Welding material taking mechanical arm

A technology of retrieving manipulators and machine bases, which is applied in the direction of manipulators, program-controlled manipulators, welding equipment, etc., can solve the problems of long motion trajectory, slow operation speed, and slow speed, and achieve simple motion trajectory, fast reclaiming speed, The effect of low procurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

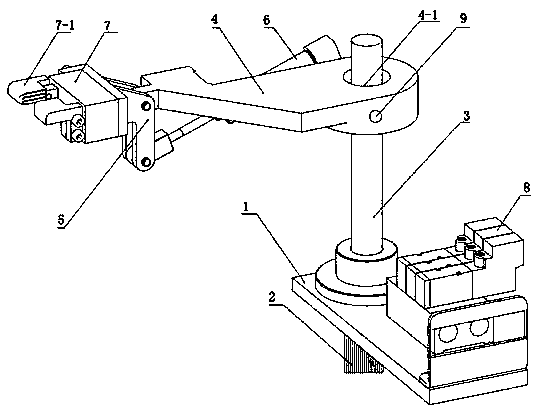

[0010] Embodiment: the welding retrieving manipulator of present embodiment is as figure 1 As shown, it includes machine base 1, servo motor 2, connecting rod 3, cantilever 4, connecting block 5, cylinder 6, pneumatic finger 7, pneumatic pipeline (not shown in the figure) and electromagnetic reversing valve 8, wherein connecting rod 3 Installed vertically on the base 1, the bottom of the connecting rod 3 is connected with the servo motor 2 through a coupling, and the top of the connecting rod 3 is equipped with a cantilever 4. The middle part of the cantilever 4 has a vertical installation hole 4-1, the installation hole 4-1 is sleeved on the connecting rod 3, and the hole wall of the installation hole 4-1 is provided with a screw for locking the connecting rod 3 and the cantilever 4 9. A connection block 5 is hinged at the end of the cantilever 4, and a pneumatic finger 7 is installed at one end of the connection block 5. In order to prevent the clamp block 7-1 on the pneuma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com