Patents

Literature

56 results about "Release date" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

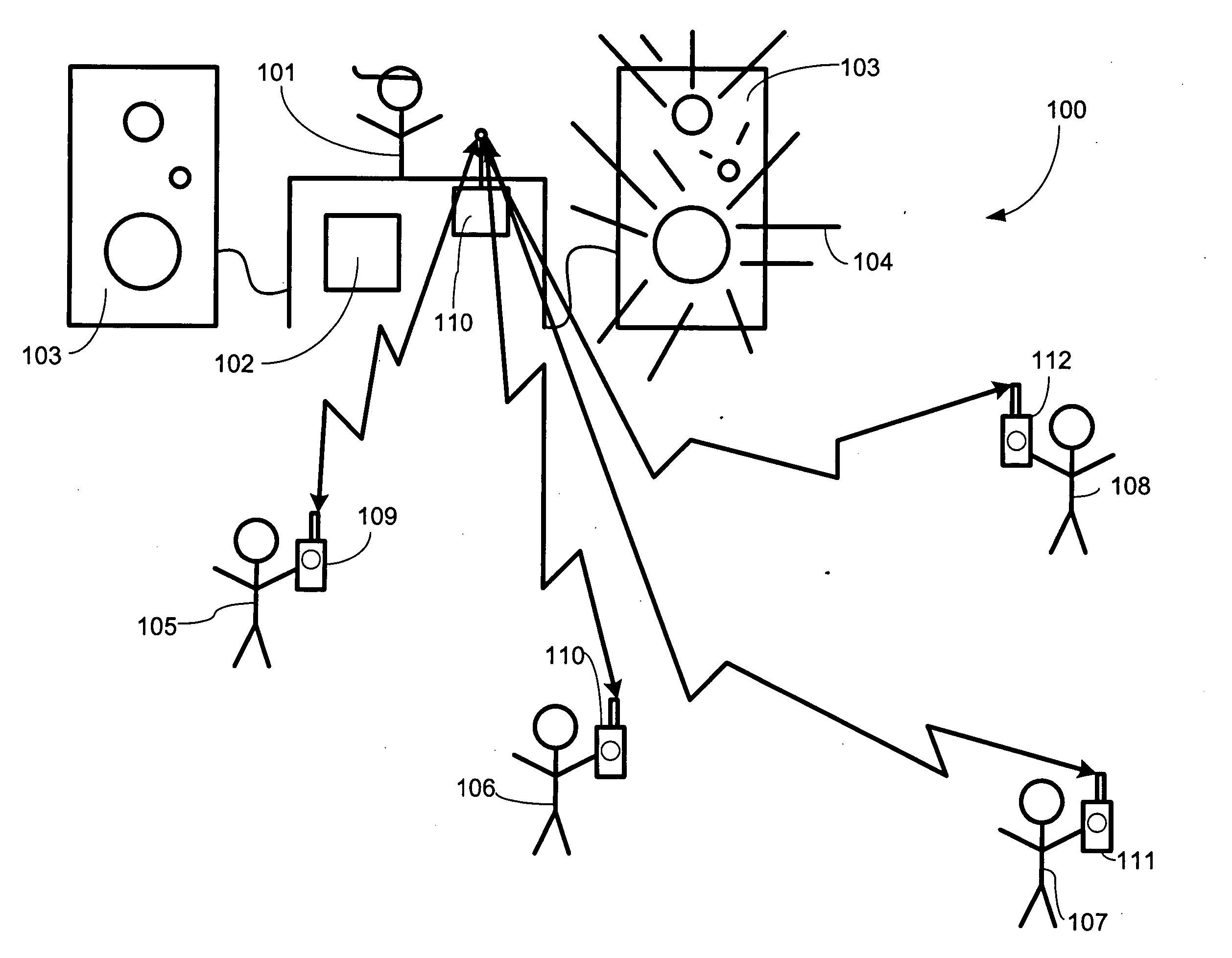

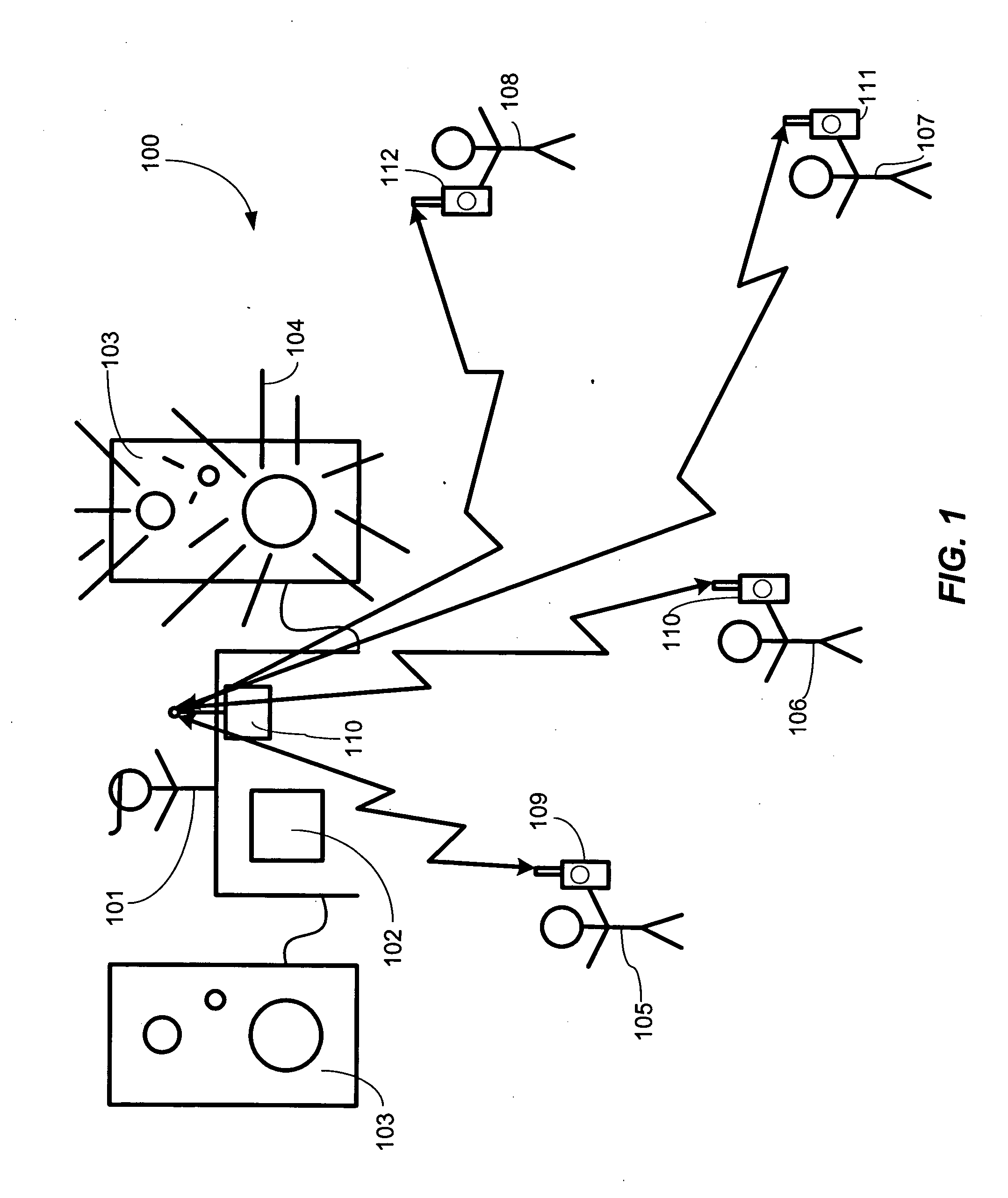

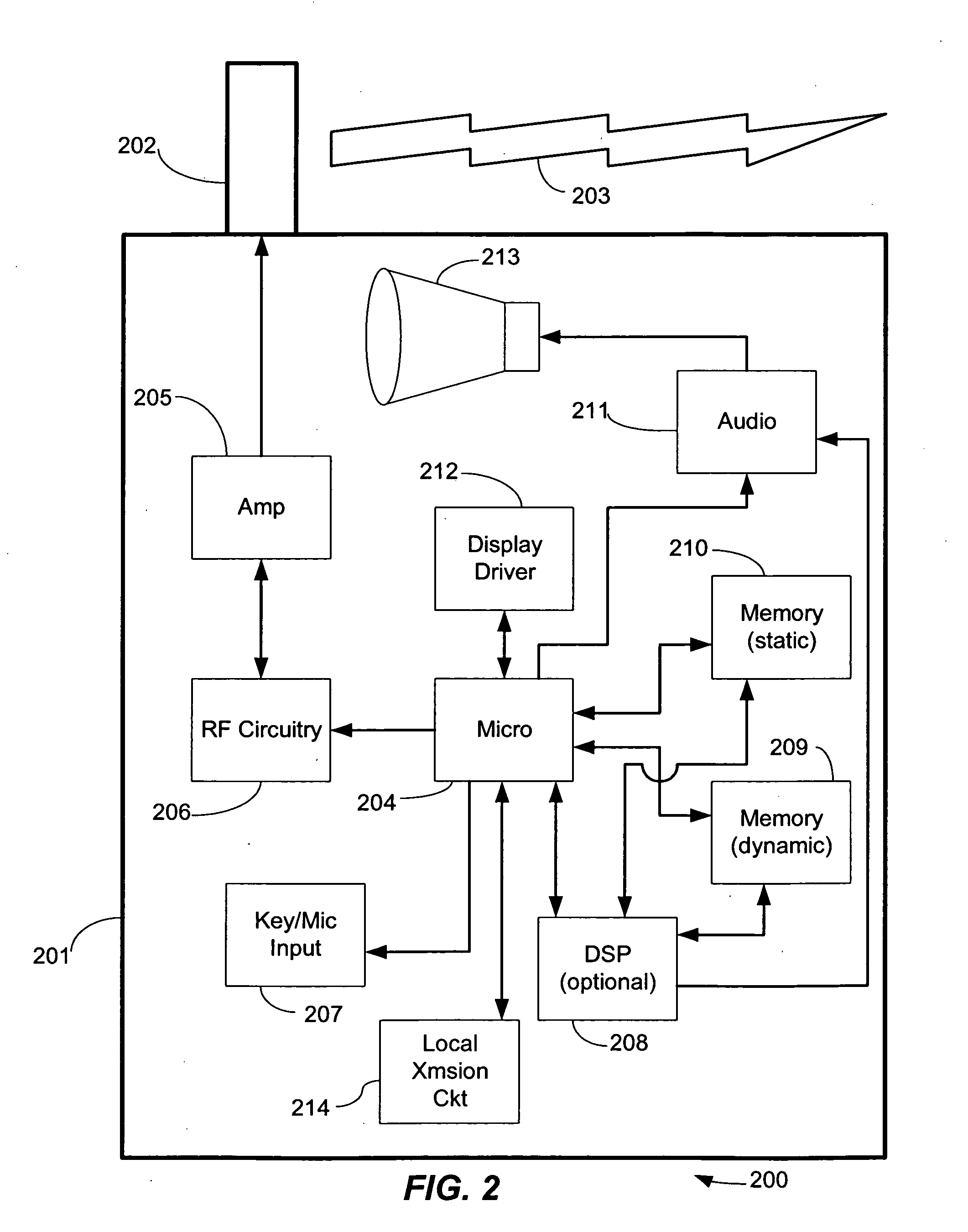

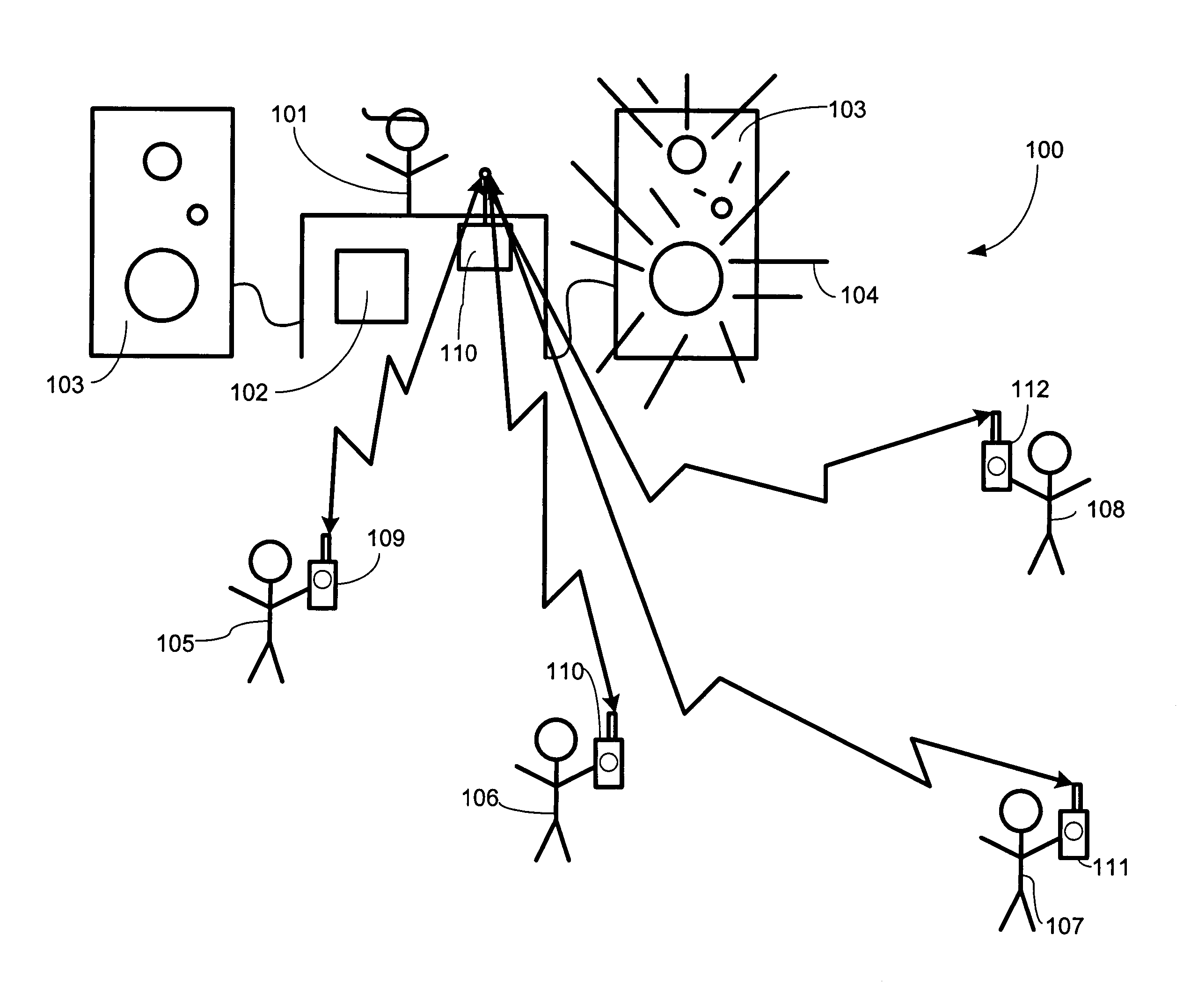

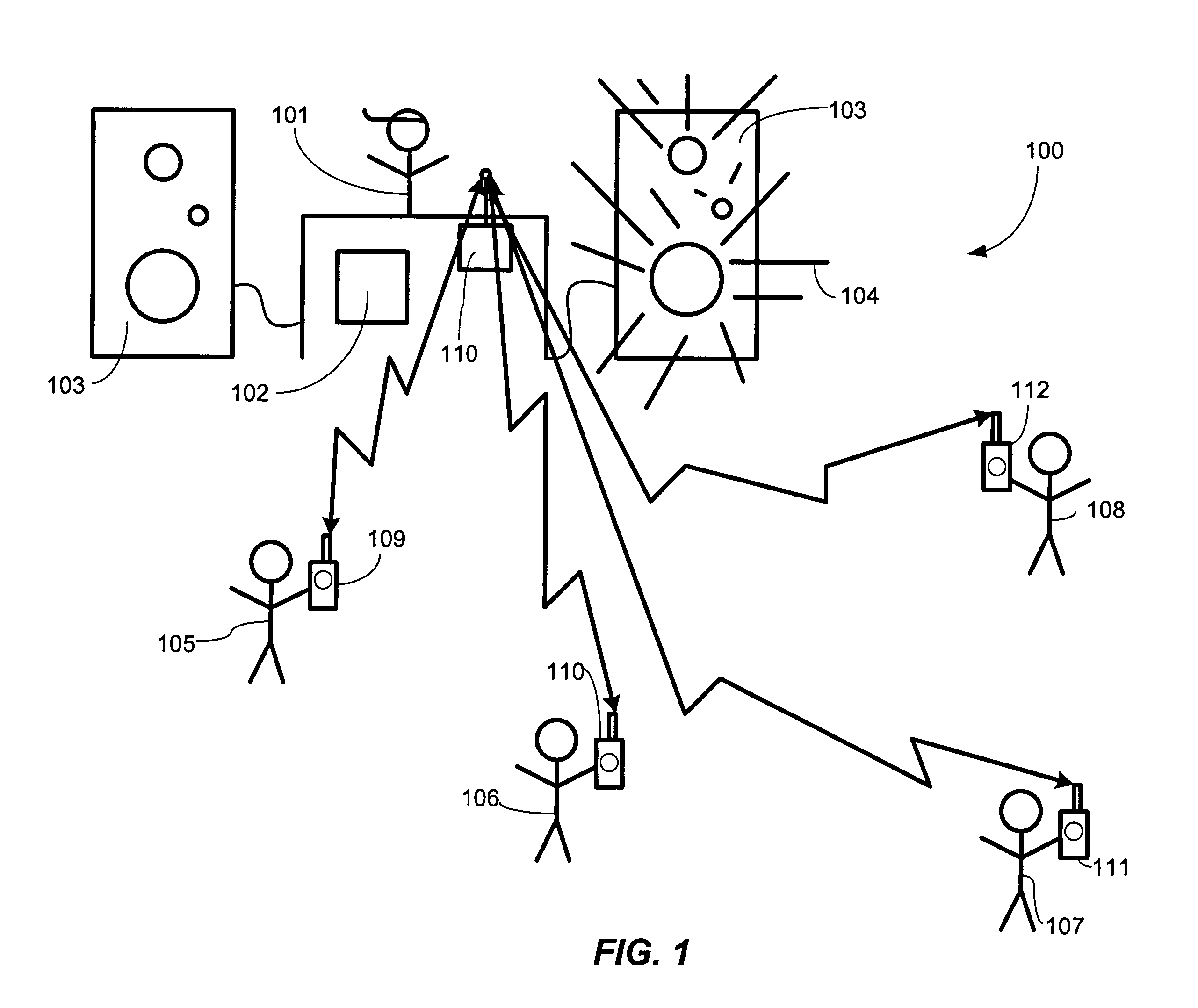

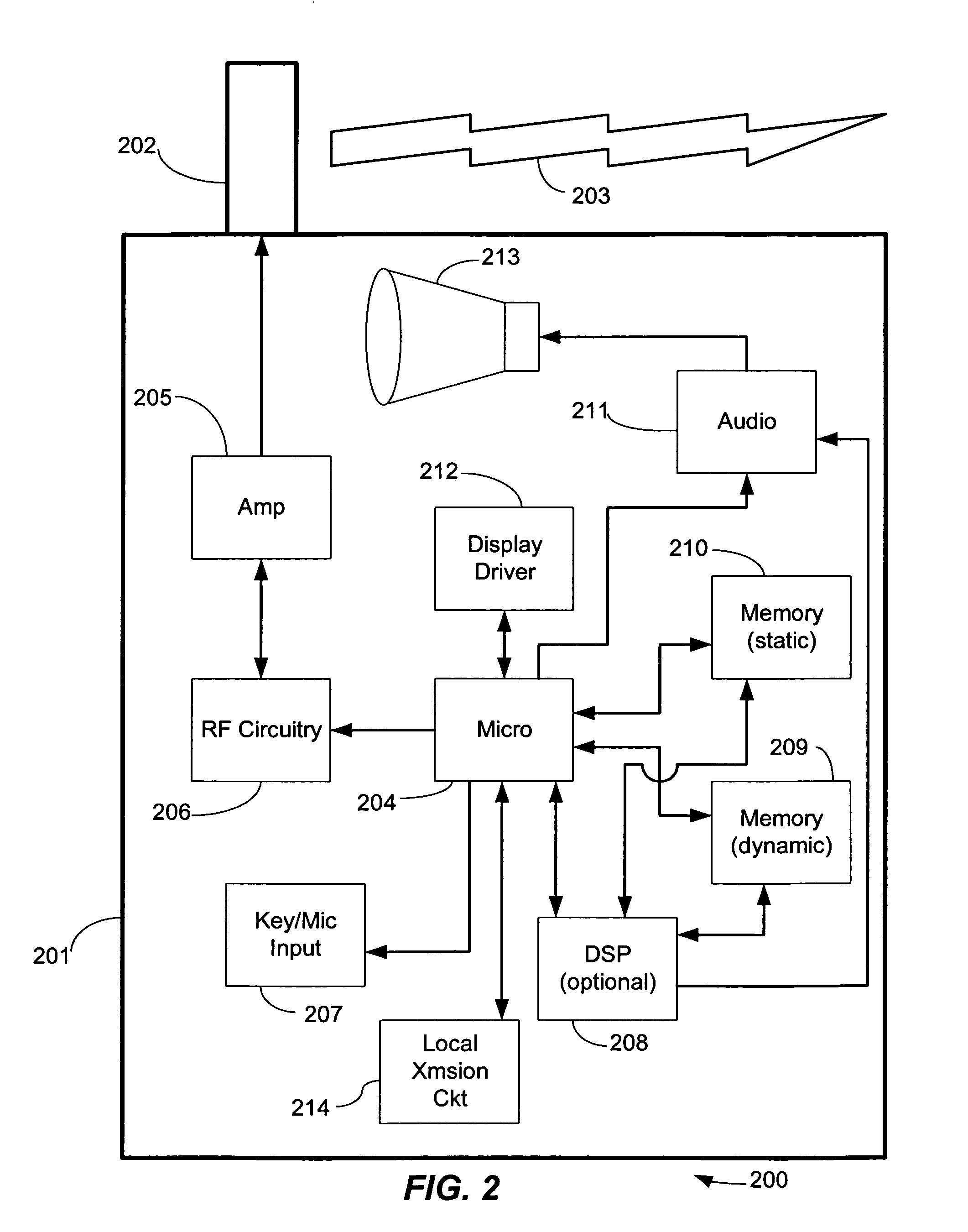

Local area preference determination system and method

A preference determination system allows a music provider, like a band or disc jockey, to determine the musical preferences of the members at a gathering. As many members of a gathering use electronic devices, like cellular telephones, that include music and video players, these devices include a corresponding play list that includes information about the music or video. When at a gathering the music provider, for example, interrogates the devices of the members of the group and uploads their respective play lists. The music provider then compiles information about the music into a data compilation. The information may include artist, song title, release date, genre, etc. The music provider then sorts the data compilation to select information that is popular to a significant number of members in the group. The music provider then selects and plays music to the group consistent with the selected information. For example, if 50 people are at a gathering, and 30 have digital music by the Tom Waits on their devices, the music provider may decide to play “Innocent When You Dream” for the group.

Owner:GOOGLE TECH HLDG LLC

Local area preference determination system and method

Owner:GOOGLE TECHNOLOGY HOLDINGS LLC

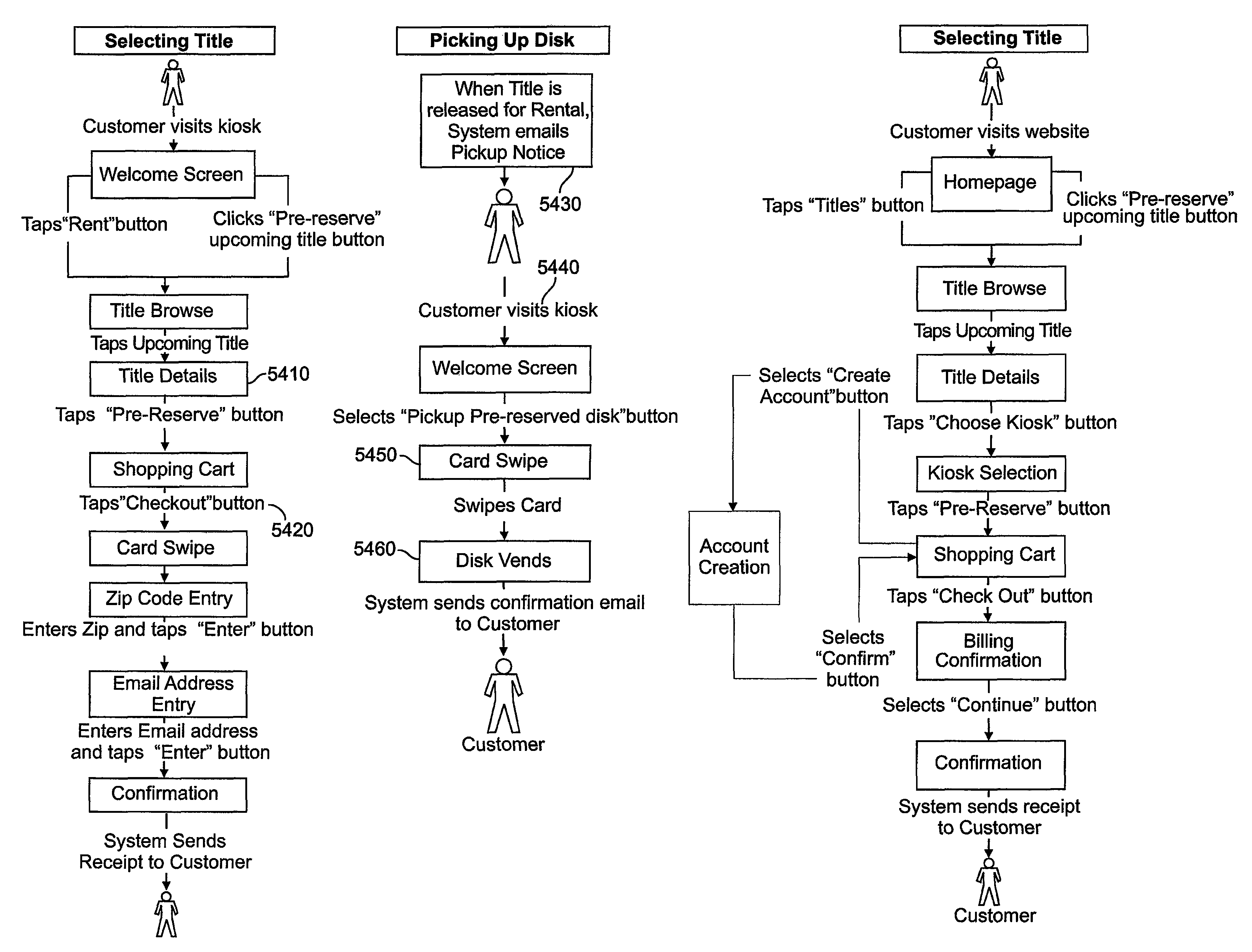

System and method for communicating secondary vending options

ActiveUS20100057871A1Reduce expensesShorten the timeCoin-freed apparatus detailsMultiple digital computer combinationsDigital videoEmail address

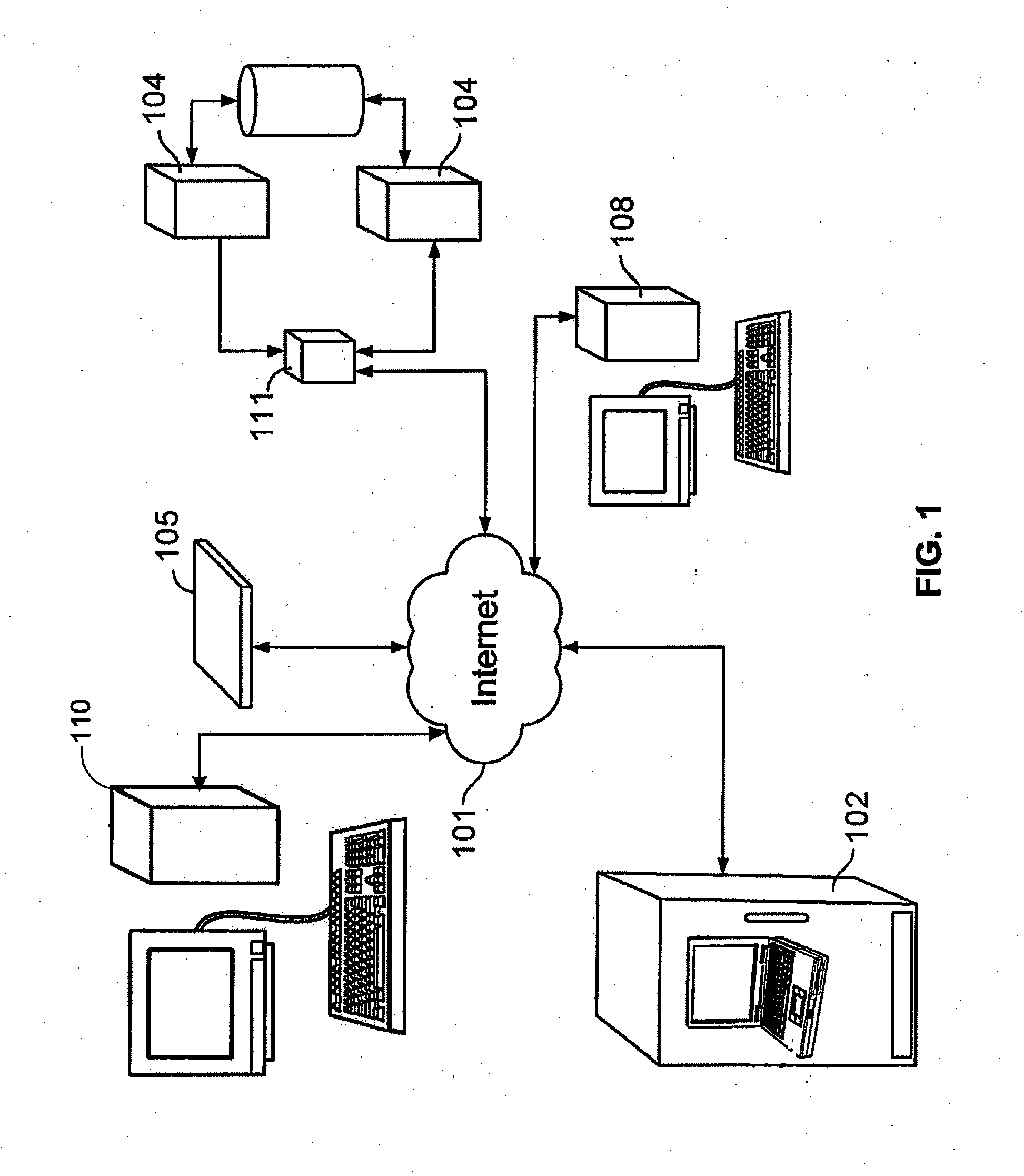

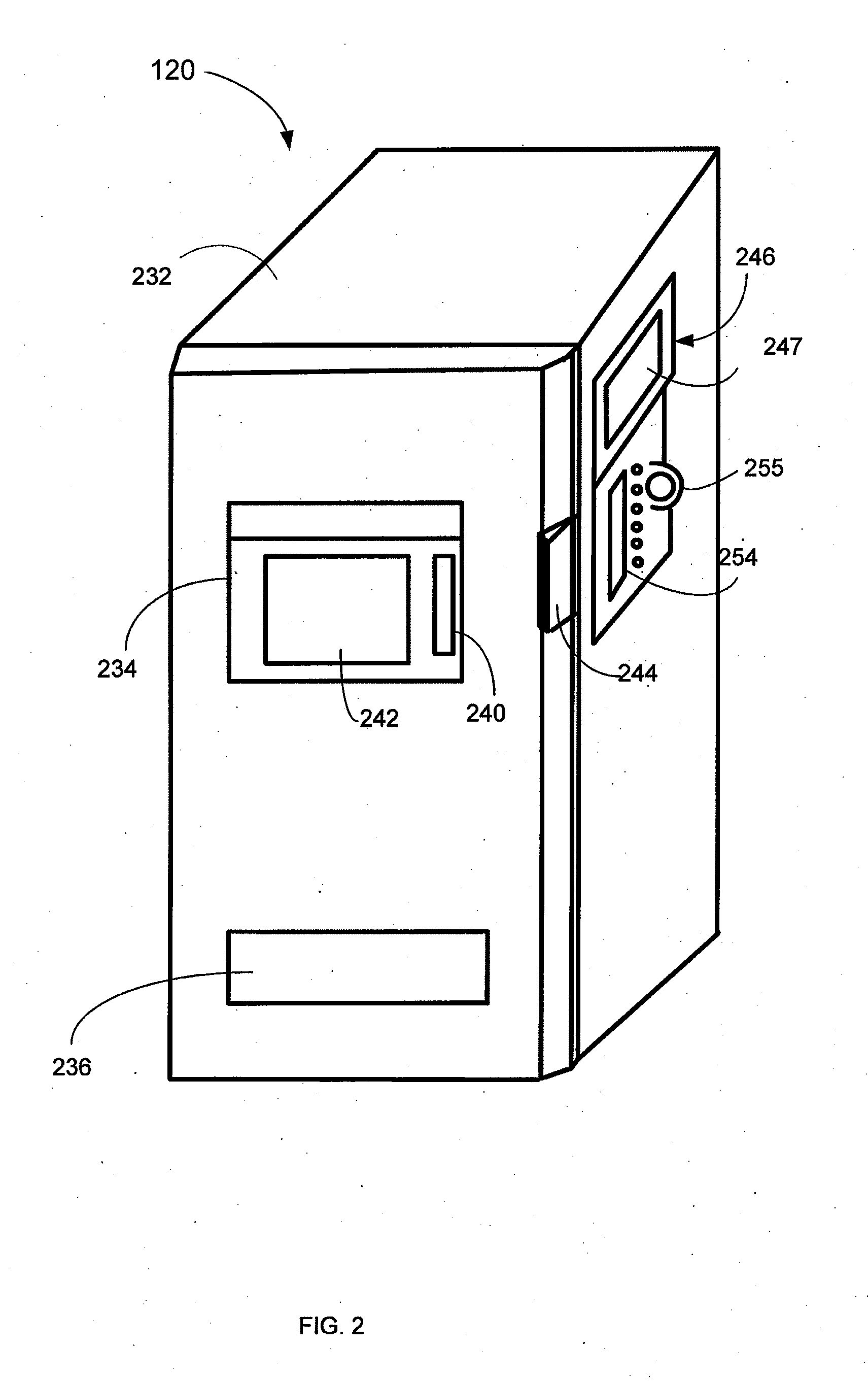

A system and method for communicating secondary vending options for a vendible media product having entertainment content therein is provided. The system comprises a transaction network, and a database in communication with the transaction network, wherein the database stores a plurality of digital video disc titles and a plurality of locations and release dates corresponding to the digital video disc titles. A vending controller at a vending location receives a user request signal for a digital video disc, and determines whether the digital video disc is available in a vending inventory at the vending location. A central controller receives a first signal from the vending controller, wherein the first signal comprises a secondary vending option and a user electronic mail address. The central controller receives a second signal from the vending controller, wherein the second signal comprises an indication that the digital video disc is available in the vending inventory.

