Pushing card chipless assembling electromagnetic relay and assembling method thereof

A technology of electromagnetic relay and push card, which is applied in the direction of electromagnetic relay, electromagnetic relay details, relay, etc., can solve the problems of complex process, poor effect, and influence on the reliability of electrical contact, etc., and achieve the effect of simple motion trajectory and precise assembly precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

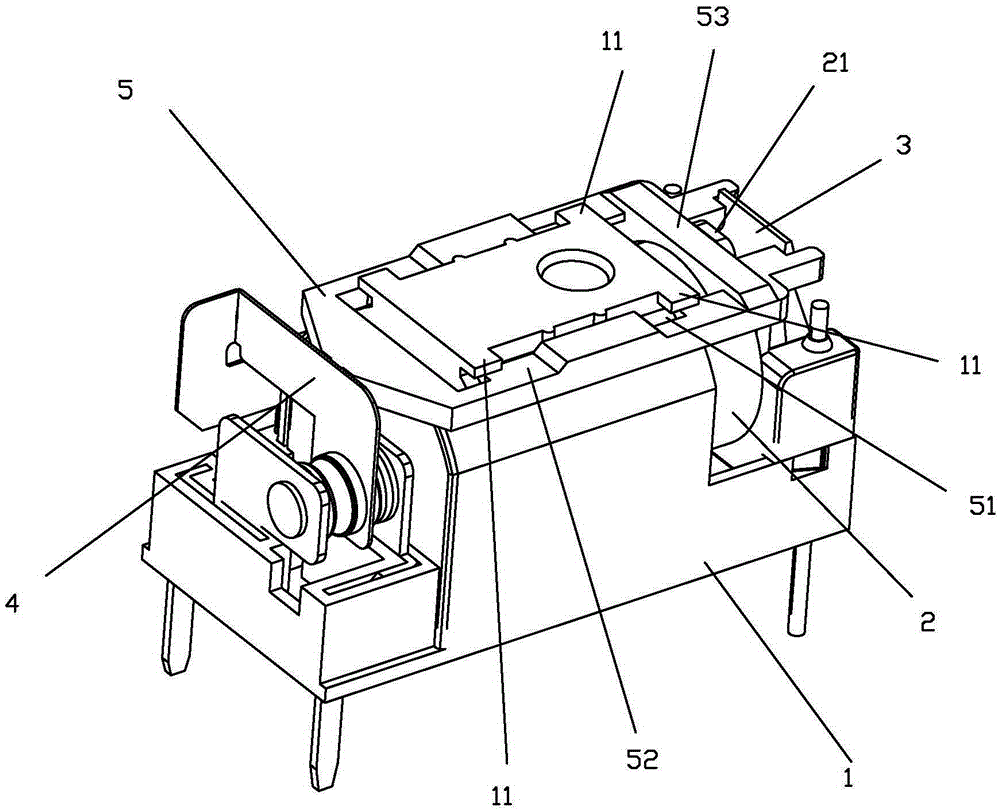

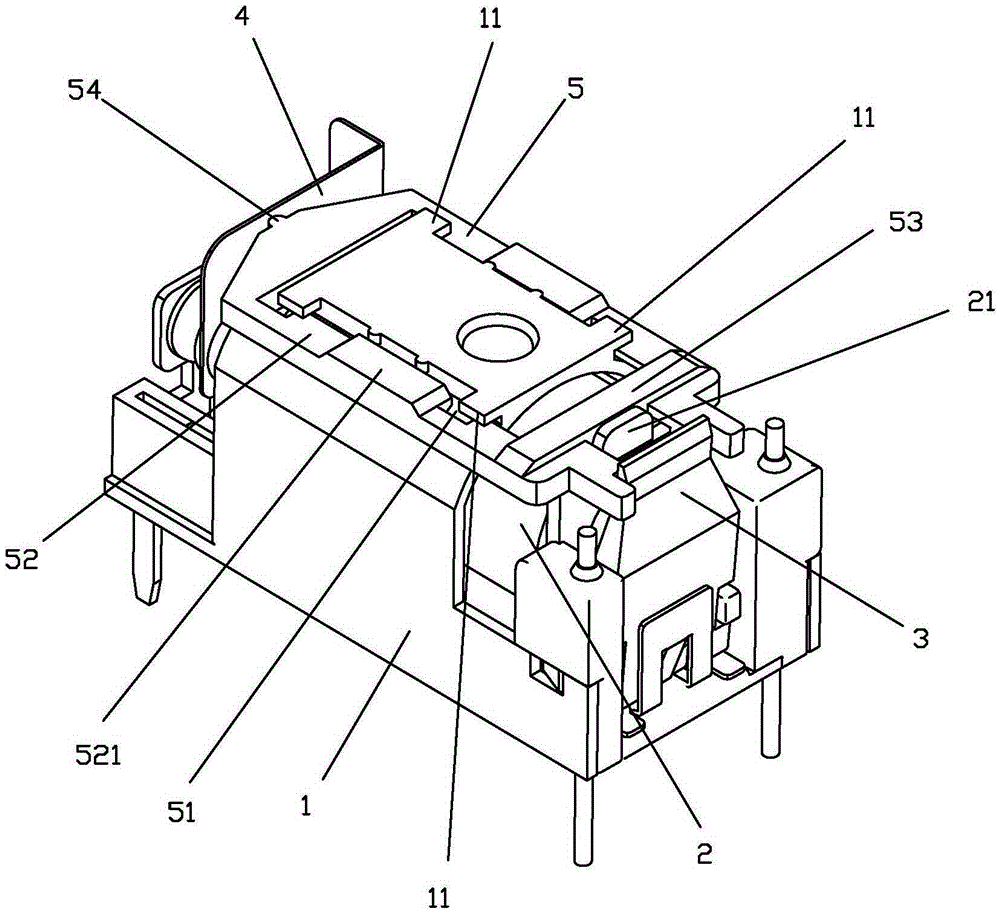

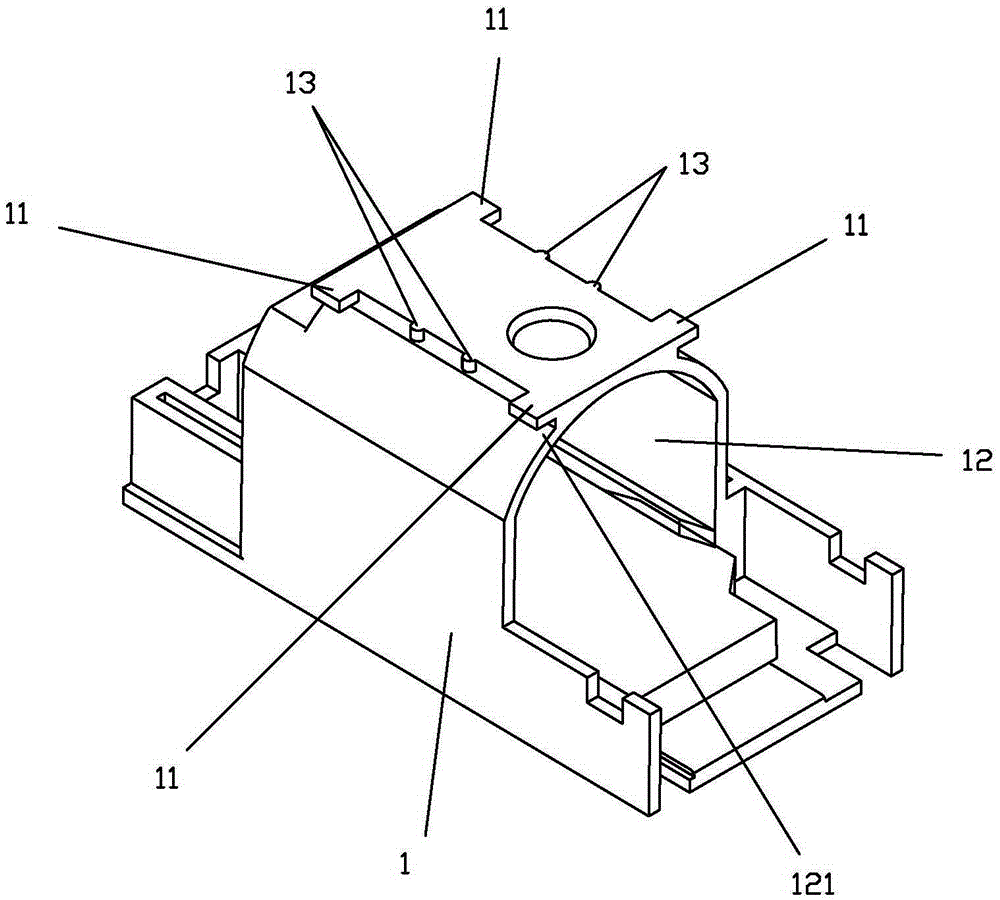

[0043] see Figure 1 to Figure 14 As shown, an electromagnetic relay for chipless assembly of a push card of the present invention includes a contact system, a magnetic circuit system, a base 1 and a pushing part, the magnetic circuit system is composed of a magnetic circuit part 2 and an armature part, and the armature part includes an armature 3 , The contact system includes a moving spring 4 and a static spring; the push part is the push card 5. Wherein, the magnetic circuit part 2 adopts a horizontal magnetic circuit.

[0044] The push card 5 is inserted into the track of the base 1 through the non-interference clamping structure between the push card and the base, and can only move back and forth along the track limited by the base in a straight line, and the push card 5 moves back and forth in a straight line. One end of the movement cooperates with the armature 3 in a contact manner, so that the armature 3 can only push the push card 5 to move in one direction, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com