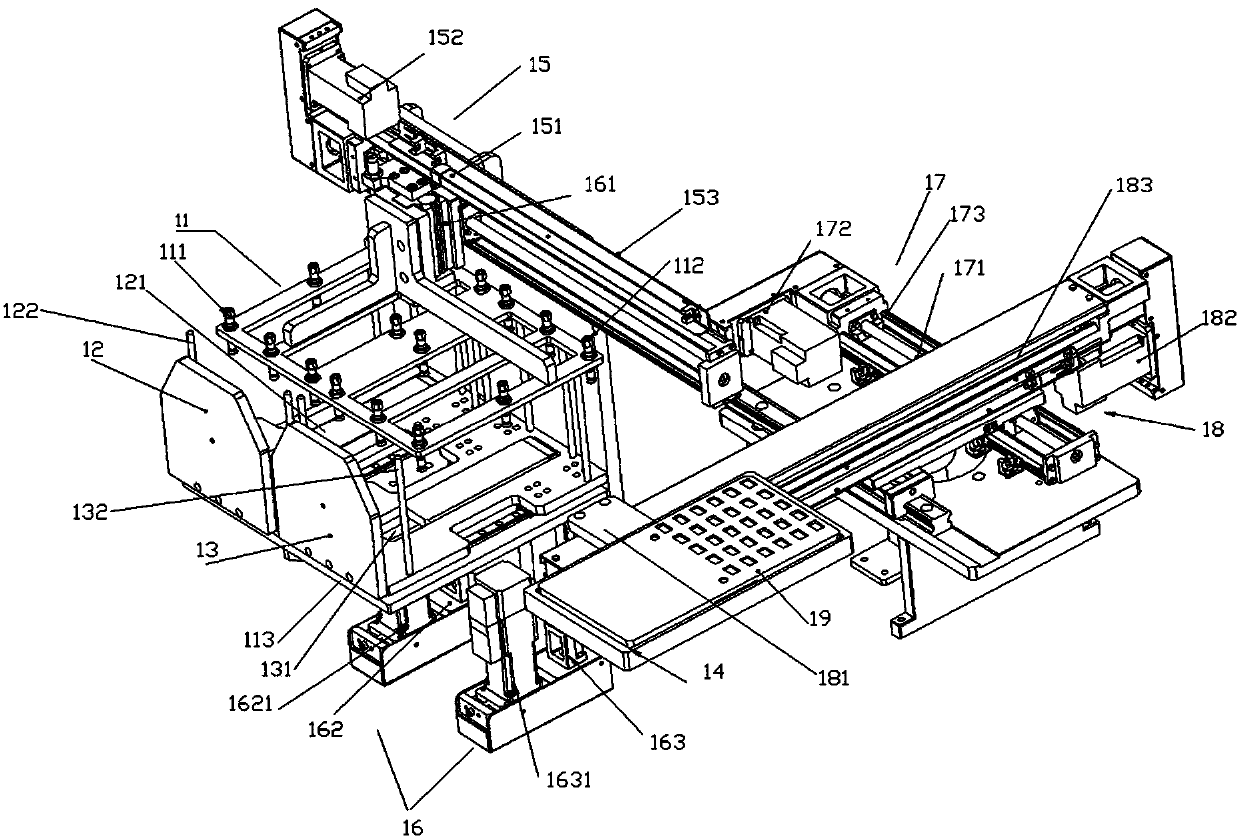

[0017] see figure 1 , is a structural schematic diagram of an embodiment of the automatic feeding mechanism. The automatic feeding mechanism includes a suction cup 11 , a feeding bin 12 , a receiving bin 13 , a working disk 14 , an X-direction driving mechanism 15 and a Z-direction driving mechanism 16 . Wherein, the suction cup 11 is divided into two areas, one area is provided with a feeding suction cup group 111 , and the other area is provided with a material receiving suction cup group 112 . In a preferred solution, the two regions are arranged symmetrically. The feeding bin 12 and the receiving bin 13 are respectively arranged / installed below the feeding suction cup group 111 and the receiving suction cup group 112. The bins 13 are respectively set / installed directly below the feeding suction cup group 111 and the receiving suction cup group 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com