Owner:REDBOX AUTOMATED RETAIL

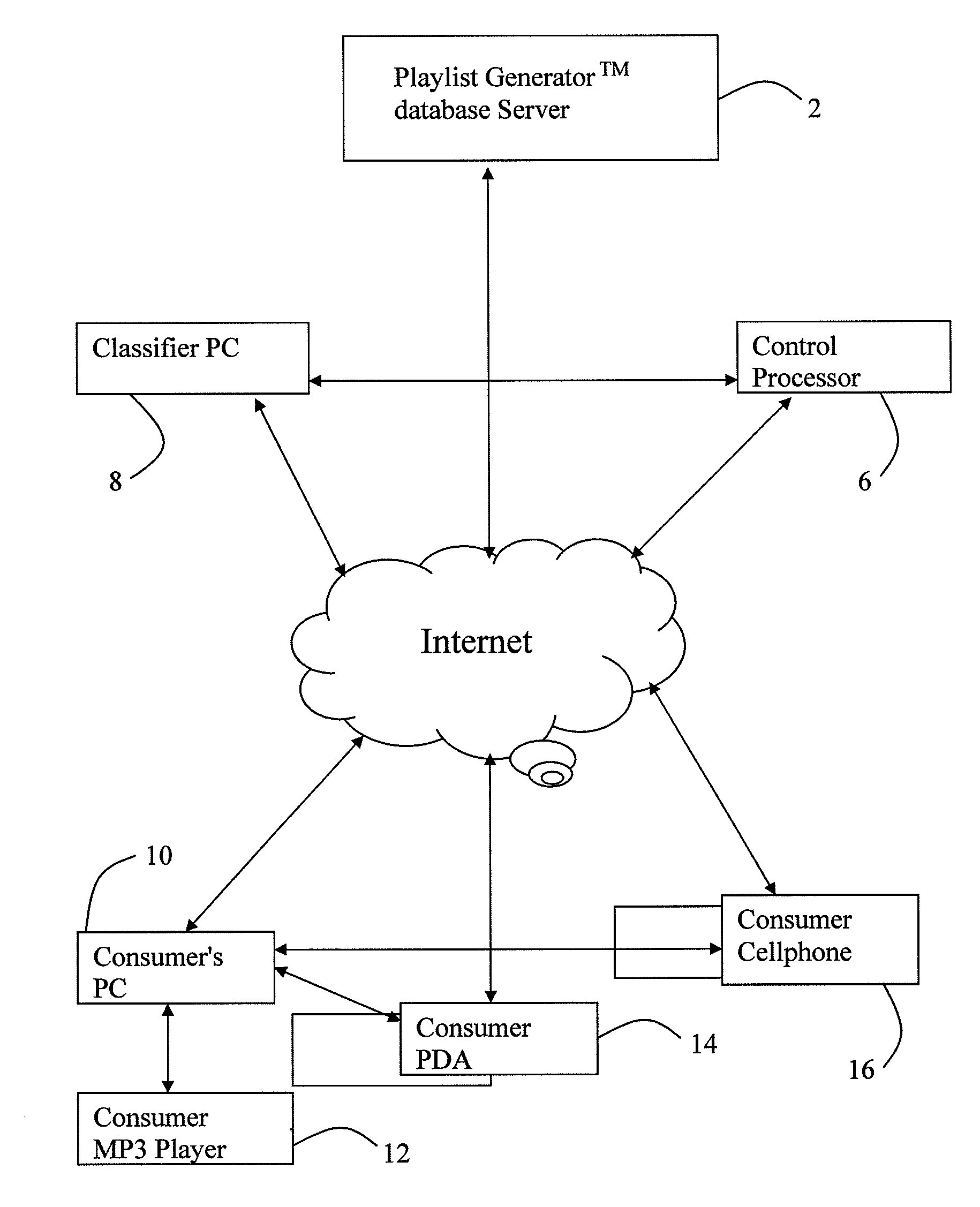

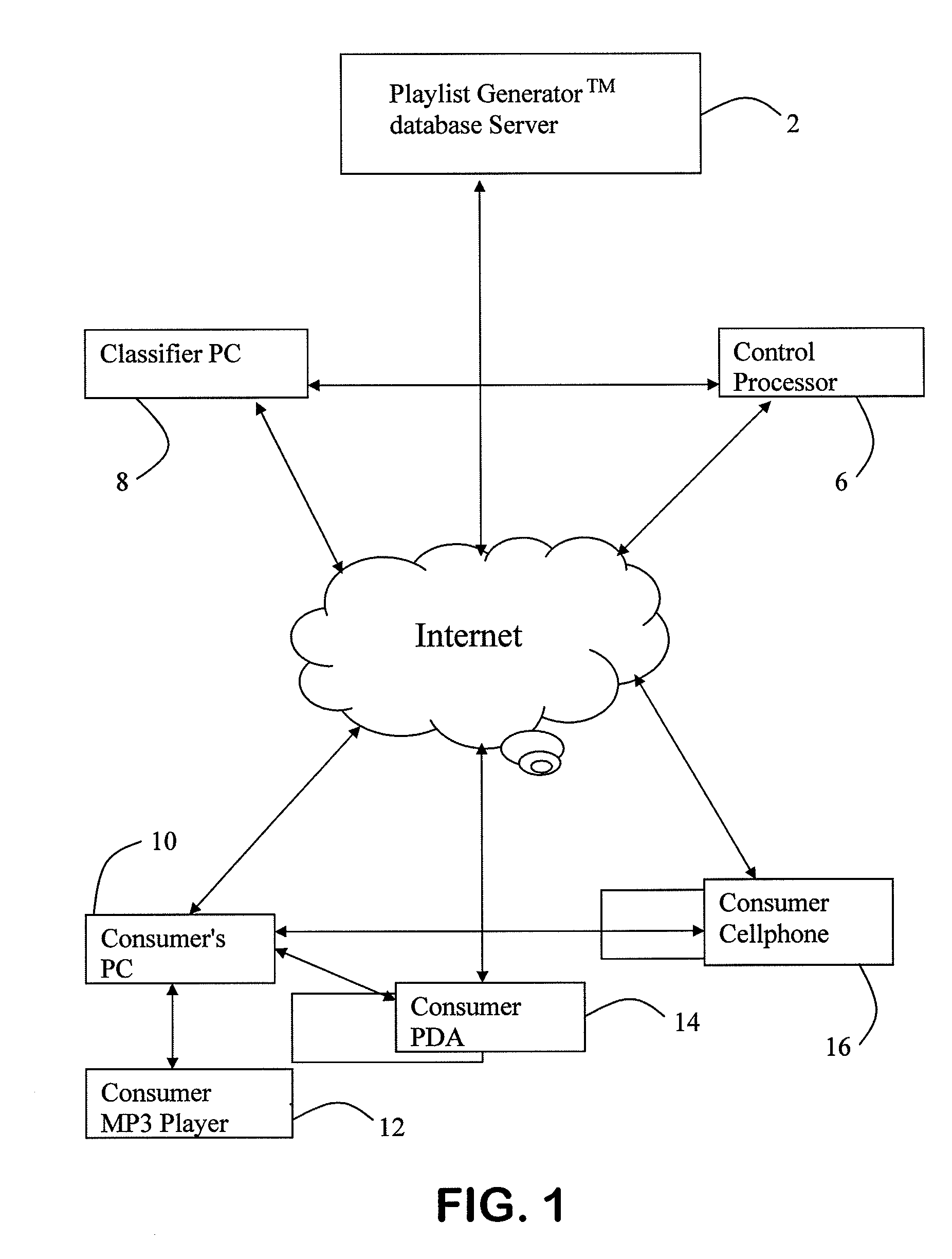

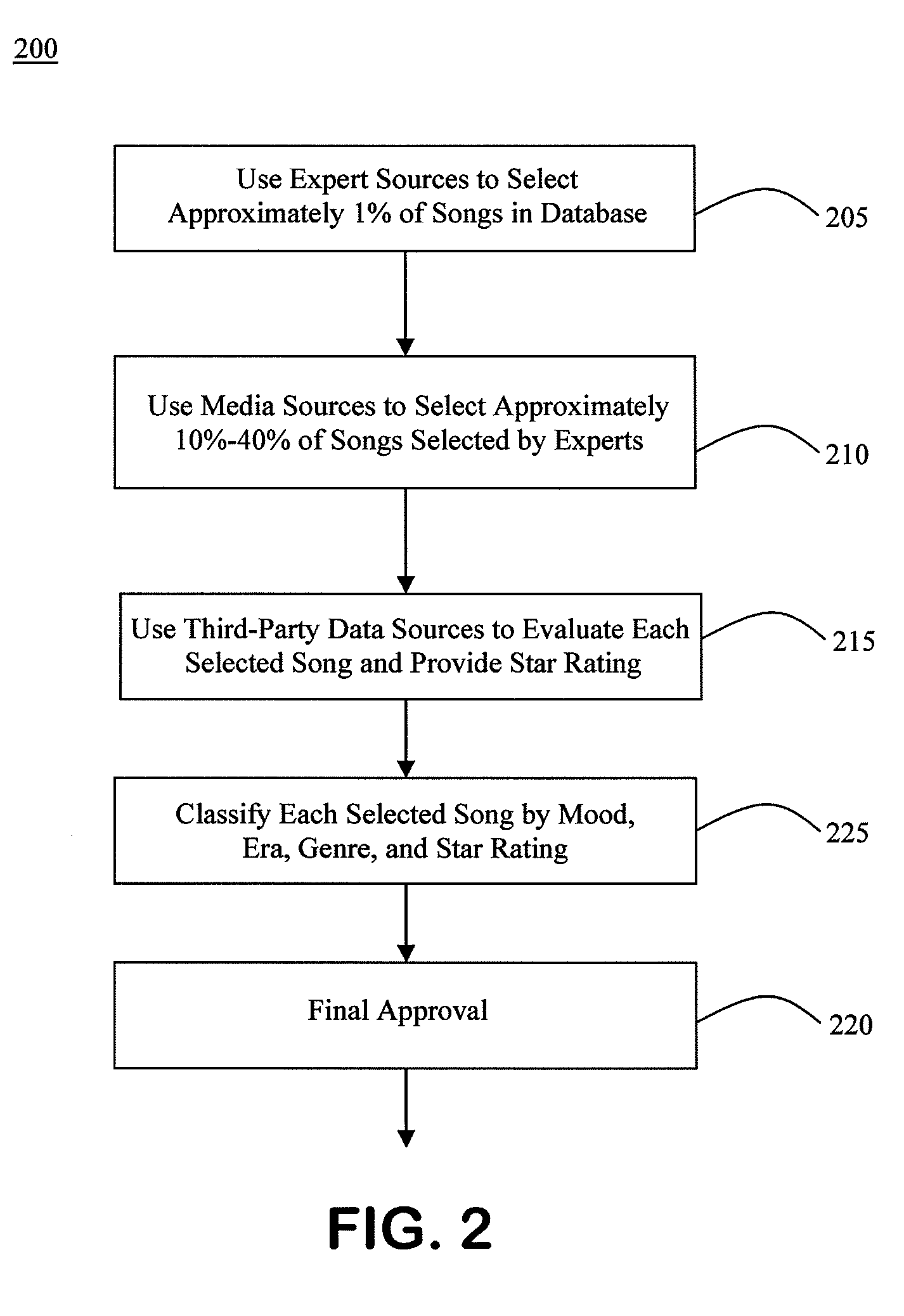

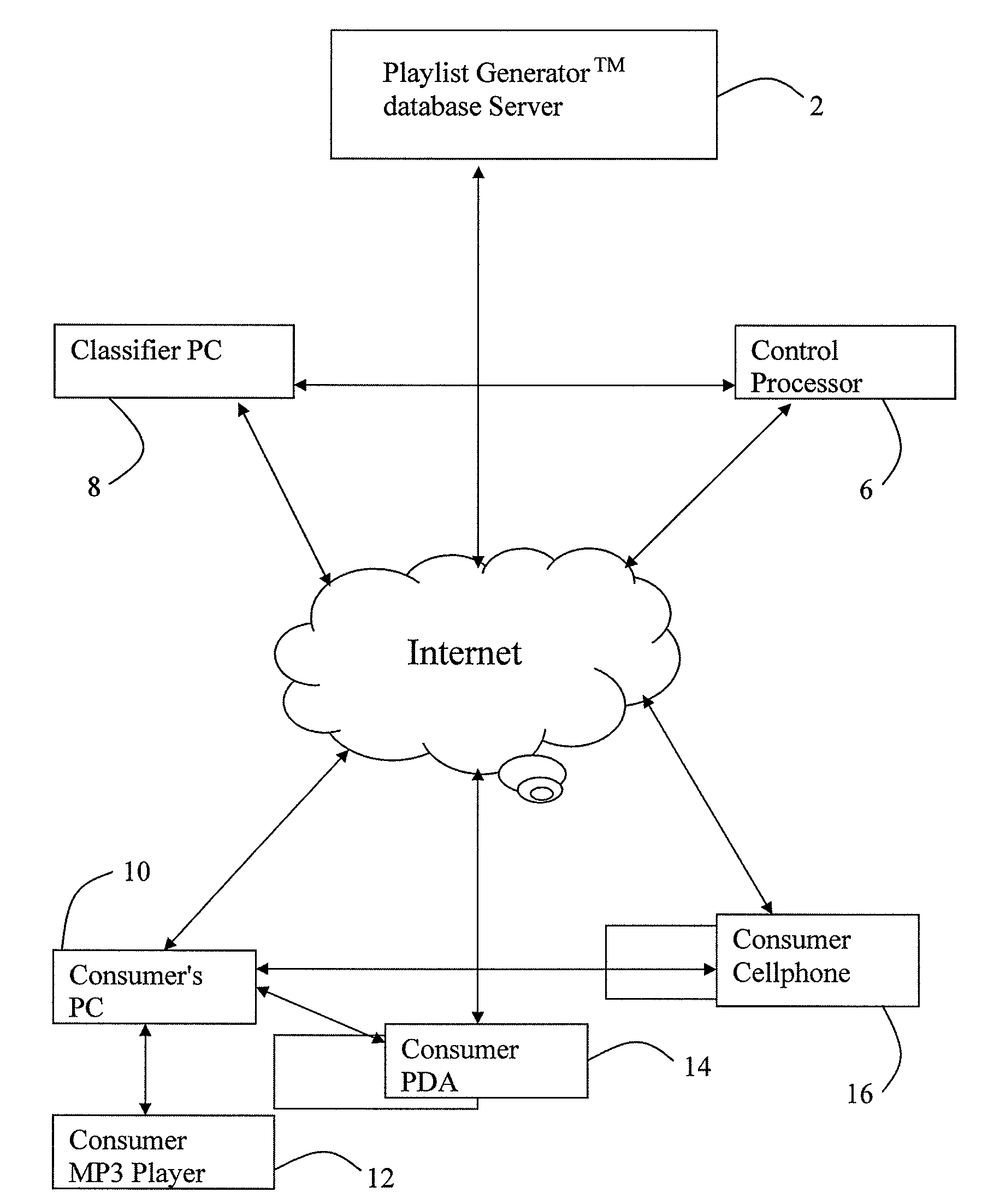

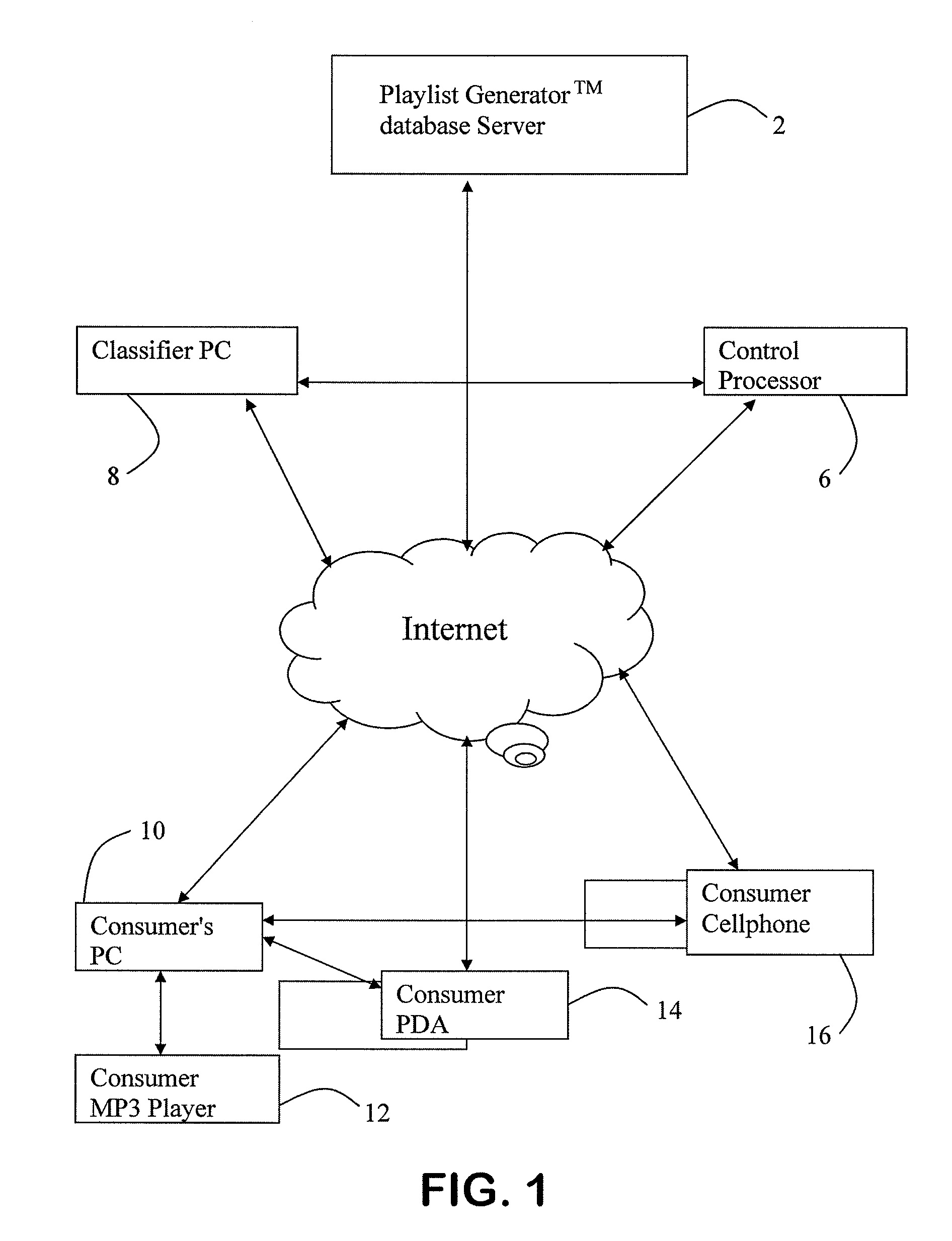

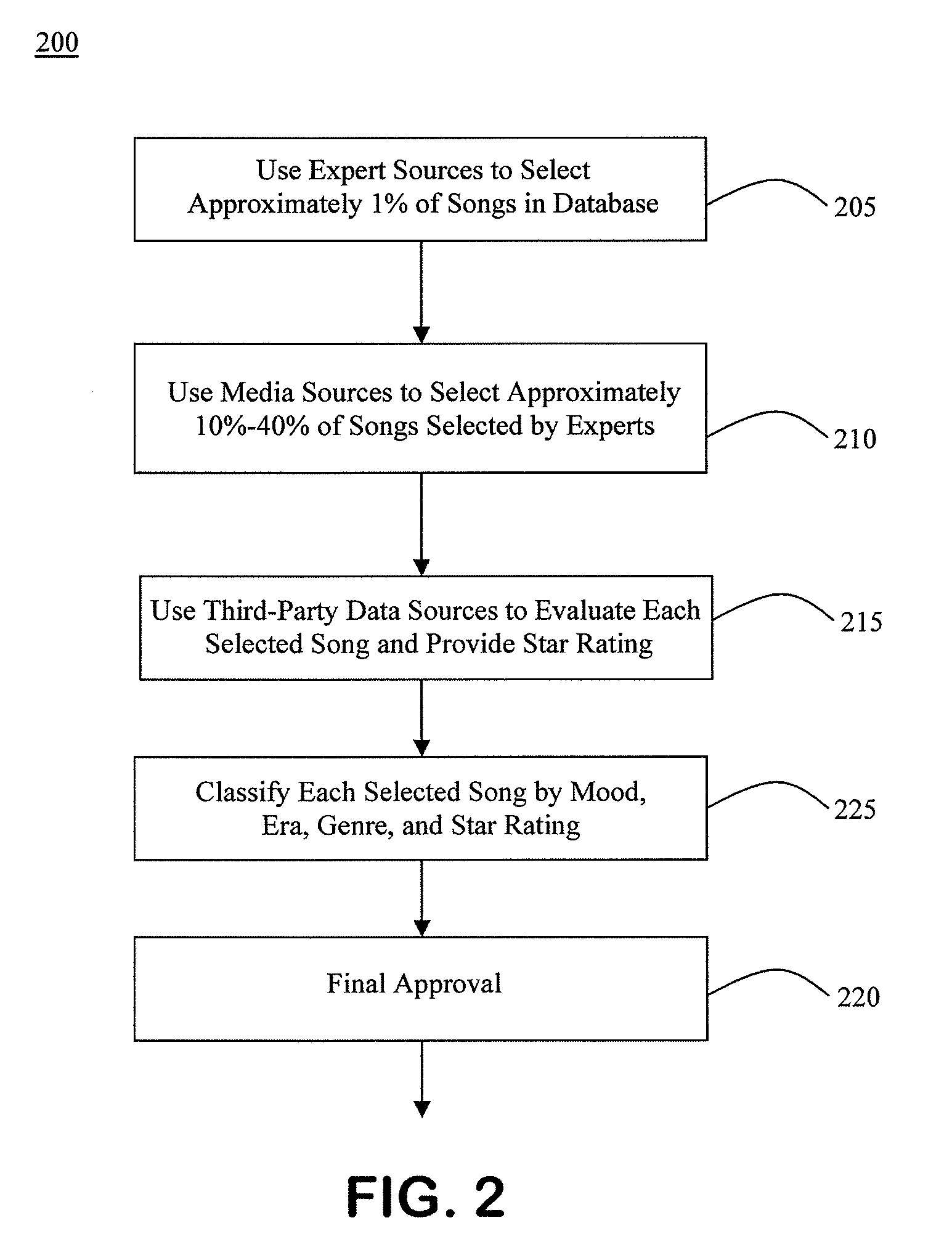

Method And Apparatus For Generating And Updating A Pre-Categorized Song Database From Which Consumers May Select And Then Download Desired Playlists

InactiveUS20080257134A1High subscriptionLimited abilityGearworksMusical toysThe InternetRadio channel

Apparatus, methods, systems, and data structures for organizing music files such that consumers can download single songs or entire predetermined libraries of songs with one or two clicks on an Internet browser. For passive listeners without the time to generate their own playlists, 500 to 30,000 song libraries can be downloaded to a PC, and then side loaded to an MP3 player. This will enable users to replicate the experience of listening to a favorite broadcast radio channel having songs most likely to please the listener, with zero interruptions. The stored and downloaded songs are individually categorized by song title, artist, mood / tempo, multiple genres, era, original song release date, and audience reach (e.g., audience crossover potential). For a subscription fee, the consumer will have continued access to listen to the downloaded and side loaded songs, but without the ability to copy or transfer the song. For an additional fee (or a higher subscription fee) the consumer can take actual ownership of downloaded song libraries and / or individual songs.

