Patents

Literature

36results about How to "Easy to rub" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Eye shadow cream

InactiveCN103655411ANon-irritatingNo side effectsCosmetic preparationsMake-upMicrocrystalline waxEye shadow

The invention discloses an eye shadow cream, which is prepared from the following raw materials in parts by weight: 15-25 parts of microcrystalline wax, 6-12 parts of vaseline, 3-6 parts of squalane, 4-8 parts of beeswax, 12-20 parts of white oil, 2-6 parts of titanium dioxide, 2-4 parts of essence, 15-20 parts of almasilate, 3-6 parts of glyceryl monostearate, 2-5 parts of silicon wax, 3-7 parts of phenoxyethanol, 5-15 parts of pearl powder, 4-8 parts of glycerol and 3-7 parts of hydrogenated lanolin. The eye shadow cream provided by the invention is mild in texture, excellent in effect, convenient to use, nontoxic and harmless for human body.

Owner:QINGDAO CHENXUTONG COMMERCE & TRADE

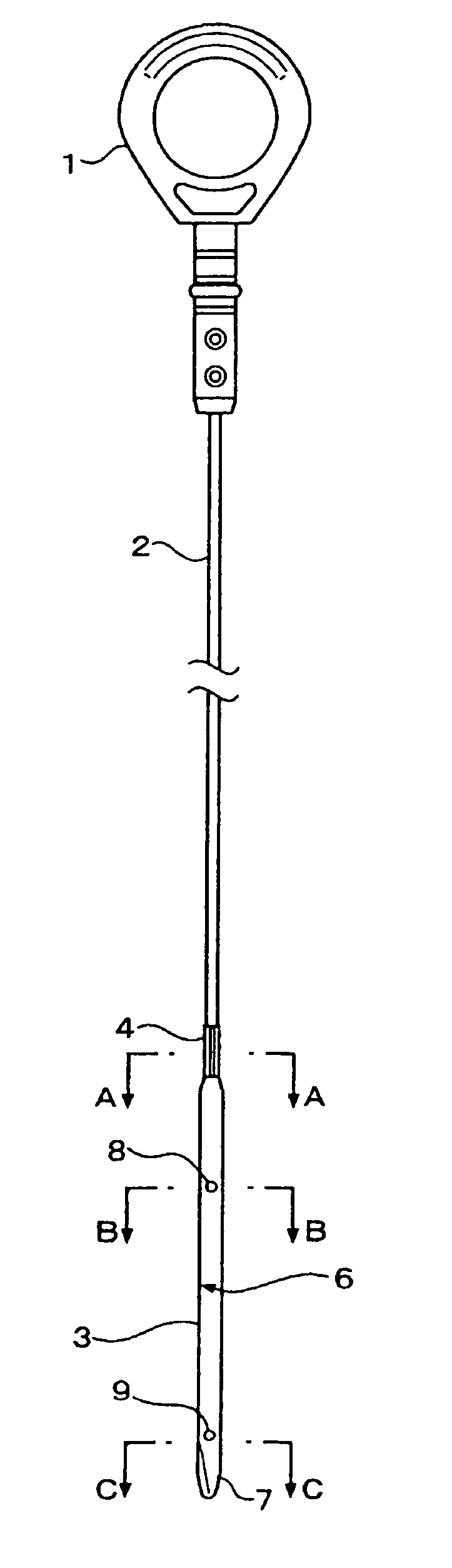

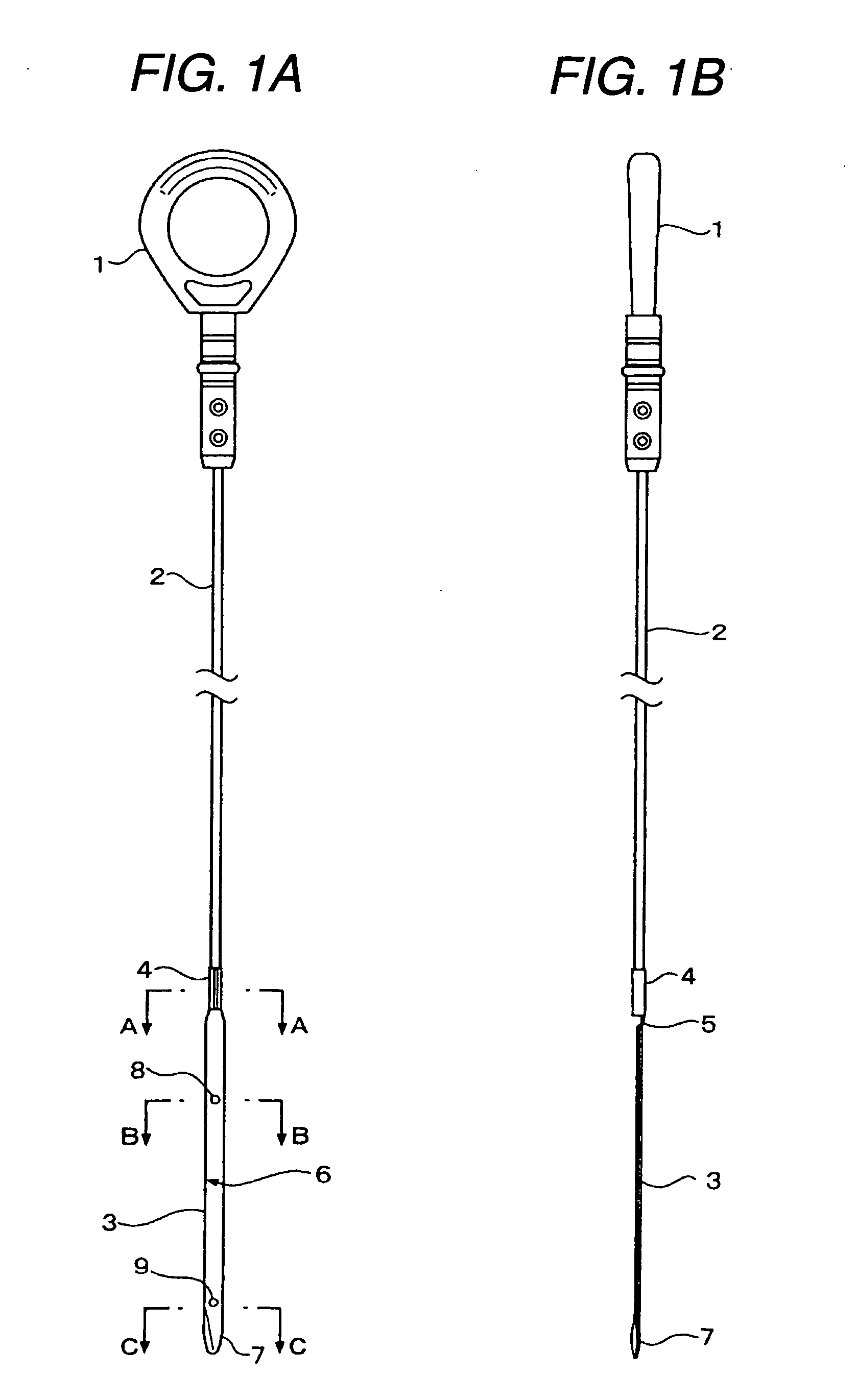

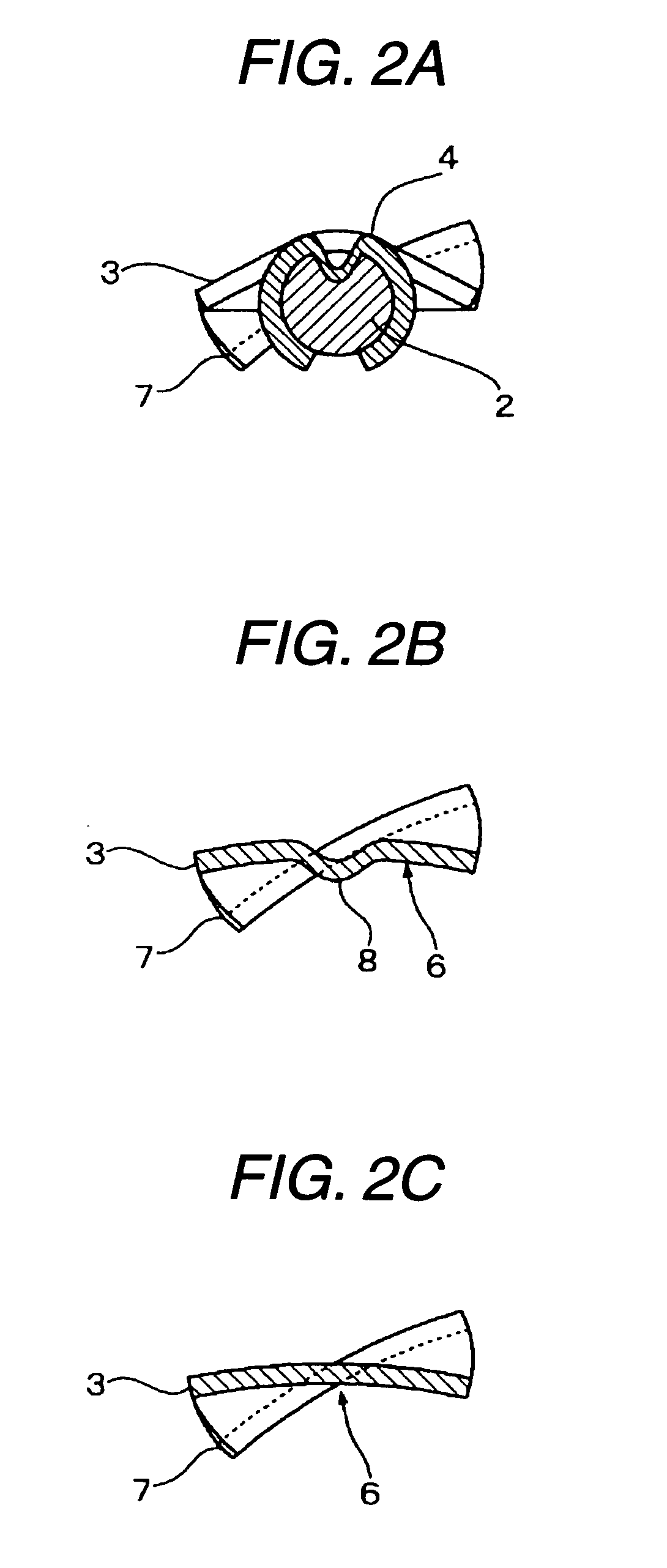

Oil level gauge

InactiveUS20050241171A1Easy to rubAccurate measurementLevel indicators by dip membersElectric circuit arrangementsCurve shapeLower limit

An oil level gauge includes a handle section, a shank section, and a measuring section. The measuring section includes an upper limit mark and a lower limit mark in an up and down direction. The measuring section has a curved shape in a direction perpendicular to a longitudinal direction of the measuring section.

