Patents

Literature

261results about How to "Won't turn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

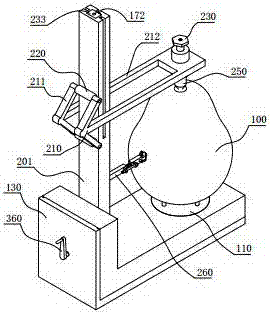

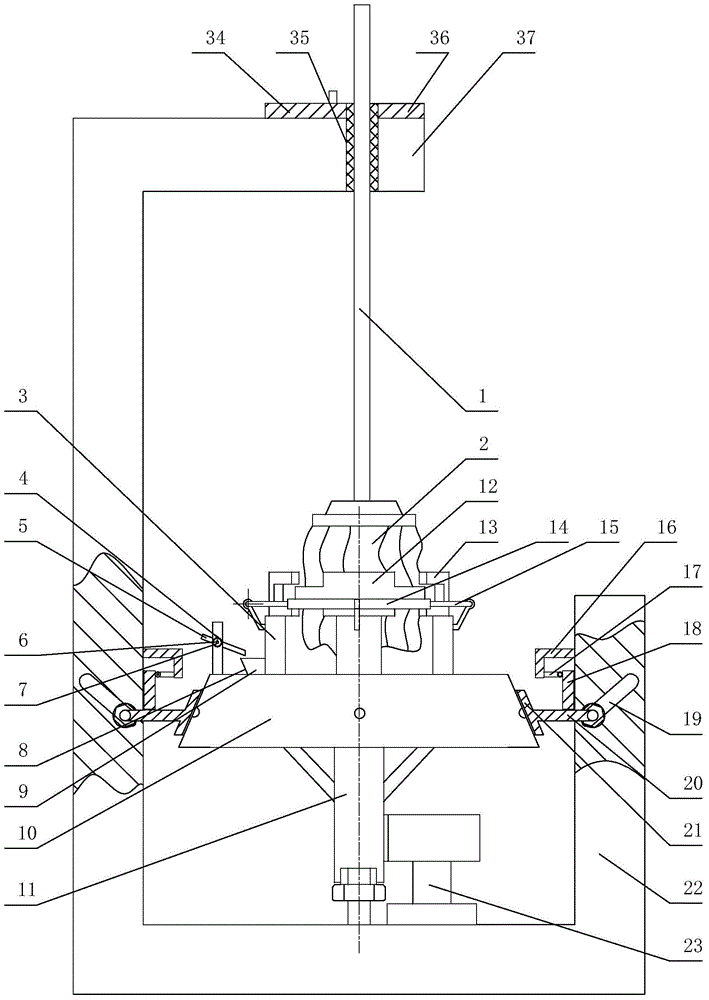

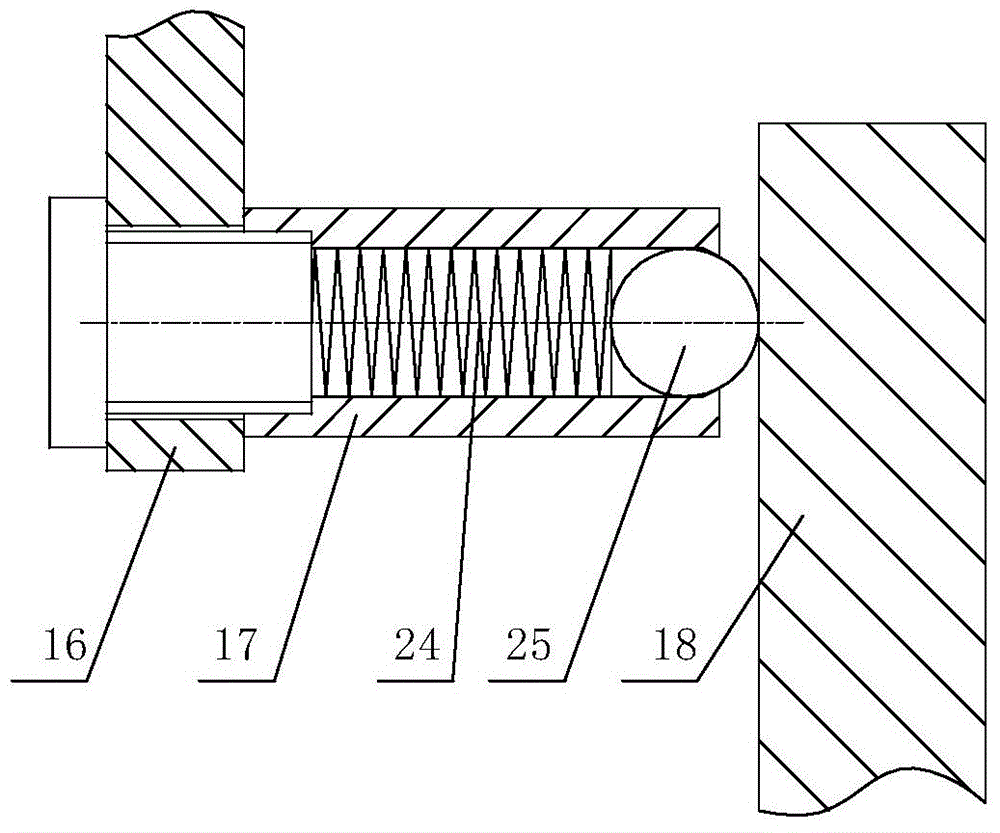

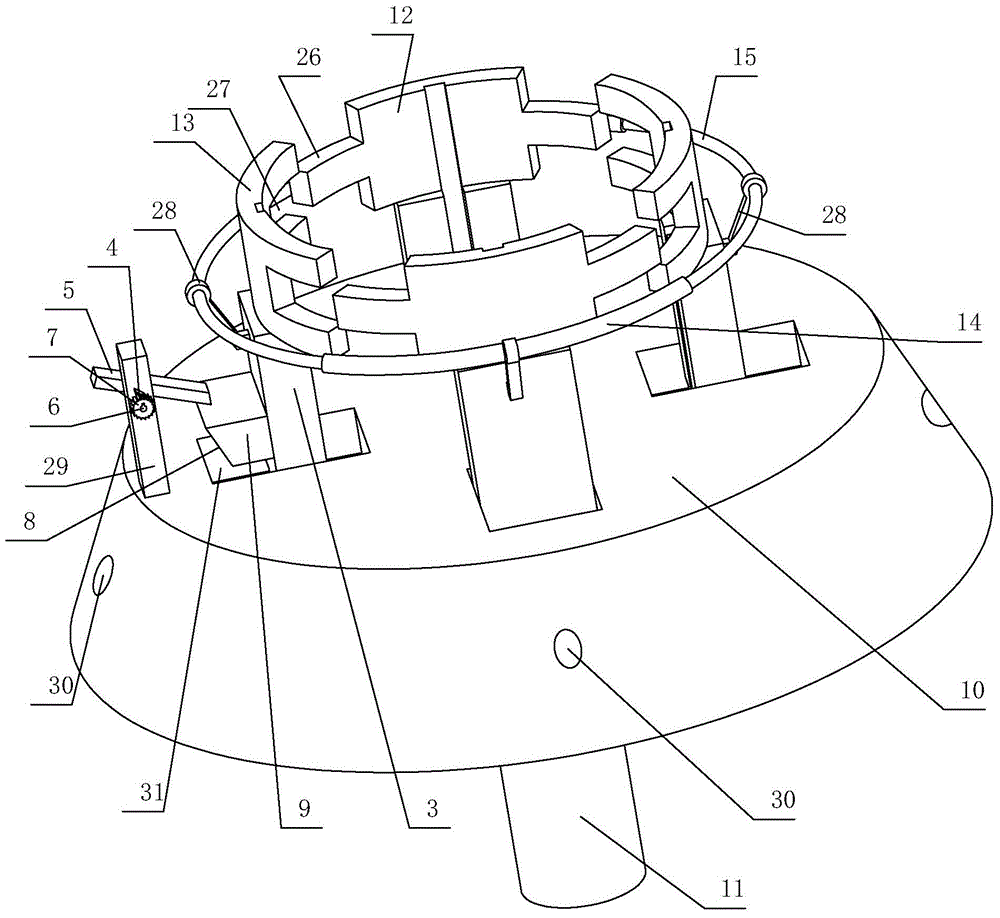

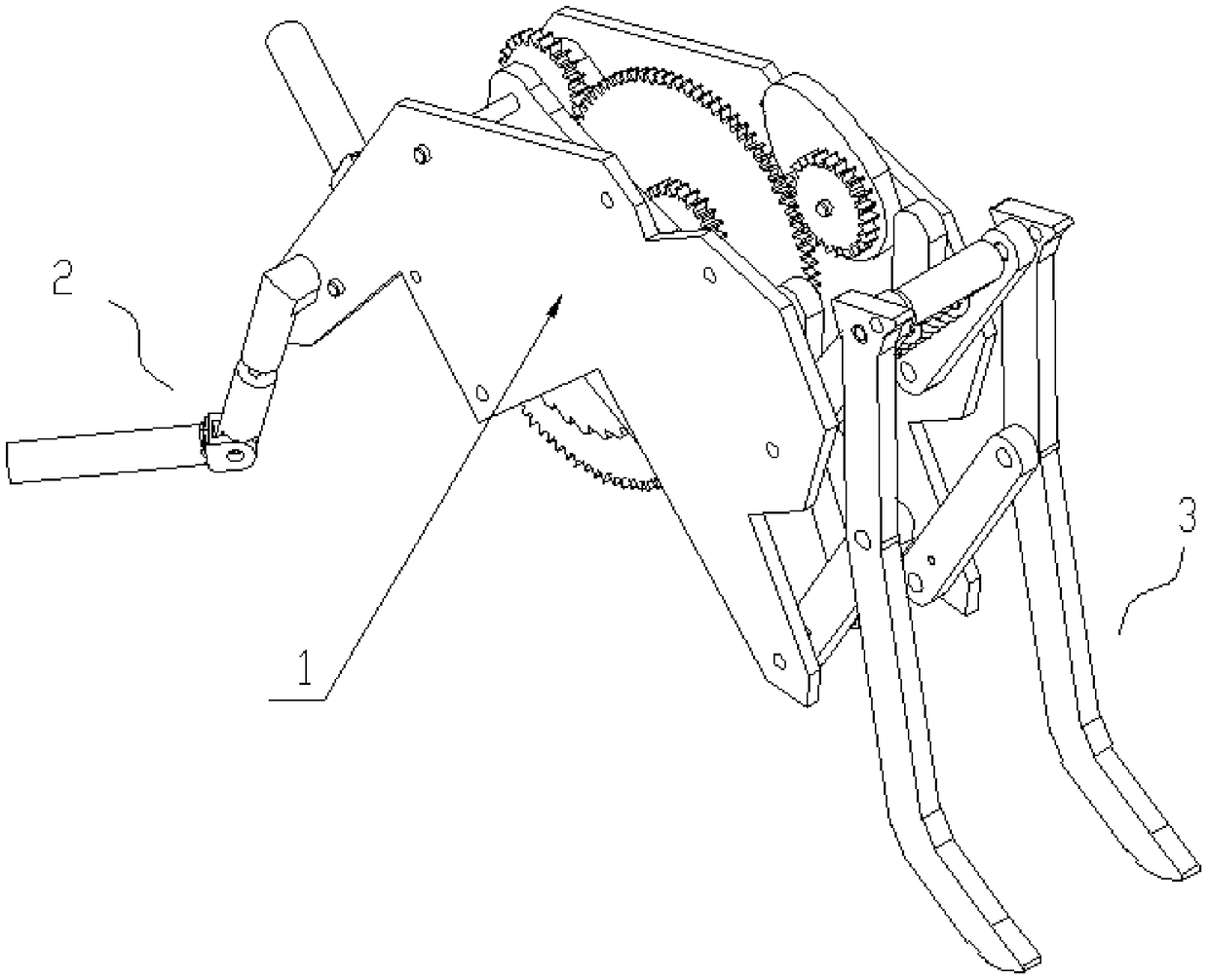

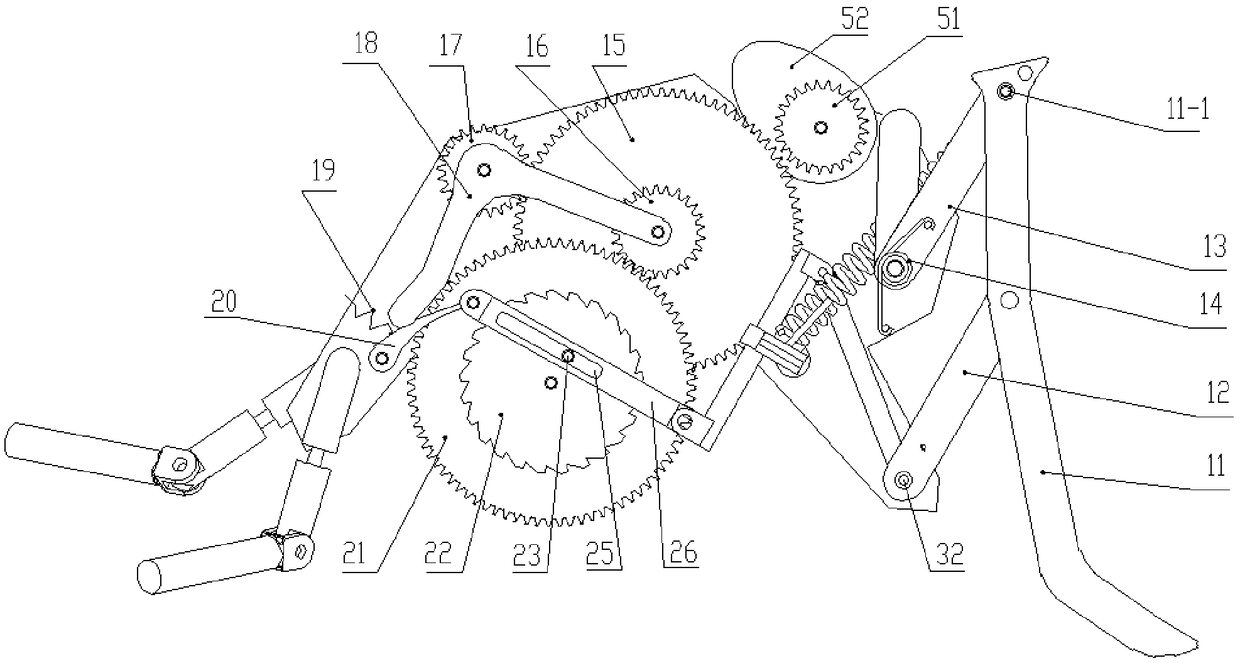

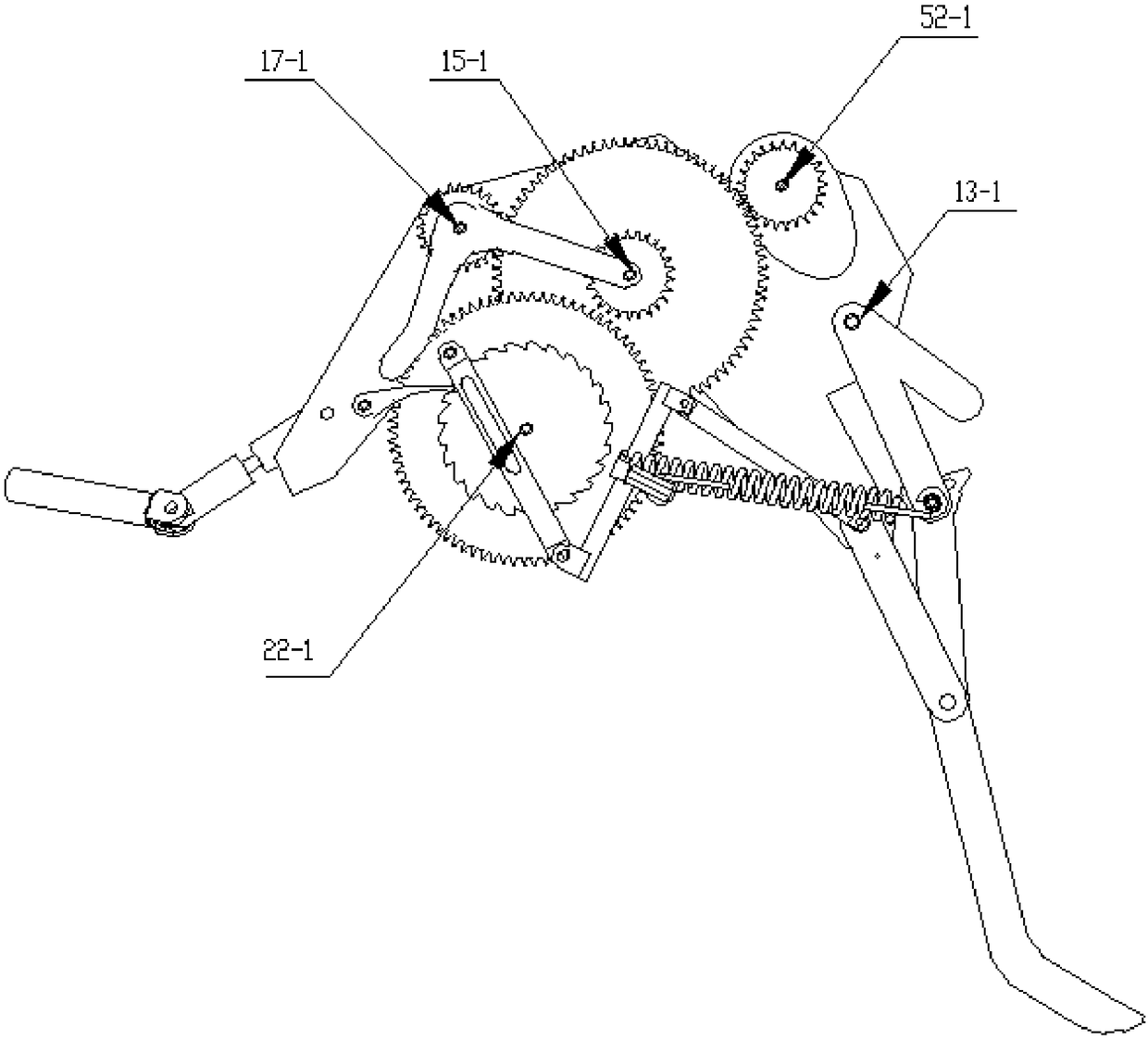

Axisymmetric melon-fruit peeling machine tool and assembling method thereof

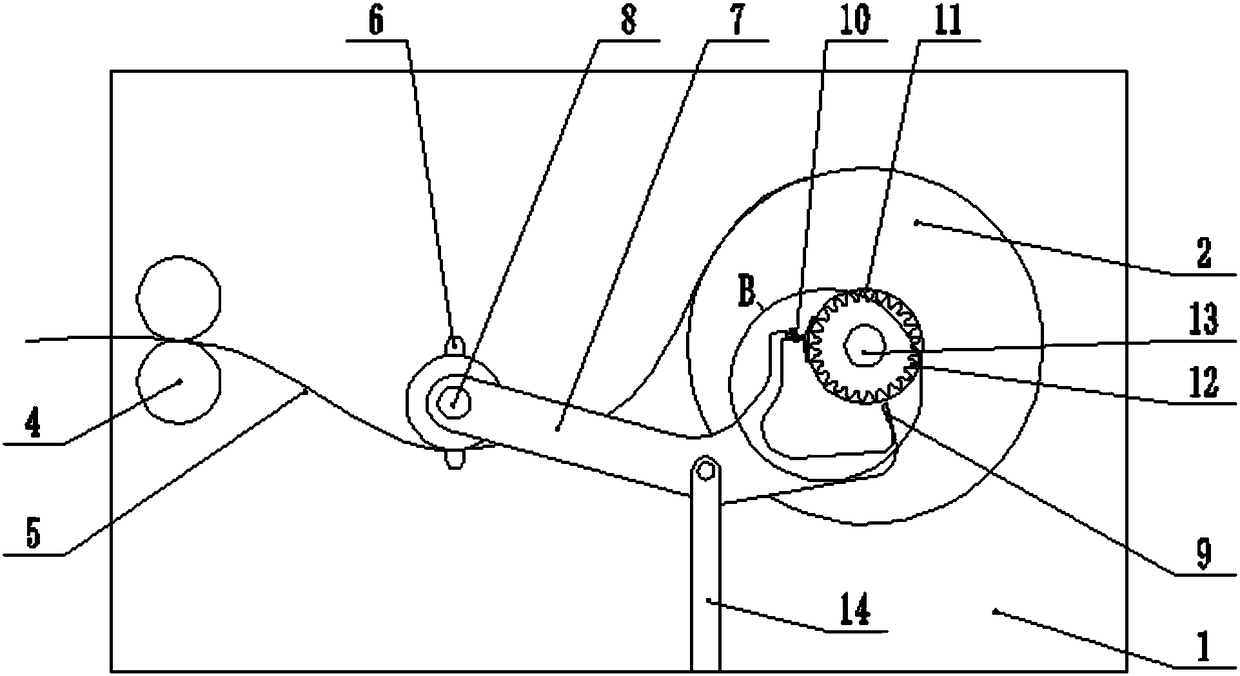

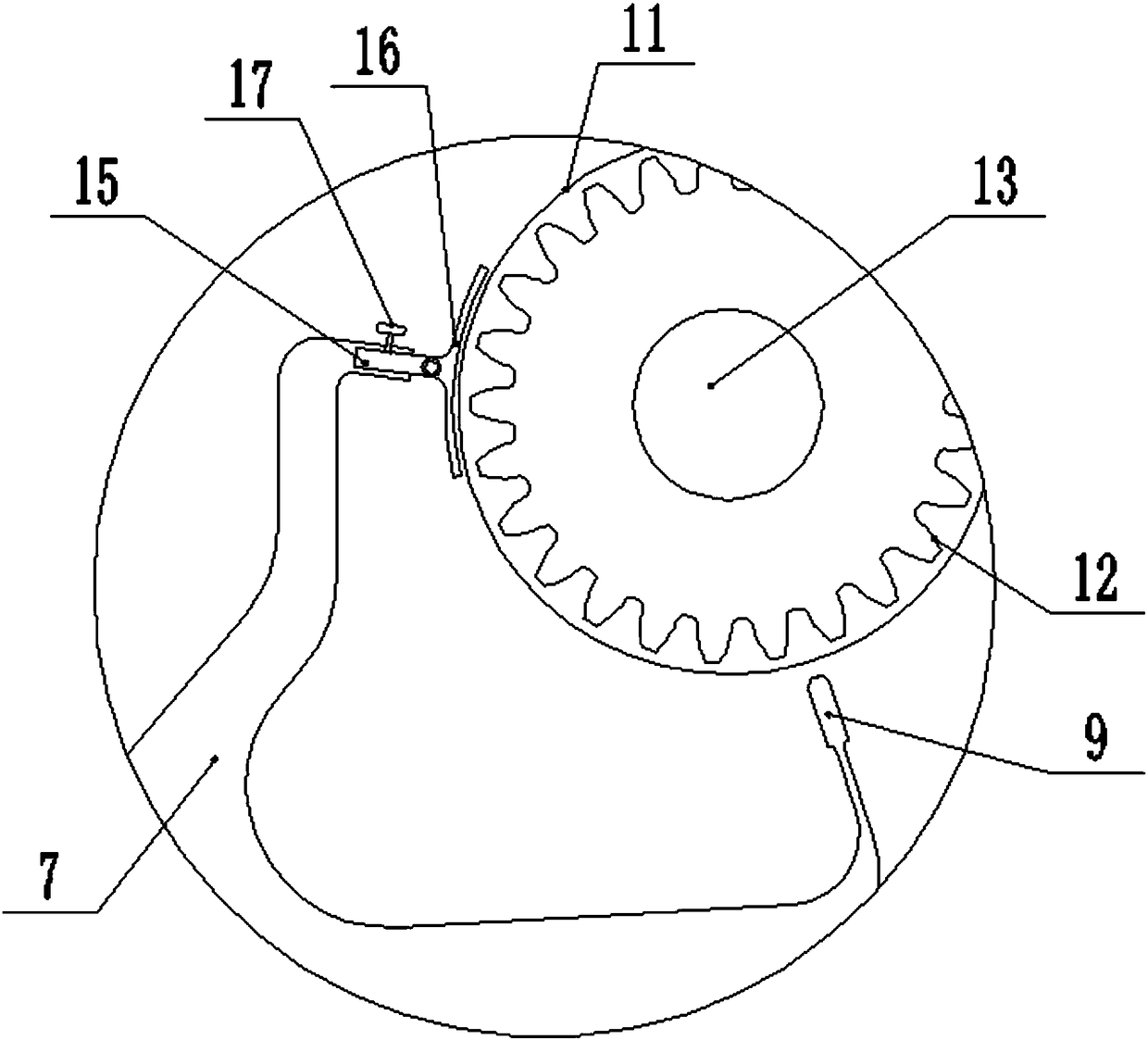

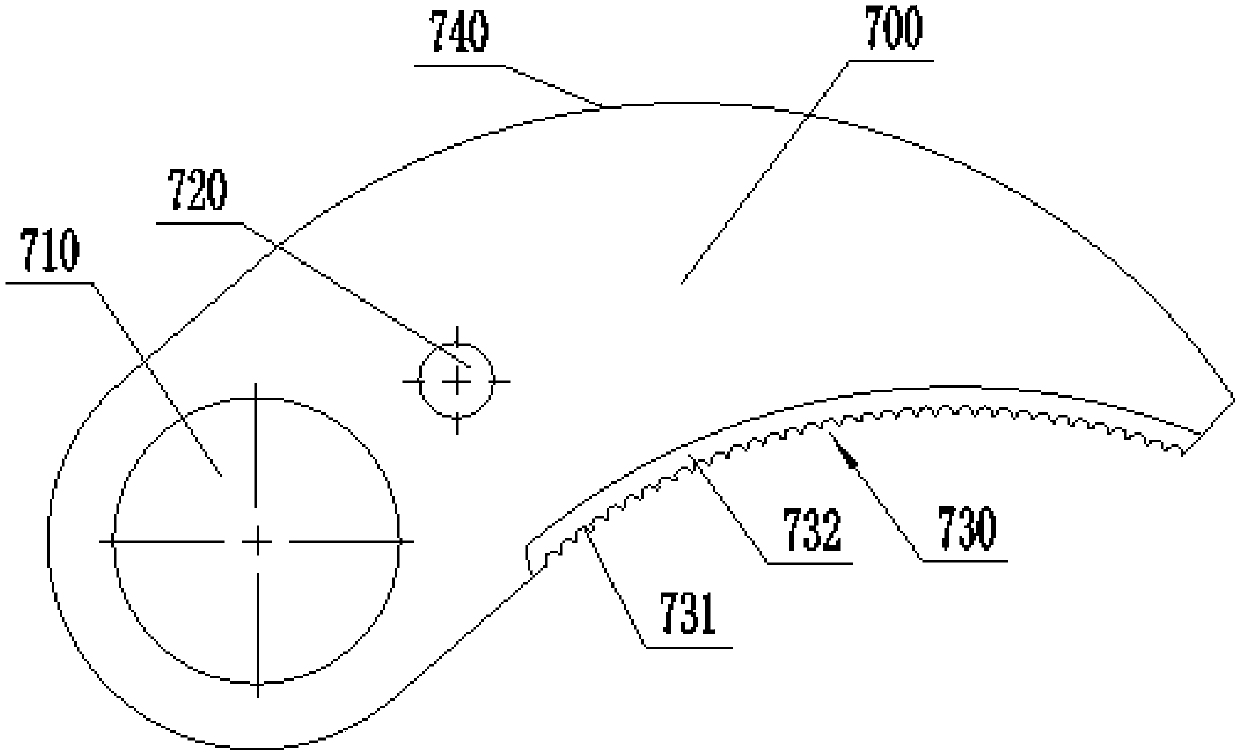

The present invention and a peel processing tool, in particular, relate to an axisymmetric melon and fruit peeling tool and its assembly method. The tool box is formed between the machine base shell and the machine cover shell, and a transmission mechanism is arranged in the machine tool box. As an improvement: on the machine cover shell The machine cover column is set, and the machine cover column is provided with the column inner groove and the column outer groove; the machine cover column can slide up and down to fix the knife cutting mechanism and the stabilizing device, and the knife cutting mechanism is also equipped with an adjustment device; the transmission mechanism will be simple The action of the hand crank is converted into the rotation of the axisymmetric melon and fruit and the up and down movement of the peeling blade, which realizes the whole process of peeling, which is convenient and labor-saving; the manual shaking method is used to achieve fast peeling, which is safe It is environmentally friendly, and can adjust the peeling speed in real time according to the needs; the combination of the knife holder guide rod, the guide sub-shaft and the compression spring enables the peeling blade to cling to the surface of the axisymmetric melon and fruit under the elastic force of the compression spring, adapting to different sizes and sizes. Shaped axisymmetric melon and fruit peeler.