Owner:3B MUSIC

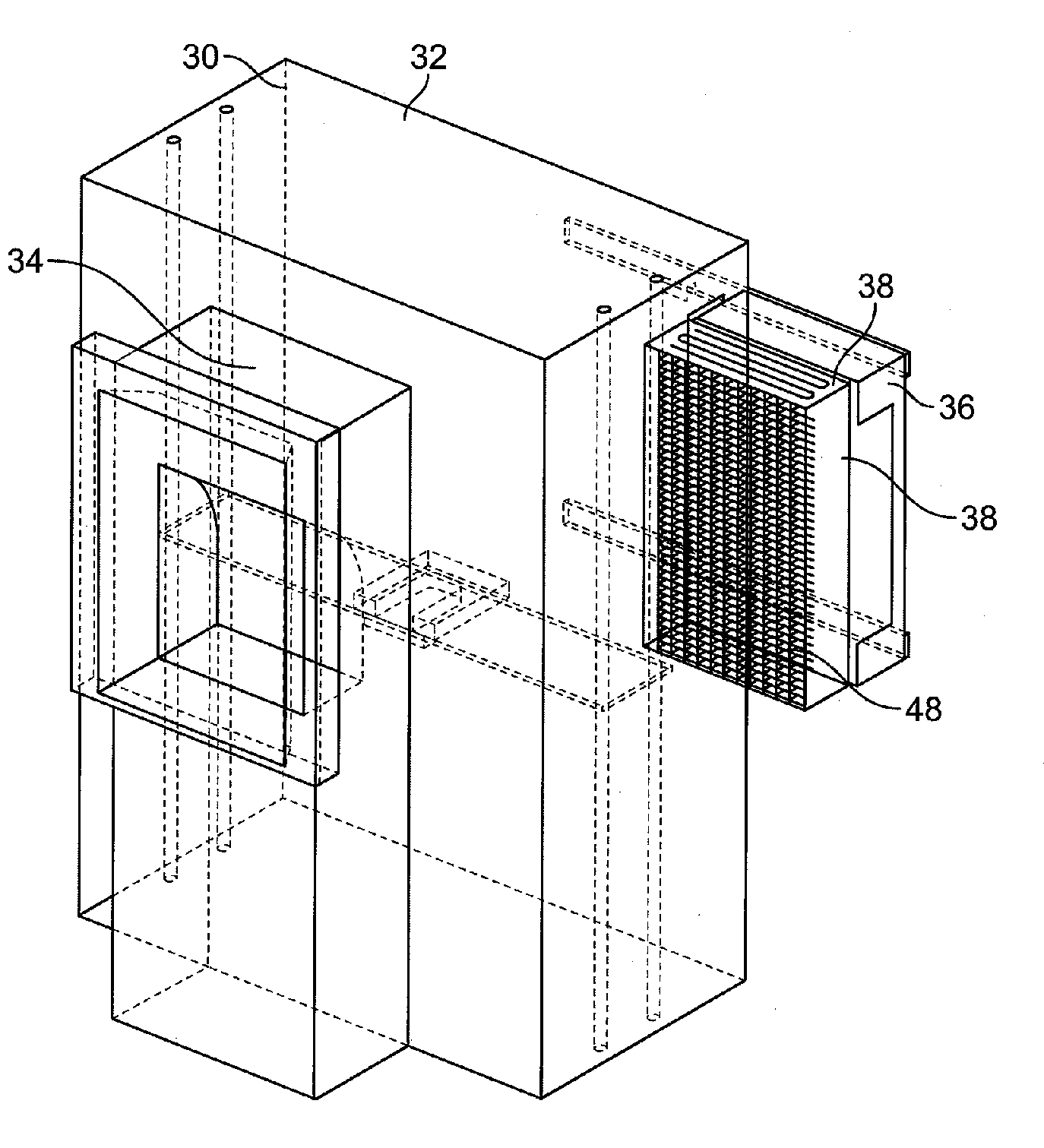

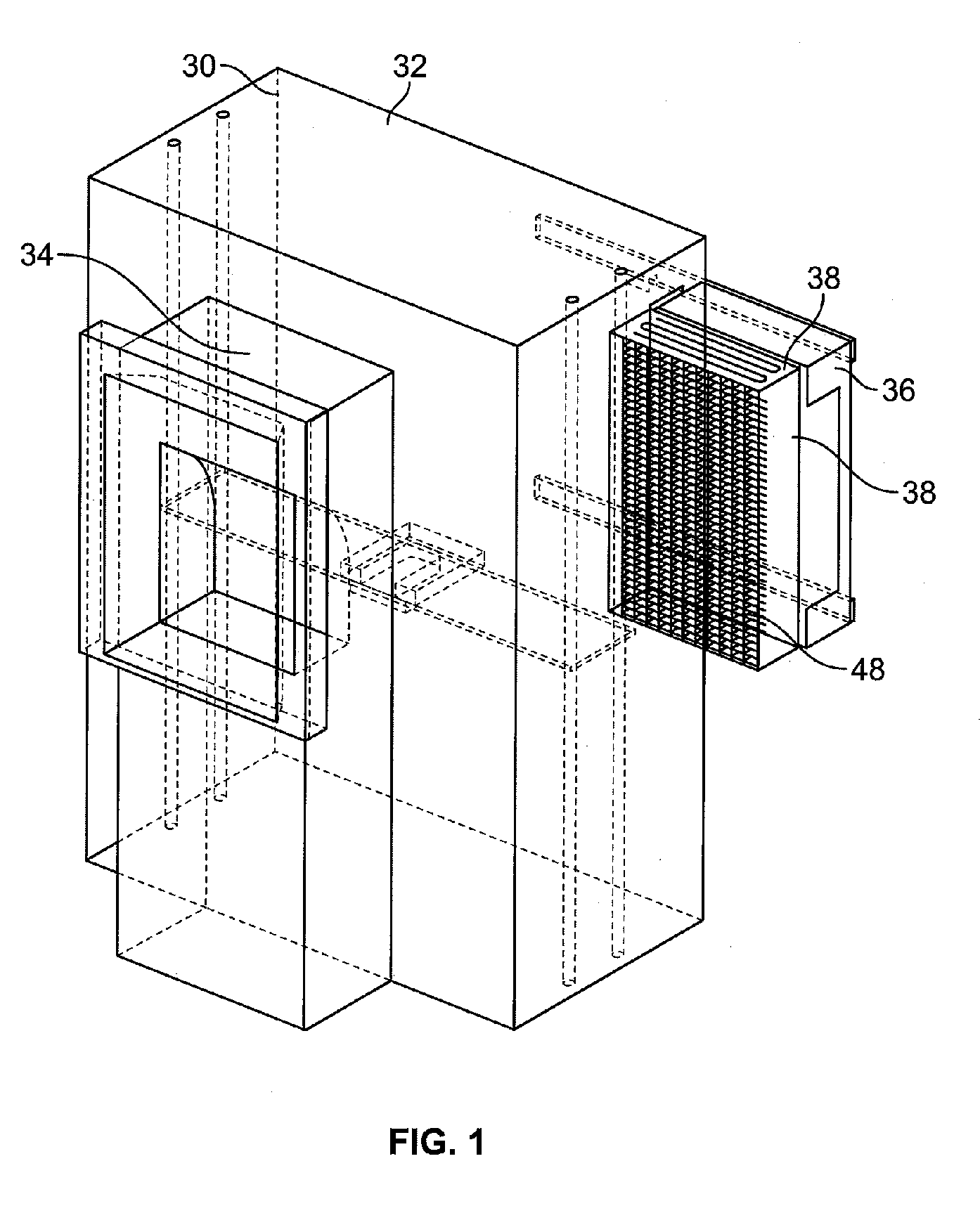

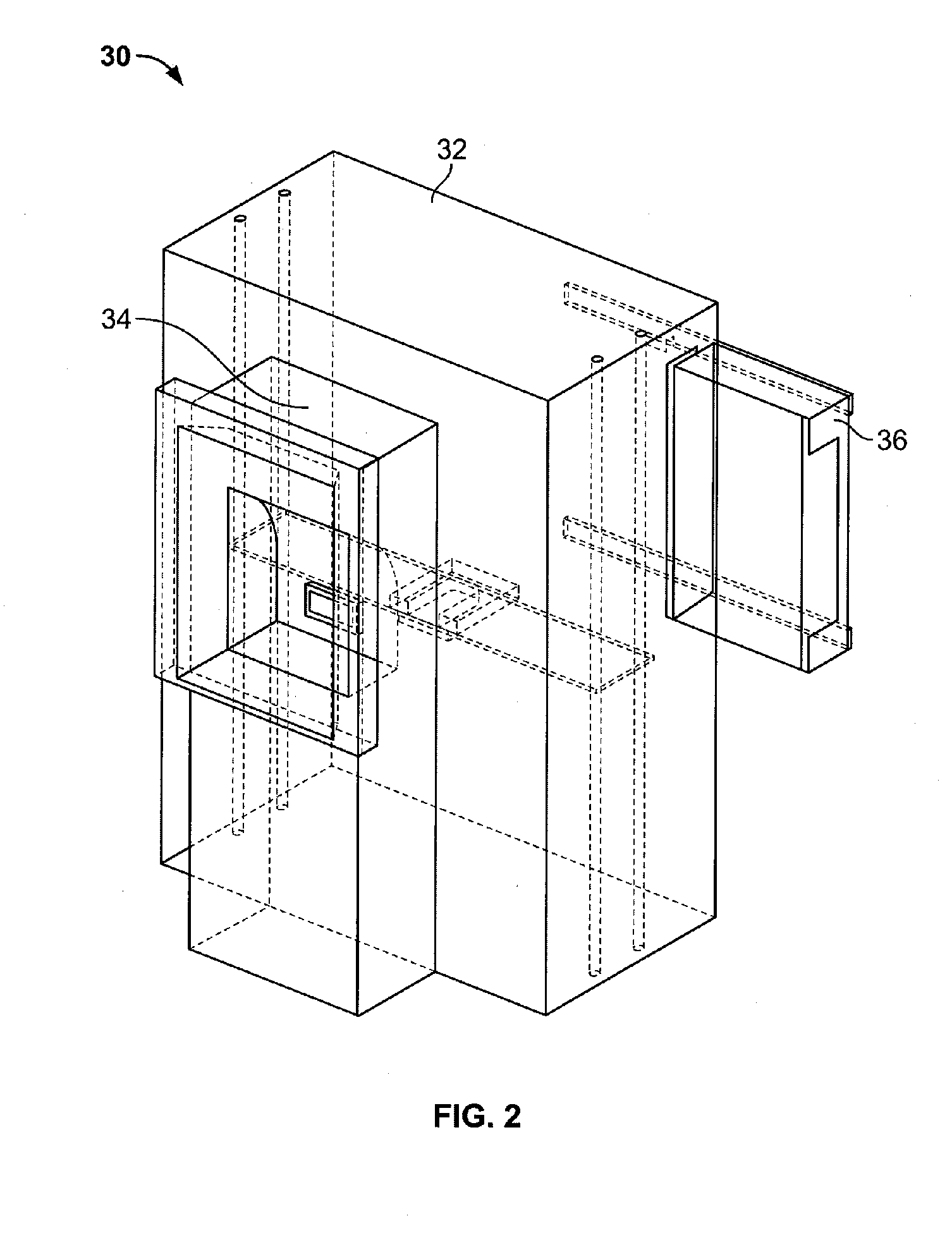

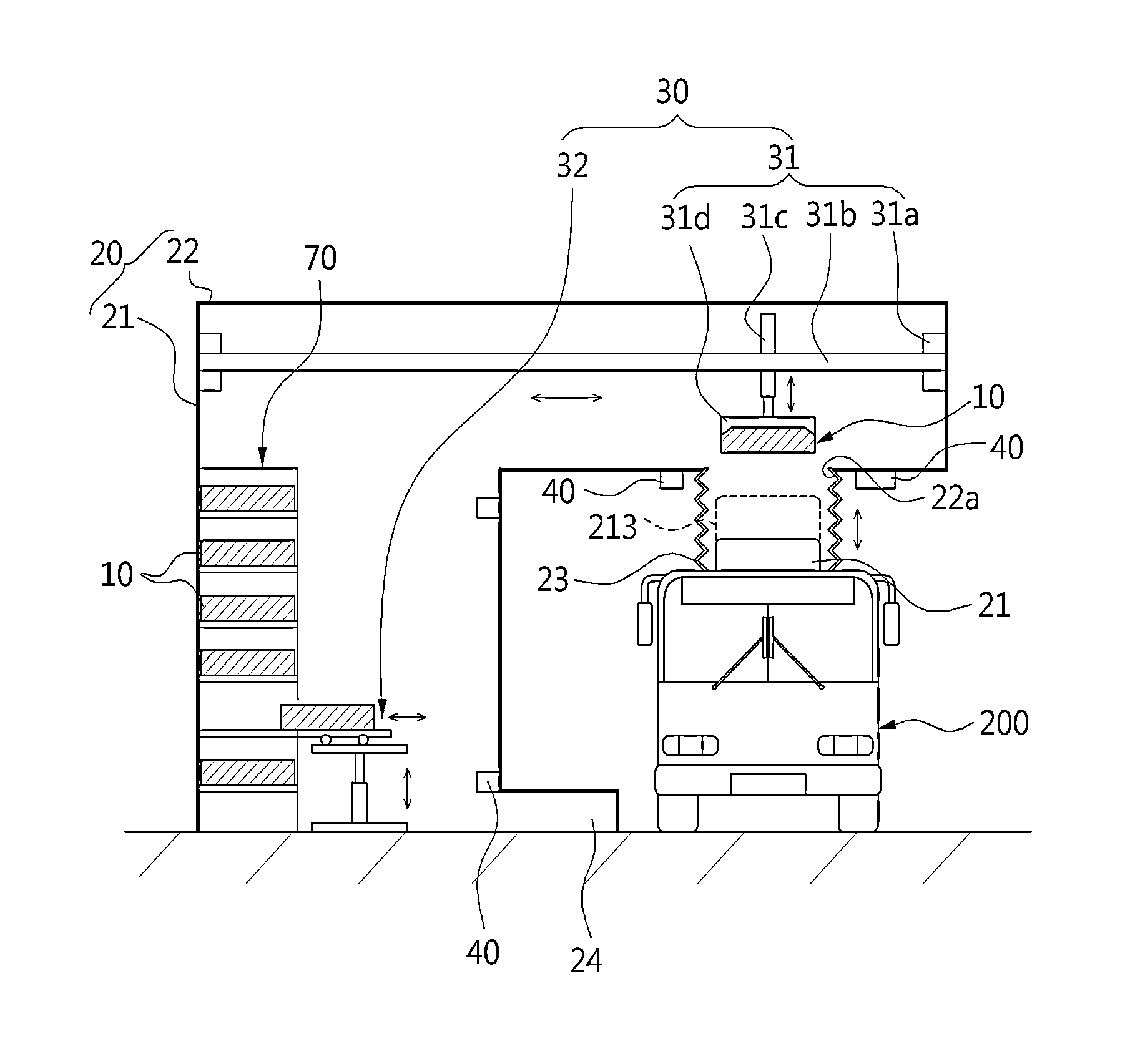

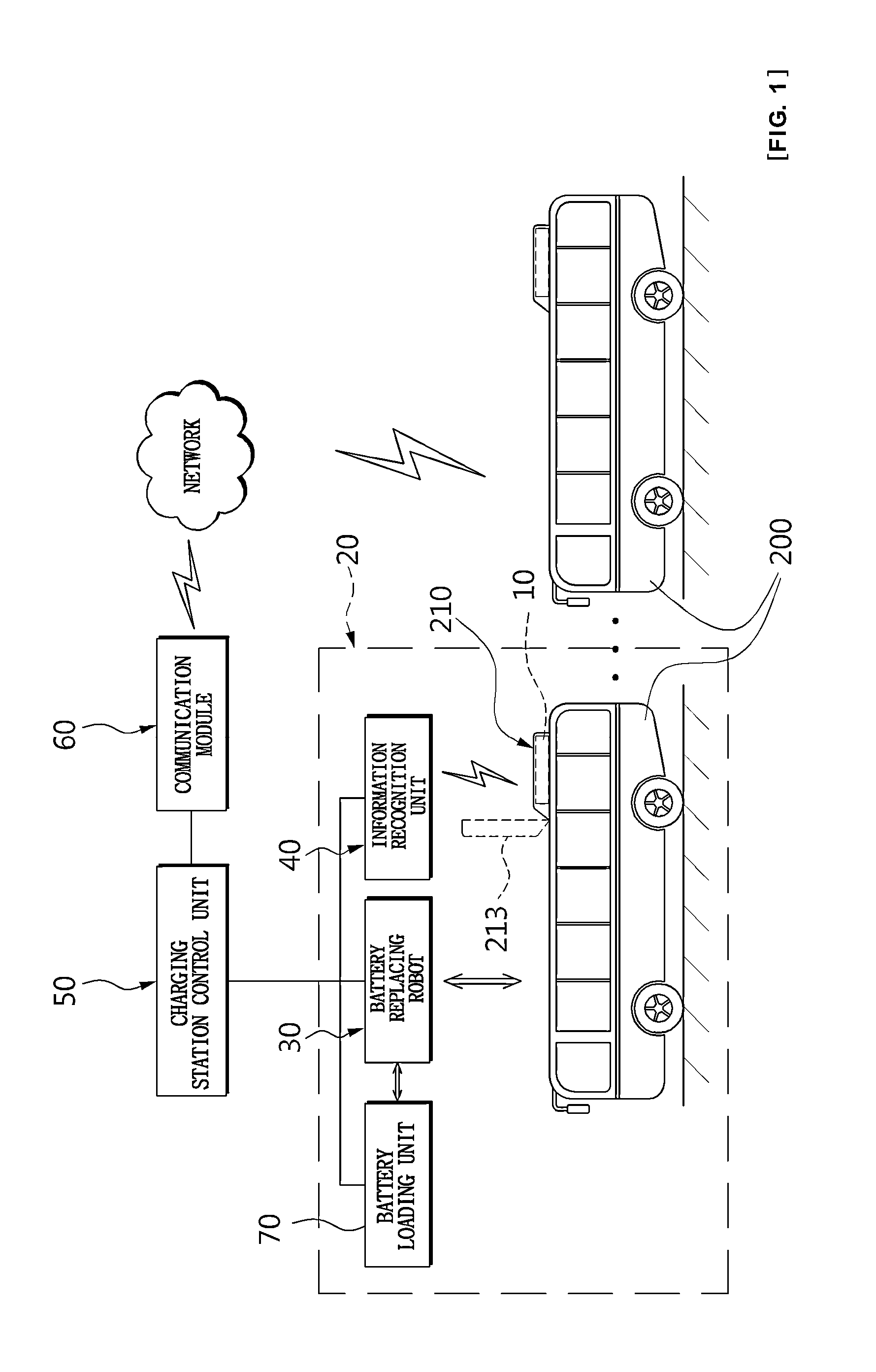

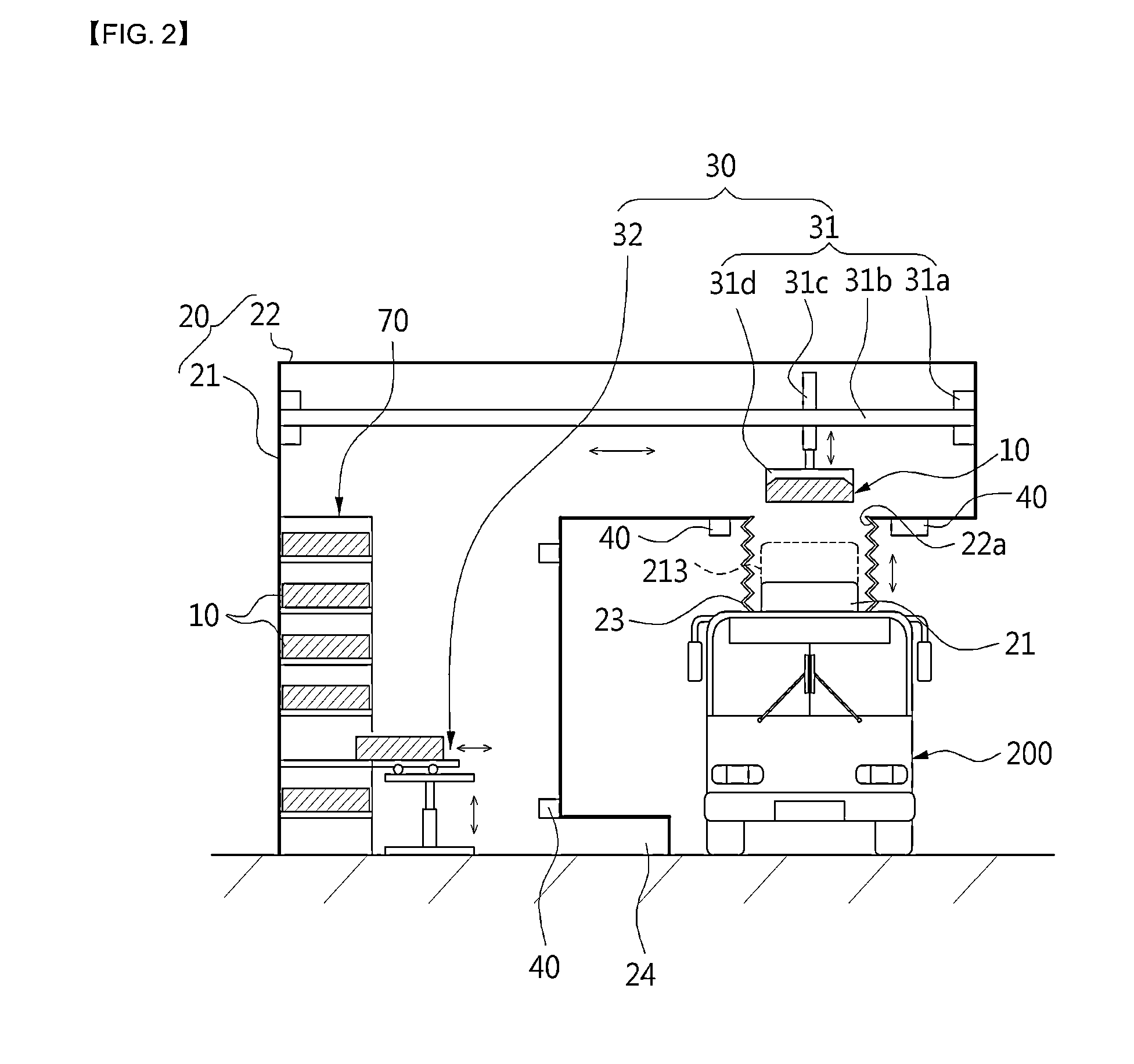

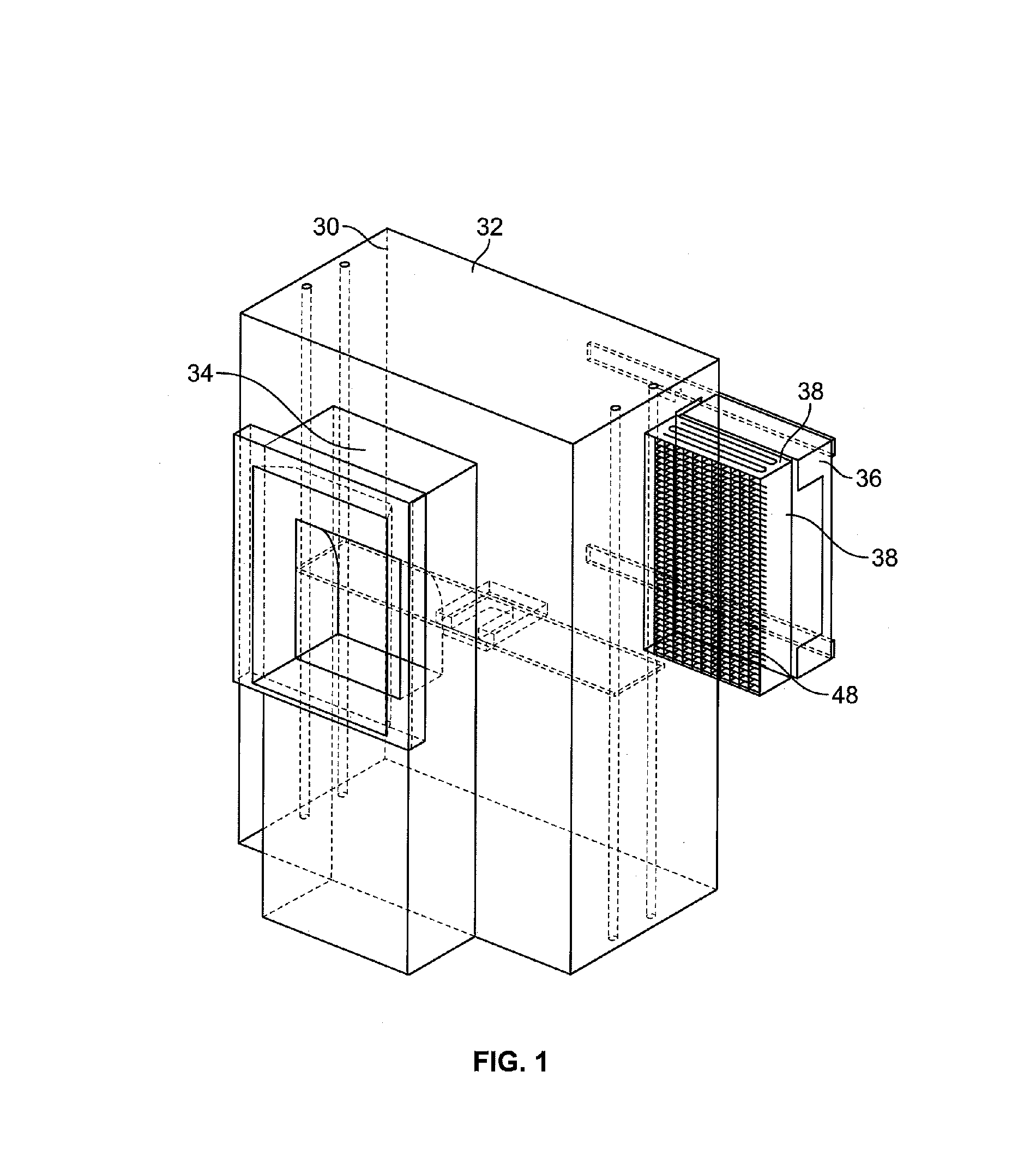

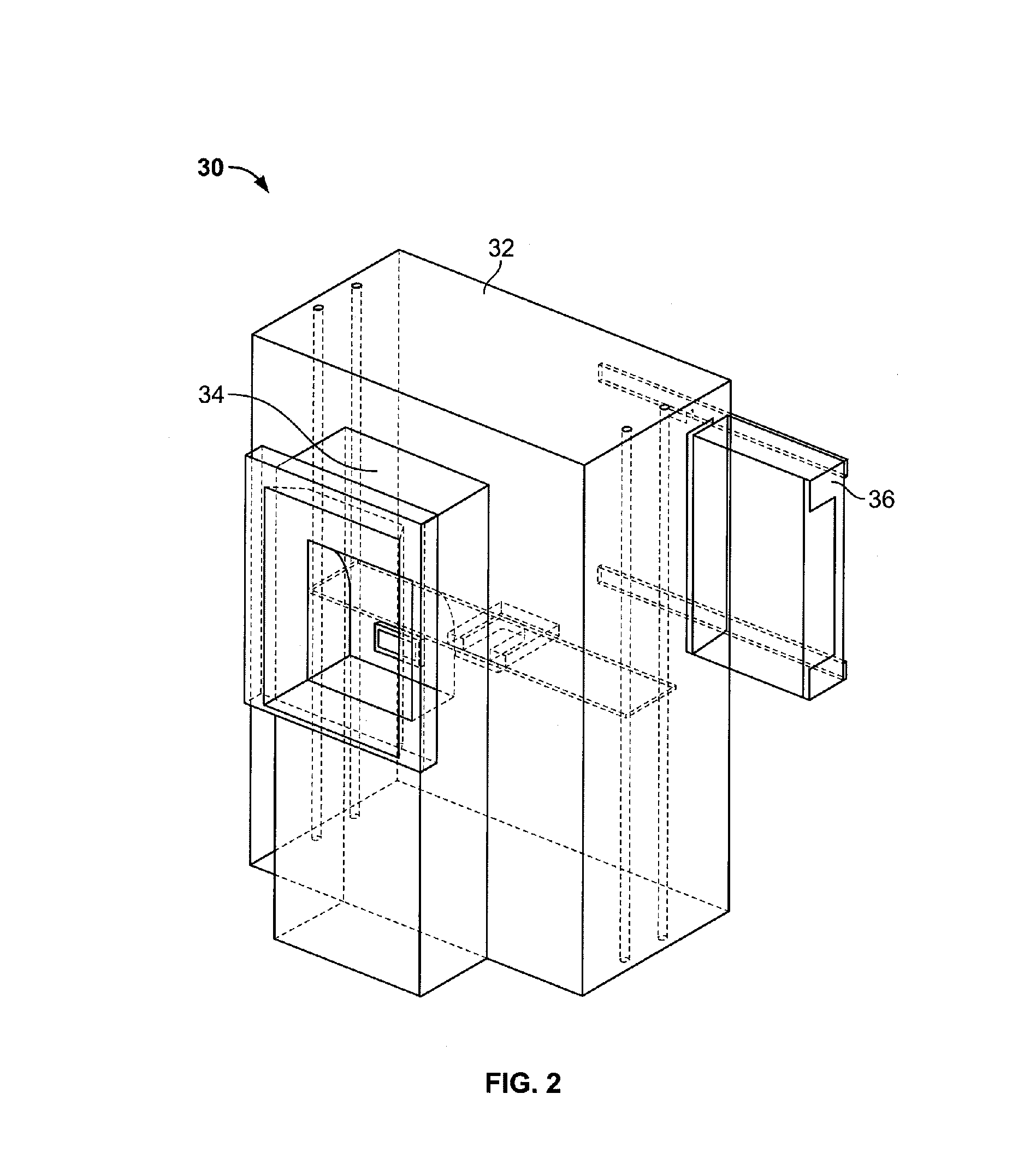

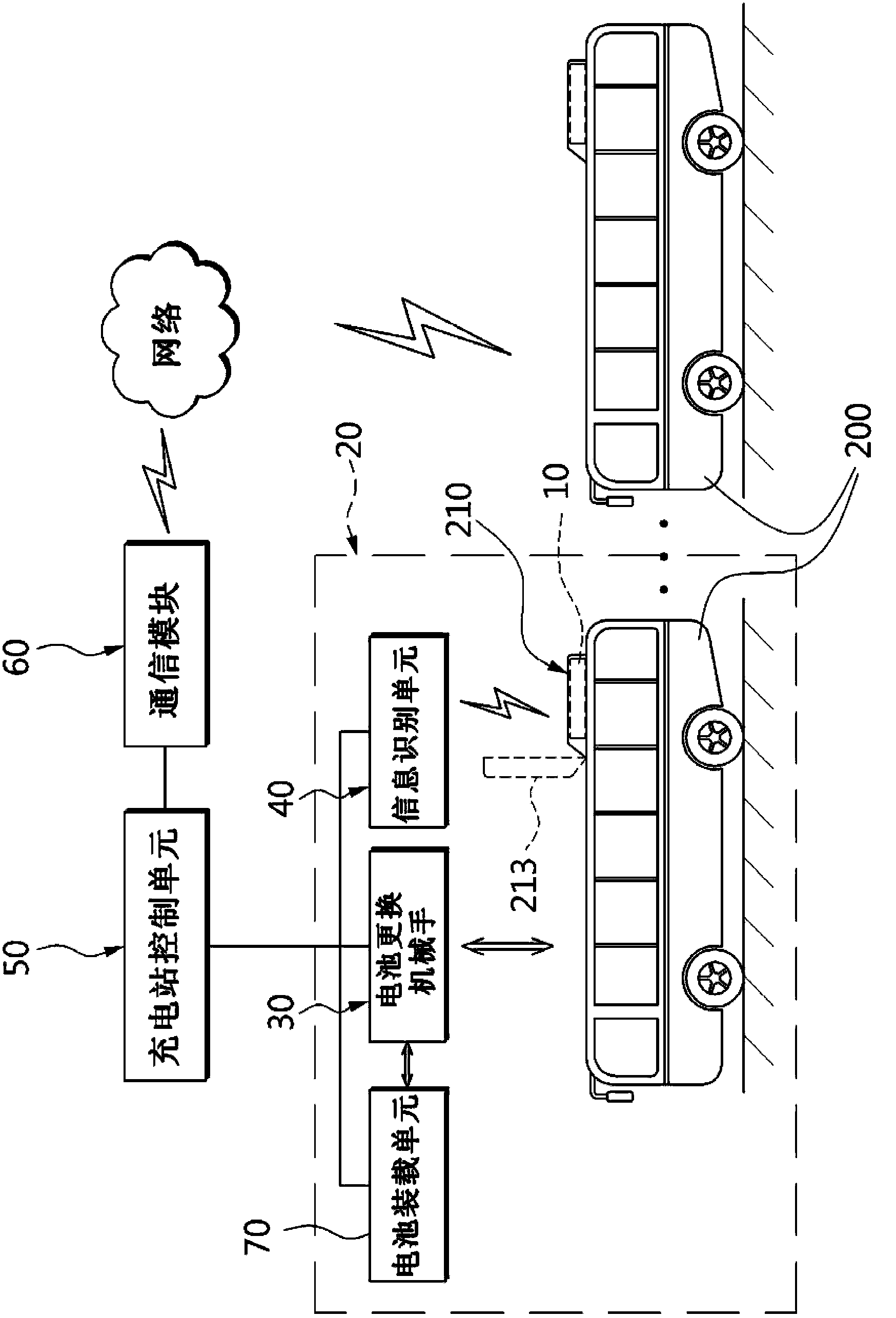

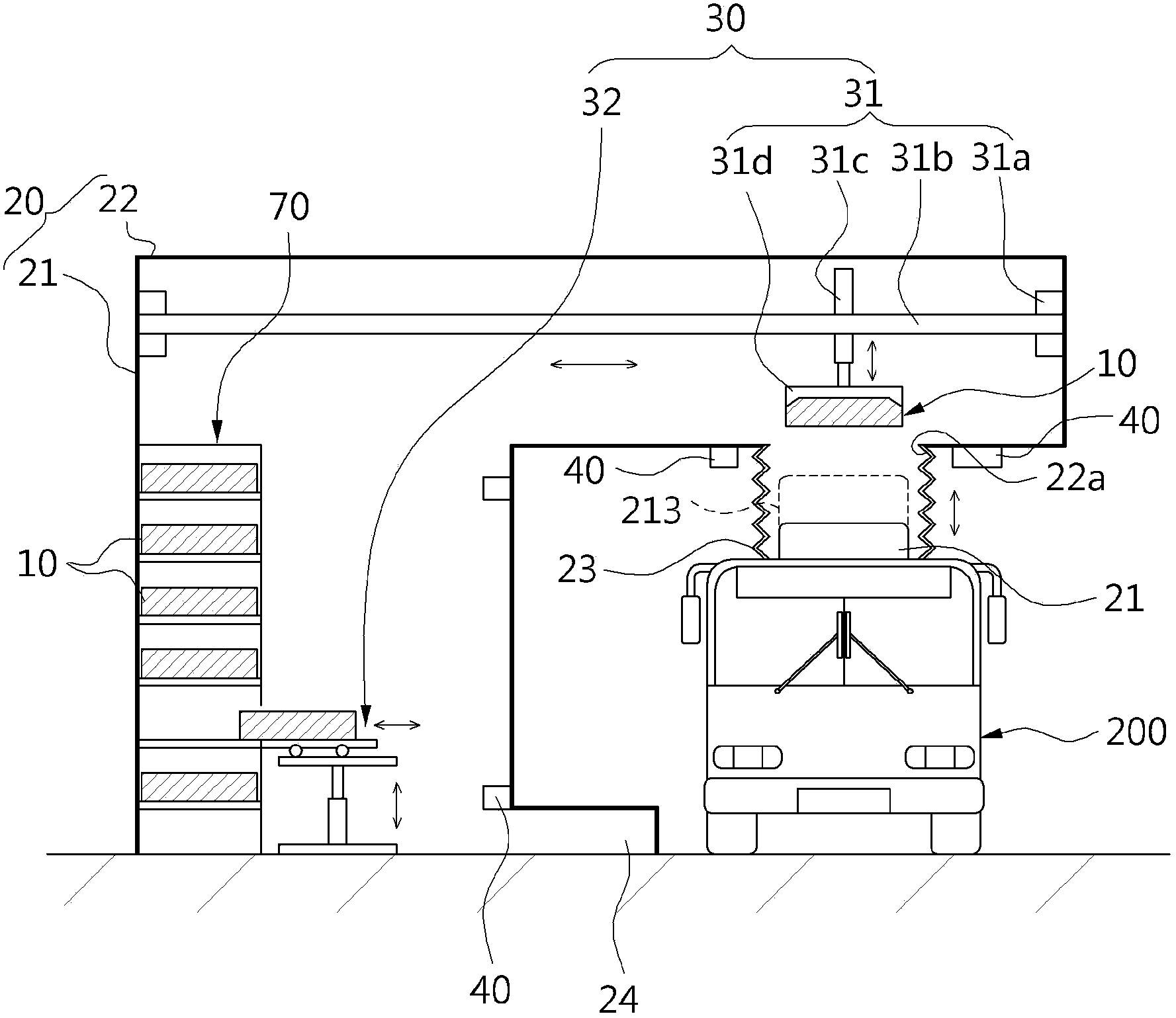

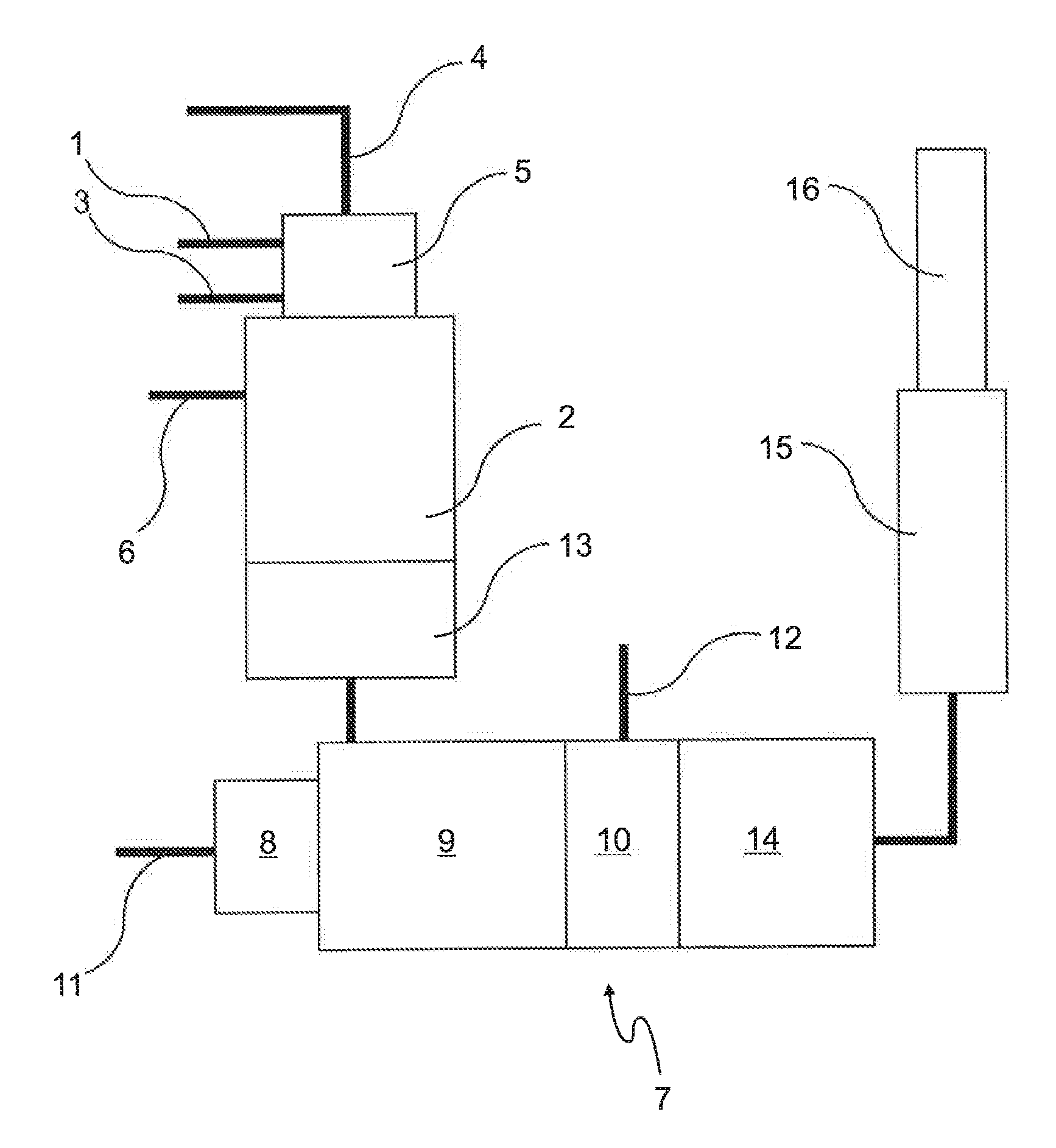

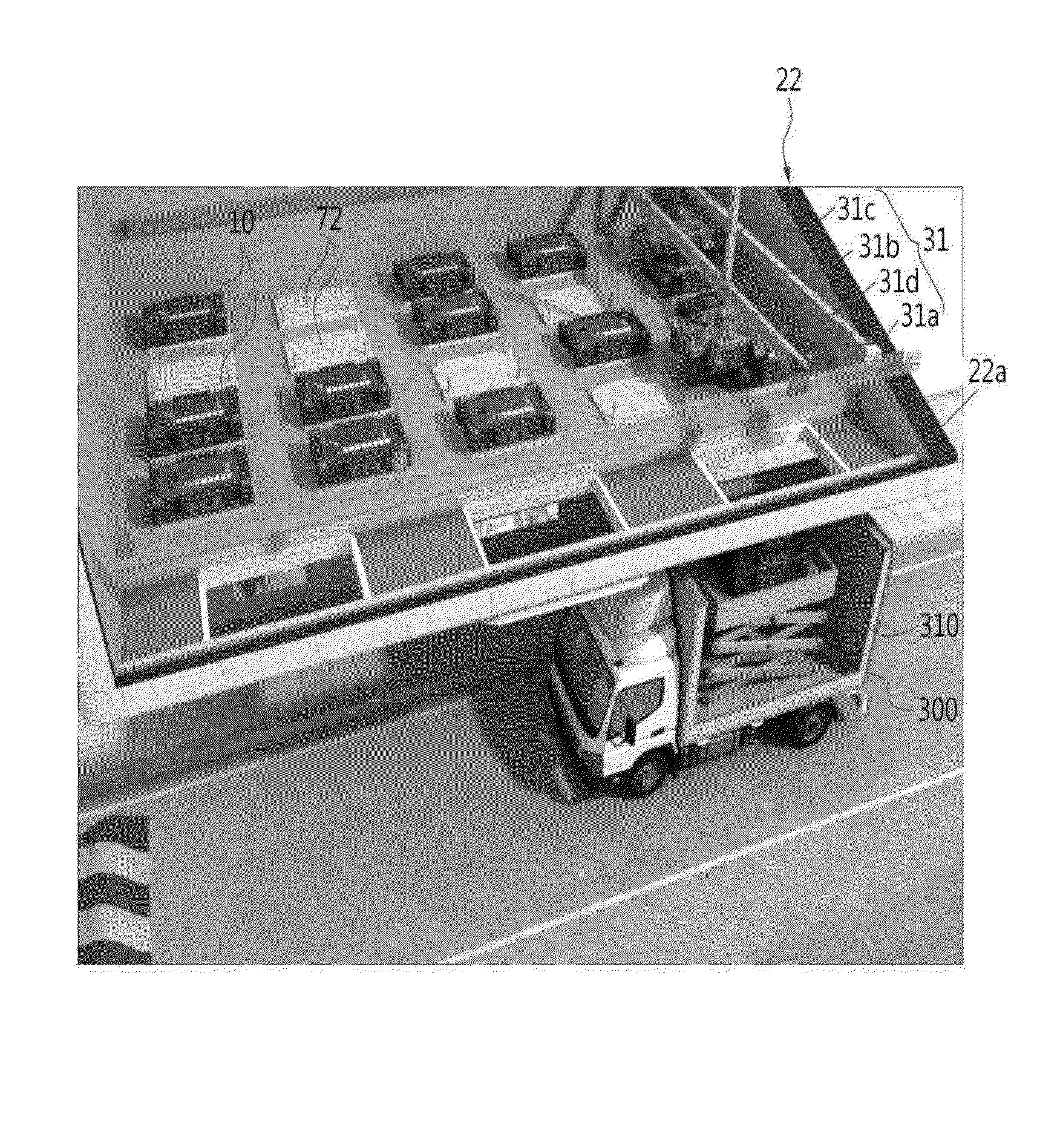

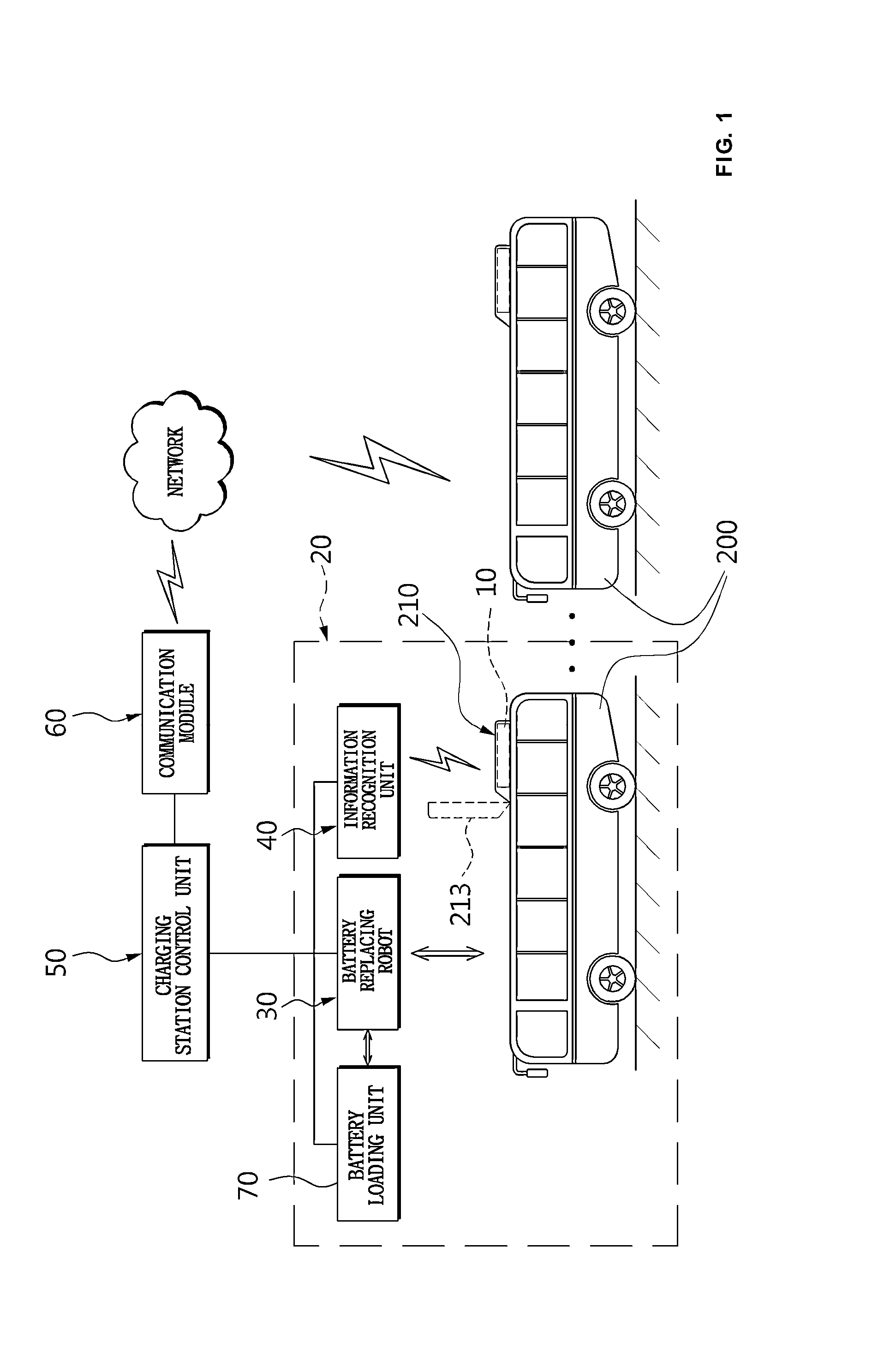

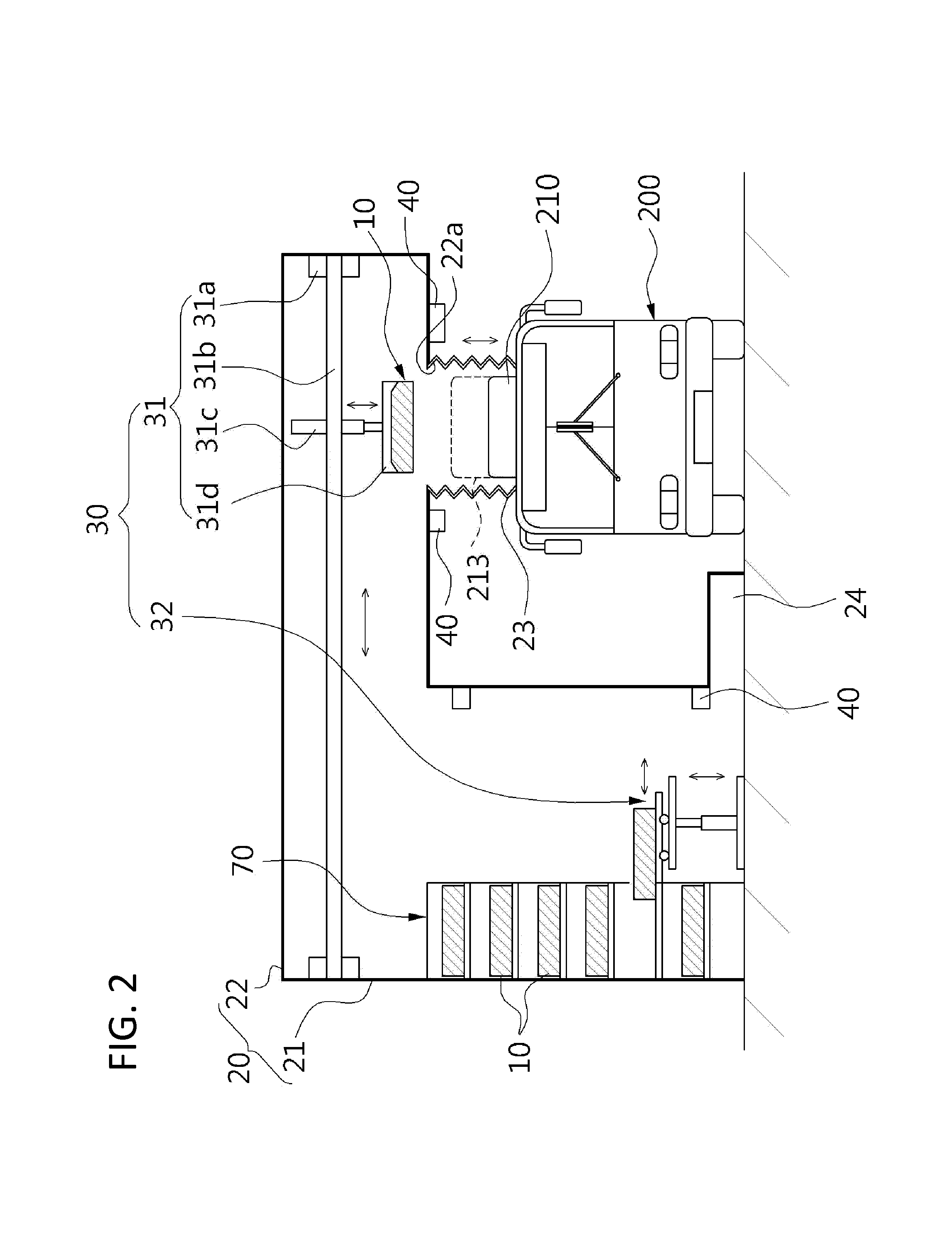

Battery exchanging-type charging station system for electric vehicle

ActiveUS20140002019A1Exchanged quickly and accuratelyEasy to chargeBatteries circuit arrangementsCharging stationsEngineeringCharging station

Provided is a battery exchanging type charging station system for an electric vehicle. The battery exchanging type charging station system includes a charging station body formed with a structure in which the electric vehicle freely enters and exits and including a battery loading unit for receiving the battery, a battery replacing robot mounted in the charging station body to perform a battery replacement operation, a charging station control unit to control the battery replacing robot such that the battery replacement operation is performed by controlling the battery replacing robot, an information recognition unit configured to obtain data on an electric vehicle that enters the charging station body and / or data on a type, size, charging state, release date, charging date or the like of the battery, and a charging station control unit that allows a replacement operation of the battery to be performed by controlling the battery replacing robot.