Owner:PIOLAX CO LTD

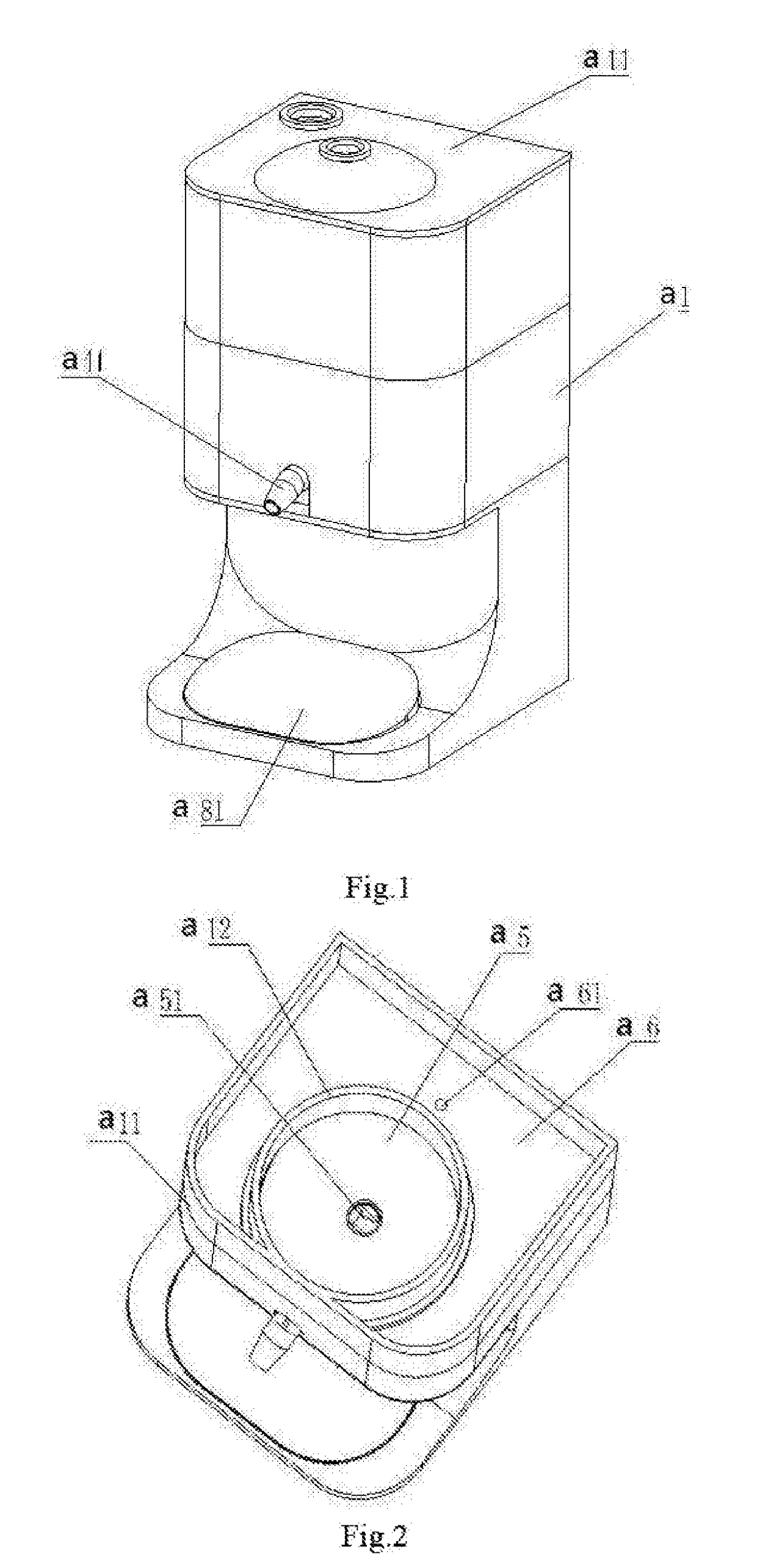

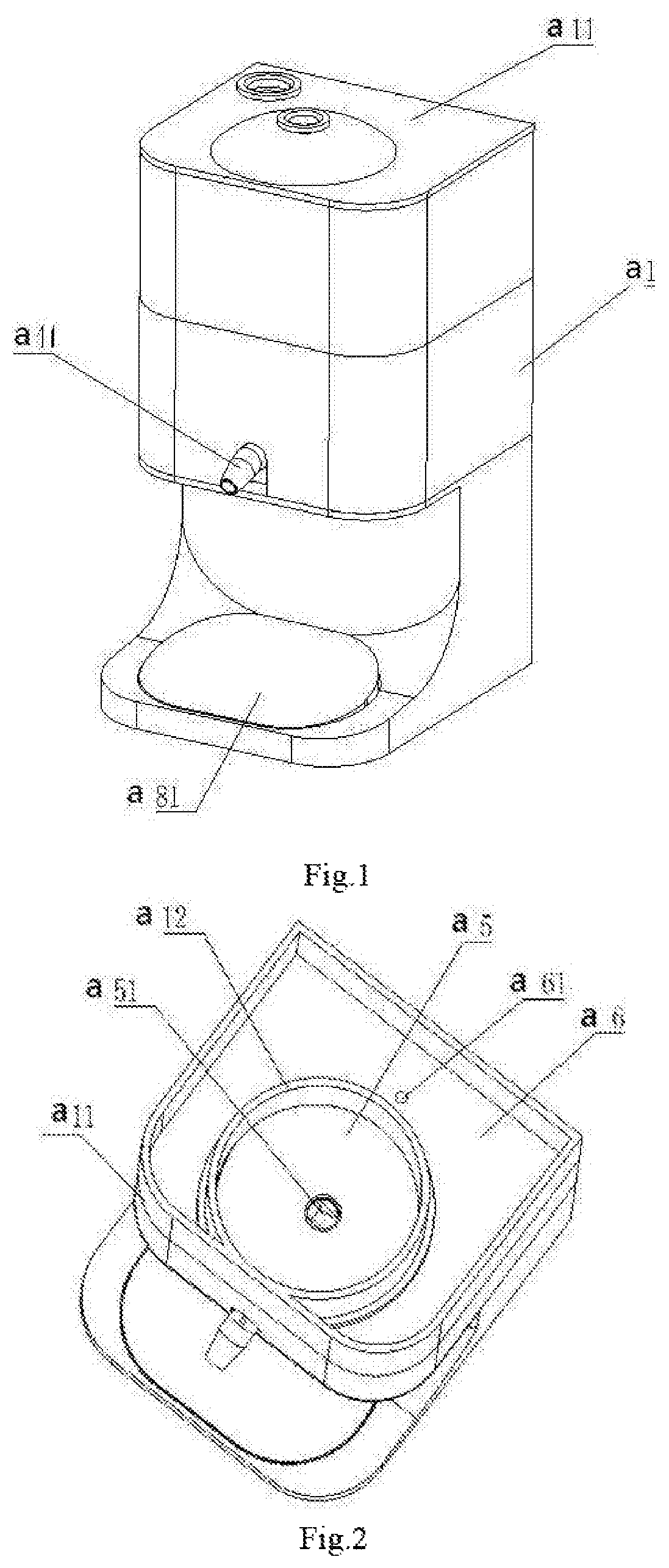

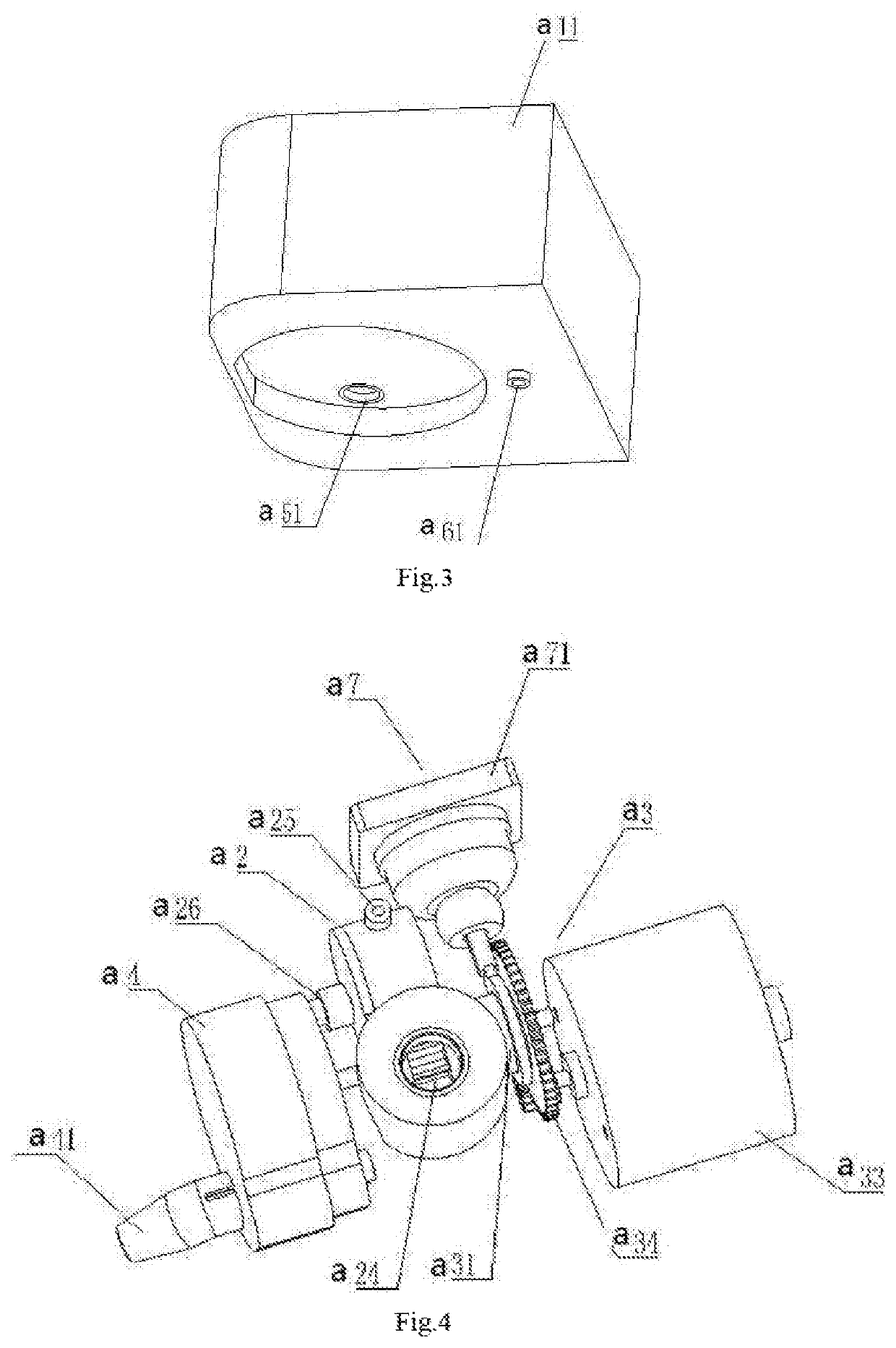

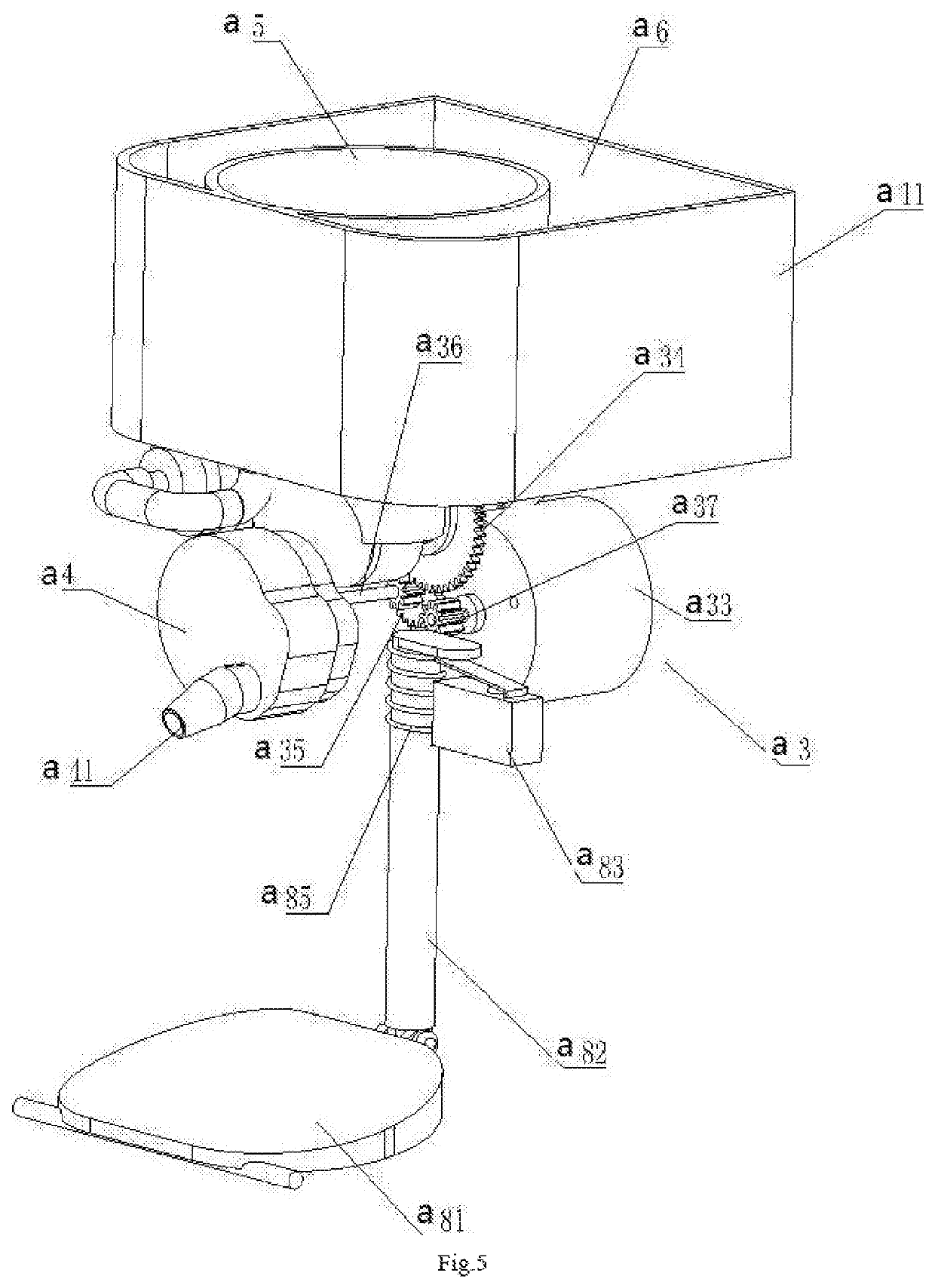

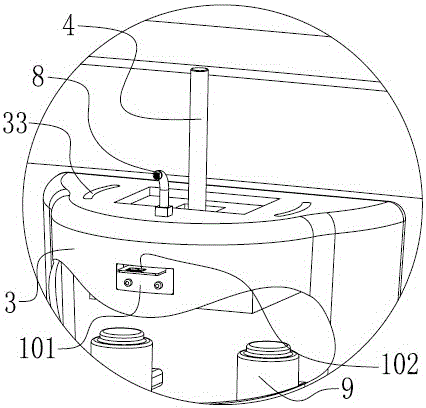

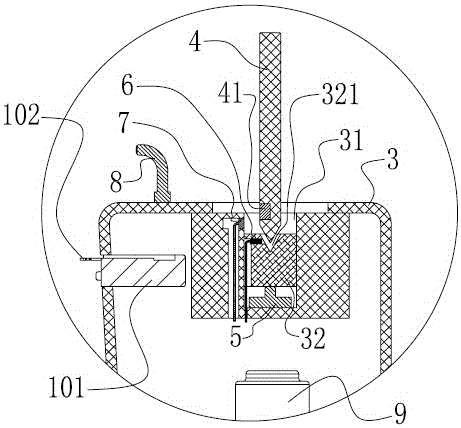

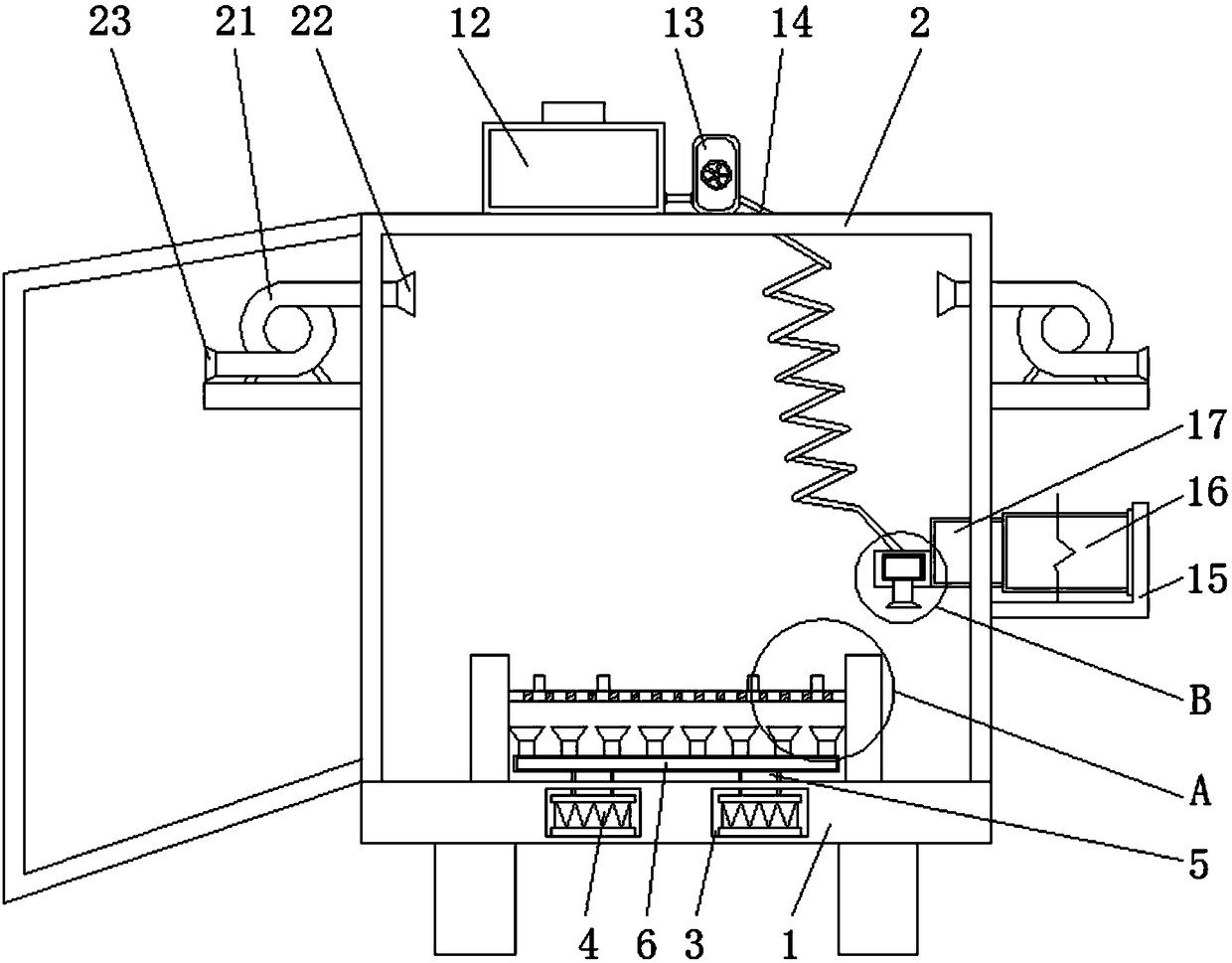

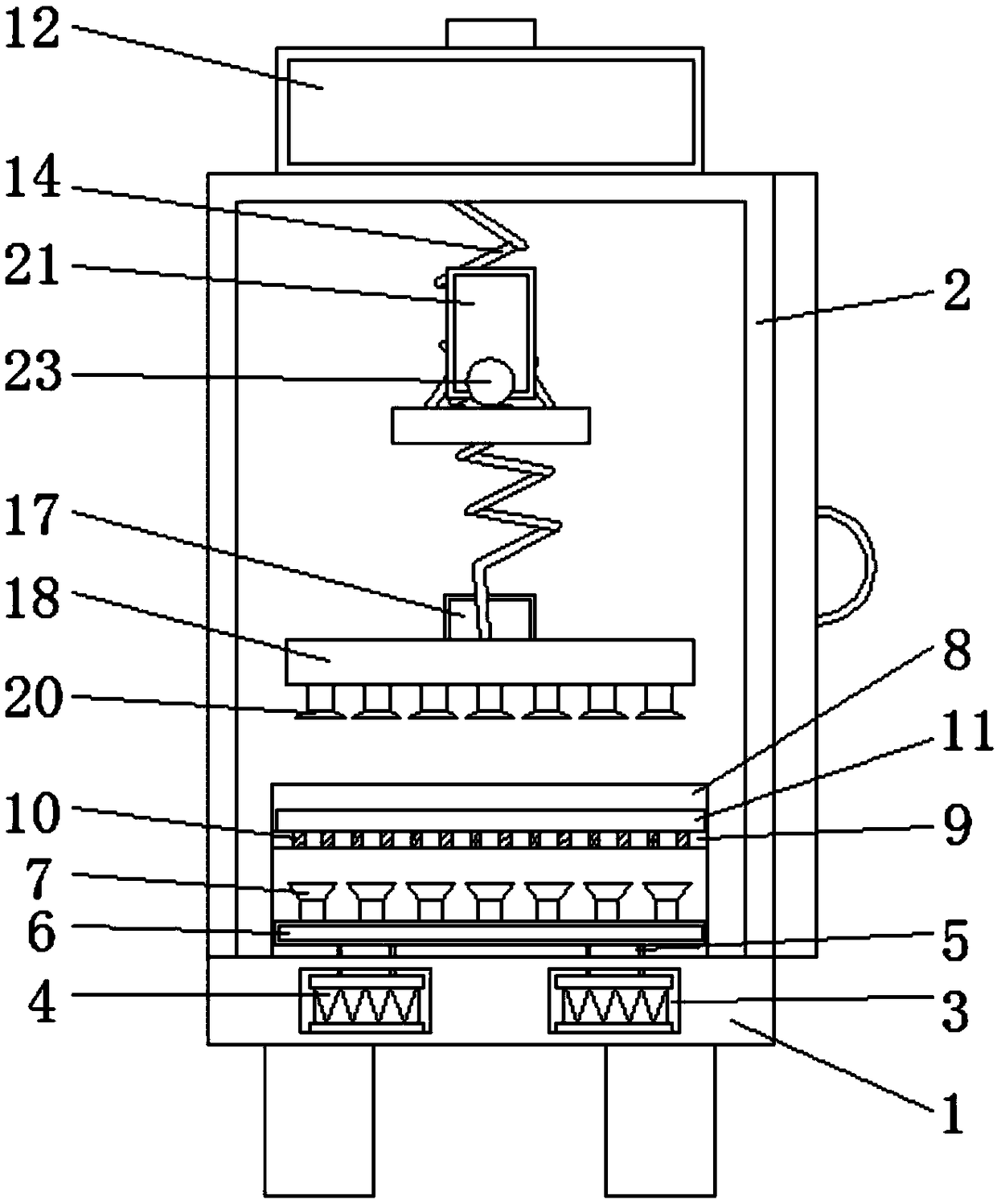

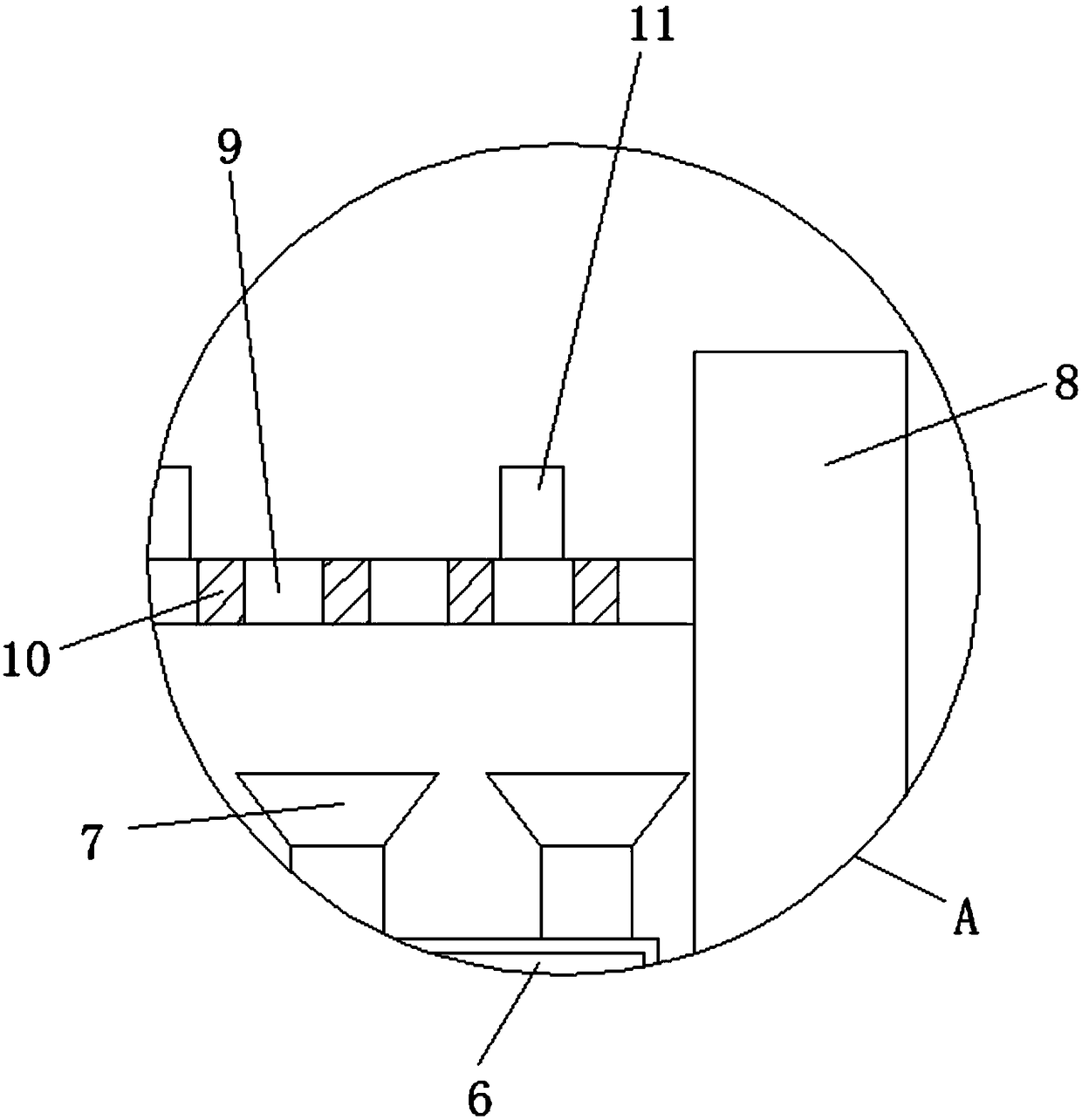

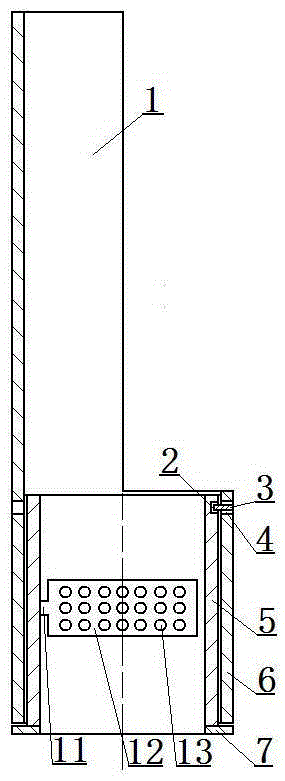

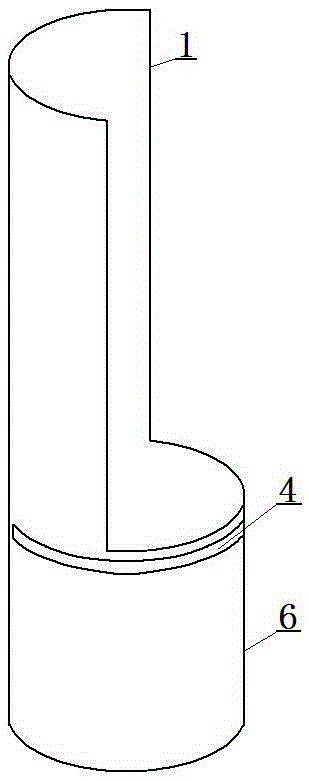

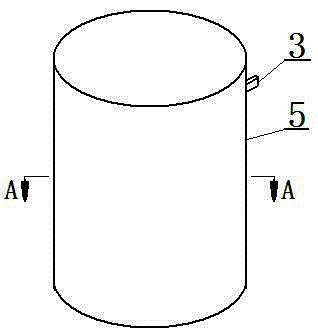

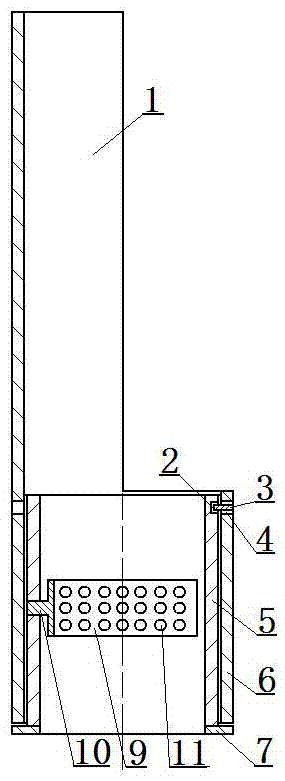

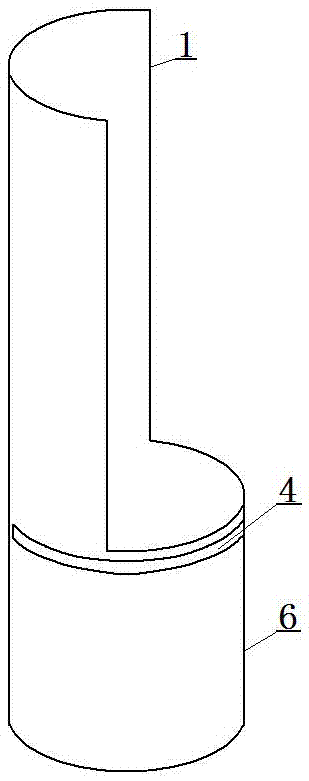

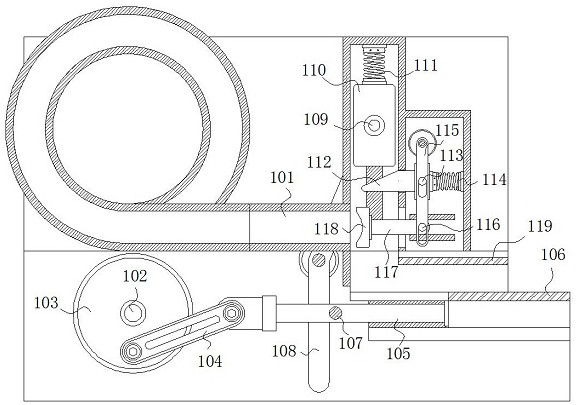

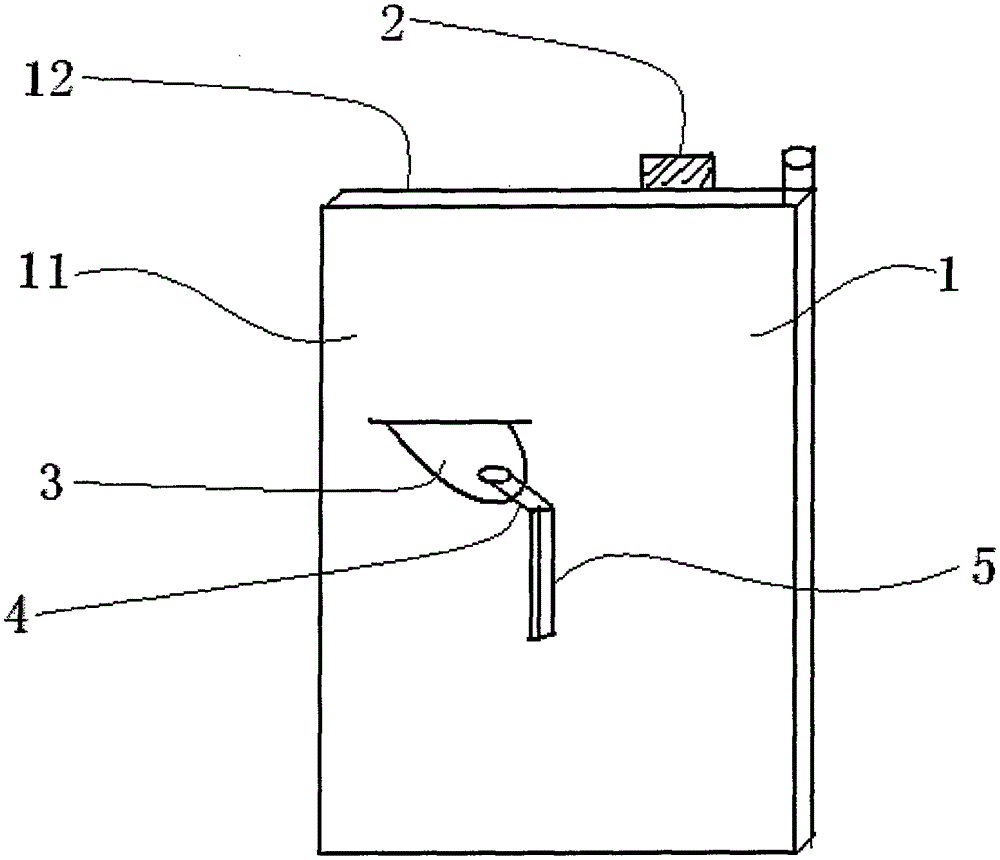

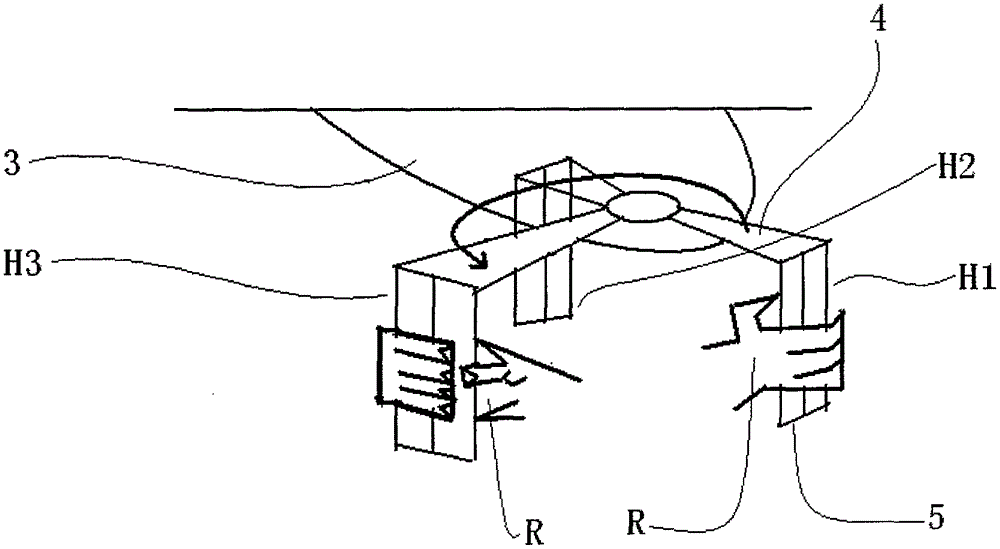

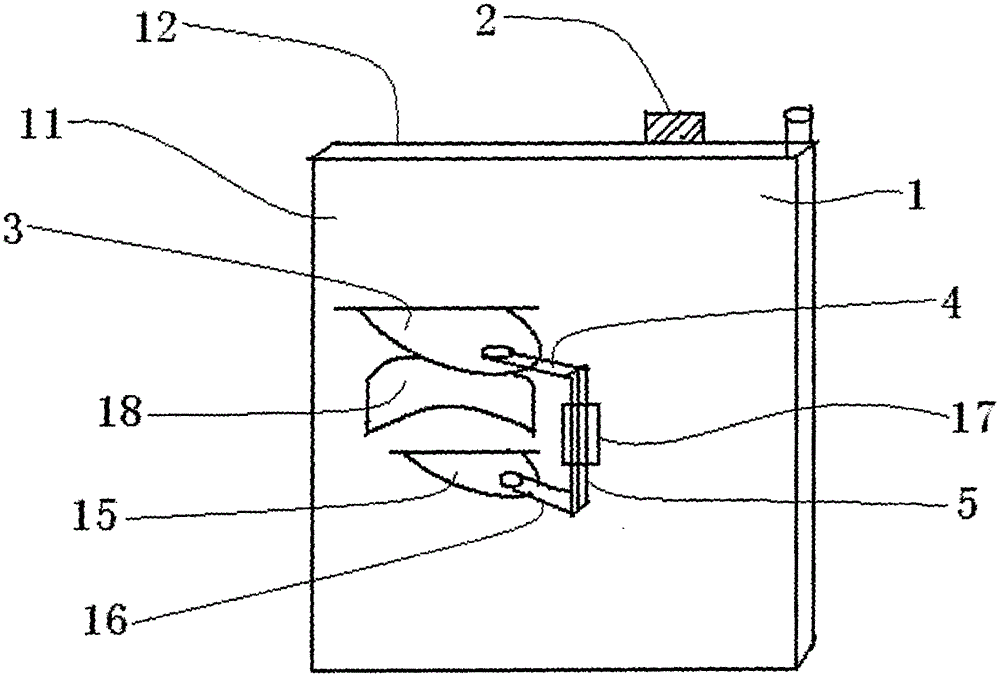

Foam soap dispenser

ActiveUS20190008331A1Efficient productionReduce manufacturing costHolders and dispensersSoap dispenserPiston

The present invention relates to the technical field of soap dispenser, particularly to a foam soap dispenser including a housing, a raw material chamber, and a liquid soap outlet, and further includes a water chamber, a drive device, and a foaming device; the liquid soap outlet is arranged on the housing; the raw material chamber, the water chamber, the drive device, and the foaming device are arranged inside the housing; a raw material chamber outlet and a water chamber outlet are connected to a foaming device inlet; a foaming device outlet is connected to the soap liquid outlet. The present invention can produce plentiful foam, and the piston assembly thereof is not easy to be stuck, and is provided with a longer service life. Moreover, the produced foam has a uniform size while the discharge speed of foam is faster and more stable than ever.

Owner:YAN JIANZHI

Composite lubricating grease for heavy load bearing and preparation method thereof

PendingCN107502405AUniform sizeImproves strength and hardnessCarbon preparation/purificationAdditivesLithiumEvaporation

The invention relates to the field of lubricating grease, in particular to composite lubricating grease for a heavy load bearing and a preparation method thereof. The composite lubricating grease is prepared from the following ingredients in percentage by weight: 99.2 to 99.8 percent of lithium-based lubricating grease and 0.2 to 0.8 percent of micro carbon spheres and nanometer particles. The micro carbon spheres and nanometer particles are uniformly distributed in the lithium-based lubricating grease by using ethanol as carriers. Compared with the existing ordinary lithium-based lubricating grease, the composite lubricating grease prepared after the ethanol evaporation has the advantage that the improvement is realized in aspects of friction heating, friction mark area and the like.

