Weighing system communication method based on digital sensor

A digital sensor and weighing system technology, applied in the direction of digital transmission system, transmission system, signal transmission system, etc., can solve the problem of forged weighing data, etc., to eliminate inaccuracy, ensure accuracy and reliability, and ensure security and confidentiality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

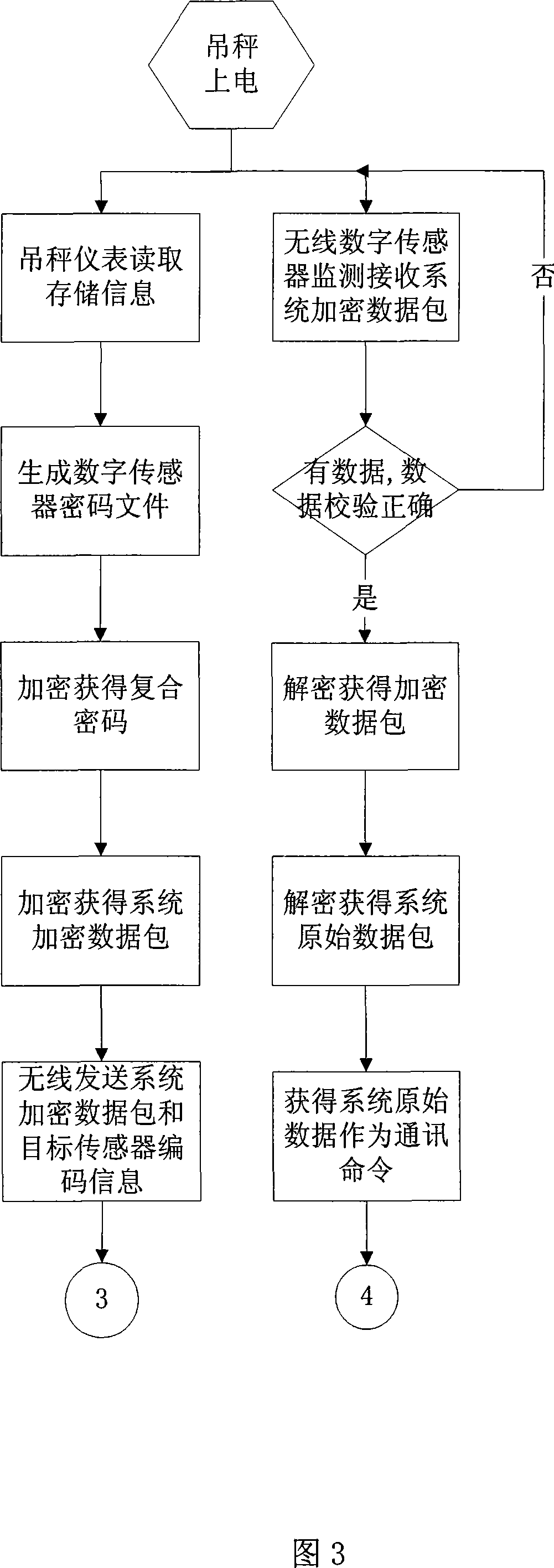

Embodiment 1

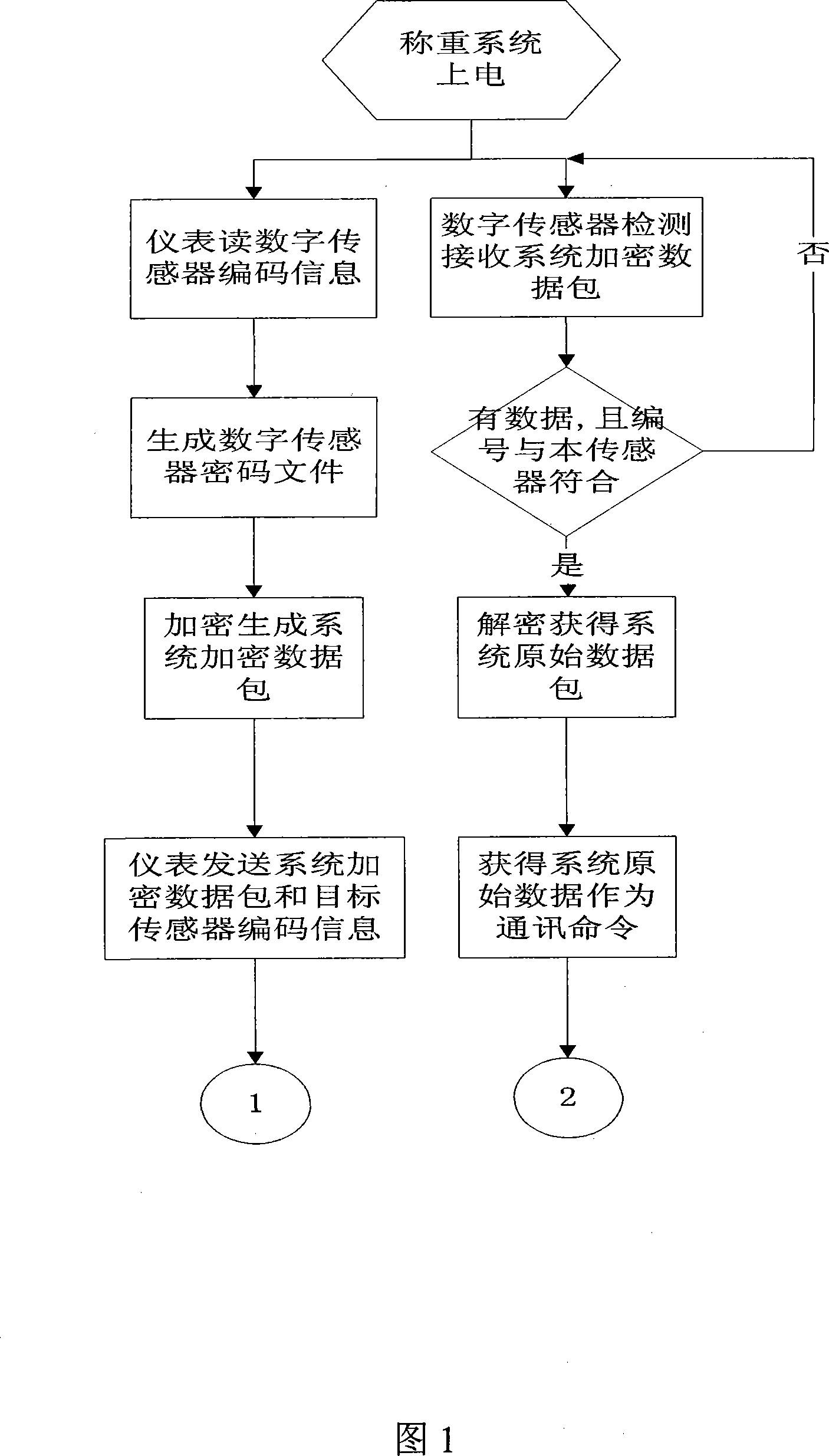

[0029] For digital truck scales, the weighing system includes a digital instrument, a digital sensor and a scale body. The digital sensor is connected to the digital instrument through the CAN bus. format to exchange data.

[0030](1) The manufacturer establishes a digital sensor key file for each digital sensor. The digital sensor key file contains a set of 12-byte binary codes, consisting of a 12-digit digital sensor serial number and a set of 12-digit random codes. Generated by operation, the random code is the factory password. For example, the serial number of the digital sensor is: UAFD12345678, and the random code is 987654321012. Then UAFD12345678 is converted into ASCII code and expressed as: 0x35, 0x21, 0x26, 0x24, 0x11, 0x12, 0x13, 0x14, 0x15 , 0x16, 0x17, 0x18; the random code is converted into ASCII code and expressed as: 0x19, 0x18, 0x17, 0x16, 0x15, 0x14, 0x13, 0x12, 0x11, 0x10, 0x11, 0x12; two sets of data obtained through XOR operation The hexadecimal code is...