Owner:KOOKMIN UNIV IND ACAD COOP FOUND

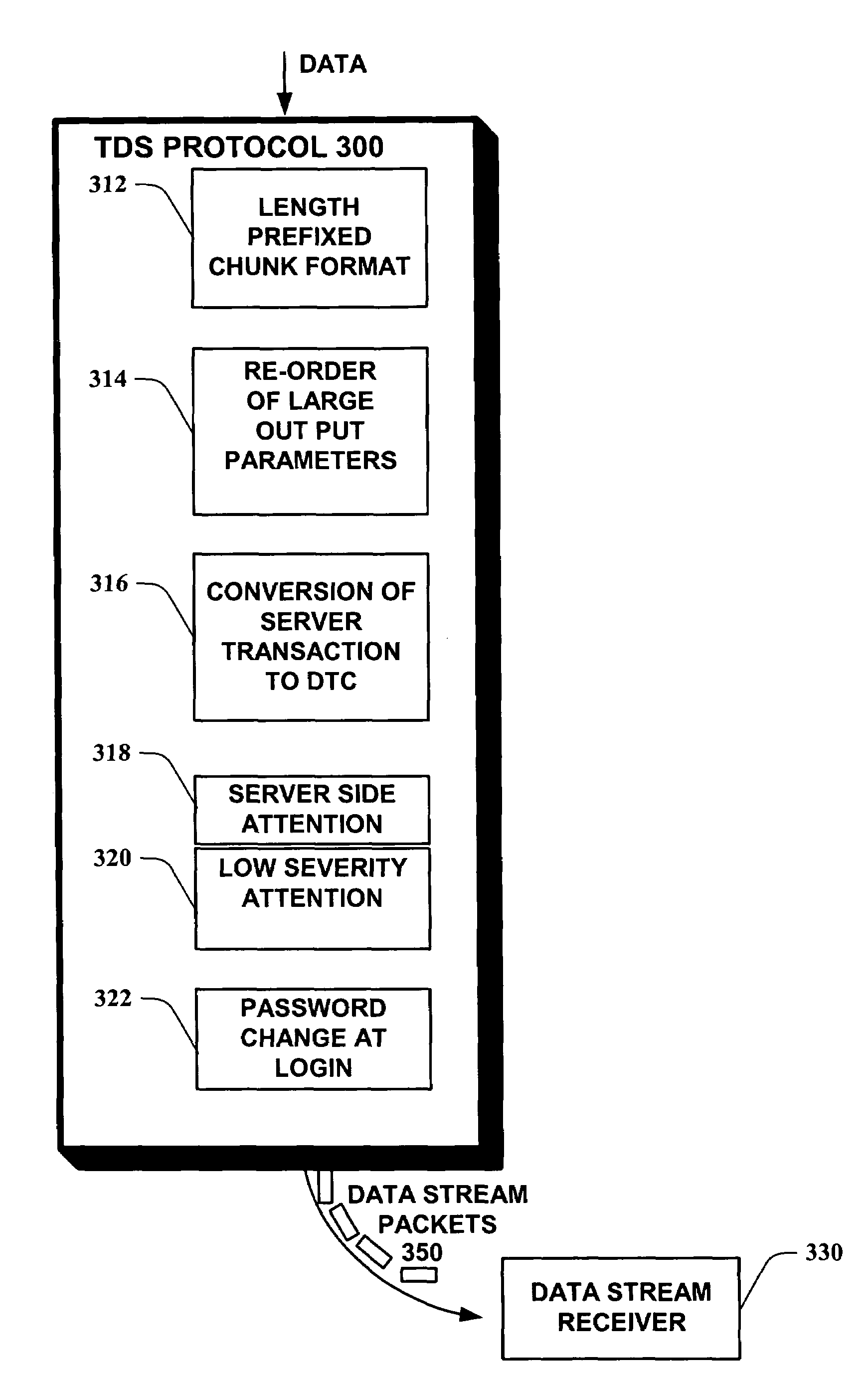

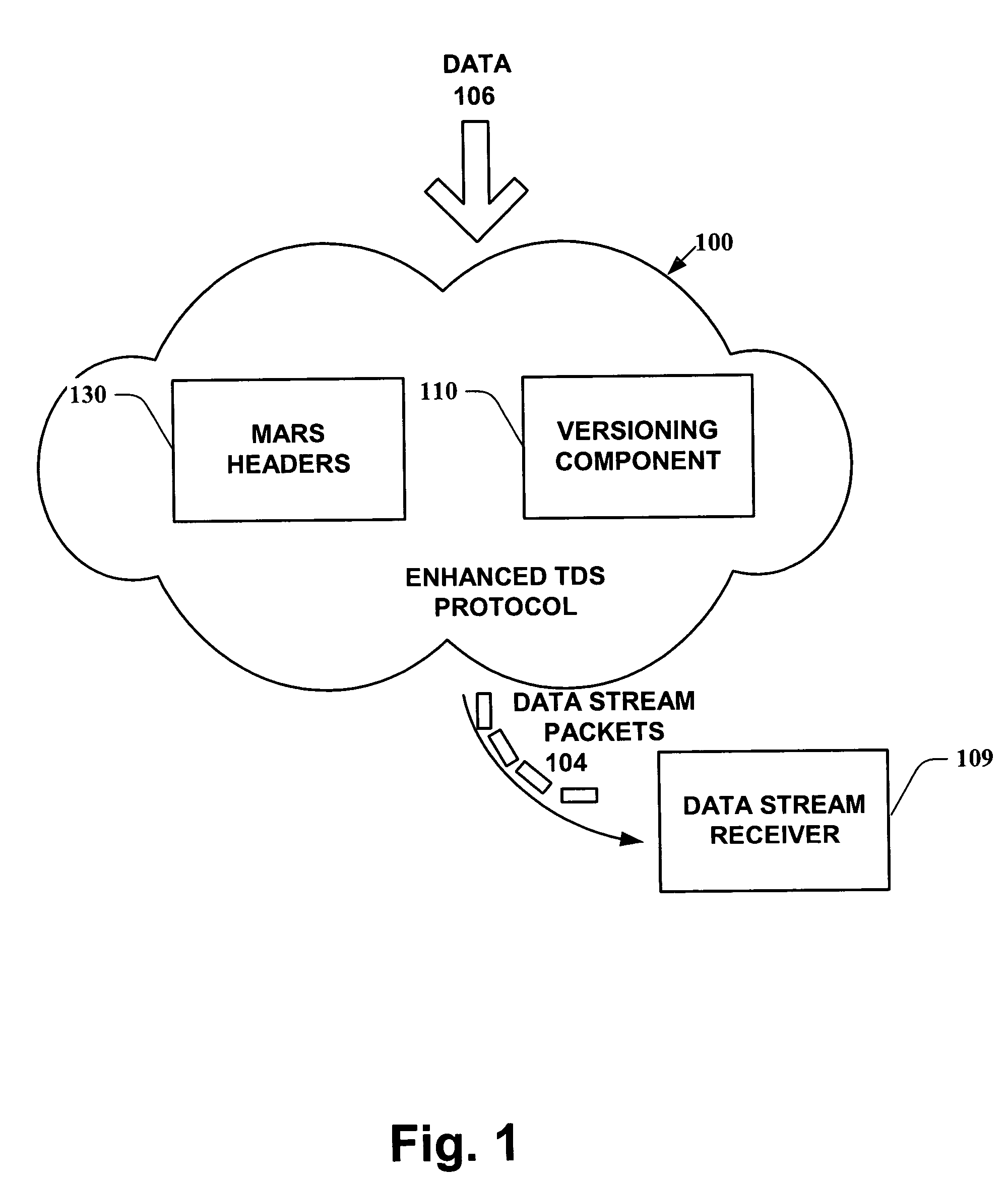

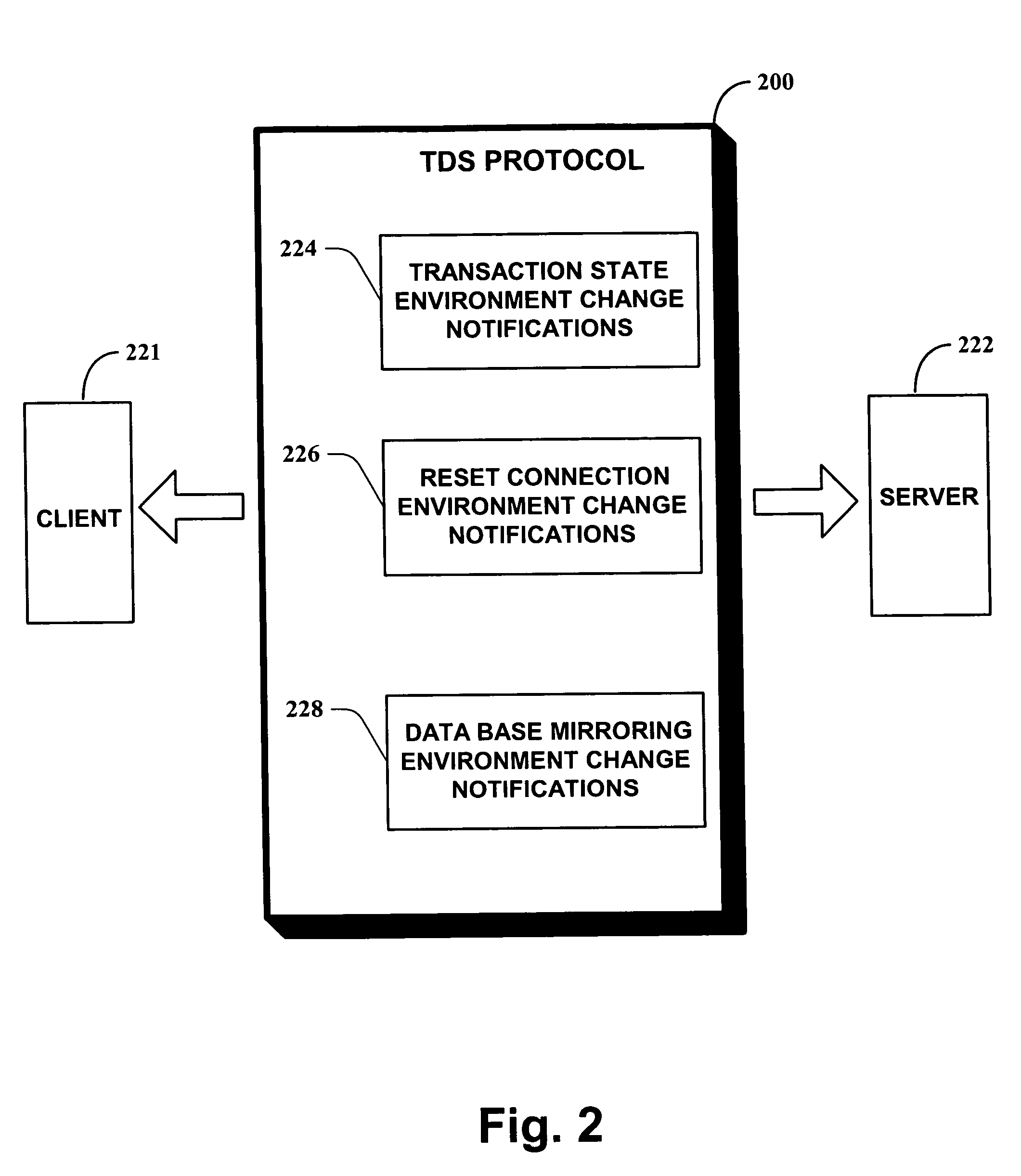

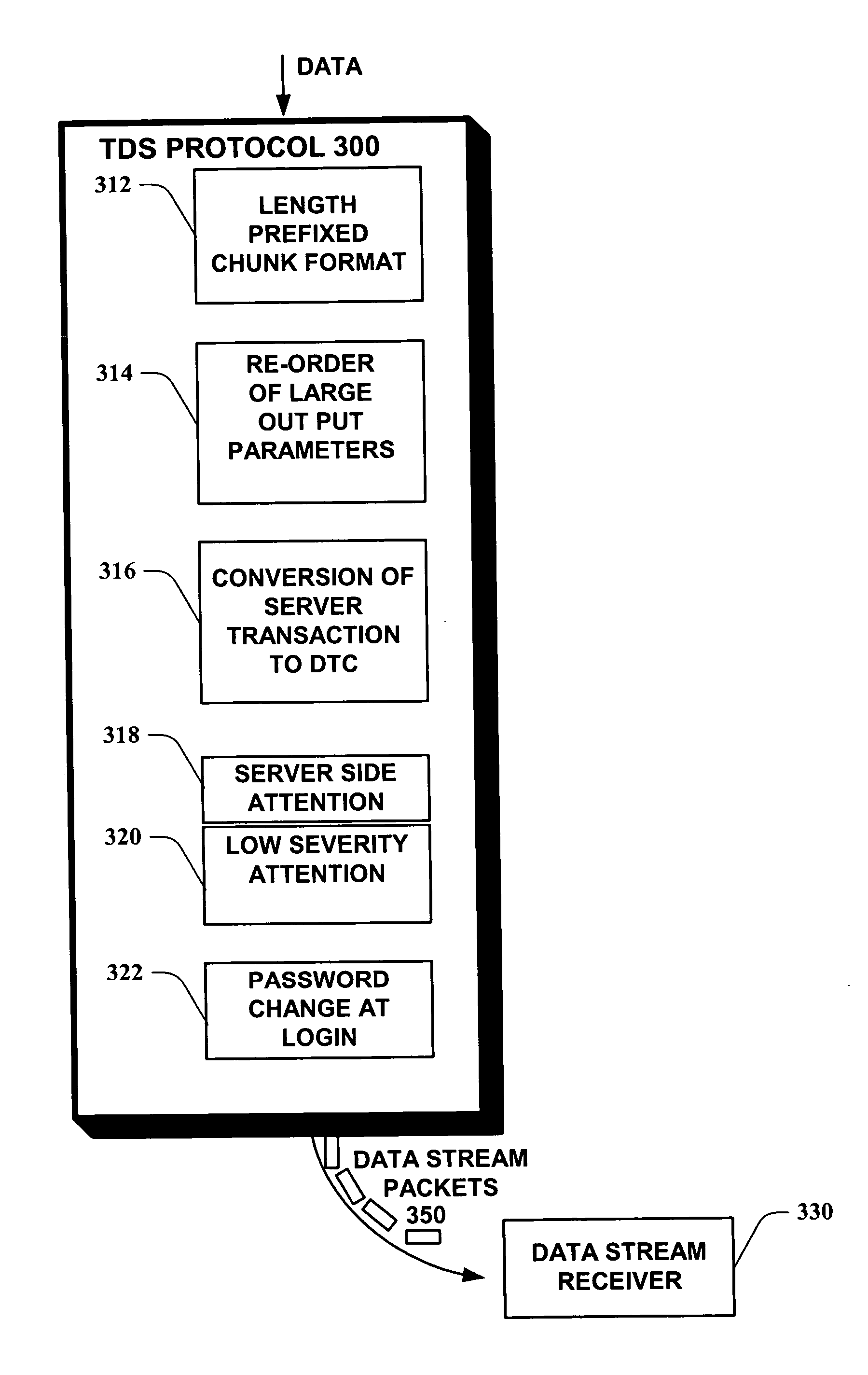

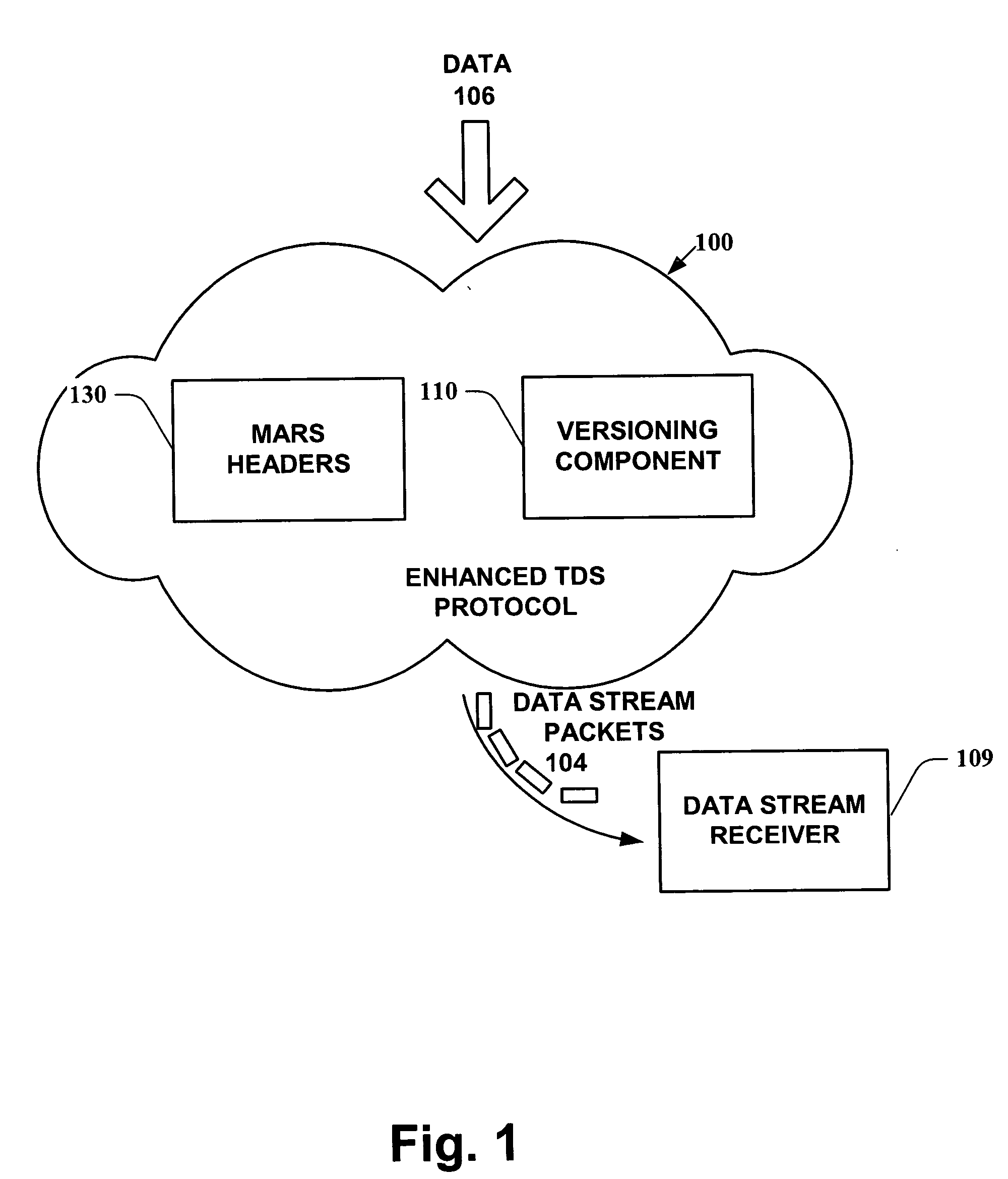

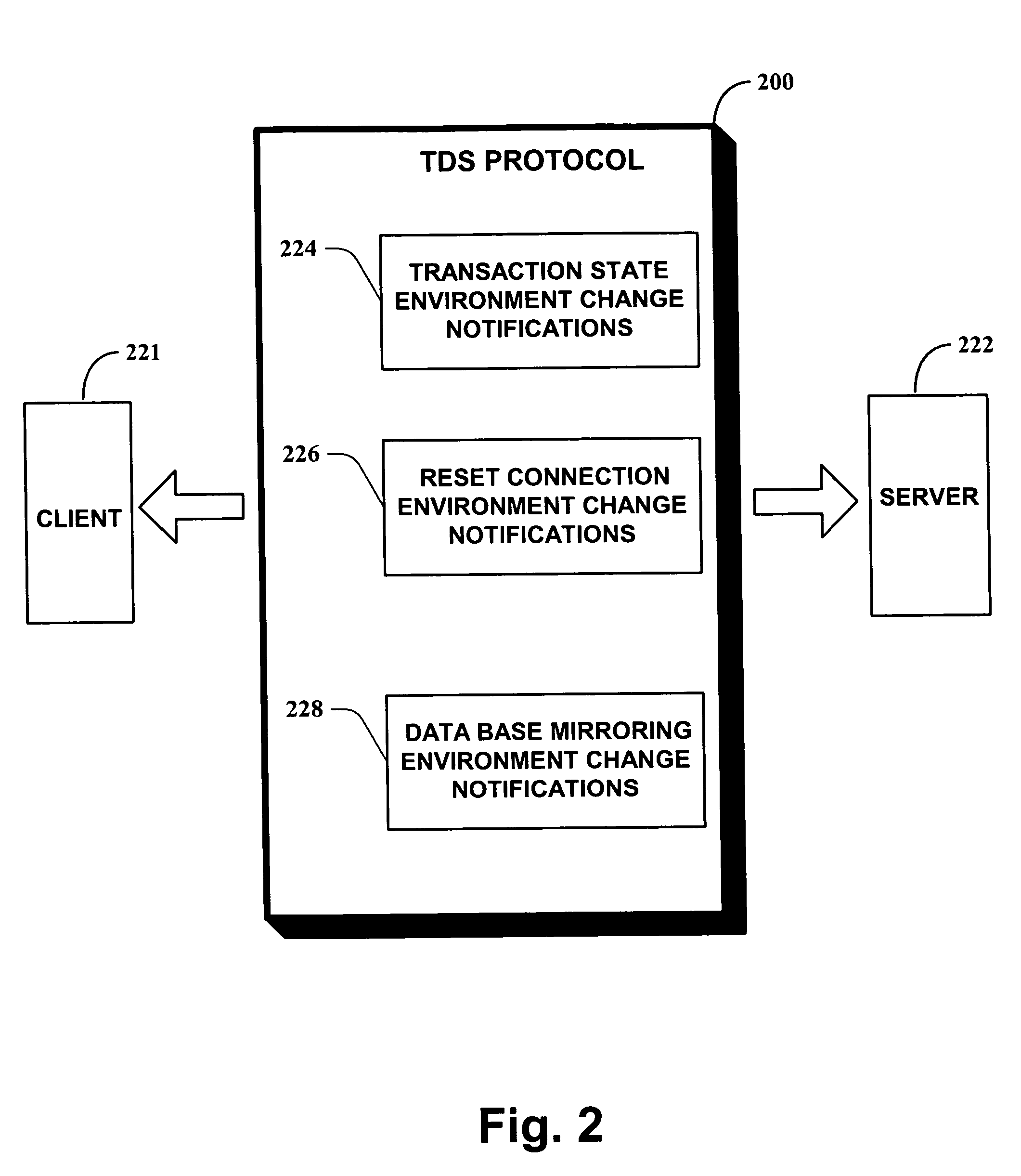

Enhanced tabular data stream protocol

InactiveUS7318075B2Good synchronizationFacilitate administrationData processing applicationsMultiple digital computer combinationsComputer hardwareData stream

Owner:MICROSOFT TECH LICENSING LLC

System and method for communicating secondary vending options

ActiveUS8060247B2Reliable constructionSuitable for useCoin-freed apparatus detailsMultiple digital computer combinationsDigital videoEmail address

A system and method for communicating secondary vending options for a vendible media product having entertainment content therein is provided. The system comprises a transaction network, and a database in communication with the transaction network, wherein the database stores a plurality of digital video disc titles and a plurality of locations and release dates corresponding to the digital video disc titles. A vending controller at a vending location receives a user request signal for a digital video disc, and determines whether the digital video disc is available in a vending inventory at the vending location. A central controller receives a first signal from the vending controller, wherein the first signal comprises a secondary vending option and a user electronic mail address. The central controller receives a second signal from the vending controller, wherein the second signal comprises an indication that the digital video disc is available in the vending inventory.

Owner:REDBOX AUTOMATED RETAIL

Enhanced tabular data stream protocol

InactiveUS20050182800A1Good synchronizationFacilitate administrationData processing applicationsMultiple digital computer combinationsComputer hardwareData stream

Systems and methodologies are provided as part of a computing environment that implements an enhanced tabular data stream (TDS) protocol. Such enhanced TDS protocol can mitigate synchronization inconsistencies between client and servers, improve robustness of the data transfer, facilitate password specification as part of login procedures, and reduce administration overhead. Various headers are provided as part of the data stream protocol, and a versioning scheme is established that facilitates proper communication between servers and clients having different release dates and versions of the TDS protocol.

Owner:MICROSOFT TECH LICENSING LLC

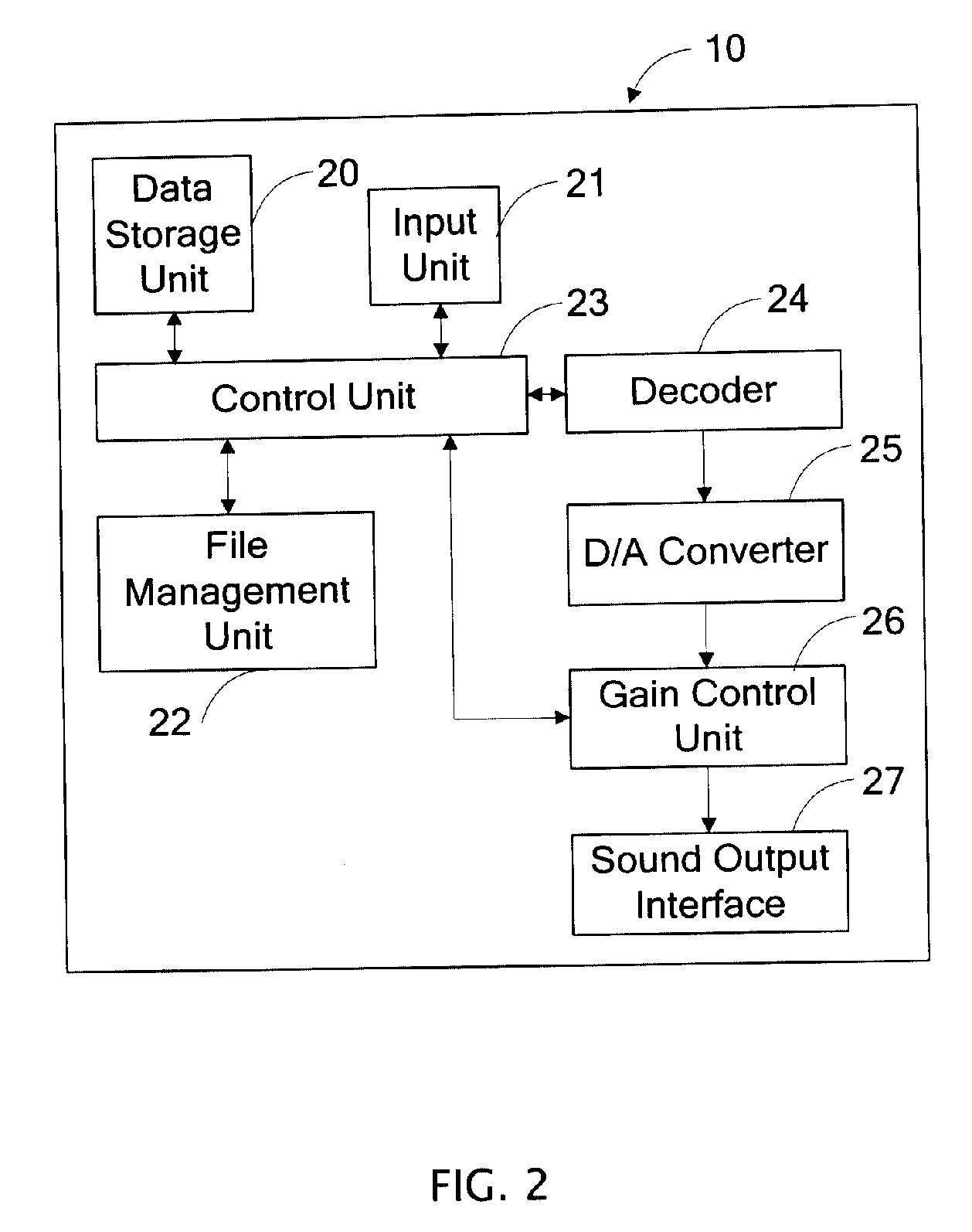

Apparatus for controlling music storage

InactiveUS20090071316A1High subscriptionLimited abilityGearworksMusical toysPersonal computerMusic player

Apparatus for controlling music storage includes a memory, and a processor configured to (i) control the storing of a plurality of digital song files in the memory, and (ii) control the storing in the memory of a plurality of song indicia corresponding to each digital song file. The plurality of song indicia for each digital song file preferably includes artist, song title, and at least one of (i) audience reach, (ii) song original release date, (iii) plural different genres, (iv) mood, and (v) era. The apparatus may comprise on or more of a portable music player, a personal computer, an Internet server, or a cable or satellite device.

Owner:3B MUSIC

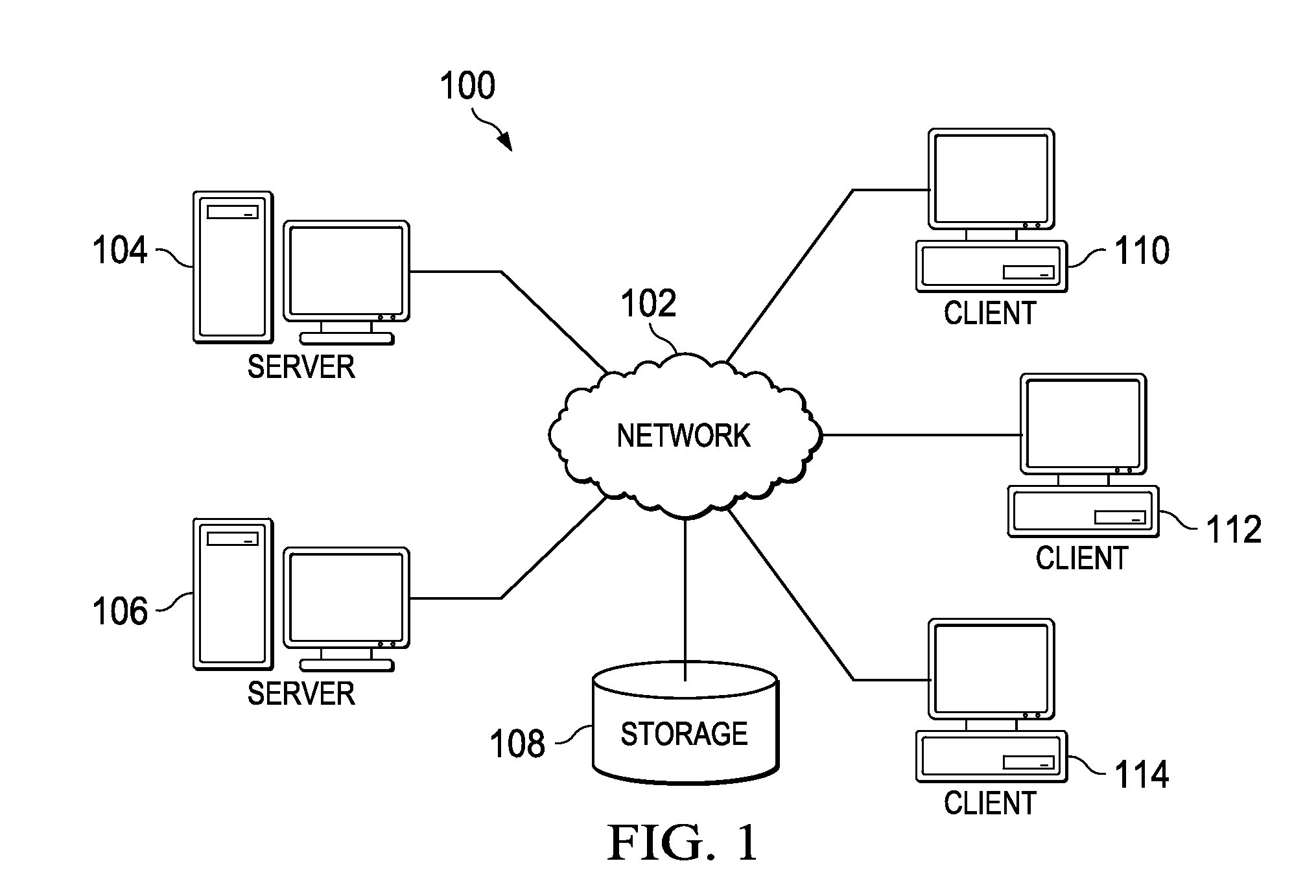

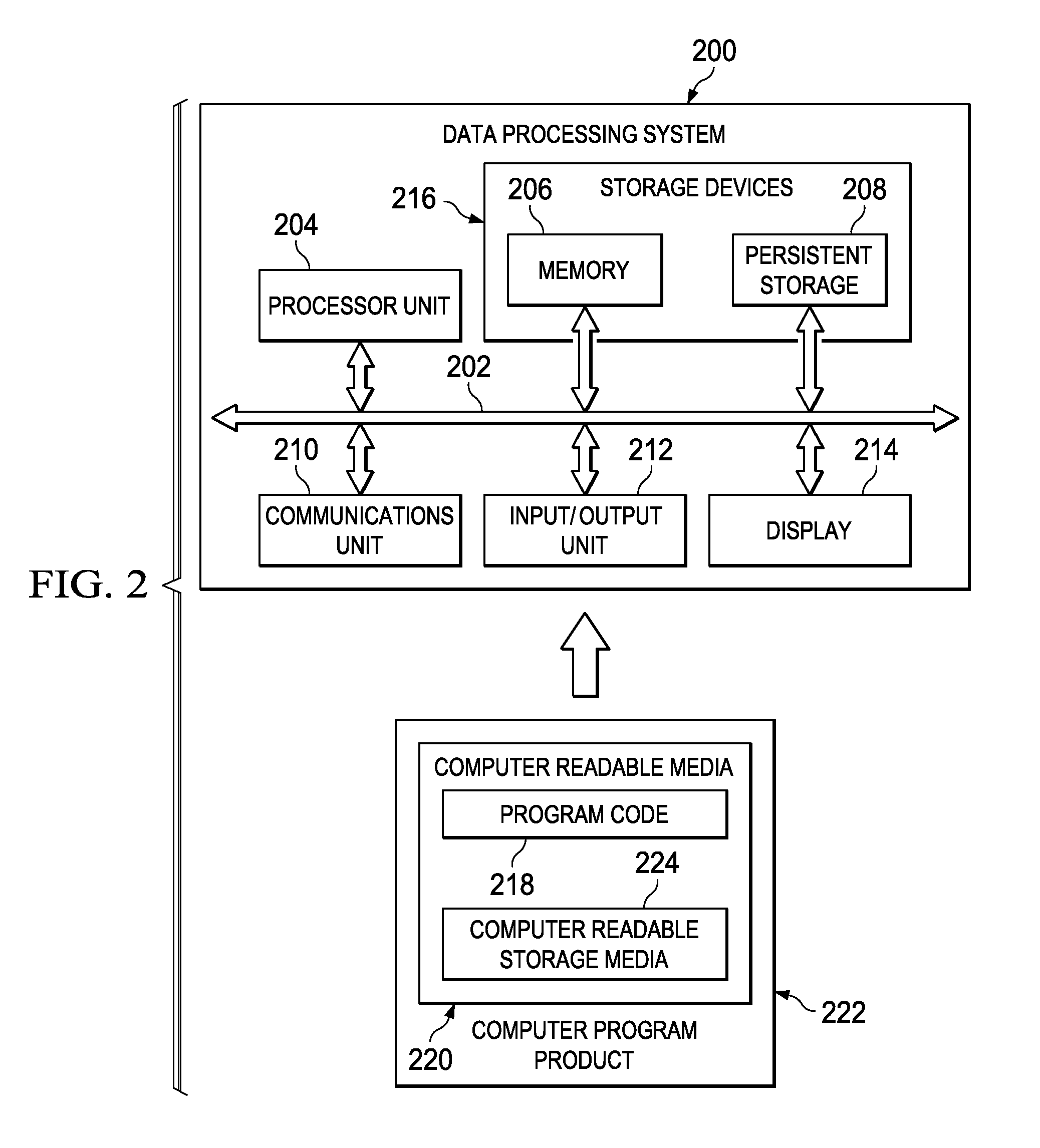

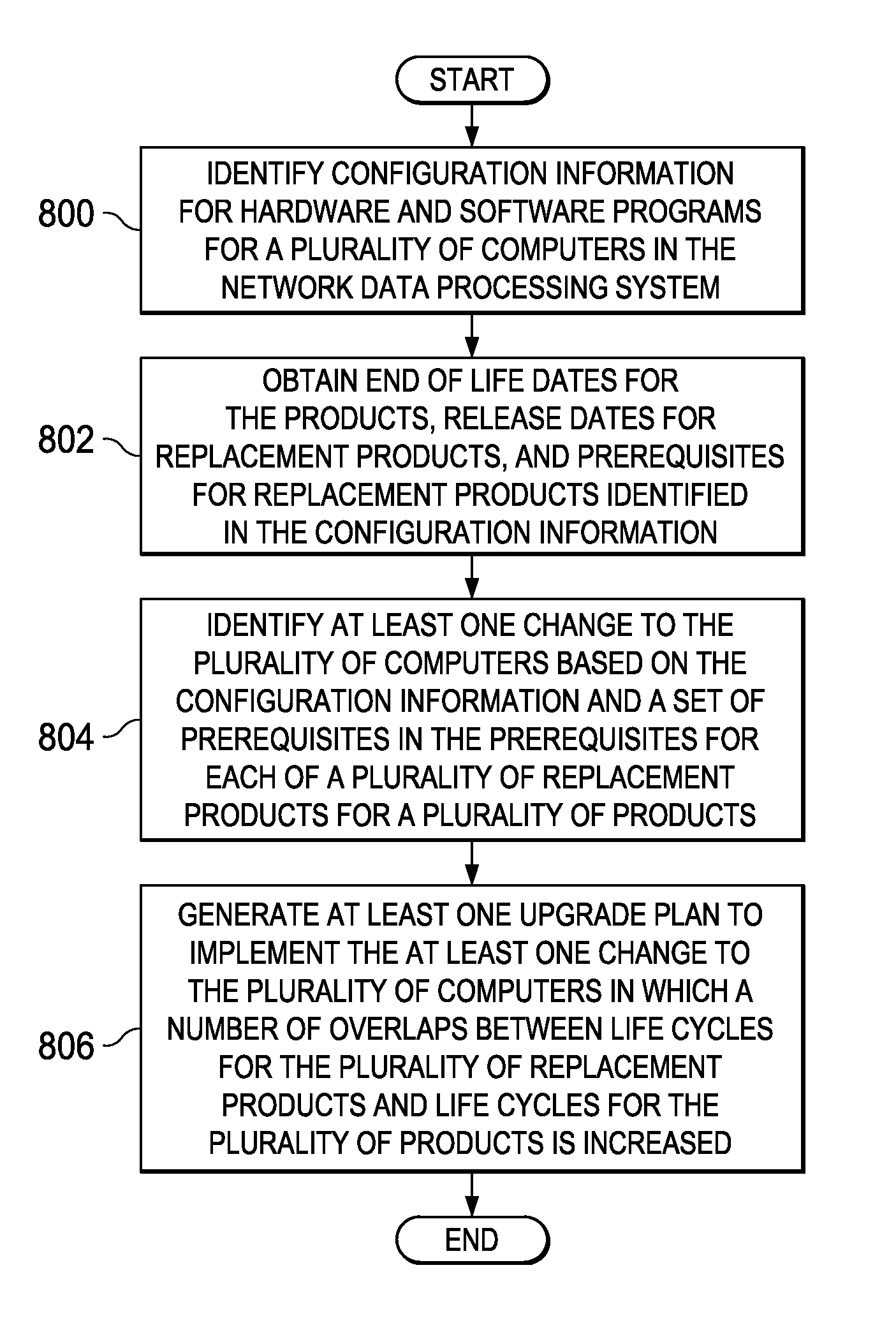

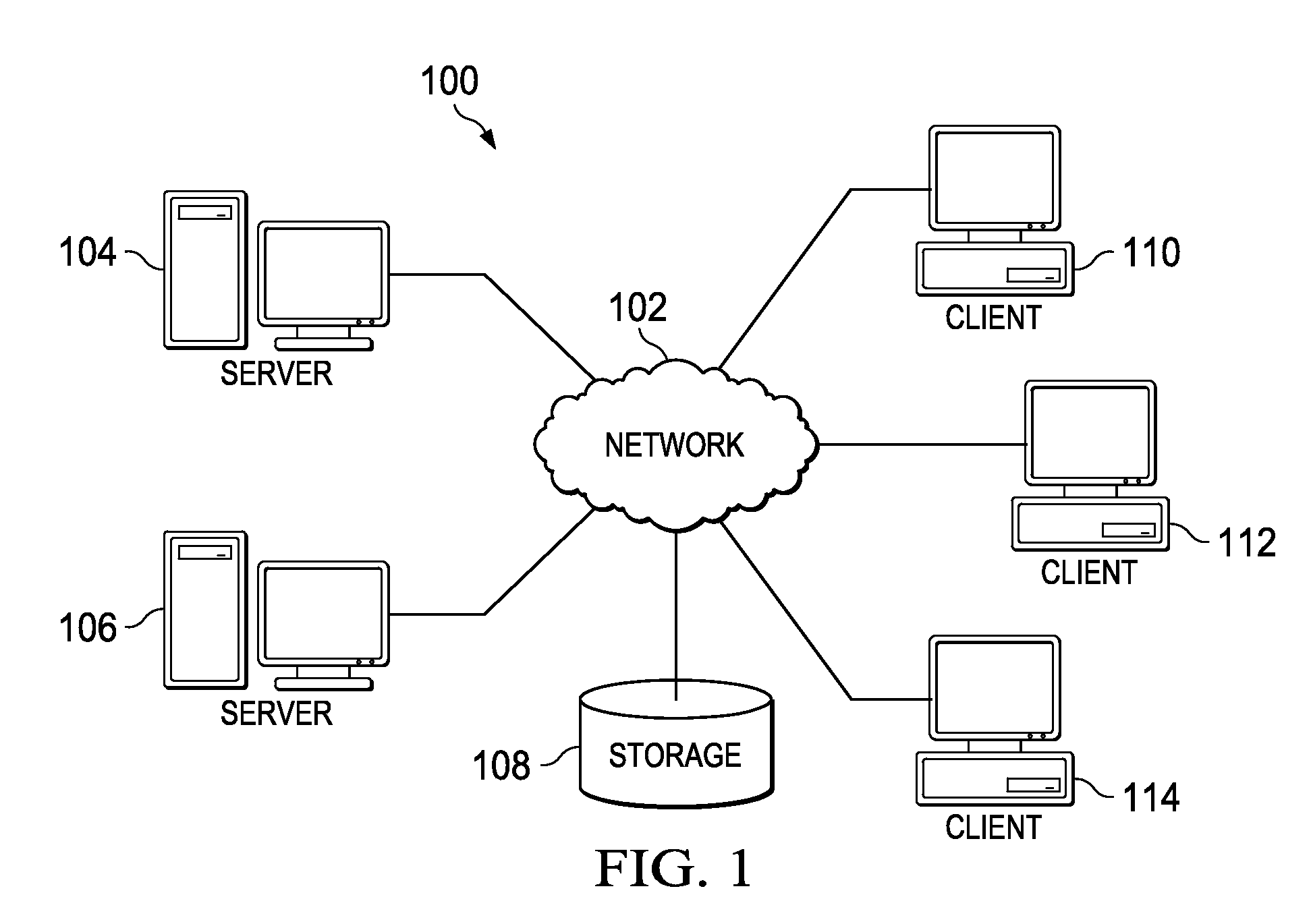

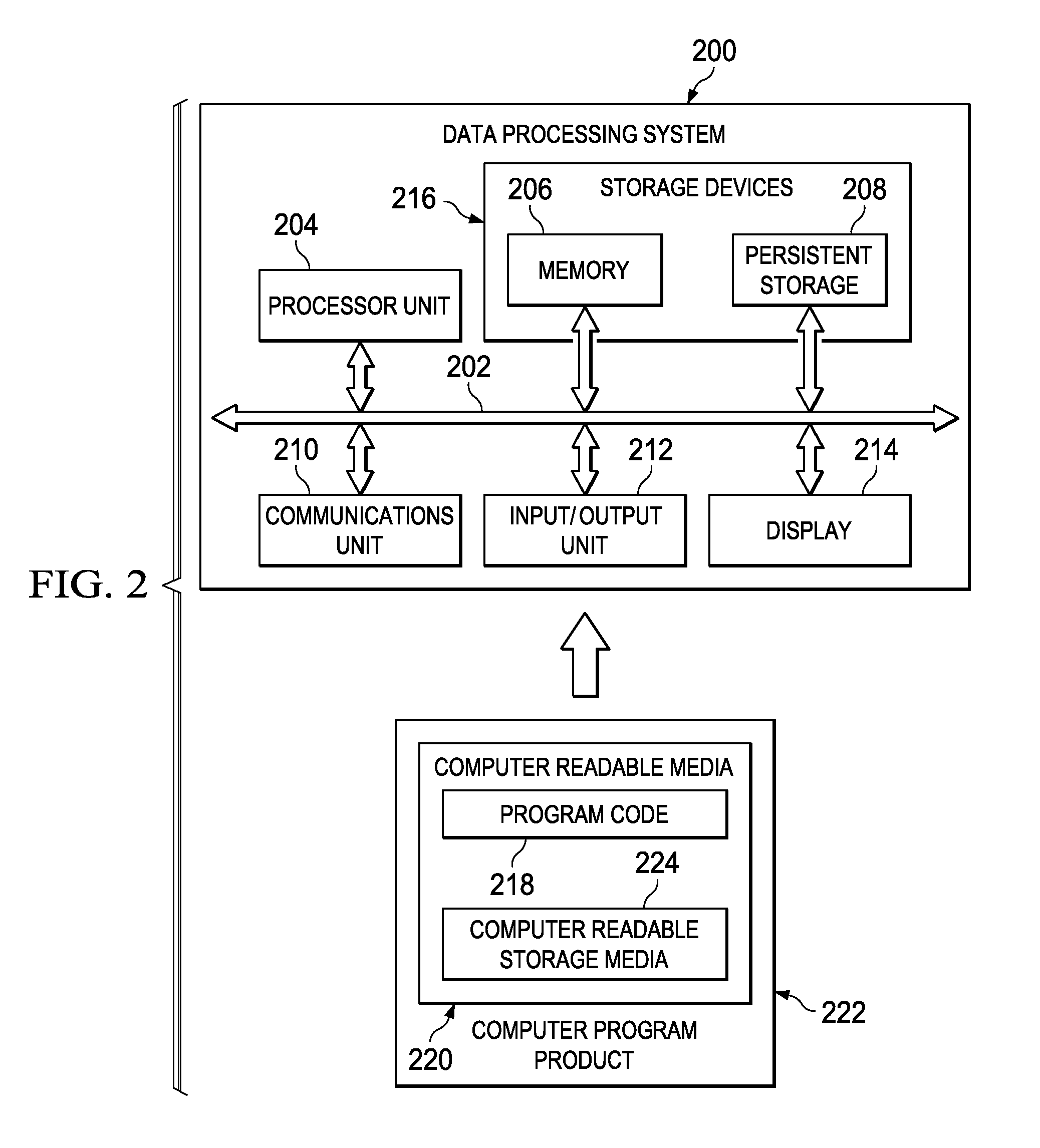

Software management system for network data processing systems

ActiveUS20110239189A1Digital data processing detailsTransmissionData processing systemSoftware engineering

A method, data processing system, and computer program product are presented for planning upgrades to a network data processing system. A processor unit identifies configuration information for hardware and software programs for a plurality of computers in the network data processing system. The processor unit obtains end of life dates for the software programs, release dates for the replacement software programs, and prerequisites for replacement software programs for the software programs identified in the configuration information. The processor unit identifies at least one change to the plurality of computers based on the configuration information and a set of prerequisites in the prerequisites for each of a plurality of replacement software programs for a plurality of software programs in the software programs. The processor unit generates at least one upgrade plan to implement at least one change to the plurality of computers in which a number of overlaps between life cycles for the plurality of replacement software programs and life cycles for the plurality of software programs in the software programs is increased.