Owner:晋江杰雄机电科技有限公司

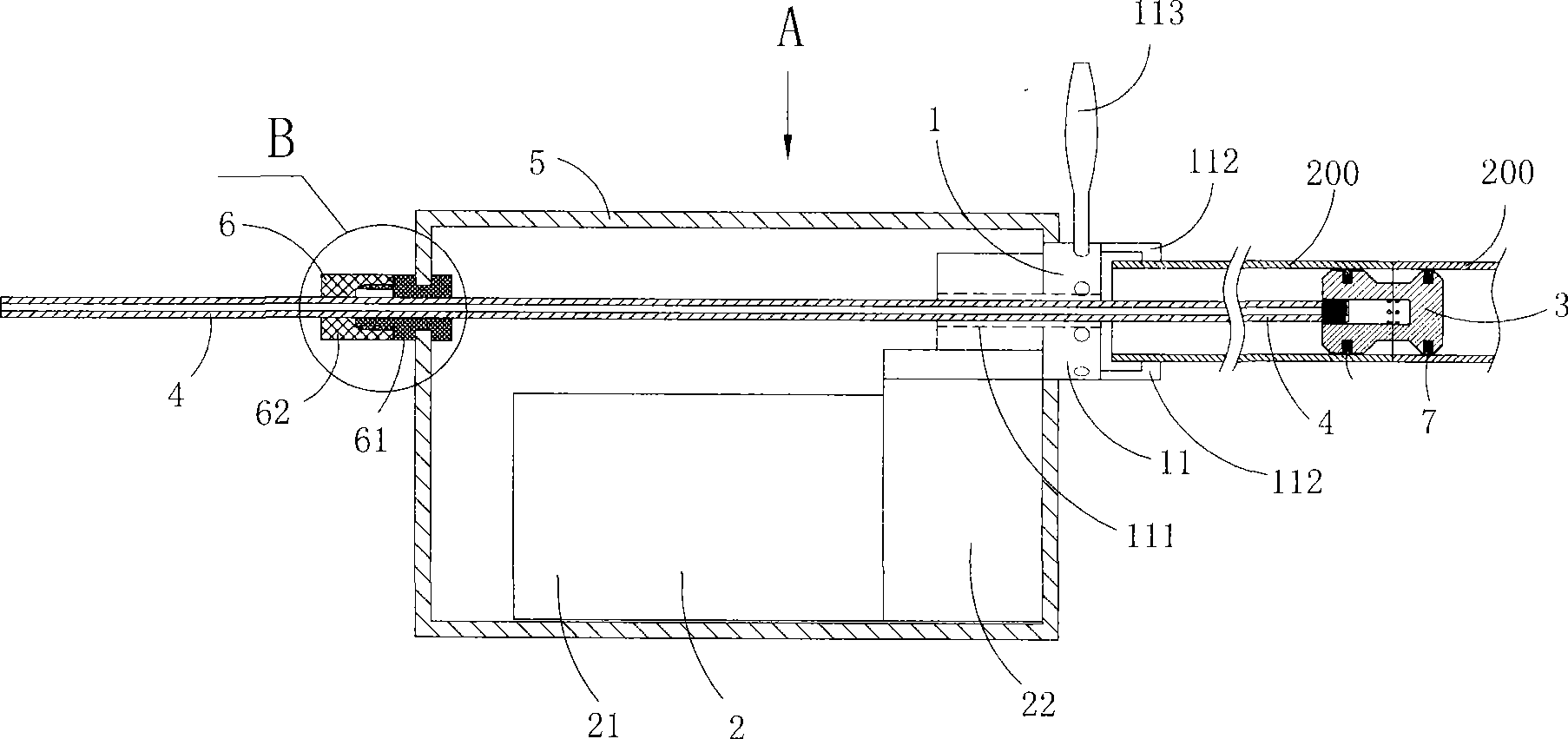

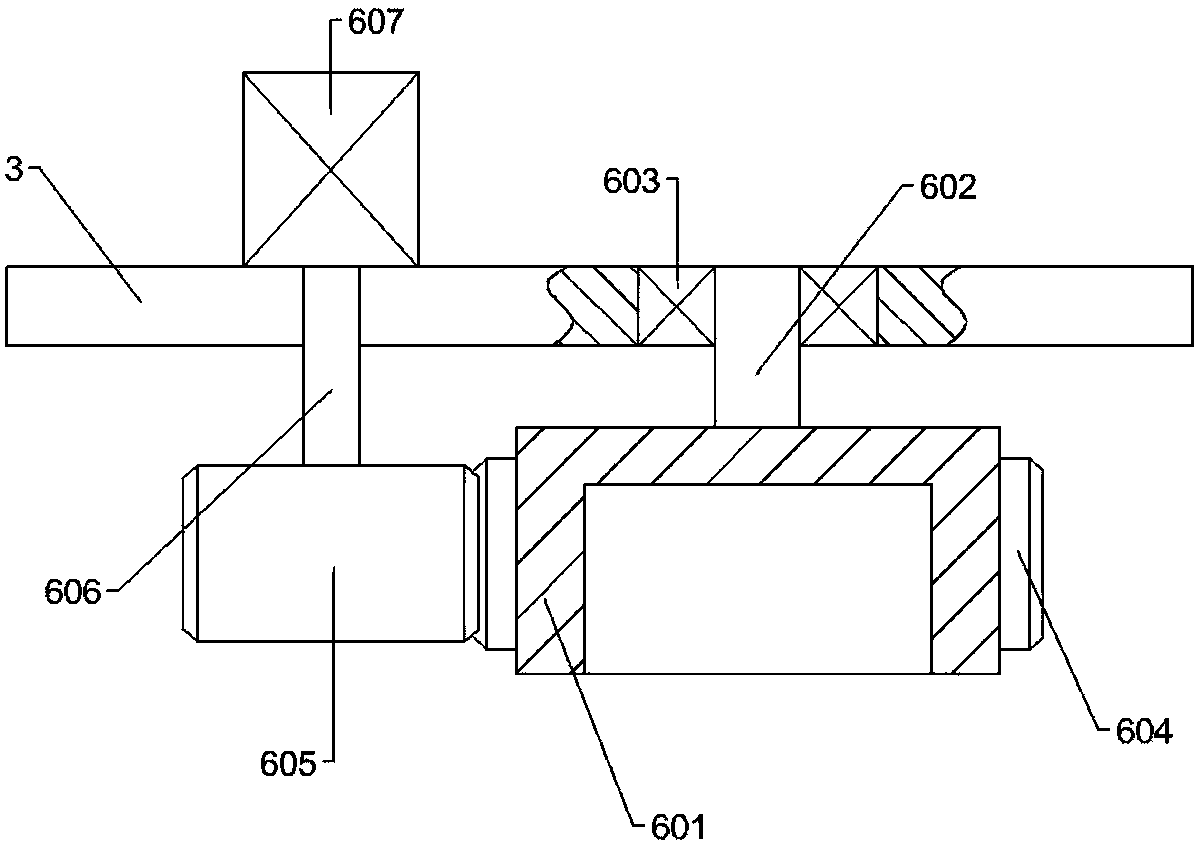

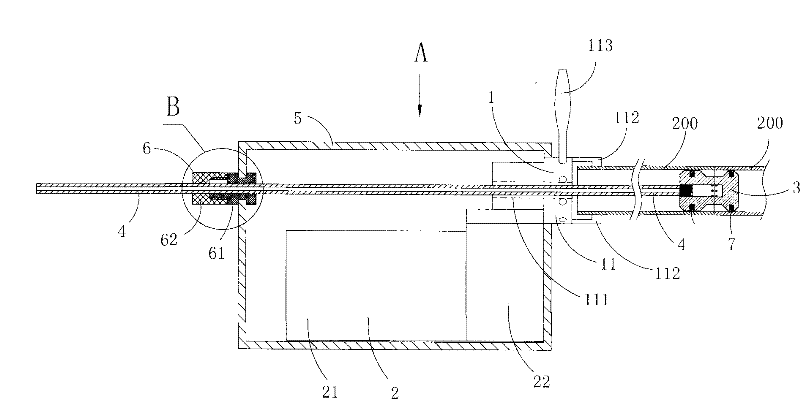

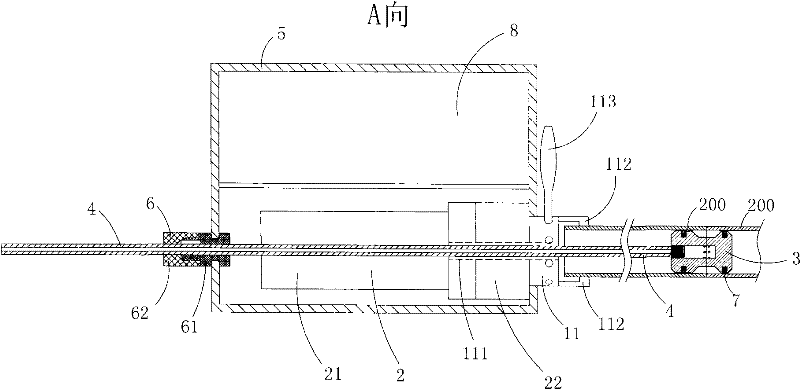

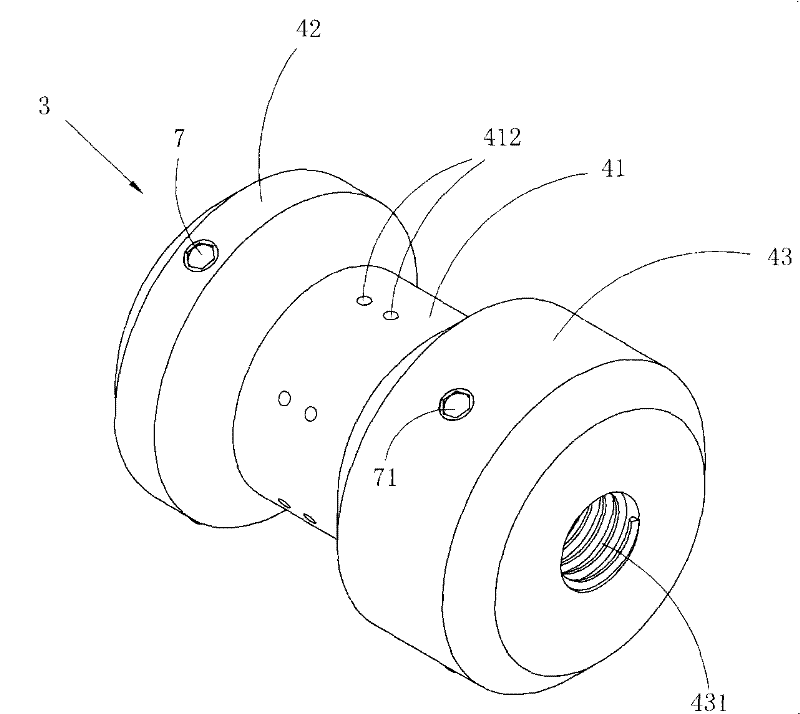

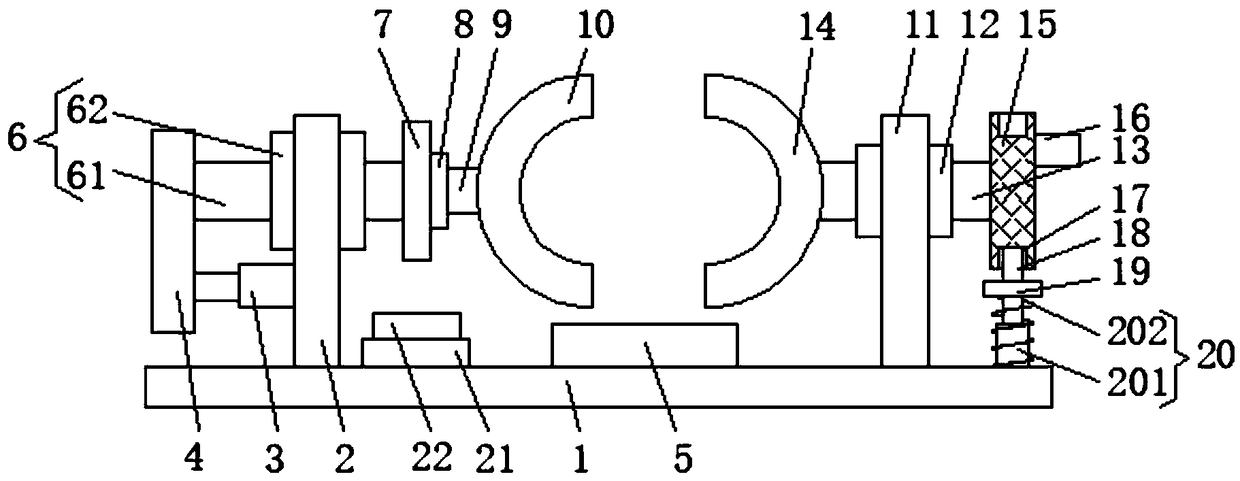

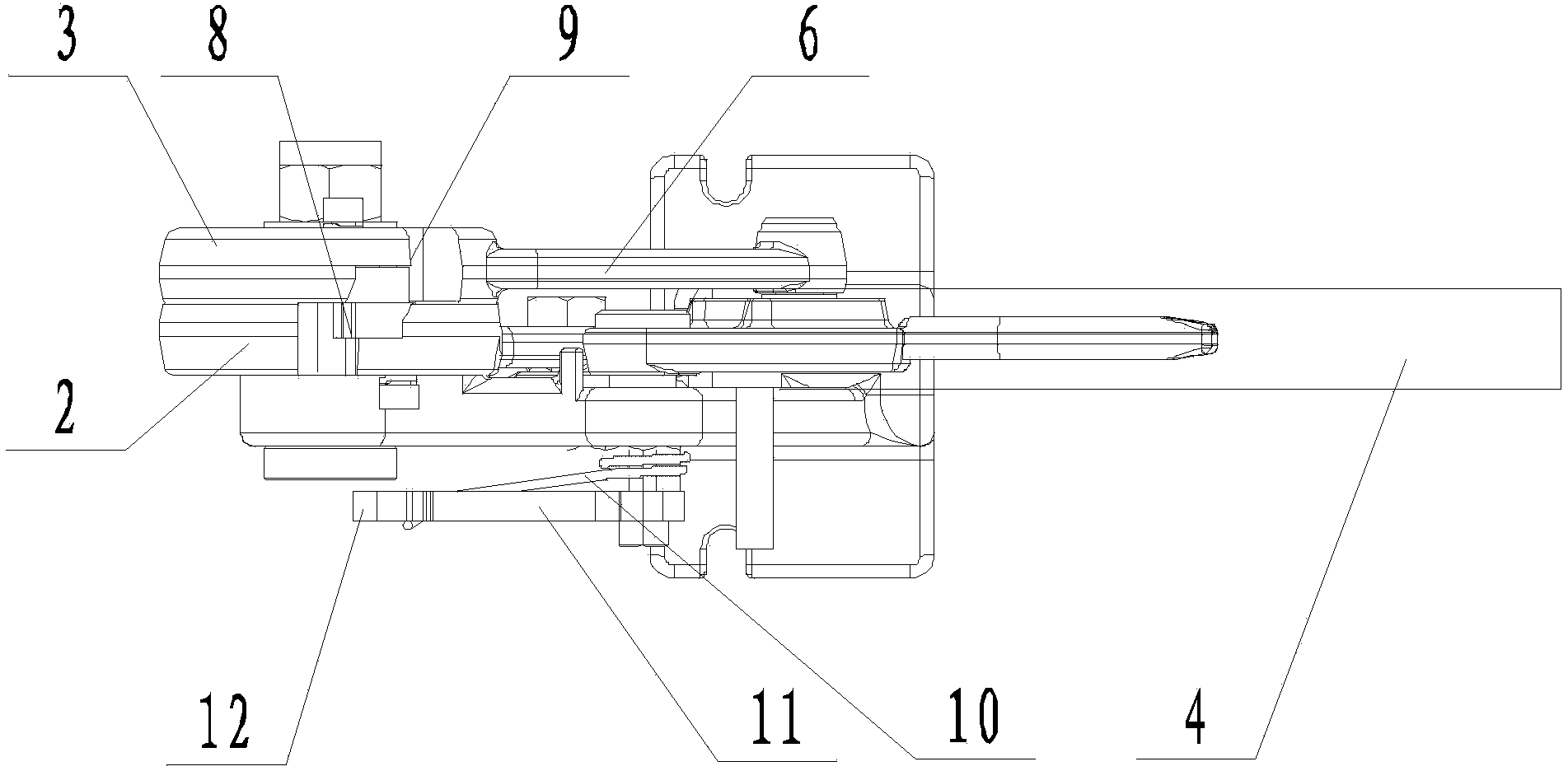

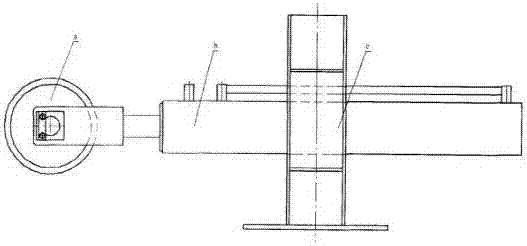

Shield-arc welding device with aerating device inside tube

InactiveCN101486125AEasy to useGuarantee welding qualityWelding accessoriesGas-filled tubeArc welding

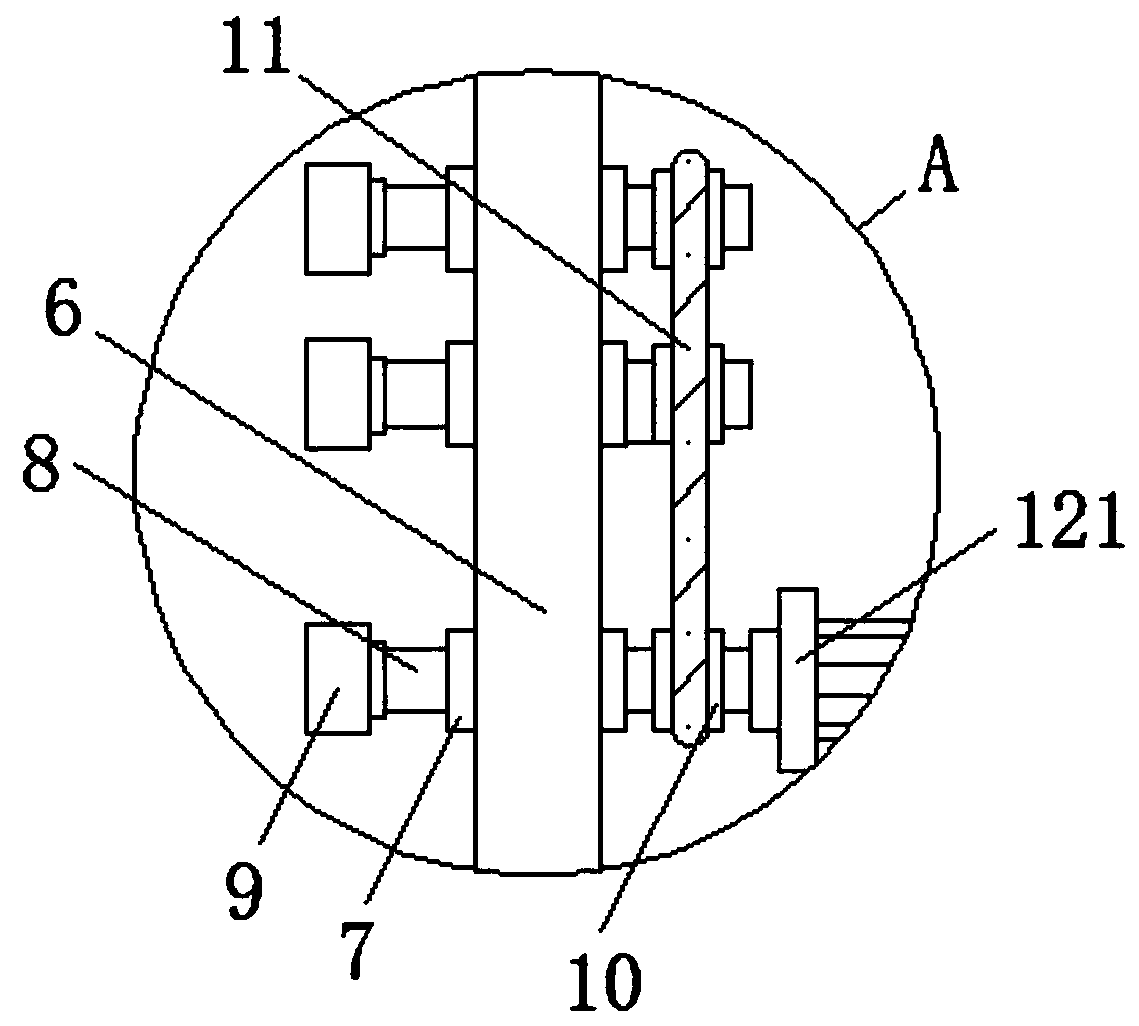

The invention discloses a gas shielded welding device with an air charging device inside a tube. The gas shielded welding device comprises a locking device with a chuck for clamping a pipeline to be welded, a drive mechanism for driving the chuck to rotate, the air charging device inside the tube for charging protective gas from a pore space of the pipeline to be welded, and an air charging pipe communicated with the air charging device inside the tube. The gas shielded welding device has the advantages that the device has a semiautomatic structure and convenient operation, and can improve welding quality.

Owner:浙江天力久田管业有限公司

High-speed plate placing machine for PCB production

The invention provides a high-speed plate placing machine for PCB production. The high-speed plate placing machine for the PCB production comprises two supporting plates, a mounting plate, a first sliding groove, a cross rod, a pushing structure, a first spring and a supporting rod, wherein the mounting plate is fixedly installed at the tops of the two supporting plates, the first sliding groove is formed in the top of the mounting plate, the cross rod is fixedly installed in the first sliding groove, the pushing structure is installed on the cross rod in a sliding mode, the first spring is arranged on the outer side of the cross rod in a sliding mode, one end of the first spring is fixedly connected with the inner wall of the first sliding groove, the supporting rod is fixedly installed at the bottom of the pushing structure, and the bottom end of the supporting rod extends out of the first sliding groove. The high-speed plate placing machine for the PCB production has the advantagesof being convenient to use, the PCB with different thicknesses can be placed, the plate placing speed is high, and mistakes are not prone to being caused.

Owner:AOSHIKANG TECH CO LTD

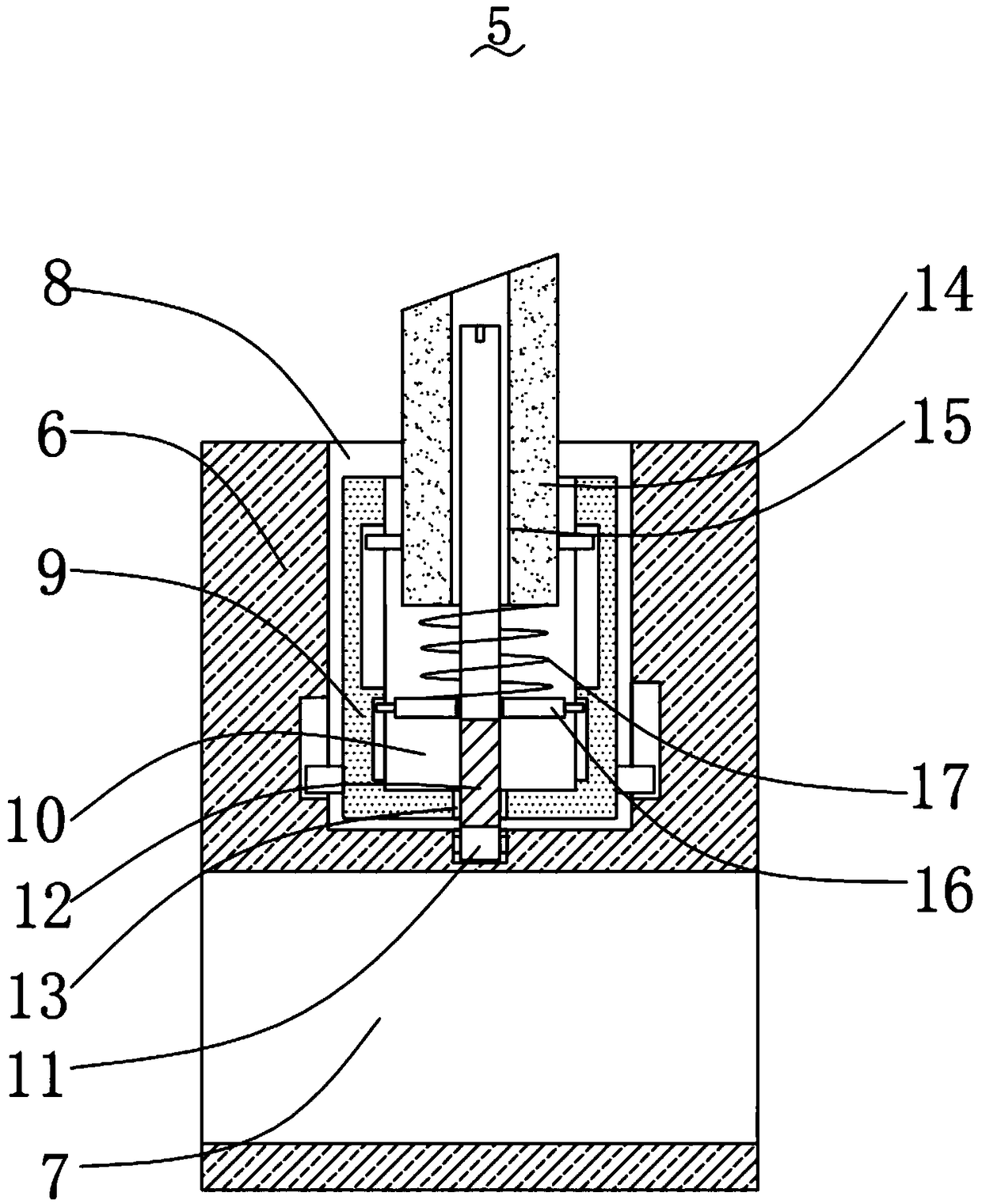

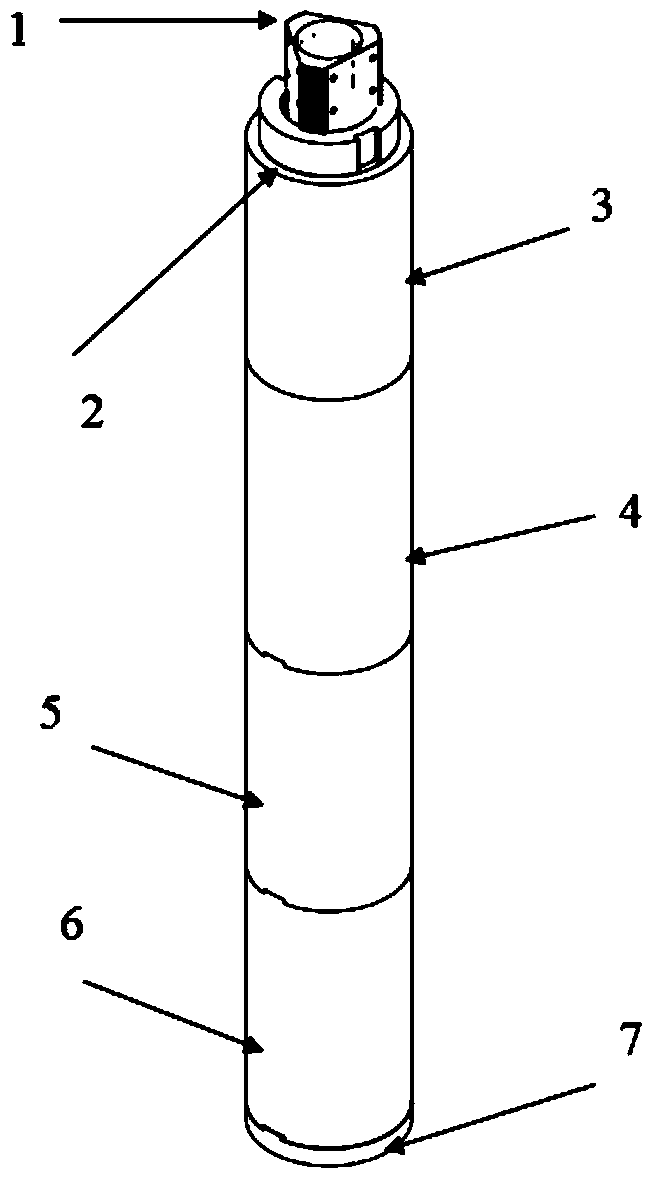

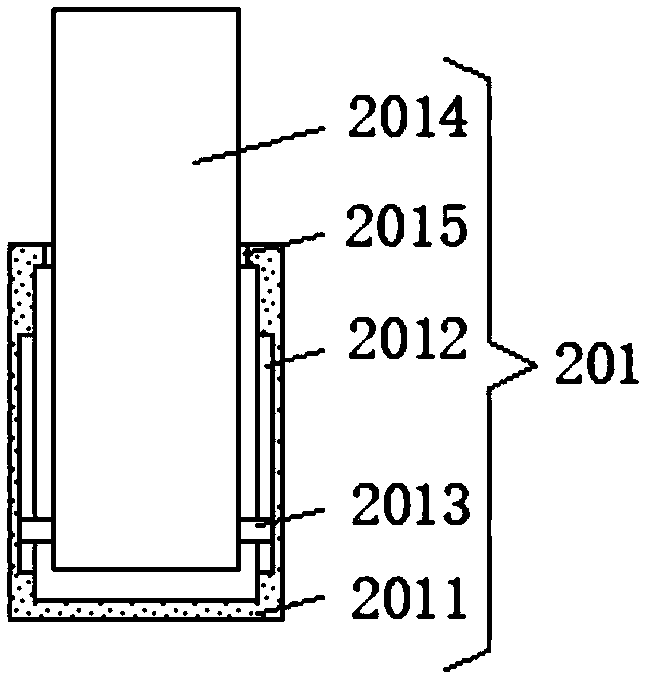

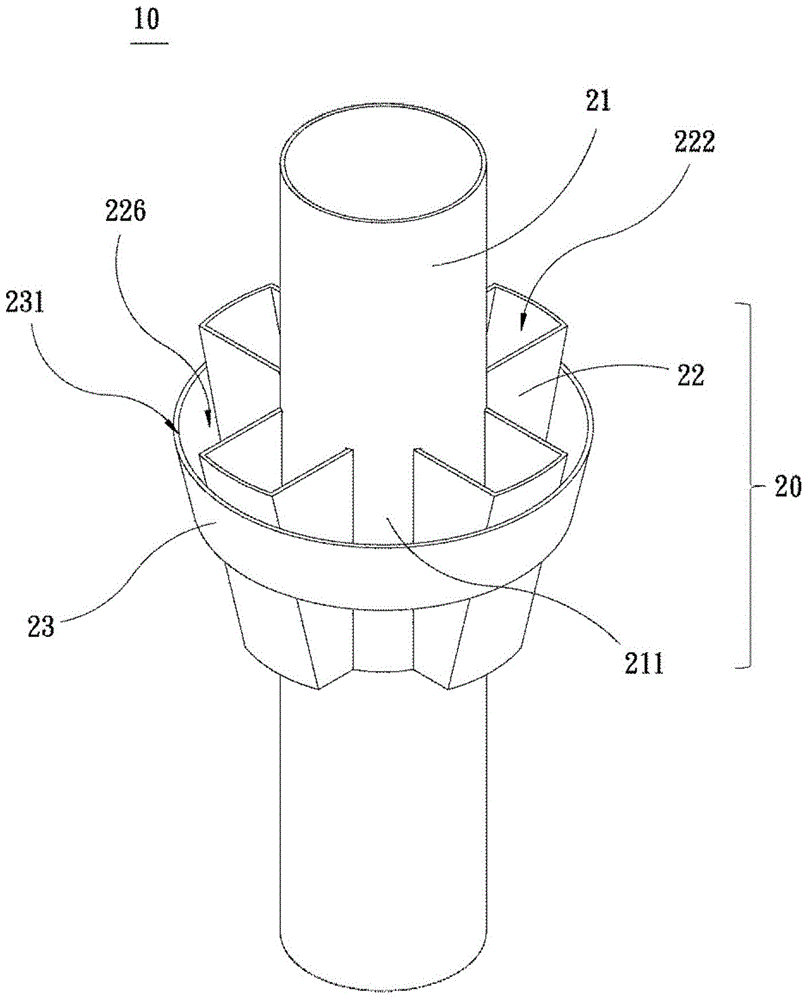

Metallic material irradiation device used in reactor

ActiveCN103971773ASimple structureWon't turnNuclear energy generationNuclear elementsBiochemical engineeringMetallic materials