Embodiment 2

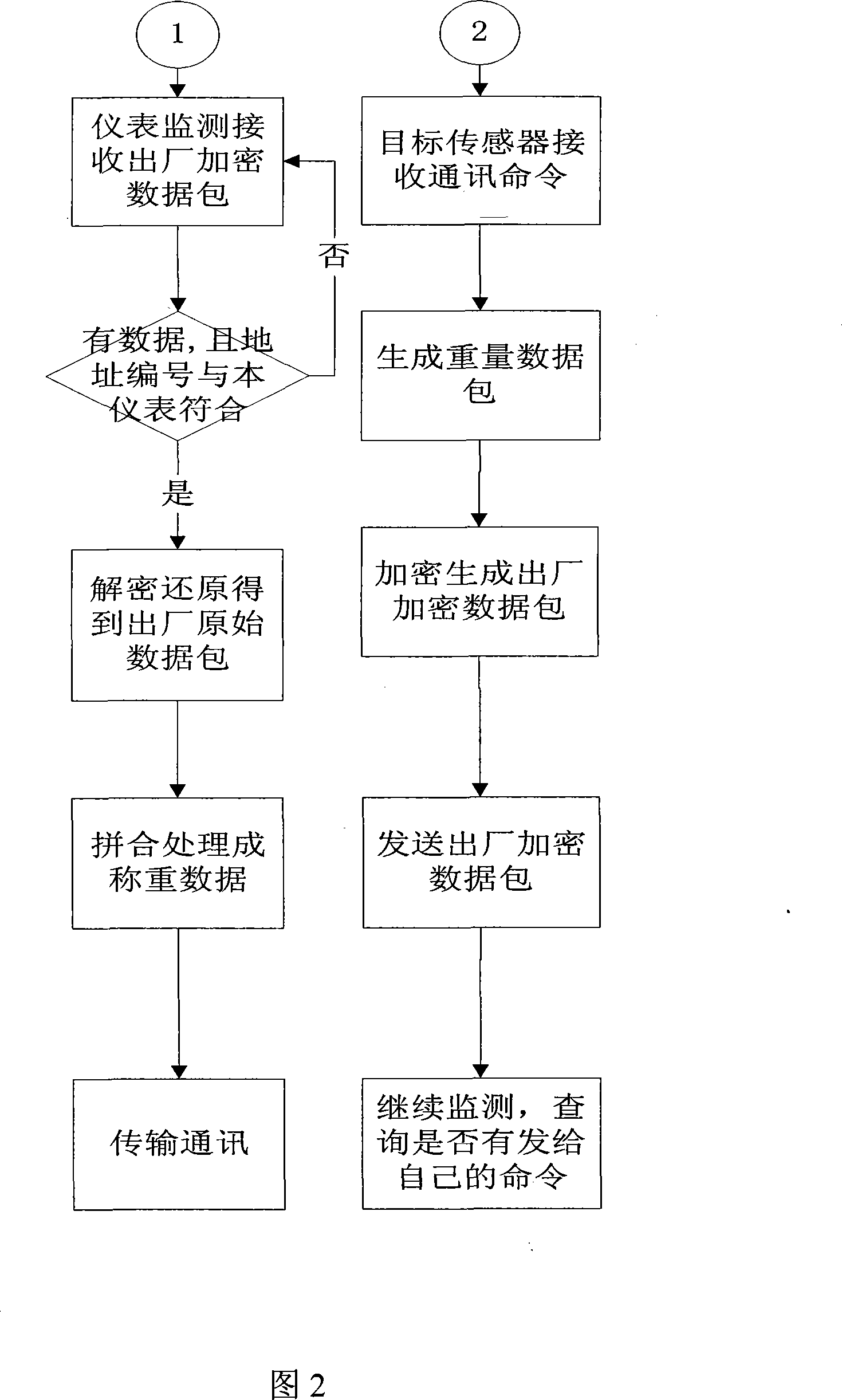

[0036] The digital truck scale is also used. The weighing system includes a digital instrument, a digital sensor and a scale body. The digital sensor is connected to the digital instrument through the CAN bus. format to exchange data.

[0037] (1) The manufacturer establishes a digital sensor key file for each digital sensor. The digital sensor key file contains a set of 12-byte binary codes, consisting of a 12-digit digital sensor serial number and a set of 12-digit random codes. Generated by operation, the random code is the factory password. For example, the serial number of the digital sensor is: UAFD12345678, and the random code is 987654321012. Then UAFD12345678 is converted into ASCII code and expressed as: 0x35, 0x21, 0x26, 0x24, 0x11, 0x12, 0x13, 0x14, 0x15 , 0x16, 0x17, 0x18; the random code is converted into ASCII code and expressed as: 0x19, 0x18, 0x17, 0x16, 0x15, 0x14, 0x13, 0x12, 0x11, 0x10, 0x11, 0x12; two sets of data obtained through XOR operation The hexade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com