Owner:KYNDRYL INC

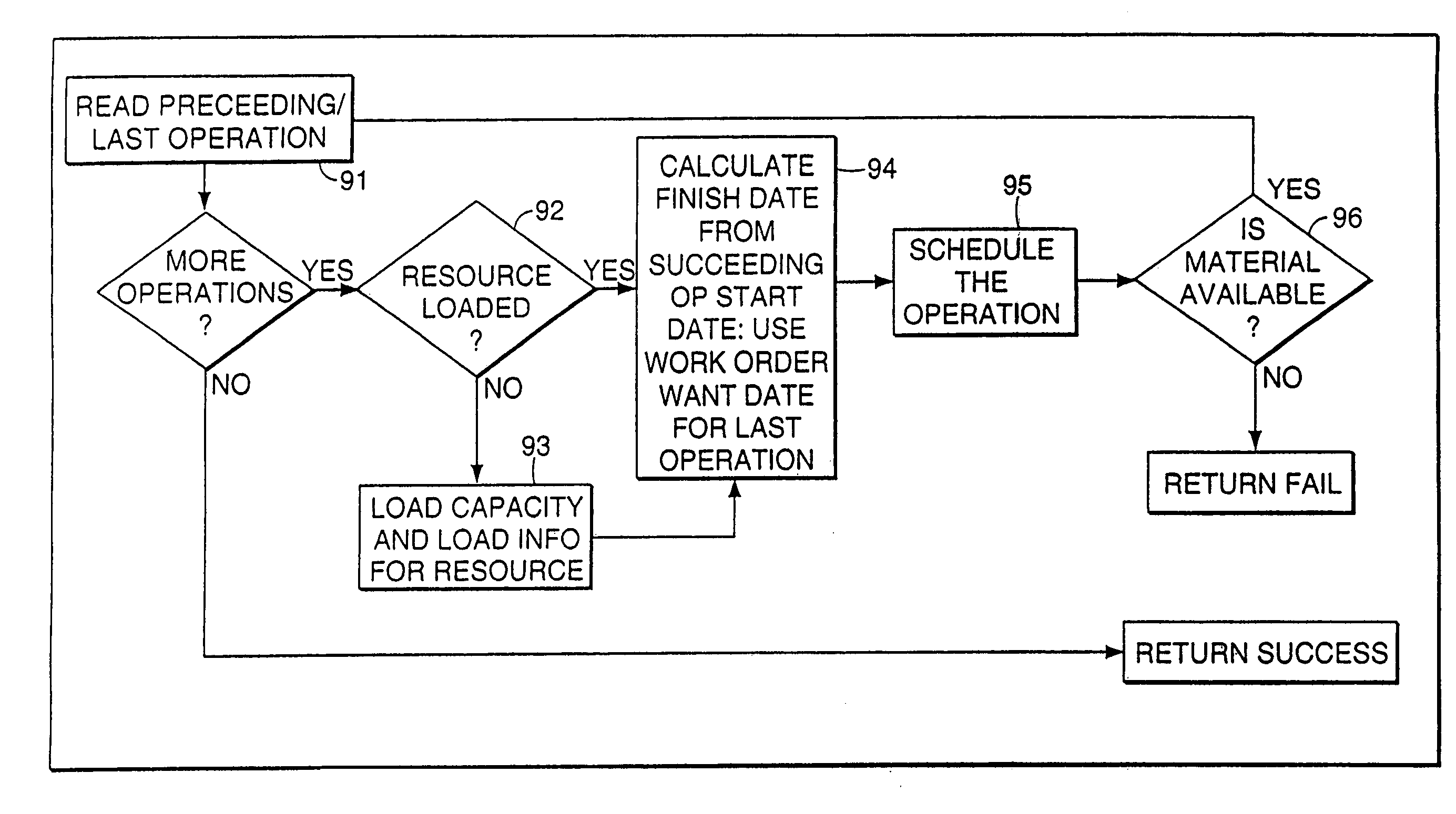

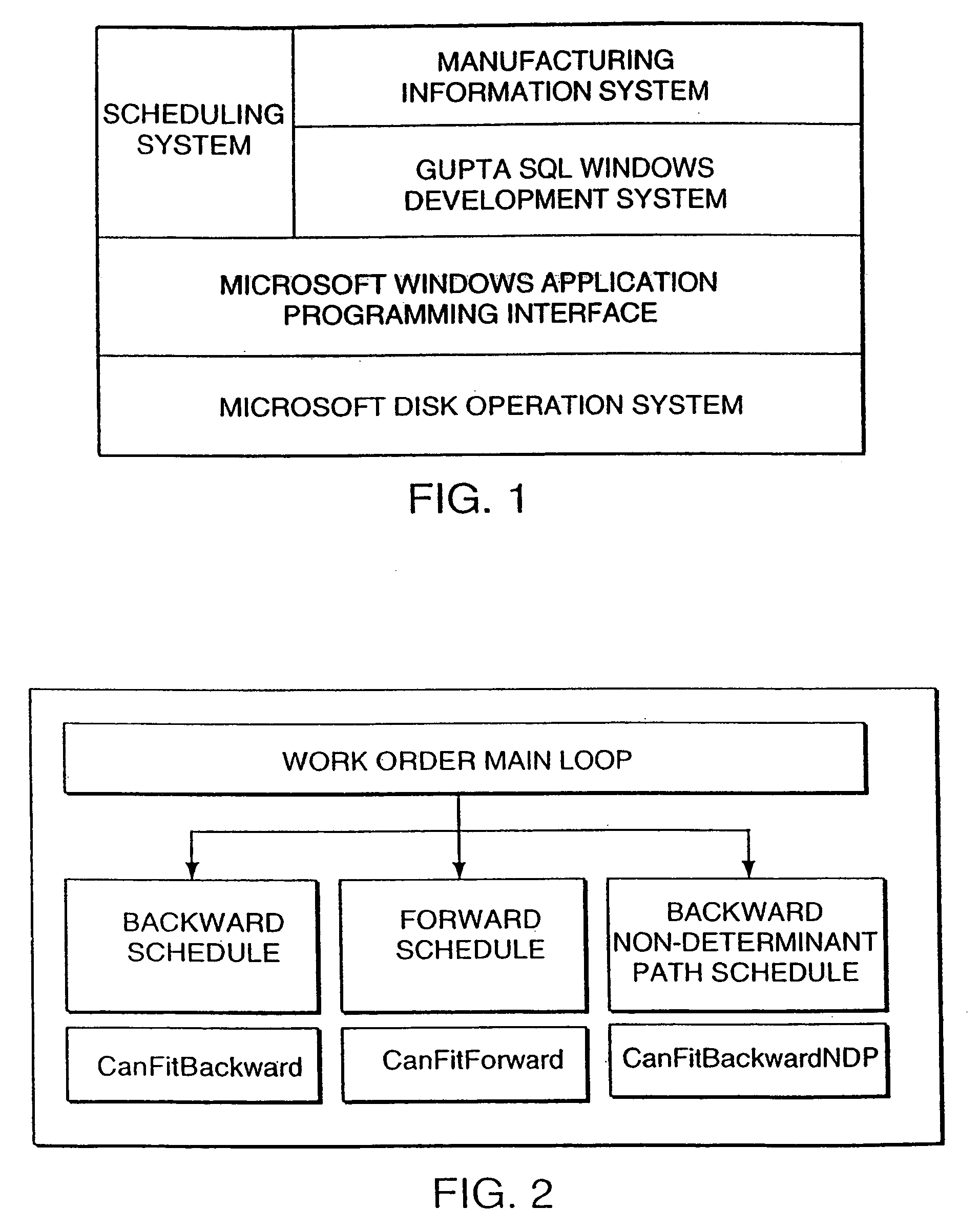

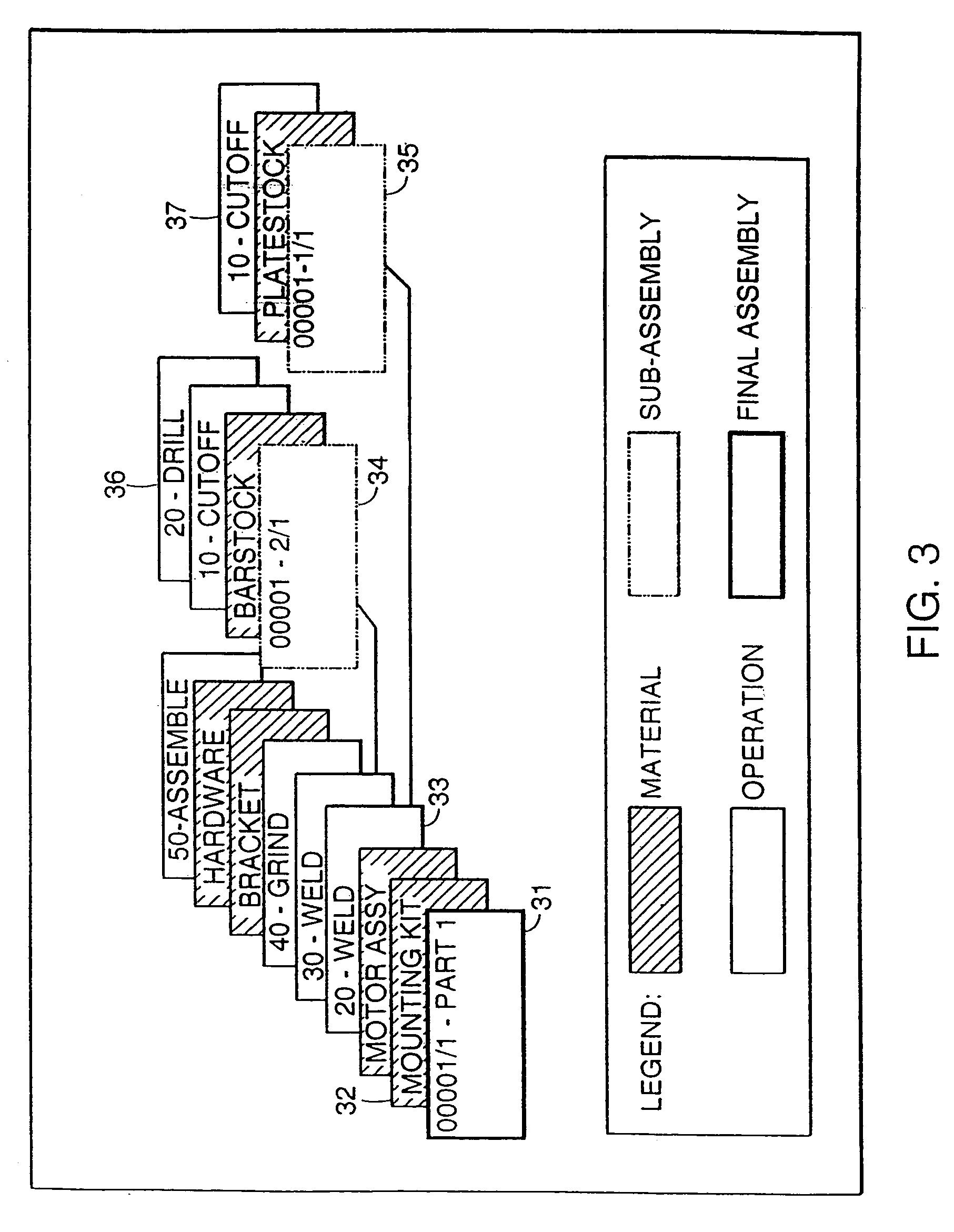

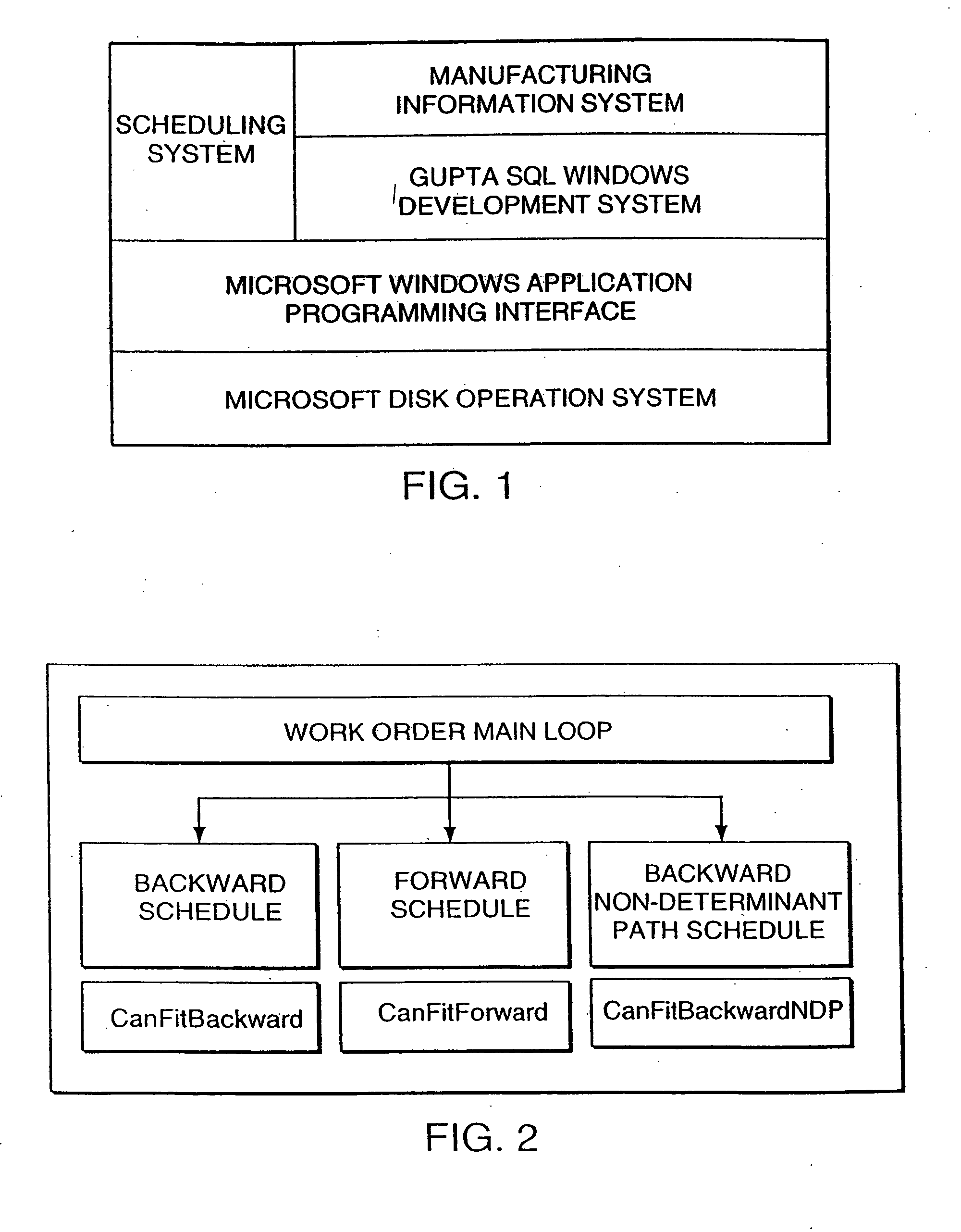

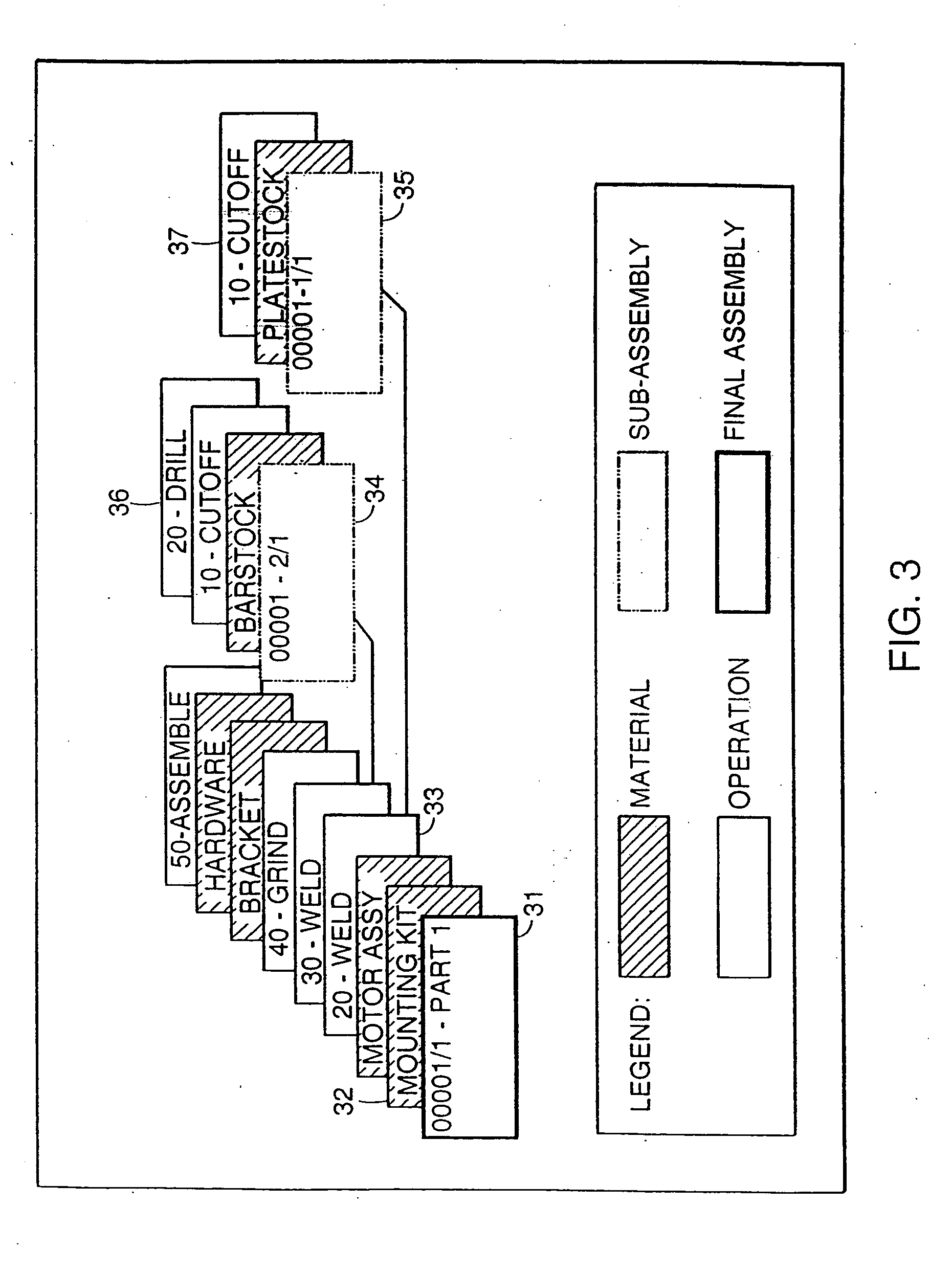

Method and apparatus for scheduling work orders in a manufacturing process

InactiveUS7089071B2Improve overall utilizationResourcesTotal factory controlGraphicsComputerized system

A computerized system is provided for scheduling a plurality of work orders in a manufacturing process. Each work order to be scheduled specifies a set of operations to be performed using a plurality of resources and materials. Data including resource availability information for each resource used in the manufacturing process, material availability information for each material used in the manufacturing process, and work order information is received and stored in a computer. The work order information includes a release date for the work order, a want date for the work order, operations information, and material requirements information. The operations information includes the identity and sequence of operations to be performed for the work order, the identity of the resources needed to perform each operation, a minimum resource capacity needed to perform each operation, and the time needed to perform the operation. The materials information includes the identity of the materials needed to perform each operation and the quantity of each material needed for the operation. Resource capacity and a start date / time and a finish date / time are assigned to each operation based upon the resource availability information, the material availability information, and the work order information. The assigned resource-capacity, the assigned start date / time, and the assigned finish date / time for each operation are displayed on a computer screen in a graphical format.

Owner:INFOR VEENENDAAL

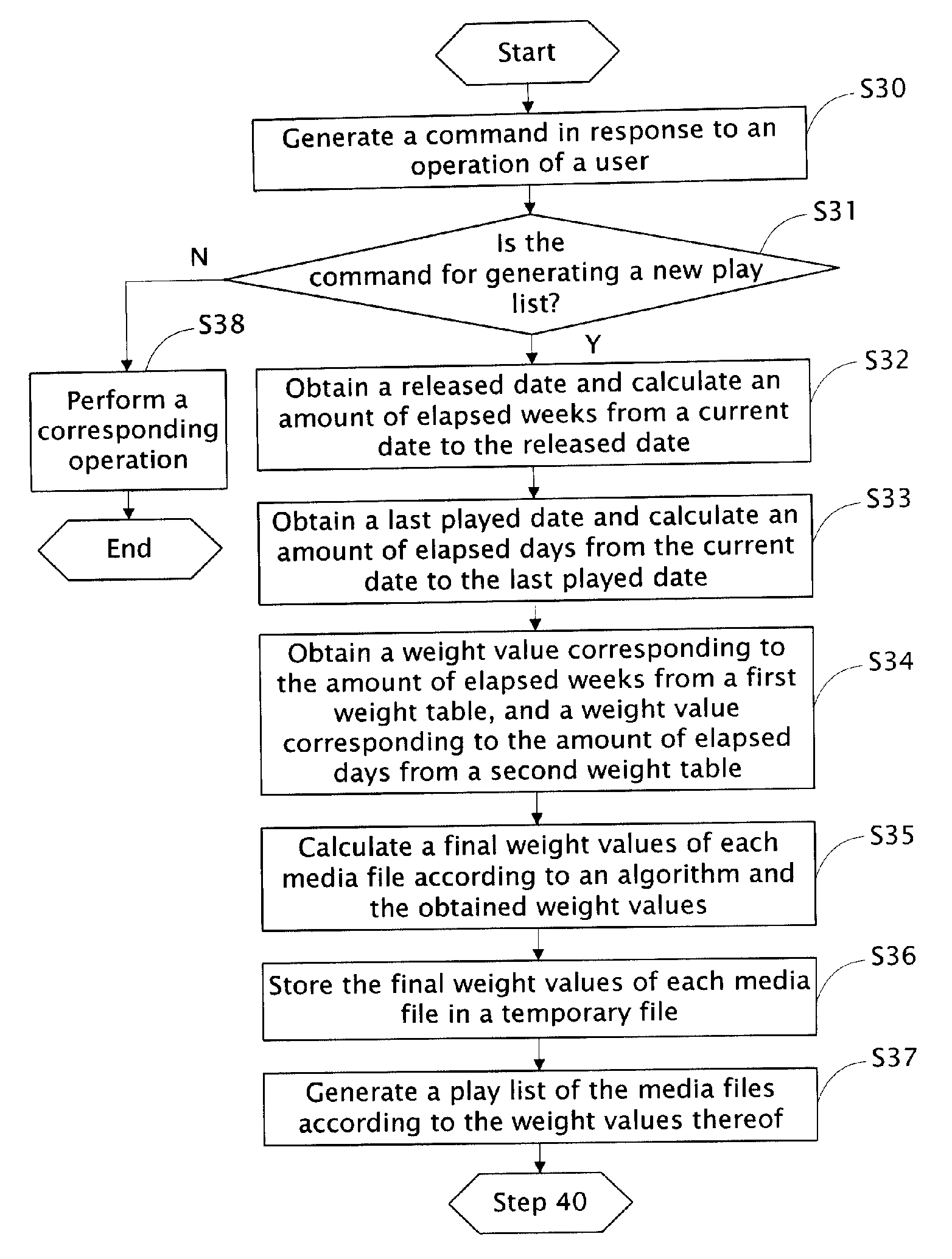

System and method for generating a play-list

InactiveUS20060294132A1Digital data information retrievalDigital data processing detailsComputer hardwareRelease date

A method for automatically generating a play list based on the age of the media recording (based on released date) and the time period the media file was last played. This method uses tags on the media file to store the corresponding dates and generates a weight value on each media file by using an algorithm based on settable values for each elapsed time period of the released date and the last played date. The present invention makes the play-list more tailored to a user's listening preferences.

Owner:HON HAI PRECISION IND CO LTD

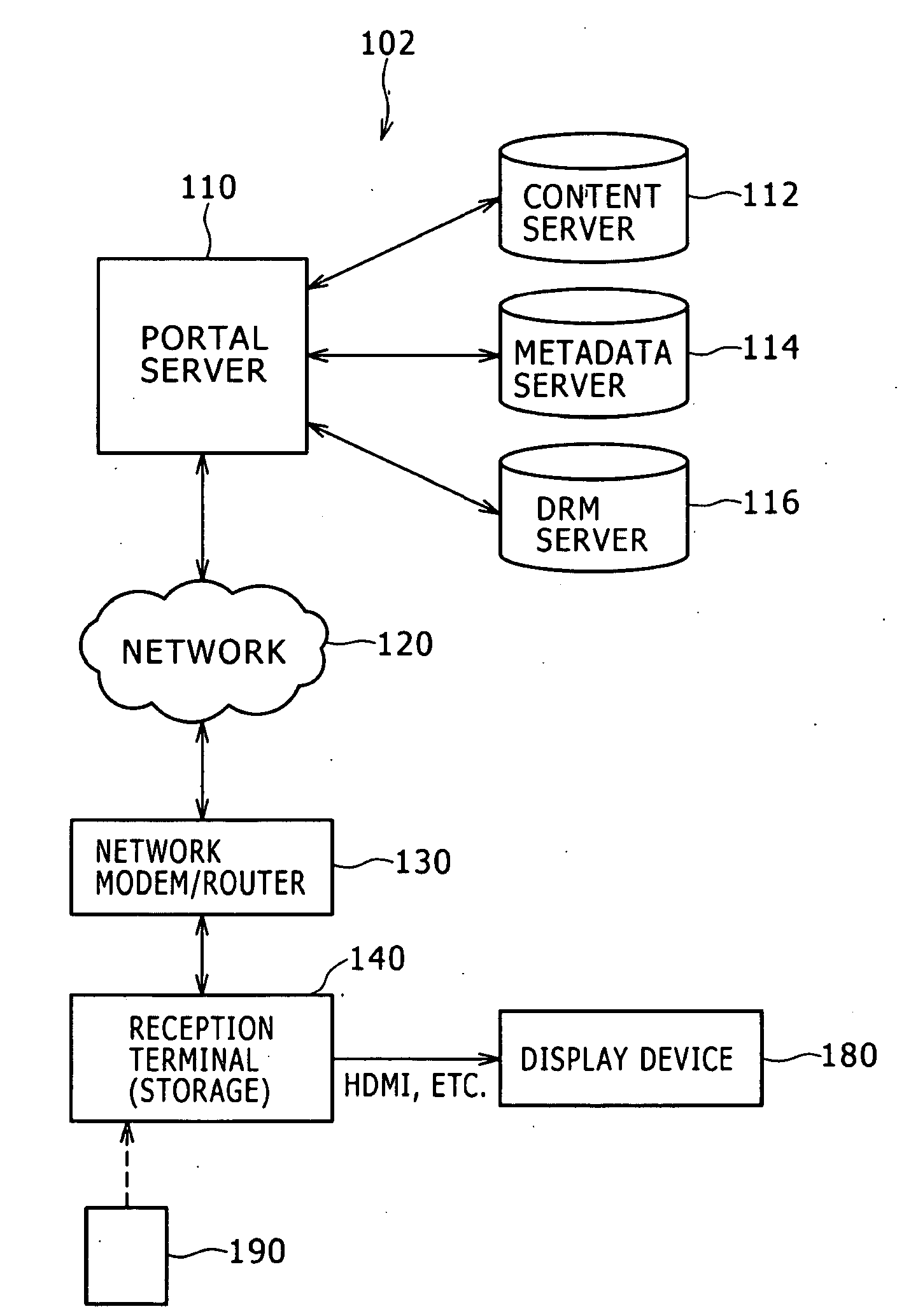

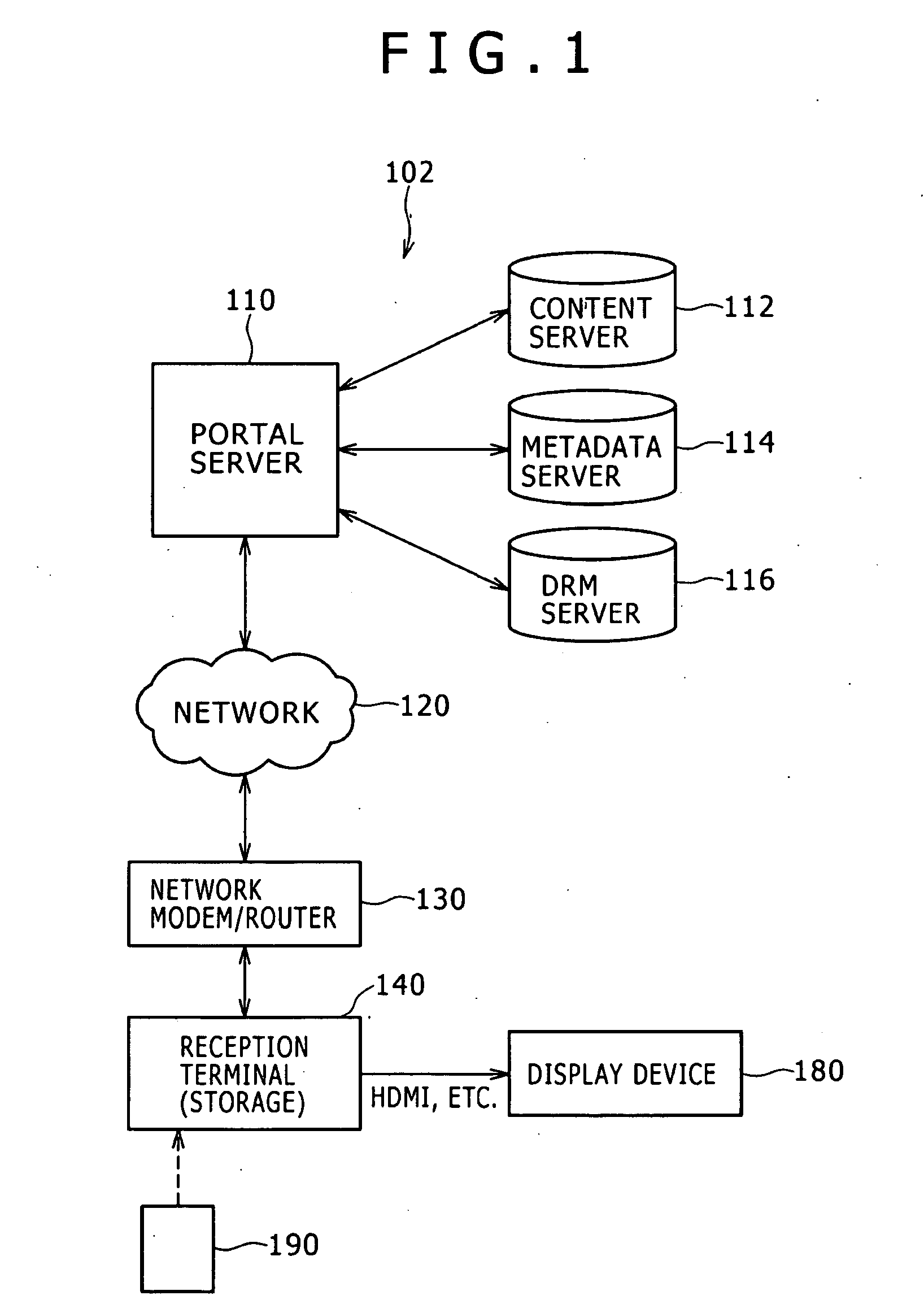

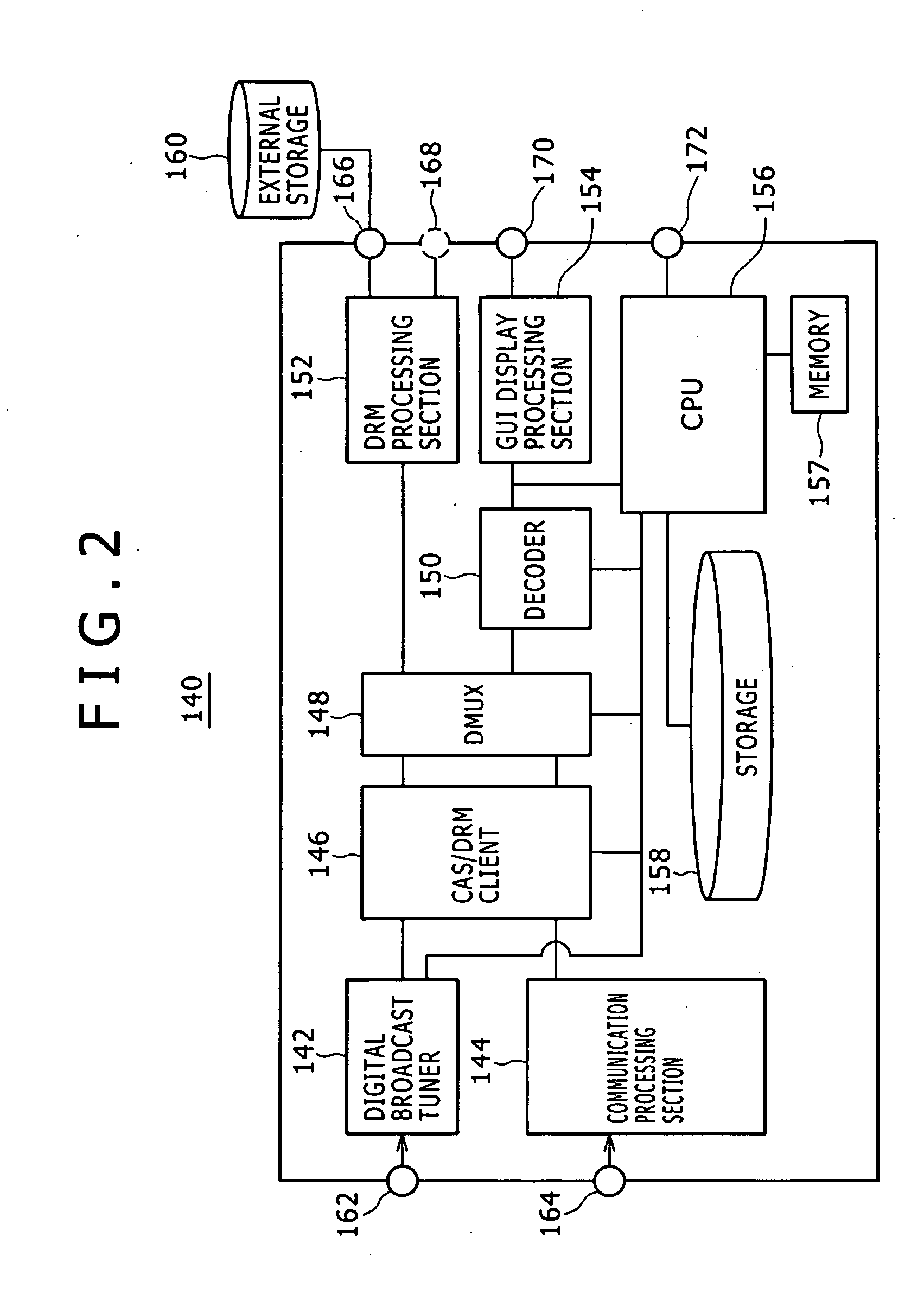

Content delivery system, delivery server, user terminal, and method

A system including a delivery server and a user terminal is disclosed. The deliver server includes a processor configured to transmit metadata including schedule information about release dates for content items, receive a request for one of the content items, the request being based on the schedule information included in the metadata, and transmit the requested content item in response to the request. The user terminal includes a processor configured to receive the metadata including the schedule information about release dates for the content items, send the request for one of the content items based on the schedule information included in the metadata, and receive the requested content item.