The invention belongs to the technical field of reactor material irradiation performances and discloses a metallic material irradiation device used in a reactor. The device comprises a packaging casing, a sample casing, a core shaft, a base and a pressing cover, wherein the packaging casing is positioned above the sample casing and is connected with the sample casing by a clamping groove; the sample casing comprises one or more sub-casings; the inner side of each sub-casing is provided with one or more isolating devices which can be used for placing standard samples. The device disclosed by the invention has the characteristics that the temperature distribution is uniform and a plurality of samples can be placed.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

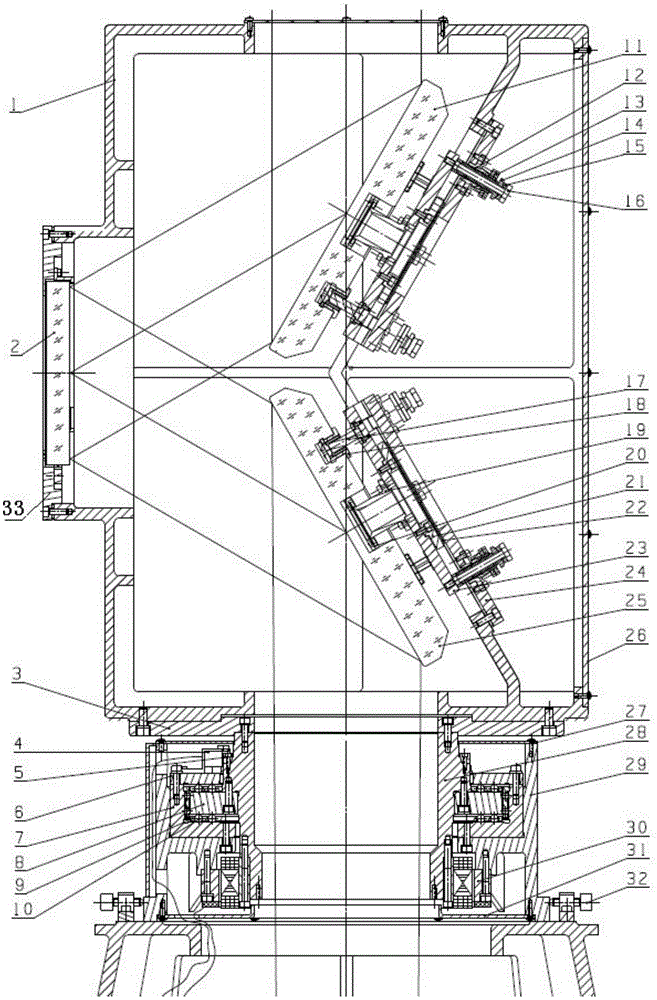

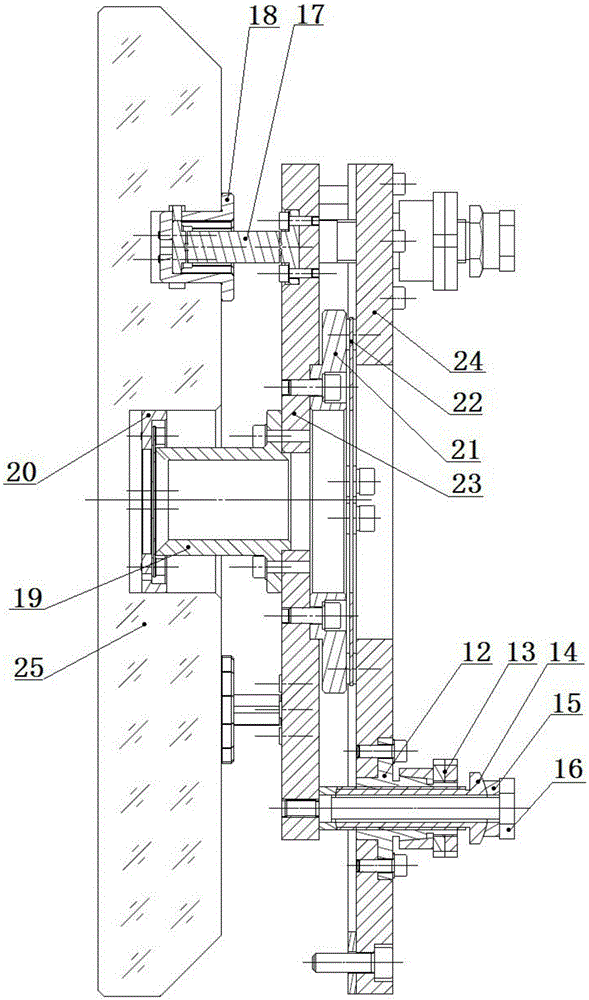

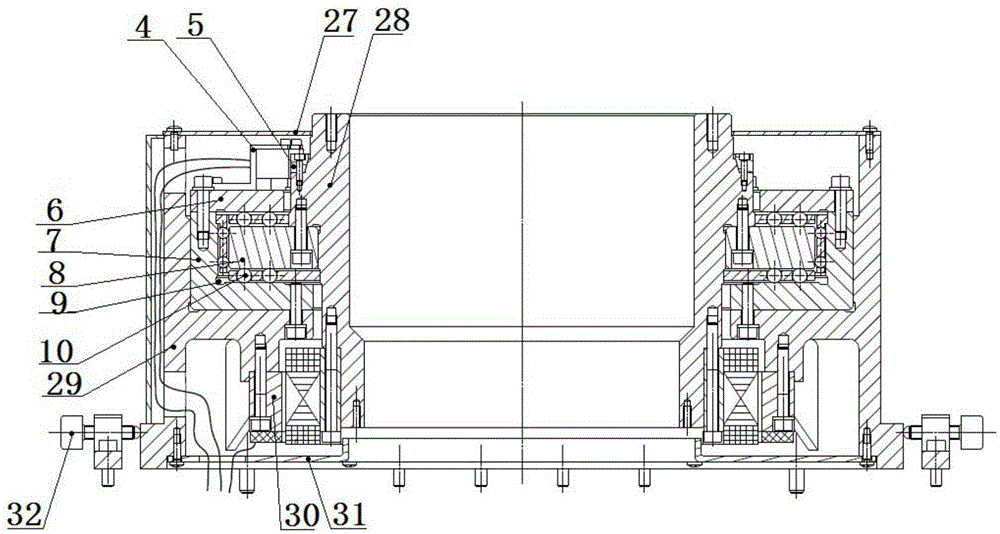

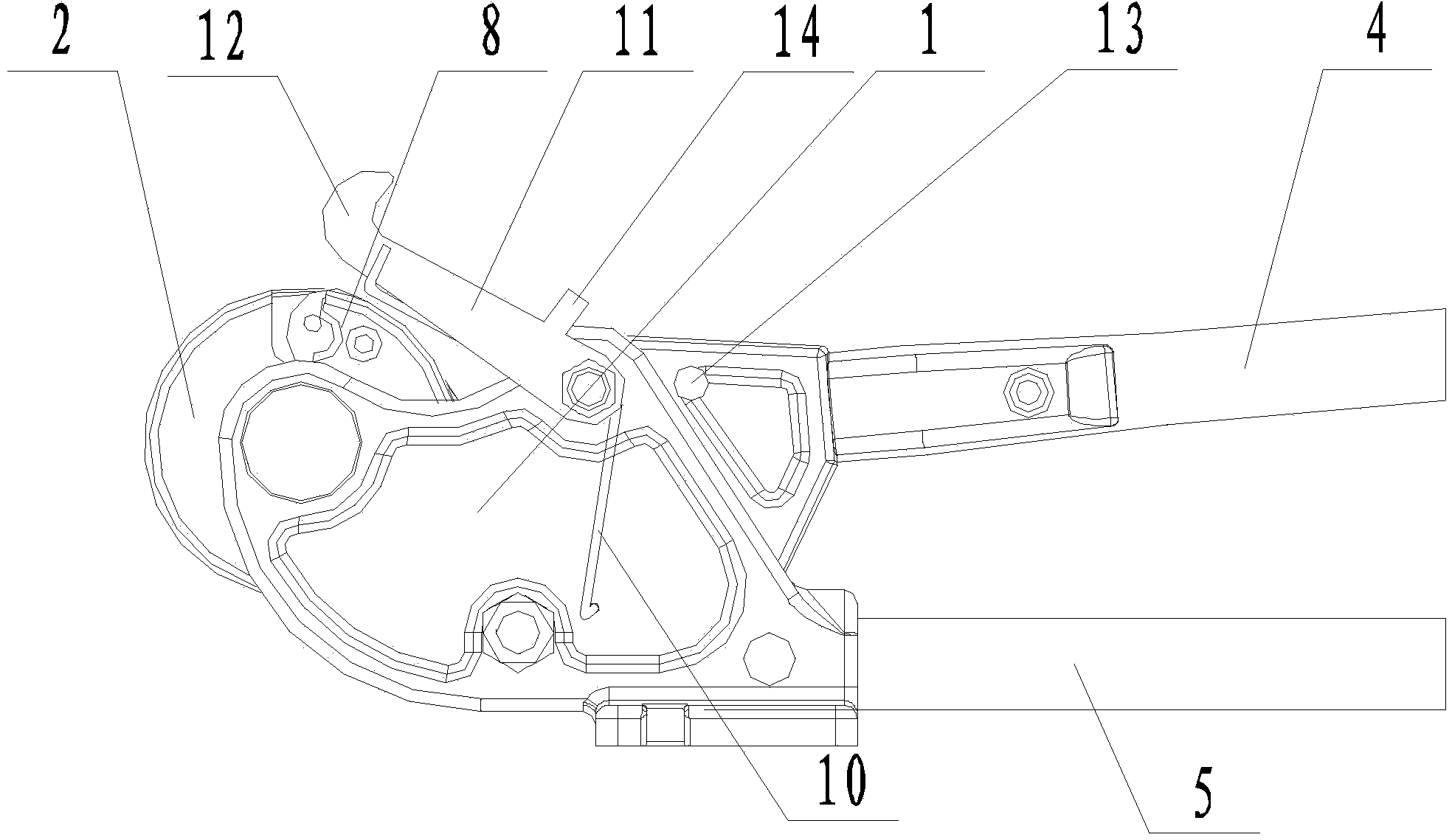

Telescope image derotator apparatus and collimation adjustment method thereof

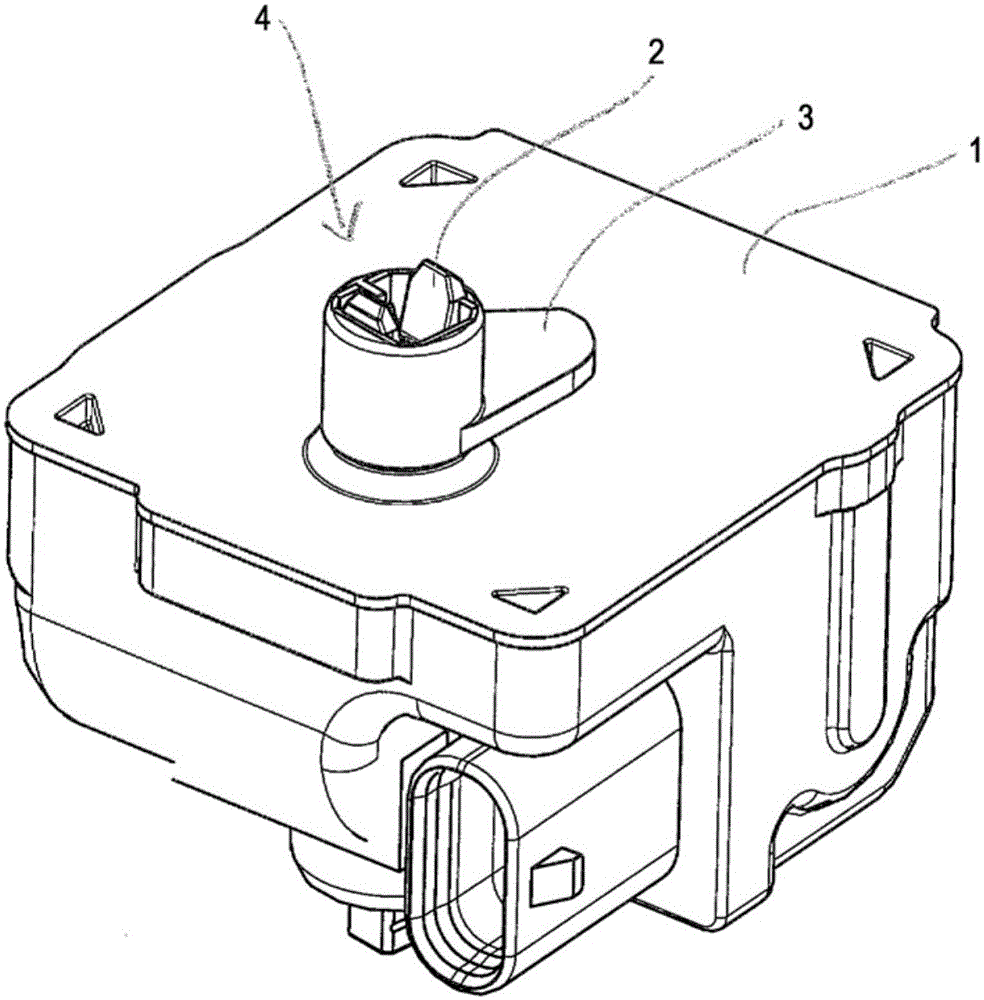

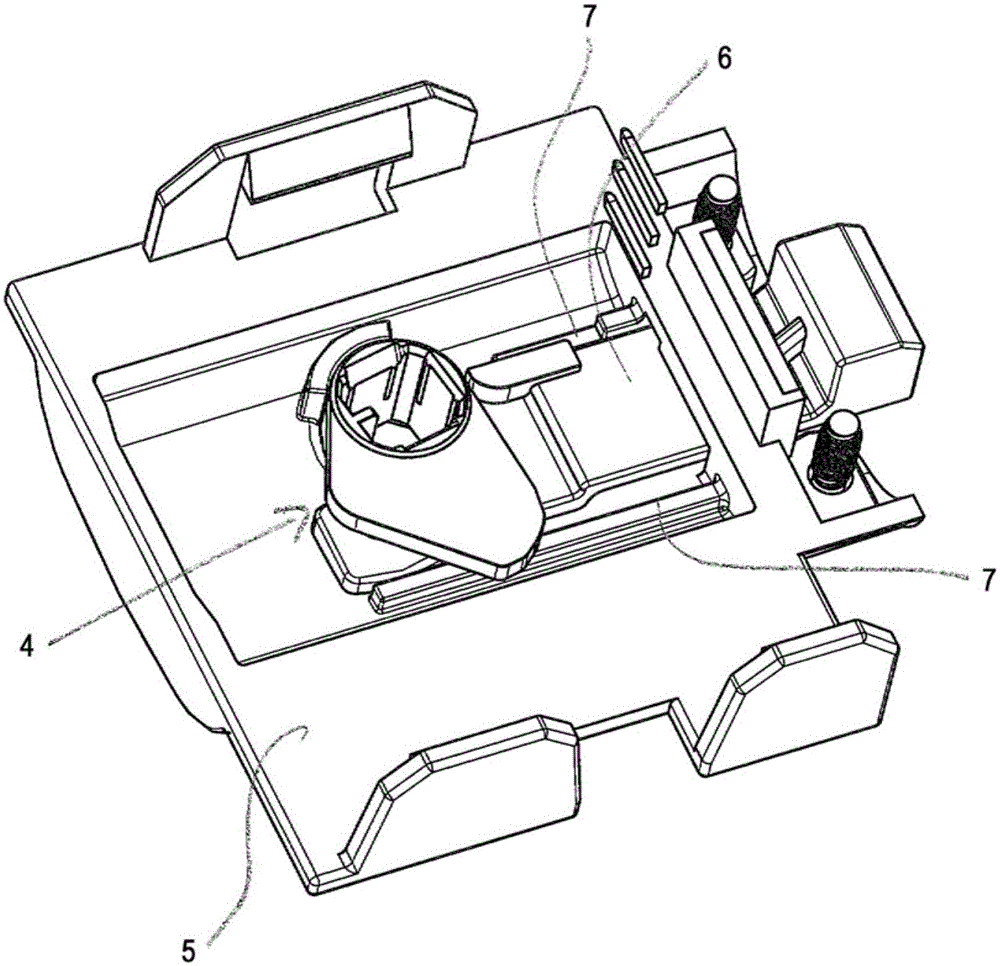

The invention provides a telescope image derotator apparatus and a collimation adjustment method thereof, and relates to the field of image derotator, being able to solve the problem for tracking rotation of image space field for a telescope. The telescope image derotator apparatus comprises a box body, a reflector, a fixed plate, a connection board, two steering mirrors, a box body cover plate, two sets of steering mirror adjusting assemblies for adjusting the steering mirrors, two sets of steering mirror assemblies for mounting the steering mirrors, and a precision rotary table assembly. The internal of the box body is provided with an interface for mounting the steering mirror adjusting assemblies and the steering mirror assemblies; the reflector is fixed on the side wall in the box body through the fixed plate; the lower end of the box body is fixedly connected with the precision rotary table assembly through the connection board; after mounting of the steering mirror adjusting assemblies and the steering mirror assemblies, the steering mirror adjusting assemblies and the steering mirror assemblies are sealed and protected by the box body cover plate; and the box body cover plate is fixed on the side wall outside of the box body through screws. The telescope image derotator apparatus has the advantages of being simple in structure, being low in processing and manufacturing difficulty, and being convenient to mount. The collimation adjustment method for the telescope image derotator apparatus is concise in operation and high in efficiency.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Reconstructable tool

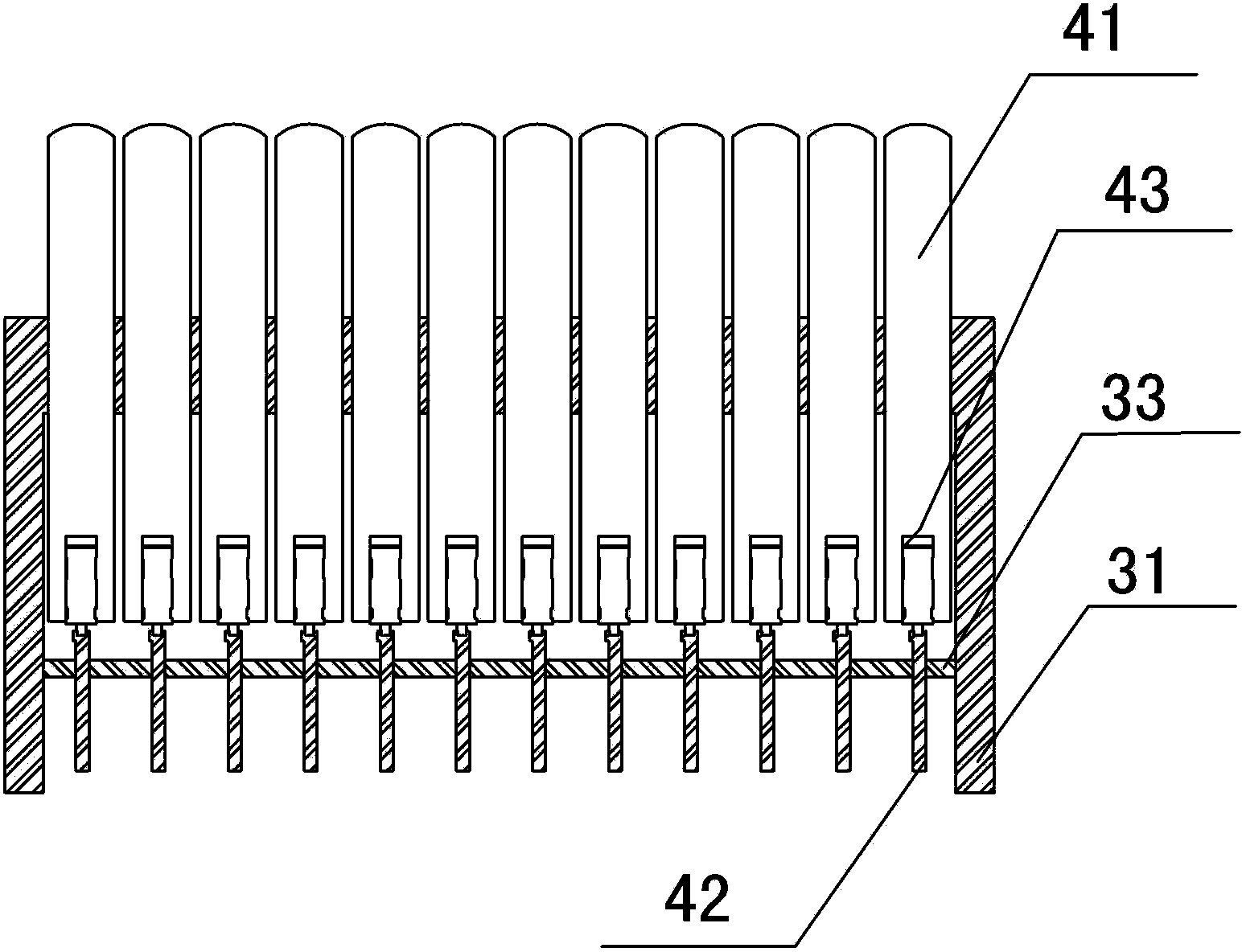

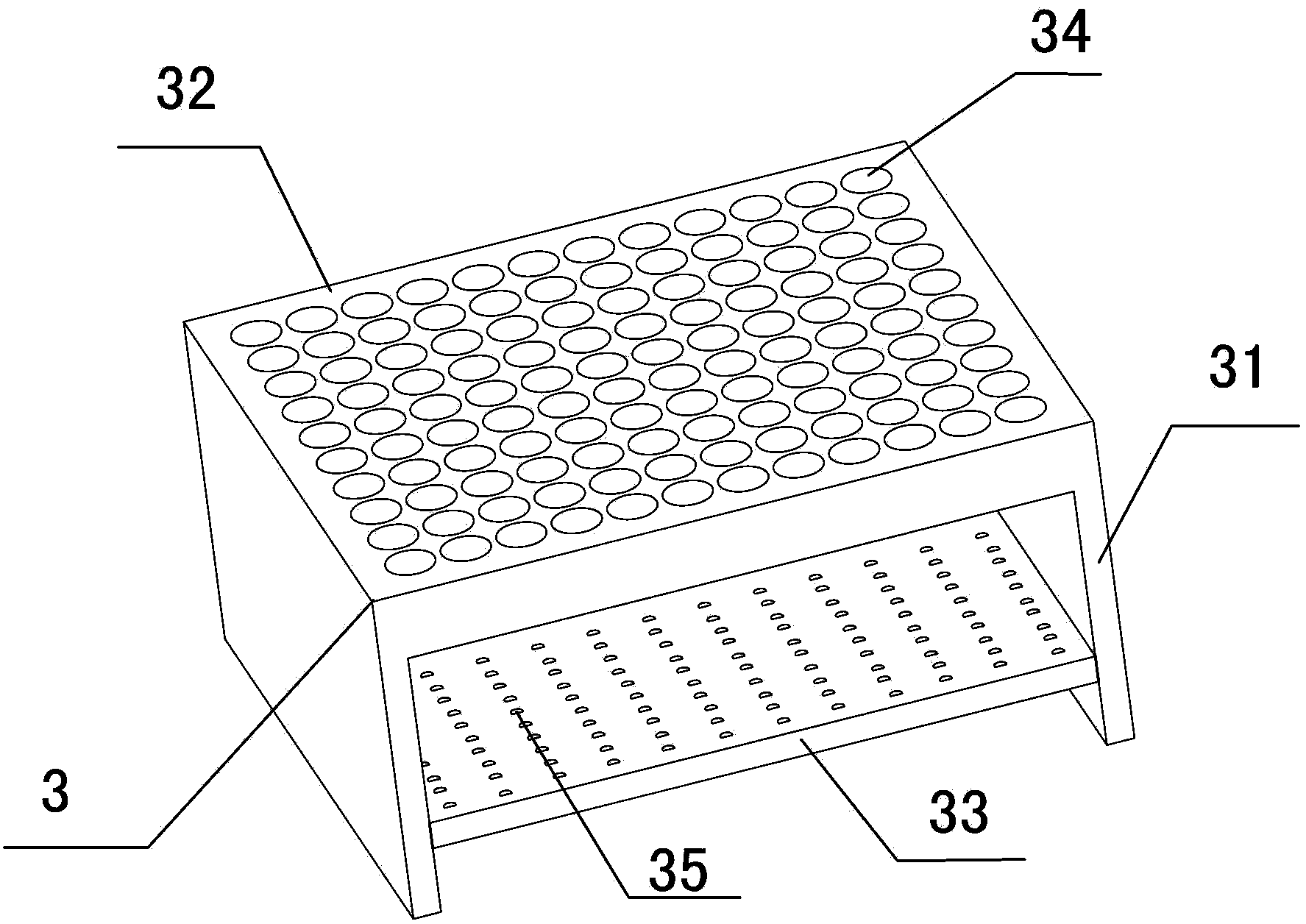

The invention discloses a reconstructable tool comprising a first module and a second module. The first module comprises a base and a plurality of reconstructable units. The base comprises a support, a base plate and a limit plate, wherein the base plate and the limit plate are fixed on the support, the base plate is provided with a plurality of threaded holes, the limit plate is provided with a plurality of limit holes, and the threaded hole are in coaxial one-to-one correspondence to the limit holes. Each reconstructable unit comprises a screw, a guide bar and a small motor, wherein a motor body of the small motor is embedded in the tail of the screw, the tail end of the screw is provided with a stopper used for fixing the small motor, the tail of the screw is in threaded connection with the one threaded hole, a motor shaft of the small motor extends out of the tail of the screw and is fixedly connected with the guide bar, and the guide bar locating in the corresponding limit hole matches with the corresponding limit hole in shape. The reconstructable tool has the advantages that the structure is simple, the cost is low, different surfaces can be changed fast, and the efficiency is high.