Owner:HENAN UNIV OF SCI & TECH

Foundation liquid containing panax notoginseng extract

InactiveCN104688596AUniform toneNo precipitation and coagulationCosmetic preparationsBody powdersBiotechnologyWhite petrolatum

The present invention discloses a cosmetic, and particularly relates to a foundation liquid containing a panax notoginseng extract. The foundation liquid is characterized by comprising, by weight, 15-25 parts of panax notoginseng saponin, 10-14 parts of angelica saponin, 6-8 parts of kaolin, 0.1-0.3 part of essence, 50-60 parts of distilled water, 3-5 parts of polyethylene glycol, 4-6 parts of white vaseline, 1-3 parts of glycerin, 3-5 parts of glycerol, 2-4 parts of lanolin, and 6-8 parts of talc powder. The foundation liquid of the present invention has effects of skin moisturizing, air permeability, beneficial nutrient absorbing, moisturizing, whitening, aging preventing, color spot covering, and skin elasticity enhancing, has characteristics of uniform foundation liquid color, no precipitation agglomeration, easy coating, and firm powder attaching, and is the green beautifying skin care product.

Owner:霍兆健

Polyester-cotton fiber burnt-out fabric dyeing and finishing processing technology

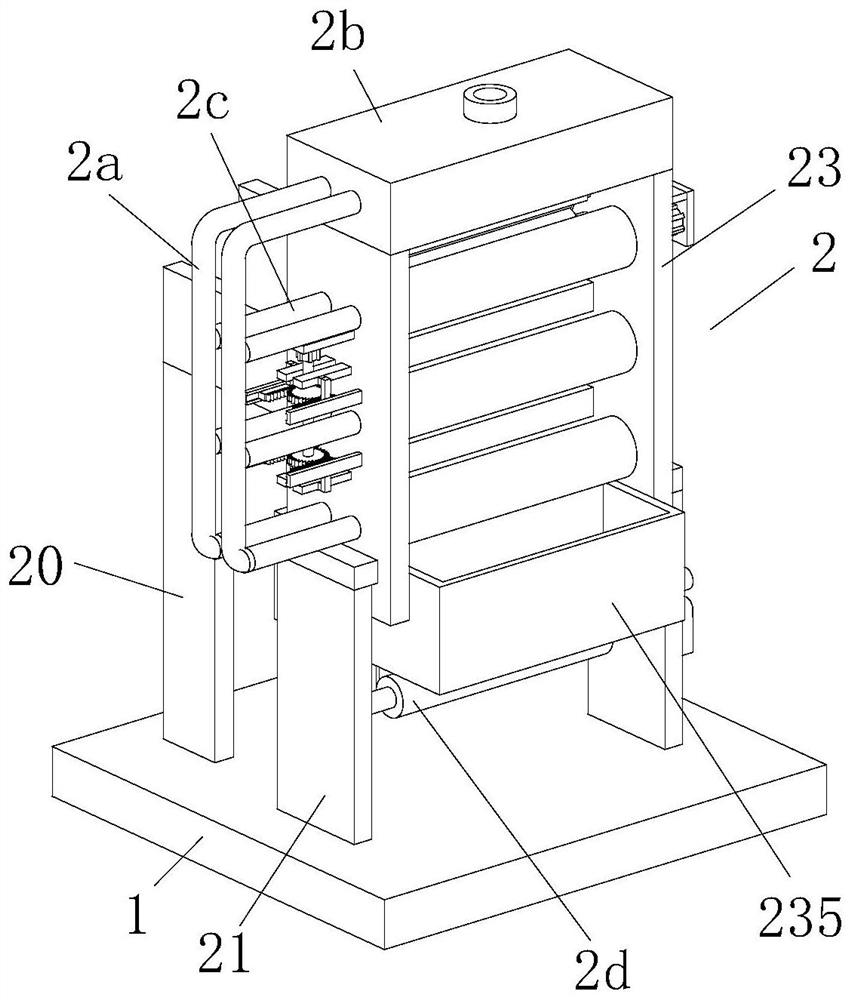

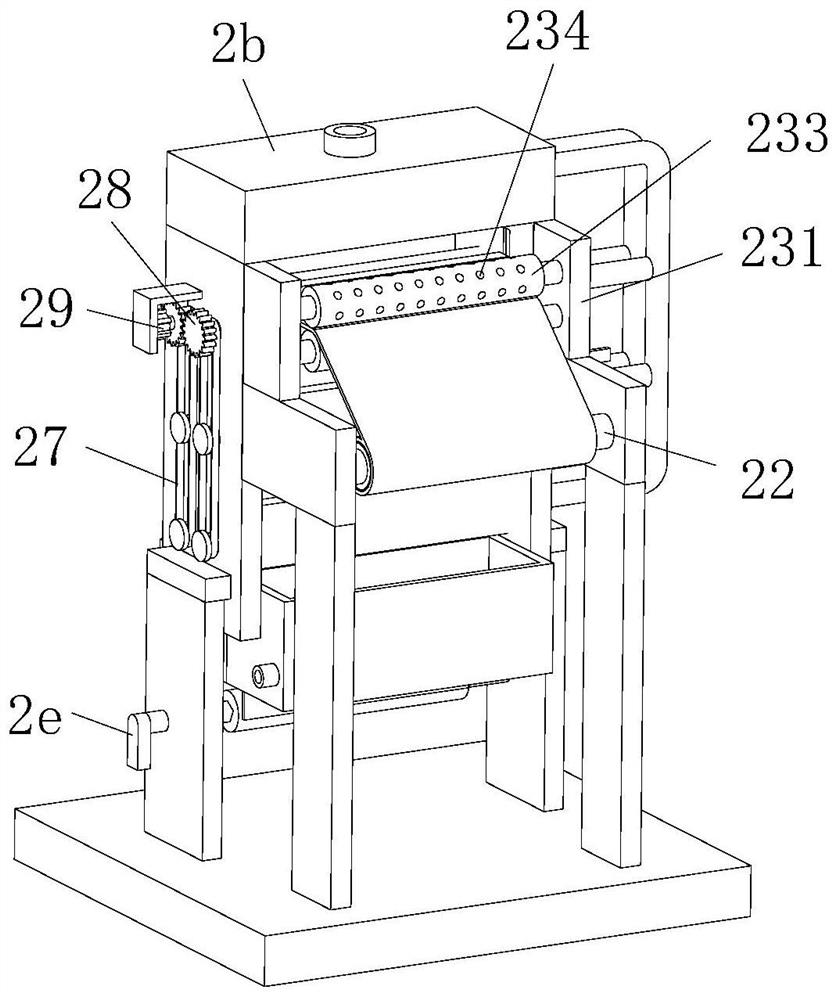

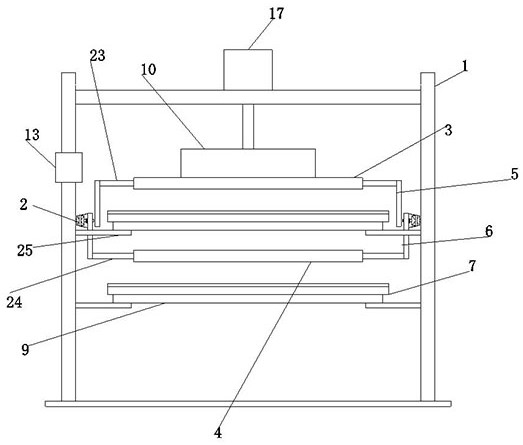

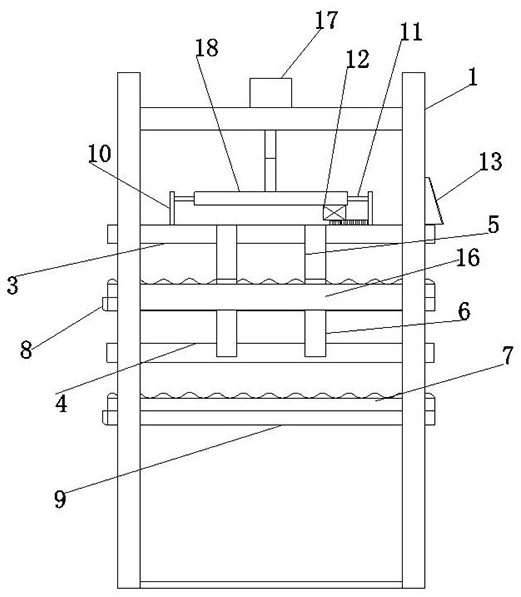

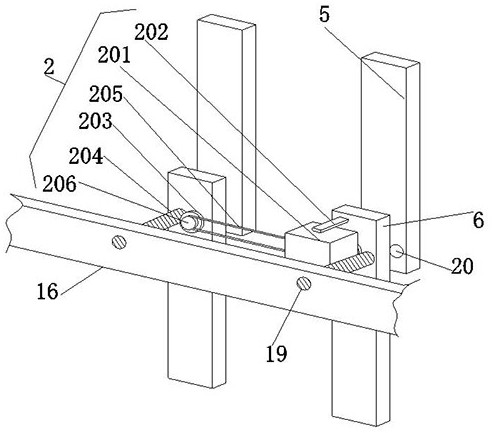

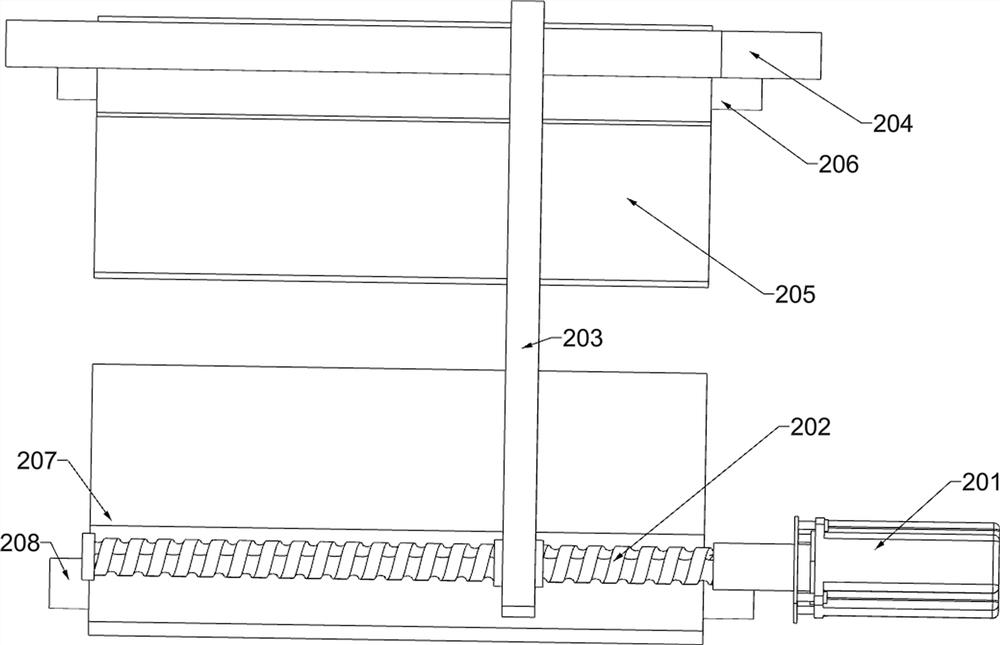

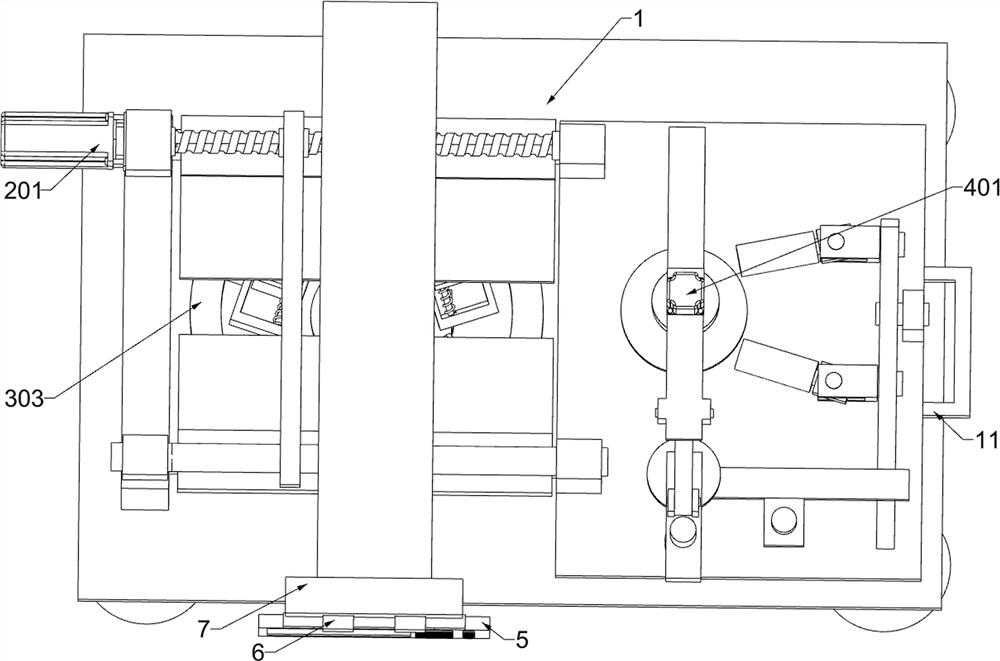

InactiveCN113445228AImprove washing effectImprove the efficiency of washingMechanical cleaningPressure cleaningChemistryPolyester

The invention provides a polyester-cotton fiber burnt-out fabric dyeing and finishing processing technology. The polyester-cotton fiber burnt-out fabric dyeing and finishing processing technology adopts the following equipment for processing: the equipment comprises a base and a water washing device; the lower end of the base is connected with the existing ground; and the water washing device is mounted at the upper end of the base. According to the processing technology, a rubbing device can repeatedly rub the polyester cotton fiber burnt-out fabric in a double-sided manner, so that burnt-out scraps on the surface of the fabric can be quickly separated from the fabric, the washing effect is enhanced, and the washing efficiency is improved; a plurality of groups of extrusion conveying rollers are matched with one another; and by means of the arrangement, the fabric can be in a tiled state in the rubbing and washing process, wrinkles are not prone to occurring in the washing process, the contact area between water and the fabric is increased, the water utilization rate of the equipment is increased, and therefore water resources are saved.

