Cable transmission clustering perforation operation explosion jam release method

A cable conveying and clustering technology, applied in earth-moving drilling, wellbore/well components, etc., can solve problems such as unfavorable jam accidents, secondary engineering accidents, pipe string jams, etc., to reduce economic losses and applicability Strong, prevent cable curling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A cable-transported cluster perforation operation explosive release method, comprising the following steps:

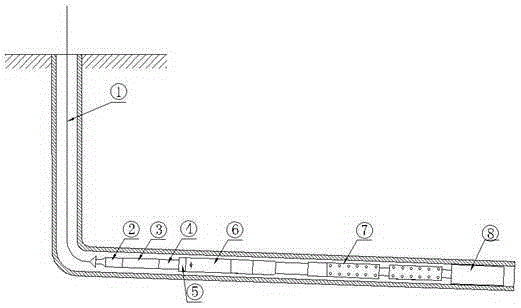

[0032] a. Connect the fishing head 2, the weight 3, the magnetic locator 4, the conversion joint 5, the electromechanical release device 6, the multi-stage perforating gun string 7 and the bridge plug tool 8 in sequence, and the connected pipe string is connected with the cable 1, go down the well;

[0033] b. If the perforating gun string needs to be discarded during the construction process, an electric signal is sent to the firing block 9 to detonate the detonator 10 and the detonating cord 11 in the electromechanical throwing device 6, so that the weak point on the weak point explosive rod 12 is blown off , the well fluid enters the inner cavity of the electromechanical throwing device 6 through the through hole on the explosion bypass 13, pushes the piston rod 16 to move downward, and recovers the claw end of the throwing claw 15, and the throwing sleeve 18...

Embodiment 2

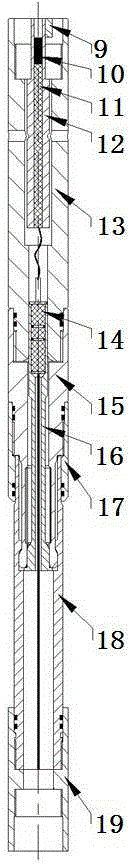

[0043] Such as figure 2 As shown, the assembly steps of the electromechanical throwing device in the present invention are as follows: 1) Connect one end of the throwing claw 15 to the explosion bypass 13, and the other end to the claw jacket 17; 2) Press one end of the throwing sleeve 18 3) Press the sealed wire column 14 into the piston rod 16, pull out the wires at both ends, and then press into the throwing sleeve 18 until it enters the inner cavity of the claw cover 17; 4) Connect with the first stage The relay sub-joint 19 connected with the perforating gun; 5) connect the selection block 9, the detonator 10 and the detonating cord 11, and then connect with the lead wire at one end of the sealed wire column 14, insert the weak point explosive rod 12, and finally install it as a whole into the side of the explosion Pass 13.

[0044] The specific implementation steps of the explosive release of jamming hands during cable conveying cluster perforating operations: 1) Conne...

Embodiment 3

[0046] The electromechanical device for throwing hands among the present invention comprises weak point explosive rod 12, explosion bypass 13, piston rod 16, insulating sealing plug, bullet claw 15, throwing gloves sleeve 18 and gun string connection joint.

[0047] Design ring-shaped weak points and through holes on the weak point explosive rod 12. The weak point explosive rod 12 has built-in pyrotechnics and wires. The rod 12 is placed inside the explosion bypass 13, and the weak point of the explosion rod 12 has the function of resisting pressure of 105MPa.

[0048] Explosion bypass 13 has 4 through holes in the annular design, and the position of the annular weak point is exactly the same as that of the through holes. One end of the female button is connected to the ignition head; the insulating sealing plug has the function of insulating the movable piston rod 16, and can realize normal power supply and signal transmission. Be installed on movable piston rod 16 upper ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com