Owner:NINGBO UNIV

Quick detaching device for automobile tire maintenance

InactiveCN108909365AQuick and easy disassemblyEasy to moveWheel mounting apparatusTyre repairingTire maintenance

The invention discloses a quick detaching device for automobile tire maintenance and relates to the technical field of automobile part maintenance equipment. The quick detaching device for automobiletire maintenance comprises a supporting seat; rolling wheels are fixedly connected to four corners of the lower surface of the supporting seat; a bracket is fixedly connected to the upper surface of the supporting seat; a slide groove is formed in the left side surface of the bracket; two slide blocks are slidingly connected to the interior of the slide groove; connecting plates are both fixedly connected to the left side surfaces of the two slide blocks; and the opposite surfaces of the two connecting plates are fixedly connected with each other through a wheel disc. According to the quick detaching device for automobile tire maintenance, through coordination between a first electric push rod, a driving device and a second electric push rod, a motor can drive five sleeves to move in the same direction during working so that five tire bolts can be simultaneously taken off; and finally, the supporting seat is pulled to move in a direction far away from the tire; and the supporting seatcan also drive the tire to synchronously move in the moving process so that maintenance personnel can more rapidly detach the tire.

Owner:嘉兴日昌汽车配件股份有限公司

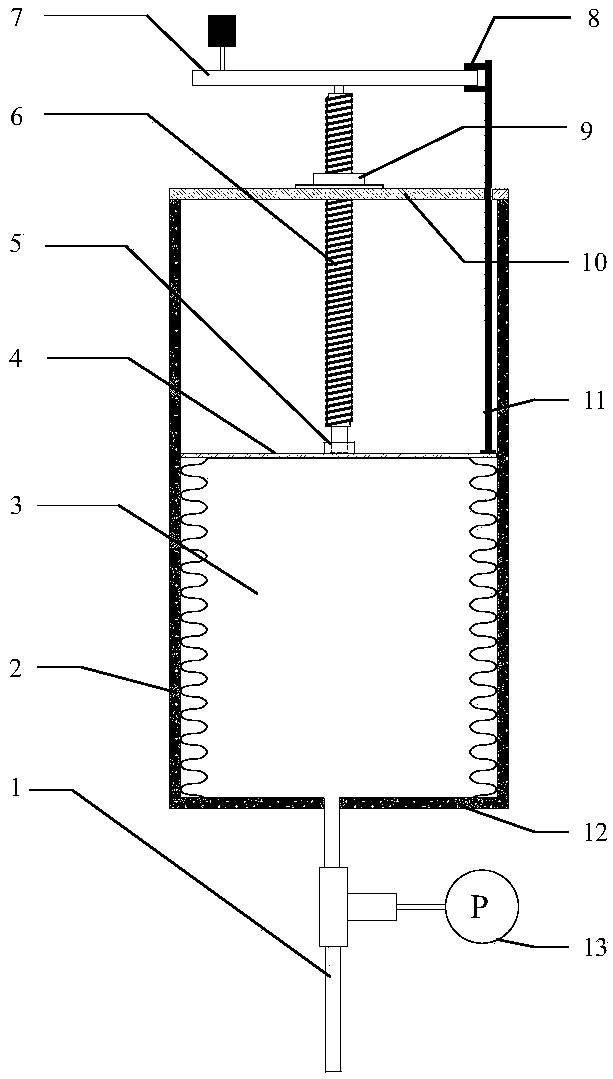

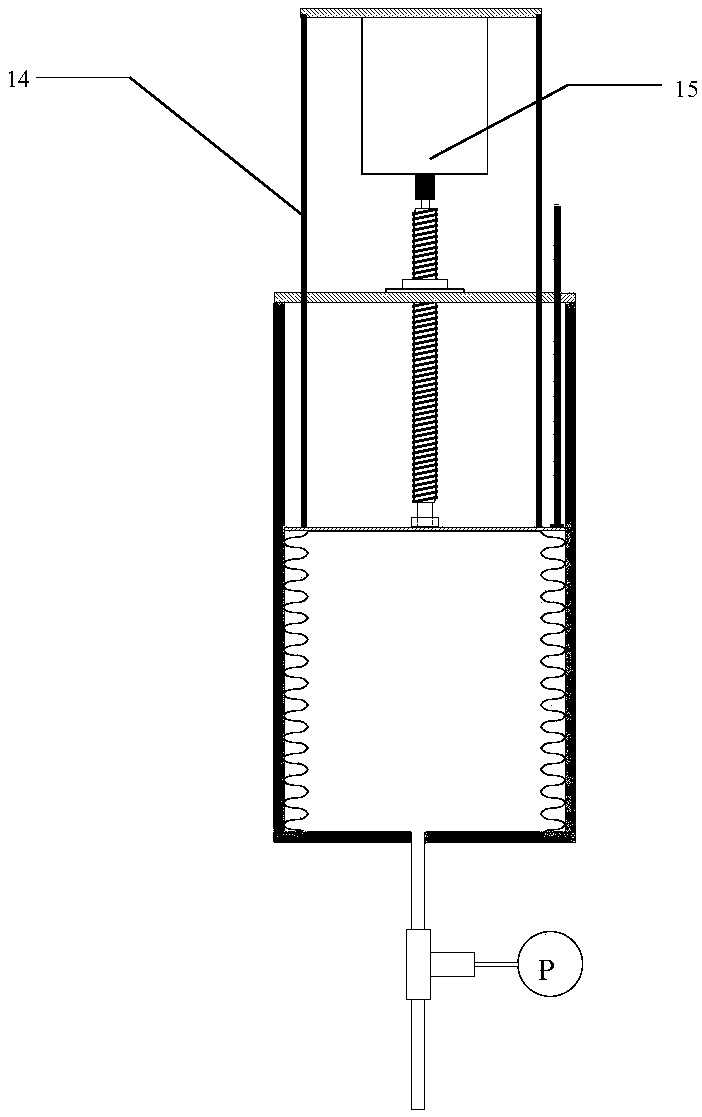

Thermoacoustic oscillation suppression device based on variable-volume damping gas storage for liquid helium container

ActiveCN107917337ACircumferential distortion does not occurImprove sealingContainer filling methodsPressure vesselsFixed bearingThermoacoustics

The invention discloses a thermoacoustic oscillation suppression device based on a variable-volume damping gas storage for a liquid helium container. The thermoacoustic oscillation suppression devicecomprises a capillary tube, a gas storage sleeve, the damping gas storage, a moving plate, a screw rod fixing bearing, a ball screw, a nut pair, a screw nut fixing plate, a scaleplate, a gas storage fixing plate and a pressure sensor, wherein a corrugated pipe is adopted for the damping gas storage, so that the gas storage has the characteristics of being resistant to high pressure and high in sealing performance, and change for the volume of the damping gas storage can also be realized by virtue of the axial scalability of the corrugated pipe. Manual or automatic adjustment can be carried outon the volume of the gas storage according to the different use working conditions of the liquid helium container, so that the optimal suppression effect of the device for the thermoacoustic oscillation of the liquid helium container is guaranteed.

Owner:SHANGHAI JIAO TONG UNIV +1

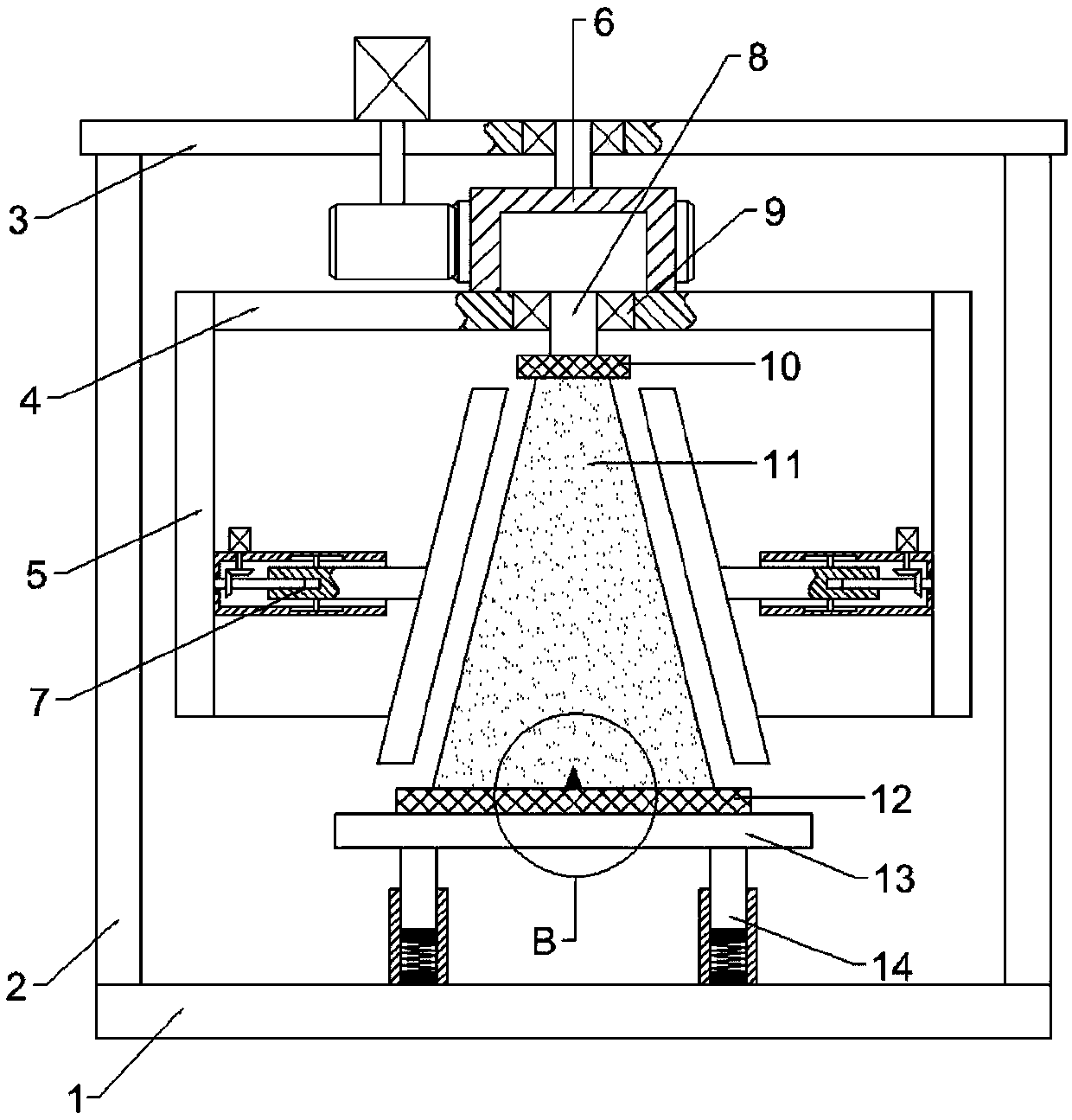

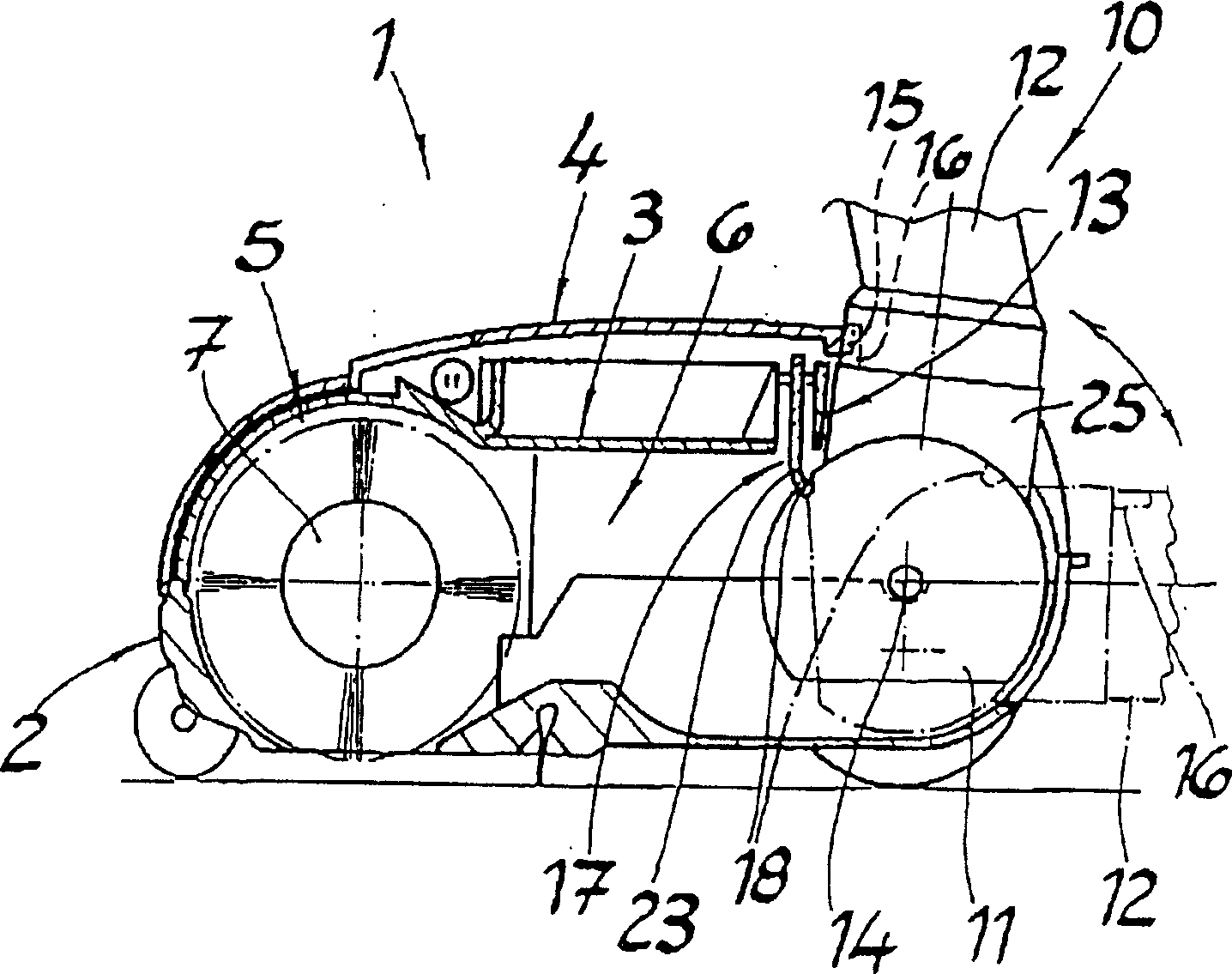

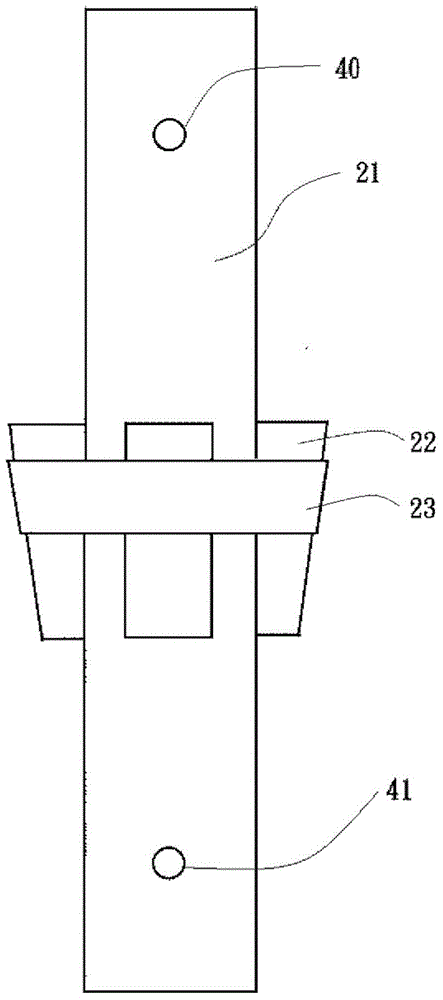

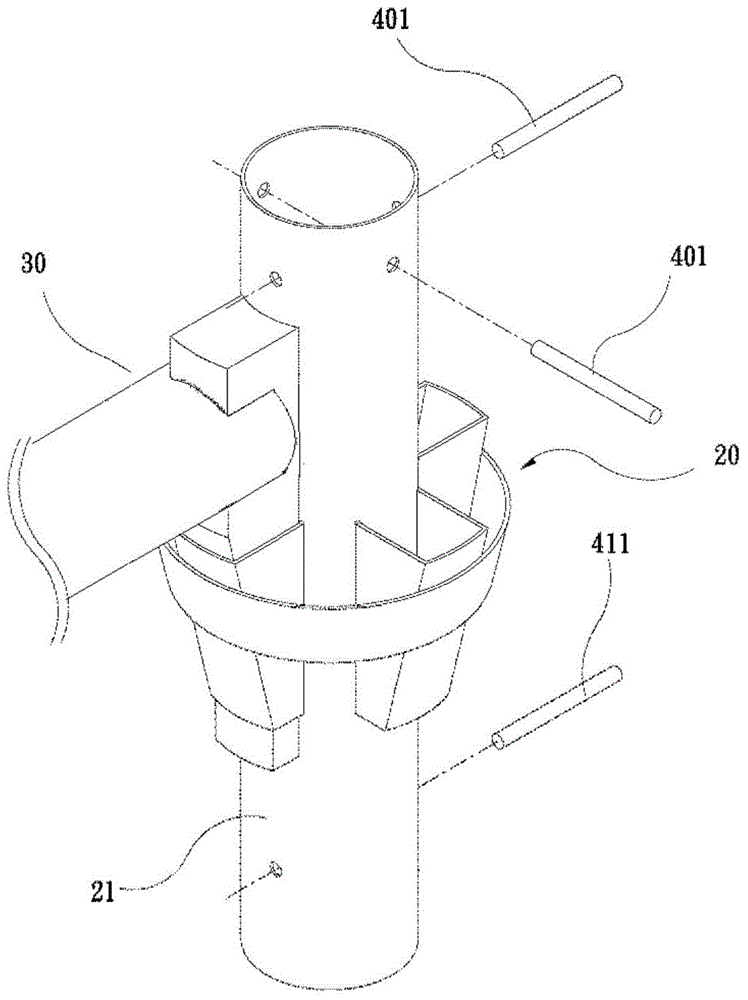

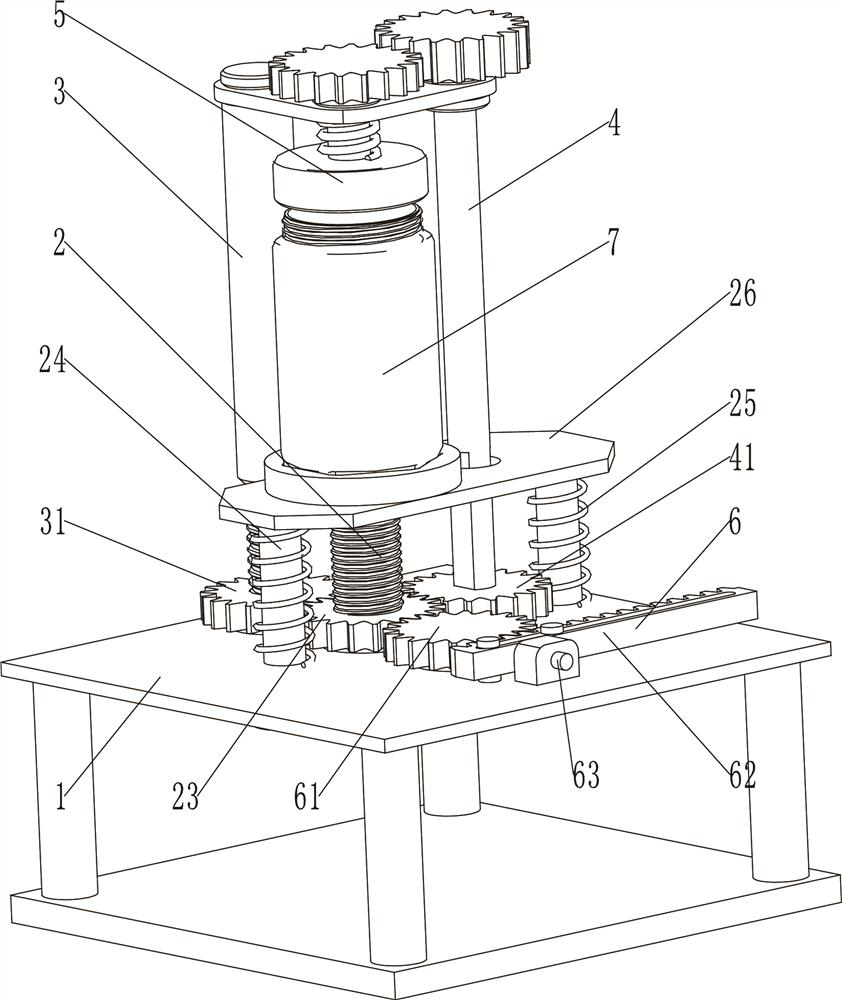

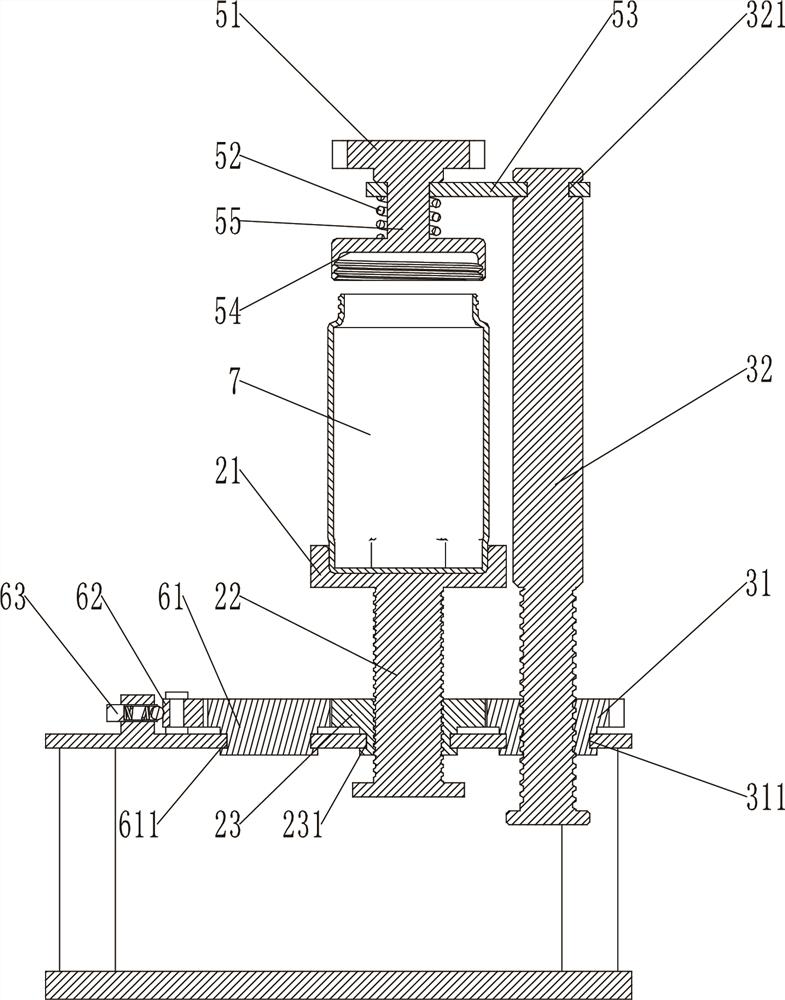

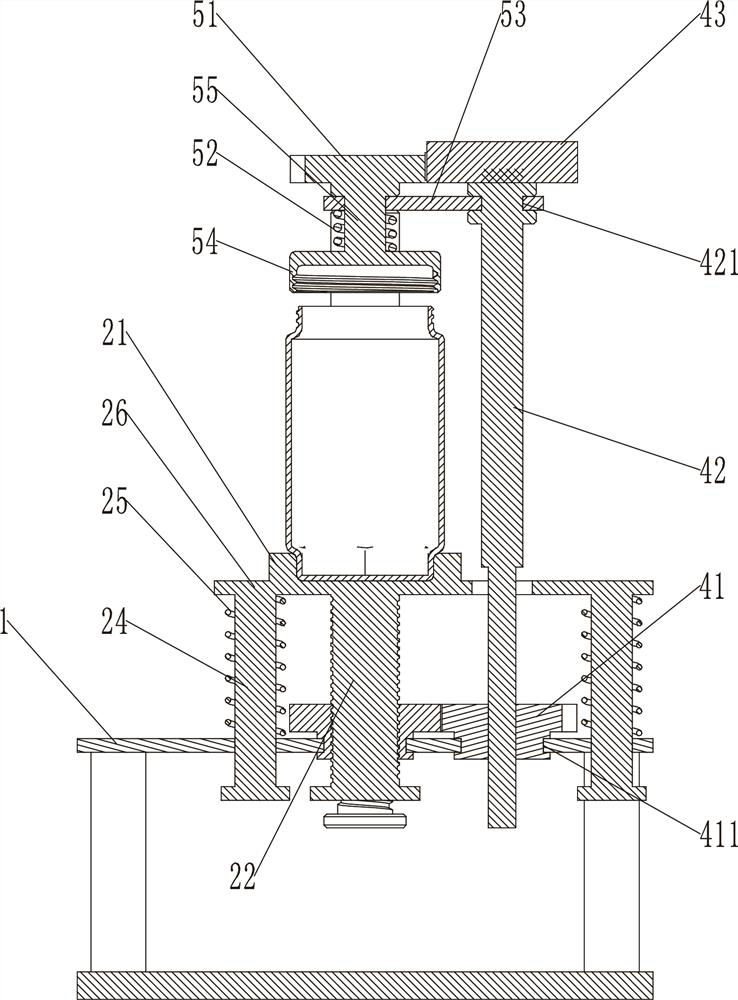

Rotary peeling based rapid shelling equipment of fresh bamboo shoots

The invention provides rotary peeling based rapid shelling equipment of fresh bamboo shoots. The equipment comprises a base, wherein first supporting columns are fixedly connected to both ends of thebase; a first supporting plate is fixedly connected to the top ends of the two first supporting columns; a second supporting plate is arranged below the first supporting plate; a rotary driving deviceis arranged on the upper side of the second supporting plate; long-strip vertical plates are fixedly connected to the lower sides of both ends of the second supporting plate; and peeling devices arefixedly connected to the inner sides of the long-strip vertical plates. The equipment disclosed by the invention has the following beneficial effects: first, because the polarities of a first magneticpole and a second magnetic pole are the same, repulsive force exists between the first magnetic pole and the second magnetic pole; a supporting spring also has upward acting force on the second magnetic pole to enable the second magnetic pole to move upward, so that a vertical rod is driven to move upward, and a first rubber pad and a second rubber pad tightly clamp the bamboo shoots to guaranteethat the bamboo shoots cannot rotate together with the peeling devices; and through the adoption of the rubber pads, the friction force between the bamboo shoots and the rubber pads is increased.

Owner:重庆沁旭熊猫雷笋股份有限公司

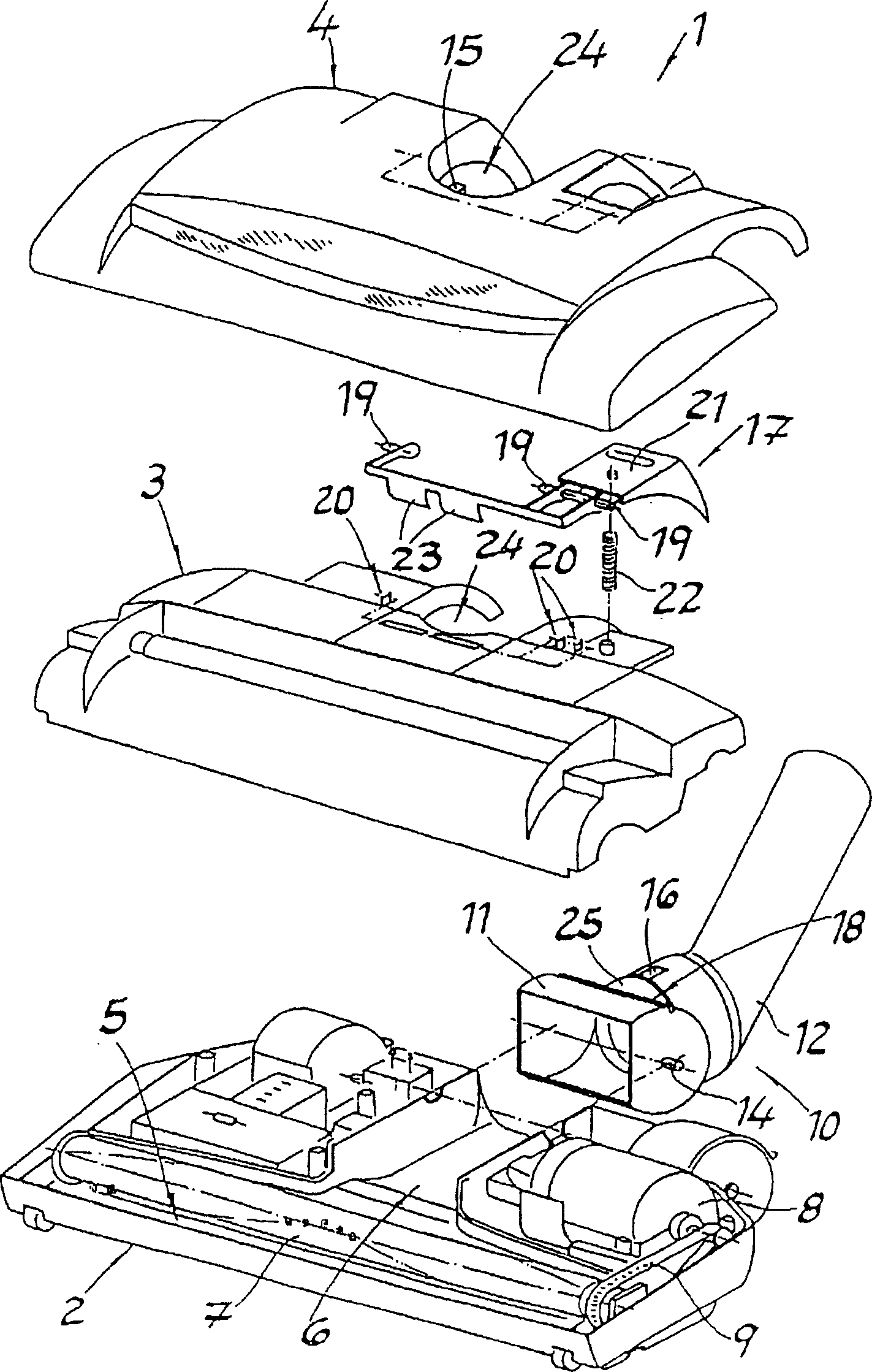

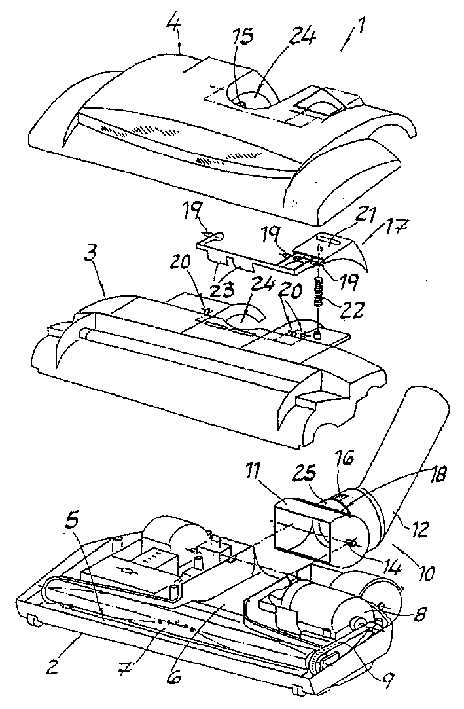

Front brush auxiliary device for vacuum cleaner

A front brush attachment device for a vacuum cleaner comprises a multi-component housing, a rotationally driven brush roller, and a rotating and tilting joint for connecting the vacuum cleaner. The rotating and tilting joint has a tilting joint piece inserted in a suction duct of the housing, as well as a short, rotatable joint tube, which is connected with the tilting joint piece in a rotating manner. The tilting joint piece is supported in the housing in a manner permitting it to revolve about an axle aligned transversely in relation to the suction duct. The short, rotatable joint tube is mounted on a cylindrical connector piece with rotational mobility. A protrusion on the housing and a recess on the rotatable joint tube engage each other in the locking position and secure the short, rotatable joint tube against rotation. A spring-loaded locking lever is supported on the housing, which, in the locking position, engages a shoulder located on the periphery of the tilting joint piece.