Owner:武汉哈呢哈呢贸易有限公司

Foam soap dispenser

ActiveUS10624505B2Lower usage limitReduce space consumptionHolders and dispensersSoap dispenserMechanical engineering

Owner:YAN JIANZHI

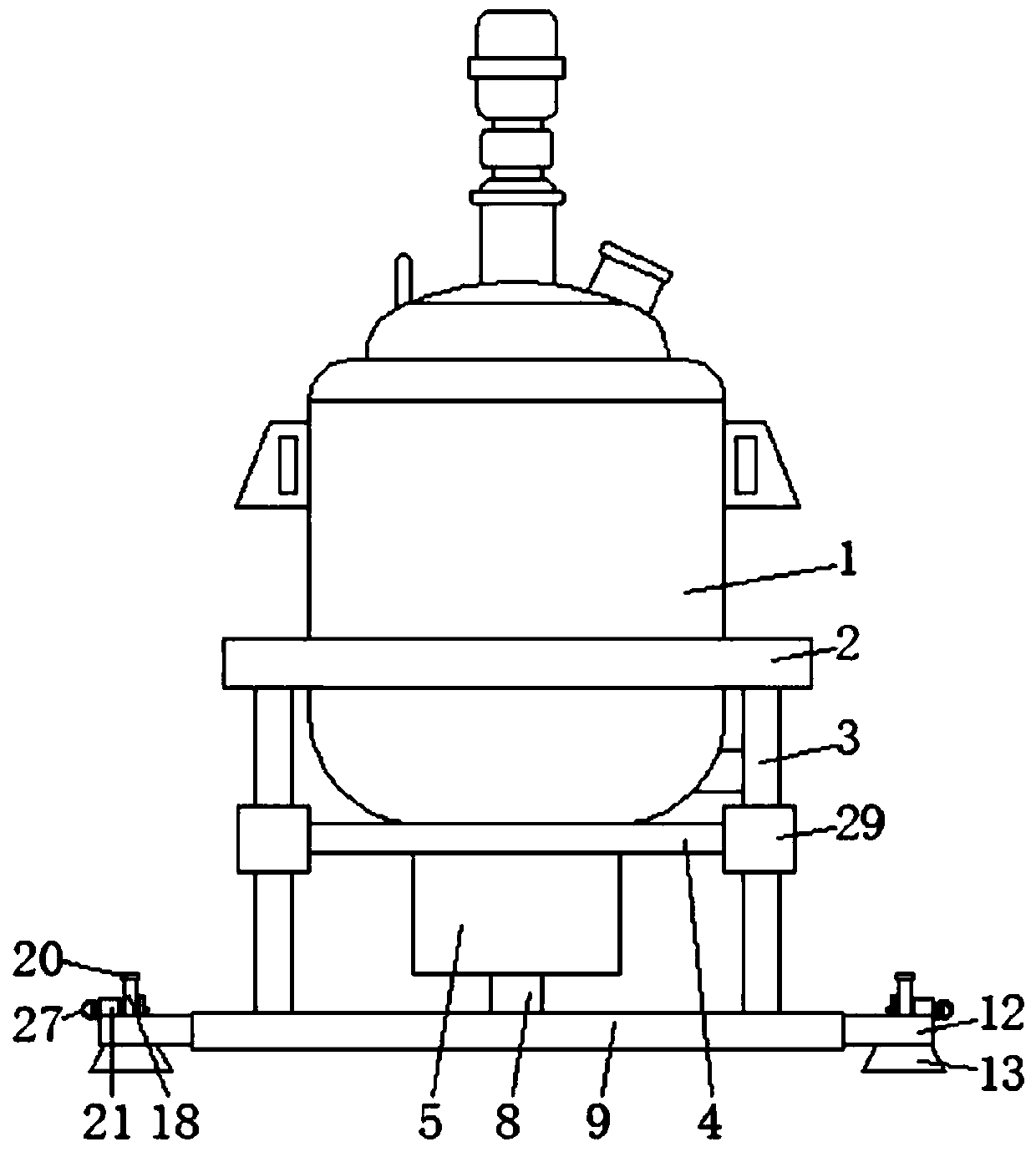

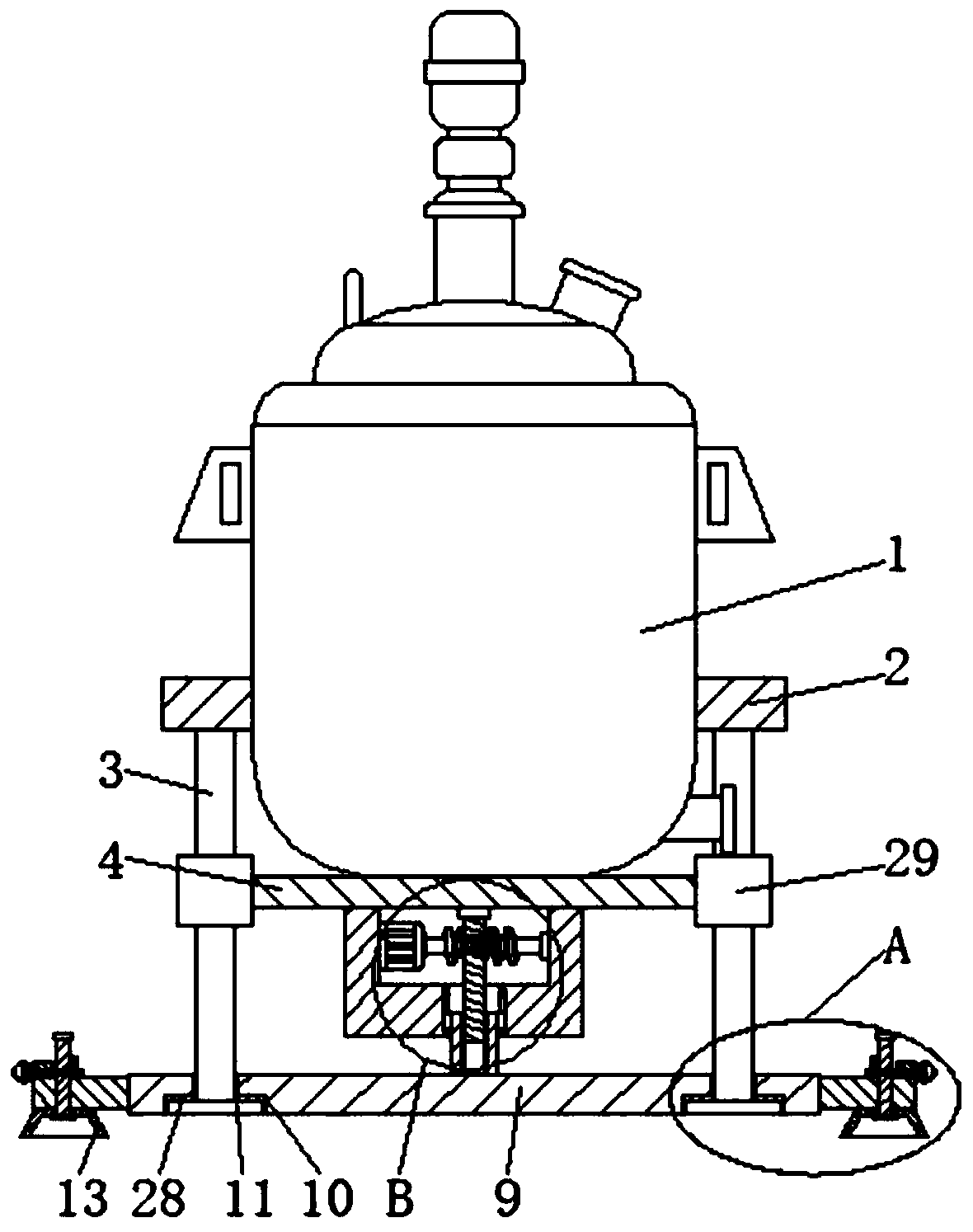

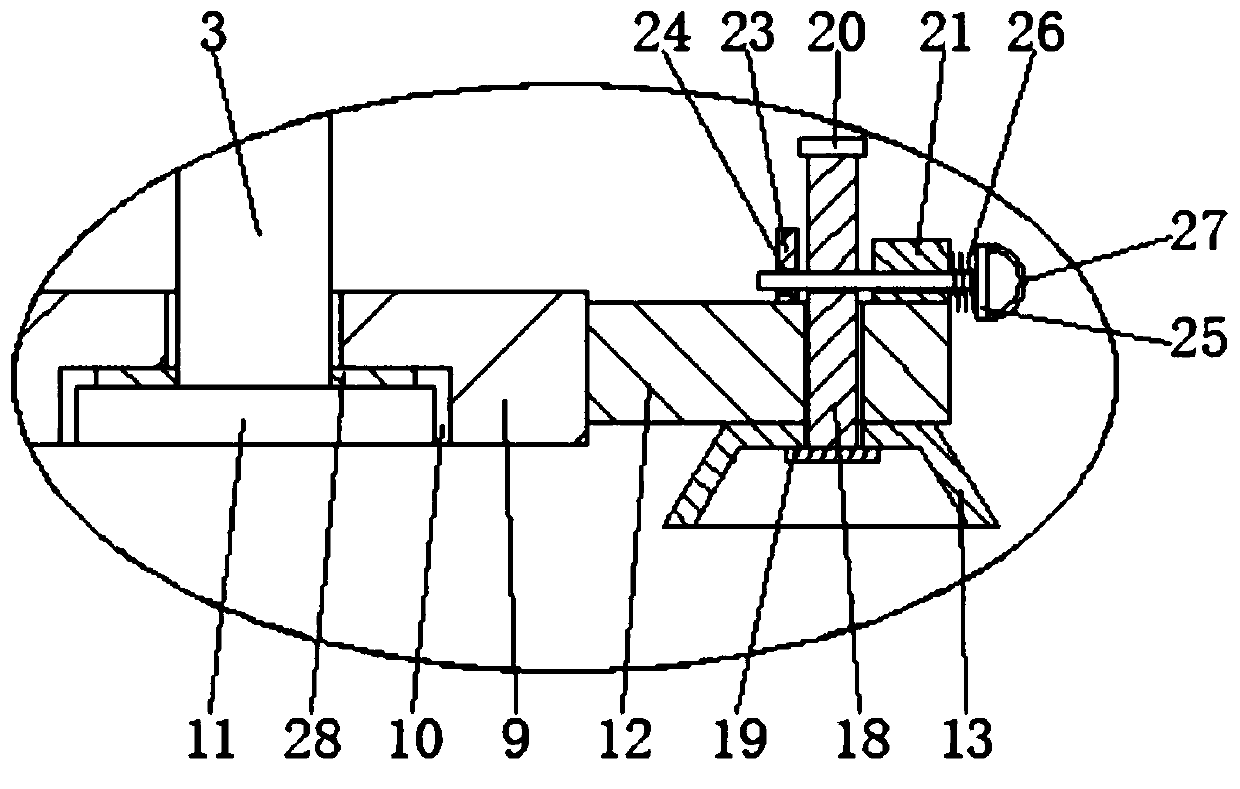

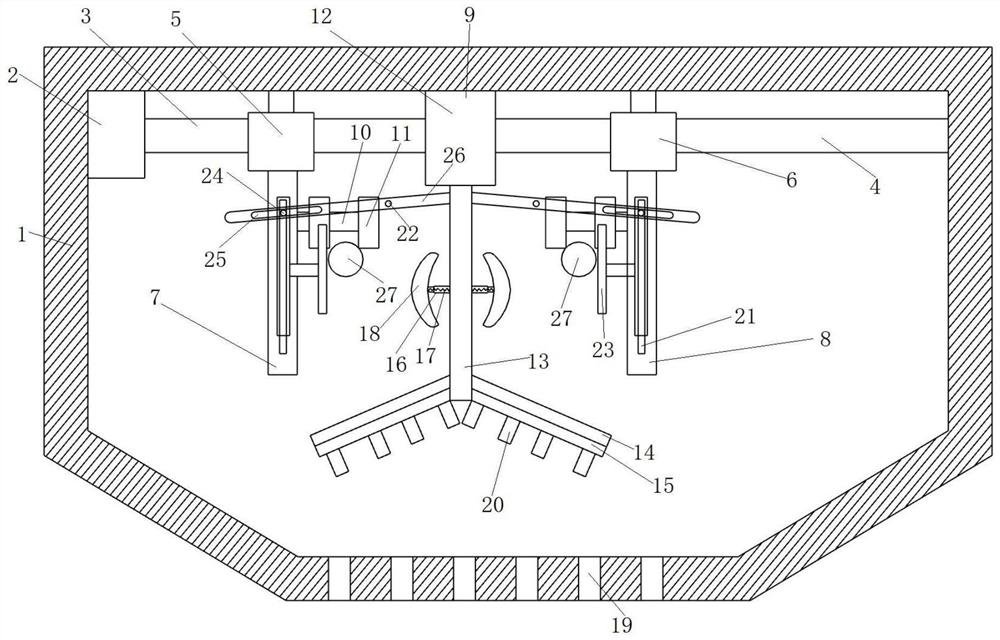

Ammonium paratungstate crystallization kettle with strong stability

InactiveCN110393942AImprove stabilityReduce frictionSolution crystallizationTungsten compoundsAmmonium paratungstateCrystallization

The invention discloses an ammonium paratungstate crystallization kettle with strong stability. The crystallization kettle comprises a crystallization kettle body, wherein the surface of the crystallization kettle body is fixedly connected with a top plate, four corners of the bottom of the top plate are fixedly connected with support columns, the bottom of the crystallization kettle body is fixedly connected with a bottom plate, and the bottom of the bottom plate is fixedly connected with a transmission box. A transmission mechanism drives a bearing plate to move downwards by a lead screw anda thread sleeve, the bearing plate compresses pressing blocks tightly, and at the same time the bottom of the bearing plate also contacts with the ground, and the bearing plate drives sucking discs to move downwards to adsorb the ground, so that the crystallization kettle has the advantages of strong stability, and the problem that an existing crystallization kettle is supported only by triangular support columns at the bottom, and stability is poor is solved. The ammonium paratungstate crystallization kettle with strong stability avoids the phenomenon that a service life of the triangular support columns is reduced because the triangular support columns are easy to rub against the ground due to shaking, and is convenient for people to use.