Owner:SONY CORP

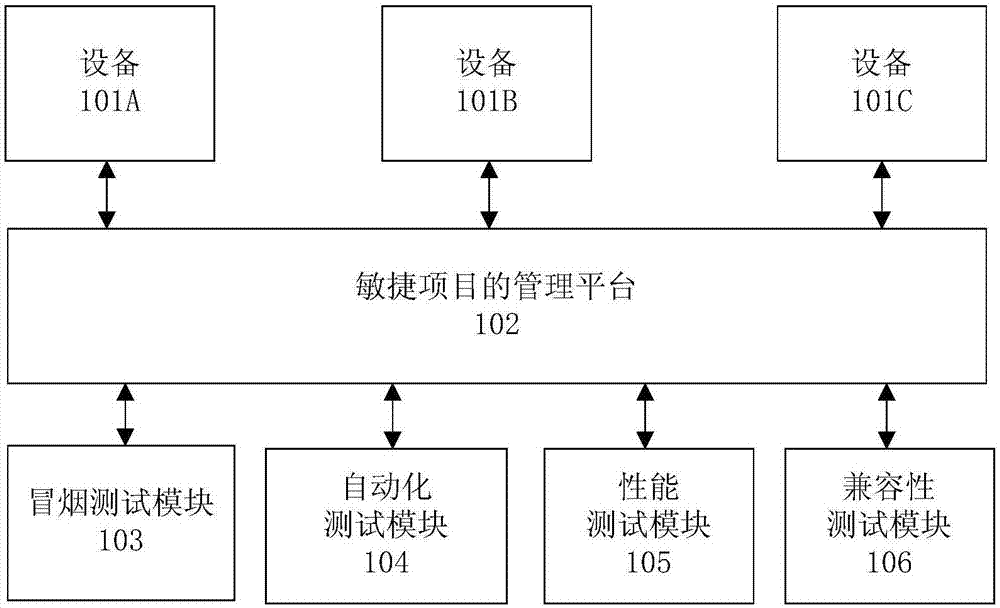

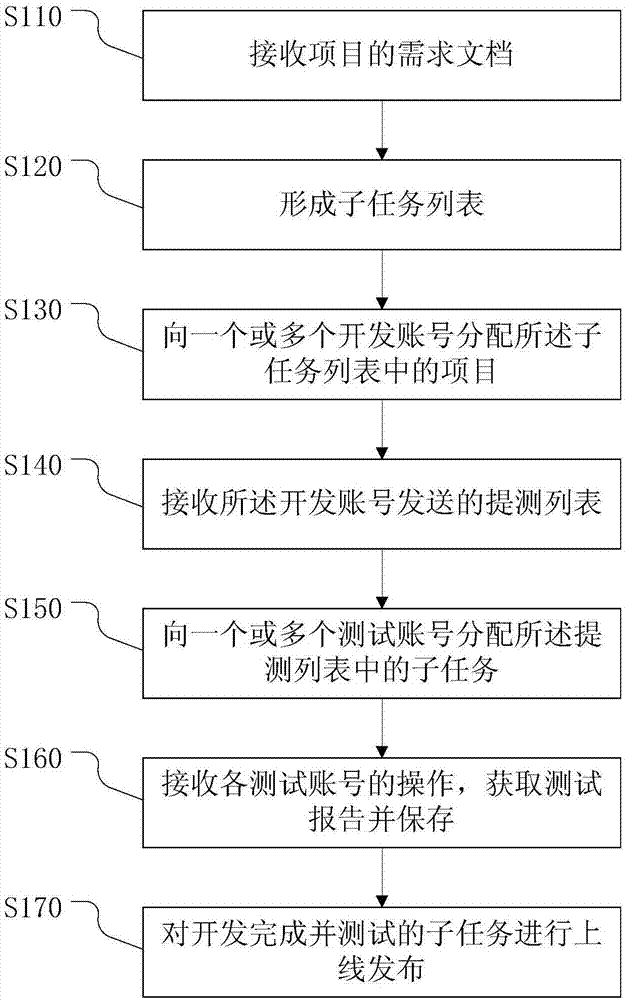

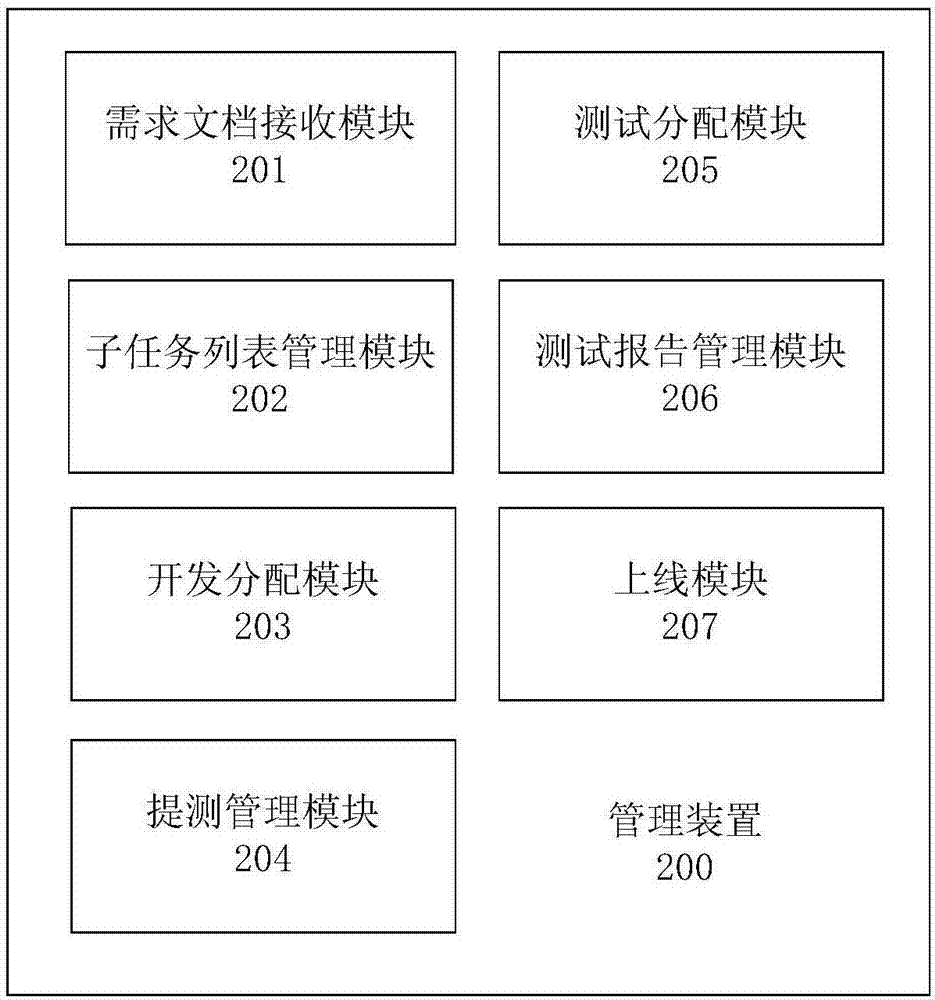

Agile project management method, device and system, electronic equipment and storage medium

ActiveCN107516192AFunction increaseImprove work efficiencySoftware testing/debuggingOffice automationProject managementDocumentation

The invention provides an agile project management method, device and system, electronic equipment and a storage medium. The management method includes: receiving a requirement document of project; splitting the project into multiple subtasks according to the requirement document to form a subtask list; according to the number of currently-uncompleted subtasks of development accounts and the scheduled releasing date of the uncompleted tasks, assigning the subtasks in the subtask list to one development account or more; receiving a test mentioning list sent by the development accounts; according to the number of the currently-untested subtasks of test accounts and scheduled releasing date of the untested subtasks, assigning the subtasks in the test mentioning list to one test account or more; receiving operations of the test accounts and acquiring one test report or more from the subtasks in the test mentioning list; releasing the subtasks completed in development and tested on line. With the method and device, integral management of the agile project is achieved.

Owner:携程旅游信息技术(上海)有限公司

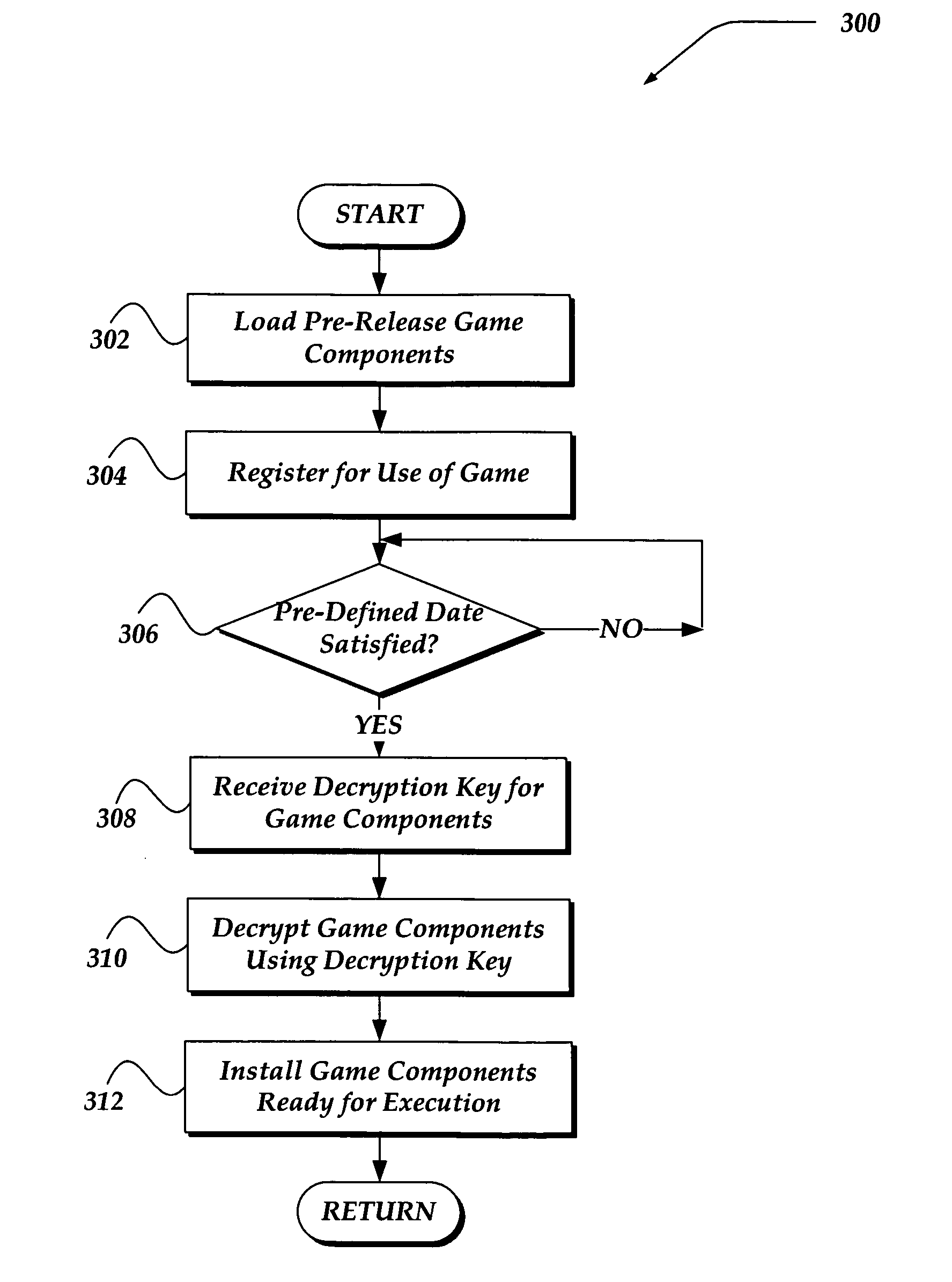

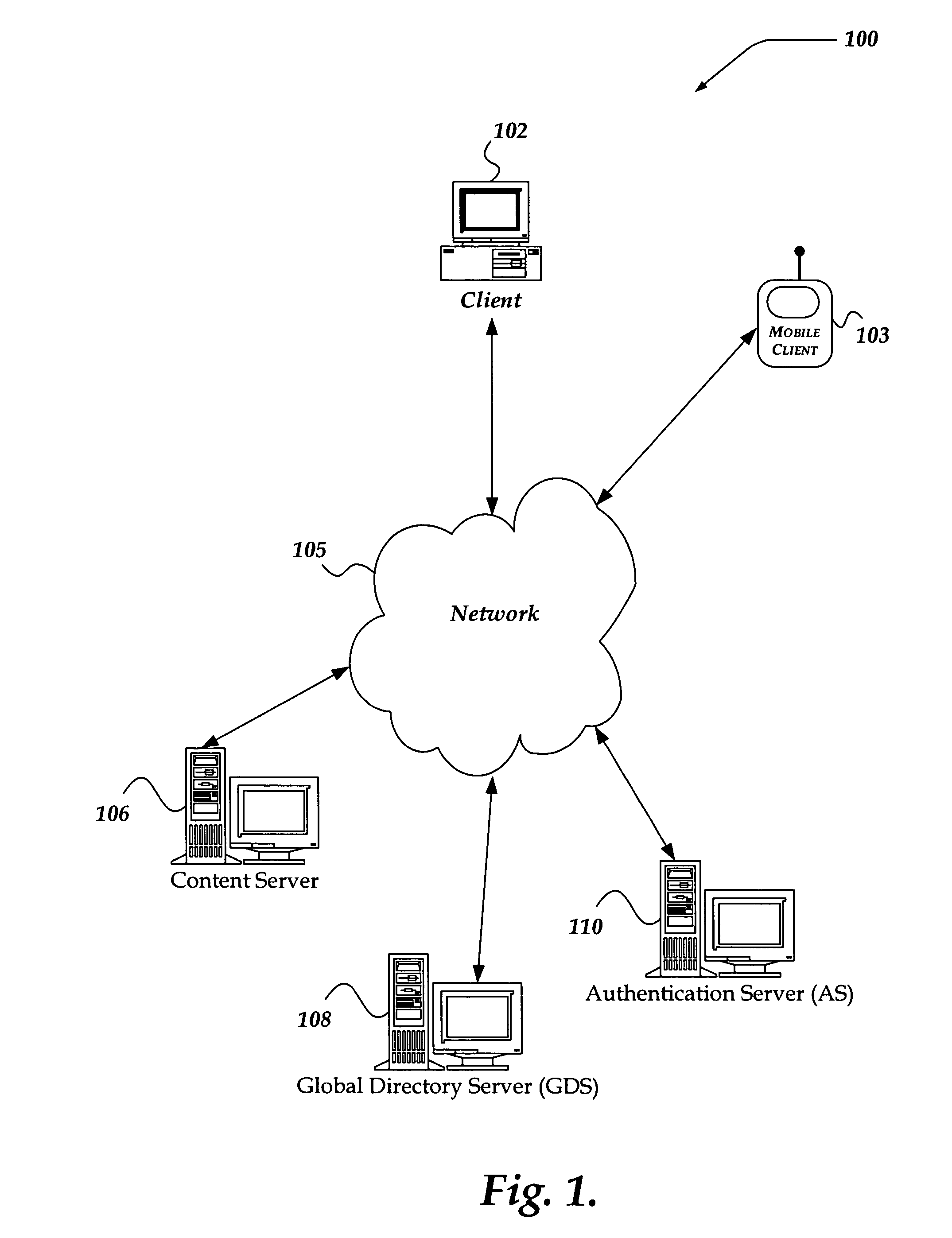

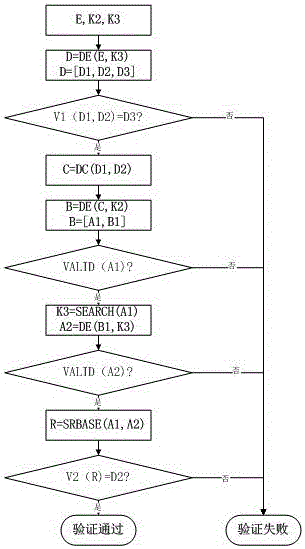

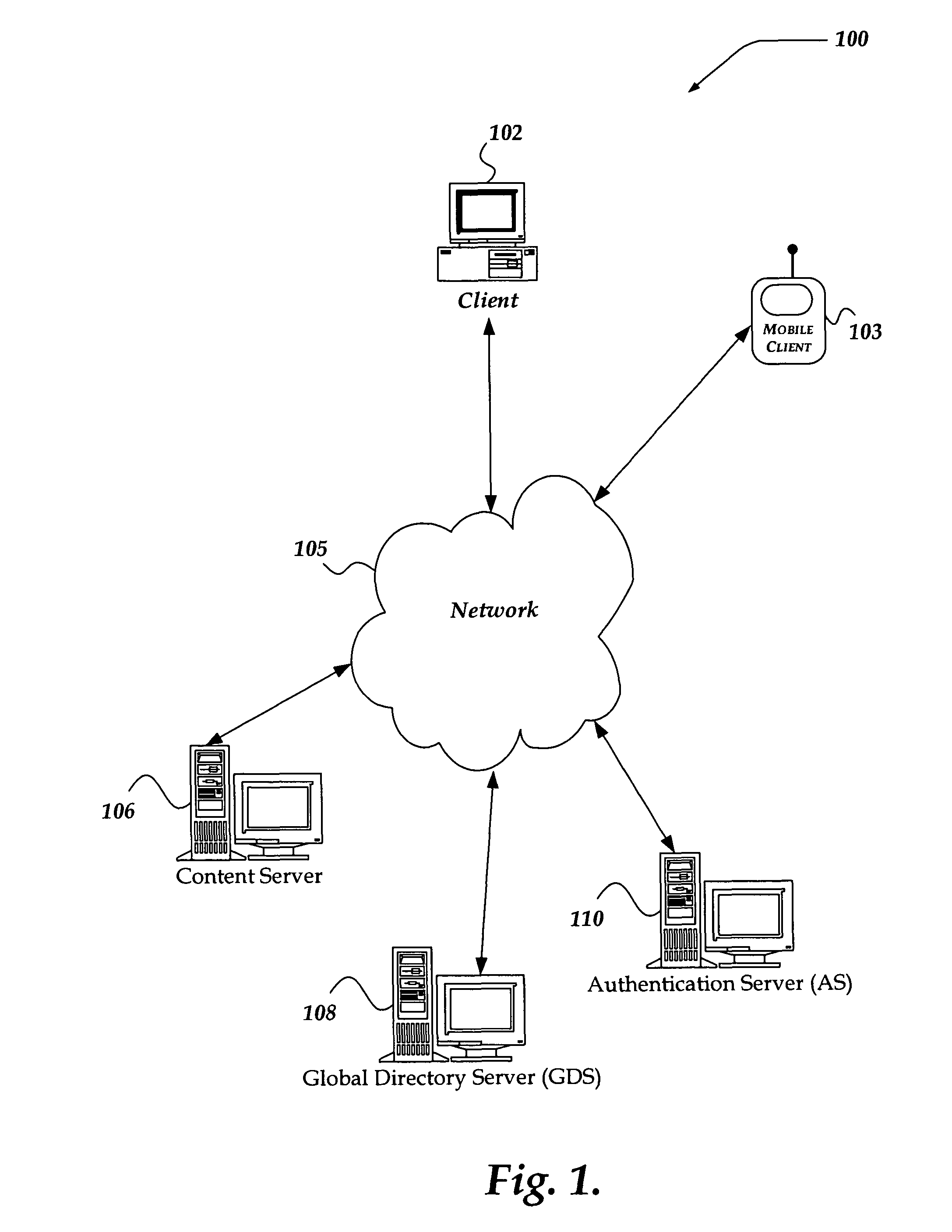

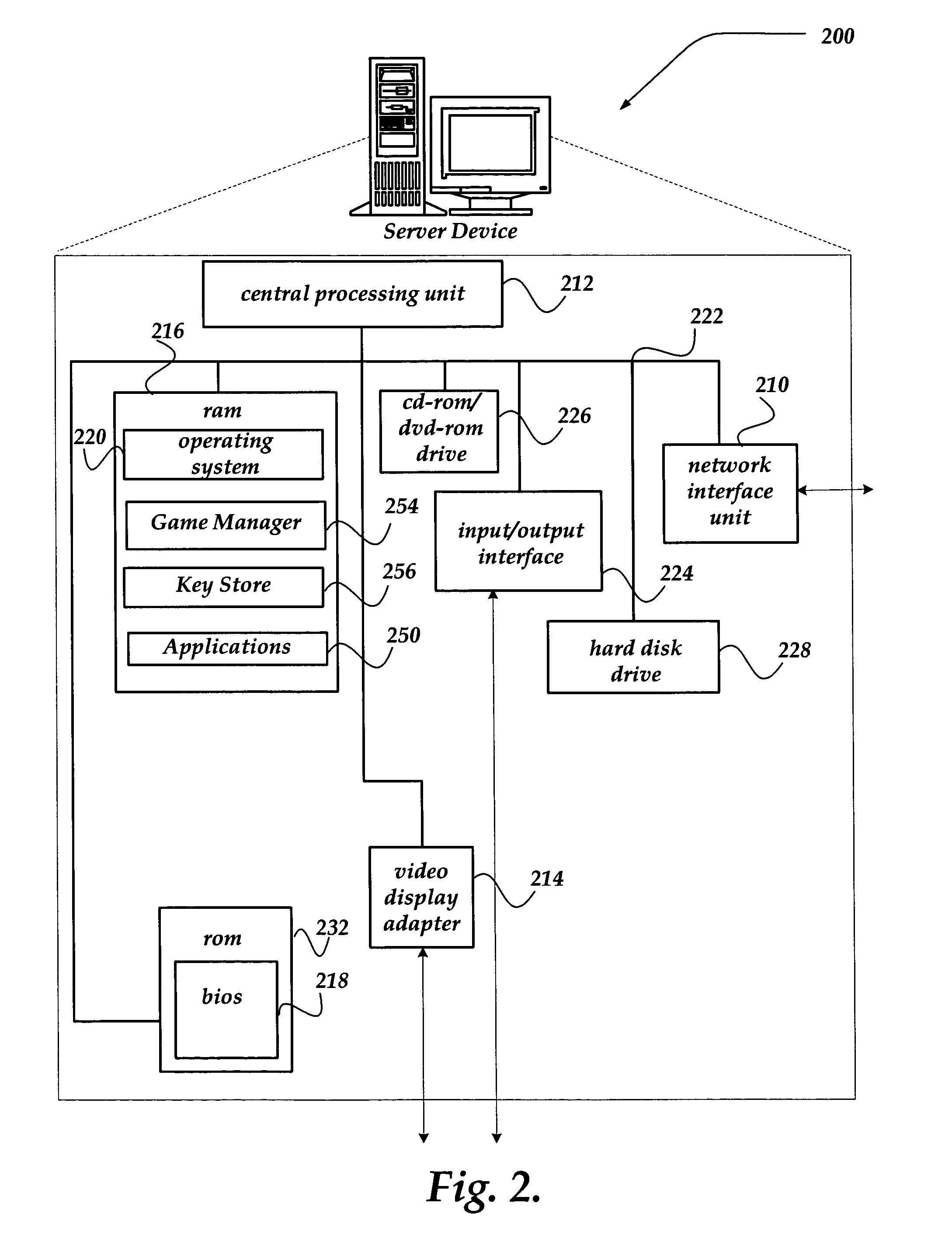

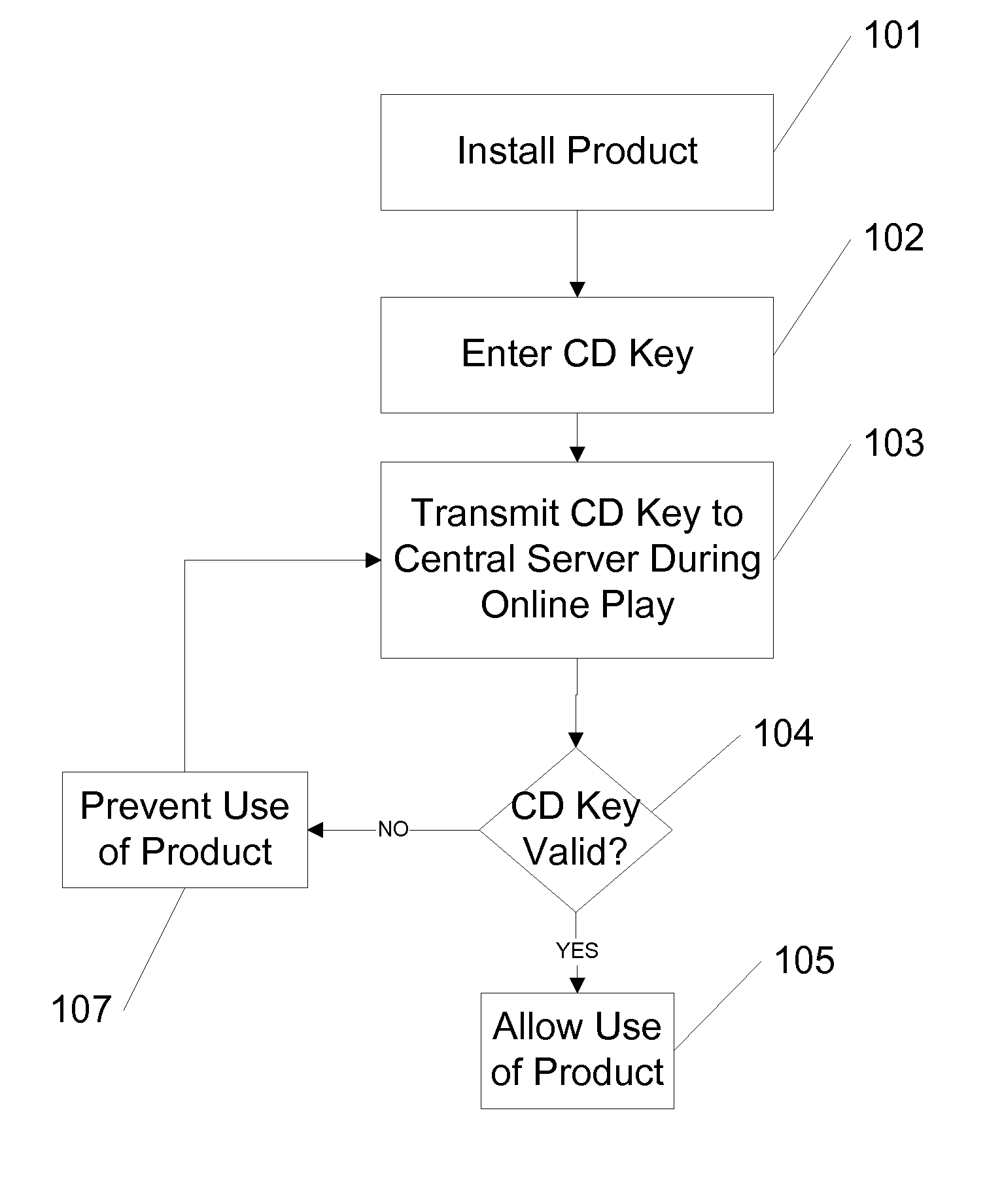

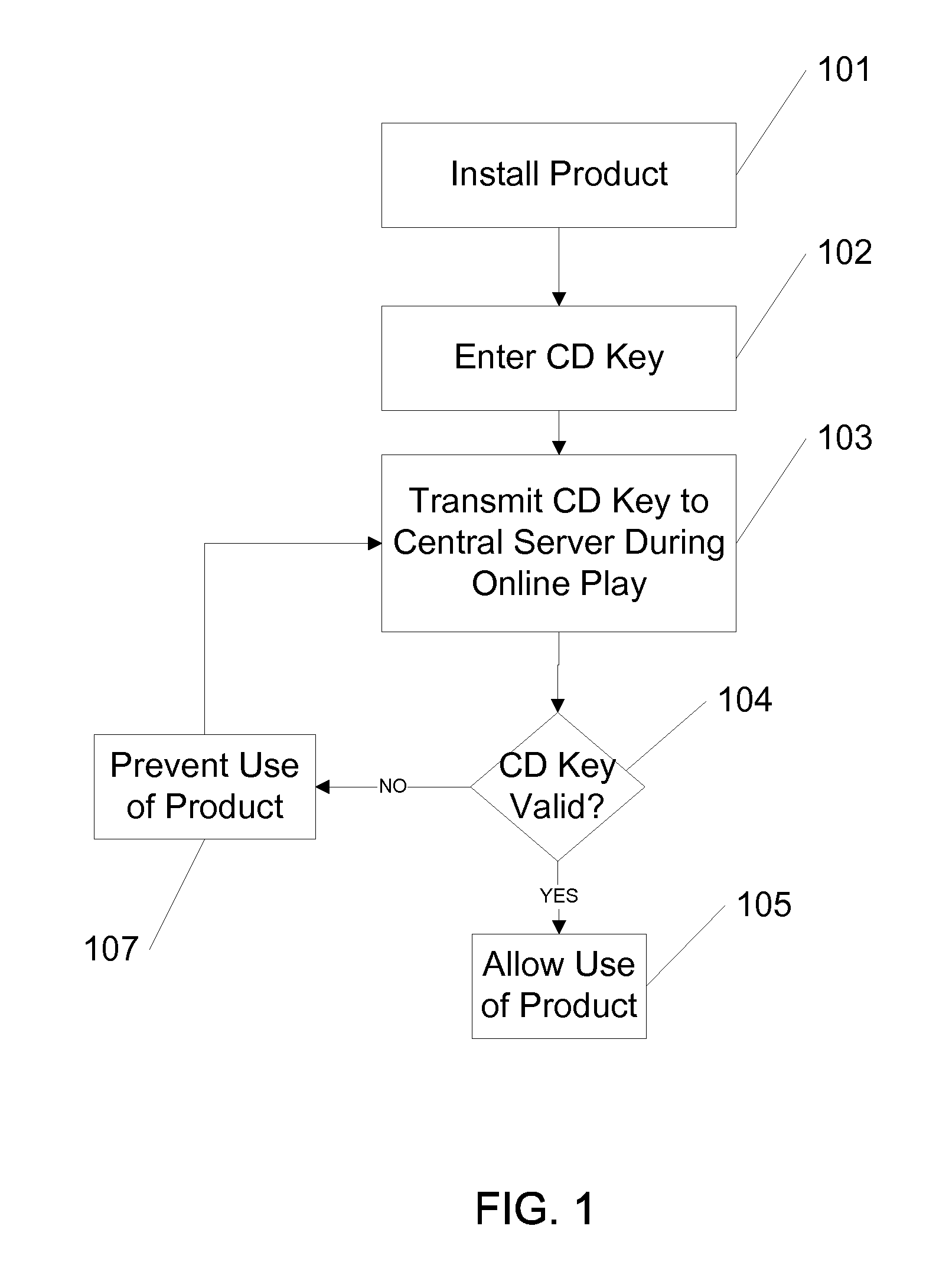

Managing pre-release of a game application over a network

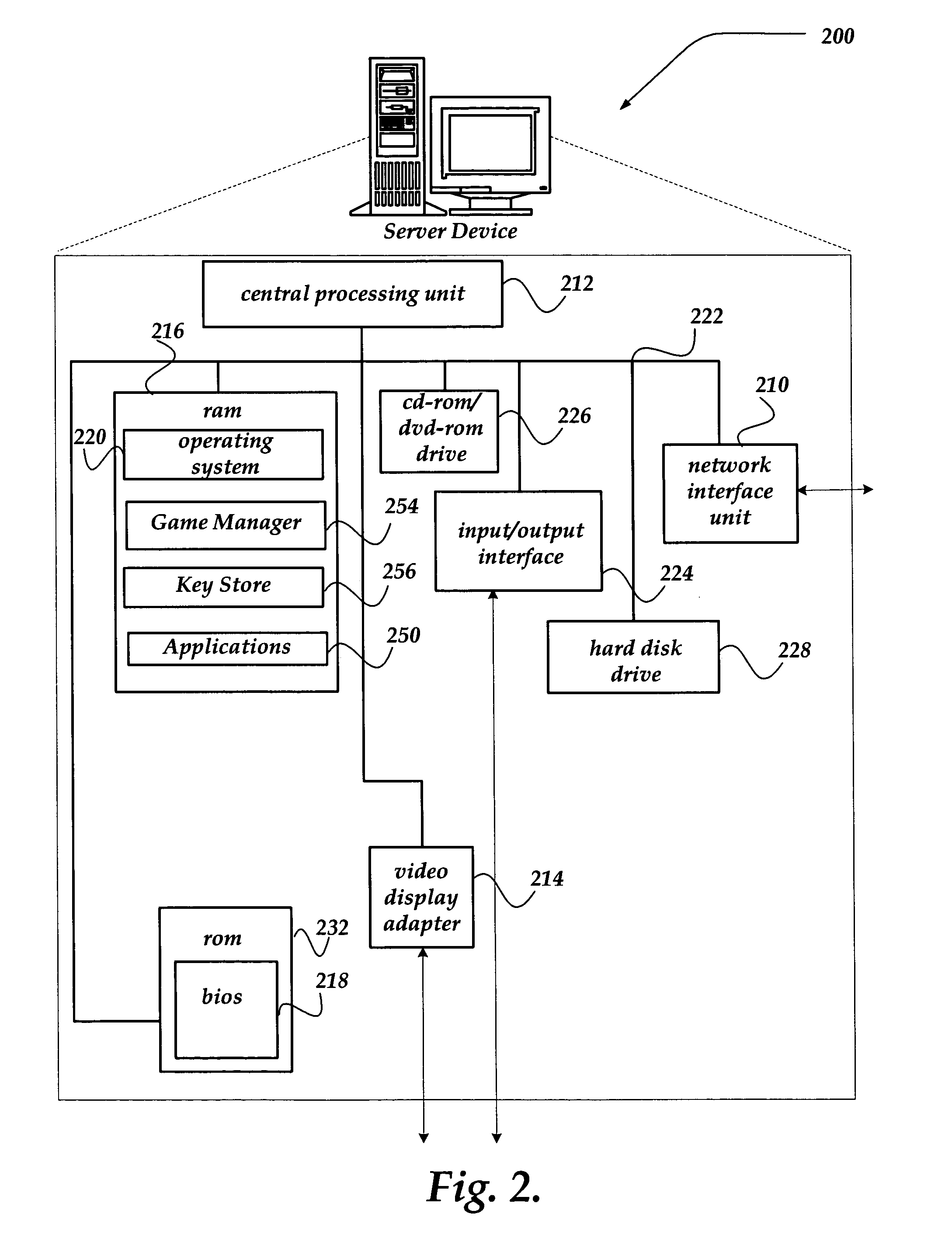

ActiveUS20060236090A1Key distribution for secure communicationPublic key for secure communicationNetwork managementEnd user

A system, method, and apparatus are arranged to enable loading of an application, such as a game application, prior to a formal release date of the application. An end-user is provided components of the application either over a network, CD, DVD, or the like. At least one component of the application is encrypted. The end-user may register with an application provider. At a pre-defined time, such as a release date for the application, a decryption key is made available to the end-user. The decryption key may be employed to decrypt the encrypted component(s) of the application, such that the application may be readied for execution. In addition, bug fixes, additions, or the like, may also be pre-loaded to release of the application, thereby ensuring that the end-user has the most current application configuration.