Owner:WESSEL WERK

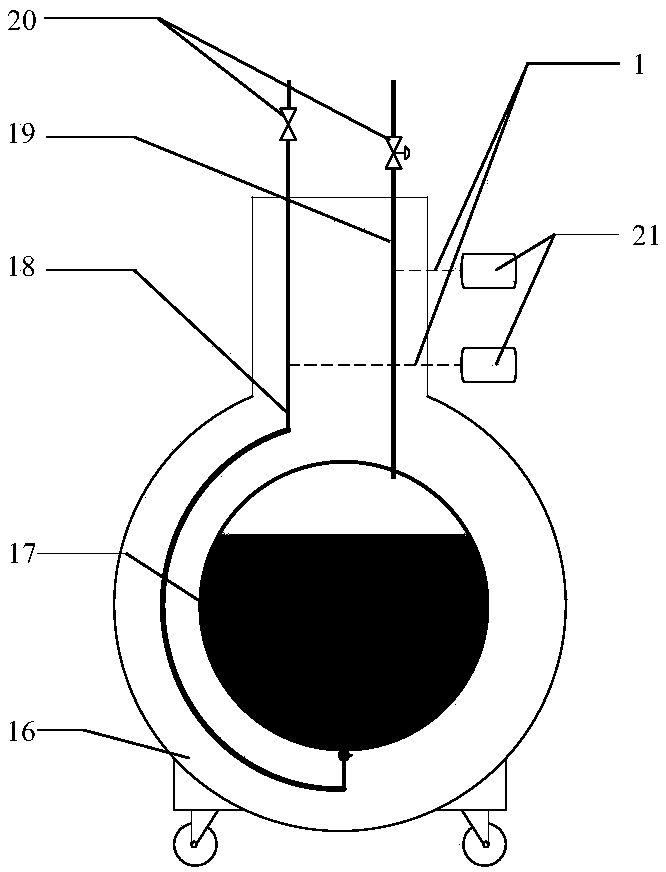

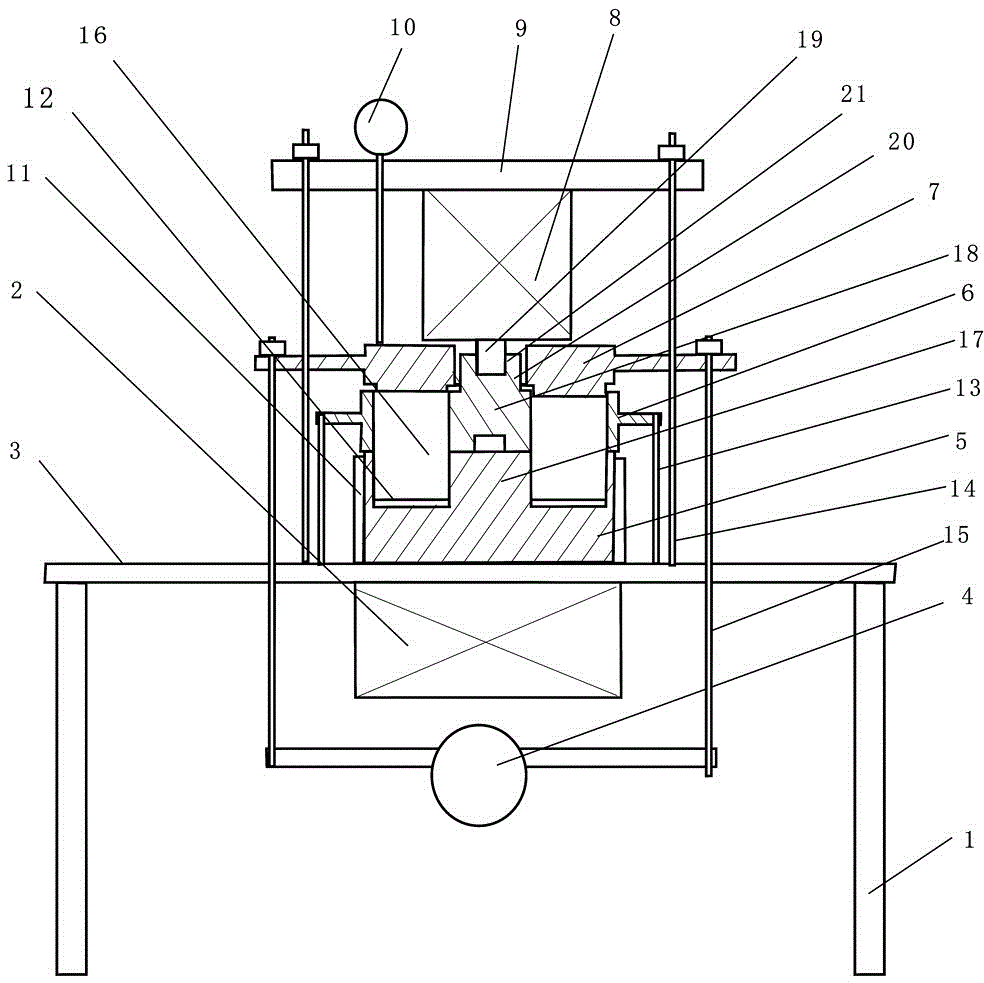

Ring shear apparatus for circular-ring-shaped soil sample

InactiveCN105067453AWon't turnComprehensive understanding of mechanical propertiesMaterial strength using steady shearing forcesCircular discEngineering

The invention discloses a ring shear apparatus for a circular-ring-shaped soil sample. The ring shear apparatus comprises a working frame, a driving device and a pressurizing device and further comprises a rotary disk, a fixed sleeve, a pressurizing cake, a torque sensor and a torque sensor fixing frame; a cylindrical rotary table is fixed in the center of the disk of the rotary disk; the rotary disk is in transmission connection with the driving device; the fixed sleeve is arranged above the rotary disk and fixed to a workbench; a fixed table can be rotationally fixed on the rotary table; a through hole is formed in the center of the pressurizing cake; pressurizing connecting blocks are arranged on the two sides of the pressurizing cake; the pressurizing cake is connected with the pressurizing device; a ring-shaped bulge is arranged at the lower end of the pressurizing cake; supporting rods are fixed on the workbench; the torque sensor fixing frame is fixed on the supporting rods; the torque sensor is fixed on the torque sensor fixing frame; a positioning pin is arranged at the lower end of the torque sensor; the upper end of the fixed table is connected with a connecting column; a positioning hole is formed in the upper end face of the connecting column; the positioning pin falls into the positioning hole. By adopting the ring shear apparatus provided by the invention, shearing strength of the circular-ring-shaped soil sample in the annular direction can be measured, so as to conveniently know mechanical properties of soil and sand stone more comprehensively.