Owner:赣州市聚鑫矿业有限公司

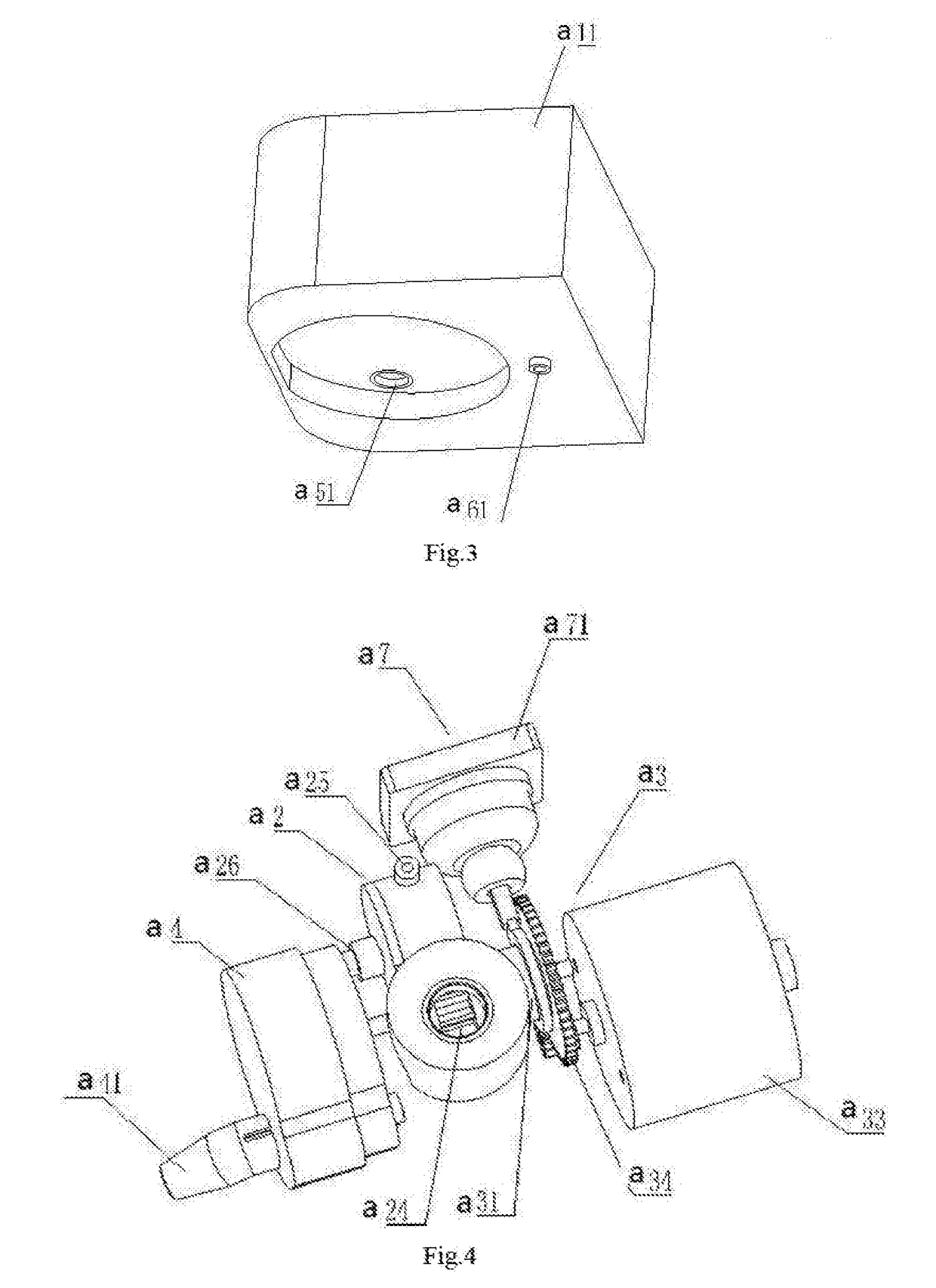

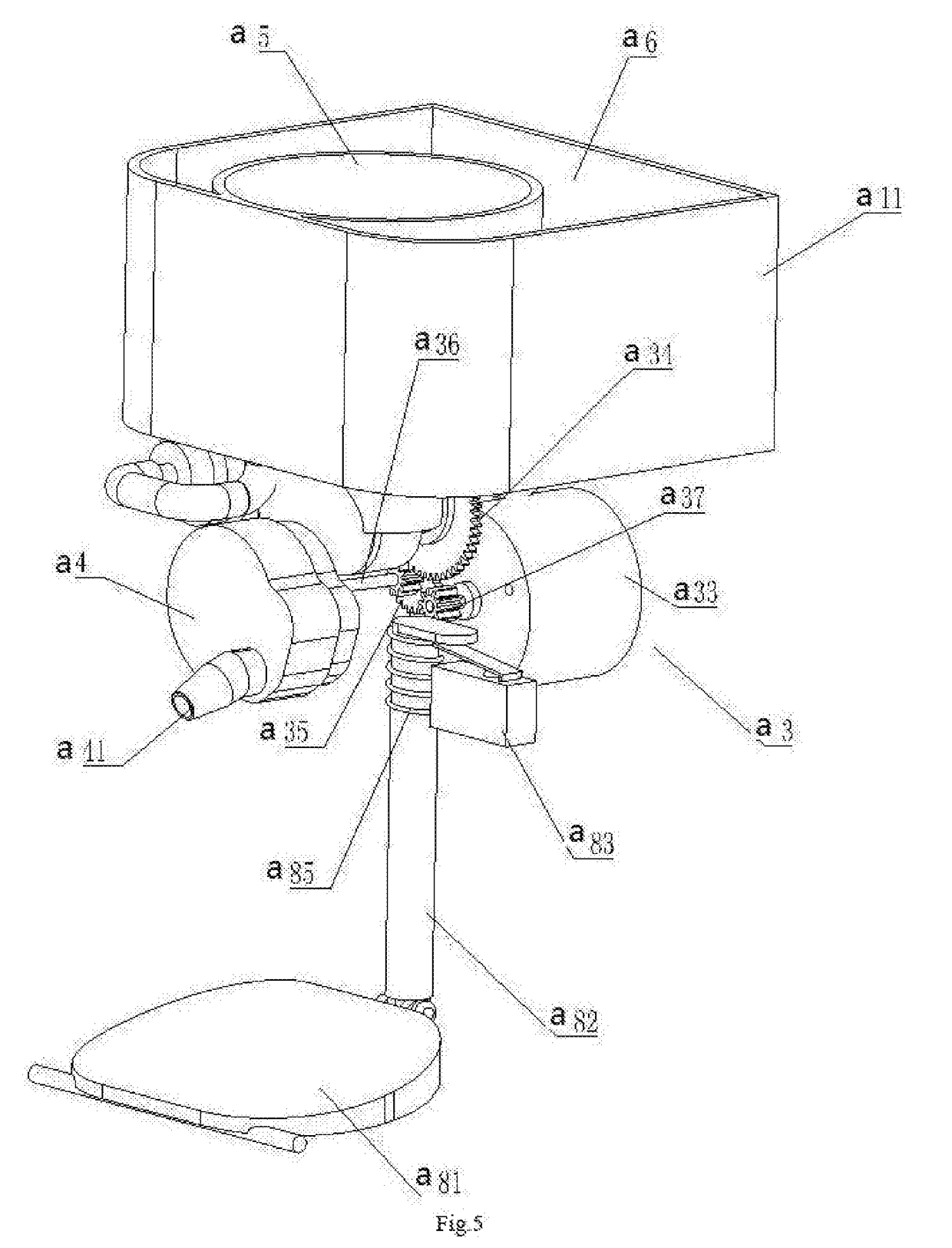

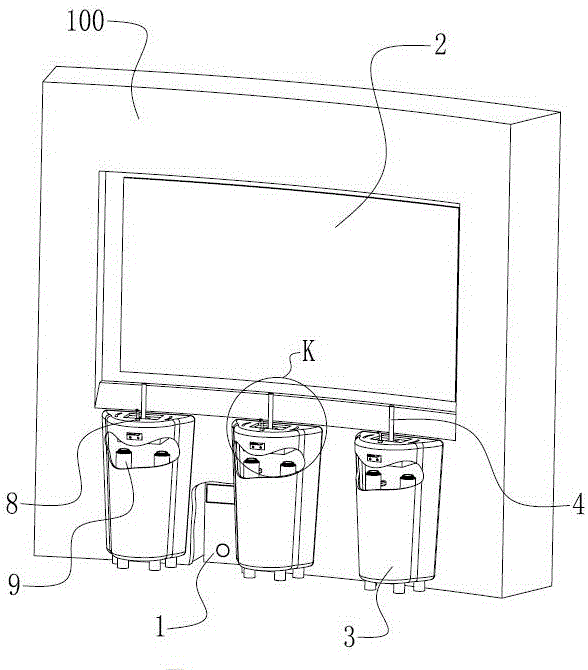

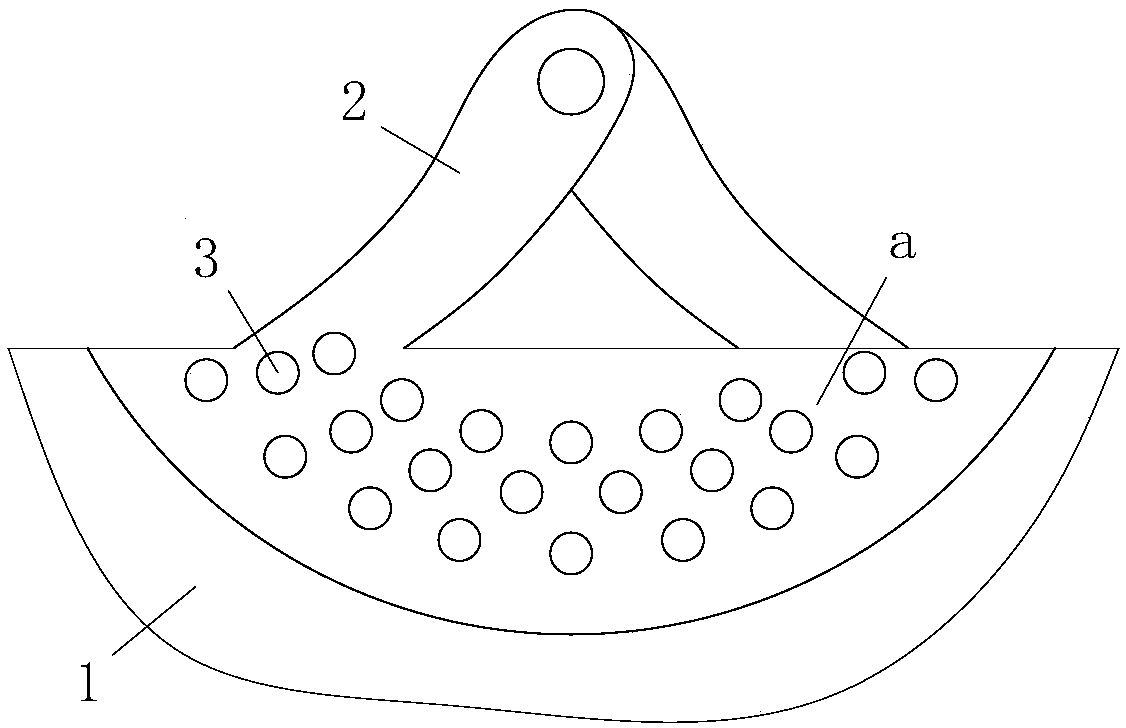

Bow-drill fire making simulation exhibition item and control method thereof

ActiveCN106023711AEasy to rubAvoid it happening againCosmonautic condition simulationsSimulatorsComputer moduleData acquisition

The invention relates to the technical field of combined audio and visual display equipment and discloses a bow-drill fire making simulation exhibition item and a control method thereof. The bow-drill fire making simulation exhibition item comprises a background wall, an operating floor, a display screen and a control host. A data acquisition and conversion module is arranged in the control host, a square groove is formed in the operating floor, a pressure sensor is arranged in the groove, a square block is placed on the pressure sensor, the square block is in sliding fit with the groove, a conical groove is formed in the square block, and a rod-shaped object with one conical end is placed in the conical groove; a temperature sensor probe is installed in the square block, a rotating speed sensor probe is arranged on the side wall of the groove, and the electronic detection elements are all in circuit connection with the data acquisition and conversion module. A visitor can experience the bow-drill fire making process firsthand through actual operation, the interestingness of the visiting process is improved, and the visitor can experience the wisdom and tough living conditions of the ancients more deeply.

Owner:深圳市艺博堂文化科技集团有限公司

Bulge type titanium alloy self-plugging rivet manufacturing technology

ActiveCN111571142AImprove corrosion resistanceIncrease usageManufacturing technologyHeat conservation

The invention discloses a bulge type titanium alloy self-plugging rivet manufacturing technology. The technology comprises rivet body manufacturing, rivet sleeve manufacturing and driving ring manufacturing. The rivet body manufacturing includes the following steps of 1, preparing a blank; 2, performing tampering to obtain a semi-finished product; 3, cleaning and removing surface dirt and raw material coatings formed by tampering; 4, performing thermal treatment, wherein a, first-time thermal treatment is performed, the cleaned semi-finished product is placed into a thermal treatment furnace under the temperature of 680-720 DEG C for production, the temperature is kept for 10-20 min, and then post-air-cooling is performed; b, secondary thermal treatment, the semi-finished product obtainedafter air cooling is placed into a thermal treatment furnace under the temperature of 450-500 DEG C for heat preservation for 8-10 h, and then post-air-cooling is performed; 5, performing centerless grinding, wherein the semi-finished product obtained after thermal treatment is placed into a centerless grinding machine for rod diameter grinding; 6, rolling threads, wherein the ground semi-finishedproduct is rolled to obtain a thread and a ring groove; 7, performing surface treatment. The machining efficiency and the yield are high, the product corrosion resistance, structural strength, surface hardness, the tissue uniformity and other properties are excellent, the mass is low, and the product usage rate is increased.

Owner:王丽

Self-plugging rivet manufacturing process

ActiveCN111571143AImprove structural strength and surface hardnessImprove product performanceHeat conservationManufacturing engineering

The invention discloses a self-plugging rivet manufacturing process. The self-plugging rivet manufacturing process comprises rivet body manufacturing and rivet sleeve manufacturing, wherein the rivetbody manufacturing process comprises the following steps of 1, preparation of rivet body blanks: selecting an A286 raw material with the appropriate specification and mass; 2, upsetting forming: conducting upsetting on the selected A286 raw material through molds with the corresponding specifications in a cold upsetting machine 2-3 times to form heads, steps and rod parts of rivets to obtain semifinished rivet bodies; 3, cleaning: feeding the semifinished rivet bodies onto a corresponding cleaning line to remove oil dirt and blasted surface sand generated after upsetting; 4, heat treatment: feeding the cleaned semifinished rivet bodies into a heat treatment furnace of 650-700 DEG C for production heat preservation for 8-10 h, and then conducting air-cooling; 5, thread rolling: conducting thread rolling on the semifinished rivet bodies subjected to heat treatment to form knurls, threads and grooves; and 6, surface treatment: conducting surface treatment on the semifinished rivet bodiessubjected to thread rolling to obtain finished products. The self-plugging rivet manufacturing process is simple in working procedure, high in machining efficiency and qualified rate of the products and good in quality.

Owner:王丽

PE plastic packaging bag

ActiveCN109677768AEasy to openImprove the efficiency of rubbing bagsBagsSacksPlastic packagingEngineering

The invention belongs to the technical field of packaging bags, and particularly relates to a PE plastic packaging bag. The PE plastic packaging bag comprises a bag body and a hanging piece used for threading and connecting a plurality of packaging bags in series, wherein No.1 concave grains are pressed in an a zone in the middle of the upper end of the bag body through debossing treatment; and the No.1 concave grains are used for allowing a user to easily twist open the packaging bag with fingers. According to the PE plastic packaging bag, the packaging bag can be quickly opened, the user canput objects in the packaging bag more easily, bearing capacity of the packaging bag is good, and tensile strength is high.

Owner:ZHEJIANG GANGFA SOFT PACKAGE

Manufacturing process for titanium alloy Huck rivet

PendingCN111421309AImprove corrosion resistanceIncrease usageTitanium alloyUltimate tensile strength

The invention discloses a manufacturing process for a titanium alloy Huck rivet. The manufacturing process is characterized by comprising the steps of rivet body manufacturing and lining manufacturing, wherein rivet body manufacturing comprises the following steps that 1, a rivet body blank is prepared; 2, upsetting forming is carried out; 3, washing is carried out; 4, heat treatment is carried out, specifically, a, solid solution heat treatment is carried out, specifically, a washed rivet body semi-finished product is put into a vacuum water quenching furnace at the temperature of 800 DEG C -950 DEG C to be subjected to production heat preservation for 1.5 h - 2 h, and then water-cooled; b, aging heat treatment is carried out, specifically, the water-cooled rivet body semi-finished product is put into a vacuum furnace at the temperature of 550 DEG C - 600 DEG C to be subjected to heat preservation for 8 h -10 h, and then air-cooled; 5, turning is carried out, specifically, the headouter diameter and the tail end thread bottom diameter of the rivet body semi-finished product subjected to heat treatment are turned; 6, centerless grinding is carried out, specifically, the turned rivet body semi-finished product is put into a centerless grinding machine to grind the rod diameter, the head R angle and the head lower supporting surface; 7, thread rolling is carried out; and 8, surface treatment is carried out to obtain a rivet body finished product. The manufacturing process is high in machining efficiency and qualified rate, and the product is excellent in corrosion resistance, structural strength, surface hardness, structure uniformity and the like.

Owner:王丽

Multifunctional costume design board

ActiveCN113662307AEasy to rubReduce frictionClothes making applicancesProtractorStructural engineering

The invention discloses a multifunctional costume design board. Themultifunctional costume design board structurally comprises a bottom plate, a drawing base plate, a cutting base plate and an assembling side plate and is characterized in that a measuring device composed of a lifting ruler, an indicating rod in linkage rotation with the ruler and a bevel protractor is arranged, so that when the equipment is used for drawing, the ruler is normally lifted to be higher than drawing paper, the ruler can be directly pressed to descend for use when needing to be used, and the ruler can drive the indicating rod to rotate together when rotating, so the indicating rod carries out angle indication on the bevel protractor, the ruler can be better prevented from rubbing the drawing paper, meanwhile, angle measurement can be carried out when the ruler is used for drawing, convenient use is achieved, by arranging the drawing base plate which can be moved, lifted and overturned and arranging the cutting base plate below the drawing base plate, the equipment can move the drawing base plate to use the cutting base plate, the drawing plate can be moved and lifted for positioning through the drawing plate adjusting device, the drawing base plate can be conveniently lifted for cutting reference, and functionality is more.

Owner:CHONGQING COLLEGE OF FINANCE ECONOMICS

Hot coating device for accelerating cooling

The invention discloses a hot coating device for accelerating cooling. The hot coating device for accelerating cooling comprises a base, a fixed plate, a workbin and an air extractor, wherein a shellis arranged on the upper side surface of the base; a groove is formed in the base; meanwhile, an air cooler is arranged in the groove; an air inlet pipe is arranged on the upper side surface of the air cooler and penetrates through the upper side surface of the base; an air inlet hollow plate is arranged on the upper side surface of the air inlet pipe; an air outlet is formed in the upper side surface of the air inlet hollow plate; the fixed plate is arranged on the upper side surface of the base and is arranged on the upper side of the air inlet hollow plate; meanwhile, the fixed plate is arranged on the inner side of the shell; a storage plate is arranged on the inner side surface of the fixed plate and is arranged on the upper side of the air outlet; and meanwhile, a through hole is formed in the upper surface of the storage plate. According to the hot coating device for accelerating cooling, the air outlet is formed, and after an object is sprayed, through the work of the air cooler, the air outlet blows air to dry the object on the upper side of the storage plate through the through hole, so that the working efficiency is improved.

Owner:江苏纵湖涂装设备产业研究院有限公司

Novel guitar slide rod with elastic structure

PendingCN105427842AAchieve rotationWon't turnStringed musical instrumentsEngineeringMechanical engineering

The invention discloses a novel guitar slide rod with an elastic structure. Half of the wall thickness portion of the upper portion of a tubular slide bar is cut along the center line of a length direction, and a half-pipe with a semicircular cross section is left. The novel guitar slide bar is mainly characterized in that the internal diameter of the tubular slide bar is sleeved by a circular pipe; the external diameter end of the upper portion of the circular pipe is provided with a square groove, and the square groove is internally provided with a square column; the wall thickness portion of the middle and lower portion of the tubular slide bar is provided with an annular groove hole corresponding to the square column; the bottom end of the circular pipe is provided with a retainer ring; and the internal diameter of the central portion of the circular pipe is provided with an upper semicircular elastic steel sheet and a second semicircular elastic steel sheet which are symmetrical at the same axial center, a first support strip is arranged outside the diameter of the left end of the upper semicircular elastic steel sheet, and a second support strip is arranged outside the diameter of the right end of the lower semicircular elastic steel sheet. According to the invention, after performance skills of the guitar slide bar are completed, the tubular slide bar can be conveniently rotated 180 degrees for stringing; and the tightness of fingers can also be flexibly adjusted.

Owner:罗洋洋

A novel guitar slide bar with an elastic structure

PendingCN105448278AFlexible adjustment of tightnessAvoid itchingStringed musical instrumentsSheet steelEngineering

The invention discloses a novel guitar slide bar with an elastic structure. One half of the wall thickness portion of the upper portion of the tubular slide bar is cut off along the center line of the wall thickness portion in the length direction in order to leave a half-tube, of which the cross section is semicircular. The main characteristics of the present invention are that the internal diameter of the tubular slide bar sleeves a circular pipe; the external diameter terminal of the upper portion of the circular pipe is provided with a square groove; a square column is arranged in the square groove; the wall thickness portion of the middle-lower portion of the tubular bar is provided with an annular groove aperture corresponding to the square column; the bottom terminal of the circular pipe is provided with a back-up ring; an elastic sheet steel ring with a notch is arranged on the internal diameter of the circular pipe around the same axis; the wall thickness portion of the elastic sheet steel ring is provided with a plurality of uniformly distributed apertures; a support bar is arranged outside the diameter of the left end of the elastic sheet steel ring; and the support strip is embedded into and fixed in the wall thickness portion of the circular pipe along the a radial direction. According to the invention, after playing skills of the guitar sliding bar are shown, rotating of the tubular slide bar for 180 degrees to carry out string pressing is convenient, and adjusting of tightness of string playing by fingers is flexible.

Owner:罗洋洋

A kind of multifunctional regenerated cellulose fiber

ActiveCN106591990BExcellent radiation resistanceSlow reaction speedArtificial filaments from viscoseCellulose fiberPhthalimide

The invention discloses a multi-effect regenerated cellulose fiber. The multi-effect regenerated cellulose fiber is mainly prepared from hydroxyl ferrite nano-powder, silver nano-powder, guanidine carbonate, phthalimide, sodium hydroxide and regenerated bamboo cellulose through a viscose spinning process, wherein the hydroxyl ferrite nano-powder and the silver nano-powder are prepared by making nitrate containing metal ions and low-polymer chitosan perform complexing reaction and then making a reactant react with ammonia water or hydrazine hydrate. The prepared multi-effect regenerated cellulose fiber has a good antibacterial effect and a magnetic therapy health-care effect, and a manufactured fabric is soft and comfortable and good in air permeability, does not easily produce static electricity, is resistant to washing and rubbing and is extremely convenient to finish.

Owner:浙江三佳制衣有限公司

Blind rivet manufacturing process

The invention discloses a manufacturing process of a blind rivet, which includes the manufacture of a nail body and the manufacture of a nail sleeve; the manufacture of the nail body includes the following steps: Step 1, the preparation of the nail body blank: selecting A286 raw materials with suitable specifications and quality; Step 2, upsetting Molding: The selected A286 raw material is passed through the mold of the corresponding specification in the cold pier machine to form the head, steps and rods of the nail body 2-3 times to obtain the semi-finished nail body; step 3, cleaning: Put the semi-finished nail body into the corresponding cleaning line to remove the oil dirt and surface sandblasting caused by upsetting; step 4, heat treatment: put the semi-finished nail body after cleaning into a heat treatment furnace at 650°C-700°C for production and heat preservation for 8 hours ‑10h, then air cooling; step 5, thread rolling: rolling the heat-treated semi-finished nail body to produce knurls, threads and grooves; step 6, surface treatment: surface-treating the semi-finished nail body after thread rolling to obtain a finished product . The invention has the advantages of simple process, high processing efficiency, high product qualified rate and good quality.

Owner:王丽

Transmission line protection device

ActiveCN113595005BImprove processing efficiencySmooth rotationOverhead installationStructural engineeringIndustrial engineering

The invention discloses a transmission line protection device, comprising a casing, wherein an up and down moving piece, a first connecting frame and a second connecting frame are arranged in the casing, and rollers are provided on the opposite sides of the first connecting frame and the second connecting frame. The first connecting frame and the second connecting frame are both provided with vertical grooves, the cleaning rods are slidably connected in the vertical grooves, the upper and lower moving parts are connected with a moving frame, and the moving frame is located between the first connecting frame and the second connecting frame, and the moving frame The side wall is connected with an arc-shaped cleaning plate through an elastic spring, and the lower end of the moving frame is connected with two inclined plates. The inclined plates are hingedly arranged with the moving frame. The end face is provided with a heating plate, the lower end of the heating plate is provided with a plurality of impact rods, and the lower end of the casing is provided with a plurality of circulation holes matched with the impact rods. The present invention facilitates the protection of power transmission lines.