Owner:VALVE

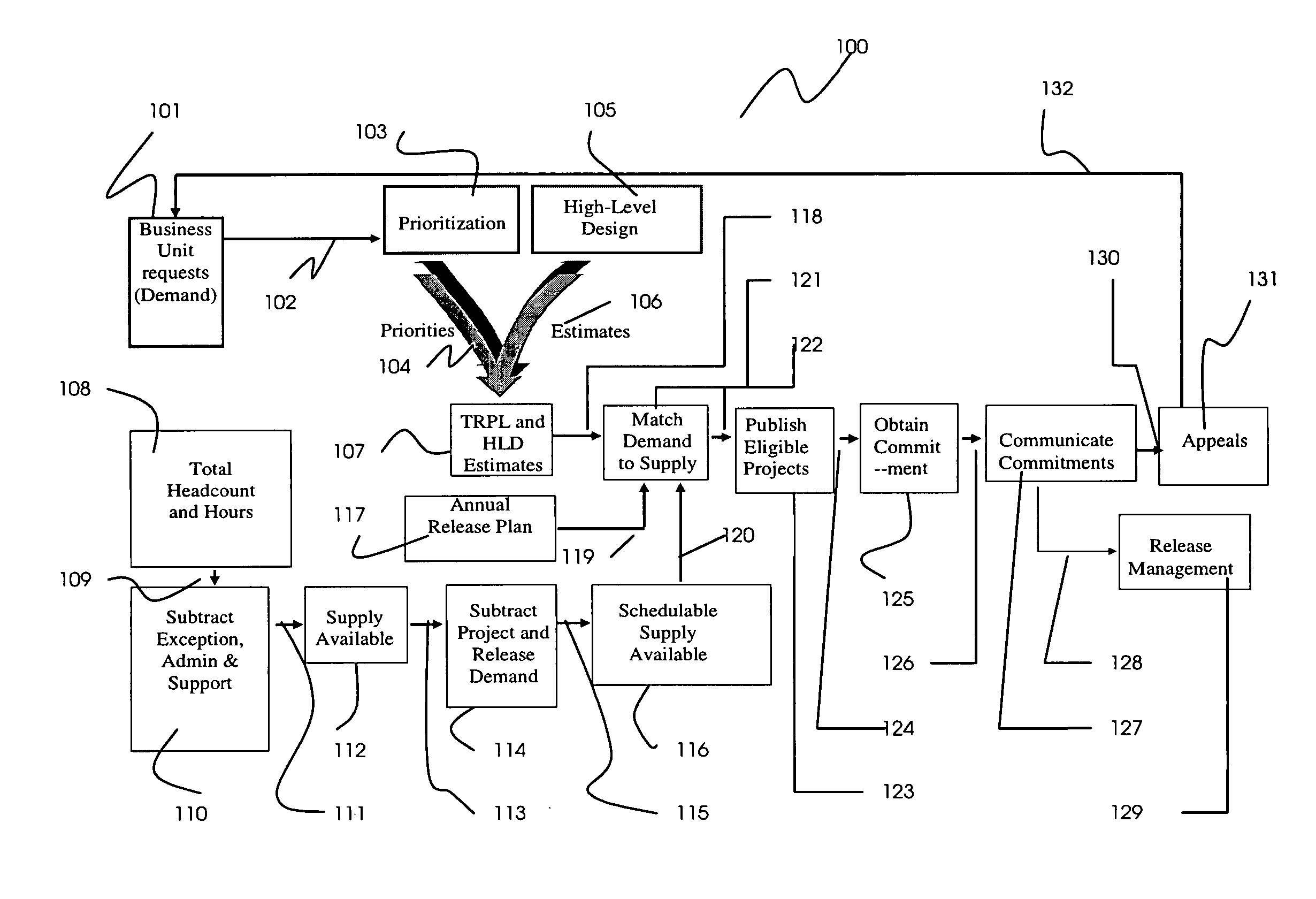

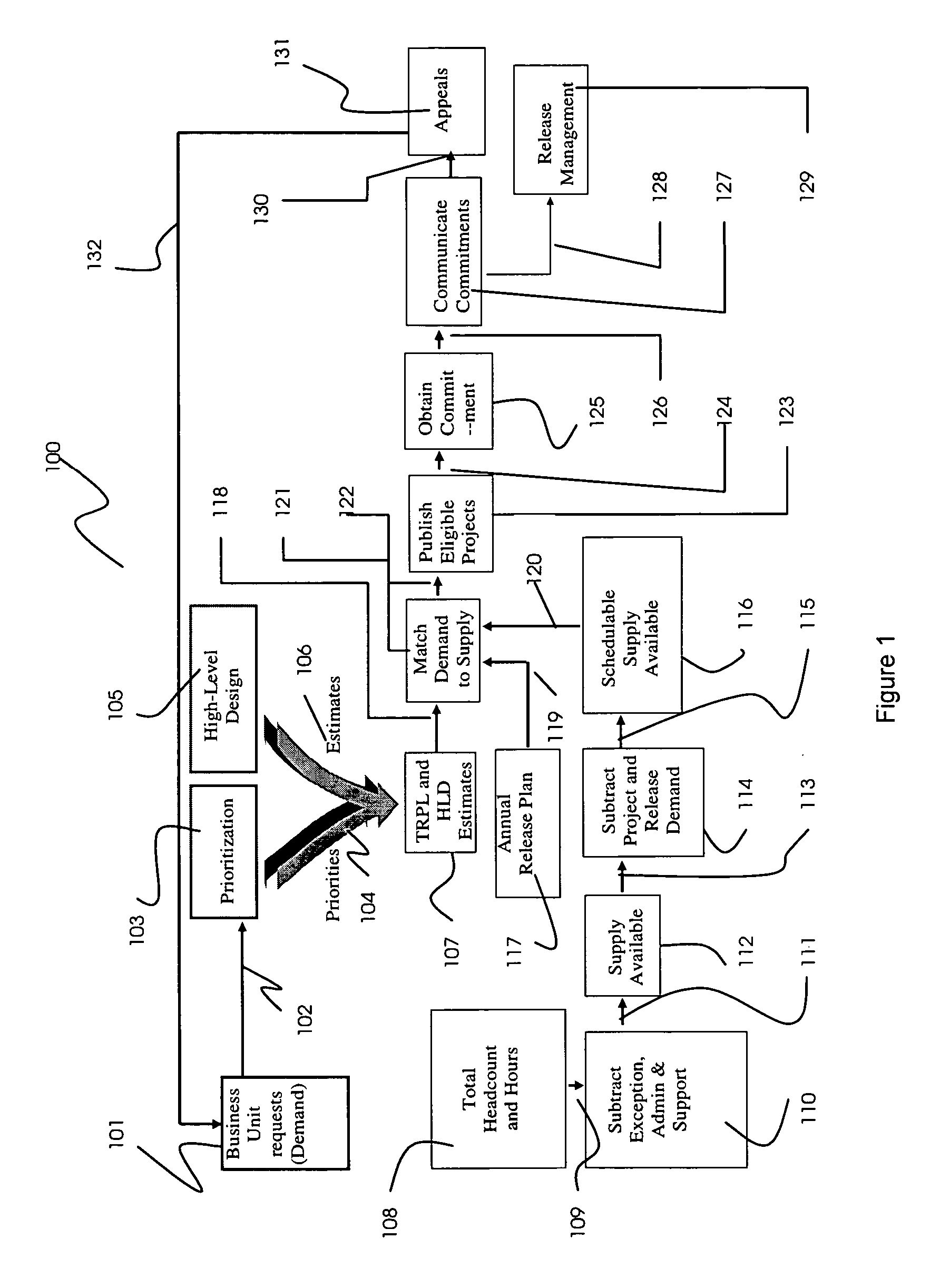

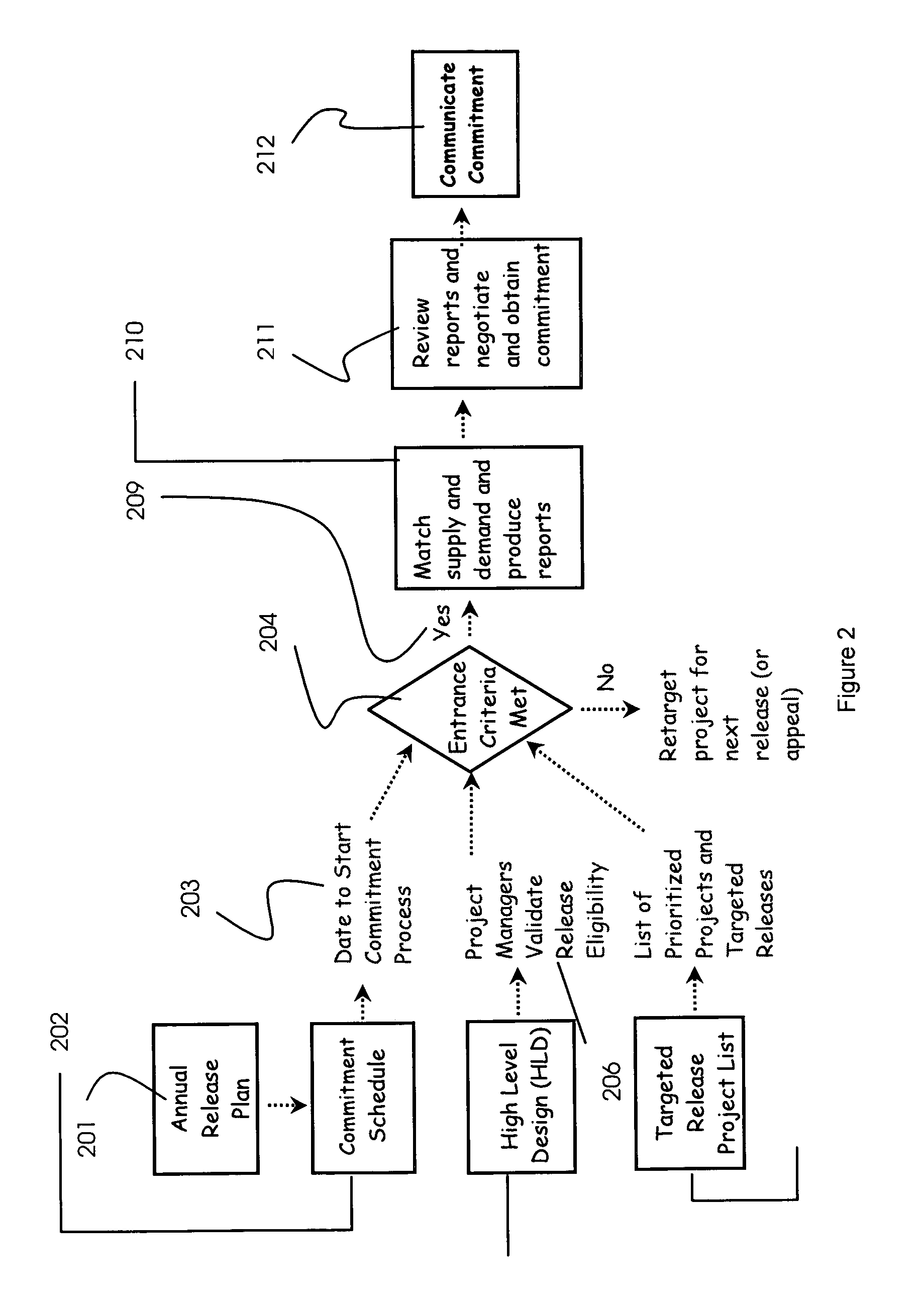

Supply and demand project management tool

A scheduling engine calculates a difference between a forecast supply of Information Technology (IT) resources and a forecast demand for the IT resources at an application team level. One or more teams may impact the release of a product of a project, whether or not a specific team is assigned to the project. The scheduling engine has a release calendar to allocate IT resources on the basis of a calculated difference between a forecast IT team resource supply and a forecast IT team resource demand to achieve product deployment by a scheduled release date.

Owner:SBC KNOWLEDGE VENTURES LP

Software management system for network data processing systems

ActiveUS8713525B2Digital data processing detailsComputer security arrangementsData processing systemProgram planning

A method, data processing system, and computer program product are presented for planning upgrades to a network data processing system. A processor unit identifies configuration information for hardware and software programs for a plurality of computers in the network data processing system. The processor unit obtains end of life dates for the software programs, release dates for the replacement software programs, and prerequisites for replacement software programs for the software programs identified in the configuration information. The processor unit identifies at least one change to the plurality of computers based on the configuration information and a set of prerequisites in the prerequisites for each of a plurality of replacement software programs for a plurality of software programs in the software programs. The processor unit generates at least one upgrade plan to implement at least one change to the plurality of computers in which a number of overlaps between life cycles for the plurality of replacement software programs and life cycles for the plurality of software programs in the software programs is increased.

Owner:KYNDRYL INC

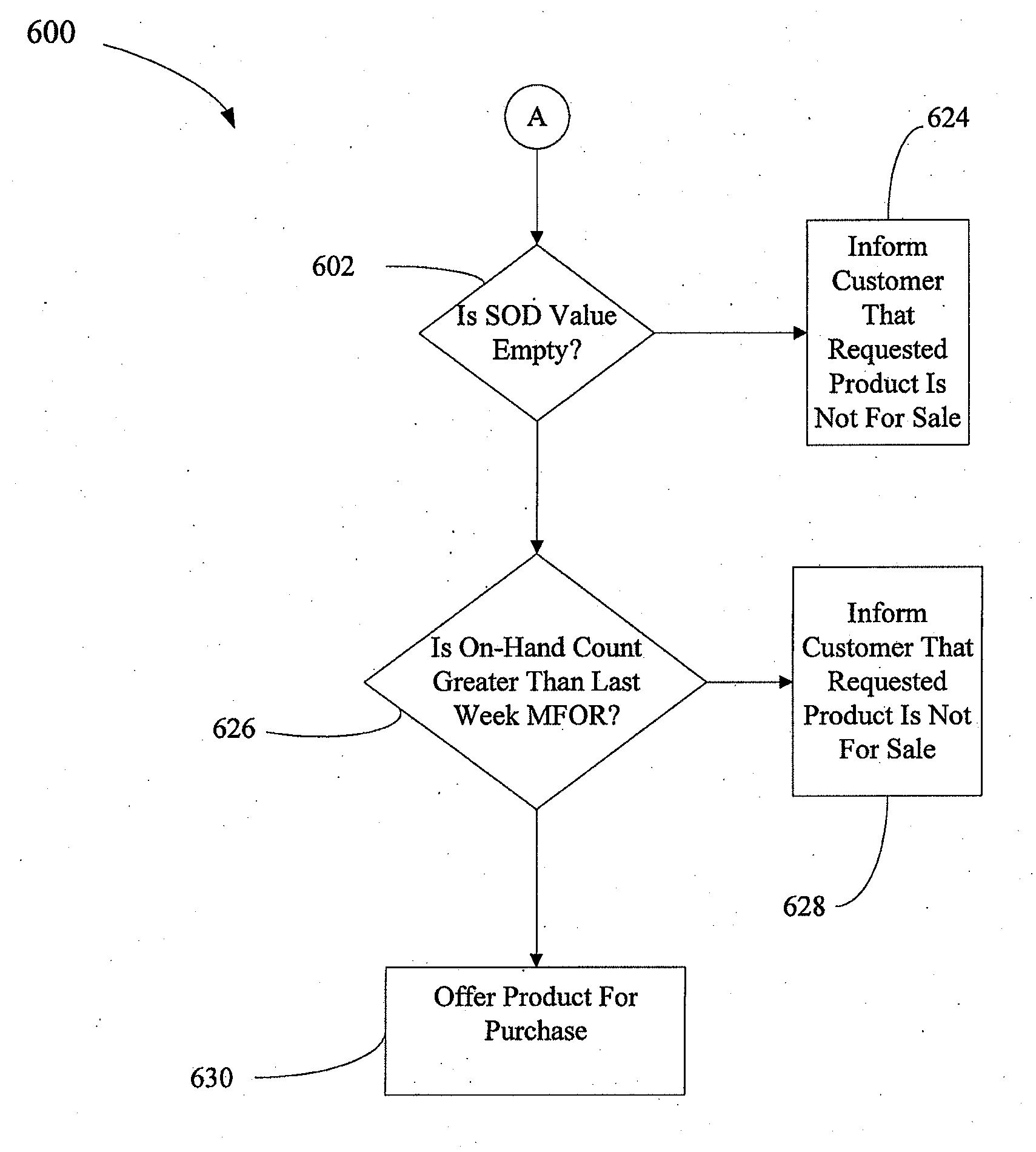

System and method for making rental inventory available for sale

InactiveUS20120290423A1Hand manipulated computer devicesBuying/selling/leasing transactionsData miningComputer science

A system and method for selling a rental media product having entertainment content therein via an automated vending machine are provided. The method receives a request from a user, the request identifying the rental media product, retrieves, from a database, product rental information relating to the rental media product, wherein the product rental information comprises a product release date, a last maximum out-of-rent value, a sold-out date value, and a current on-hand count, determines whether the product rental information satisfies a set of sales decision criteria, wherein the set of sales decision criteria includes a product release date threshold, a last maximum out-of-rent value threshold, a sold-out date requirement, and a current on-hand count threshold. The method further provides an offer to sell the rental media product if the plurality of sales decision criteria is satisfied, and vends the rental product from a vending apparatus to the user if the user accepts the offer for sale.

Owner:REDBOX AUTOMATED RETAIL

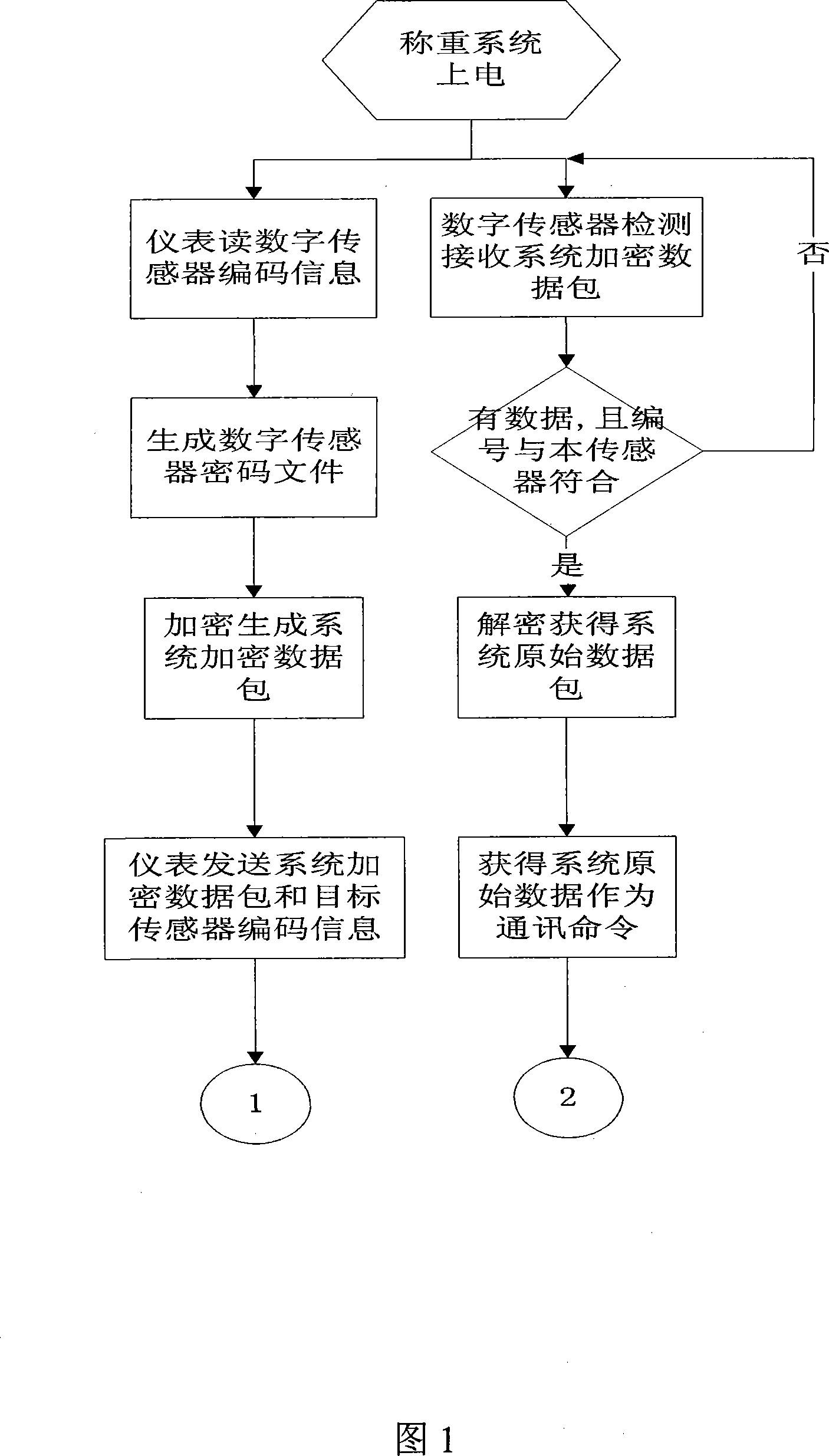

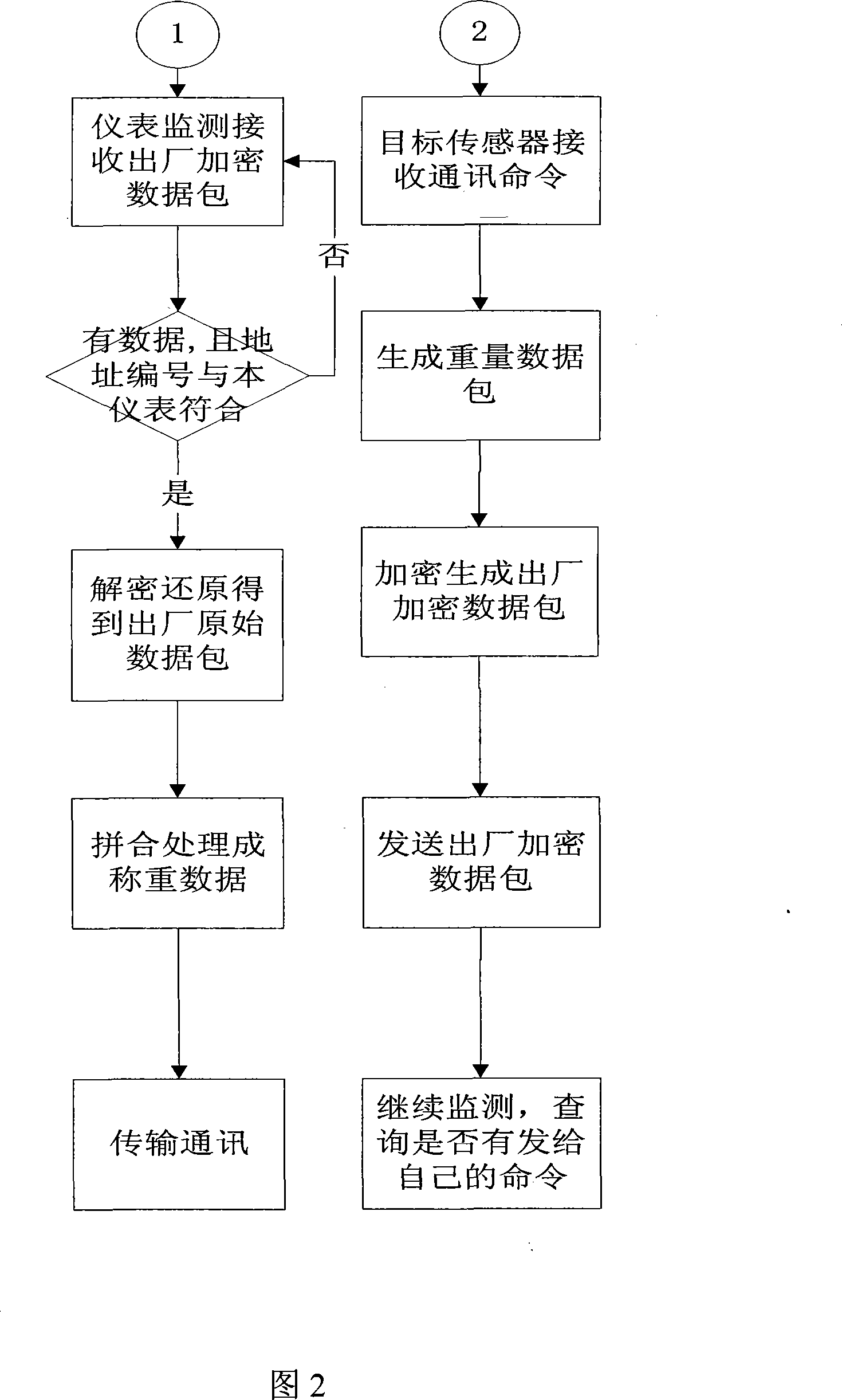

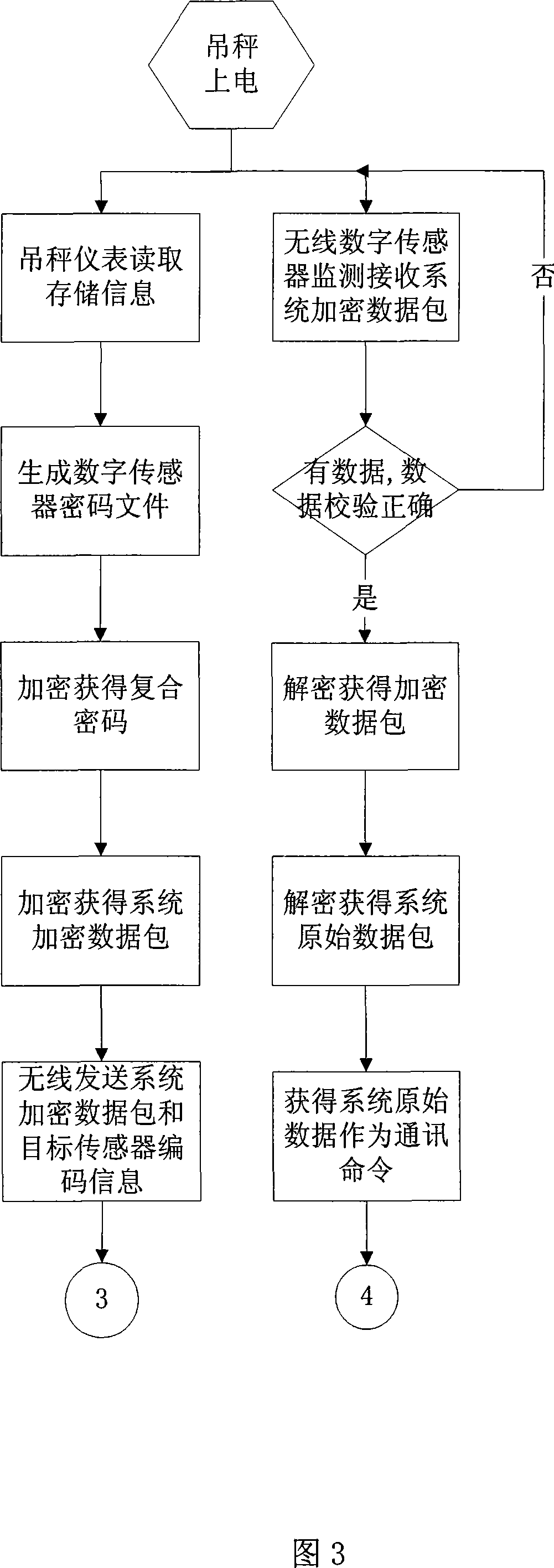

Weighing system communication method based on digital sensor

ActiveCN101140692AAvoid inaccuraciesGuaranteed accuracy and reliabilityTransmission systemsSecuring communicationComputer hardwareData stream

The invention relates to a communication method for weighing system based on digital sensor, which requires files building of a key and its password on release date as well as a key for digital sensor. The process of the said method is that: firstly, the key and its password for the storage system of the weighing instrument are downloaded to the digital sensor, from which the key and its password on release date can be obtained; secondly, the weighing instrument sends the communication orders to the target digital sensor, and the encrypted data packet, encrypted and generated through key files of digital sensor, data flow and system cipher, is sent to the target digital sensor; thirdly, after monitoring and receiving the packet, the target digital sensor will make a deciphering and recovery to obtain the system raw data by system key and key on release date, and then take it as the communication order; fourthly, after receiving the communication order, the target digital sensor will make a data packet of the sampled weights, and the data packet, the key on release date and the system cipher, encrypted and generated as the release encrypted data packet, will be sent to the weighing instrument; lastly, after monitoring and receiving the release encrypted data packet, the weighing instrument will make a encryption to obtain the weight data by system cipher and key on release date. Thus the transmission and communication of weight data is achieved. The invention ensures a security and reliability of the channels for weight data transmission.

Owner:METTLER TOLEDO CHANGZHOU PRECISION INSTR +2

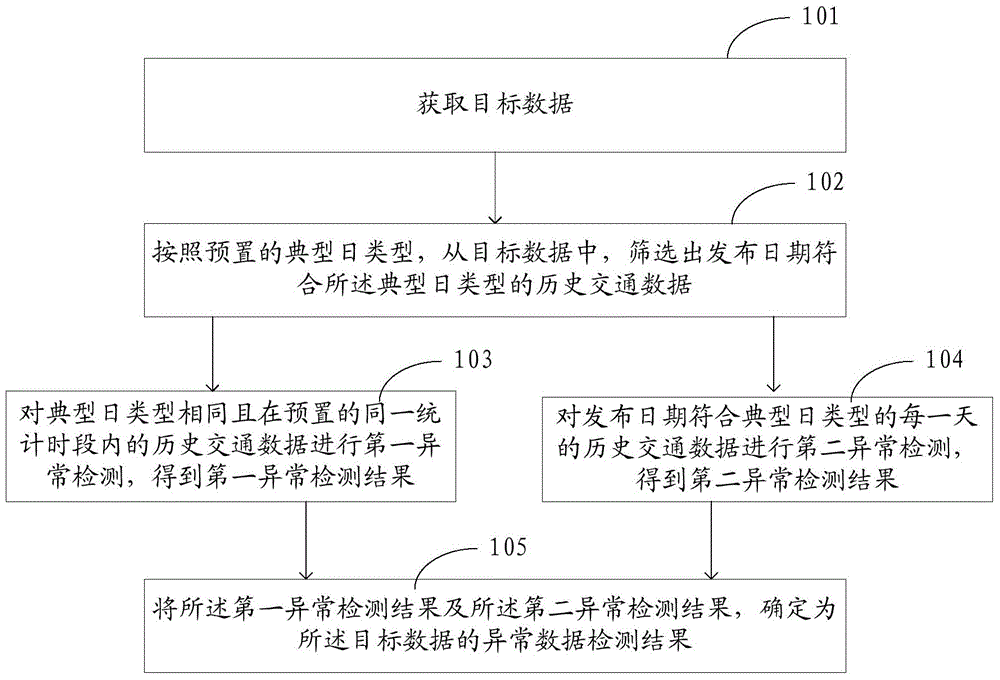

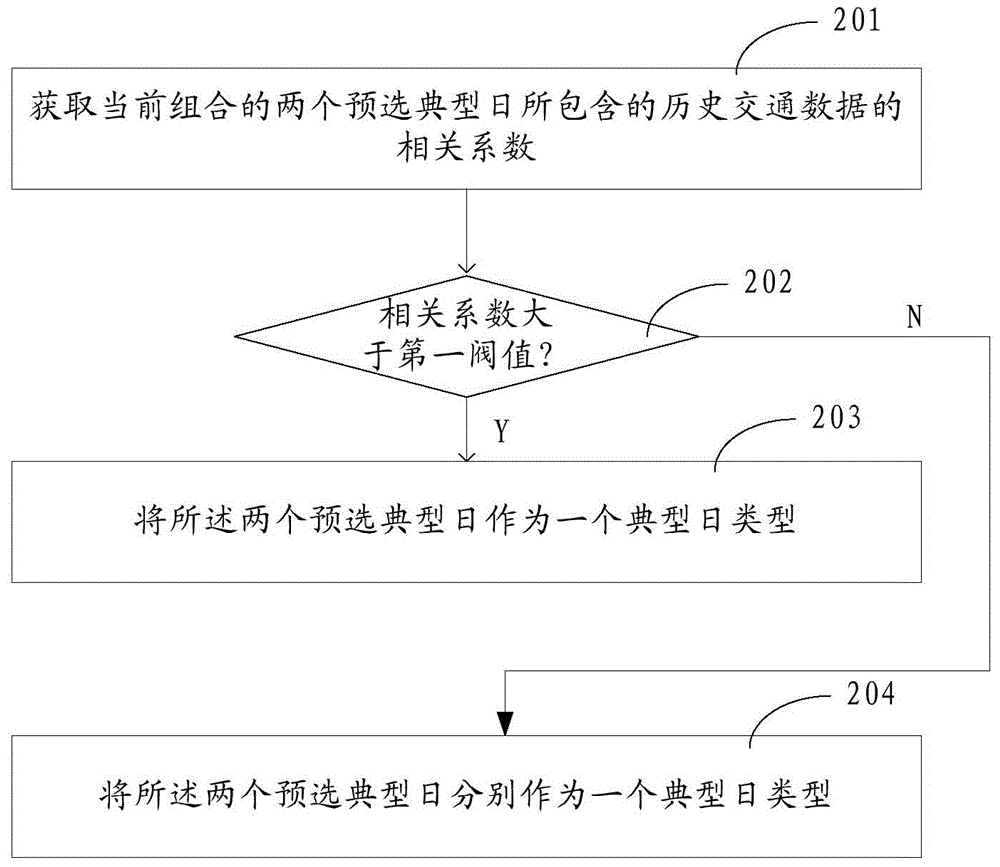

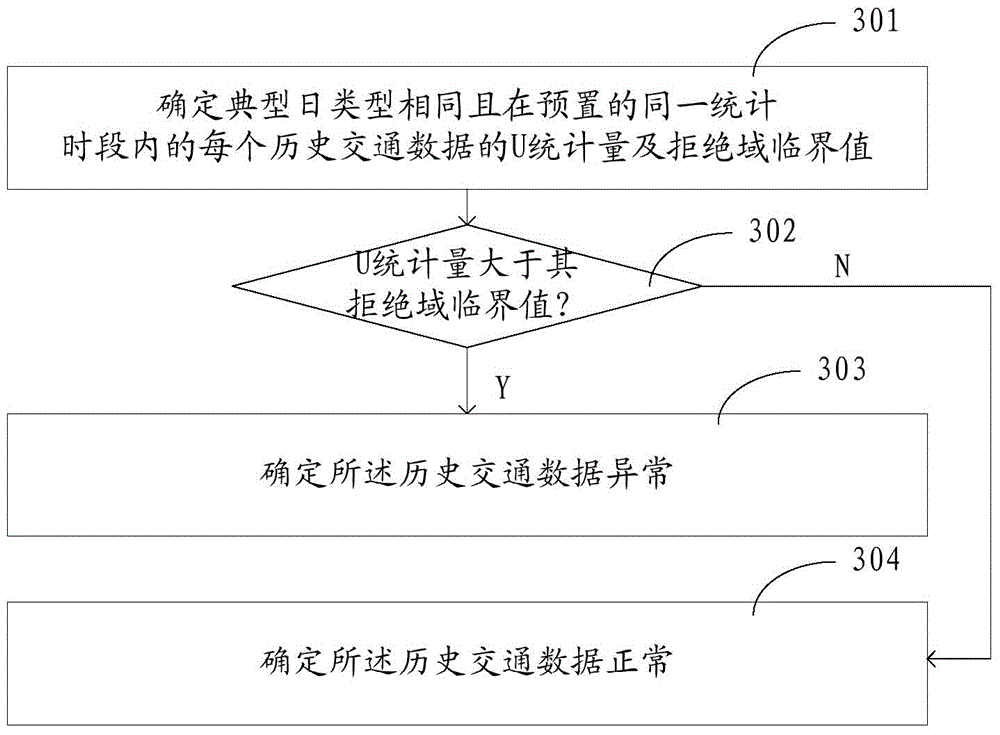

Data detection method and device

ActiveCN104679970AImprove accuracyRoad vehicles traffic controlSpecial data processing applicationsTime segmentAnomaly detection

The application discloses a data detection method and a data detection device. The data detection method includes: obtaining target data which includes history traffic data of a target road in each day of a preset statistic period; screening out the history traffic data of release dates which conform to preset typical day types according to the preset typical day types; performing first abnormal detection on the history traffic data of the same preset typical day type and in the same preset statistic time segment so as to obtain a first abnormal detection result; performing second abnormal detection on the history traffic data of the release dates which conform to the typical day types by the day so as to obtain a second abnormal detection result; confirming the first abnormal detection result and the second abnormal detection result as an abnormal data detection result of the target data. The data detection method and the data detection device can detect abnormal data of the history traffic data of the target road so as to guarantee that the history traffic data for analyzing typicality is the data which can truly reflect traffic conditions of the road, and thereby improve accuracy of an analysis result.

Owner:ALIBABA (CHINA) CO LTD

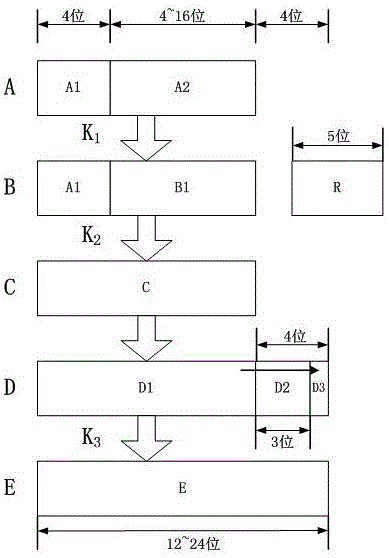

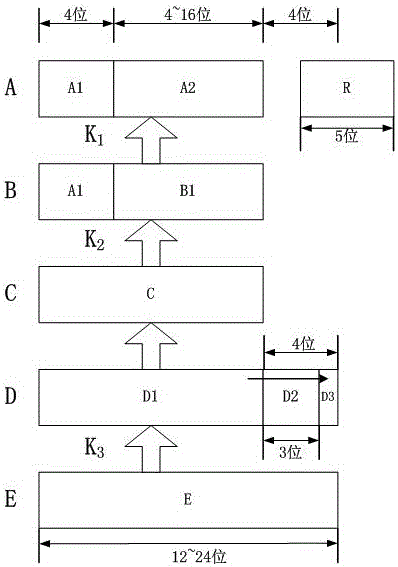

Commodity anti-counterfeit code generation and verification method

ActiveCN106548353AMeet the uniquenessSatisfy confidentialityEncryption apparatus with shift registers/memoriesCommercePlaintextValidation methods

The invention discloses a commodity anti-counterfeit code generation and verification method. According to the generation of a commodity anti-counterfeit code, a production center generates a 0-level plaintext A according to the basic information of a product, wherein the basic information of the product contains an enterprise code A1 and a sequence code A2; the production center obtains an enterprise key K1 corresponding to the enterprise code according to the enterprise code A1 and encrypts the sequence code plaintext A2 according to the enterprise key K1 so as to obtain an encrypted ciphertext B1; the ciphertext B1 and the plaintext A1 constitute a 1-level ciphertext B; the production center encrypts the 1-level ciphertext B according to a production key K2 so as to obtain a 2-level ciphertext C, and then carries out confused encryption so as to generate a ciphertext D, wherein D is composed of D1, D2 and D3; and D is encrypted by a website key K3, so that an anti-counterfeit code E can be obtained. The anti-counterfeit code obtained by using the method of the invention can satisfy uniqueness, confidentiality and irregularity and can help a consumer to verify the authenticity of a commodity and all characteristic information related to the commodity such as a factory release date, a production place and a warranty period.

Owner:KUNMING UNIV OF SCI & TECH

Managing pre-release of a game application over a network

ActiveUS8341753B2Key distribution for secure communicationPublic key for secure communicationNetwork managementApplication software

A system, method, and apparatus are arranged to enable loading of an application, such as a game application, prior to a formal release date of the application. An end-user is provided components of the application either over a network, CD, DVD, or the like. At least one component of the application is encrypted. The end-user may register with an application provider. At a pre-defined time, such as a release date for the application, a decryption key is made available to the end-user. The decryption key may be employed to decrypt the encrypted component(s) of the application, such that the application may be readied for execution. In addition, bug fixes, additions, or the like, may also be pre-loaded to release of the application, thereby ensuring that the end-user has the most current application configuration.

Owner:VALVE

Battery replacing type charging station system for electric car

Provided is a battery replacing type charging station system for an electric car. The battery replacing type charging station system for the electric car comprises a charging type battery, a charging station main body, a battery replacing manipulator, a charging station control unit, an information recognizing unit and a charging station control unit, wherein the charging type battery is arranged on a battery installation module of the electric car, the charging station main body is of a structure that the electric car can freely run in and out and comprises a battery loading unit for accommodating the battery, the battery replacing manipulator is arranged in the charging station main body and used for carrying out battery replacing operation, the charging station control unit is used for controlling the battery replacing manipulator to carry out battery replacing operation, the information recognizing unit is configured to acquire data of electric cars driving into the charging station and / or data relative to battery types, sizes, charging states, releasing dates, charging dates and the like, and the charging station control unit can control the battery replacing manipulator to carry outer battery replacing operation according to information acquired by the information recognizing unit.