Owner:ZHEJIANG TUGONG INSTR

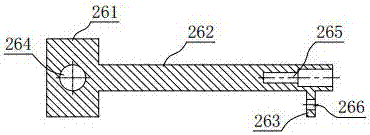

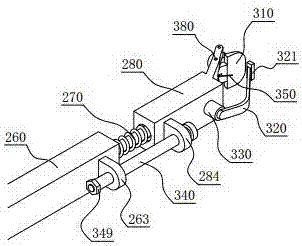

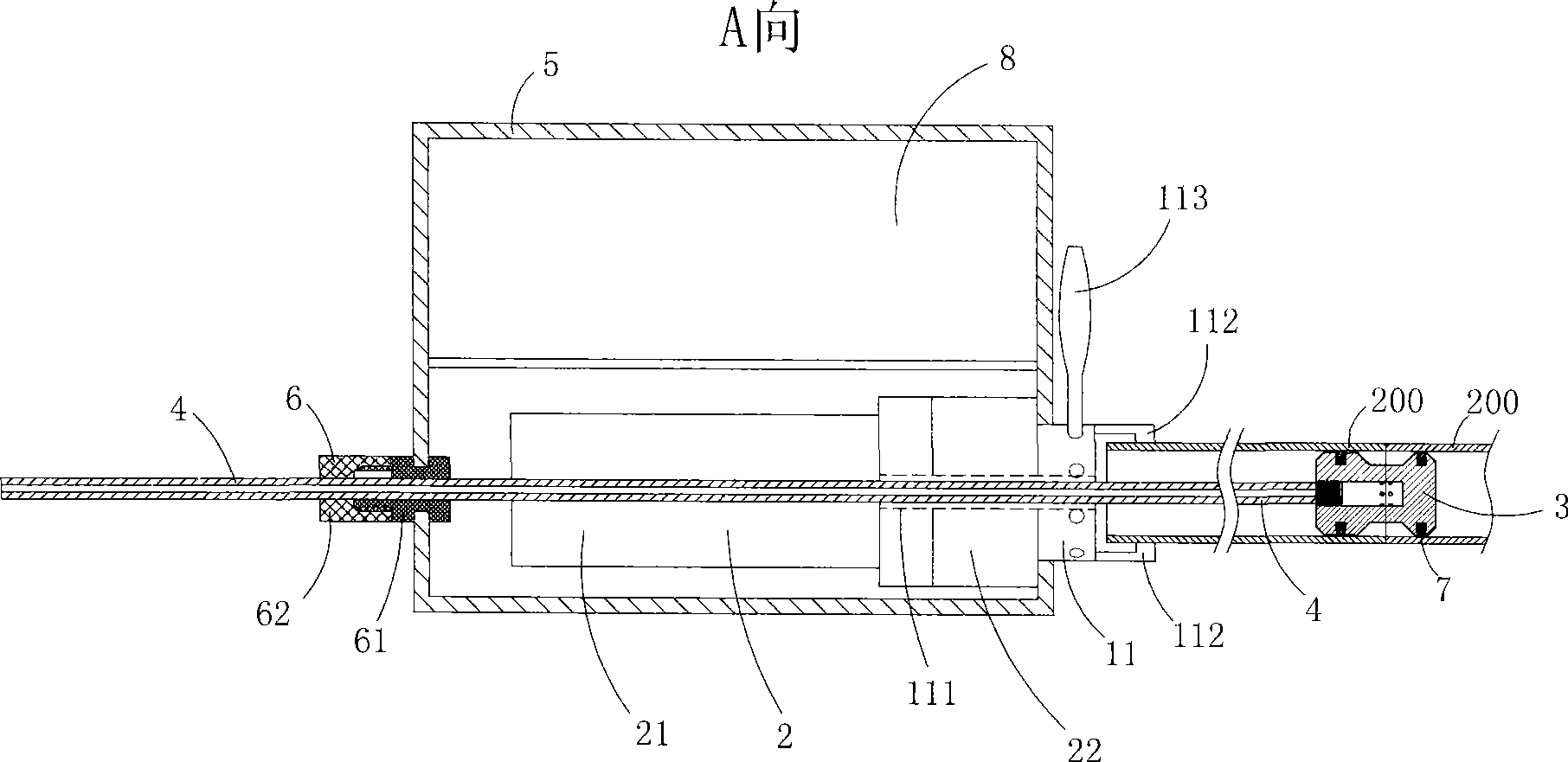

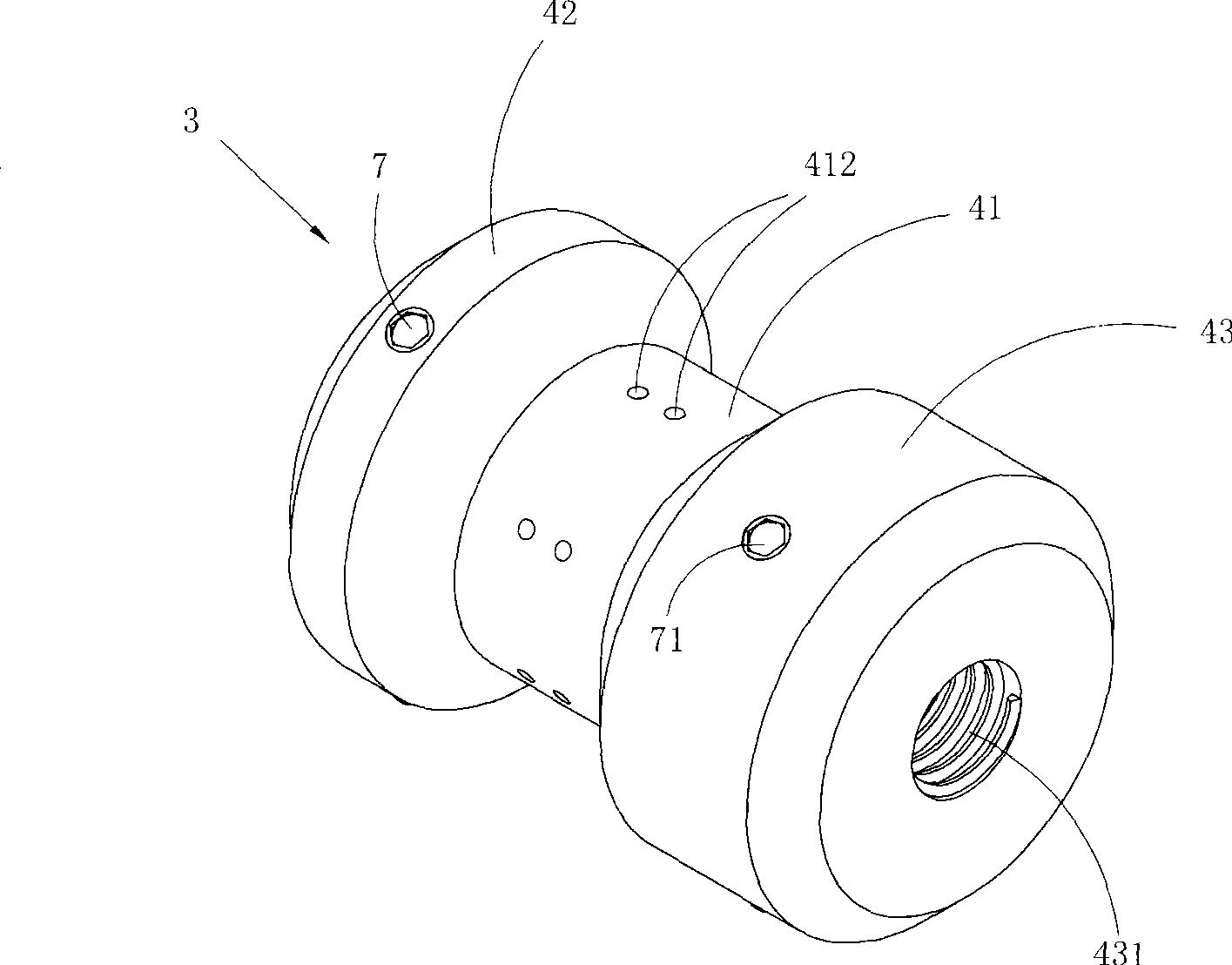

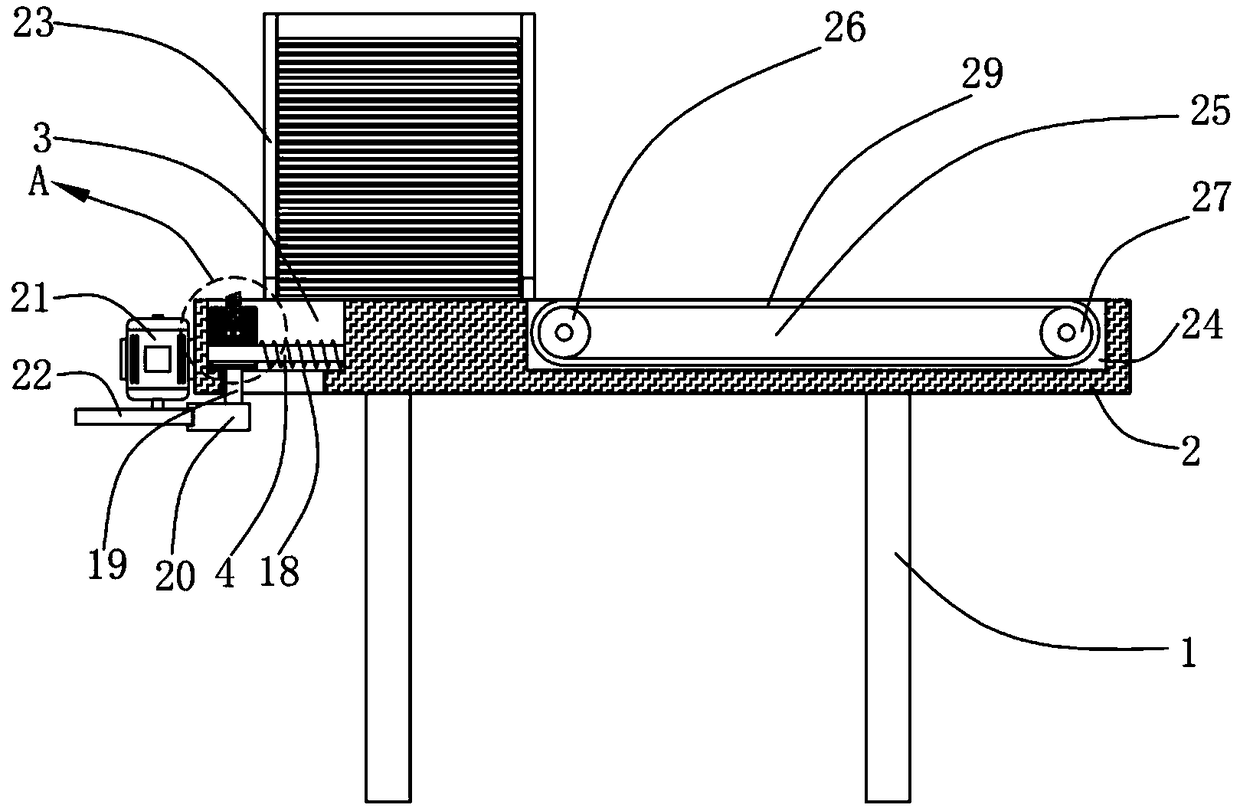

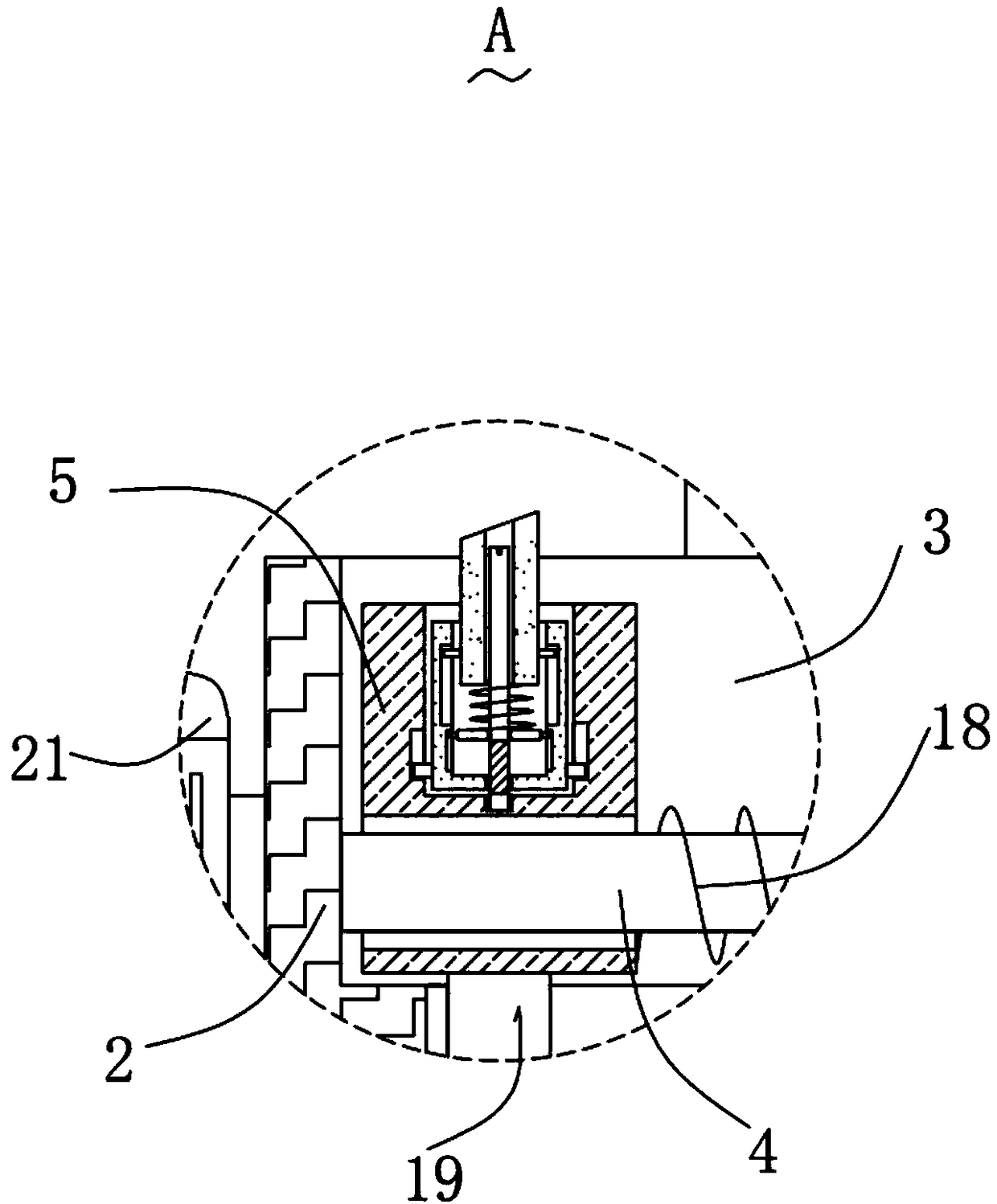

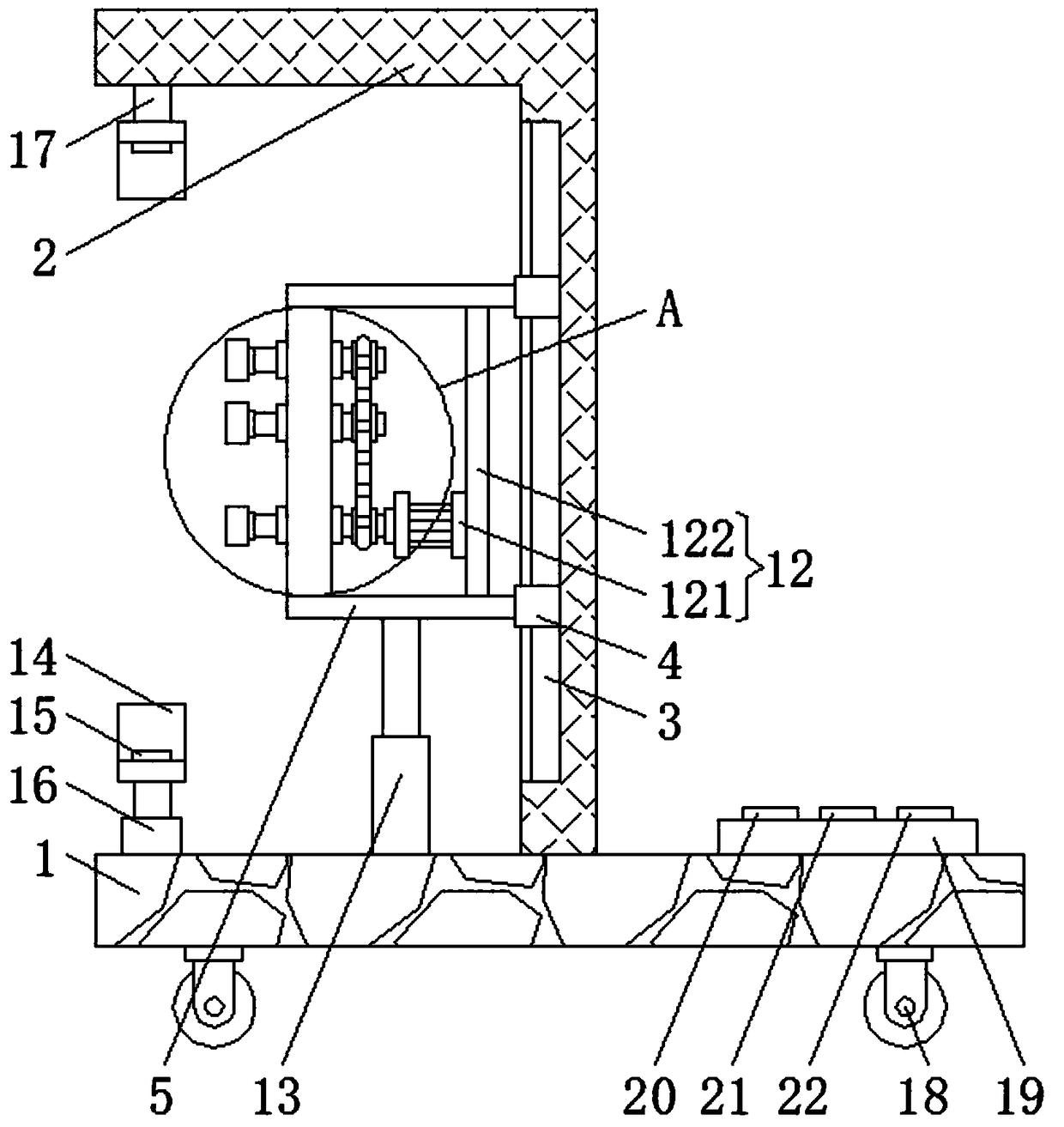

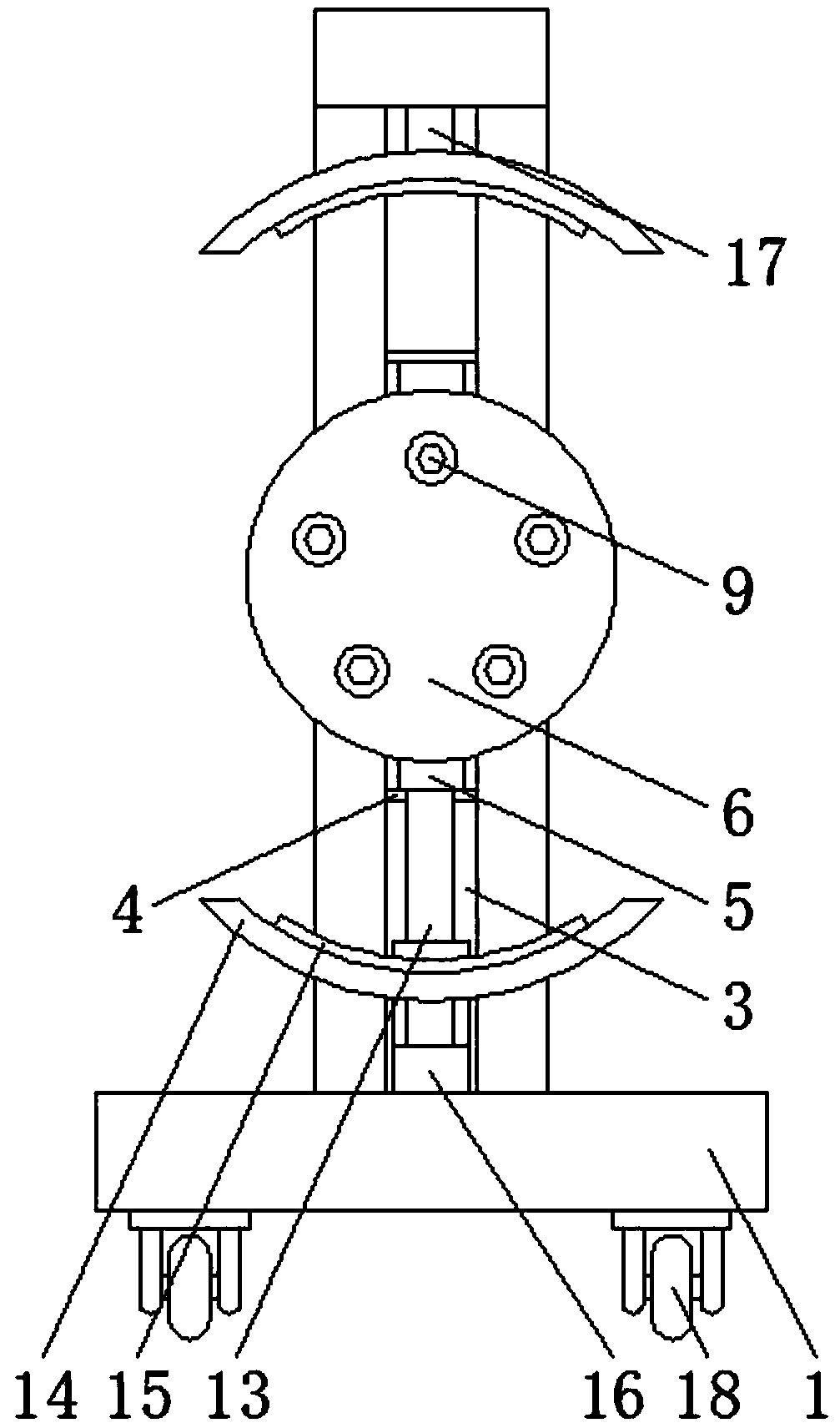

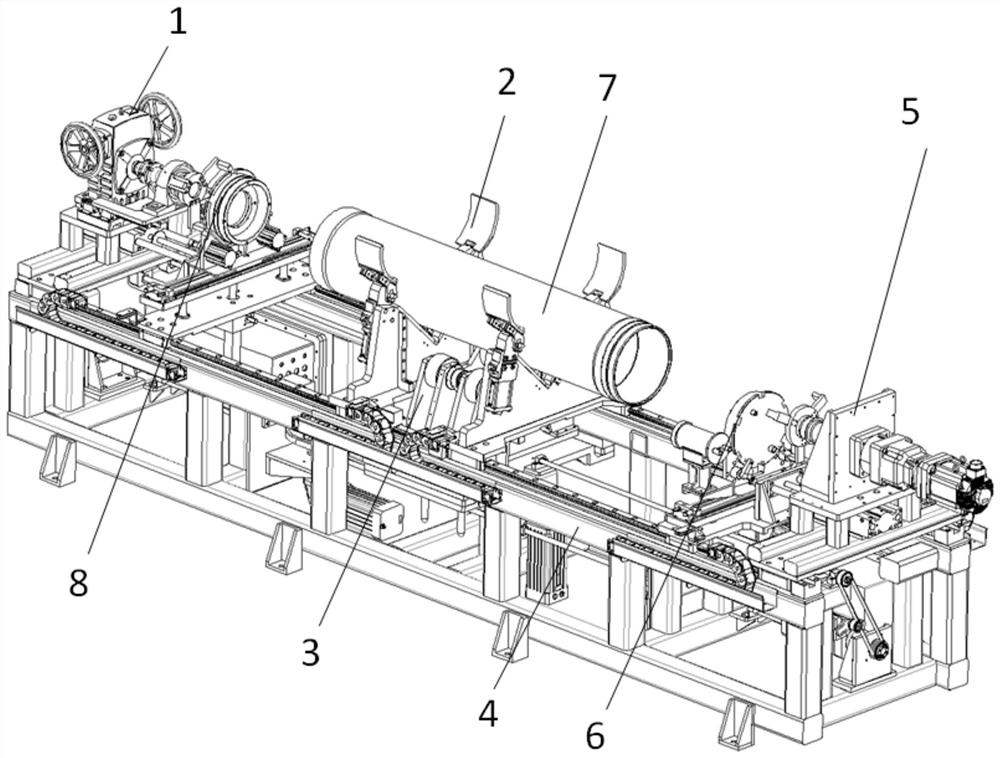

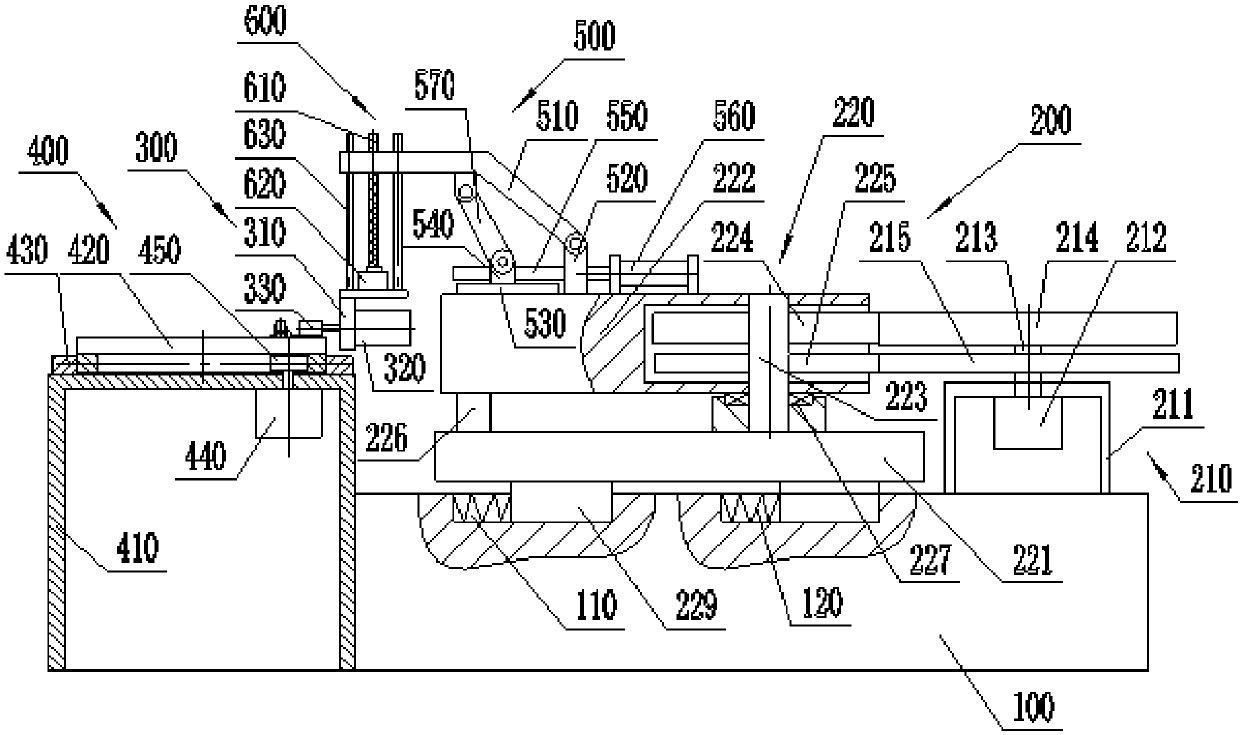

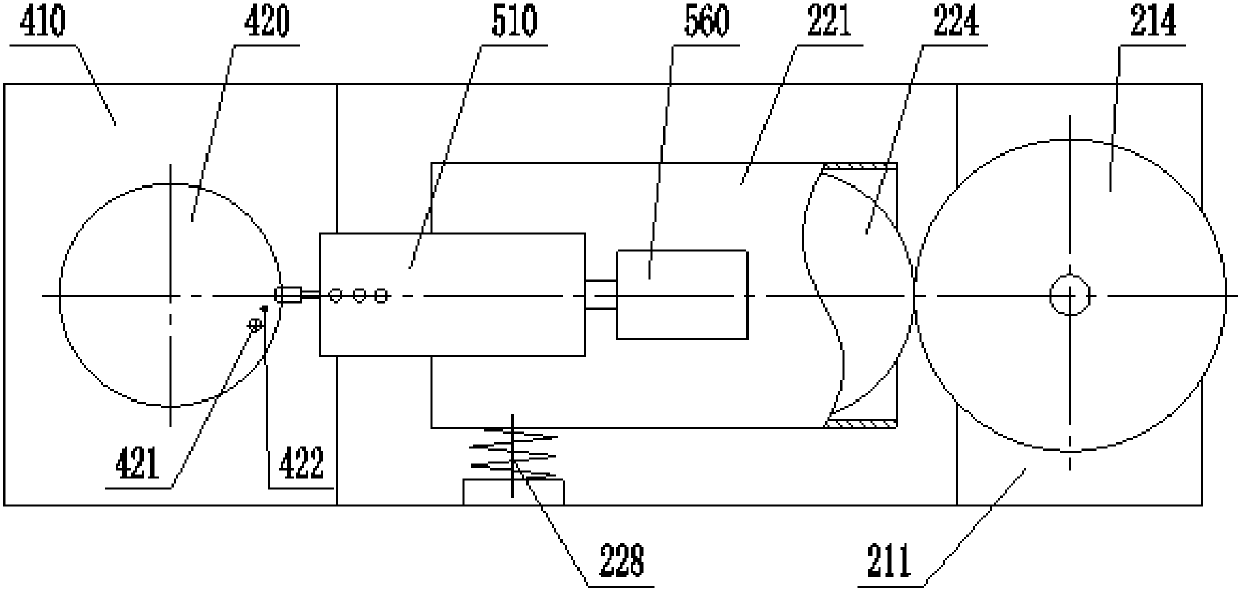

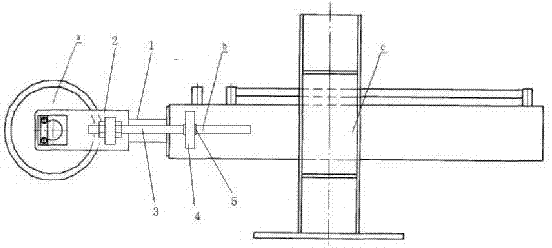

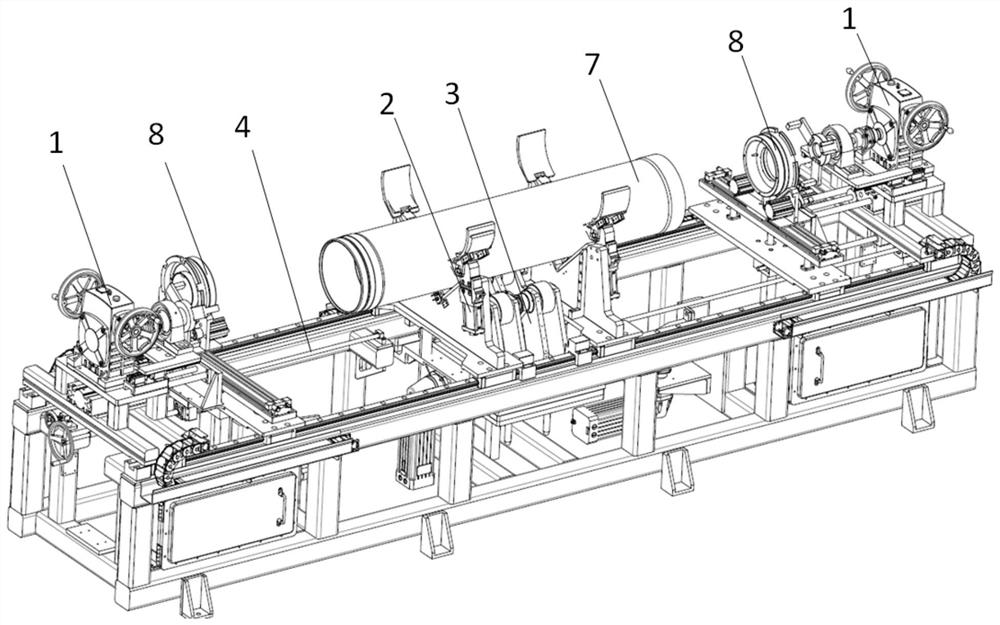

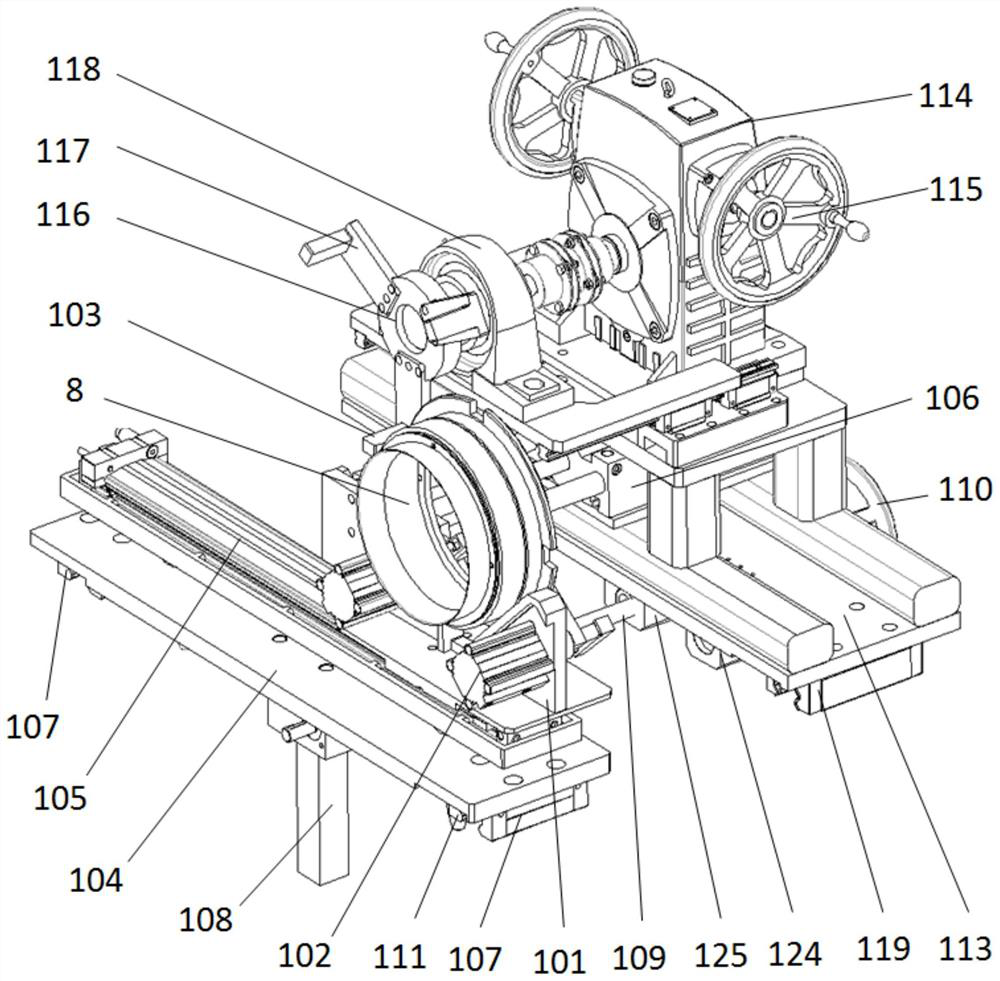

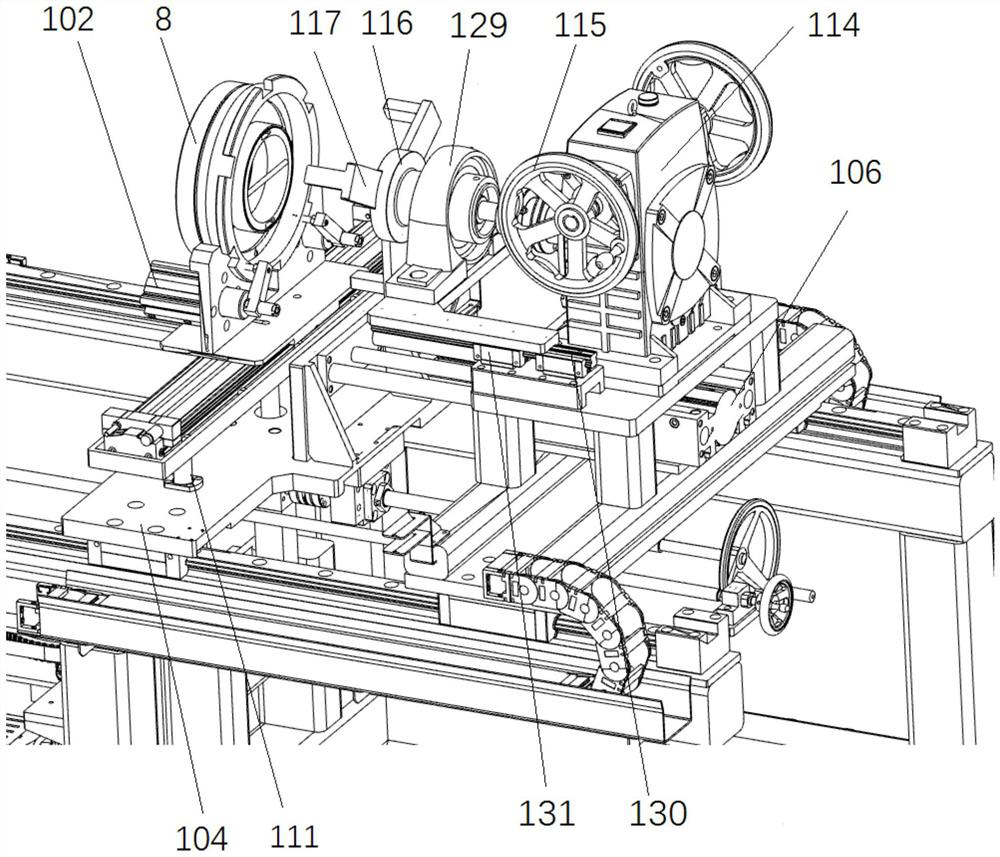

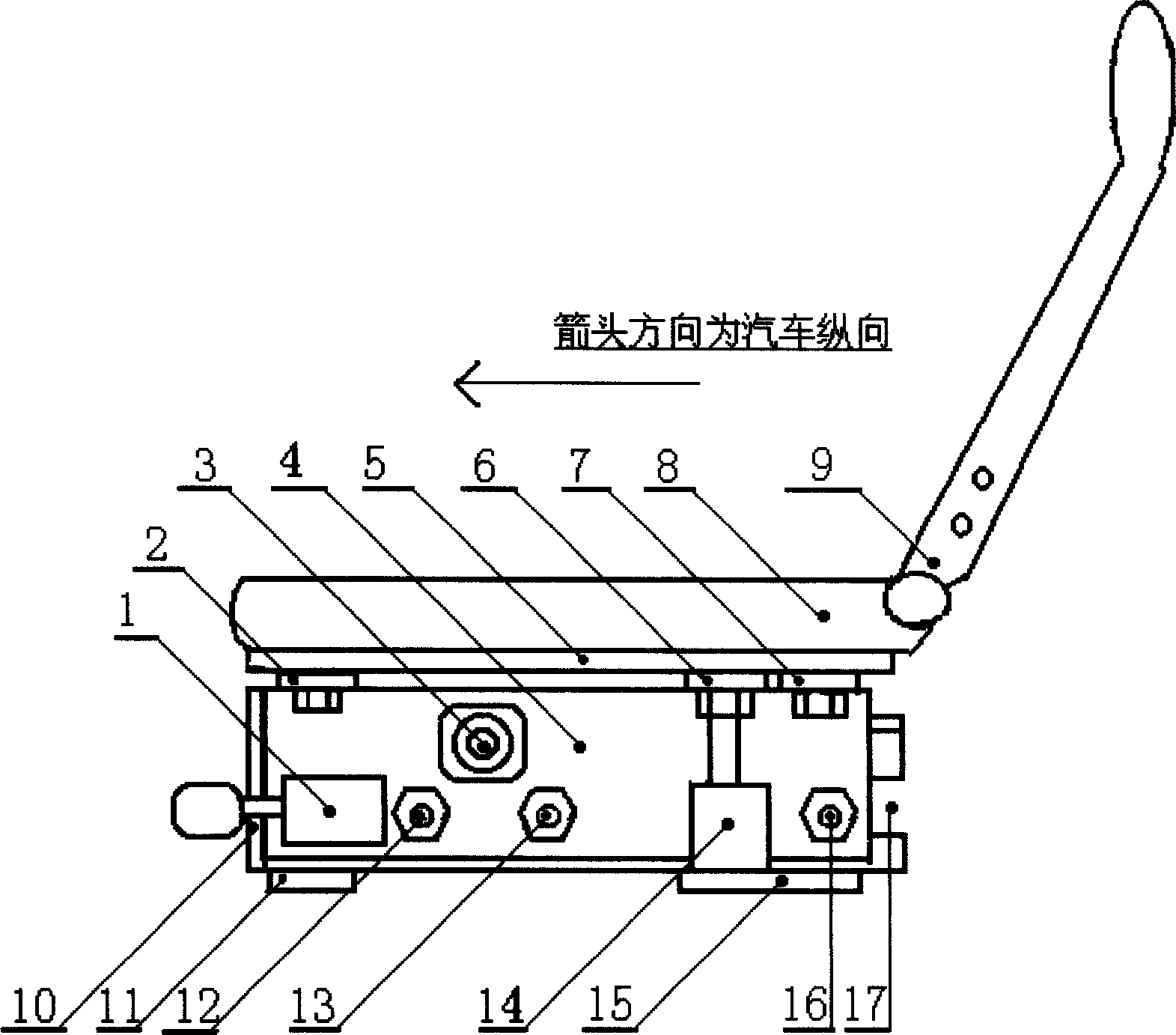

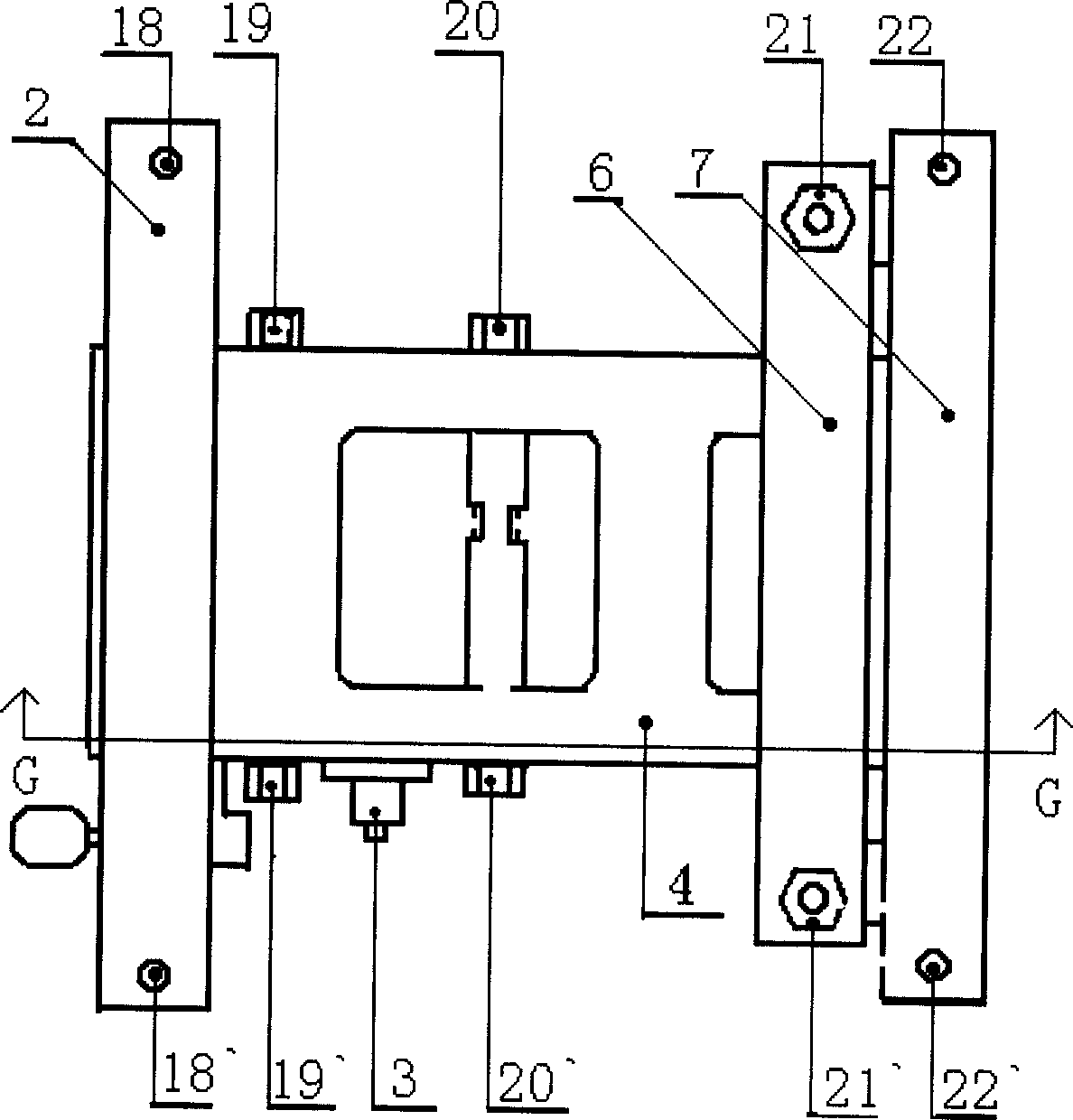

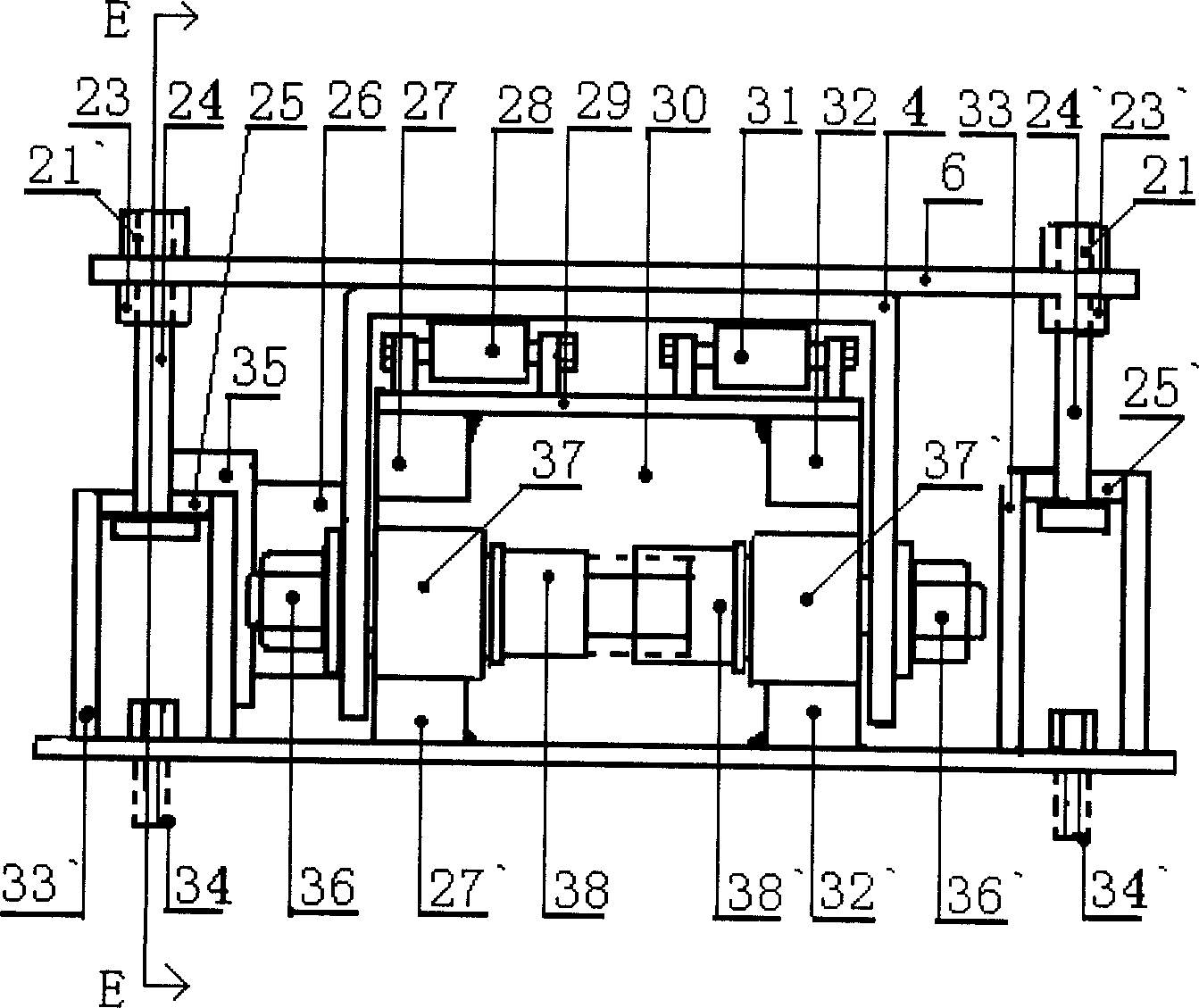

Equipment for installing and disassembling large-diameter non-standard threads

ActiveCN111775113ARealize assembly and disassemblyRealize automatic tighteningMetal-working hand toolsScrew threadPressure pipe