Owner:ANHUI POLYTECHNIC UNIV

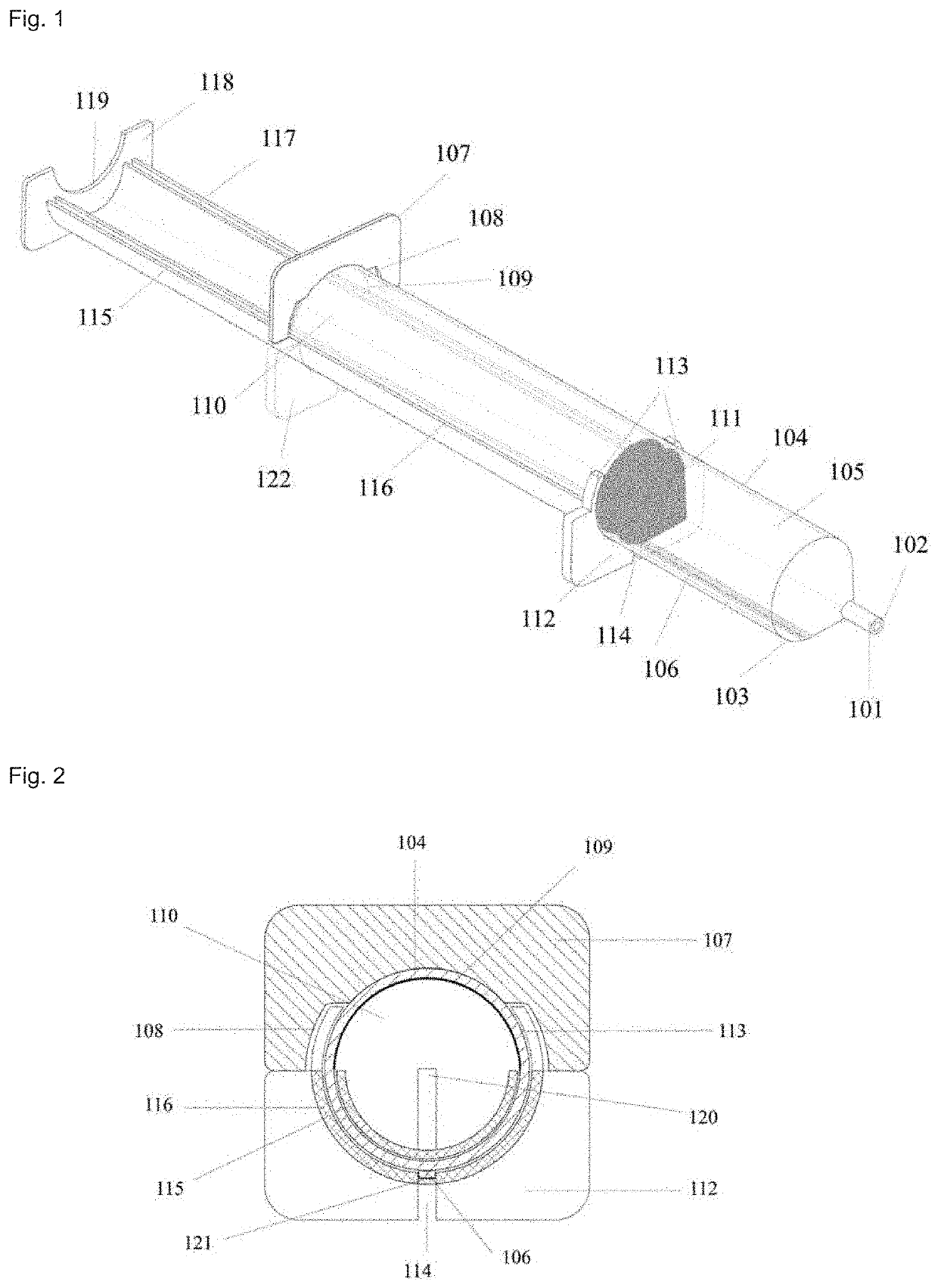

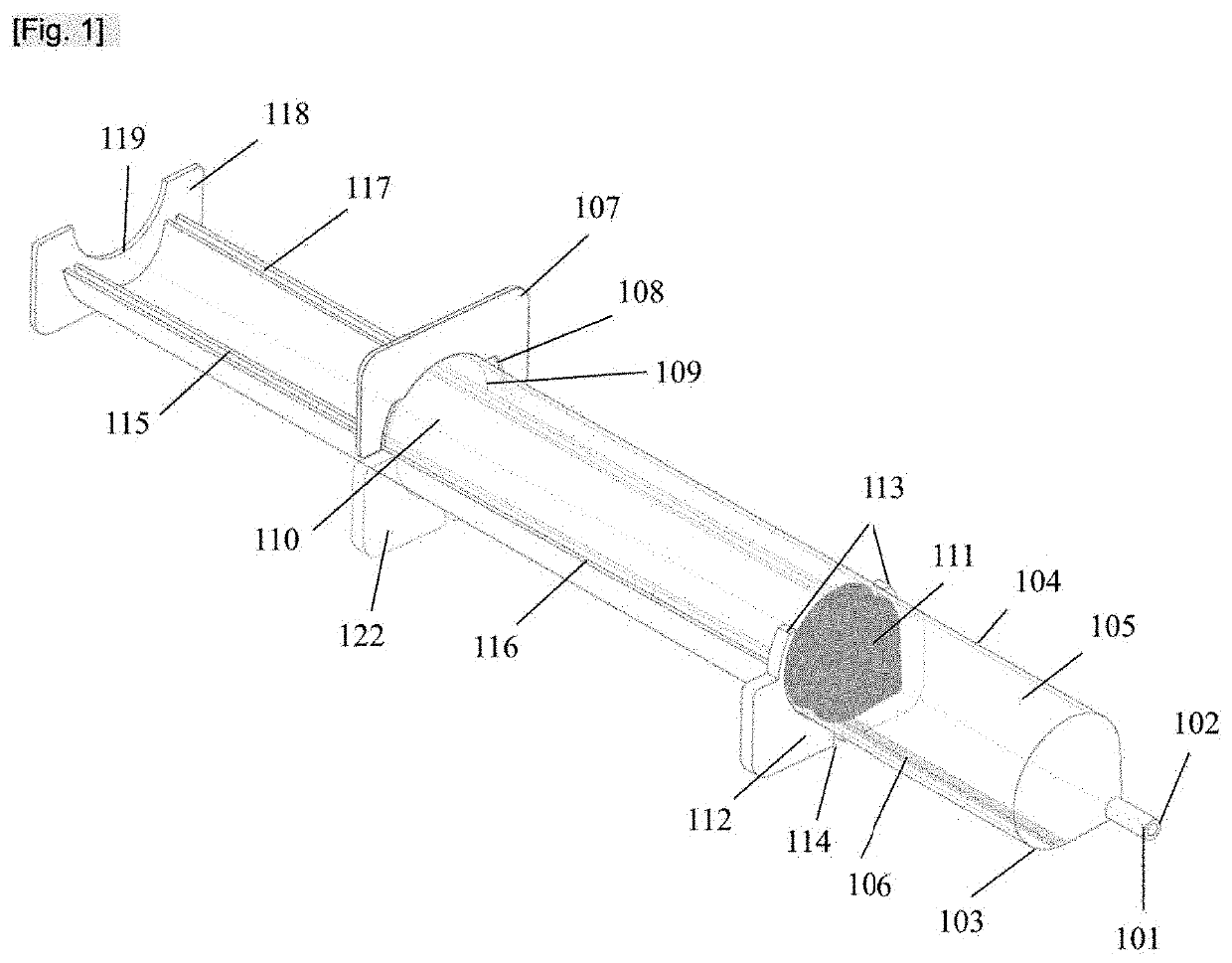

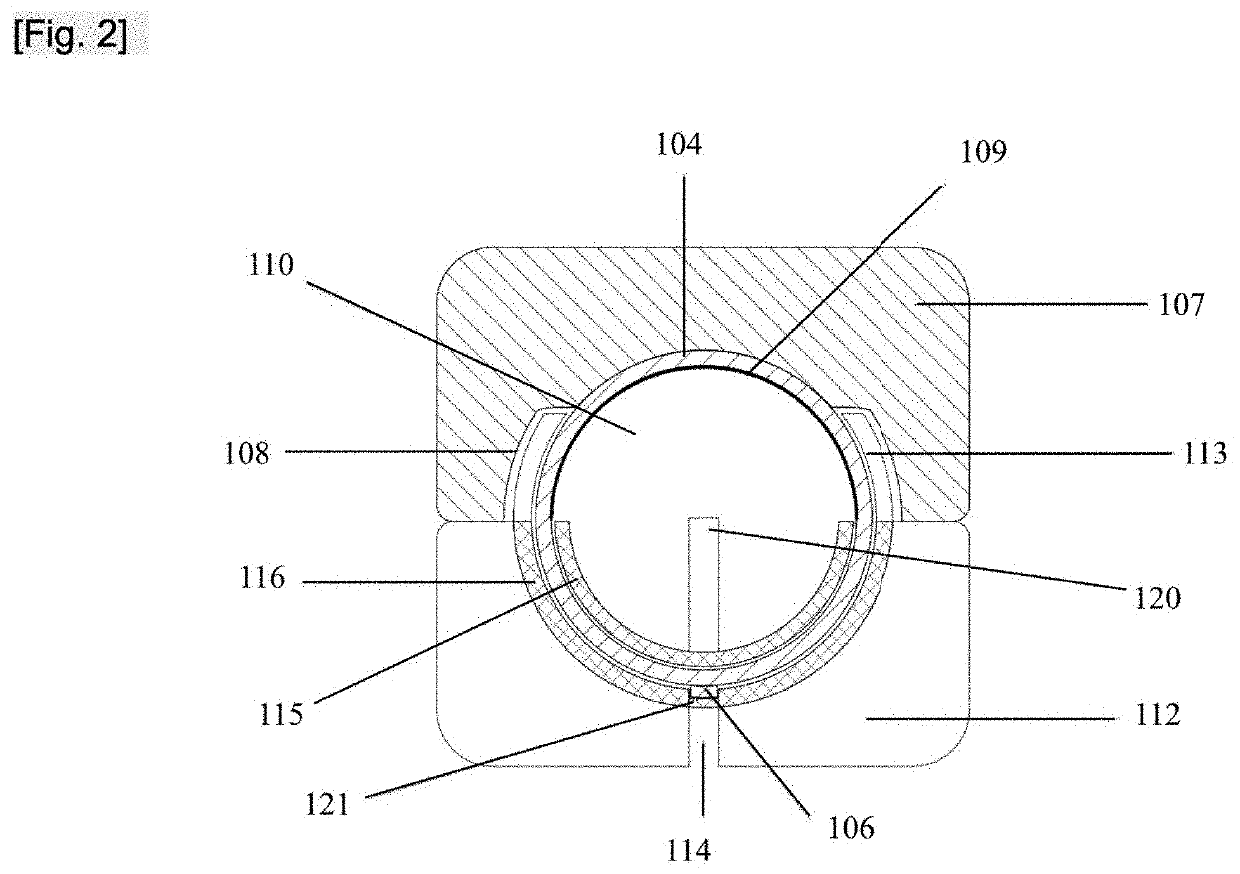

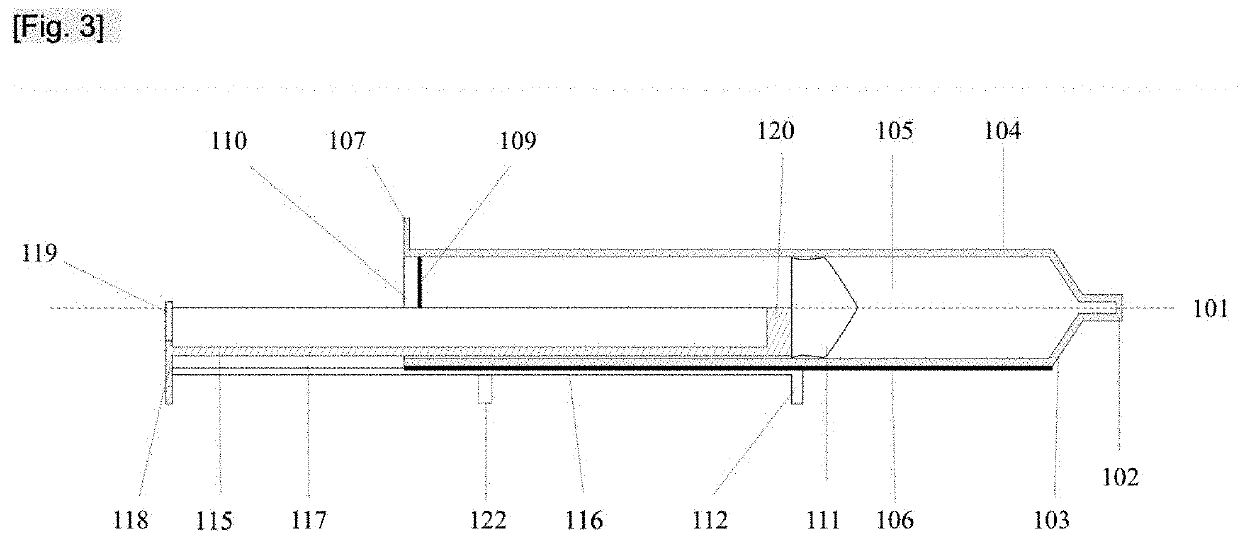

Syringe for one-handed injection and aspiration

ActiveUS20200405962A1Safe and easy injectionSafe and easy and aspirationInfusion syringesIntravenous devicesEngineeringPlunger

A single-handed syringe may be used in injection and in aspiration for stable and consistent single-handed use. The syringe includes a hollow cylinder body, which has a front tip that the aspirated materials pass through toward / from a cylinder cavity. A rear plunger handle and a front plunger handle, in combination with a straight external prominence formed longitudinally along an outer surface of the cylinder body permits ease, accuracy, and precision of plunger movement during aspiration and injection functions.

Owner:ALSAHAB MEDICAL CO

Moss-eliminating medicinal wine and preparation method thereof

InactiveCN107648381AEffective moss removalStable efficacyAntimycoticsAnthropod material medical ingredientsSide effectTraditional medicine

The invention discloses moss-eliminating medicinal wine and belongs to the field of traditional Chinese medicine. The moss-eliminating medicinal wine is prepared from, by weight, 15-25 parts of fructus cnidii, 7-15 parts of periostracum cicada, 9-11 parts of fructus forsythiae, 11-18 parts of radix scrophulariae, 2-5 parts of rhizoma rehmanniae, 13-20 parts of herba patriniae, 3-10.5 parts of radix linderae and 7-15 parts of radix glycyrrhizae. The invention further provides a preparation method of the medicinal wine. The medicinal wine can effectively eliminate moss, and active pharmaceuticalingredients are scientifically combined, so that the medicinal wine is stable in efficacy, convenient for patients to smear, safe and free of side effect.

Owner:GUANGXI UNIV FOR NATITIES

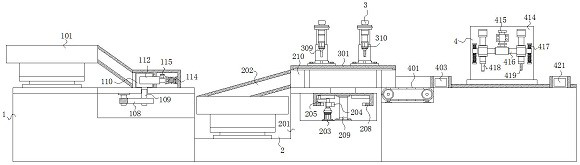

Special-shaped nut machining equipment capable of detecting internal and external threads

PendingCN113547054ARealize automatic pushingEasy to rubThread cutting feeding devicesThread cutting machinesSlide plateRolling sliding

The invention disclose special-shaped nut machining equipment capable of detecting internal and external threads. The equipment comprises a thread rolling mechanism, a feeding mechanism, a tapping mechanism and a detection mechanism, the feeding mechanism is installed on the right side of the thread rolling mechanism, the tapping mechanism is fixed to the upper portion of the feeding mechanism, the detection mechanism is installed on the right side of the tapping mechanism, a conveying belt is fixed to the upper left end of the detection mechanism, a first material pushing air cylinder is arranged behind the right end of the conveying belt, and a first material pushing plate is fixed to the front end of the first material pushing air cylinder. The special-shaped nut machining equipment capable of detecting the internal and external threads is compared with existing common special-shaped nut machining equipment, a material pushing rotating plate and a thread rolling limiting plate are arranged, through the arrangement of the material pushing rotating plate, when a thread rolling sliding plate is retracted, a material pushing rotating plate can rotate around a center through a sliding plate push rod, therefore a material pushing plate limiting rod is driven through a groove in the upper end to enable a thread rolling material pushing plate to move, and automatic material pushing operation on parts is achieved.

Owner:成都市惠迈锐智能装备科技有限公司

a sliding door

The invention discloses a sliding door. The sliding door comprises a door body, and a limiting piece for limiting the door body to inwards rotate, wherein one outward surface of the door body is a door outer side surface, and one inward surface of the door body is a door inner side surface. The sliding door further comprises a first convex block, a first rotating piece and a handheld rod, wherein the tail of the first convex part is arranged on the door outer side surface, and the head of the first convex block is outwards projected; and the head end of the first rotating piece is rotationally connected to the lower side of the head of the first convex block. Thus, the first rotating piece can horizontally rotate; the handheld rod is vertically arranged; and the upper end of the handheld rod is connected to the tail end of the first rotating piece. The sliding door has the advantage of capability of reasonably converting a door pushing action to a door pulling action.

Owner:广州市禹恒五金制品有限公司

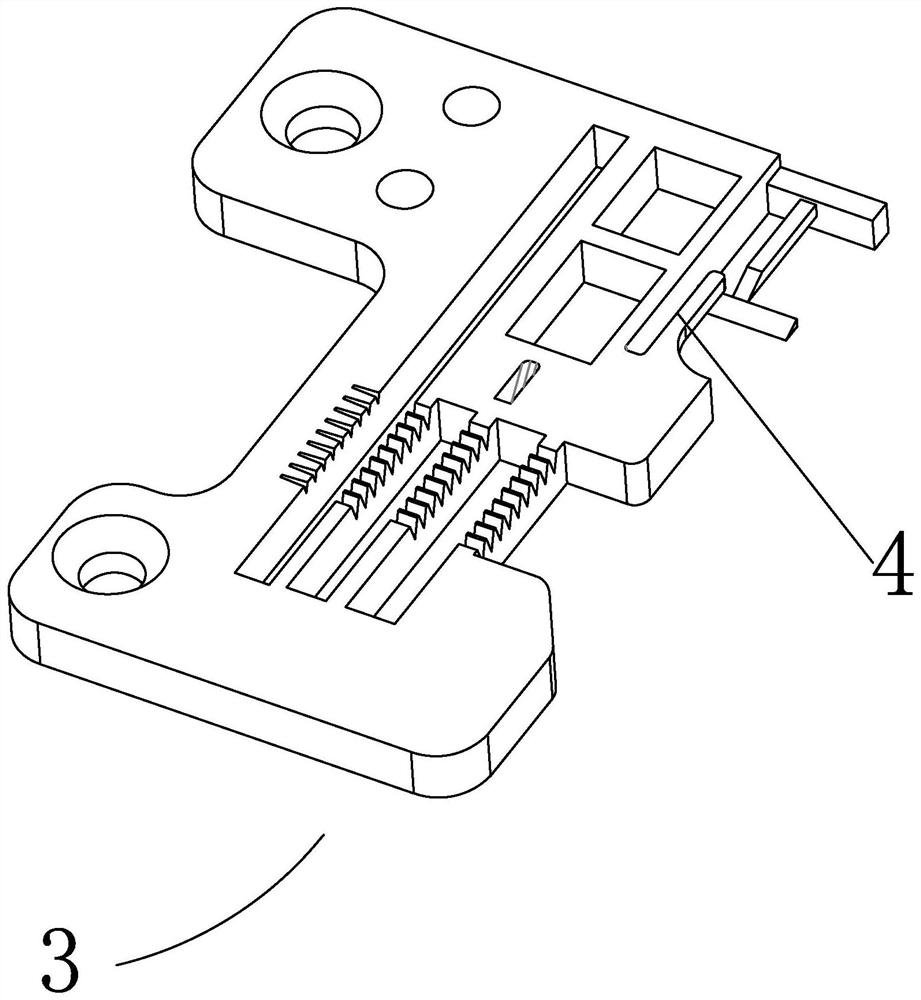

Clothing fabric three-line serging and splicing process

PendingCN112493598ASmooth structureNot easy to rub the skinSewing apparatusClothes making applicancesStructural engineeringMechanical engineering

The invention relates to the field of clothing, in particular to a clothing fabric three-line serging and splicing process, which comprises the following steps of flatly paving and overlapping two pieces of clothing fabric to be spliced in a manner that the front surfaces of the two pieces of clothing fabric are tightly attached to the front surface, and sewing along an aligned edge to form a lockrand. And meanwhile, adjusting a needle plate tongue and a thread tensioner of the serger. According to the three-line serging and splicing process for the garment materials, the overlock at the overlapping position of the two garment materials is smooth, and the overlapping position and the two garment materials are close to the same plane. The garment fabric is firm in splicing position, not prone to thread disengaging, smooth in structure and not prone to rubbing the skin, the decoration effect on the whole garment can be achieved, and the garment value is improved.