Owner:KOOKMIN UNIV IND ACAD COOP FOUND

Online product distribution using fingerprint and encryption

InactiveUS20070143212A1Easy to controlComputer security arrangementsBuying/selling/leasing transactionsSoftware errorEncryption

An online product distribution method provides copyright protection and enhanced control over user access to an online product through the use of a fingerprint combined with a double encryption method that provides two layers of protection against unauthorized access to a product prior to a release date. The double encryption is carried out by using two different keys, a first key which is a customer-specific key and a second key which is a failsafe key. The failsafe key is a protection against software errors or system misconfiguration resulting in the premature release of the keys necessary for decryption. A fingerprint containing a validation code can be used for an additional level of protection. The validation code can be dynamically allocated or predetermined. In one aspect, the validation codes are embedded into the data of the online product and can provide a fingerprint which traces the product as coming from a particular source.

Owner:ELECTRONICS ARTS INC

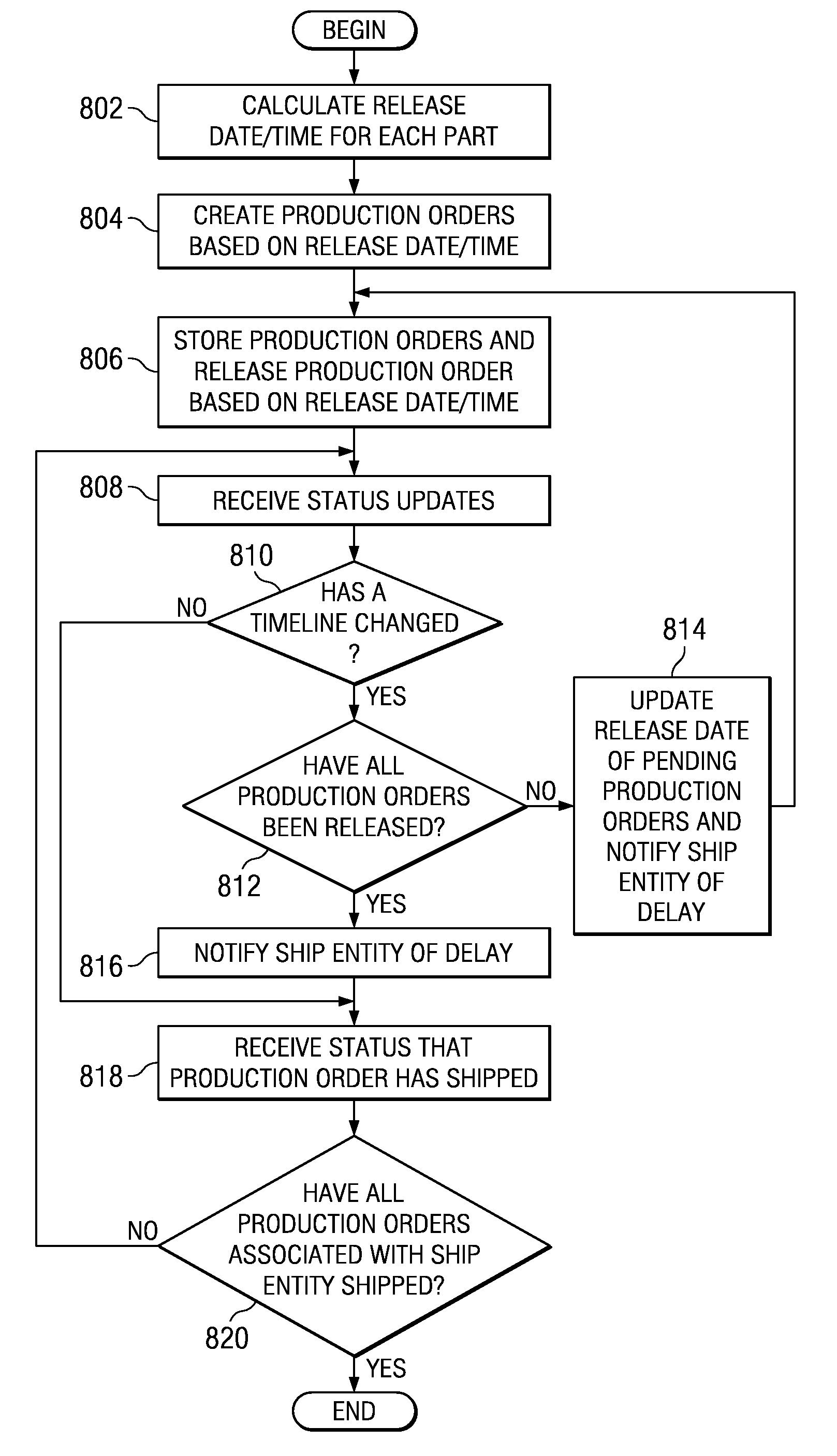

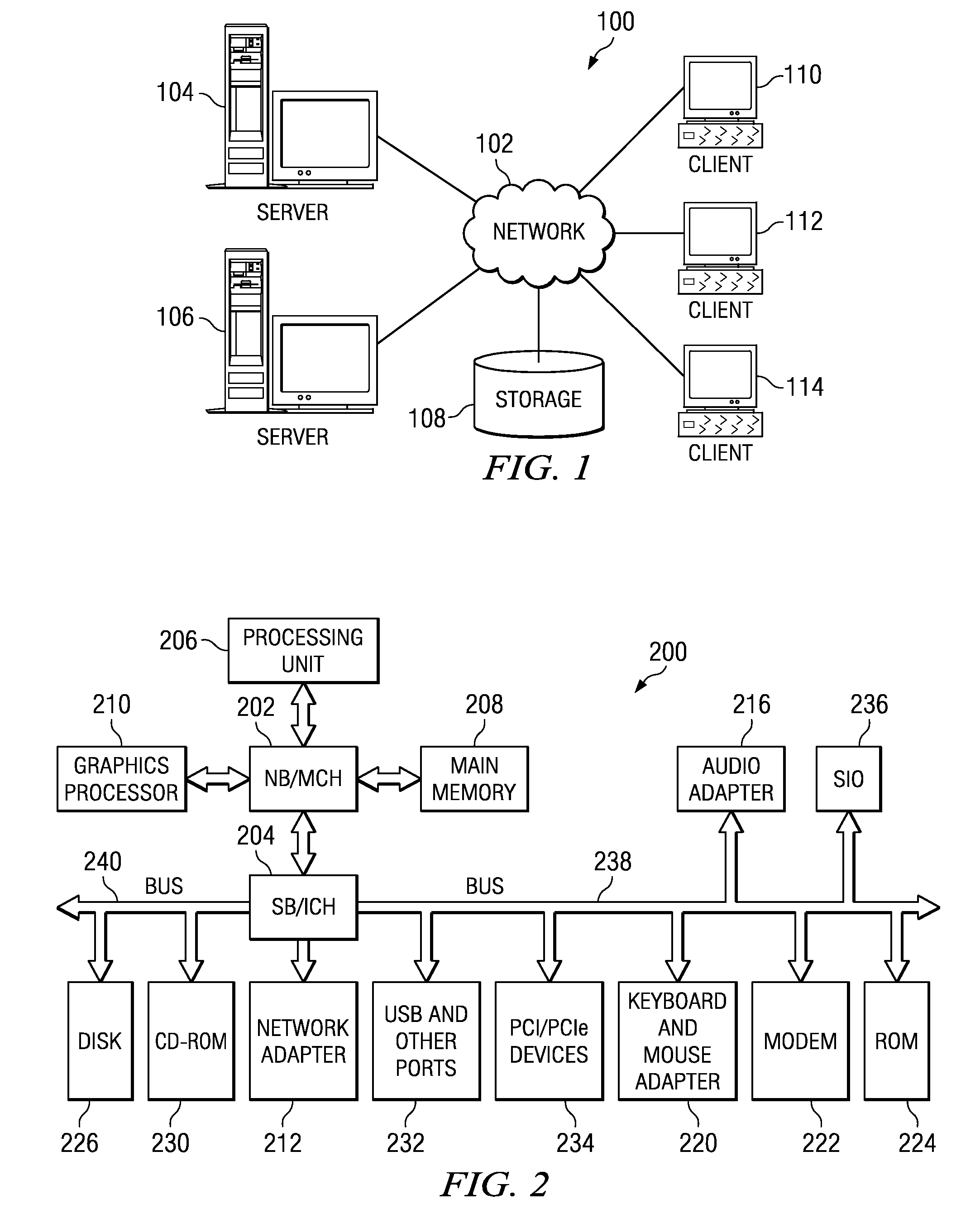

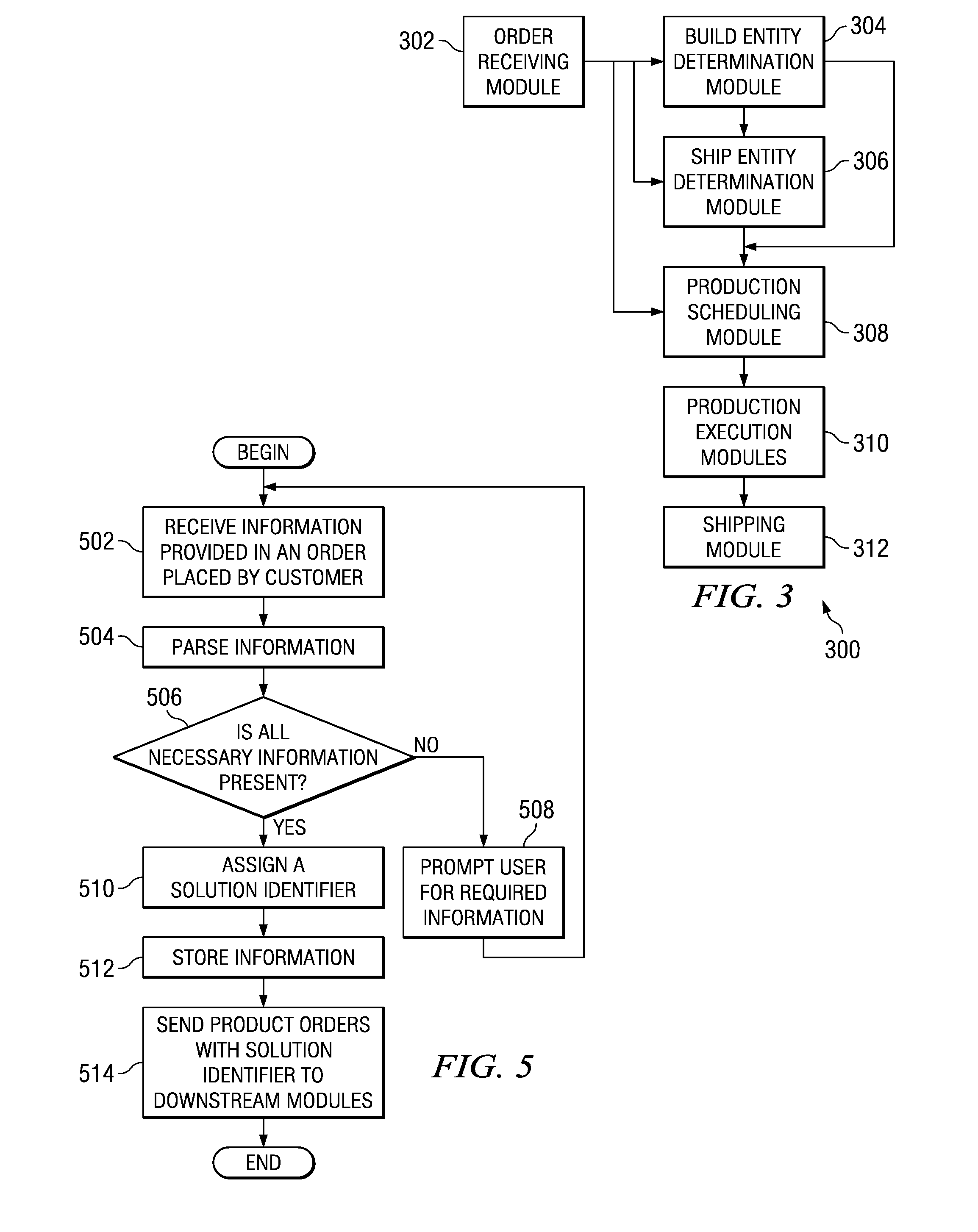

Manufacturing optimization in support of complex solution delivery

A computer implemented method, system, and computer usable program code are provided for processing orders. An order is received for processing and each order may contain a plurality of products. A set of build entities is formed from the order. Each build entity in the set of build entities corresponds to one or more products in the plurality of products. Finally, a set of production orders is created for the set of build entities. Release dates / times for the set of production orders are formed using a shipping entity for the order and production for the set of production orders is configured to minimize work-in-progress.

Owner:IBM CORP

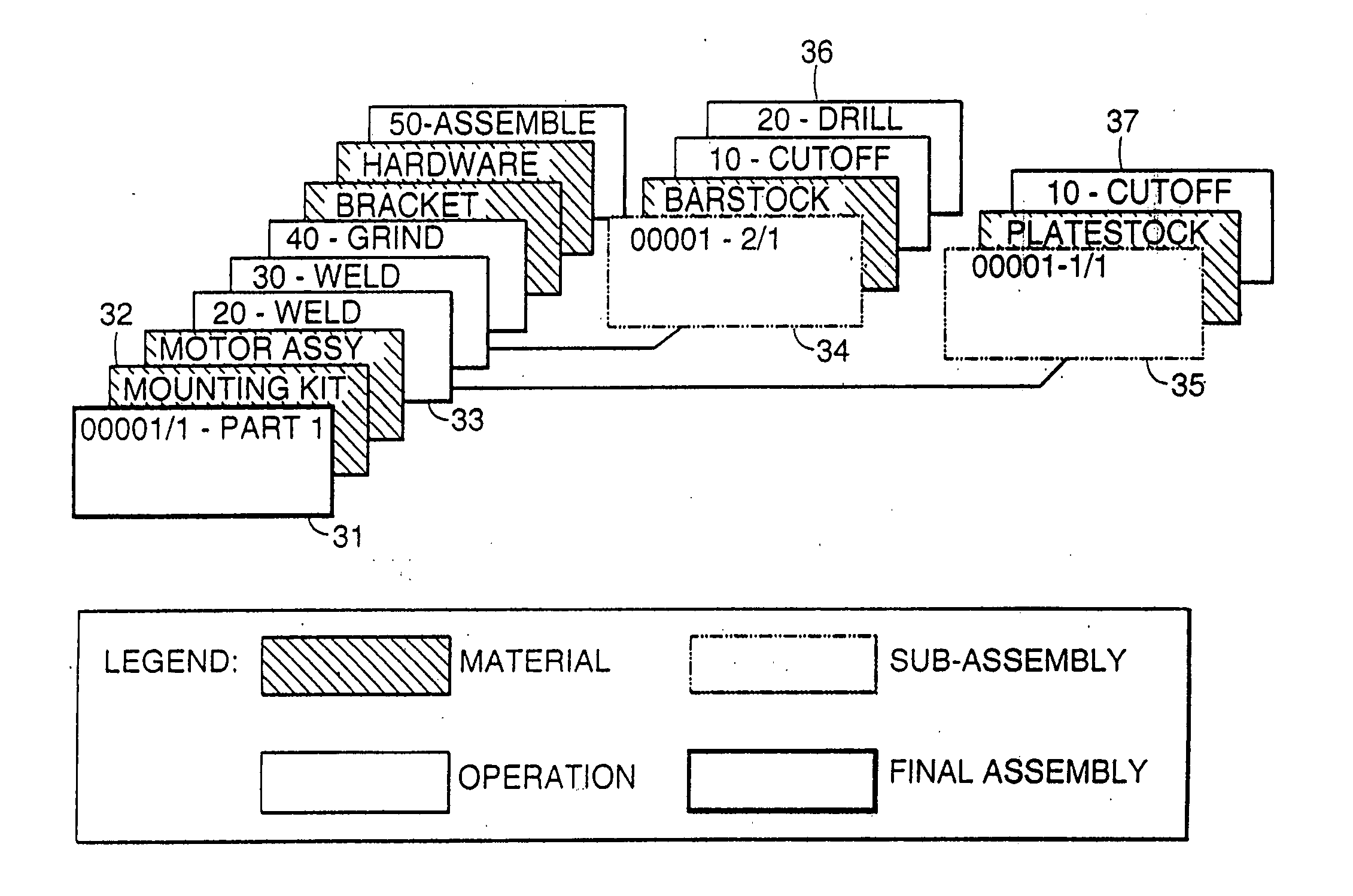

Method and apparatus for scheduling work orders in a manufacturing process

A computerized system is provided for scheduling a plurality of work orders in a manufacturing process. Each work order to be scheduled specifies a set of operations to be performed using a plurality of resources and materials. Data including resource availability information for each resource used in the manufacturing process, material availability information for each material used in the manufacturing process, and work order information is received and stored in a computer. The work order information includes a release date for the work order, a want date for the work order, operations information, and material requirements information. The operations information includes the identity and sequence of operations to be performed for the work order, the identity of the resources needed to perform each operation, a minimum resource capacity needed to perform each operation, and the time needed to perform the operation. The materials information includes the identity of the materials needed to perform each operation and the quantity of each material needed for the operation. Resource capacity and a start date / time and a finish date / time are assigned to each operation based upon the resource availability information, the material availability information, and the work order information. The assigned resource-capacity, the assigned start date / time, and the assigned finish date / time for each operation are displayed on a computer screen in a graphical format.

Owner:INFOR VEENENDAAL

Method and apparatus for denenoxing waste gases from nitration

The invention relates to a method for reducing the concentration of nitrogen oxides in waste gases released dating the production of organic amino compounds, wherein an organic compound is first reacted with NOx and / or nitric acid to form an organic nitro compound with the formation of an NOx-containing waste gas stream and the organic nitro compound is converted to the organic ammo compound by means of hydrogen-containing reaction gas, the reaction of the organic nitro compound with the hydrogen-containing reduction gas taking place with the formation of a hydrogen-containing waste gas stream, the method being characterised in that the NOx-containing waste gas stream is combined with the hydrogen-containing waste gas stream and / or an externally supplied hydrogen stream and is reacted at a temperature of 800 to 1700° C. for the at least partial reduction of the NOx concentration. The invention additionally relates to an apparatus for carrying out the method.

Owner:COVESTRO DEUTSCHLAND AG +1

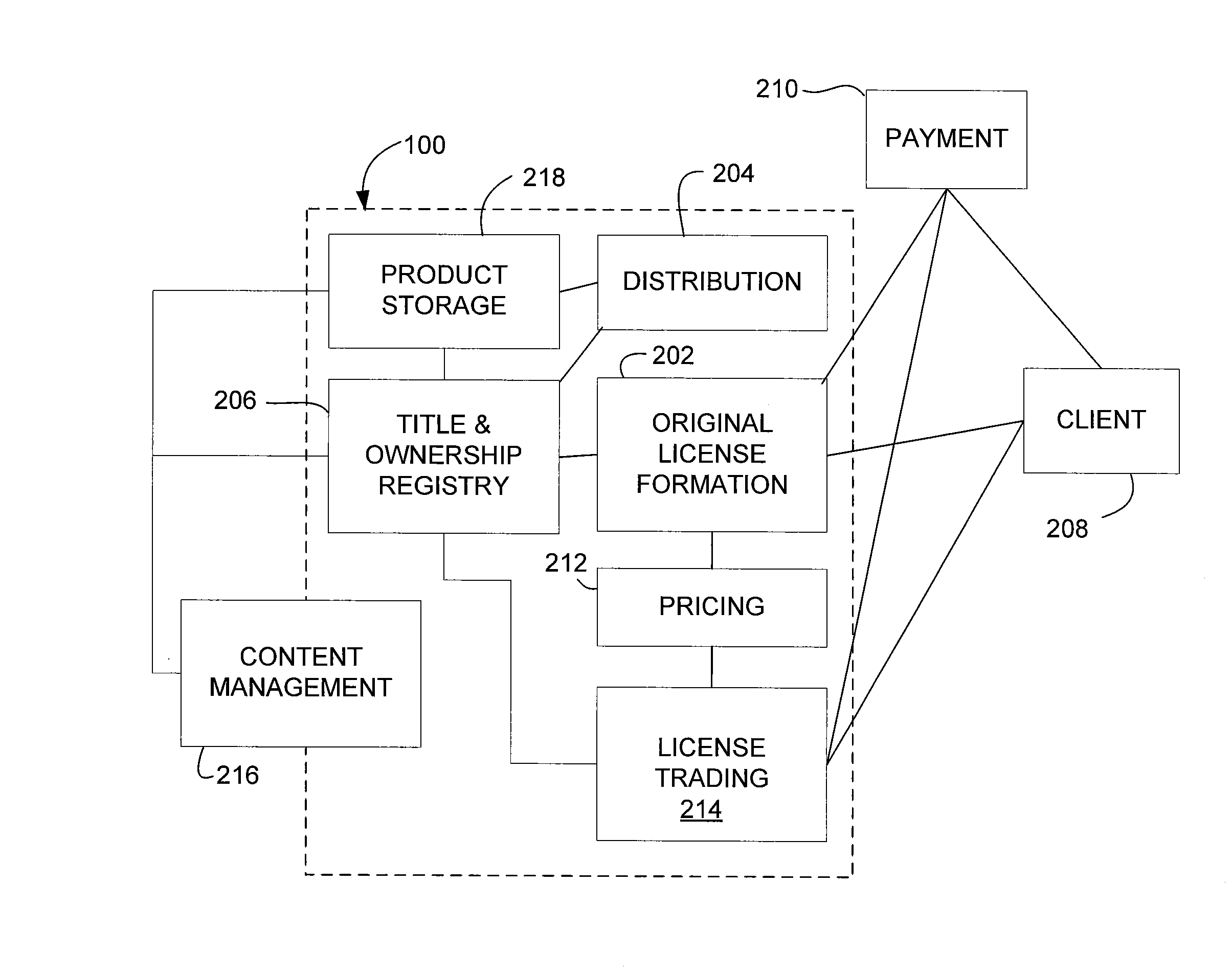

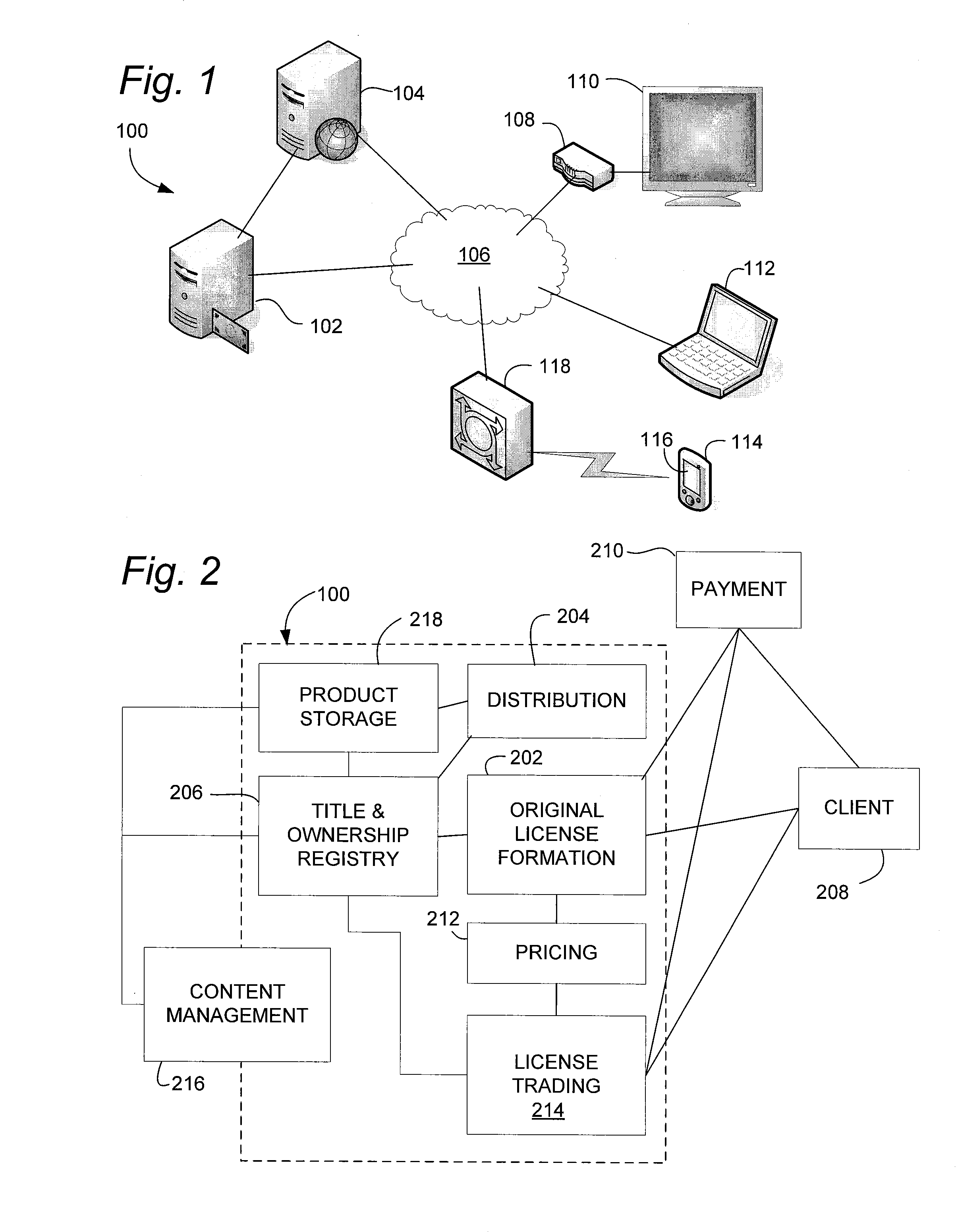

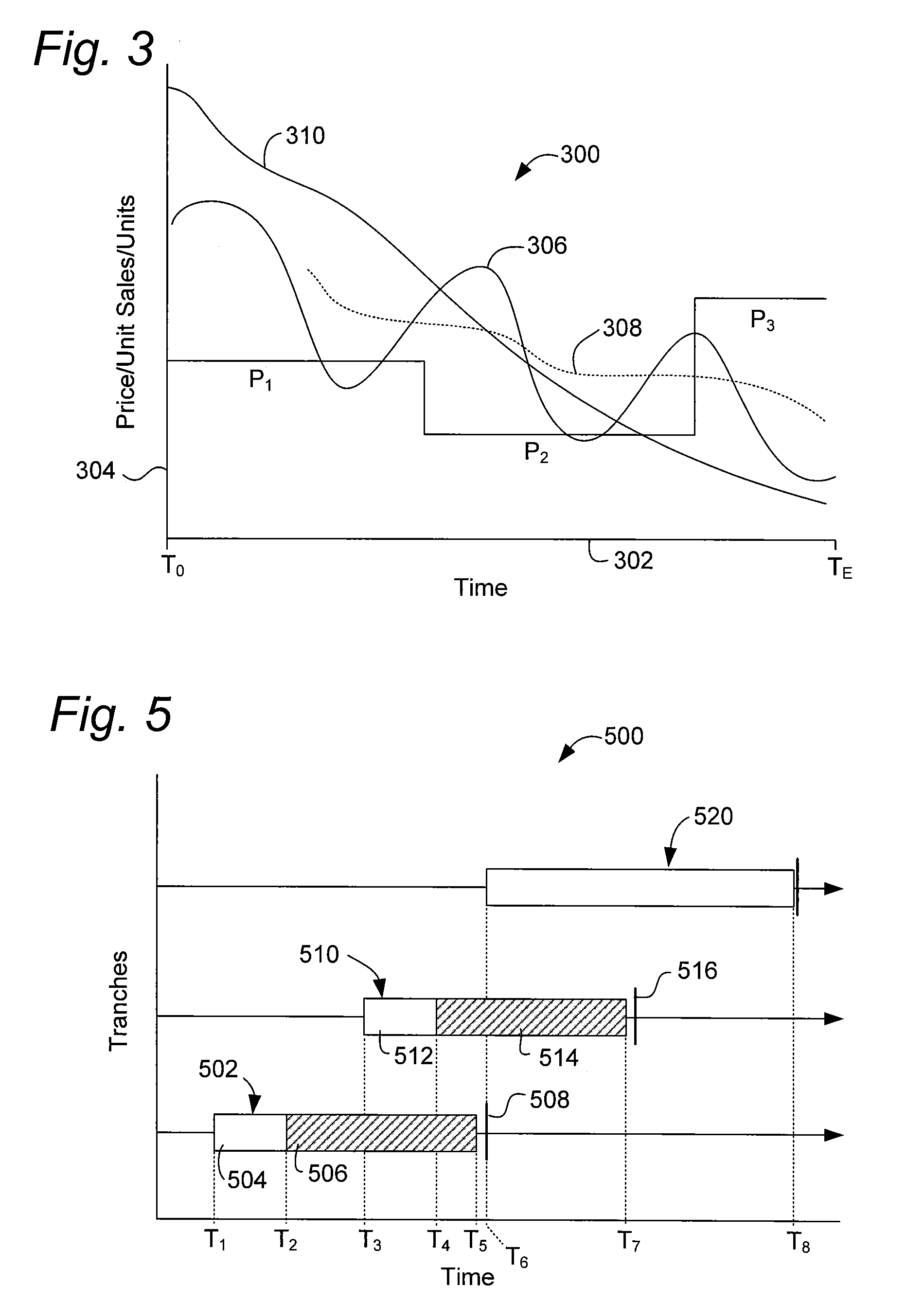

Trading and distribution system for audio-video content

InactiveUS20110264551A1Complete understandingEnhanced advantageBuying/selling/leasing transactionsDistribution systemClient-side

Non-exclusive license rights to discrete data products for audio-visual content are licensed to users connecting via a plurality of clients, using a computer. Each of the discrete data products is controlled such that each data product cannot be used to produce audio-visual output for a licensed user until a respective one of release dates defined in a computer memory. In addition, the computer may serve an electronic trading interface to the clients, which is configured to enable any current licensee holding any one of the licenses during a trading period prior to the respective release date for the discrete data product licensed thereby to complete a sale of the any one of the licenses to a participating bidder in an online electronic marketplace publishing current bid prices and ask prices for ones of the licenses offered for sale. The computer may also register successful trades resulting in license transfers.

Owner:WARNER BROS ENTERTAINMENT INC

Battery exchanging-type charging station system for electric vehicle

ActiveUS9156360B2Stimulate interestSecurement of international competitivenessCharging stationsSecondary cellsElectrical batteryCharging station

Provided is a battery exchanging type charging station system for an electric vehicle. The battery exchanging type charging station system includes a charging station body formed with a structure in which the electric vehicle freely enters and exits and including a battery loading unit for receiving the battery, a battery replacing robot mounted in the charging station body to perform a battery replacement operation, a charging station control unit to control the battery replacing robot such that the battery replacement operation is performed by controlling the battery replacing robot, an information recognition unit configured to obtain data on an electric vehicle that enters the charging station body and / or data on a type, size, charging state, release date, charging date or the like of the battery, and a charging station control unit that allows a replacement operation of the battery to be performed by controlling the battery replacing robot.

Owner:KOOKMIN UNIV IND ACAD COOP FOUND

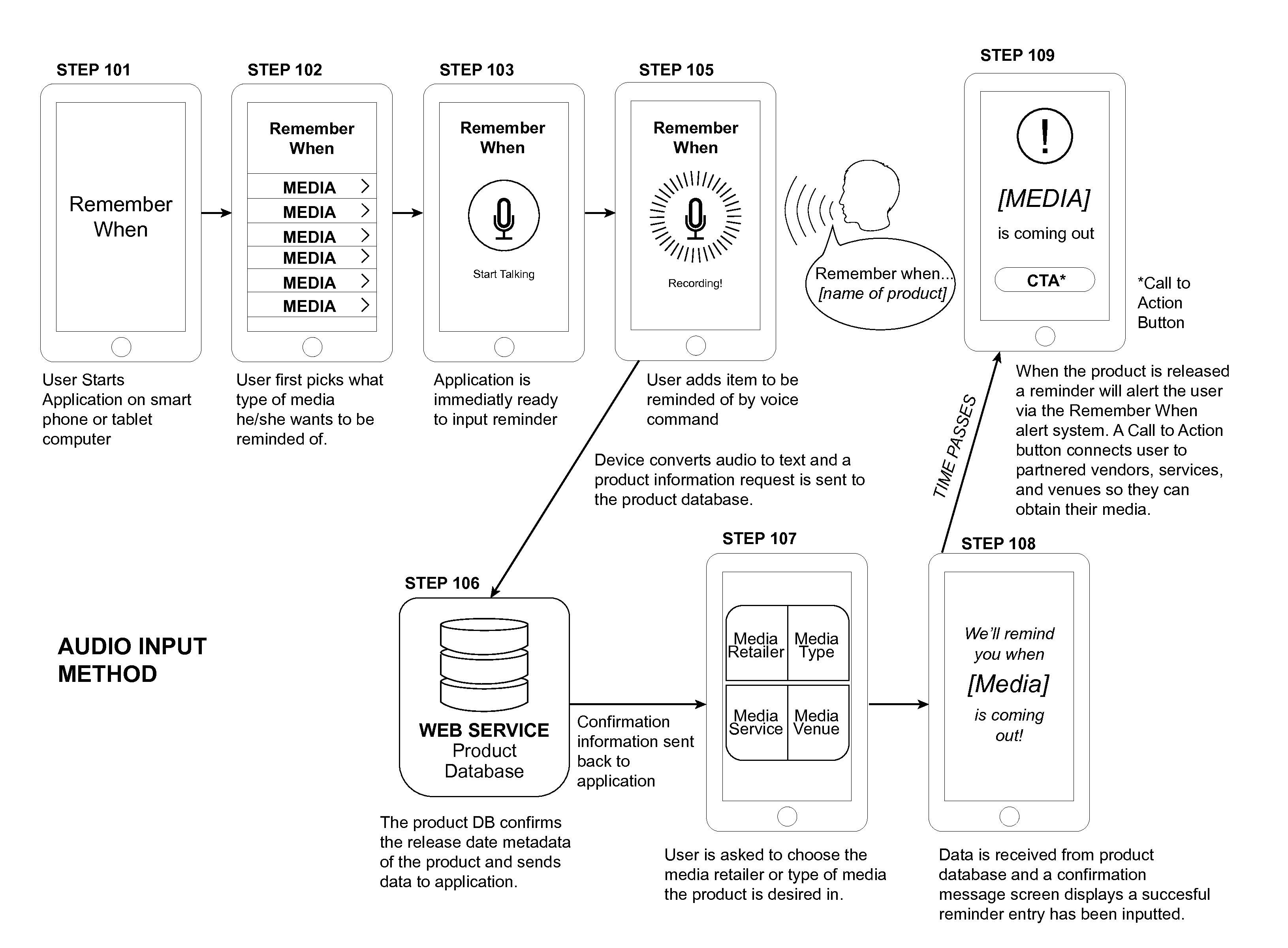

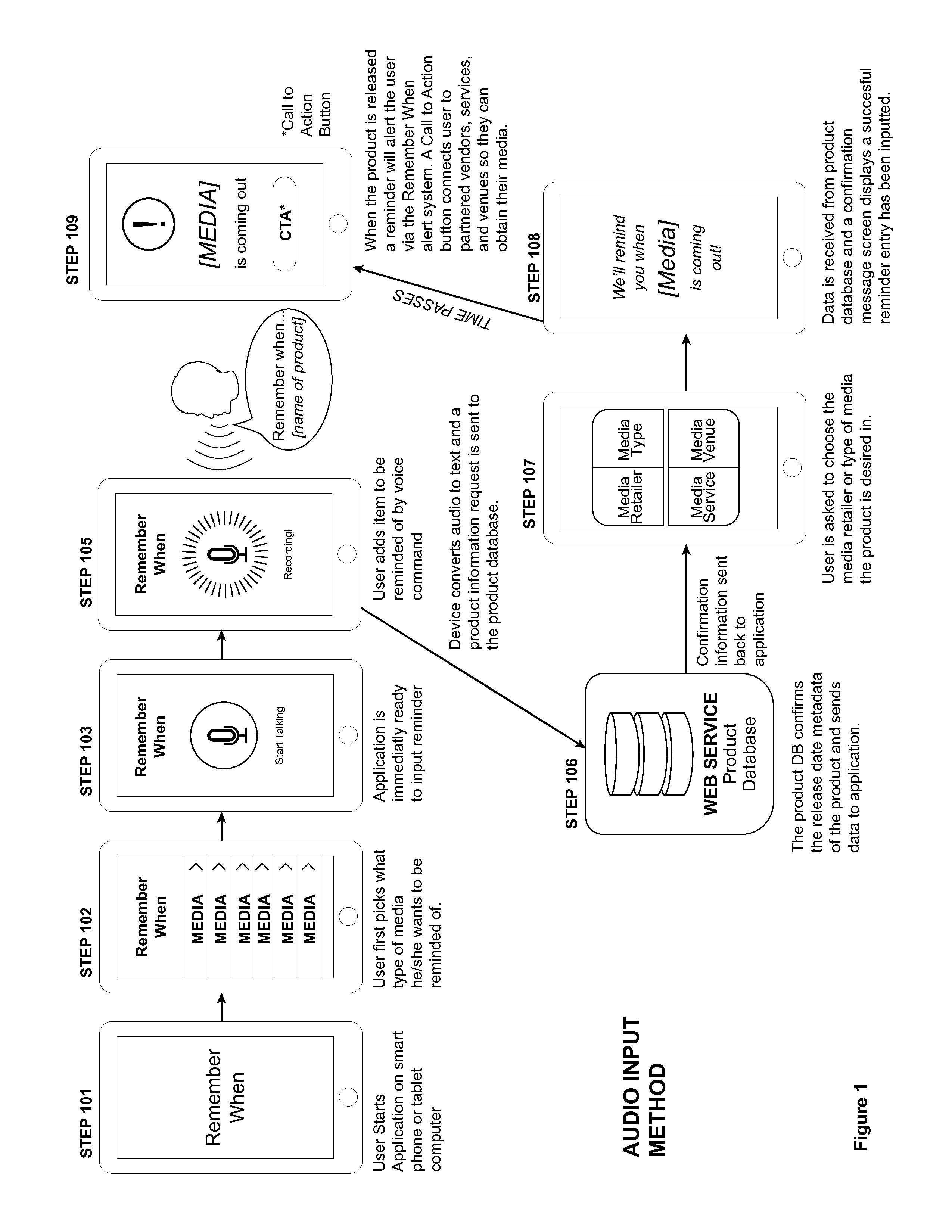

Release Date Notification System

An application software for smartphones and tablets works with a cooperating website. The app will compile a calendar and notify the user of the dates of release or availability of selected events, media and / or products, based on a targeted item database compiled by the user and stored locally on the smart device as well as remotely accessible through the website. Items can be added to the database by voice commands or keyboard entries to the smart device or by password-protected website access. Each time the app is activated, it contacts the website to launch a web crawler which retrieves and / or updates the relevant release dates. Optionally, the app / website can also retrieve price information, determine the lowest price vendor, and complete purchase transactions.

Owner:DAMIANO DEREK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com