The invention provides equipment for installing and disassembling large-diameter non-standard threads. By means of the equipment, the problems existing in installing of existing thread tools that production efficiency is low, larger operation space is needed and tool threads are extremely easy to damage are solved. The equipment for installing and disassembling the large-diameter non-standard threads comprises a supporting device, an automatic clamping device, a jacking rolling device, a manual tightening device and an automatic tightening device. The automatic tightening device is arranged onthe right side of the supporting device and used for achieving automatic installing or disassembling of a first thread tool. The manual tightening device is arranged on the left side of the supporting device, capable of moving along the supporting device and used for achieving manual installing or disassembling of a second thread tool. The automatic clamping device is arranged on the supporting device, located between the manual tightening device and the automatic tightening device, capable of moving on the supporting device and used for achieving clamping of a pressure pipe. The jacking rolling device is arranged on the supporting device, located between the manual tightening device and the automatic tightening device and used for achieving jacking and rolling of the pressure pipe.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

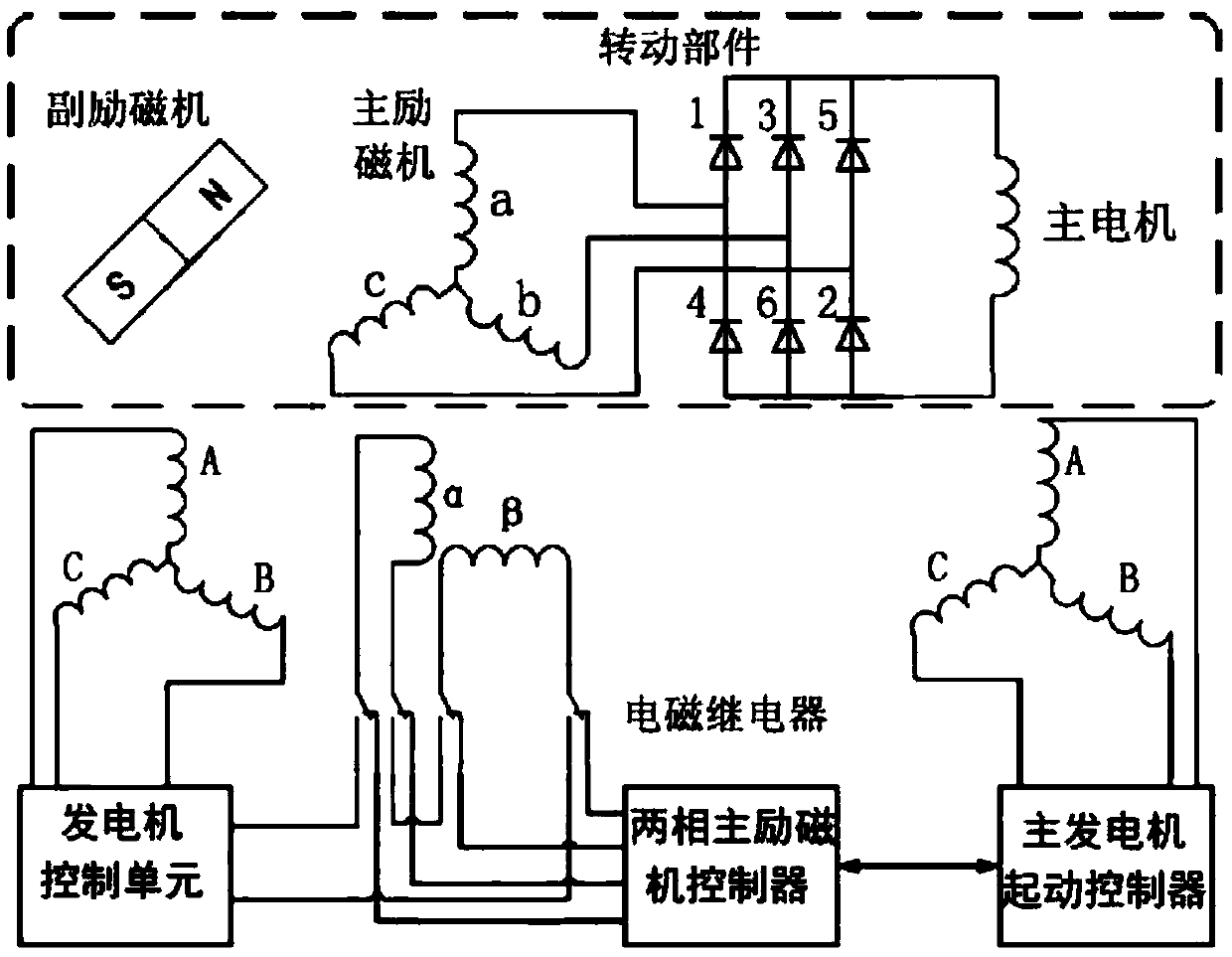

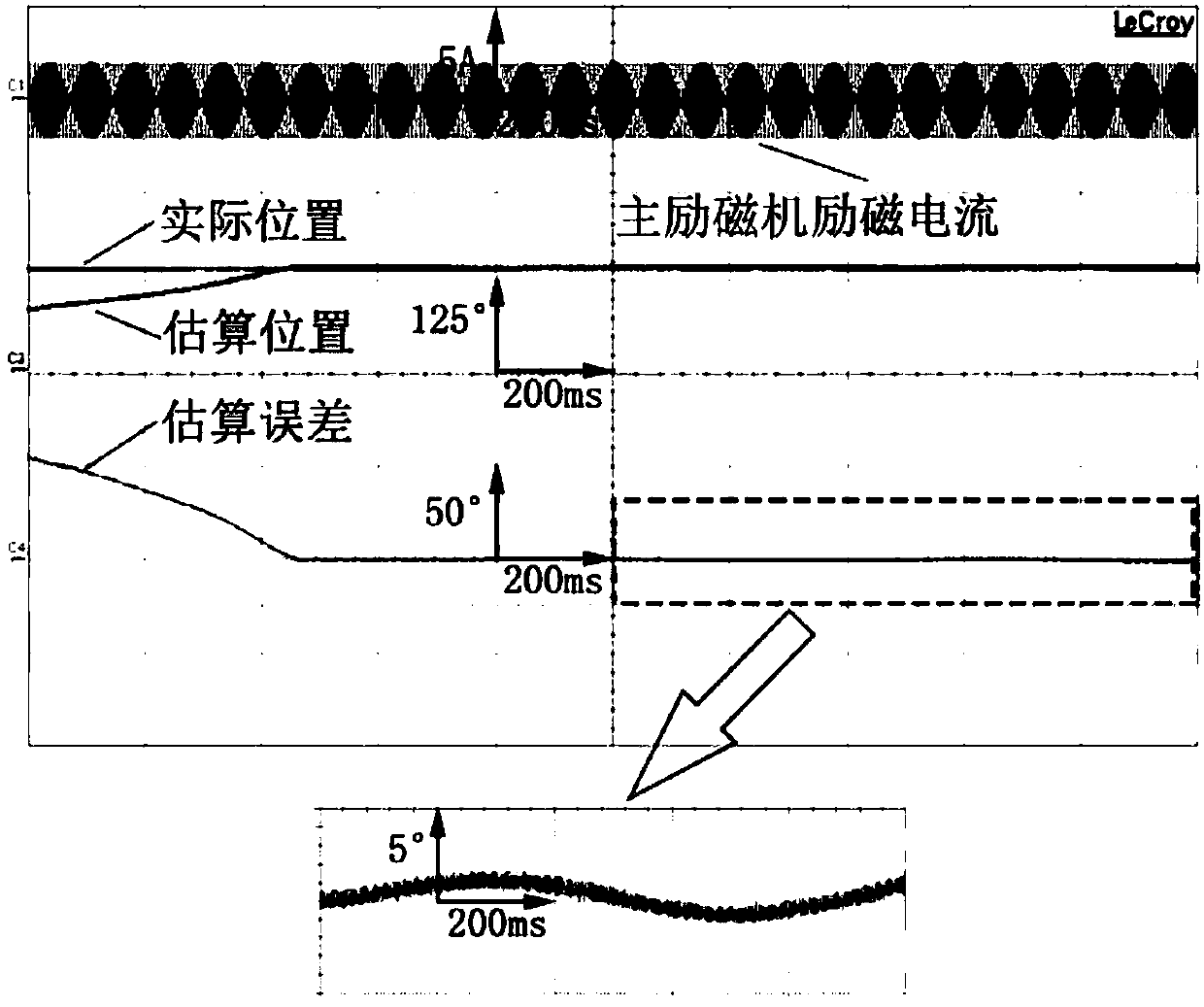

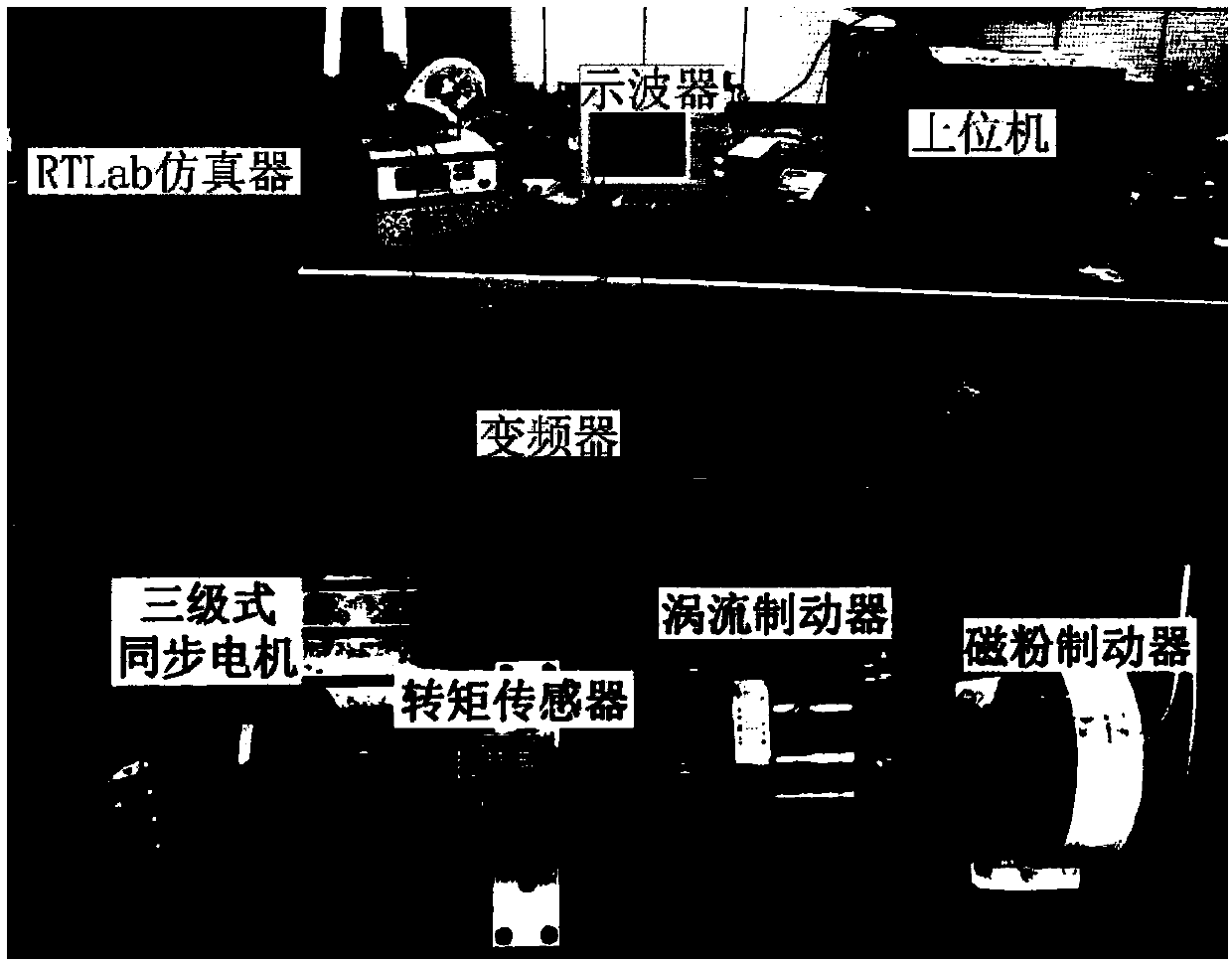

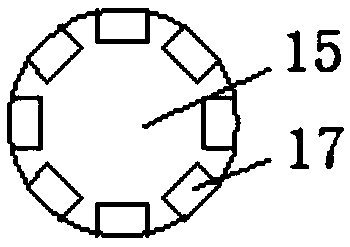

Method for detecting initial position of rotor of three-stage synchronous motor

InactiveCN108039842AHigh-precision detectionSimple hardware structureVector control systemsDynamo-electric converter controlLocation detectionHardware structure

The invention relates to a method for detecting an initial position of a rotor of a three-stage synchronous motor. The method comprises the following steps: injecting a rotary high-frequency voltage signal into a main motor stator side, detecting a high-frequency current response signal on a main exciter stator side, and performing filtering, Park transformation, arc tangent and other processing on a current signal, thereby obtaining the initial position of the rotor. Experimental results show that the method has the advantages that the initial position of the rotor can be rapidly and accurately detected, the rotor does not rotate, parameters of the motor do not need to be known, the hardware structure is simple, and the detection accuracy of the initial position of the rotor can meet thestationary start requirements of the three-stage synchronous motor.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

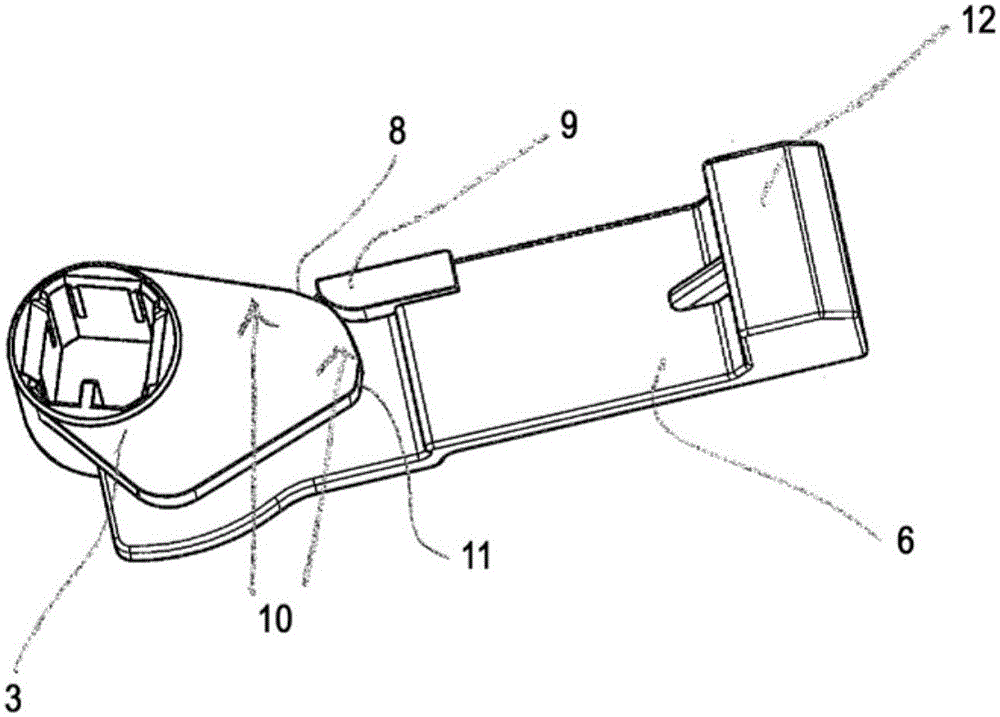

Locking device for a plug-in connection

InactiveCN105122558AEasy to moveAchieve interactionCoupling device detailsElectric propulsionEngineeringActuator

The invention relates to a locking device for a plug-in connection between a plug and a socket. According to the invention, an actuator (4) and a blocking slide (6) are provided, wherein the actuator (4) can be rotated about an axis of rotation, the blocking slide (6) can be moved between an unlocking position and a locking position in the longitudinal direction of the blocking slide, and the actuator (4) and the blocking slide (6) are designed in such a way and interact with each other in such a way that a rotation of the actuator (4) is always accompanied by a longitudinal movement of the blocking slide (6) and vice versa, wherein a longitudinal movement of the blocking slide (6) by means of a rotation of the actuator (4) is always possible, while conversely a rotation of the actuator (4) by means of a longitudinal movement of the blocking slide (6) is possible only outside of the locking position. Thus, simple and economical axial locking that cannot be manipulated is enabled.

Owner:菲尼克斯电子有限公司

Gas shielded welding device with in-pipe charging device

InactiveCN101486125BEasy to useGuarantee welding qualityWelding accessoriesSemi automaticEngineering

The invention discloses a gas shielded welding device with an inflatable device in a pipe, comprising: a locking device with a chuck for clamping a pipe to be welded; a driving mechanism for driving the chuck to rotate; a An inflatable device for inflating shielding gas from the cavity of the pipe to be welded; and an inflatable tube communicated with the inflatable device in the pipe. The invention has the advantages of semi-automatic structure, relatively convenient operation and improved welding quality.

Owner:浙江天力久田管业有限公司

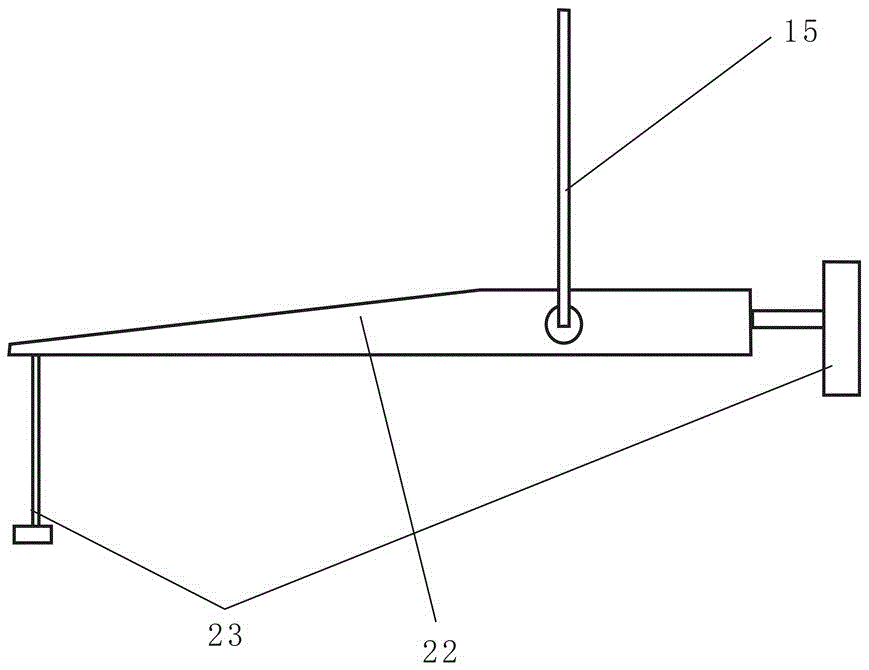

Small spray painting cloth unwinding mechanism and use method thereof

The invention relates to the technical field of glass reinforced plastic pipelines, and specifically discloses a small spray painting cloth unwinding mechanism and a use method thereof. The small spray painting cloth unwinding mechanism comprises an upper pressing wheel, a lower pressing wheel and a rotating shaft. The upper pressing wheel, the lower pressing wheel and the rotating shaft are connected to frame plates on the two sides in a rotating manner. An upper pressing plate is located above a lower pressing plate, and the upper pressing plate and the lower pressing plate are in close cooperation. A spray painting cloth roll is coaxially and fixedly arranged on the rotating shaft. A gear and a friction wheel are coaxially fixed to one end of the rotating shaft. A supporting rod is arranged between the lower pressing wheel and the rotating shaft. The upper end portion of the supporting rod is connected with a lever in a rotating manner. One end of the lever is connected with a balance weight roller in a rotating manner. Slide grooves are formed in the frame plates and correspond to the balance weight roller. A rotating shaft of the balance weight roller is located in the slide grooves and can slide. The other end of the lever is of a forked structure, a tooth block facing the gear is arranged on the end portion of the lower end of a fork, a groove hole is formed in the end portion of the upper end of the fork, and a friction block facing the friction wheel is arranged in the groove hole. By means of the small spray painting cloth unwinding mechanism and the use method, unwinding stability can be improved, and the unwinding speed can be automatically controlled.

Owner:温岭市锦绣机电有限公司

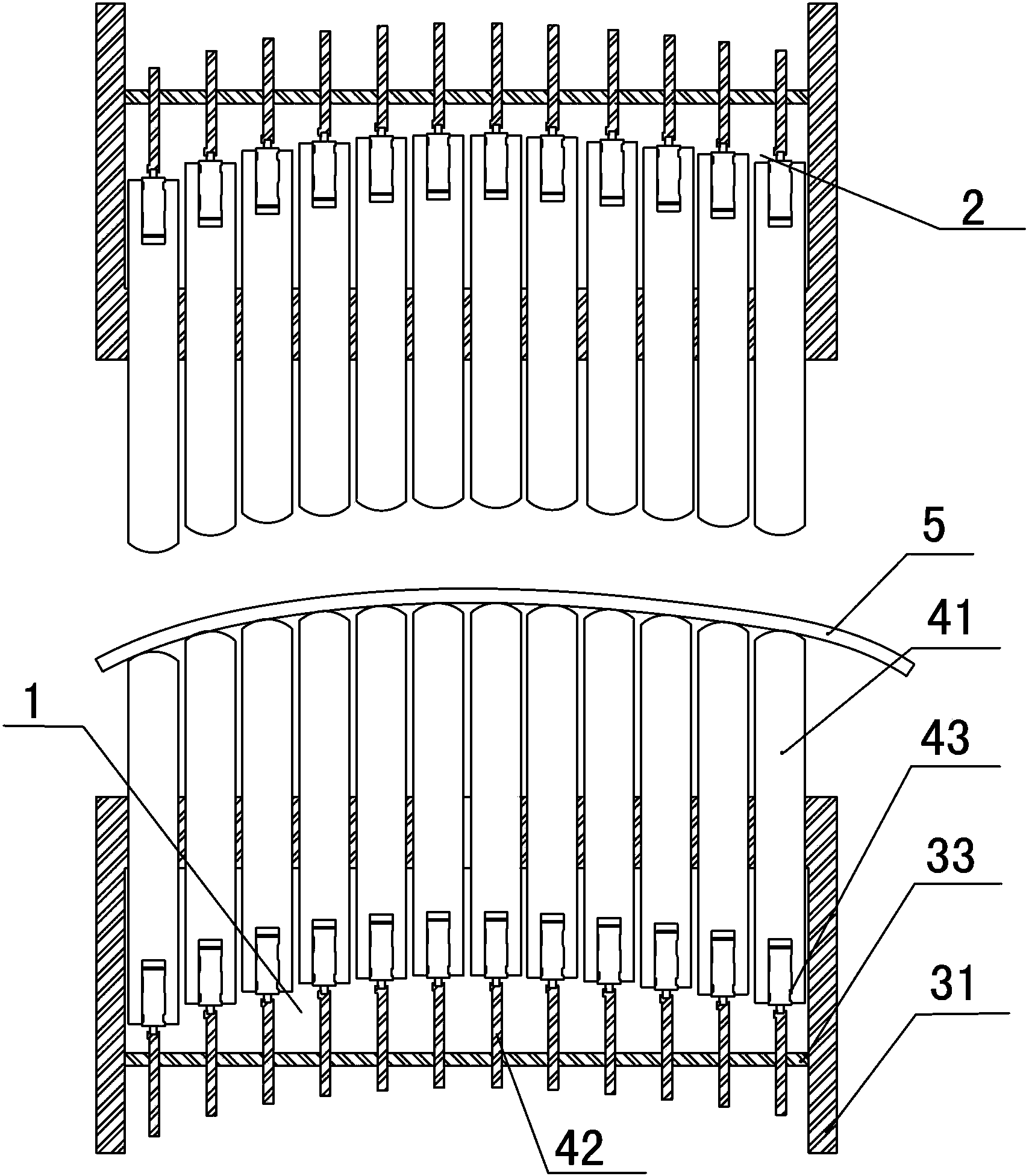

Arc edge grinding device

ActiveCN107855839AImprove consistencyIncrease arcOther manufacturing equipments/toolsEdge surfaceDrive shaft

The invention discloses an arc edge grinding device, and belongs to the field of cutter sharpening equipment. The arc edge grinding device comprises a base, a grinding wheel module, a worktable moduleand a swing mechanism; the swing mechanism is arranged on the base, is connected with the grinding wheel module, and is used for driving the grinding wheel module to perform the arc swing; the swingmechanism comprises a power module and a swing module; the swing module comprises a slide base arranged above the base, a swing base connected with the grinding wheel module, and a swing spring; a driven shaft is arranged on the slide base; the swing base is fixed on the driven shaft; one end of the swing spring is connected with the slide base, and the other end is connected to one side of the swing base; and the power module is used for driving the driven shaft to perform intermittent rotation. The device can finish grinding of an arc edge surface on one side of an arc blade through once clamping; the grinded edge surface is better in arc; and the edge angle consistency is better, so that the grinding efficiency and quality are greatly improved.

Owner:马鞍山市利成刀片制造厂

Fixture facilitating polishing of circular-arc-shaped part

InactiveCN108838882AEasy to polishShorten the timePolishing machinesGrinding work supportsEngineeringElectric drive

The invention discloses a fixture facilitating polishing of a circular-arc-shaped part. The fixture comprises a placement plate, wherein the upper surface of the placement plate is fixedly connected with the lower surface of a first support plate, the left side surface of the first support plate is fixedly connected with the right end of an electric drive pusher; the left end of the electric drivepusher is fixedly connected with the right side surface of a first connecting plate, the right side surface of the first connecting plate is fixedly connected with the left end of a sliding device, and the sliding device is clamped to the right side surface of the first support plate. According to the fixture facilitating polishing of the circular-arc-shaped part, under cooperation of the electric drive pusher, a sliding rod, a sliding sleeve, the first connecting plate and a first clamping plate, a handle is rotated, so that a second clamp plate and an arc-shaped workpiece are enabled to rotate, after the arc-shaped workpiece rotates to the appropriate position, the next surface of the arc-shaped workpiece can be polished, the arc-shaped workpiece is not required to be polished after being taken down for angle adjustment and fixation, time is saved, and work efficiency is guaranteed.

Owner:柳州市钜嘉机械有限公司

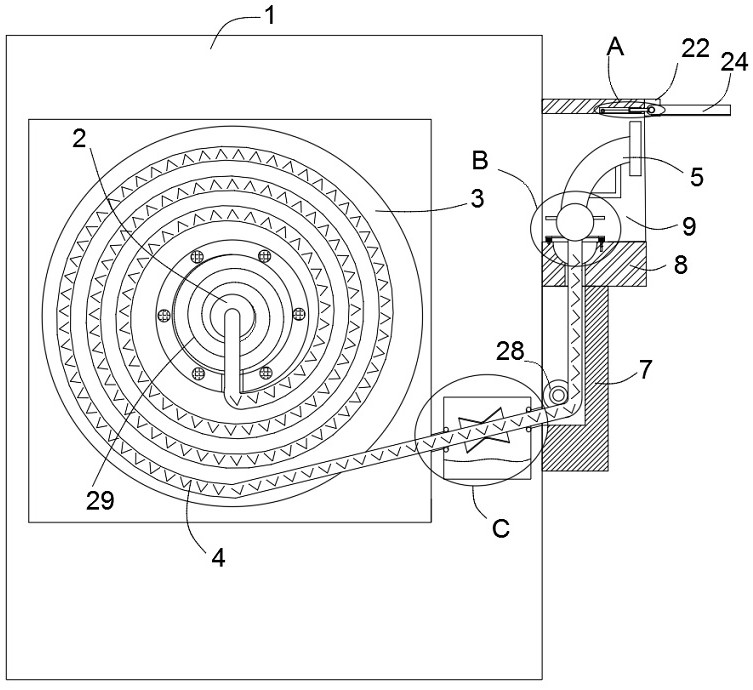

Mop dehydrator

The invention discloses a mop dehydrator which comprises a motor (23), a round table (10), a mop rod clamping device, a mop head clamping device and a mop head clamp driving device, wherein the mop head clamp driving device comprises a pressing block (9), a pressing lever (5), a ratchet wheel (7) and a pawl (4); one end of the pressing block (9) is connected with the mop head clamping device in a sliding manner in the vertical direction and buckled with the mop head clamping device in the horizontal direction; one end of the pressing lever (5) is compressed to the upper end surface of the pressing block (9); the round table (10) is a frustum of which the upper end is smaller than the lower end in diameter; an adjustment device for keeping the round table (10) in a horizontal state is also arranged between the round table (10) and a support base (22). Through adoption of the mop dehydrator, the operation noise is reduced greatly, and the mop can be better to be wrung out, so as to be more conducive to floor cleaning; in addition, the mop head clamping device is simple in structure and convenient to operate.