Owner:ELEGANT PROSPER ZHEJIANG GARMENT

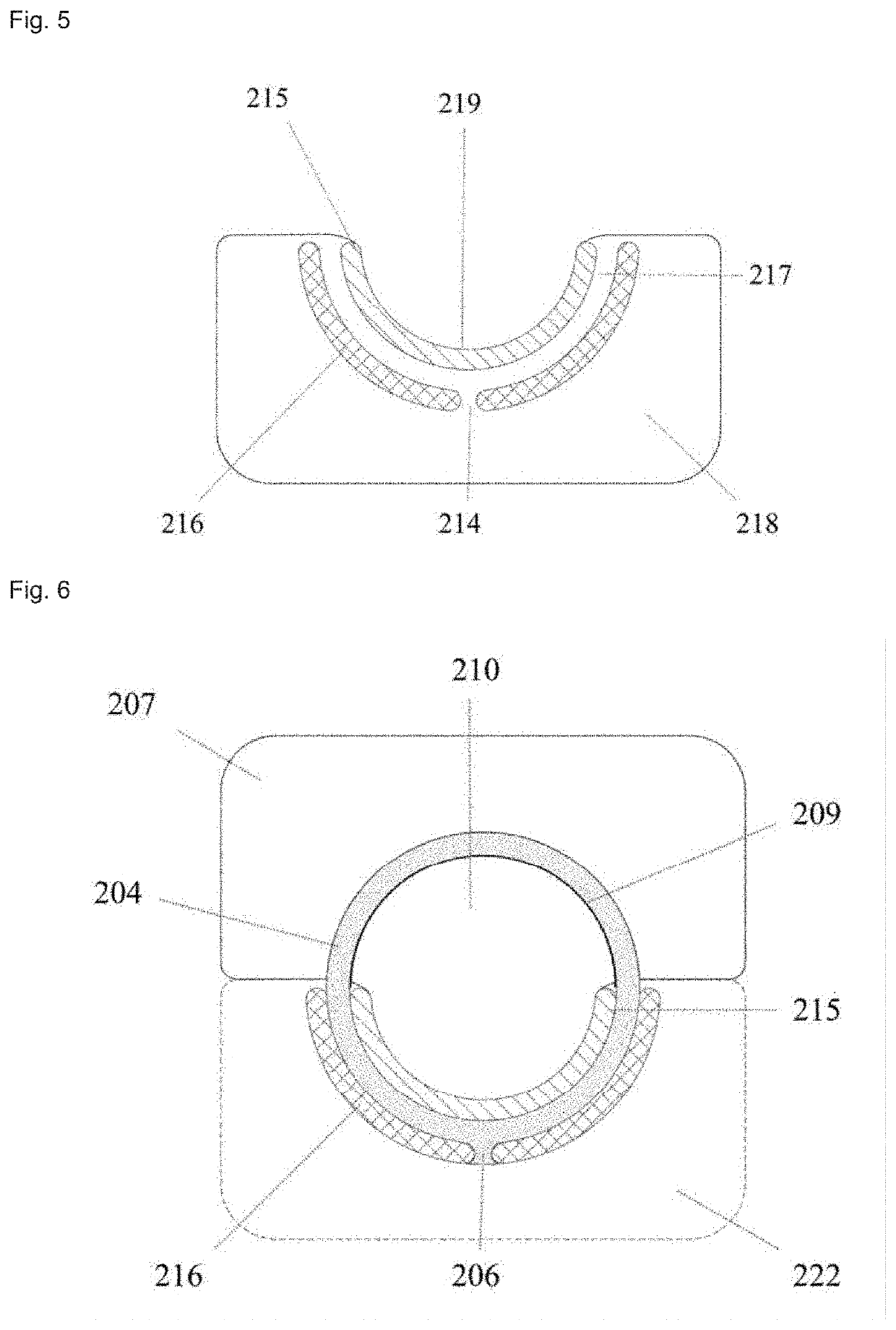

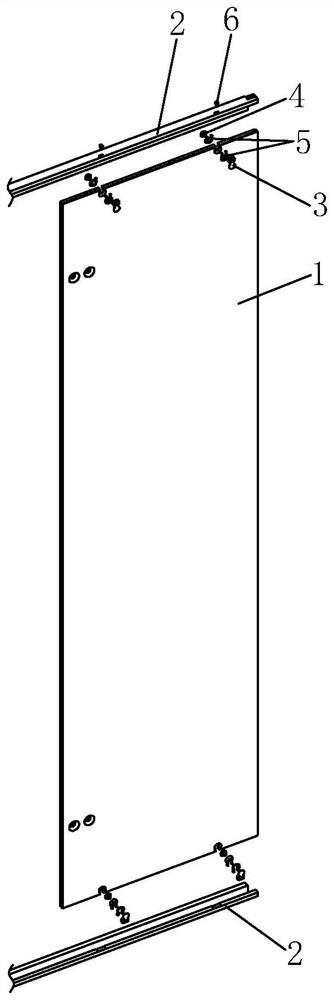

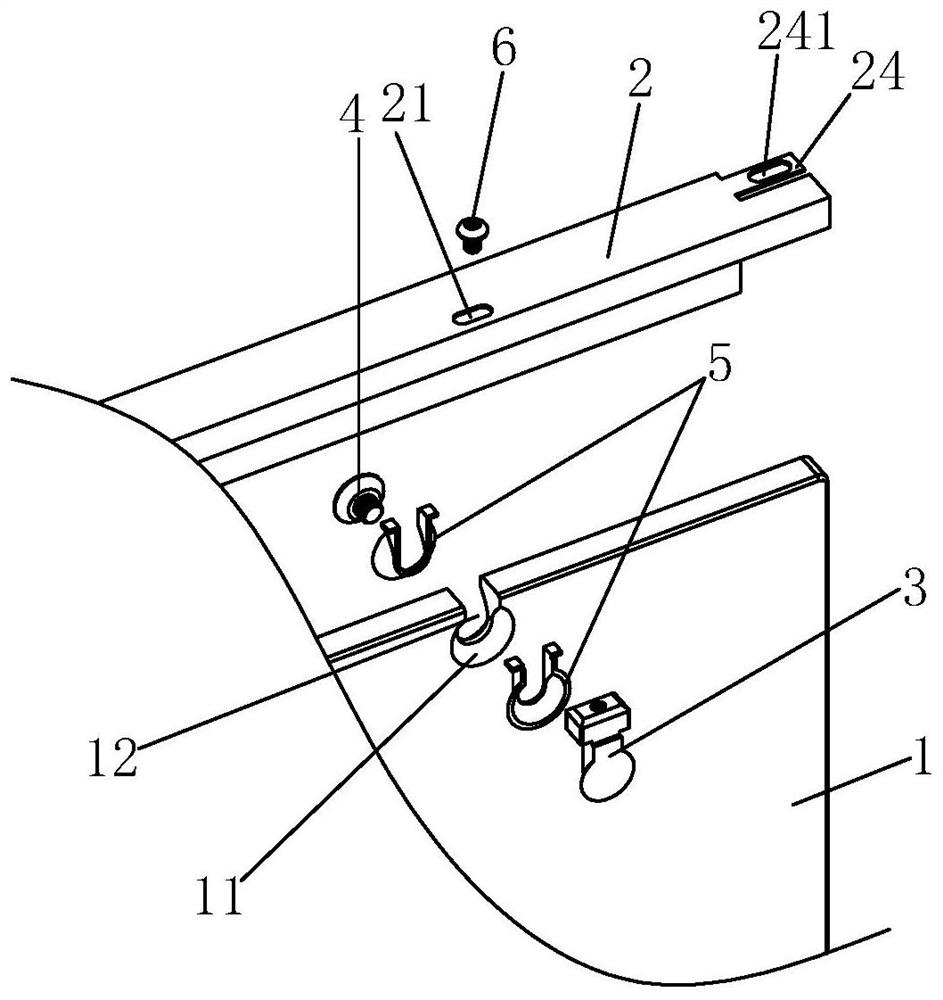

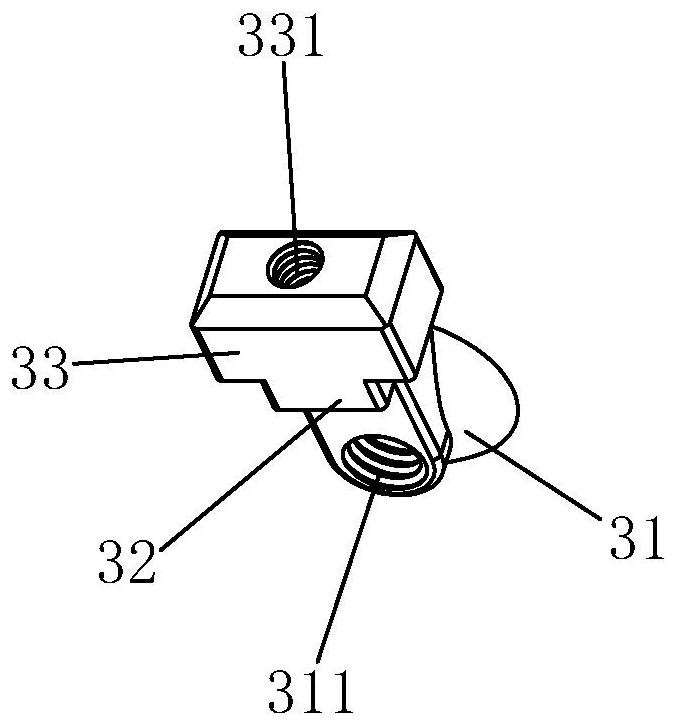

Glass plate connecting structure and shower room applying the connecting structure

ActiveCN113175128AThe fastening process is convenient and fastEasy to fixWallsSpecial buildingEngineeringMechanical engineering

The invention discloses a glass plate connecting structure and a shower room applying the connecting structure. The connecting structure comprises a glass plate, a glass fixing sectional material and at least one connecting piece, and the glass plate is provided with a first side face and a second side face which are back to back in the thickness direction of the glass plate; the connecting piece is provided with a first fixing part and a connecting part; the edge part of the glass plate is provided with at least one mounting part, the mounting part comprises a first sinking groove and a through-out groove which are positioned on the first side face of the glass plate, one end of the through-out groove communicates with the first sinking groove, and the other end of the through-out groove extends out from the edge of the glass plate; and the first fixing part of the connecting piece is fixed to the first sinking groove, and the connecting part is contained in the through-out groove and connected with the glass fixing sectional material. According to the connecting structure, the first fixing part and the connecting part of the connecting piece are easily flush with the first side face of the glass plate, so that the problem that the portion, matched with the connecting piece, of the first side face of the glass plate is uneven and is difficult to clean is solved.

Owner:JOMOO KITCHEN & BATHROOM

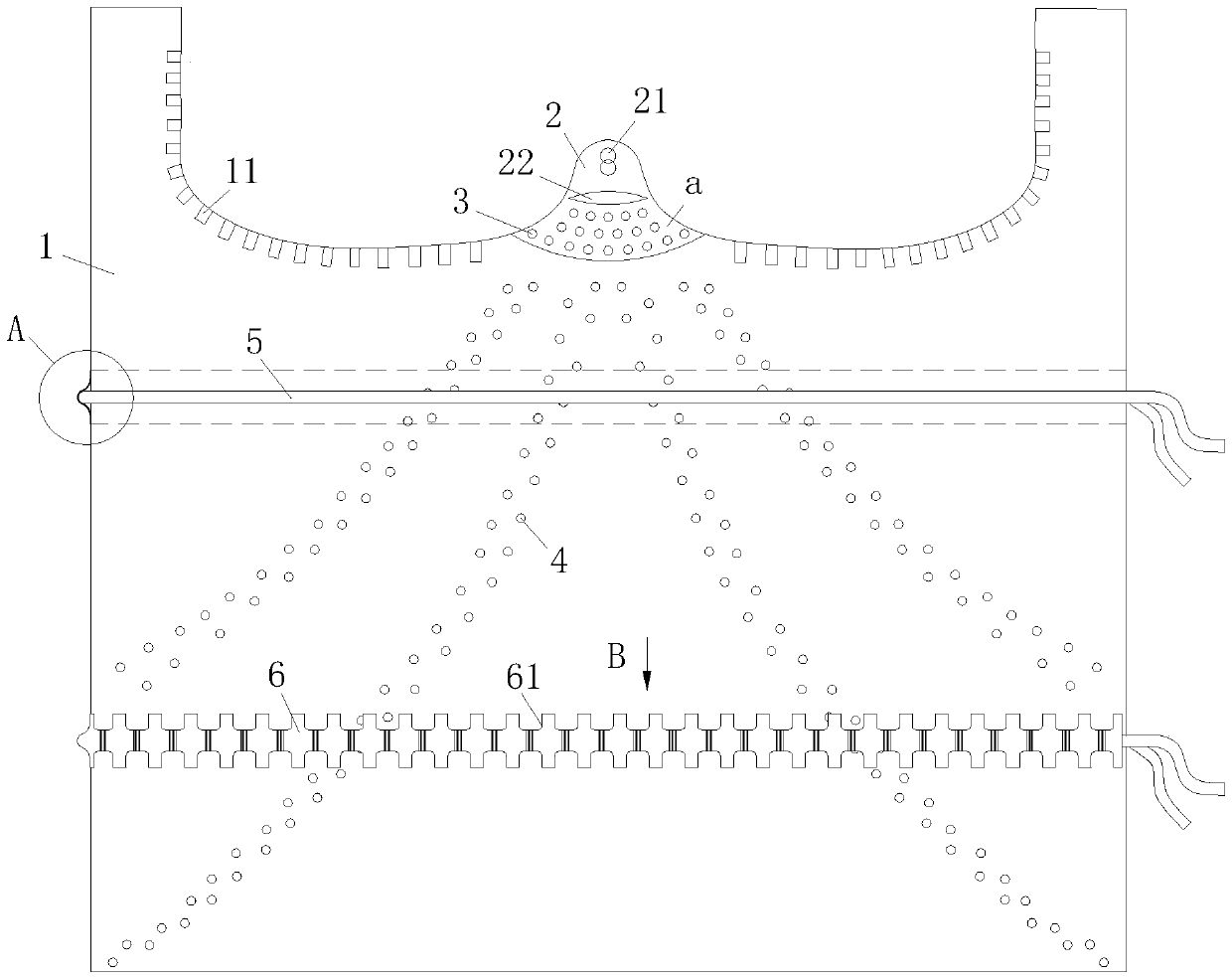

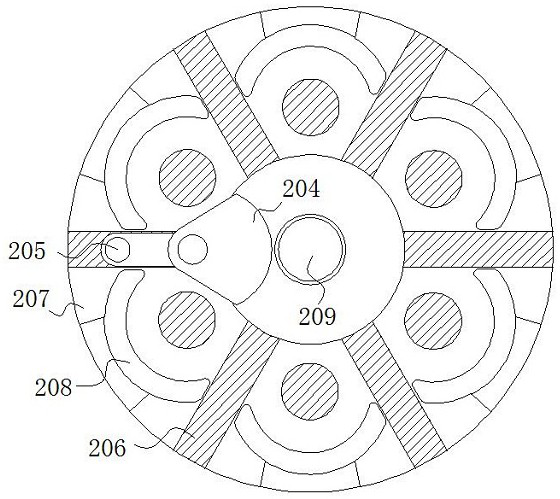

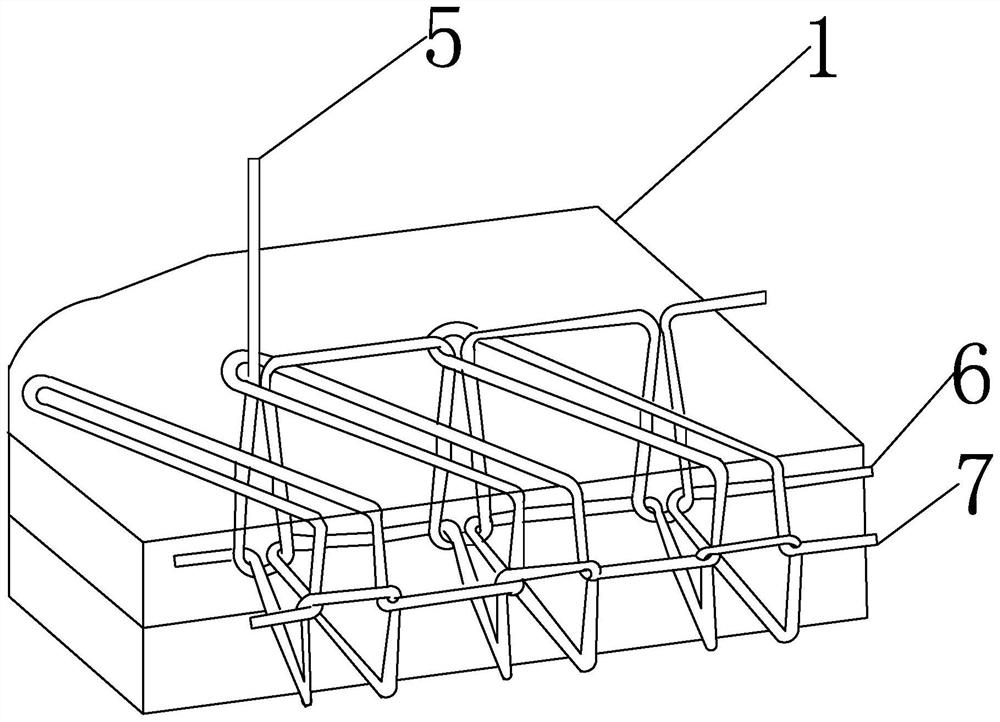

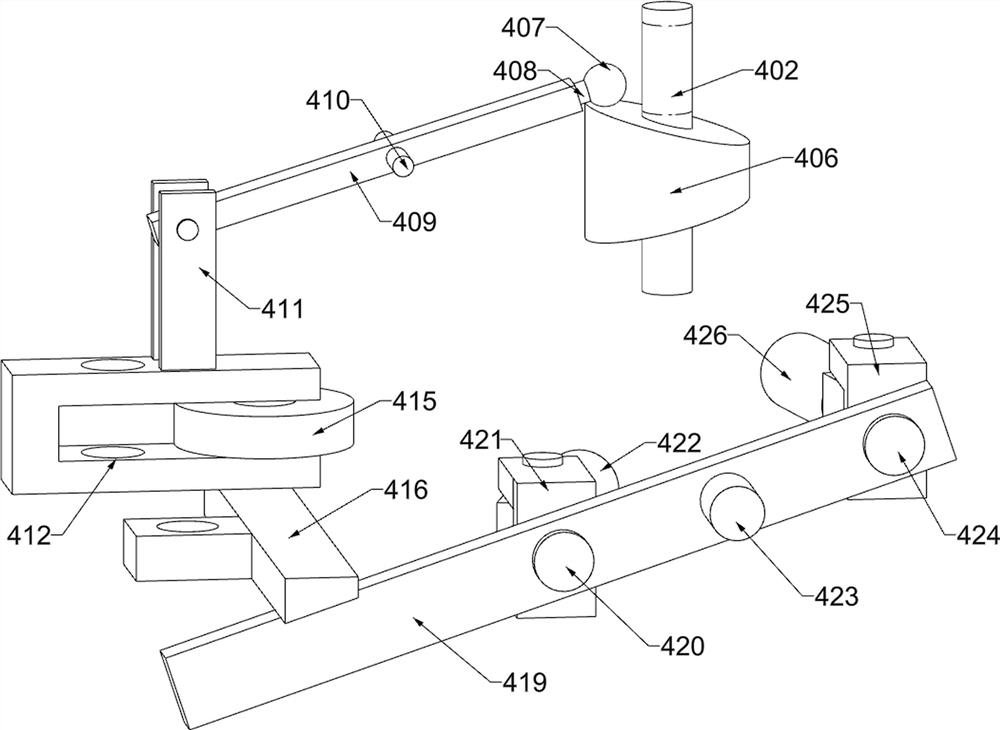

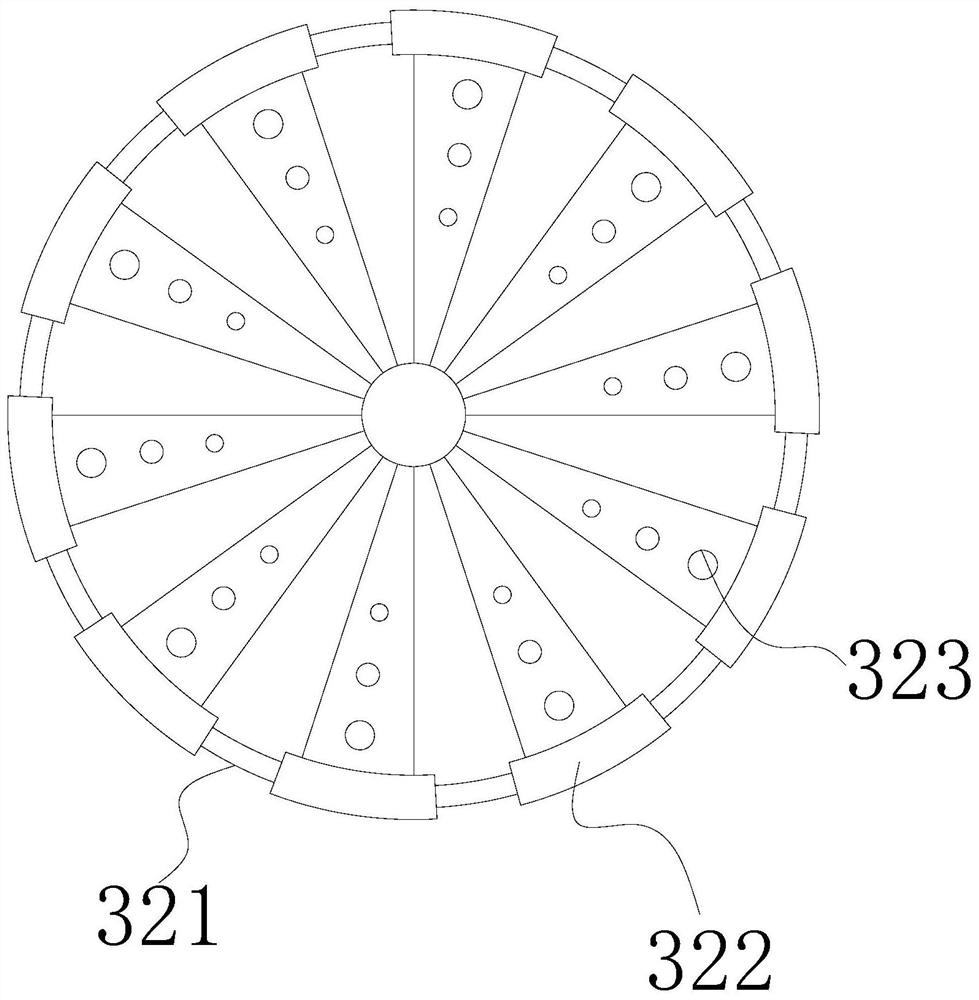

Cotton kneading machine for textile processing

ActiveCN113638175BImprove kneading efficiencyReduce energy consumptionFabric breaking/softeningNon-woven fabricsElectric machineryDrive motor