Owner:黄山市黄山区五丰源种养专业合作社

New energy automobile charging pile charging cable storage device

InactiveCN111731133ARealize storageEasy to useCharging stationsElectric vehicle charging technologyNew energyStructural engineering

The invention discloses a new energy automobile charging pile charging cable storage device which comprises a charging pile body, a storage cavity is formed in the charging pile body, a fixing shaft is fixedly connected to the inner side wall of the storage cavity, the fixing shaft is connected with an I-shaped storage cylinder through a force storage mechanism, a limiting mechanism is arranged onthe storage cylinder, a charging cable is wound around the storage cylinder, and a charging gun is arranged at the end of the charging cable. According to the invention, a spring device is arranged between the fixing shaft and the storage cylinder; an electromagnetic block is adopted to drive a limiting column to move into a limiting arc-shaped groove; it is ensured that the storage cylinder doesnot rotate during charging; the storage of the charged charging cable is realized; the charging cable can be cleaned through a cleaning ring arranged in a cleaning cavity while automatic storage is conducted; a protective cover is adopted, the protective cover automatically falls down through the gravity of the cable on a charging gun after the cable is collected, the end of the charging gun is protected, and the situation that dust enters the charging gun and affects charging is avoided.

Owner:陈剑平

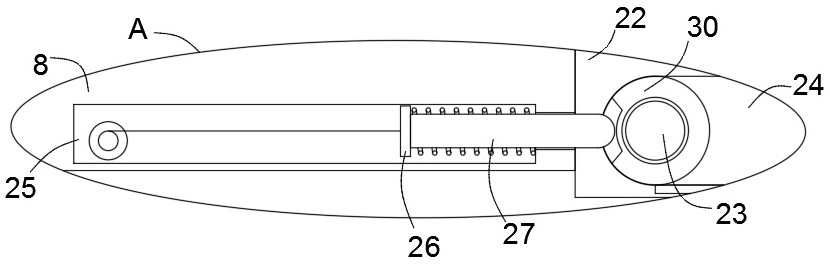

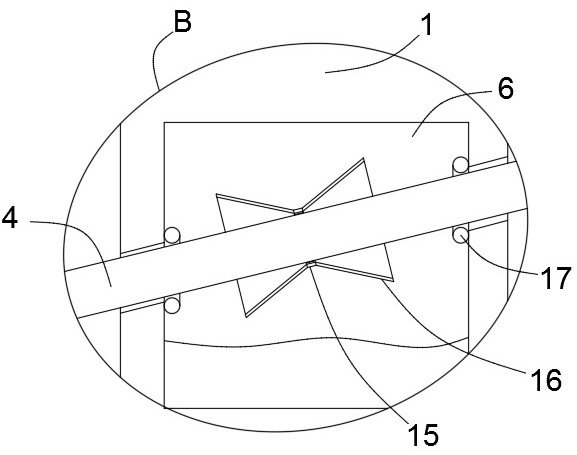

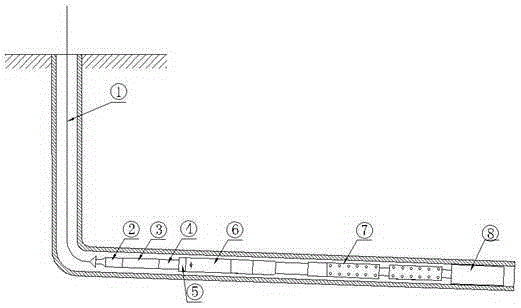

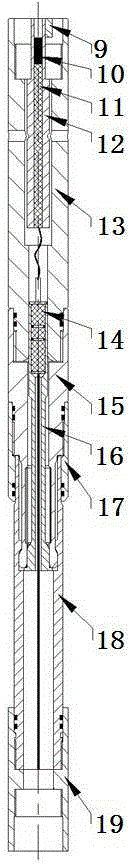

Cable transmission clustering perforation operation explosion jam release method

ActiveCN105201435ALow costOvercomes the need for dedicated ground powered equipmentBorehole/well accessoriesCable transmissionDetonator

The invention discloses a cable transmission clustering perforation operation explosion jam release method, comprising the following steps: a, connecting a fishing spear, an added weight, a magnetic locator, a crossover coupling, an electromechanical release device, a multi-level perforation gun string and a bridge plug tool in sequence, connecting a pipe string with a cable, and descending the pipe string in a well; b, if blockage occurs in a construction process, releasing the perforation gun string, sending an electric signal to an ignition selection block, and detonating a detonator and a detonating fuse in the electromechanical release device, so that a weak point on a weak point exploding rod is broken by exploding and well liquid enters an inner cavity of the electromechanical release device by a through hole in an exploding bypass,; pushing a piston to move downward, and withdrawing a claw end of an out-of-hand elastic claw, so that a release sleeve is released together with the perforation gun string under the action of the self gravity of the pipe string or the tensile force of the external cable, and jam release is realized. The weak point tensile force of the cable can be increased, the weight of the cable and a tool string in the well is enabled ensured not to be less than wellhead pressure load in case of jam lease, and the safety of the cable is ensured.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Screw rod shear

InactiveCN103846493AWon't turnImprove aestheticsPortable handheld shearing machinesShearing machine accessoriesEngineeringTorsion spring

The invention discloses a screw rod shear. A screw rod shorn by the screw rod shear has flat and sloth section. The screw rod shear comprises a base, a fixed cutter fixed on the base, a movable cutter rotationally arranged on the fixed cutter and matched with the fixed cutter, an upper pipe hinged to the base, and a lower pipe fixed on the base; the upper pipe is provided with a waists-shaped hole; a connection plate is connected to one side of the movable cutter and is provided with a guide pin; the guide pin is positioned in the waist-shaped hole in the upper pipe; the fixed cutter is provided with a fixed shearing edge for containing the screw rod; the movable cutter is provided with a movable shearing edge for containing the screw rod and matched with the fixed hearing edge; a support hook is hinged to the base by a torsion spring. The fixed cutter is positioned between the movable cutter and the support hook; the upper pipe is provided with a push block which is capable of pushing the support hook to rotate and can rotate a bending part of the support hook to be the straight line same as that of the movable shearing edge and the fixed shearing edge. The screw rod shear has the advantages that the screw rod is not influenced by the shearing torsion during to rotate during shearing, so the smoothness and flatness of the section of the screw rod are ensured and the attraction and use of the screw rod are improved.

Owner:ZHANGJIAGANG TIANDA TOOLS

Support steel pipe for scaffolding or timbering

InactiveCN104487637AHigh strengthEnsure safetyScaffold connectionsRod connectionsUltimate tensile strengthSteel tube

The present invention provides prefabricated scaffolding and timbering that are easy to assemble and have sufficient strength and a high degree of safety. The present invention provides a support steel pipe having a horizontal member connection portion provided with a circular outer edge portion at the outer edges of receiving metal fittings each having a wedge hole in prefabricated scaffolding or timbering set up by coupling supports and horizontal members using wedges. The horizontal member connection portions are provided at regular intervals on the side surface of the support or the assembled support. A plurality of safety belt hooks can be hung to the circular outer edge portion, and safety belt hook hanging portions are provided at regular intervals in the support. Consequently, workers can each always hang the safety belt hook in the vicinity thereof not only while working but also while moving. Further, the circular outer edge portion also has a function of reinforcing the receiving metal fittings. Furthermore, the degree of safety is increased by the shapes of safety pins and wedge portions.

Owner:山根幸夫

Telescopic hydraulic cylinder capable of bearing rotary torque

InactiveCN107152431AAvoid bending deformationWon't turnConveyorsFluid-pressure actuatorsHydraulic cylinderBlock and tackle

The invention discloses a telescopic hydraulic cylinder capable of bearing rotational torque, which belongs to the field of telescopic belt conveyors. It includes a cylinder body fixed on the support, and a piston rod matched with the cylinder body; a connection mechanism is fixed at the end of the piston rod; a pulley block is installed on the connection mechanism; the front and rear sides of the connection mechanism are respectively fixed with A sliding rod; the sliding rod is arranged in parallel with the piston rod; a support plate is respectively fixed on the front and rear sides of the cylinder body; a through hole is opened on the support plate, and the sliding rod is slidably installed on the corresponding support in the board through hole. The two sliding rods of the present invention are used in combination with the piston rod of the hydraulic cylinder. When the object of the present invention has a rotational torque, the piston rod of the hydraulic cylinder will not rotate together with the object. In addition, due to the support effect of the two sliding rods, the piston rod of the hydraulic cylinder can bear a large radial force, preventing the piston rod of the hydraulic cylinder from bending and deforming, and realizing the function of transmitting a large force with a small hydraulic cylinder.

Owner:徐州昊圣机械制造有限公司

Vacuum cup assembly

The invention discloses a vacuum cup assembly which comprises a bottle body and further comprises a base and a bottle cap. A gravity descending device, a bottle cap descending device and a bottle cap screwing device are arranged on the base, the gravity descending device is connected with the bottle cap descending device and the bottle cap screwing device in a matched mode, and after the bottle body is placed on the gravity descending device, the gravity descending device can provide power for the bottle cap descending device and the bottle cap screwing device, the bottle cap is matched with the bottle cap descending device and the bottle cap screwing device at the same time, the bottle cap descending device can drive the bottle cap to slide up and down, and the bottle cap screwing device can drive the bottle cap to rotate. By means of the vacuum cup assembly, a screwed bottle can be opened and closed with a single hand, so that a person does not need to leave a steering wheel with two hands when driving, the driving safety is improved, and the bottle cap can be conveniently opened and closed by the person.

Owner:永康市康多机械科技有限公司

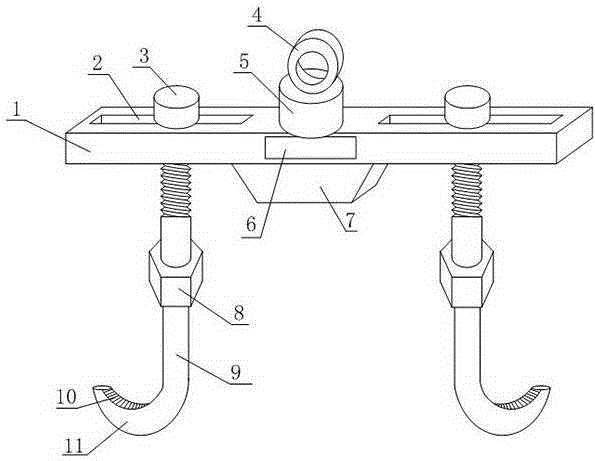

Safety hoisting tool for large-sized pump bodies applied to petroleum transportation

The invention discloses a safety hoisting tool for large-sized pump bodies applied to petroleum transportation. The safety hoisting tool comprises a balance plate and pothooks, wherein a weighting block is arranged at the upper end of the middle part of the balance plate; a hoisting ring is arranged at the upper end of the weighting block; the balance plate is provided with clamping notches at the two ends of the weighting block along the axial direction; the pothooks are arranged in the clamping notches of the two ends; each pothook comprises a fixture block clamped at the upper end of the clamping notch and a pothook rod connected to the fixture block and passing through the clamping notch; a locknut is sleeved on the pothook rod; a thread segment matched with the locknut is arranged at the upper end of the pothook rod; and pothook bodies are arranged at the lower ends of the pothook rods. The safety hoisting tool has the beneficial effects that the interval between the pothooks can be adjusted according to the pump bodies of different sizes, thereby meeting the hoisting of the pump bodies of different sizes, after hoisting, the pothooks are locked through the locknuts, do not shift and are safe for the pump bodies, and the safety hoisting tool is stable in structure on the whole during hoisting, does not cause the rotation of the pump bodies and is good in hoisting safety and stability.

Owner:黄霞

Jumping degree-adjustable bionic bouncing device

PendingCN108908367AGuaranteed stabilityEnhance jumping abilityProgramme-controlled manipulatorEngineeringCam

The invention relates to the technical field of robots. According to the technical scheme, a jumping degree-adjustable bionic bouncing device is characterized by comprising a machine frame, and further comprising a driving mechanism, a transmission mechanism, hind leg mechanisms, fore leg mechanisms and a controller which are mounted on the machine frame; two groups of the fore leg mechanisms andtwo groups of the hind leg mechanisms are symmetrically mounted on the machine frame; and the driving mechanism comprises a first small gear which is rotatably positioned on the machine frame and is driven by a stepping motor, a first big gear which is engaged with the first small gear and is coaxially fixed to a second small gear, a second big gear which is rotatably positioned on the machine frame and is coaxially fixed to a ratchet, a pawl which is hinged to the machine frame and is matched with the ratchet, a third small gear which is rotatably positioned on the machine frame and is fixedto a cam, and an L-shaped rod which is positioned on the machine frame in a swinging manner. The bouncing device can realize adjustable control over the jumping degree, and has the characteristics ofhigh jumping ability, the stable structure and convenience in control.

Owner:ZHEJIANG SCI-TECH UNIV

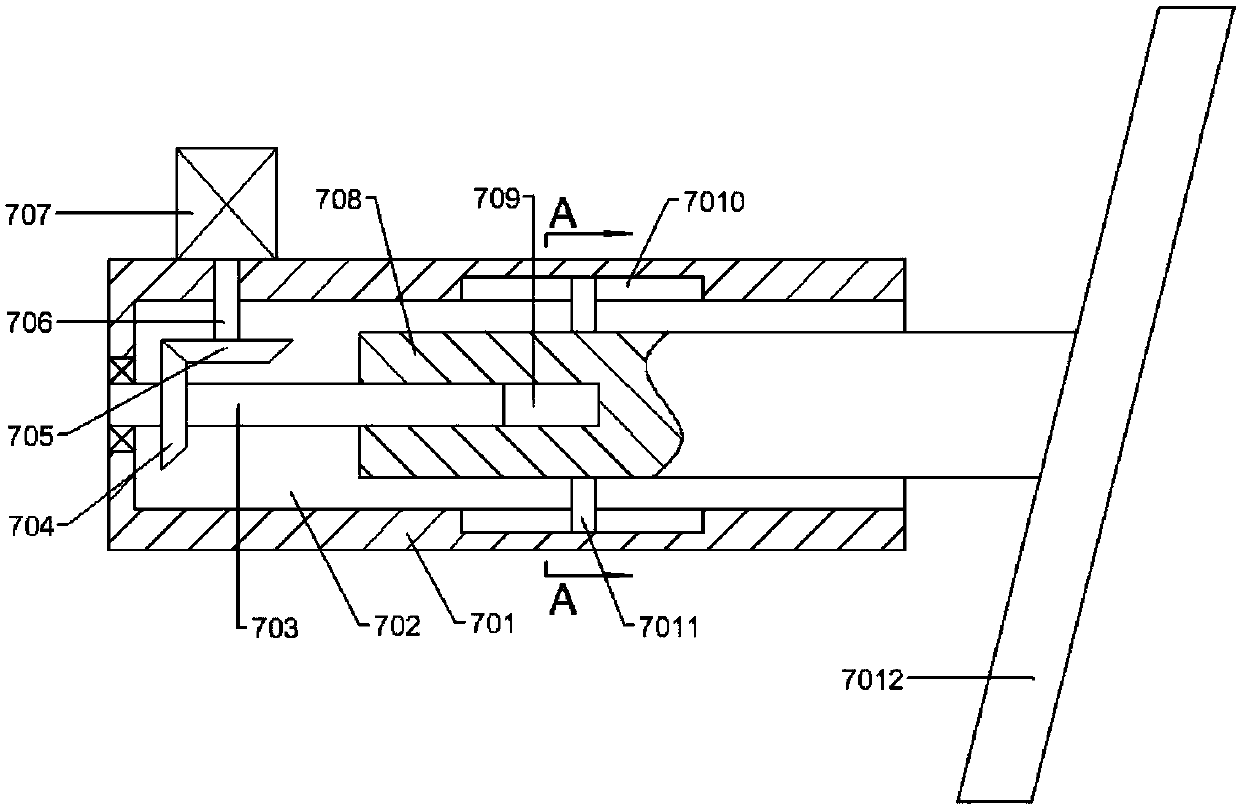

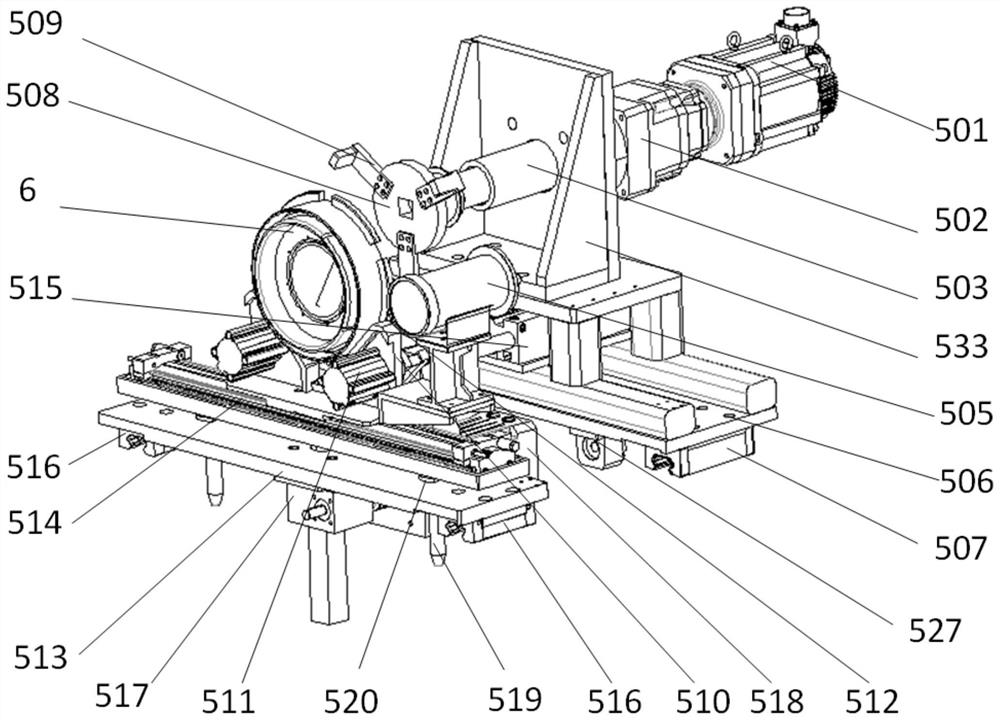

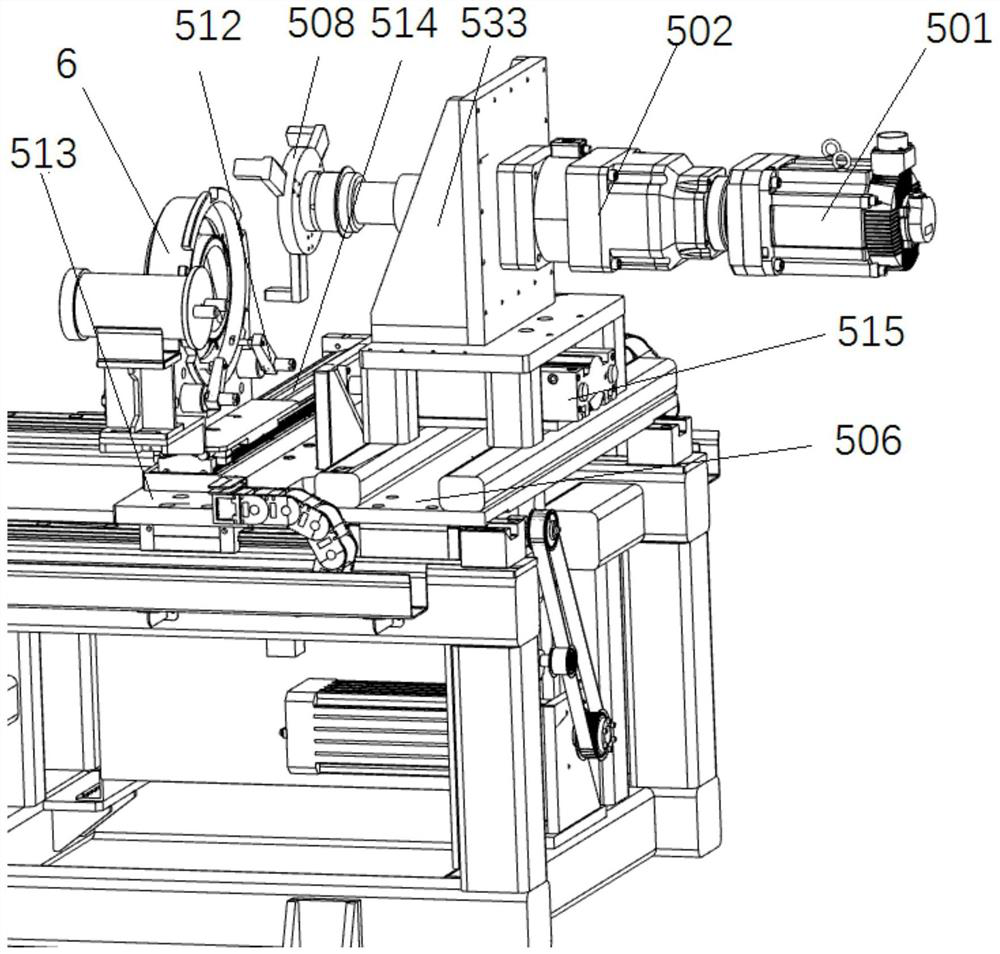

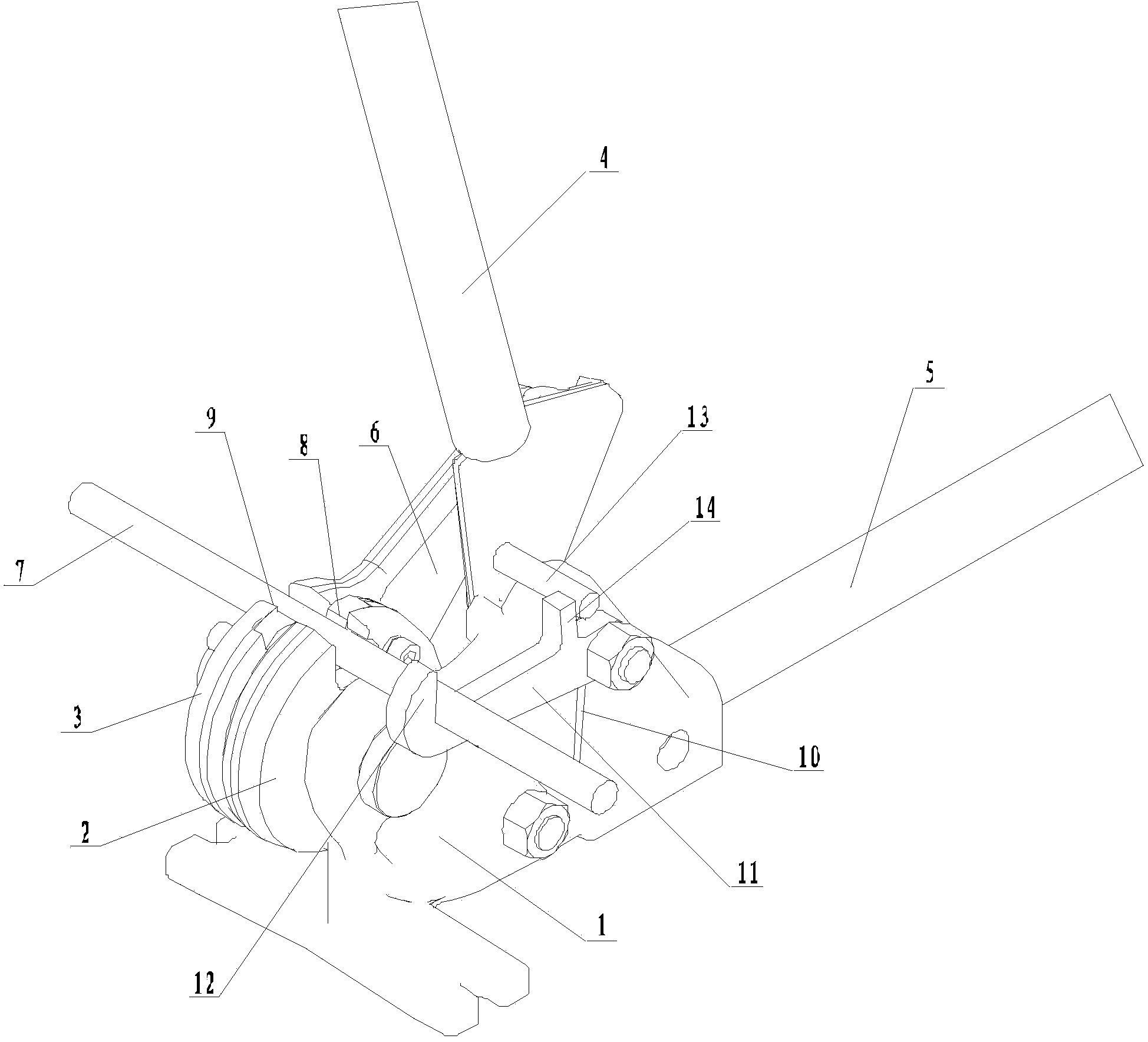

Manual tightening device and large-caliber non-standard threaded manual mounting and demounting equipment

ActiveCN111775112AAvoid damageReduce the number of workersMetal-working hand toolsRotational axisReduction drive

The invention provides a manual tightening device and large-caliber non-standard threaded manual mounting and demounting equipment. The problems that when an existing threaded tool is mounted, the production efficiency is low, a large operation space is needed, and threads of the tool are extremely likely to be damaged are solved. The manual tightening device comprises a threaded tool grabbing unit, a threaded tool adjusting unit, a manual tightening unit and a manual driving unit. The threaded tool grabbing unit comprises a tool V-shaped support, tool clamping cylinders and tool clamping arms. The tool V-shaped support is arranged on the threaded tool adjusting unit, and the threaded tool adjusting unit is used for achieving three-dimensional position adjustment of the tool V-shaped support. The two tool clamping cylinders are arranged on the two sides of the tool V-shaped support correspondingly, and rotary shafts of the tool clamping cylinders are connected with the tool clamping arm. The tool clamping arms are used for clamping the threaded tool. The manual tightening unit is used for achieving clamping of the threaded tool and comprises a tightening frame, a worm reducer, a rotary disc, a clamping finger, a tightening hand wheel and a follow-up assembly. The manual driving unit is used for driving the manual tightening unit to move front and back.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

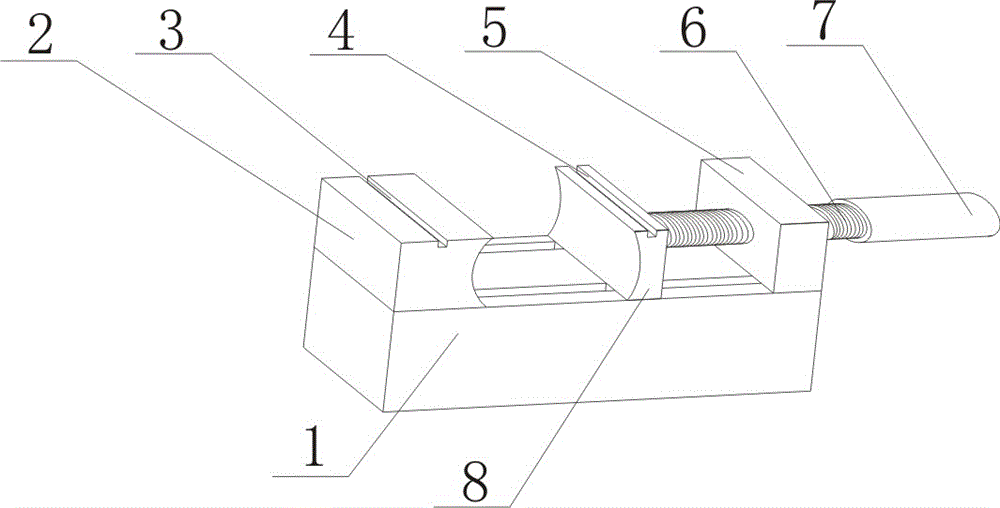

Supporting device for plastic pipe

The invention discloses a supporting device for a plastic pipe. The supporting device comprises a pedestal, a baffle, a clamping plate, a screw and a screw holder; one end of the upper surface of the pedestal is fixedly connected with the baffle; the other end of the upper surface of the pedestal is fixedly connected with the screw holder; the screw holder is provided with a threaded through hole; the screw is arranged inside the threaded through hole in the screw holder in a matched manner; one end of the screw is connected with the clamping plate; two sliders are arranged at the lower end face of the clamping plate; each slider is adaptively mounted in a corresponding sliding chute formed in the upper surface of the pedestal.

Owner:河南省汉盛新型材料科技有限公司

Special front row chair for small vehicle

The special front row chair for small vehicle has one control system to control the chair by means of the inertia force installed below the chair track, one bounce preventer operating in pressing in mode, and one movable frame with rollers mounted on the fixing frame comprising two parallel tracks on the floor and one energy absorber. In emergency, the energy absorber absorbs and converts the kinetic energy of the chair, the control system operates, the locked chair and the rider move backwards and the chair is locked with the bounce preventer to protect the ride.

Owner:刘熙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com