The invention relates to a high-efficiency kneading machine for textile processing, comprising a frame, a first upper kneading plate, a second upper kneading plate and a bearing plate, a cylinder is fixedly installed in the center of the top of the frame, and the output shaft of the cylinder is movably interspersed The top of the frame is fixedly connected with the lifting plate, and two sliding bars are interspersed horizontally on the lifting plate, both ends of the sliding bars are fixedly connected to the side fixing rods, and both ends of the first upper kneading plate are fixedly connected There is an upper horizontal plate, two upper support plates are fixedly connected to the side of the upper horizontal plate deviated from the first upper kneading plate, the bottom end of the side fixing rod is fixedly connected to the top of the first upper kneading plate, and the lifting plate The drive motor 2 is fixedly installed on the bottom of one end, the two ends of the second upper kneading plate are fixedly connected with the lower horizontal plate, and the two ends of the lower horizontal plate deviated from the second upper kneading plate are fixedly connected with a lower horizontal plate. As for the supporting board, the ends on both sides of the bearing board are fixedly connected with fixing rods.

Owner:JIANGSU DADAO MACHINE GROUP

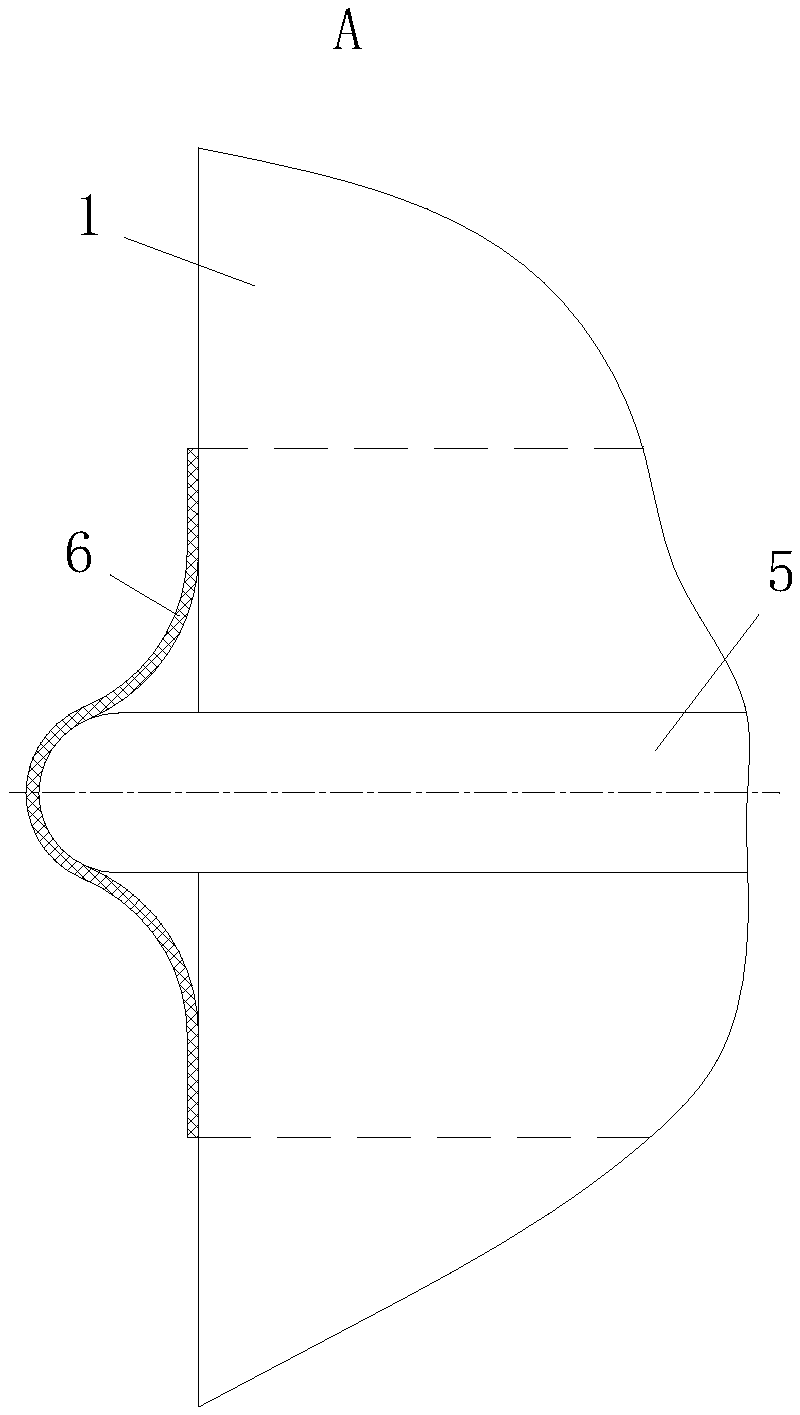

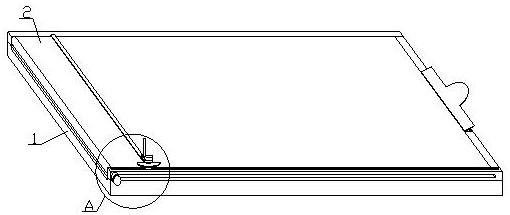

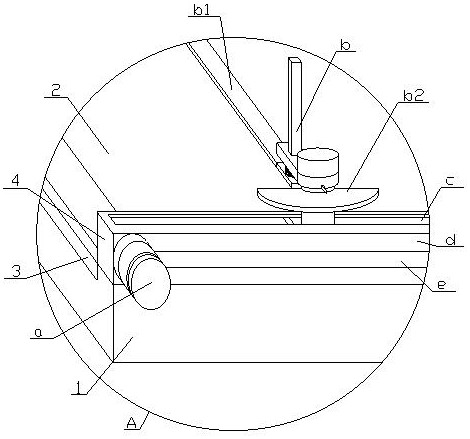

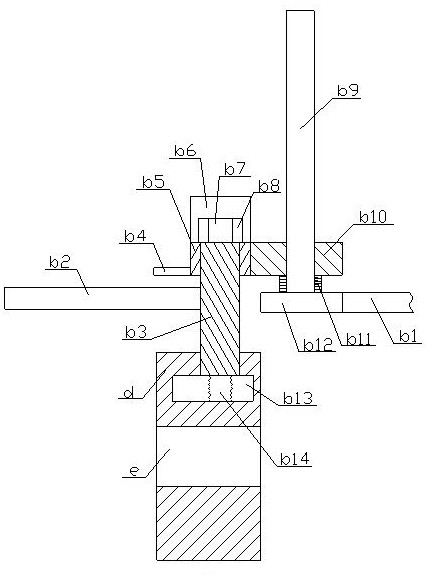

Kaplan turbine blade machining equipment based on ship

InactiveCN113601301AHigh dimensional accuracySmall weight errorEdge grinding machinesGrinding carriagesWater turbineStructural engineering

The invention relates to the field of ships, in particular to Kaplan turbine blade machining equipment based on a ship. The technical problem to be solved by the invention is to provide the Kaplan turbine blade machining equipment based on the ship. According to the technical scheme, the Kaplan turbine blade machining equipment based on the ship comprises a bottom plate assembly, a cleaning unit, a polishing unit and the like; the bottom plate assembly is fixedly connected with the cleaning unit; and the bottom plate assembly is fixedly connected with the polishing unit. After a blade is conveyed to a designated position, impurities left on the upper face and the lower face of the blade are removed, then a center supporting column of the blade is polished, then the outer contour of the blade is polished, burrs and deckle edges in the blade are removed, meanwhile, the two sides of the blade are polished by adapting to the height of the blade, the size precision of the blades is improved, the weight error of each blade is reduced, and meanwhile the unbalanced weight of a balance test is reduced.

Owner:李红

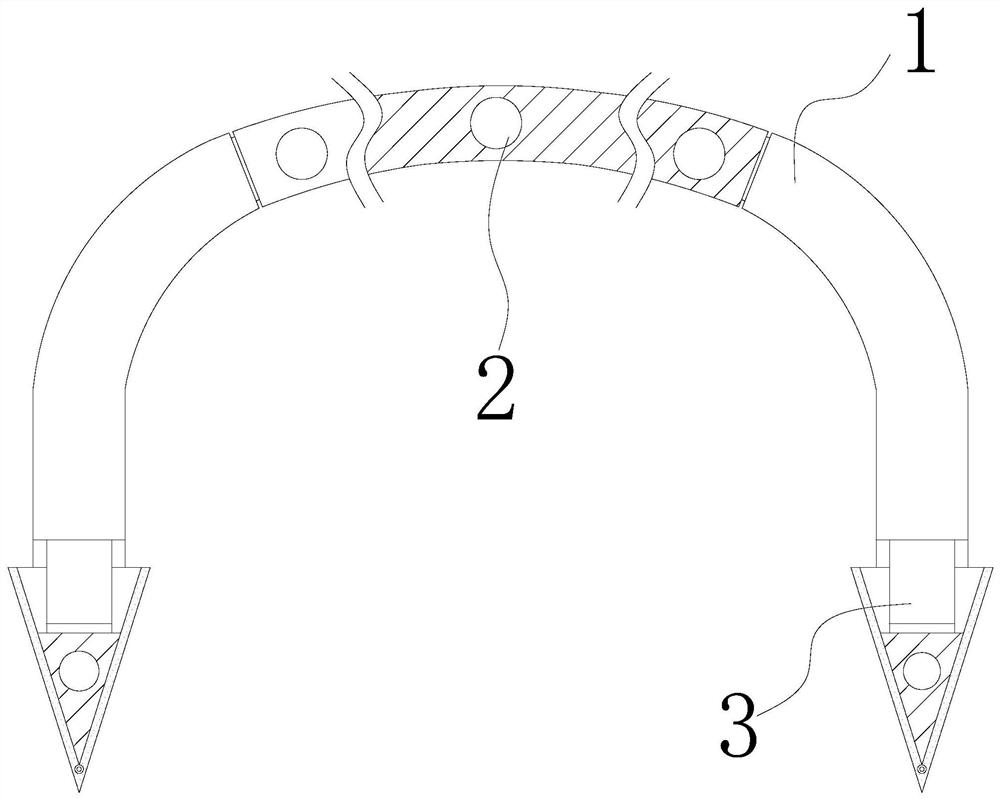

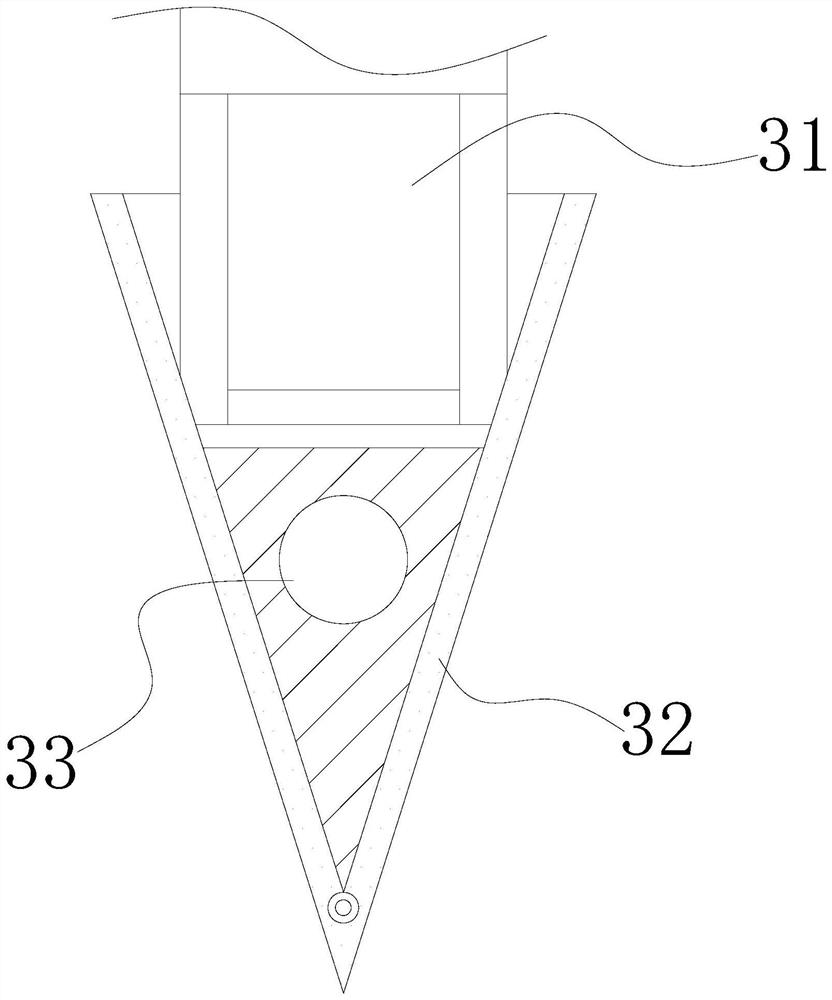

Solar vegetable greenhouse heat preservation equipment

InactiveCN113711813AIncrease resistanceEasy to rubClimate change adaptationRenewable energy machinesThermodynamicsSoil science

The invention discloses solar vegetable greenhouse heat preservation equipment. The equipment structurally comprises supporting structures, a splicing pipe and fixing structures, the supporting structures are fixedly embedded in the left side and the right side of the splicing pipe, the fixing structures are installed at the lower ends of the supporting structures, and after the fixing structures at the lower ends of the supporting structures enter soil, the soil is broken through drilling structures; meanwhile, the surfaces of inclined structures are fully attached to the soil, spring rods on the outer sides of fixing shafts are used for supporting the outer side, resistance to the soil is prevented from being increased, the friction effect on the soil is enhanced through plastic blocks, gaps caused by sliding of the plastic blocks and the soil are prevented, friction to the interior of the soil is enhanced, and the fixing structures are prevented from easily generating a gap during inclination so as not to loosen; meanwhile, the plastic film is attached to the outer sides of blocking structures, friction resistance of the plastic film is increased, a gap is prevented from being generated between the plastic film and the outer sides of the supporting structures, the plastic film is prevented from generating too large acting force on a force bearing point borne by wind power, and uneven stress of the wind power on the plastic film is avoided.

Owner:魏雪宇

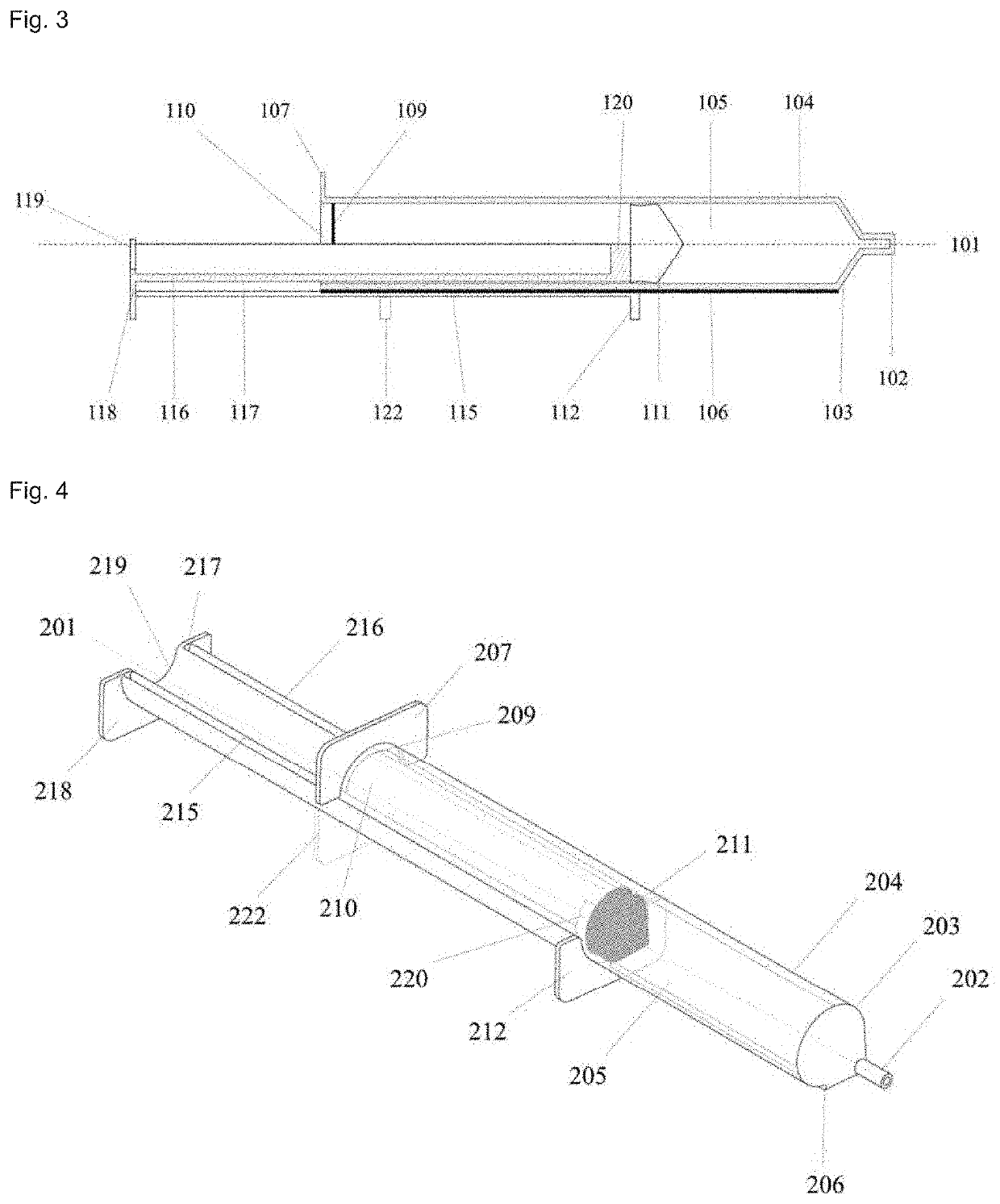

Syringe for one-handed injection and aspiration

ActiveUS11202865B2Easy to useEasy to rubInfusion syringesIntravenous devicesEngineeringCylinder block

A single-handed syringe may be used in injection and in aspiration for stable and consistent single-handed use. The syringe includes a hollow cylinder body, which has a front tip that the aspirated materials pass through toward / from a cylinder cavity. A rear plunger handle and a front plunger handle, in combination with a straight external prominence formed longitudinally along an outer surface of the cylinder body permits ease, accuracy, and precision of plunger movement during aspiration and injection functions.

Owner:ALSAHAB MEDICAL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com